EP0401202B1 - Fermeture à serrage - Google Patents

Fermeture à serrage Download PDFInfo

- Publication number

- EP0401202B1 EP0401202B1 EP19900890168 EP90890168A EP0401202B1 EP 0401202 B1 EP0401202 B1 EP 0401202B1 EP 19900890168 EP19900890168 EP 19900890168 EP 90890168 A EP90890168 A EP 90890168A EP 0401202 B1 EP0401202 B1 EP 0401202B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- intermediate piece

- tensioner

- tightener

- axis

- accordance

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000006073 displacement reaction Methods 0.000 claims description 26

- 230000000717 retained effect Effects 0.000 description 2

- 208000027418 Wounds and injury Diseases 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000006378 damage Effects 0.000 description 1

- 230000000881 depressing effect Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000002347 injection Methods 0.000 description 1

- 239000007924 injection Substances 0.000 description 1

- 208000014674 injury Diseases 0.000 description 1

- 230000003993 interaction Effects 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A43—FOOTWEAR

- A43C—FASTENINGS OR ATTACHMENTS OF FOOTWEAR; LACES IN GENERAL

- A43C11/00—Other fastenings specially adapted for shoes

- A43C11/14—Clamp fastenings, e.g. strap fastenings; Clamp-buckle fastenings; Fastenings with toggle levers

- A43C11/1406—Fastenings with toggle levers; Equipment therefor

- A43C11/146—Fastenings with toggle levers with adjustment means provided for on the strap, e.g. ratchet strap

- A43C11/1473—Fastenings with toggle levers with adjustment means provided for on the strap, e.g. ratchet strap characterised by means to retain the preferred position on the strap when the fastening means are in the loosened position

-

- A—HUMAN NECESSITIES

- A43—FOOTWEAR

- A43C—FASTENINGS OR ATTACHMENTS OF FOOTWEAR; LACES IN GENERAL

- A43C11/00—Other fastenings specially adapted for shoes

- A43C11/14—Clamp fastenings, e.g. strap fastenings; Clamp-buckle fastenings; Fastenings with toggle levers

- A43C11/1406—Fastenings with toggle levers; Equipment therefor

Definitions

- the invention relates to a tensioning buckle for ski boots with a tensioner which can be pivoted transversely to the direction of pull and which can be connected in length-variable manner to a tension member via an intermediate piece.

- Tension buckles for ski boots of the type mentioned at the outset can be found, for example, in US Pat. No. 4,470,175.

- the intermediate piece is variable in length and serves to fine-tune the tensioning force of the buckle, since the buckle can usually only be adjusted in steps which correspond to the distance between the hooks into which the tension member is inserted.

- the known intermediate piece is designed as a spindle, the length of which can be adjusted with a knurled nut.

- the well-known tension buckles are characterized by the fact that in their closed position they exert a defined tension on the flaps of the shoe that are to be tensioned against each other. If, for example, a pressure or strain relief is desired for walking or standing in the lift system, such a buckle must be opened. However, the opening of the buckle now causes the tensioning lever to protrude from the surface of the boot and such parts protruding from the surface of the ski boot offer the risk of injury and can also be a hindrance.

- the invention now aims to develop a tensioning buckle of the type mentioned in such a way that it is possible to provide strain relief without opening the tensioning lever and without the tensioning lever assuming a position protruding from the outer surface of the shoe, the device according to the invention also ensuring that at When the buckle is closed again, the originally selected tensioning force can be achieved immediately.

- the tensioning buckle according to the invention essentially consists in the fact that the intermediate piece is connected to the tensioner such that it can be displaced in the pulling direction and can be releasably locked to the tensioner in a first position and can be moved to a limited extent in the unlocked position in the direction of an increased effective length of the tensioning buckle .

- the intermediate piece is displaceably connected in the pulling direction to the tensioner and can assume two defined positions provides a defined position for the correct closed position under the preset pulling force and a second position in which the tensioning buckle reduces a defined amount Exerts tension without the pivotable tensioner having to be pivoted into a position protruding from the surface of the ski boot.

- the intermediate piece in the first position can be releasably locked with the tensioner and, after releasing the unlocking, can be displaced to a limited extent in the direction of an increased effective length of the tensioning buckle.

