JP2017128918A - Lifting/lowering door structure - Google Patents

Lifting/lowering door structure Download PDFInfo

- Publication number

- JP2017128918A JP2017128918A JP2016008748A JP2016008748A JP2017128918A JP 2017128918 A JP2017128918 A JP 2017128918A JP 2016008748 A JP2016008748 A JP 2016008748A JP 2016008748 A JP2016008748 A JP 2016008748A JP 2017128918 A JP2017128918 A JP 2017128918A

- Authority

- JP

- Japan

- Prior art keywords

- screw shaft

- nut member

- lifting

- door

- balance weight

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 239000000725 suspension Substances 0.000 claims abstract description 15

- 230000003028 elevating effect Effects 0.000 claims description 14

- 238000010586 diagram Methods 0.000 description 2

- 238000000034 method Methods 0.000 description 1

Images

Landscapes

- Power-Operated Mechanisms For Wings (AREA)

- Wing Frames And Configurations (AREA)

Abstract

Description

本発明は、昇降扉構造に関する。 The present invention relates to a lifting door structure.

従来、車庫の出入口を開閉するための昇降扉と、バランスウェイトとが、相互に釣合うように吊持された車庫用の昇降扉構造が知られている(特許文献1参照)。 Conventionally, a lift door structure for a garage in which a lift door for opening and closing a garage door and a balance weight are suspended so as to balance each other is known (see Patent Document 1).

しかし、特許文献1記載の昇降扉構造は、昇降扉とバランスウェイトを吊持するワイヤーが切れてしまうと、昇降扉及びバランスウェイトが不意に落下してしまう虞れがあった。車庫に設けられる昇降扉、及び、バランスウェイトは、重量が大きく、急速な落下により重大な事故が発生する危険性があった。

However, in the elevator door structure described in

そこで、本発明は、昇降扉及びバランスウェイトの不意の落下を防止できる昇降扉構造を提供することを目的とする。 Then, an object of this invention is to provide the raising / lowering door structure which can prevent the fall of a raising / lowering door and a balance weight unexpectedly.

本発明に係る昇降扉構造は、昇降扉の重量と、全てのバランスウェイトの合計重量とを、略同一に設定し、かつ、上記昇降扉と上記バランスウェイトとを、定滑車と可撓性懸架部材とを介して、相互に上下逆方向に釣合いながら昇降するように、吊持し、さらに、第1スクリューシャフトと第2スクリューシャフトを、鉛直状に、かつ、平行に設け、上記昇降扉に第1ナット部材を取着すると共に上記スクリューシャフトに該第1ナット部材を螺合し、上記バランスウェイトに対して、上下方向の余裕代を介して下方位置から対応する第2ナット部材を上記第2スクリューシャフトに螺合し、上記第1ナット部材と上記第2ナット部材が上下逆方向に同一速度で移動するように、上記第1スクリューシャフトと上記第2スクリューシャフトを回転させる駆動手段を具備するものである。

また、上記駆動手段は、上記第1スクリューシャフトと上記第2スクリューシャフトを連動連結する連動機構と、電気モータとを、有しているものである。

In the lifting door structure according to the present invention, the weight of the lifting door and the total weight of all balance weights are set to be substantially the same, and the lifting door and the balance weight are fixed to the fixed pulley and the flexible suspension. The first screw shaft and the second screw shaft are provided vertically and in parallel so as to be lifted and lowered while being balanced in opposite directions up and down via the members, The first nut member is attached and the first nut member is screwed onto the screw shaft, and the second nut member corresponding to the balance weight from the lower position through a margin in the vertical direction is attached to the first weight member. 2 screw shafts, and the first screw shaft and the second screw shaft are moved so that the first nut member and the second nut member move at the same speed in the reverse direction. Those having a driving means for rotating.

The driving means includes an interlocking mechanism that interlocks and connects the first screw shaft and the second screw shaft, and an electric motor.

本発明の昇降扉構造によれば、昇降扉とバランスウェイトとを吊持する可撓性懸架部材が切断した場合、バランスウェイトは余裕代分だけ少し降下してしまうが、直ちに第2ナット部材に当接保持されるので、落下することが防止され、安全性が高い。昇降扉は、それに取着された第1ナット部材が第1スクリューシャフトに常時螺合しているため、落下することはない。昇降扉とバランスウェイトは略同一重量で釣合っているため、駆動手段の必要動力は、重量差に概略等しいもので十分であり、駆動手段は小型・軽量化を図ることができ、しかも、軽快に昇降扉を昇降(開閉)させることができる。また、停電の際の手動操作に必要な力は、小さくて済む。 According to the lifting / lowering door structure of the present invention, when the flexible suspension member that holds the lifting / lowering door and the balance weight is cut, the balance weight is slightly lowered by the margin, but immediately becomes the second nut member. Since it is held in contact, it is prevented from falling and safety is high. The elevating door does not fall because the first nut member attached thereto is always screwed to the first screw shaft. Since the elevator door and the balance weight are balanced with substantially the same weight, it is sufficient that the required power of the drive means is approximately equal to the weight difference, and the drive means can be reduced in size and weight, and is light. The elevator door can be raised and lowered (opened and closed). Also, the force required for manual operation in the event of a power failure is small.

以下、実施の形態を示す図面に基づき本発明を詳説する。

図7に示すように、本発明の昇降扉構造は、住宅等の建物における1階(地上階)に設置されて、例えば、車庫の出入り口16を開閉するための昇降扉3を昇降自在に吊持し、かつ、所望の位置で昇降扉3を停止保持するように構成されている。

昇降扉3は、高さ寸法が2500mm〜3500mmに設定され、かつ、幅寸法が一定の正面視矩形状に形成されている。

なお、本発明の昇降扉構造は、倉庫や大型商業施設等の搬入口に設置されても良い。

Hereinafter, the present invention will be described in detail with reference to the drawings illustrating embodiments.

As shown in FIG. 7, the elevator door structure of the present invention is installed on the first floor (ground floor) of a building such as a house, and for example, the

The elevating

In addition, the raising / lowering door structure of this invention may be installed in carry-in entrances, such as a warehouse and a large commercial facility.

図1と図2に示すように、出入り口16の屋内側にて、昇降扉3とバランスウェイト4とが、定滑車5と可撓性懸架部材6を介して、相互に上下逆方向に釣合いながら昇降するように吊持されている。

図3に示すように、出入り口16の幅寸法Wより少しだけ広く左右方向に距離をとって、左右一対の支柱9,9が立設されており、各々の支柱9の上部に定滑車5が枢着されている。各定滑車5には、可撓性懸架部材6が懸けられて、昇降扉3とバランスウェイト4の荷重を支持している。なお、図1と図2に示すように、支柱9に小径の補助用定滑車15,15を設けても良い。

懸架部材6は、ワイヤーから成り、昇降扉3(バランスウェイト4)の荷重に耐え得る引っ張り強度を有するものが好ましい。懸架部材6は、各々に、一端がバランスウェイト4の上端部に連結され、他端が昇降扉3の上端の左右何れかの側端部近傍に連結されている。昇降扉3の重量は、約300kgで、2個のバランスウェイト4,4の合計重量が、昇降扉3の重量と略同一となるように設定されている。

As shown in FIGS. 1 and 2, on the indoor side of the entrance /

As shown in FIG. 3, a pair of left and

The

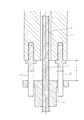

図1〜図3に示すように、第1スクリューシャフト1と第2スクリューシャフト2が、出入り口16の左右夫々に2本ずつ、鉛直状に、かつ、平行に配設されている。

図5,図1,図2に例示するように、各スクリューシャフト1,2は、スラスト軸受28等によって、上下方向の荷重を受持させ、円滑に回転するように構成する。

左右一対の第1スクリューシャフト1,1は、昇降扉3の左右両側端部に挿通されている。昇降扉3に第1ナット部材11,11を取着(固着)し、各スクリューシャフト1に第1ナット部材11を螺合させている。図1では、第1ナット部材11は、昇降扉3の下端部に埋め込み状に固着され、また、図8では、第1ナット部材11は、昇降扉3の下端部に溶接26・取付片27等にて固着されている。なお、昇降扉3の側外方に突出するように第1ナット部材11,11を取着しても良い。この場合、左右一対の第1スクリューシャフト1,1は、昇降扉3の側外方に配設されることとなる。