- the intermediate piece is unlocked for a limited increase in the effective length of the tensioning buckle without opening the tensioner.

- the limitation of the relocability and the type of locking can be selected in a different and advantageous manner within the framework of such a design of the intermediate piece.

- the training is so made that the displaceable intermediate piece can be moved in or on the tensioner.

- the design can be integrated into the tensioner, so that even with an intermediate piece displaceable in the manner according to the invention in the closed position, there are no larger overall dimensions of the tensioning buckle.

- the design is such that the intermediate piece is articulated parallel to the pivot axis of the tensioner on the tensioner, whereby opening of the tensioner is facilitated in particular with less flexible tension members.

- the intermediate piece itself can be connected or connected to the tension member and the tension member can be fixed in steps in any known manner, for example in hook-shaped extensions on the outside of the flap opposite the tensioner.

- the tension member can also be firmly connected in a defined position to the tab opposite the tensioner, the corresponding adjustability being able to be provided in or on the tensioner itself.

- a particularly compact design can be achieved in that the tensioner has a recess for receiving the intermediate piece.

- the intermediate piece can be arranged completely in a corresponding recess of the tensioner and can be pushed out of this recess in the pulling direction after releasing the locking device, the limitation of the displaceability or displaceability being ensured in different ways.

- a particularly simple limitation of the displaceability of the intermediate piece in or on the tensioner is achieved in that an axis running parallel to the pivot axis of the tensioner is arranged in or on the tensioner, which passes through an elongated hole of the intermediate piece extending transversely to this axis.

- the axis in or on the tensioner can, in combination with the corresponding elongated hole of the intermediate piece, result in the limitation of the displaceability and the pivotability of the intermediate piece to facilitate the opening of the tensioner.

- the locking member for the releasable locking of the intermediate piece in the closed position with a correspondingly shortened effective length can be designed in various ways, the design being particularly advantageous so that in or on the intermediate piece or the tensioner carries at least one locking member for the intermediate piece Actuator is arranged to pivot about an axis extending transversely to the direction of displacement of the intermediate piece or to be displaceable transversely to the direction of displacement.

- the actuating element can be designed as a pivotable lever or a displaceable element which is designed relative to the tensioner or intermediate piece and which, when actuated, cancels the locking for the intermediate piece by releasing suitable locking elements.

- the design can be such that the actuating member is designed as a two-armed lever which can be pivoted about the axis, one arm of which carries a, in particular hook-shaped, locking member which cooperates with a corresponding counter profile of the tensioner or the intermediate piece in the locking position .

- a two-armed lever can be pivoted into an unlocking position by depressing the free lever arm opposite the locking member, and in the unlocked position the displacement path is released up to the predefined enlarged effective length of the intermediate piece.

- the locking member itself can, for example, be hook-shaped, whereby naturally equivalent configurations, such as, for example, training with a crosshead, which engages in corresponding hook-shaped grooves of the locking member, can also be easily implemented.

- the design is advantageously made such that the actuating member is resiliently pressed into the locking position of the intermediate piece, so that, with the corresponding design of the actuating member provided with locking members, an automatic one Locking in the locked position is made possible.

- a resilient loading of the actuator it is sufficient for the new tensioning of the tensioning buckle to the originally set value, to open the tensioner briefly, whereby the actuator is pushed against the force of the spring into the locking position and can automatically assume the locking position.

- the pivotable articulation of the intermediate piece and the release of a predetermined displacement path after unlocking the locking member can also be ensured in a simple manner in that the intermediate piece has an axis or coaxial extensions in a plane transverse to the displacement direction, which extends in grooves or elongated holes extending in the displacement direction or in particular sawtooth-shaped locking elements of the tensioner and / or the actuating element engages (engage).

- grooves or elongated holes or locking elements are provided in or on the tensioner and / or on the actuating member itself instead of the elongated hole in the intermediate piece, wherein if grooves are used, they can be cranked, for example, in order in this way to have an automatic in the respective end position Locking to yield. Furthermore, with the arrangement of elongated holes or grooves, both in the tensioner and in the actuator with very compact and small components, the length can be found, each of which defines part of the displacement path of the intermediate piece in the manner of telescopically displaceable components.