As shown in FIGS. 1 to 3, two

As illustrated in FIGS. 5, 1, and 2, each

The pair of left and right

図9に示すように、バランスウェイト4には、第2スクリューシャフト2の直径より大きな内径の貫通孔14が上下方向に形成され、第2スクリューシャフト2は、バランスウェイト4の貫通孔14に遊嵌状に挿通されている。

第2スクリューシャフト2の各々に、バランスウェイト4に対して、上下方向の余裕代gを介して下方位置から対応する第2ナット部材12が螺着されている。

第2ナット部材12は、バランスウェイト4の下端から垂下状に設けられたピンPによって、回転を規制されており、第2スクリューシャフト2が回転すると、共回りすることなく昇降するように構成されている。なお、第2ナット部材12の回転規制手段は、前記ピンP以外のものであっても良い。

As shown in FIG. 9, the

A corresponding

The rotation of the

また、図1と図2に示すように、第1ナット部材11と第2ナット部材12が上下逆方向に同一速度で移動するように、第1スクリューシャフト1と第2スクリューシャフト2を回転させる駆動手段10を具備している。

図4に示すように、駆動手段10は、第1スクリューシャフト1と第2スクリューシャフト2を連動連結する連動機構7と、電気モータ8とを、有している。

連動機構7は、電気モータ8の出力軸18に対し直交状に配設され、ギアボックス20を介して、(電気モータ8によって)回転駆動される第1回転軸21を有し、また、第1回転軸21に対し直交状に配設され、ギアボックス20,20を介して、(第1回転軸21によって)同期的に回転駆動される第2回転軸22・第3回転軸23を有している。第2回転軸22・第3回転軸23は、その長手方向両端部から第1スクリューシャフト1・第2スクリューシャフト2に、ベベルギア24,24を介して、回転力を伝達するように構成されている。なお、駆動手段10は、電気モータ8の出力軸18又は第1回転軸21を手動操作で回転させる鎖車とチェーン、あるいは、手動ハンドル等の手動回転手段を備えている(図示省略)。

ギアボックス20は、図6に示すように、互いに噛合するねじ歯車25,25を、筐体内部に有する構造であって、相互に直交する軸に回転力を伝達するように構成されている。

Further, as shown in FIGS. 1 and 2, the

As shown in FIG. 4, the driving means 10 includes an

The

As shown in FIG. 6, the

上述した本発明の昇降扉構造の使用方法(作用)について説明する。

図5(A)に示すように、昇降扉3の重量と、2個のバランスウェイト4,4の合計重量とが、略同一に設定され、昇降扉3の左右端が、各々、定滑車5と可撓性懸架部材6とによって吊持され、昇降扉3とバランスウェイト4,4が相互に上下逆方向に釣合いながら昇降する。一方、図5(B)に示すように、駆動手段10によって、第1スクリューシャフト1と第2スクリューシャフト2が回転駆動されて、互いに反対廻りの回転方向R1,R2に、同じ回転数(回転速度)で同期的に回転する。

第1スクリューシャフト1が回転することで、第1ナット部材11が取着された昇降扉3が上昇(または降下)し、同時に、昇降扉3と釣り合うバランスウェイト4,4が、上下逆方向に降下(または上昇)する。この際、昇降扉3の昇降速度V3とバランスウェイト4の昇降速度V4とが同一となる。また、第1スクリューシャフト1と第2スクリューシャフト2が同期的に回転して、第2ナット部材12が、第1ナット部材11と上下逆方向に同一速度で昇降する。即ち、バランスウェイト4と第2ナット部材12は、同じ方向に同一速度で昇降し、この際、バランスウェイト4の昇降速度V4と第2ナット部材12の昇降速度V12とが同一となる。従って、第2ナット部材12は、バランスウェイト4に対して、上下方向の余裕代gを介して下方位置から対応する位置関係を維持しつつ、昇降扉3(第1ナット部材11)と上下逆方向に移動する。

The use method (action | operation) of the raising / lowering door structure of this invention mentioned above is demonstrated.