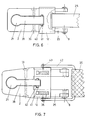

- FIG. 1 shows in section a first embodiment of a tensioning buckle according to the invention

- 2 shows an exploded view of the individual parts of the tensioning buckle shown in FIG. 1

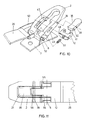

- 3 shows a plan view of a modified embodiment of a tensioning buckle according to the invention, the displaceable intermediate piece partially encompassing the tensioner

- 5, 6 and 7 are top views of further modified embodiments of a tensioning buckle according to the invention, the intermediate piece, similar to the embodiment according to FIG. 3, partially encompassing the tensioner for guiding the intermediate piece on the tensioner

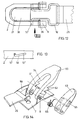

- FIGS. 8 and 9 further modified embodiments of a tensioning buckle according to the invention, wherein axes connected to the intermediate piece or extensions provided transversely to the direction of displacement are guided in grooves or elongated holes of the tensioner; 10 shows an exploded view of the design according to FIG. 9; 11 and 12, in turn, modified embodiments of a tensioning buckle according to the invention, the intermediate pieces being guided in link-like paths on the tensioner with projections provided transversely to the direction of displacement; 13 shows a partial view in the direction of arrow XIII of FIG. 12 on a slide track of the tensioner; 14 shows an exploded view of a further modified embodiment of a tensioning buckle according to the invention; and FIGS.

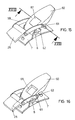

- FIGS. 15 to 18 are views of a further modified embodiment with an actuating element which is displaceably mounted on the tensioner for locking, wherein FIGS. 15 and 16 show the tensioning buckle with the tensioner partially raised in the two positions of the intermediate piece, FIG. 17 is an exploded view and Figure 18 shows a section along the line XVIII-XVIII of Figure 15.

- 1 denotes a tensioning buckle, a tensioner 2 and an element 3 interacting with the tensioning buckle 1 being fixed to overlapping shell, cuff or shaft parts or tabs 4 and 5.

- the tensioner 2 and the element 3 are fixed in a manner known per se, for example via rivets, which are schematically indicated by 6 in FIG.

- the tensioner 2 is arranged on a support element, designated 7, on the shell part 5 so as to be pivotable about an axis arranged transversely to the actuating direction of the tensioner 2.

- the element 3 shown in FIG. 1 is pivotably articulated on the support element 9 about an axis 10.

- the tensioner 2 is connected to the element 3, for example via a tension member 11 with a sawtooth profile, which is connected to the tensioner 2 via an intermediate piece 12, this intermediate piece 12 about an axis 13 parallel to the articulation axis 8 of the tensioner 2 on the support element 7 is articulated on the tensioner.

- a tension member 11 with a sawtooth profile which is connected to the tensioner 2 via an intermediate piece 12, this intermediate piece 12 about an axis 13 parallel to the articulation axis 8 of the tensioner 2 on the support element 7 is articulated on the tensioner.

- several latching points for the element 3 are provided on the tension member 11 and a threaded part 14 is provided for fine adjustment on the intermediate piece 12, which can be screwed into the sawtooth-shaped tension member 11 in a certain way .

- the tensioner 2 is actuated in the direction of the arrow 15.

- the intermediate piece 12 is designed such that it extends in the longitudinal direction of the tensioning buckle 1 and is displaceably connected to the tensioner 2 at 16 indicated pulling direction.

- an actuator 17 is provided on the intermediate piece 12, which can be pivoted about an axis 18 substantially parallel to the axes 8 and 13, the actuator 17 designed as a two-armed lever having a hook-shaped locking element at one end 19, which cooperates in the first and shortened position of the intermediate piece 12 shown in FIG. 1 with the axis 13 as a counter-profile.

- a tension member for example in the form of a bracket, can also be provided on the intermediate piece 12 and, for example, a sawtooth-shaped profile can be provided on the other part of the ski boot to achieve different locking positions, such a locking element being fixed in a known manner on the tab 4.

- the tensioner 2 has a recess 23 corresponding to the design of the intermediate piece 12 for receiving the intermediate piece 12, the axis passing through the openings for the axis 13 not shown in detail being guided in the slot 22 of the intermediate piece 12 .

- the intermediate piece 12 also has a recess 24 for receiving the actuating member 17, which is designed as a two-armed lever, and the actuating member 17 can be pivoted via an axis which is not guided through the openings 18 in the intermediate piece 12 and in the lever 17.

- the two-armed lever 17 is, as is not shown in more detail for the sake of clarity, by a spiral spring having a plurality of turns counter to the actuation direction by a force applied to the end 21 to release the locking, i.e. to disengage the hook-shaped locking member 19 from the spring-loaded in the slot 22 for the pivot axis 13.

- the tensioner 2 is in turn pivotable about the axis 8 on a ski boot part or rag articulated, which is not shown in detail.

- the intermediate piece 12 is displaceably guided on the spars 25, on which the tension member 26, which is designed in the form of a band, is fixed in this embodiment.

- An actuating member 28 is pivotably articulated on the tensioner 2 about an axis 27 parallel to the pivot axis 8, a locking member in turn being provided at a free end of this actuating member 28.

- the locking member is formed by extensions 29 which extend substantially parallel to the pivot axis 27 and which engage in corresponding recesses 30 on the intermediate piece in the locked position, as shown in FIG.

- the actuating member which is designed as a two-armed lever

- the extensions 29 disengage from the recesses 30 provided on the intermediate piece 12 and there is a displacement of the Intermediate piece 12 against the forces exerted by the springs 31 in the direction of an extension of the effective length of the tensioning buckle 1.

- a spring 32 is also indicated which loads the two-armed lever 28 in the recesses 30 in the direction of the locking position of the locking members 29.

- the recess 30 on the intermediate piece 12 is inclined against the direction of displacement in the relieved position, in order to ensure a secure reception of the extensions 29 of the two-armed lever 28.

- the intermediate piece 12 has an inclined surface 33 in the direction of the actuating member 28, which, particularly when the locking members 29 are displaced into the locked position, enable reliable guidance.

- the design can also be made as indicated in FIG. 4b.

- the two-armed lever 28 similar to the embodiment according to FIGS. 1 and 2, has a hook-shaped locking member 34 at one free end, which in extensions 12 provided on the intermediate piece 12 and extending essentially parallel to the pivot axis 27 of the two-armed lever 28 on the tensioner 2 35 or an axis 35 extending in this way is engaged in the locked position.

- the embodiment of a tensioning buckle shown in FIG. 5 is similar to the embodiment shown in FIG. 3 and the intermediate piece 12 is displaceably guided on bars 25 of the tensioner 2.

- the tensioner 2 is in turn pivotable about the axis 8.

- the intermediate piece 12 can consist of an injection molded part, wherein the band-shaped tension member 26 is also injected. Against the displacement into the relieved position, the intermediate piece 12 is in turn loaded by a spring 36 provided in the interior in the area of the one spar 25 of the tensioner 2, and just as in the embodiment according to FIG. 3, the maximum displacement path by a complete compression of the respectively provided Springs 31 and 36 is limited.

- a two-armed lever 38 can be pivoted in a recess 37 about an axis 39 parallel to the axis 8, locking members 40 being provided on a free end of the two-armed lever 38, which in an embodiment similar to FIG Intervene with intermediate piece 12.

- the locking member can also be designed in the form of a hook, which surrounds appropriately designed extensions or an axis, as is shown, for example, in FIG. 4b.

- the exemplary embodiment according to FIG. 6 differs from the configuration according to FIG. 5 essentially only in a slightly modified shape of the tensioner and of the intermediate piece guided on it, the reference symbols being retained for the same components.

- the intermediate piece 12 is in turn displaceably guided on bars 25 of the tensioner 2 and the two-armed actuating lever 38 is designed to be pivotable about the axis 39 in a recess of the tensioner 2.

- the locking members are designed essentially analogously to the embodiment according to FIG. 5.

- the tensioner 2 is in turn fixed on a tab, not shown, pivotable about the axis 8.

- the intermediate piece 12 is in turn slidably guided on bars 25, a spring 36 being provided in the interior of the intermediate piece in the area of the bars, similar to the embodiment according to FIG.

- the actuating member 38 which is designed as a two-armed lever, is again designed with its locking members 40, which interact with recesses 41 of the intermediate piece 12, in a manner similar to the design according to FIGS. 5 and 6.

- the again band-shaped tension member 26 is fixed on the intermediate piece 12 via a bracket 42, which is fixed on the intermediate piece so as to be pivotable about an axis 43.