As shown in FIG. 5A, the weight of the lifting

As the

昇降扉3とバランスウェイト4,4とが相互に釣合うように吊持されている為、第1スクリューシャフト1を小さなトルクで回転させることができ、昇降扉3の昇降にかかる駆動手段10の電気モータ8の仕事量が低く抑えられる。つまり、電気モータ8は、小馬力のコンパクトなもので良く、駆動手段10の構造を簡素なものとできるメリットがある。

第2ナット部材12は、バランスウェイト4の下方位置にて第2スクリューシャフト2に螺合して、バランスウェイト4と同じ方向に同一速度で昇降し、正常作動状態では、常時、余裕代gを維持している。懸架部材(ワイヤー)6が切れた非常時には、バランスウェイト4は、小さな寸法である上記余裕代g分だけ降下して、第2ナット部材12に当接し、バランスウェイト4を下方から支持して、落下を防ぐ。昇降扉3は、第1ナット部材11が第1スクリューシャフト1に螺合している為、懸架部材(ワイヤー)6が切れても落下することなく支持される。

また、第2ナット部材12は、バランスウェイト4に対して、上下方向の余裕代gを介して下方位置から対応し、懸架部材(ワイヤー)6が伸びても、バランスウェイト4から第2ナット部材12に荷重が付与されることがない。即ち、第2スクリューシャフト2は小さいトルクで回転させることができ、駆動手段10(電気モータ8)に過大な負荷がかかるのを防止する。なお、懸架部材6が、切断した非常時には、駆動手段10(電気モータ8)に過大な負荷がかかるので、これを電気的又は機械的に検出して駆動手段10(電気モータ8)を緊急停止させるのが望ましい。

Since the elevating

The

Further, the

なお、本発明は、設計変更可能であって、図示省略するが、例えば、第1ナット部材11と第2ナット部材12を相互左右逆ネジとして、第1スクリューシャフト1と第2スクリューシャフト2の回転方向を同じとしても良い。

Although the present invention can be modified in design and is not shown in the drawings, for example, the

以上のように、本発明に係る昇降扉構造は、昇降扉3の重量と、全てのバランスウェイト4,4の合計重量とを、略同一に設定し、かつ、上記昇降扉3と上記バランスウェイト4,4とを、定滑車5と可撓性懸架部材6とを介して、相互に上下逆方向に釣合いながら昇降するように、吊持し、さらに、第1スクリューシャフト1と第2スクリューシャフト2を、鉛直状に、かつ、平行に設け、上記昇降扉3に第1ナット部材11を取着すると共に上記スクリューシャフト1に該第1ナット部材11を螺合し、上記バランスウェイト4に対して、上下方向の余裕代gを介して下方位置から対応する第2ナット部材12を上記第2スクリューシャフト2に螺合し、上記第1ナット部材11と上記第2ナット部材12が上下逆方向に同一速度で移動するように、上記第1スクリューシャフト1と上記第2スクリューシャフト2を回転させる駆動手段10を具備するので、昇降扉3とバランスウェイト4とを吊持する可撓性懸架部材6が切断した場合、バランスウェイト4は余裕代g分だけ少し降下してしまうが、直ちに第2ナット部材12に当接保持されるので、落下することが防止され、安全性が高い。昇降扉3は、それに取着された第1ナット部材11が第1スクリューシャフト1に常時螺合しているため、落下することはない。昇降扉3とバランスウェイト4,4は略同一重量で釣合っているため、駆動手段10の必要動力は、重量差に概略等しいもので十分であり、駆動手段10は小型・軽量化を図ることができ、しかも、軽快に昇降扉3を昇降(開閉)させることができる。また、停電の際の手動操作に必要な力は、小さくて済み、手動操作で軽く昇降扉3を開閉作動できる。

。

As described above, the elevator door structure according to the present invention sets the weight of the

.