- FIG. 8 The embodiment shown in FIG. 8 is similar to the previous embodiment of the tensioning buckle, in which case the bracket connecting the tension member 26 to the intermediate piece 12 with its extensions 44 forming the pivot axis on the intermediate piece 12 are both the intermediate piece 12 penetrates and also protrudes into the recesses 45 provided in the spars 25, these recesses being designed, for example, as elongated holes in the longitudinal direction of the spars 25, in order to guide the intermediate piece 12 and the tension member 26 on the tensioner when relieved by increasing the effective length of the splines effect entire tension buckle.

- springs 46 are provided to act on the bracket 42 in the direction of the closed position.

- the intermediate piece 12 is displaceably guided in a recess 47 of the tensioner fixed pivotably about the axis 8 on a rag, the intermediate piece being penetrated by an axis 48 which is formed by recesses 49 which are essentially of Elongated holes are formed, is passed and on the axis 48 in turn a bracket 50 is provided for connecting the intermediate piece 12 to the band-shaped tension member 26.

- the intermediate piece 12 also has an extension 51 pointing in the longitudinal direction of the tensioner and thus in the direction of displacement, which is immersed in a corresponding counter-profile or a corresponding recess 52 of the tensioner, in which recess 52 there is also a spring 53 which at least partially extends from the extension 51 is spread, is arranged.

- the intermediate piece is again loaded against the pulling direction by this spring.

- the tensioning buckle is again relieved via the two-armed actuating lever 38 when the locking members 40 are released from engagement in a corresponding recess 41 in the intermediate piece 12.

- the intermediate piece 12 is in turn connected directly to the band-shaped tension member 26 and is displaceably guided in a recess 54 of the tensioner, which in turn can be pivoted about the axis 8.

- the actuator 38 which is designed as a two-armed lever, is in turn pivoted about an axis 39 on the tensioner.

- the intermediate piece 12 When a pressure force is exerted on the free end 21 of the two-armed lever 38, the intermediate piece 12 is raised in the region of the end 55 of the actuating member 38, so that a locking member 56 of the intermediate piece 12, again formed by a hook, disengages from the axis 39 and a displacement of the intermediate piece relative to the tensioner 2 in the direction of an extension of the effective length of the entire tensioning buckle 1 is achieved.

- the pivot axis 39 provided on the tensioner is provided for the actuating member 38 near the pivot axis 8 of the tensioner on the tab.

- this lever acts on extensions 57 of the intermediate piece 12 connected to the tension member 26 and the intermediate piece is in a cranked path, which is designated 58 in FIG. 13, in the direction of an extension of the effective length of the entire buckle moves.

- the position of the extensions 57 shown in FIG. 12 is shown in full in FIG. 13, while the relieved position is indicated by dashed lines at 57 ′.

- FIG. 14 shows a modified embodiment, the intermediate piece connected to the tension member 26 being formed by a bracket 59 which can be displaced relative to the tensioner 60, which in turn is fastened to the ski boot flap pivotably about the axis 8.

- the intermediate piece formed by the bracket 59 interacts via an axis 61 with the tensioner 60, this axis 61 in two, the locked and the positions corresponding to the relaxed position cooperate with locking elements 62 of the tensioner.

- the actuator is designated 63 in this embodiment and is pivotable about the axis 8, about which the tensioner 60 can be pivoted on the support element 7, in a recess 64 of the tensioner.

- the actuator 63 has an elongated recess 65 extending in the direction of displacement, which is penetrated by the axis 61 of the intermediate piece 59 in the assembled state.

- the actuating member 63 is prestressed via a spring 66 into a position in which the axis 61 is held in a defined position relative to the latching elements 62. In the position shown in FIG. 14, the relaxed position is assumed, the tensioner 60 being designed to be slightly raised to clarify the illustration.

- the axis 61 of the intermediate piece guided in the recess 65 is brought out of engagement with the latching element 62 which is further away from the pivot axis 8 and the position shown in FIG. 14 can be assumed by a guide in the recess 65.

- the tensioning buckle is shown in FIGS. 15 and 16 in the two possible positions of the intermediate piece, again formed by a bracket 59, relative to the tensioner 60.