また、上記駆動手段10は、上記第1スクリューシャフト1と上記第2スクリューシャフト2を連動連結する連動機構7と、電気モータ8とを、有しているので、電気モータ8にかかる負荷を低く抑え、簡素な構造で、かつ、確実に、第1ナット部材11と第2ナット部材12を上下逆方向に同一速度で移動させることができる。

Moreover, since the drive means 10 includes the

1 第1スクリューシャフト

2 第2スクリューシャフト

3 昇降扉

4 バランスウェイト

5 定滑車

6 可撓性懸架部材

7 連動機構

8 電気モータ

10 駆動手段

11 第1ナット部材

12 第2ナット部材

g 余裕代

DESCRIPTION OF

Claims (2)

さらに、第1スクリューシャフト(1)と第2スクリューシャフト(2)を、鉛直状に、かつ、平行に設け、

上記昇降扉(3)に第1ナット部材(11)を取着すると共に上記スクリューシャフト(1)に該第1ナット部材(11)を螺合し、上記バランスウェイト(4)に対して、上下方向の余裕代(g)を介して下方位置から対応する第2ナット部材(12)を上記第2スクリューシャフト(2)に螺合し、

上記第1ナット部材(11)と上記第2ナット部材(12)が上下逆方向に同一速度で移動するように、上記第1スクリューシャフト(1)と上記第2スクリューシャフト(2)を回転させる駆動手段(10)を具備することを特徴とする昇降扉構造。 The weight of the elevating door (3) and the total weight of all the balance weights (4) (4) are set substantially the same, and the elevating door (3) and the balance weights (4) (4) Is suspended through the fixed pulley (5) and the flexible suspension member (6) so as to move up and down while balancing each other in the opposite direction.

Furthermore, the first screw shaft (1) and the second screw shaft (2) are provided vertically and in parallel,

The first nut member (11) is attached to the elevating door (3), and the first nut member (11) is screwed to the screw shaft (1). The corresponding second nut member (12) is screwed onto the second screw shaft (2) from a lower position via a margin of direction (g),

The first screw shaft (1) and the second screw shaft (2) are rotated so that the first nut member (11) and the second nut member (12) move in the reverse direction at the same speed. A lifting door structure characterized by comprising driving means (10).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2016008748A JP6645840B2 (en) | 2016-01-20 | 2016-01-20 | Lifting door structure |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2016008748A JP6645840B2 (en) | 2016-01-20 | 2016-01-20 | Lifting door structure |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2017128918A true JP2017128918A (en) | 2017-07-27 |

| JP6645840B2 JP6645840B2 (en) | 2020-02-14 |

Family

ID=59396069

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2016008748A Active JP6645840B2 (en) | 2016-01-20 | 2016-01-20 | Lifting door structure |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP6645840B2 (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111561243A (en) * | 2020-06-18 | 2020-08-21 | 同高先进制造科技(太仓)有限公司 | Laser house active type protection electric sliding door system |

| KR102232472B1 (en) * | 2020-07-30 | 2021-03-26 | 세홍엔지니어링 주식회사 | Fault section detection system monitoring system of urban underground distribution line |

| WO2022000751A1 (en) * | 2020-07-01 | 2022-01-06 | 国为(南京)软件科技有限公司 | Visualization-based data warehousing dedicated door |

| CN113914749A (en) * | 2021-09-25 | 2022-01-11 | 上海睿风建筑设计咨询有限公司 | Linkage type outer facade system |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2922780A1 (en) * | 1979-06-05 | 1980-12-11 | Werner Bruno | Cupboard with vertically sliding doors - has doors moving along guide pieces, and has weight balance using cables, roller and spring |

| JPS5969U (en) * | 1982-06-21 | 1984-01-05 | 株式会社日立製作所 | Automatic vehicle window opening/closing device |

| JPH02103488U (en) * | 1989-02-02 | 1990-08-16 | ||

| JPH07217346A (en) * | 1994-02-03 | 1995-08-15 | Sankei:Kk | Opening-closing drive mechanism of door of gate |

| JPH11152959A (en) * | 1997-11-20 | 1999-06-08 | Mizuta Bounetsutobira Seisakusho:Kk | Open-close device for thermal insulation door |

| US20160312532A1 (en) * | 2014-01-03 | 2016-10-27 | Jacek KUHNL-KINEL | Gate with counterweight and lowering exchangeable span |