- the tensioner 60 is again shown partially raised from the support element 7, it being pointed out again that the displacement of the intermediate piece in the direction of an increased effective length of the entire tensioning buckle is carried out in the adjacent position of the tensioner 60 on the ski shoe flap or support part 7.

- the tensioner 60 in turn has latching elements 62, in which the axis 61 of the intermediate piece 59 extending transversely to the direction of displacement engages. 15 shows the first locked position of the intermediate piece 59 on the tensioner 60 and in FIG.

- an actuating member 67 with a substantially U-shaped cross section is guided in a recess 68 in the tensioner 60 so that it can be moved normally to the direction of displacement of the intermediate piece, as can be seen more clearly from FIGS. 17 and 18.

- the actuator 67 has elongated holes 69 in the direction of displacement, which can also be designed as longitudinal grooves, in which the axis 61 of the displaceable intermediate piece designed as a bracket 59 is slidably mounted.

- the positions of the axis 61 corresponding to the locking elements 62 on the tensioner 60 are indicated in FIG. 17 by 61 ′ and 61 ⁇ , position 61 ′ representing the locked position according to FIG.

- the actuating member 67 is pretensioned by a leaf spring 70 in order to hold the axis 61 which is displaceable in the elongated holes 69 in a defined contact position against the sawtooth-shaped latching elements 62.

- the axis 61 comes out of engagement with the sawtooth-shaped locking element 62 facing away from the pivot axis 8 when an essentially normal force is applied to the actuating member 67 and becomes in the direction of an increased effective length of the entire tensioning buckle in the elongated hole guides 69 of the actuator guided into the position indicated by 61 ⁇ .

- the position of the axis 61 of the intermediate piece 59 is locked in this way in the interaction of the latching elements 62 with the elongated holes 69 which extend over a limited length.

- the locking in the originally set position takes place by briefly pivoting the tensioner about the pivot axis on the ski boot flap, as a result of which the locking members come into engagement with one another again and in this way the shortened length of the tensioning buckle is set again.

Landscapes

- Footwear And Its Accessory, Manufacturing Method And Apparatuses (AREA)

- Automotive Seat Belt Assembly (AREA)

Claims (9)

- Boucle de serrage (1) pour chaussures de ski, comprenant un tendeur (2, 60) pivotant transversalement à la direction de traction qui, au moyen d'un élément intermédiaire (12, 59), peut être rattaché de manière réglable en longueur à un élément de traction (11, 26) caractérisée en ce que l'élément intermédiaire (12, 59) est couplé avec le tendeur (2, 60) de manière mobile dans la direction de traction (16), que dans une première position, il peut être verrouillé de manière amovible avec le tendeur (2, 60) et que dans la position déverrouillée, il est guidé de manière à pouvoir être déplacé de façon limitée dans le sens d'une longueur active accrue de la boucle de serrage (1).

- Boucle de serrage selon la revendication 1, caractérisée en ce que l'élément intermédiaire mobile (12, 59) peut être déplacé dans ou sur le tendeur (2, 60).

- Boucle de serrage selon l'une des revendications 1 ou 2, caractérisée en ce que l'élément intermédiaire (12, 59) est articulé sur le tendeur (2, 60) de manière à pouvoir pivoter parallèlement à l'axe de pivotement (8) du tendeur (2, 60).

- Boucle de serrage selon l'une des revendications 1, 2 ou 3, caractérisée en ce que le tendeur (2) présente un évidement (23) pour la réception de l'élément intermédiaire (12).

- Boucle de serrage selon l'une des revendications 1 à 4, caractérisée en ce que dans ou sur le tendeur (2) est disposé un axe (13) qui s'étend parallèlement à l'axe de pivotement (8) du tendeur (2) et qui traverse un trou oblong (22) dudit élément intermédiaire (12) orienté transversalement audit axe (8).

- Boucle de serrage selon l'une des revendications 1 à 5, caractérisée en ce que dans ou sur l'élément intermédiaire (12, 59) ou le tendeur (2, 60), un organe de manoeuvre (17, 28, 38) portant au moins un organe de verrouillage (19, 29, 34, 40, 57) pour l'élément intermédiaire (12, 59) est disposé de manière à pouvoir pivoter autour d'un axe (18, 27, 39) s'étendant transversalement à la direction de déplacement de l'élément intermédiaire (12, 59) ou à pouvoir être déplacé transversalement à la direction de déplacement.

- Boucle de serrage selon la revendication 6, caractérisée en ce que l'organe de manoeuvre (17, 28, 38) est réalisé sous la forme d'un levier à deux bras pivotant autour de l'axe (18, 27, 39), dont l'un des bras porte un organe de verrouillage (19, 29, 34, 40, 57), notamment en forme de crochet, qui coopère dans la position de verrouillage avec un profil conjugué correspondant (13, 30, 35, 41) du tendeur (2) ou de l'élément intermédiaire (12).

- Boucle de serrage selon l'une des revendications 6 ou 7, caractérisée en ce que l'organe de manoeuvre est poussé élastiquement dans la position de verrouillage de l'élément intermédiaire (12).

- Boucle de serrage selon l'une des revendications 1 à 8, caractérisée en ce que, dans un plan orienté transversalement à la direction de déplacement, l'élément intermédiaire (12, 59) comporte un axe (61) ou des prolongements coaxiaux qui s'engage(nt) dans des rainures ou trous oblongs (65) orientés dans la direction de déplacement, ou notamment dans des éléments à crans (62) en dents de scie du tendeur (60) et/ou de l'organe de manoeuvre (63).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT1350/89 | 1989-06-02 | ||

| AT135089A AT397603B (de) | 1989-06-02 | 1989-06-02 | Spannschnalle |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0401202A2 EP0401202A2 (fr) | 1990-12-05 |

| EP0401202A3 EP0401202A3 (fr) | 1991-07-31 |

| EP0401202B1 true EP0401202B1 (fr) | 1994-07-13 |

Family

ID=3511995

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19900890168 Expired - Lifetime EP0401202B1 (fr) | 1989-06-02 | 1990-05-30 | Fermeture à serrage |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0401202B1 (fr) |

| AT (1) | AT397603B (fr) |

| DE (1) | DE59006404D1 (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8060990B2 (en) | 2006-01-27 | 2011-11-22 | Skis Rossignol | Binding buckle with secure docking element |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| IT1257572B (it) * | 1992-01-16 | 1996-02-01 | Nordica Spa | Struttura di leva di serraggio particolarmente per calzature sportive |

| IT226867Z2 (it) * | 1992-08-13 | 1997-07-22 | Canstar Italia | Allacciatura di scarponi da sci con dispositivo di regolazione della tensione di allacciatura |

| EP0705545B1 (fr) | 1994-10-07 | 1999-05-06 | Lange International S.A. | Dispositif de fermeture et de serrage pour chaussure de ski |

| FR2729547A1 (fr) * | 1995-01-19 | 1996-07-26 | Salomon Sa | Dispositif de verrouillage et de serrage |

| IT239590Y1 (it) * | 1995-10-04 | 2001-03-05 | Tecnica Spa | Dispositivo di chiusura per calzature sportive, in particolare perscarponi da sci avente un elemento a rastrelliera allungabile |

| IT242084Y1 (it) * | 1996-02-05 | 2001-06-04 | Nordica Spa | Dispositivo di serraggio per calzature sportive |

| US5720084A (en) * | 1996-12-31 | 1998-02-24 | Chen; Chin Chu | Securing device for footwear |

| FR2784554B1 (fr) | 1998-10-20 | 2000-12-15 | Salomon Sa | Dispositif de reglage/fermeture d'une chaussure de sport |

| DE10155922B4 (de) * | 2000-11-17 | 2010-04-01 | Benetton Group S.P.A., Ponzano Veneto | Hebelverschlußvorrichtung |

| ITPN20030012U1 (it) * | 2003-04-23 | 2004-10-24 | Luigi Sa Societe Anonyme Holding | Dispositivo di serraggio, particolarmente per calzature sportive. |

| IT1392758B1 (it) * | 2009-01-27 | 2012-03-16 | Premec Spa | Dispositivo di chiusura a leva per calzature sportive. |

| IT1399820B1 (it) * | 2010-03-23 | 2013-05-03 | Premec Spa | Dispositivo di chiusura, particolarmente per calzature sportive. |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3363288A (en) * | 1966-08-29 | 1968-01-16 | Robert B. Lange | Boot buckle |

| AT370595B (de) * | 1980-06-27 | 1983-04-11 | Koeflach Sportgeraete Gmbh | Schnalle zum schliessen von schuhen |

| US4470175A (en) * | 1981-06-16 | 1984-09-11 | Warrington Inc. | Fastening device for ski-boots |

-

1989

- 1989-06-02 AT AT135089A patent/AT397603B/de not_active IP Right Cessation

-

1990

- 1990-05-30 EP EP19900890168 patent/EP0401202B1/fr not_active Expired - Lifetime

- 1990-05-30 DE DE59006404T patent/DE59006404D1/de not_active Expired - Fee Related

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8060990B2 (en) | 2006-01-27 | 2011-11-22 | Skis Rossignol | Binding buckle with secure docking element |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0401202A2 (fr) | 1990-12-05 |

| ATA135089A (de) | 1993-10-15 |

| EP0401202A3 (fr) | 1991-07-31 |

| AT397603B (de) | 1994-05-25 |

| DE59006404D1 (de) | 1994-08-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| AT402900B (de) | Kupplungsvorrichtung zwischen schi und schischuh mit einer längenverstellvorrichtung | |

| EP0401202B1 (fr) | Fermeture à serrage | |

| CH645254A5 (de) | Schuh mit spannhebelverschluss. | |

| AT401710B (de) | Skischuh | |

| DE2516985A1 (de) | Verstelleinrichtung fuer skibindungen | |

| DE3151584A1 (de) | Bindungsgesamtheit eines schuhs mit einem ski, insbesondere einem langlaufski | |

| DE2406646A1 (de) | Skibindungselement | |

| DE4010118A1 (de) | Bindungsvorrichtung eines paares von schuhen eines skilaeufers auf einem gleitbrett auf schnee | |

| EP0259896A1 (fr) | Chaussure de sport, en particulier chaussure de ski | |

| AT402795B (de) | Bindungseinheit zwischen einem schuh und einem sportgerät, insbesondere schibindung | |

| DE2656814A1 (de) | Skistockgriff | |

| EP0169315B1 (fr) | Elément de fixation de ski en particulier mâchoire avant | |

| EP0098515B1 (fr) | Dispositif de réglage en longueur pour fixations de ski | |

| DE2332656A1 (de) | Sicherheitsbindung fuer ski | |

| DE3143974A1 (de) | "fersenhalter fuer eine sicherheitsskibindung" | |

| DE2711213A1 (de) | Kniehebelverschluss fuer stiefel | |

| EP0495192A1 (fr) | Fixation de ski pour ski de fond | |

| DE2804986A1 (de) | Sicherheits-skibindung | |

| DE2707838A1 (de) | Sicherheitsskibindung mit an einem grundkoerper schwenkbar angeordnetem sohlenhalter und einer eingebauten skibremse | |

| AT376374B (de) | Sicherheitsskibindung | |

| DE9117298U1 (de) | Kupplungsvorrichtung zwischen Schi und Schischuh mit einer Längenverstellvorrichtung | |

| WO1991011231A1 (fr) | Elements de fixation de ski, en particulier machoires avant | |

| EP0129535A1 (fr) | Ensemble de fixation pour ski de fond avec la chaussure | |

| DE2658999A1 (de) | Ausloeseskibindung | |

| CH652576A5 (de) | Schnalle zum schliessen von schuhen. |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): CH DE FR IT LI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): CH DE FR IT LI |

|

| 17P | Request for examination filed |

Effective date: 19911231 |

|

| 17Q | First examination report despatched |

Effective date: 19930928 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: KOFLACH SPORT GESELLSCHAFT M.B.H. & CO. KG |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): CH DE FR IT LI |

|

| REF | Corresponds to: |

Ref document number: 59006404 Country of ref document: DE Date of ref document: 19940818 |

|

| ITF | It: translation for a ep patent filed | ||

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19970418 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19970421 Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PFA Free format text: KOFLACH SPORT GESELLSCHAFT MBH & CO. KG TRANSFER- KOFLACH SPORT GESELLSCHAFT M.B.H. * KOFLACH SPORT GESELLSCHAFT M.B.H. TRANSFER- KOFLACH SPORT GESELLSCHAFT M.B.H. |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19970731 Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: TP Ref country code: FR Ref legal event code: CA |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980531 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980531 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980531 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: RM |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990302 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050530 |