-

2016

- 2016-01-20 JP JP2016008748A patent/JP6645840B2/en active Active

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2922780A1 (en) * | 1979-06-05 | 1980-12-11 | Werner Bruno | Cupboard with vertically sliding doors - has doors moving along guide pieces, and has weight balance using cables, roller and spring |

| JPS5969U (en) * | 1982-06-21 | 1984-01-05 | 株式会社日立製作所 | Automatic vehicle window opening/closing device |

| JPH02103488U (en) * | 1989-02-02 | 1990-08-16 | ||

| JPH07217346A (en) * | 1994-02-03 | 1995-08-15 | Sankei:Kk | Opening-closing drive mechanism of door of gate |

| JPH11152959A (en) * | 1997-11-20 | 1999-06-08 | Mizuta Bounetsutobira Seisakusho:Kk | Open-close device for thermal insulation door |

| US20160312532A1 (en) * | 2014-01-03 | 2016-10-27 | Jacek KUHNL-KINEL | Gate with counterweight and lowering exchangeable span |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111561243A (en) * | 2020-06-18 | 2020-08-21 | 同高先进制造科技(太仓)有限公司 | Laser house active type protection electric sliding door system |

| WO2022000751A1 (en) * | 2020-07-01 | 2022-01-06 | 国为(南京)软件科技有限公司 | Visualization-based data warehousing dedicated door |

| KR102232472B1 (en) * | 2020-07-30 | 2021-03-26 | 세홍엔지니어링 주식회사 | Fault section detection system monitoring system of urban underground distribution line |

| CN113914749A (en) * | 2021-09-25 | 2022-01-11 | 上海睿风建筑设计咨询有限公司 | Linkage type outer facade system |

Also Published As

| Publication number | Publication date |

|---|---|

| JP6645840B2 (en) | 2020-02-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6645840B2 (en) | Lifting door structure | |

| GB2610951A (en) | Lifting device and plastering apparatus | |

| CN110723681A (en) | Lifting device and well repairing platform | |

| JP2016523214A5 (en) | ||

| TWI697609B (en) | Split gate structure | |

| KR101036020B1 (en) | Fall prevention device of industrial lift | |

| US6857529B2 (en) | Pantographic device for conveying loads in vehicle assembly lines | |

| JP4404999B2 (en) | Elevator equipment | |

| KR20140046271A (en) | Firefighting lift | |

| CN110565935B (en) | Attached scaffold for building | |

| KR101406018B1 (en) | Safety equipment of vertically driven type | |

| JP4547395B2 (en) | lift device | |

| KR20110035373A (en) | Lift for a back cage door opening apparatus | |

| KR101776219B1 (en) | Apparatus for screen doors of vertical open-close type having rack-pinion power transmitting structure | |

| CN105113936A (en) | Folding door applied to slope surface | |

| CN206886493U (en) | Construction elevator | |

| KR200444238Y1 (en) | Lifted or lowered guiding apparatus of canvas door | |

| CN111217289A (en) | Lifter and glass substrate conveying system | |

| CN201269035Y (en) | Electric self-balancing door curtain | |

| JP2019218038A (en) | Elevating-type platform fence | |

| CN204251137U (en) | screw type elevator | |

| KR200269290Y1 (en) | safety device for lift | |

| CN207017622U (en) | A kind of elevator safe construction operating platform | |

| KR200423756Y1 (en) | The installation structure of the lift for a task | |

| JP3014765U (en) | Home elevator |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20180921 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20190731 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20190805 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20190821 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20191223 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20200109 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6645840 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |