EP0401202B1 - Clamp fastening - Google Patents

Clamp fastening Download PDFInfo

- Publication number

- EP0401202B1 EP0401202B1 EP19900890168 EP90890168A EP0401202B1 EP 0401202 B1 EP0401202 B1 EP 0401202B1 EP 19900890168 EP19900890168 EP 19900890168 EP 90890168 A EP90890168 A EP 90890168A EP 0401202 B1 EP0401202 B1 EP 0401202B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- intermediate piece

- tensioner

- tightener

- axis

- accordance

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000006073 displacement reaction Methods 0.000 claims description 26

- 230000000717 retained effect Effects 0.000 description 2

- 208000027418 Wounds and injury Diseases 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000006378 damage Effects 0.000 description 1

- 230000000881 depressing effect Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000002347 injection Methods 0.000 description 1

- 239000007924 injection Substances 0.000 description 1

- 208000014674 injury Diseases 0.000 description 1

- 230000003993 interaction Effects 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A43—FOOTWEAR

- A43C—FASTENINGS OR ATTACHMENTS OF FOOTWEAR; LACES IN GENERAL

- A43C11/00—Other fastenings specially adapted for shoes

- A43C11/14—Clamp fastenings, e.g. strap fastenings; Clamp-buckle fastenings; Fastenings with toggle levers

- A43C11/1406—Fastenings with toggle levers; Equipment therefor

- A43C11/146—Fastenings with toggle levers with adjustment means provided for on the strap, e.g. ratchet strap

- A43C11/1473—Fastenings with toggle levers with adjustment means provided for on the strap, e.g. ratchet strap characterised by means to retain the preferred position on the strap when the fastening means are in the loosened position

-

- A—HUMAN NECESSITIES

- A43—FOOTWEAR

- A43C—FASTENINGS OR ATTACHMENTS OF FOOTWEAR; LACES IN GENERAL

- A43C11/00—Other fastenings specially adapted for shoes

- A43C11/14—Clamp fastenings, e.g. strap fastenings; Clamp-buckle fastenings; Fastenings with toggle levers

- A43C11/1406—Fastenings with toggle levers; Equipment therefor

Definitions

- the invention relates to a tensioning buckle for ski boots with a tensioner which can be pivoted transversely to the direction of pull and which can be connected in length-variable manner to a tension member via an intermediate piece.

- Tension buckles for ski boots of the type mentioned at the outset can be found, for example, in US Pat. No. 4,470,175.

- the intermediate piece is variable in length and serves to fine-tune the tensioning force of the buckle, since the buckle can usually only be adjusted in steps which correspond to the distance between the hooks into which the tension member is inserted.

- the known intermediate piece is designed as a spindle, the length of which can be adjusted with a knurled nut.

- the well-known tension buckles are characterized by the fact that in their closed position they exert a defined tension on the flaps of the shoe that are to be tensioned against each other. If, for example, a pressure or strain relief is desired for walking or standing in the lift system, such a buckle must be opened. However, the opening of the buckle now causes the tensioning lever to protrude from the surface of the boot and such parts protruding from the surface of the ski boot offer the risk of injury and can also be a hindrance.

- the invention now aims to develop a tensioning buckle of the type mentioned in such a way that it is possible to provide strain relief without opening the tensioning lever and without the tensioning lever assuming a position protruding from the outer surface of the shoe, the device according to the invention also ensuring that at When the buckle is closed again, the originally selected tensioning force can be achieved immediately.

- the tensioning buckle according to the invention essentially consists in the fact that the intermediate piece is connected to the tensioner such that it can be displaced in the pulling direction and can be releasably locked to the tensioner in a first position and can be moved to a limited extent in the unlocked position in the direction of an increased effective length of the tensioning buckle .

- the intermediate piece is displaceably connected in the pulling direction to the tensioner and can assume two defined positions provides a defined position for the correct closed position under the preset pulling force and a second position in which the tensioning buckle reduces a defined amount Exerts tension without the pivotable tensioner having to be pivoted into a position protruding from the surface of the ski boot.

- the intermediate piece in the first position can be releasably locked with the tensioner and, after releasing the unlocking, can be displaced to a limited extent in the direction of an increased effective length of the tensioning buckle.

- the intermediate piece is unlocked for a limited increase in the effective length of the tensioning buckle without opening the tensioner.

- the limitation of the relocability and the type of locking can be selected in a different and advantageous manner within the framework of such a design of the intermediate piece.

- the training is so made that the displaceable intermediate piece can be moved in or on the tensioner.

- the design can be integrated into the tensioner, so that even with an intermediate piece displaceable in the manner according to the invention in the closed position, there are no larger overall dimensions of the tensioning buckle.

- the design is such that the intermediate piece is articulated parallel to the pivot axis of the tensioner on the tensioner, whereby opening of the tensioner is facilitated in particular with less flexible tension members.

- the intermediate piece itself can be connected or connected to the tension member and the tension member can be fixed in steps in any known manner, for example in hook-shaped extensions on the outside of the flap opposite the tensioner.

- the tension member can also be firmly connected in a defined position to the tab opposite the tensioner, the corresponding adjustability being able to be provided in or on the tensioner itself.

- a particularly compact design can be achieved in that the tensioner has a recess for receiving the intermediate piece.

- the intermediate piece can be arranged completely in a corresponding recess of the tensioner and can be pushed out of this recess in the pulling direction after releasing the locking device, the limitation of the displaceability or displaceability being ensured in different ways.

- a particularly simple limitation of the displaceability of the intermediate piece in or on the tensioner is achieved in that an axis running parallel to the pivot axis of the tensioner is arranged in or on the tensioner, which passes through an elongated hole of the intermediate piece extending transversely to this axis.

- the axis in or on the tensioner can, in combination with the corresponding elongated hole of the intermediate piece, result in the limitation of the displaceability and the pivotability of the intermediate piece to facilitate the opening of the tensioner.

- the locking member for the releasable locking of the intermediate piece in the closed position with a correspondingly shortened effective length can be designed in various ways, the design being particularly advantageous so that in or on the intermediate piece or the tensioner carries at least one locking member for the intermediate piece Actuator is arranged to pivot about an axis extending transversely to the direction of displacement of the intermediate piece or to be displaceable transversely to the direction of displacement.

- the actuating element can be designed as a pivotable lever or a displaceable element which is designed relative to the tensioner or intermediate piece and which, when actuated, cancels the locking for the intermediate piece by releasing suitable locking elements.

- the design can be such that the actuating member is designed as a two-armed lever which can be pivoted about the axis, one arm of which carries a, in particular hook-shaped, locking member which cooperates with a corresponding counter profile of the tensioner or the intermediate piece in the locking position .

- a two-armed lever can be pivoted into an unlocking position by depressing the free lever arm opposite the locking member, and in the unlocked position the displacement path is released up to the predefined enlarged effective length of the intermediate piece.

- the locking member itself can, for example, be hook-shaped, whereby naturally equivalent configurations, such as, for example, training with a crosshead, which engages in corresponding hook-shaped grooves of the locking member, can also be easily implemented.

- the design is advantageously made such that the actuating member is resiliently pressed into the locking position of the intermediate piece, so that, with the corresponding design of the actuating member provided with locking members, an automatic one Locking in the locked position is made possible.

- a resilient loading of the actuator it is sufficient for the new tensioning of the tensioning buckle to the originally set value, to open the tensioner briefly, whereby the actuator is pushed against the force of the spring into the locking position and can automatically assume the locking position.

- the pivotable articulation of the intermediate piece and the release of a predetermined displacement path after unlocking the locking member can also be ensured in a simple manner in that the intermediate piece has an axis or coaxial extensions in a plane transverse to the displacement direction, which extends in grooves or elongated holes extending in the displacement direction or in particular sawtooth-shaped locking elements of the tensioner and / or the actuating element engages (engage).

- grooves or elongated holes or locking elements are provided in or on the tensioner and / or on the actuating member itself instead of the elongated hole in the intermediate piece, wherein if grooves are used, they can be cranked, for example, in order in this way to have an automatic in the respective end position Locking to yield. Furthermore, with the arrangement of elongated holes or grooves, both in the tensioner and in the actuator with very compact and small components, the length can be found, each of which defines part of the displacement path of the intermediate piece in the manner of telescopically displaceable components.

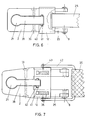

- FIG. 1 shows in section a first embodiment of a tensioning buckle according to the invention

- 2 shows an exploded view of the individual parts of the tensioning buckle shown in FIG. 1

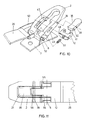

- 3 shows a plan view of a modified embodiment of a tensioning buckle according to the invention, the displaceable intermediate piece partially encompassing the tensioner

- 5, 6 and 7 are top views of further modified embodiments of a tensioning buckle according to the invention, the intermediate piece, similar to the embodiment according to FIG. 3, partially encompassing the tensioner for guiding the intermediate piece on the tensioner

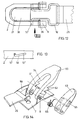

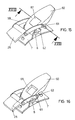

- FIGS. 8 and 9 further modified embodiments of a tensioning buckle according to the invention, wherein axes connected to the intermediate piece or extensions provided transversely to the direction of displacement are guided in grooves or elongated holes of the tensioner; 10 shows an exploded view of the design according to FIG. 9; 11 and 12, in turn, modified embodiments of a tensioning buckle according to the invention, the intermediate pieces being guided in link-like paths on the tensioner with projections provided transversely to the direction of displacement; 13 shows a partial view in the direction of arrow XIII of FIG. 12 on a slide track of the tensioner; 14 shows an exploded view of a further modified embodiment of a tensioning buckle according to the invention; and FIGS.

- FIGS. 15 to 18 are views of a further modified embodiment with an actuating element which is displaceably mounted on the tensioner for locking, wherein FIGS. 15 and 16 show the tensioning buckle with the tensioner partially raised in the two positions of the intermediate piece, FIG. 17 is an exploded view and Figure 18 shows a section along the line XVIII-XVIII of Figure 15.

- 1 denotes a tensioning buckle, a tensioner 2 and an element 3 interacting with the tensioning buckle 1 being fixed to overlapping shell, cuff or shaft parts or tabs 4 and 5.

- the tensioner 2 and the element 3 are fixed in a manner known per se, for example via rivets, which are schematically indicated by 6 in FIG.

- the tensioner 2 is arranged on a support element, designated 7, on the shell part 5 so as to be pivotable about an axis arranged transversely to the actuating direction of the tensioner 2.

- the element 3 shown in FIG. 1 is pivotably articulated on the support element 9 about an axis 10.

- the tensioner 2 is connected to the element 3, for example via a tension member 11 with a sawtooth profile, which is connected to the tensioner 2 via an intermediate piece 12, this intermediate piece 12 about an axis 13 parallel to the articulation axis 8 of the tensioner 2 on the support element 7 is articulated on the tensioner.

- a tension member 11 with a sawtooth profile which is connected to the tensioner 2 via an intermediate piece 12, this intermediate piece 12 about an axis 13 parallel to the articulation axis 8 of the tensioner 2 on the support element 7 is articulated on the tensioner.

- several latching points for the element 3 are provided on the tension member 11 and a threaded part 14 is provided for fine adjustment on the intermediate piece 12, which can be screwed into the sawtooth-shaped tension member 11 in a certain way .

- the tensioner 2 is actuated in the direction of the arrow 15.

- the intermediate piece 12 is designed such that it extends in the longitudinal direction of the tensioning buckle 1 and is displaceably connected to the tensioner 2 at 16 indicated pulling direction.

- an actuator 17 is provided on the intermediate piece 12, which can be pivoted about an axis 18 substantially parallel to the axes 8 and 13, the actuator 17 designed as a two-armed lever having a hook-shaped locking element at one end 19, which cooperates in the first and shortened position of the intermediate piece 12 shown in FIG. 1 with the axis 13 as a counter-profile.

- a tension member for example in the form of a bracket, can also be provided on the intermediate piece 12 and, for example, a sawtooth-shaped profile can be provided on the other part of the ski boot to achieve different locking positions, such a locking element being fixed in a known manner on the tab 4.

- the tensioner 2 has a recess 23 corresponding to the design of the intermediate piece 12 for receiving the intermediate piece 12, the axis passing through the openings for the axis 13 not shown in detail being guided in the slot 22 of the intermediate piece 12 .

- the intermediate piece 12 also has a recess 24 for receiving the actuating member 17, which is designed as a two-armed lever, and the actuating member 17 can be pivoted via an axis which is not guided through the openings 18 in the intermediate piece 12 and in the lever 17.

- the two-armed lever 17 is, as is not shown in more detail for the sake of clarity, by a spiral spring having a plurality of turns counter to the actuation direction by a force applied to the end 21 to release the locking, i.e. to disengage the hook-shaped locking member 19 from the spring-loaded in the slot 22 for the pivot axis 13.

- the tensioner 2 is in turn pivotable about the axis 8 on a ski boot part or rag articulated, which is not shown in detail.

- the intermediate piece 12 is displaceably guided on the spars 25, on which the tension member 26, which is designed in the form of a band, is fixed in this embodiment.

- An actuating member 28 is pivotably articulated on the tensioner 2 about an axis 27 parallel to the pivot axis 8, a locking member in turn being provided at a free end of this actuating member 28.

- the locking member is formed by extensions 29 which extend substantially parallel to the pivot axis 27 and which engage in corresponding recesses 30 on the intermediate piece in the locked position, as shown in FIG.

- the actuating member which is designed as a two-armed lever

- the extensions 29 disengage from the recesses 30 provided on the intermediate piece 12 and there is a displacement of the Intermediate piece 12 against the forces exerted by the springs 31 in the direction of an extension of the effective length of the tensioning buckle 1.

- a spring 32 is also indicated which loads the two-armed lever 28 in the recesses 30 in the direction of the locking position of the locking members 29.

- the recess 30 on the intermediate piece 12 is inclined against the direction of displacement in the relieved position, in order to ensure a secure reception of the extensions 29 of the two-armed lever 28.

- the intermediate piece 12 has an inclined surface 33 in the direction of the actuating member 28, which, particularly when the locking members 29 are displaced into the locked position, enable reliable guidance.

- the design can also be made as indicated in FIG. 4b.

- the two-armed lever 28 similar to the embodiment according to FIGS. 1 and 2, has a hook-shaped locking member 34 at one free end, which in extensions 12 provided on the intermediate piece 12 and extending essentially parallel to the pivot axis 27 of the two-armed lever 28 on the tensioner 2 35 or an axis 35 extending in this way is engaged in the locked position.

- the embodiment of a tensioning buckle shown in FIG. 5 is similar to the embodiment shown in FIG. 3 and the intermediate piece 12 is displaceably guided on bars 25 of the tensioner 2.

- the tensioner 2 is in turn pivotable about the axis 8.

- the intermediate piece 12 can consist of an injection molded part, wherein the band-shaped tension member 26 is also injected. Against the displacement into the relieved position, the intermediate piece 12 is in turn loaded by a spring 36 provided in the interior in the area of the one spar 25 of the tensioner 2, and just as in the embodiment according to FIG. 3, the maximum displacement path by a complete compression of the respectively provided Springs 31 and 36 is limited.

- a two-armed lever 38 can be pivoted in a recess 37 about an axis 39 parallel to the axis 8, locking members 40 being provided on a free end of the two-armed lever 38, which in an embodiment similar to FIG Intervene with intermediate piece 12.

- the locking member can also be designed in the form of a hook, which surrounds appropriately designed extensions or an axis, as is shown, for example, in FIG. 4b.

- the exemplary embodiment according to FIG. 6 differs from the configuration according to FIG. 5 essentially only in a slightly modified shape of the tensioner and of the intermediate piece guided on it, the reference symbols being retained for the same components.

- the intermediate piece 12 is in turn displaceably guided on bars 25 of the tensioner 2 and the two-armed actuating lever 38 is designed to be pivotable about the axis 39 in a recess of the tensioner 2.

- the locking members are designed essentially analogously to the embodiment according to FIG. 5.

- the tensioner 2 is in turn fixed on a tab, not shown, pivotable about the axis 8.

- the intermediate piece 12 is in turn slidably guided on bars 25, a spring 36 being provided in the interior of the intermediate piece in the area of the bars, similar to the embodiment according to FIG.

- the actuating member 38 which is designed as a two-armed lever, is again designed with its locking members 40, which interact with recesses 41 of the intermediate piece 12, in a manner similar to the design according to FIGS. 5 and 6.

- the again band-shaped tension member 26 is fixed on the intermediate piece 12 via a bracket 42, which is fixed on the intermediate piece so as to be pivotable about an axis 43.

- FIG. 8 The embodiment shown in FIG. 8 is similar to the previous embodiment of the tensioning buckle, in which case the bracket connecting the tension member 26 to the intermediate piece 12 with its extensions 44 forming the pivot axis on the intermediate piece 12 are both the intermediate piece 12 penetrates and also protrudes into the recesses 45 provided in the spars 25, these recesses being designed, for example, as elongated holes in the longitudinal direction of the spars 25, in order to guide the intermediate piece 12 and the tension member 26 on the tensioner when relieved by increasing the effective length of the splines effect entire tension buckle.

- springs 46 are provided to act on the bracket 42 in the direction of the closed position.

- the intermediate piece 12 is displaceably guided in a recess 47 of the tensioner fixed pivotably about the axis 8 on a rag, the intermediate piece being penetrated by an axis 48 which is formed by recesses 49 which are essentially of Elongated holes are formed, is passed and on the axis 48 in turn a bracket 50 is provided for connecting the intermediate piece 12 to the band-shaped tension member 26.

- the intermediate piece 12 also has an extension 51 pointing in the longitudinal direction of the tensioner and thus in the direction of displacement, which is immersed in a corresponding counter-profile or a corresponding recess 52 of the tensioner, in which recess 52 there is also a spring 53 which at least partially extends from the extension 51 is spread, is arranged.

- the intermediate piece is again loaded against the pulling direction by this spring.

- the tensioning buckle is again relieved via the two-armed actuating lever 38 when the locking members 40 are released from engagement in a corresponding recess 41 in the intermediate piece 12.

- the intermediate piece 12 is in turn connected directly to the band-shaped tension member 26 and is displaceably guided in a recess 54 of the tensioner, which in turn can be pivoted about the axis 8.

- the actuator 38 which is designed as a two-armed lever, is in turn pivoted about an axis 39 on the tensioner.

- the intermediate piece 12 When a pressure force is exerted on the free end 21 of the two-armed lever 38, the intermediate piece 12 is raised in the region of the end 55 of the actuating member 38, so that a locking member 56 of the intermediate piece 12, again formed by a hook, disengages from the axis 39 and a displacement of the intermediate piece relative to the tensioner 2 in the direction of an extension of the effective length of the entire tensioning buckle 1 is achieved.

- the pivot axis 39 provided on the tensioner is provided for the actuating member 38 near the pivot axis 8 of the tensioner on the tab.

- this lever acts on extensions 57 of the intermediate piece 12 connected to the tension member 26 and the intermediate piece is in a cranked path, which is designated 58 in FIG. 13, in the direction of an extension of the effective length of the entire buckle moves.

- the position of the extensions 57 shown in FIG. 12 is shown in full in FIG. 13, while the relieved position is indicated by dashed lines at 57 ′.

- FIG. 14 shows a modified embodiment, the intermediate piece connected to the tension member 26 being formed by a bracket 59 which can be displaced relative to the tensioner 60, which in turn is fastened to the ski boot flap pivotably about the axis 8.

- the intermediate piece formed by the bracket 59 interacts via an axis 61 with the tensioner 60, this axis 61 in two, the locked and the positions corresponding to the relaxed position cooperate with locking elements 62 of the tensioner.

- the actuator is designated 63 in this embodiment and is pivotable about the axis 8, about which the tensioner 60 can be pivoted on the support element 7, in a recess 64 of the tensioner.

- the actuator 63 has an elongated recess 65 extending in the direction of displacement, which is penetrated by the axis 61 of the intermediate piece 59 in the assembled state.

- the actuating member 63 is prestressed via a spring 66 into a position in which the axis 61 is held in a defined position relative to the latching elements 62. In the position shown in FIG. 14, the relaxed position is assumed, the tensioner 60 being designed to be slightly raised to clarify the illustration.

- the axis 61 of the intermediate piece guided in the recess 65 is brought out of engagement with the latching element 62 which is further away from the pivot axis 8 and the position shown in FIG. 14 can be assumed by a guide in the recess 65.

- the tensioning buckle is shown in FIGS. 15 and 16 in the two possible positions of the intermediate piece, again formed by a bracket 59, relative to the tensioner 60.

- the tensioner 60 is again shown partially raised from the support element 7, it being pointed out again that the displacement of the intermediate piece in the direction of an increased effective length of the entire tensioning buckle is carried out in the adjacent position of the tensioner 60 on the ski shoe flap or support part 7.

- the tensioner 60 in turn has latching elements 62, in which the axis 61 of the intermediate piece 59 extending transversely to the direction of displacement engages. 15 shows the first locked position of the intermediate piece 59 on the tensioner 60 and in FIG.

- an actuating member 67 with a substantially U-shaped cross section is guided in a recess 68 in the tensioner 60 so that it can be moved normally to the direction of displacement of the intermediate piece, as can be seen more clearly from FIGS. 17 and 18.

- the actuator 67 has elongated holes 69 in the direction of displacement, which can also be designed as longitudinal grooves, in which the axis 61 of the displaceable intermediate piece designed as a bracket 59 is slidably mounted.

- the positions of the axis 61 corresponding to the locking elements 62 on the tensioner 60 are indicated in FIG. 17 by 61 ′ and 61 ⁇ , position 61 ′ representing the locked position according to FIG.

- the actuating member 67 is pretensioned by a leaf spring 70 in order to hold the axis 61 which is displaceable in the elongated holes 69 in a defined contact position against the sawtooth-shaped latching elements 62.

- the axis 61 comes out of engagement with the sawtooth-shaped locking element 62 facing away from the pivot axis 8 when an essentially normal force is applied to the actuating member 67 and becomes in the direction of an increased effective length of the entire tensioning buckle in the elongated hole guides 69 of the actuator guided into the position indicated by 61 ⁇ .

- the position of the axis 61 of the intermediate piece 59 is locked in this way in the interaction of the latching elements 62 with the elongated holes 69 which extend over a limited length.

- the locking in the originally set position takes place by briefly pivoting the tensioner about the pivot axis on the ski boot flap, as a result of which the locking members come into engagement with one another again and in this way the shortened length of the tensioning buckle is set again.

Landscapes

- Footwear And Its Accessory, Manufacturing Method And Apparatuses (AREA)

- Automotive Seat Belt Assembly (AREA)

Description

Die Erfindung bezieht sich auf eine Spannschnalle für Skischuhe mit einem quer zur Zugrichtung schwenkbaren Spanner, welcher über ein Zwischenstück längenveränderlich mit einem Zugglied verbindbar ist.The invention relates to a tensioning buckle for ski boots with a tensioner which can be pivoted transversely to the direction of pull and which can be connected in length-variable manner to a tension member via an intermediate piece.

Spannschnallen für Skischuhe der eingangs genannten Art sind beispielsweise der US-PS 4 470 175 zu entnehmen. Bei derartigen bekannten Spannschnallen ist das Zwischenstück längenveränderlich und dient der Feineinstellung der Spannkraft der Schnalle, da die Schnalle üblicherweise nur in Stufen, welche dem Abstand der Haken entsprechen, in welche das Zugglied eingelegt ist, verstellt werden kann. Um eine Feineinstellung zwischen der durch die Stufen vorgegebenen gröberen Einstellung zu ermöglichen, ist das bekannte Zwischenstück als Spindel ausgebildet, welches mit einer Rändelmutter in seiner Länge verstellt werden kann.Tension buckles for ski boots of the type mentioned at the outset can be found, for example, in US Pat. No. 4,470,175. In such known tensioning buckles, the intermediate piece is variable in length and serves to fine-tune the tensioning force of the buckle, since the buckle can usually only be adjusted in steps which correspond to the distance between the hooks into which the tension member is inserted. In order to enable a fine adjustment between the coarser setting specified by the steps, the known intermediate piece is designed as a spindle, the length of which can be adjusted with a knurled nut.

Die bekannten Spannschnallen zeichnen sich durchwegs dadurch aus, daß sie in ihrer Schließlage einen definierten Zug auf die gegeneinander zu spannenden Lappen des Schuhes ausüben. Wenn nun beispielsweise zum Gehen oder beim Stehen bei Liftanlagen eine Druck- bzw. Zugentlastung gewünscht wird, muß eine derartige Schnalle geöffnet werden. Die Öffnung der Schnalle führt aber nun dazu, daß der Spannhebel von der Oberfläche des Schuhes absteht und derartige über die Oberfläche des Skischuhes vorstehende Teile bieten die Gefahr von Verletzungen und können auch sonst hinderlich sein.The well-known tension buckles are characterized by the fact that in their closed position they exert a defined tension on the flaps of the shoe that are to be tensioned against each other. If, for example, a pressure or strain relief is desired for walking or standing in the lift system, such a buckle must be opened. However, the opening of the buckle now causes the tensioning lever to protrude from the surface of the boot and such parts protruding from the surface of the ski boot offer the risk of injury and can also be a hindrance.

Die Erfindung zielt nun darauf ab, eine Spannschnalle der eingangs genannten Art dahingehend weiterzubilden, daß es ohne Öffnen des Spannhebels, und ohne daß der Spannhebel eine von der Schuhaußenfläche abstehende Lage einnimmt, möglich wird, eine Zugentlastung vorzunehmen, wobei die erfindungsgemäße Einrichtung darüberhinaus sicherstellen soll, daß bei einem neuerlichen Schließen der Schnalle unmittelbar die ursprünglich gewählte Spannkraft wiederum erreicht werden kann. Zur Lösung dieser Aufgabe besteht die erfindungsgemäße Spannschnalle im wesentlichen darin, daß das Zwischenstück in Zugrichtung verlagerbar mit dem Spanner verbunden ist und in einer ersten Stellung lösbar mit dem Spanner verriegelbar ist und in entriegelter Stellung in Richtung einer vergrößerten wirksamen Länge der Spannschnalle begrenzt verlagerbar geführt ist. Dadurch, daß das Zwischenstück in Zugrichtung verlagerbar mit dem Spanner verbunden ist und zwei definierte Stellungen einnehmen kann, wird eine definierte Stellung für die korrekte Schließlage unter der voreingestellten Zugkraft und eine zweite Stellung zur Verfügung gestellt, bei welcher die Spannschnalle eine um ein definiertes Maß verringerte Spannkraft ausübt, ohne daß hiefür der schwenkbare Spanner in eine von der Oberfläche des Skischuhes abstehende Lage verschwenkt werden muß. Zu diesem Zweck ist das Zwischenstück in der ersten Stellung lösbar mit dem Spanner verriegelbar und nach Lösen der Entriegelung in Richtung einer vergrößerten wirksamen Länge der Spannschnalle begrenzt verlagerbar geführt. Die Entriegelung des Zwischenstückes für eine begrenzte Vergrößerung der wirksamen Länge der Spannschnalle erfolgt somit ohne Öffnen des Spanners.The invention now aims to develop a tensioning buckle of the type mentioned in such a way that it is possible to provide strain relief without opening the tensioning lever and without the tensioning lever assuming a position protruding from the outer surface of the shoe, the device according to the invention also ensuring that at When the buckle is closed again, the originally selected tensioning force can be achieved immediately. To achieve this object, the tensioning buckle according to the invention essentially consists in the fact that the intermediate piece is connected to the tensioner such that it can be displaced in the pulling direction and can be releasably locked to the tensioner in a first position and can be moved to a limited extent in the unlocked position in the direction of an increased effective length of the tensioning buckle . The fact that the intermediate piece is displaceably connected in the pulling direction to the tensioner and can assume two defined positions provides a defined position for the correct closed position under the preset pulling force and a second position in which the tensioning buckle reduces a defined amount Exerts tension without the pivotable tensioner having to be pivoted into a position protruding from the surface of the ski boot. For this purpose, the intermediate piece in the first position can be releasably locked with the tensioner and, after releasing the unlocking, can be displaced to a limited extent in the direction of an increased effective length of the tensioning buckle. The intermediate piece is unlocked for a limited increase in the effective length of the tensioning buckle without opening the tensioner.

Die Begrenzung der Verlagerbarkeit und die Art der Verriegelung kann im Rahmen einer derartigen Ausbildung des Zwischenstückes in unterschiedlicher und vorteilhafter Weise gewählt werden. Mit Vorteil und zur Erzielung geringer Baumaße ist die Ausbildung hiebei so getroffen, daß das verlagerbare Zwischenstück im oder am Spanner verschiebbar ist. Vor allen Dingen bei einer Verlagerbarkeit des Zwischenstückes im Spanner selbst kann die Ausbildung in den Spanner integriert werden, so daß sich auch bei einem in der erfindungsgemäßen Weise verlagerbaren Zwischenstück in geschlossener Lage keine größeren Gesamtabmessungen der Spannschnalle ergeben.The limitation of the relocability and the type of locking can be selected in a different and advantageous manner within the framework of such a design of the intermediate piece. Advantageously and to achieve small dimensions, the training is so made that the displaceable intermediate piece can be moved in or on the tensioner. Above all, if the intermediate piece can be displaced in the tensioner itself, the design can be integrated into the tensioner, so that even with an intermediate piece displaceable in the manner according to the invention in the closed position, there are no larger overall dimensions of the tensioning buckle.

Mit Vorteil ist die Ausbildung so getroffen, daß das Zwischenstück zur Schwenkachse des Spanners parallel verschwenkbar am Spanner angelenkt ist, wodurch insbesondere bei weniger flexiblen Zuggliedern ein Öffnen des Spanners erleichtert wird. Das Zwischenstück selbst ist mit dem Zugglied verbindbar oder verbunden und das Zugglied kann in beliebiger bekannter Weise, beispielsweise in hakenförmige Fortsätze an der Außenseite des dem Spanner gegenüberliegenden Lappens in Stufen festgelegt sein. Das Zugglied kann aber prinzipiell auch in einer definierten Lage fest mit dem dem Spanner gegenüberliegenden Lappen verbunden sein, wobei die entsprechende Verstellbarkeit im oder am Spanner selbst vorgesehen sein kann.Advantageously, the design is such that the intermediate piece is articulated parallel to the pivot axis of the tensioner on the tensioner, whereby opening of the tensioner is facilitated in particular with less flexible tension members. The intermediate piece itself can be connected or connected to the tension member and the tension member can be fixed in steps in any known manner, for example in hook-shaped extensions on the outside of the flap opposite the tensioner. In principle, however, the tension member can also be firmly connected in a defined position to the tab opposite the tensioner, the corresponding adjustability being able to be provided in or on the tensioner itself.

Eine besonders kompakte Bauweise läßt sich dadurch verwirklichen, daß der Spanner eine Ausnehmung für die Aufnahme des Zwischenstückes aufweist. Bei einer derartigen Bauweise kann das Zwischenstück vollständig in einer entsprechenden Ausnehmung des Spanners angeordnet sein und kann nach Lösen der Verriegelung in Zugrichtung aus dieser Ausnehmung herausgeschoben werden, wobei die Begrenzung der Verlagerbarkeit bzw. Verschiebbarkeit auf unterschiedliche Weise sichergestellt werden kann.A particularly compact design can be achieved in that the tensioner has a recess for receiving the intermediate piece. With such a construction, the intermediate piece can be arranged completely in a corresponding recess of the tensioner and can be pushed out of this recess in the pulling direction after releasing the locking device, the limitation of the displaceability or displaceability being ensured in different ways.

Eine besonders einfache Begrenzung der Verschiebbarkeit des Zwischenstückes im oder am Spanner wird dadurch erzielt, daß im oder am Spanner eine parallel zur Schwenkachse des Spanners verlaufende Achse angeordnet ist, welche ein quer zu dieser Achse sich erstreckendes Langloch des Zwischenstückes durchsetzt. Die Achse im oder am Spanner kann hiebei gleichzeitig in Kombination mit dem entsprechenden Langloch des Zwischenstückes die Begrenzung der Verlagerbarkeit und die Schwenkbarkeit des Zwischenstückes zum Erleichtern des Öffnens des Spanners ergeben.A particularly simple limitation of the displaceability of the intermediate piece in or on the tensioner is achieved in that an axis running parallel to the pivot axis of the tensioner is arranged in or on the tensioner, which passes through an elongated hole of the intermediate piece extending transversely to this axis. The axis in or on the tensioner can, in combination with the corresponding elongated hole of the intermediate piece, result in the limitation of the displaceability and the pivotability of the intermediate piece to facilitate the opening of the tensioner.

Auch das Verriegelungsglied für die lösbare Verriegelung des Zwischenstückes in der Schließlage mit entsprechend verkürzter wirksamer Länge kann in verschiedener Weise ausgebildet sein, wobei die Ausbildung besonders vorteilhaft so getroffen werden kann, daß im oder am Zwischenstück oder dem Spanner ein wenigstens ein Verriegelungsglied für das Zwischenstück tragendes Betätigungsglied um eine sich quer zur Verschieberichtung des Zwischenstückes erstreckende Achse schwenkbar oder quer zur Verschieberichtung verschiebbar angeordnet ist. Das Betätigungsglied kann dabei als schwenkbarer Hebel oder relativ zum Spanner oder Zwischenstück ausgebildetes verschiebbares Element ausgebildet sein, welches bei einer Betätigung die Verriegelung für das Zwischenstück über ein Lösen geeigneter Verriegelungselemente aufhebt. Gemäß einer bevorzugten Ausführungsform kann die Ausbildung dabei so getroffen sein, daß das Betätigungsglied als um die Achse schwenkbarer zweiarmiger Hebel ausgebildet ist, dessen einer Arm ein, insbesondere hakenförmiges, Verriegelungsglied trägt, welches in der Verriegelungsstellung mit einem entsprechenden Gegenprofil des Spanners oder des Zwischenstückes zusammenwirkt. Ein derartiger zweiarmiger Hebel kann durch Niederdrücken des dem Verriegelungsglied gegenüberliegenden freien Hebelarmes in eine Entriegelungslage verschwenkt werden und in der entriegelten Lage wird der Verschiebeweg bis zur vordefinierten vergrößerten wirksamen Länge des Zwischenstückes freigegeben. Das Verriegelungsglied selbst kann beispielsweise hakenförmig ausgebildet sein, wobei naturgemäß äquivalente Ausbildungen, wie beispielsweise Ausbildungen mit einem Querhaupt, welches in entsprechende hakenförmig gestaltete Nuten des Verriegelungsgliedes eingreift, gleichfalls ohne weiteres verwirklicht werden können. Mit Vorteil ist in jedem Falle die Ausbildung so getroffen, daß das Betätigungsglied federnd in die Verriegelungslage des Zwischenstückes gedrückt ist, wodurch bei entsprechender Ausbildung des mit Verriegelungsgliedern versehenen Betätigungsgliedes eine selbsttätige Verrastung in der verriegelten Stellung ermöglicht wird. Bei einer derartigen federnden Beaufschlagung des Betätigungsgliedes genügt es für das neuerliche Spannen der Spannschnalle auf den ursprünglich eingestellten Wert, den Spanner kurz zu öffnen, wodurch das Betätigungsglied mit dem Verriegelungsglied entgegen der Kraft der Feder in die Verriegelungslage geschoben wird und die Verriegelungslage selbsttätig einnehmen kann.The locking member for the releasable locking of the intermediate piece in the closed position with a correspondingly shortened effective length can be designed in various ways, the design being particularly advantageous so that in or on the intermediate piece or the tensioner carries at least one locking member for the intermediate piece Actuator is arranged to pivot about an axis extending transversely to the direction of displacement of the intermediate piece or to be displaceable transversely to the direction of displacement. The actuating element can be designed as a pivotable lever or a displaceable element which is designed relative to the tensioner or intermediate piece and which, when actuated, cancels the locking for the intermediate piece by releasing suitable locking elements. According to a preferred embodiment, the design can be such that the actuating member is designed as a two-armed lever which can be pivoted about the axis, one arm of which carries a, in particular hook-shaped, locking member which cooperates with a corresponding counter profile of the tensioner or the intermediate piece in the locking position . Such a two-armed lever can be pivoted into an unlocking position by depressing the free lever arm opposite the locking member, and in the unlocked position the displacement path is released up to the predefined enlarged effective length of the intermediate piece. The locking member itself can, for example, be hook-shaped, whereby naturally equivalent configurations, such as, for example, training with a crosshead, which engages in corresponding hook-shaped grooves of the locking member, can also be easily implemented. In any case, the design is advantageously made such that the actuating member is resiliently pressed into the locking position of the intermediate piece, so that, with the corresponding design of the actuating member provided with locking members, an automatic one Locking in the locked position is made possible. With such a resilient loading of the actuator, it is sufficient for the new tensioning of the tensioning buckle to the originally set value, to open the tensioner briefly, whereby the actuator is pushed against the force of the spring into the locking position and can automatically assume the locking position.

Die schwenkbare Anlenkung des Zwischenstückes sowie die Freigabe eines vorbestimmten Verschiebeweges nach Entriegelung des Verriegelungsgliedes kann in einfacher Weise auch dadurch sichergestellt werden, daß das Zwischenstück in einer quer zur Verschieberichtung verlaufenden Ebene eine Achse oder koaxiale Fortsätze aufweist, welche in in Verschieberichtung verlaufende Nuten bzw. Langlöcher oder insbesondere sägezahnförmige Rastelemente des Spanners und/oder des Betätigungsgliedes eingreift (eingreifen). Bei einer derartigen Ausbildung werden Nuten bzw. Langlöcher oder Rastelemente im oder am Spanner und/oder am Betätigungsglied selbst anstelle des Langloches im Zwischenstück vorgesehen, wobei bei Verwendung von Nuten diese beispielsweise gekröpft ausgebildet sein können, um auf diese Weise in der jeweiligen Endlage eine selbsttätige Verriegelung zu ergeben. Weiters kann bei Anordnung von von Langlöchern bzw. Nuten sowohl im Spanner als auch im Betätigungsglied mit sehr kompakten und kleinen Bauteilen das Auslangen gefunden werden, welche nach Art teleskopisch ineinander verschiebbarer Bauteile jeweils einen Teil des Verschiebeweges des Zwischenstückes festlegen.The pivotable articulation of the intermediate piece and the release of a predetermined displacement path after unlocking the locking member can also be ensured in a simple manner in that the intermediate piece has an axis or coaxial extensions in a plane transverse to the displacement direction, which extends in grooves or elongated holes extending in the displacement direction or in particular sawtooth-shaped locking elements of the tensioner and / or the actuating element engages (engage). With such a design, grooves or elongated holes or locking elements are provided in or on the tensioner and / or on the actuating member itself instead of the elongated hole in the intermediate piece, wherein if grooves are used, they can be cranked, for example, in order in this way to have an automatic in the respective end position Locking to yield. Furthermore, with the arrangement of elongated holes or grooves, both in the tensioner and in the actuator with very compact and small components, the length can be found, each of which defines part of the displacement path of the intermediate piece in the manner of telescopically displaceable components.

Die Erfindung wird nachfolgend an Hand von in der Zeichnung dargestellten Ausführungsbeispielen näher erläutert. In dieser zeigen Fig.1 im Schnitt eine erste Ausführungsform einer erfindungsgemäßen Spannschnalle; Fig.2 in einer Explosionsdarstellung die Einzelteile der in Fig.1 dargestellten Spannschnalle; Fig.3 eine Draufsicht auf eine abgewandelte Ausführungsform einer erfindungsgemäßen Spannschnalle, wobei das verlagerbare Zwischenstück den Spanner teilweise umgreift; Fig.4a und 4b Schnitte nach der Linie IV-IV der Fig.3 durch zwei mögliche Ausführungsformen von Verriegelungsgliedern und Gegenprofilen zum Verriegeln des Zwischenstückes in der ersten Stellung; Fig.5, 6 und 7 Draufsichten auf weitere abgewandelte Ausführungsformen einer erfindungsgemäßen Spannschnalle, wobei das Zwischenstück ähnlich zu der Ausbildung gemäß Fig.3 den Spanner für eine Führung des Zwischenstückes am Spanner teilweise umgreift; die Fig.8 und 9 weitere abgewandelte Ausführungsformen einer erfindungsgemäßen Spannschnalle, wobei mit dem Zwischenstück verbundene Achsen oder quer zur Verschieberichtung vorgesehene Fortsätze in Nuten bzw. Langlöchern des Spanners geführt sind; Fig.10 eine Explosionsdarstellung der Ausbildung gemäß Fig.9; Fig.11 und 12 wiederum abgewandelte Ausführungsformen einer erfindungsgemäßen Spannschnalle, wobei die Zwischenstücke mit quer zur Verschieberichtung vorgesehenen Fortsätzen in kulissenartigen Bahnen am Spanner geführt sind; Fig.13 eine Teilansicht in Richtung des Pfeiles XIII der Fig.12 auf eine Kulissenbahn des Spanners; Fig.14 eine Explosionsdarstellung einer weiteren abgewandelten Ausführungsform einer erfindungsgemäßen Spannschnalle; und die Fig.15 bis 18 Ansichten einer weiteren abgewandelten Ausführungsform mit einem verschiebbar am Spanner gelagerten Betätigungsglied zum Verriegeln, wobei die Fig.15 und 16 die Spannschnalle mit teilweise abgehobenem Spanner in den zwei Positionen des Zwischenstückes zeigen, Fig.17 eine Explosionsdarstellung ist und Fig.18 einen Schnitt nach der Linie XVIII-XVIII der Fig.15 darstellt.The invention is explained in more detail below with reference to exemplary embodiments shown in the drawing. 1 shows in section a first embodiment of a tensioning buckle according to the invention; 2 shows an exploded view of the individual parts of the tensioning buckle shown in FIG. 1; 3 shows a plan view of a modified embodiment of a tensioning buckle according to the invention, the displaceable intermediate piece partially encompassing the tensioner; 4a and 4b sections along the line IV-IV of Figure 3 by two possible embodiments of locking members and counter profiles for locking the intermediate piece in the first position; 5, 6 and 7 are top views of further modified embodiments of a tensioning buckle according to the invention, the intermediate piece, similar to the embodiment according to FIG. 3, partially encompassing the tensioner for guiding the intermediate piece on the tensioner; FIGS. 8 and 9 further modified embodiments of a tensioning buckle according to the invention, wherein axes connected to the intermediate piece or extensions provided transversely to the direction of displacement are guided in grooves or elongated holes of the tensioner; 10 shows an exploded view of the design according to FIG. 9; 11 and 12, in turn, modified embodiments of a tensioning buckle according to the invention, the intermediate pieces being guided in link-like paths on the tensioner with projections provided transversely to the direction of displacement; 13 shows a partial view in the direction of arrow XIII of FIG. 12 on a slide track of the tensioner; 14 shows an exploded view of a further modified embodiment of a tensioning buckle according to the invention; and FIGS. 15 to 18 are views of a further modified embodiment with an actuating element which is displaceably mounted on the tensioner for locking, wherein FIGS. 15 and 16 show the tensioning buckle with the tensioner partially raised in the two positions of the intermediate piece, FIG. 17 is an exploded view and Figure 18 shows a section along the line XVIII-XVIII of Figure 15.

In Fig.1 ist mit 1 eine Spannschnalle bezeichnet, wobei ein Spanner 2 sowie ein mit der Spannschnalle 1 zusammenwirkendes Element 3 an einander überlappenden Schalen-, Manschetten-oder Schaftteilen bzw. Lappen 4 und 5 festgelegt sind. Die Festlegung des Spanners 2 sowie des Elementes 3 erfolgt dabei in an sich bekannter Weise beispielsweise über Nieten, welche in Fig.1 schematisch mit 6 angedeutet sind. In ebenfalls bekannter Weise ist der Spanner 2 an einem mit 7 bezeichneten Auflagerelement am Schalenteil 5 um eine quer zur Betätigungsrichtung des Spanners 2 angeordnete Achse verschwenkbar angeordnet. In ähnlicher Weise ist auch das in Fig.1 dargestellte Element 3 am Auflagerelement 9 schwenkbar um eine Achse 10 angelenkt. Die Verbindung des Spanners 2 mit dem Element 3 erfolgt dabei beispielsweise über ein Zugglied 11 mit sägezahnförmigem Profil, welches über ein Zwischenstück 12 mit dem Spanner 2 verbunden ist, wobei dieses Zwischenstück 12 um eine zur Anlenkachse 8 des Spanners 2 am Auflagerelement 7 parallele Achse 13 am Spanner angelenkt ist. Für eine Einstellung der wirksamen Länge und somit der Spannkraft der Spannschnalle 1 sind am Zugglied 11 mehrere Einraststellen für das Element 3 vorgesehen und es ist für eine Feineinstellung am Zwischenstück 12 ein Gewindeteil 14 vorgesehen, welcher in das sägezahnförmige Zugglied 11 über einen gewissen Weg einschraubbar ist. Für ein Verschließen der Spannschnalle 1 erfolgt nach einem Einhängen des Elementes 3 in das Zugglied 11 in der gewünschten Stellung in bekannter Weise eine Betätigung des Spanners 2 in Richtung des Pfeiles 15.In FIG. 1, 1 denotes a tensioning buckle, a

Um eine teilweise Entlastung der gewählten Verspannung der Schalenteile 4 und 5 beispielsweise während Wartezeiten oder einer Beförderung mit Aufstiegshilfen zu erzielen, ohne die Verriegelung über die Spannschnalle vollkommen zu lösen, ist das Zwischenstück 12 derart ausgebildet, daß es in der in Längsrichtung der Spannschnalle 1 verlaufenden und mit 16 angedeuteten Zugrichtung verschiebbar mit dem Spanner 2 verbunden ist. Zu diesem Zweck ist am Zwischenstück 12 ein Betätigungsglied 17 vorgesehen, welches um eine zu den Achsen 8 und 13 im wesentlichen parallele Achse 18 verschwenkbar ist, wobei das als zweiarmiger Hebel ausgebildete Betätigungsglied 17 an einem Ende ein hakenförmiges Verriegelungsglied 19 aufweist, welches in der in Fig.1 dargestellten ersten und verkürzten Stellung des Zwischenstückes 12 mit der Achse 13 als Gegenprofil zusammenwirkt. Bei Ausübung einer Kraft in Richtung des Pfeiles 20 auf den zweiten Arm 21 des Hebels 17 erfolgt ein Verschwenken des Betätigungsgliedes 17 um die Achse 18 und der Haken 19 gerät außer Eingriff mit der Achse 13, so daß entgegen der Richtung des Pfeiles 16 eine Verschiebung der Achse 13 in einem im Zwischenstück 12 vorgesehenen Langloch 22 in Richtung einer Vergrößerung der wirksamen Länge der Spannschnalle erfolgt. Derart kann entsprechend der Länge des Langloches 22 durch die Verlagerung des Zwischenstückes 12 eine effektive Verlängerung der Spannschnalle in der entriegelten Stellung vorgenommen werden und eine teilweise Entlastung der Spannung erzielt werden. Diese Entlastung erfolgt dabei naturgemäß in der geschlossenen Stellung des Spanners 2, d.h. nach einer Bewegung des Spanners 2 in Richtung des Pfeiles 15 für ein Verschließen der Spannschnalle. Um die für den Fahrbetrieb gewünschte Spannlage nach einer durch Verlängerung der wirksamen Länge des Zwischenstückes 12 erfolgten Entlastung wiederum einstellen zu können, genügt es, den Spanner 2 geringfügig entgegen der Richtung des Pfeiles 15 anzuheben, so daß bei im wesentlichen bestehender Anlage der gesamten Spannschnalle 1 an den Außenflächen der Skischuhteile 4 und 5 eine Bewegung der Achse 13 in Richtung eines Eingriffes der Achse 13 mit dem hakenförmigen Verriegelungsglied 19 am Betätigungshebel 17 erfolgt und nach einem Einrasten der Achse 13 in der in Fig.1 gezeigten Stellung durch nochmalige kurze Betätigung des Spanners 2 in Richtung des Pfeiles 15 wiederum die gewünschte Schließstellung erzielt wird. Derart läßt sich ohne ein vollkommenes Lösen der Spannschnalle 1 eine Entlastung erzielen.In order to partially relieve the selected tensioning of the

Anstelle der in Fig.1 gezeigten Ausbildung des Zwischenstückes 12 mit dem Zugglied 11 mit dem Sägezahnprofil und dem am zweiten Skischuhteil festgelegten bügelförmigen Element 3 kann naturgemäß auch ein beispielsweise in Form eines Bügels ausgebildetes Zugglied am Zwischenstück 12 vorgesehen sein und am anderen Skischuhteil ein beispielsweise sägezahnförmiges Profil zur Erzielung unterschiedlicher Verriegelungslagen vorgesehen sein, wobei ein derartiges Verriegelungselement in bekannter Weise am Lappen 4 festgelegt ist.Instead of the design of the

Bei der in Fig.2 gezeigten Explosionsdarstellung der Einzelteile der in Fig.1 dargestellten Spannschnalle wurden die Bezugszeichen beibehalten. Dabei wurde auf die Darstellung des Auflageelementes 7 für den Spanner 2 am Schuhteil 5 verzichtet und es sind in Fig.2 die Durchbrechungen für den Durchtritt der einzelnen Anlenkachsen bzw. Schwenkachsen mit den Bezugszeichen der Achsen gemäß Fig.1 versehen, um derart eine leichtere und eindeutige Zuordnung zu ermöglichen. Aus Fig.2 ist dabei ersichtlich, daß der Spanner 2 eine der Ausbildung des Zwischenstückes 12 entsprechende Ausnehmung 23 zur Aufnahme des Zwischenstückes 12 aufweist, wobei die durch die Durchbrechungen für die Achse 13 hindurchtretende nicht näher dargestellte Achse im Langloch 22 des Zwischenstückes 12 geführt ist. Das Zwischenstück 12 weist für die Aufnahme des als zweiarmigen Hebels ausgebildeten Betätigungsgliedes 17 ebenfalls eine Ausnehmung 24 auf und das Betätigungsglied 17 ist über eine durch die Durchbrechungen 18 im Zwischenstück 12 und im Hebel 17 nicht näher dargestellte hindurchgeführte Achse schwenkbar. Der zweiarmige Hebel 17 ist dabei, wie der Übersichtlichkeit halber nicht näher dargestellt, durch eine mehrere Windungen aufweisende Biegefeder entgegen der Betätigungsrichtung durch eine auf das Ende 21 aufgebrachte Kraft zum Lösen der Verriegelung, d.h. zum außer Eingriff bringen des hakenförmigen Verriegelungsgliedes 19 aus der im Langloch 22 für den Schwenkachse 13, federbelastet.In the exploded view of the individual parts of the tensioning buckle shown in FIG. 1, the reference numerals have been retained. The

Bei der in Fig.3 dargestellten Spannschnalle 1 ist der Spanner 2 wiederum um die Achse 8 schwenkbar an einem Skischuhteil bzw. Lappen angelenkt, welcher nicht näher dargestellt ist. Am im wesentlichen in Form eines Bügels ausgebildeten Spanner 2 ist an den Holmen 25 das Zwischenstück 12 verschiebbar geführt, an welchem das in diesem Ausführungsbeispiel bandförmig ausgebildete Zugglied 26 festgelegt ist. Am Spanner 2 ist um eine zur Schwenkachse 8 parallele Achse 27 ein Betätigungsglied 28 schwenkbar angelenkt, wobei an einem freien Ende dieses Betätigungsgliedes 28 wiederum ein Verriegelungsglied vorgesehen ist. Bei dem in Fig.3 gezeigten Ausführungsbeispiel wird das Verriegelungsglied von sich im wesentlichen parallel zur Schwenkachse 27 erstreckenden Fortsätzen 29 gebildet, welche in entsprechende Ausnehmungen 30 am Zwischenstück in der verriegelten Lage, wie sie in Fig.3 dargestellt ist, eingreifen. Bei einer Betätigung des als zweiarmigen Hebels ausgebildeten Betätigungsgliedes an seinem den Verriegelungsgliedern gegenüberliegenden freien Ende 21, d.h. bei einem Verschwenken des Betätigungsgliedes 28 um die Achse 27, gelangen die Fortsätze 29 außer Eingriff mit den am Zwischenstück 12 vorgesehenen Ausnehmungen 30 und es erfolgt eine Verschiebung des Zwischenstückes 12 entgegen der durch die Federn 31 aufgebrachten Kräfte in Richtung einer Verlängerung der wirksamen Länge der Spannschnalle 1. In Fig.3 ist weiters eine Feder 32 angedeutet, welche den zweiarmigen Hebel 28 in Richtung der Verriegelungslage der Verriegelungsglieder 29 in den Ausnehmungen 30 belastet.In the

Bei der schematischen Darstellung gemäß Fig.4a ist ersichtlich, daß die Ausnehmung 30 am Zwischenstück 12 entgegen der Verschieberichtung in der entlasteten Stellung geneigt verläuft, um derart eine sichere Aufnahme der Fortsätze 29 des zweiarmigen Hebels 28 sicherzustellen. Weiters weist das Zwischenstück 12 in Richtung zum Betätigungsglied 28 eine Schrägfläche 33 auf, welche insbesondere bei einer Verschiebung der Verriegelungsglieder 29 in die verriegelte Stellung eine sichere Führung ermöglichen.In the schematic representation according to FIG. 4 a, it can be seen that the

Alternativ zu der in den Fig.3 und 4a gezeigten Verriegelung des zweiarmigen Hebels 28 am Zwischenstück 12 in der verkürzten Stellung kann die Ausbildung auch so getroffen sein, wie dies in Fig.4b angedeutet ist. Dabei weist der zweiarmige Hebel 28, ähnlich zur Ausführungsform gemäß den Fig.1 und 2, an einem freien Ende ein hakenförmiges Verriegelungsglied 34 auf, welches in am Zwischenstück 12 vorgesehene und im wesentlichen parallel zur Schwenkachse 27 des zweiarmigen Hebels 28 am Spanner 2 verlaufende Fortsätze 35 bzw. eine derart verlaufende Achse 35 in der verriegelten Stellung in Eingriff steht.As an alternative to the locking of the two-

Die in Fig.5 dargestellte Ausführungsform einer Spannschnalle ist ähnlich der in Fig.3 dargestellten Ausführungsform getroffen und es ist das Zwischenstück 12 an Holmen 25 des Spanners 2 verschieblich geführt. Der Spanner 2 ist hiebei wiederum um die Achse 8 schwenkbar. Das Zwischenstück 12 kann dabei aus einem Spritzteil bestehen, wobei das bandförmige Zugglied 26 mit eingespritzt ist. Das Zwischenstück 12 ist wiederum entgegen der Verschiebung in die entlastete Stellung von einer im Inneren im Bereich des einen Holmes 25 des Spanners 2 vorgesehenen Feder 36 belastet, wobei ebenso wie bei der Ausführungsform gemäß Fig.3 der maximale Verschiebeweg durch ein vollkommenes Zusammendrücken der jeweils vorgesehenen Federn 31 bzw. 36 begrenzt ist. Am Spanner 2 ist in einer Ausnehmung 37 ein zweiarmiger Hebel 38 um eine zur Achse 8 parallele Achse 39 schwenkbar, wobei am einen freien Ende des zweiarmigen Hebels 38 wiederum Verriegelungsglieder 40 vorgesehen sind, welche bei einer Ausführungsform ähnlich der Fig.3 in Ausnehmungen 41 am Zwischenstück 12 eingreifen. Bei einer Betätigung des zweiarmigen Hebels an dem den Verriegelungsgliedern abgewandten Ende 21 erfolgt wiederum ein Lösen der Verriegelung und eine Verschiebung des Zwischenstückes 12 in Richtung einer Verlängerung der wirksamen Länge der gesamten Spannschnalle und derart eine Entlastung. Ähnlich wie bei der Ausführungsform gemäß Fig.3 kann naturgemäß das Verriegelungsglied auch in Form eines Hakens ausgebildet sein, welcher entsprechend ausgebildete Fortsätze oder eine Achse umgibt, wie dies beispielsweise in Fig.4b dargestellt ist.The embodiment of a tensioning buckle shown in FIG. 5 is similar to the embodiment shown in FIG. 3 and the

Das Ausführungsbeispiel gemäß Fig.6 unterscheidet sich von der Ausbildung gemäß Fig.5 im wesentlichen nur durch eine etwas geänderte Ausformung des Spanners sowie des an diesem geführten Zwischenstückes, wobei für gleiche Bauteile die Bezugszeichen beibehalten wurden. Das Zwischenstück 12 ist wiederum an Holmen 25 des Spanners 2 verschieblich geführt und es ist in einer Ausnehmung des Spanners 2 der zweiarmige Betätigungshebel 38 schwenkbar um die Achse 39 ausgebildet. Die Verriegelungsglieder sind dabei im wesentlichen analog zur Ausführung gemäß Fig.5 ausgebildet.The exemplary embodiment according to FIG. 6 differs from the configuration according to FIG. 5 essentially only in a slightly modified shape of the tensioner and of the intermediate piece guided on it, the reference symbols being retained for the same components. The

Bei der Ausführung gemäß Fig.7 ist wiederum der Spanner 2 um die Achse 8 schwenkbar an einem nicht näher dargestellten Lappen festgelegt. Das Zwischenstück 12 ist wiederum an Holmen 25 verschiebbar geführt, wobei ähnlich zur Ausführungsform gemäß Fig.5 im Inneren des Zwischenstückes im Bereich der Holme eine Feder 36 vorgesehen ist. Das als zweiarmiger Hebel ausgebildete Betätigungsglied 38 ist mit seinen Verriegelungsgliedern 40, welche mit Ausnehmungen 41 des Zwischenstückes 12 zusammenwirken, wiederum ähnlich der Ausbildung gemäß den Fig.5 und 6 ausgebildet. Die Festlegung des wiederum bandförmigen Zuggliedes 26 am Zwischenstück 12 erfolgt bei der in Fig.7 gezeigten Ausführung über einen Bügel 42, welcher um eine Achse 43 schwenkbar am Zwischenstück festgelegt ist.In the embodiment according to FIG. 7, the

Die in Fig.8 dargestellte Ausführungsform ist ähnlich zur vorangehenden Ausbildung der Spannschnalle ausgebildet, wobei in diesem Fall der das Zugglied 26 mit dem Zwischenstück 12 verbindende Bügel mit seinen die Schwenkachse am Zwischenstück 12 ausbildenden Fortsätzen 44 sowohl das Zwischenstück 12 durchsetzt als auch in in den Holmen 25 vorgesehene Ausnehmungen 45 hineinragt, wobei diese Ausnehmungen beispielsweise als Langlöcher in Längsrichtung der Holme 25 ausgebildet sind, um derart eine Führung des Zwischenstückes 12 und des Zuggliedes 26 am Spanner bei einer Entlastung durch Vergrößerung der wirksamen Länge der gesamten Spannschnalle zu bewirken. In den Ausnehmungen 45 sind dabei Federn 46 zur Beaufschlagung des Bügels 42 in Richtung der Schließlage vorgesehen.The embodiment shown in FIG. 8 is similar to the previous embodiment of the tensioning buckle, in which case the bracket connecting the

Bei der Ausführungsform gemäß Fig.9 und 10 ist das Zwischenstück 12 in einer Ausnehmung 47 des um die Achse 8 schwenkbar an einem Lappen festgelegten Spanners verschieblich geführt, wobei das Zwischenstück von einer Achse 48 durchsetzt wird, welche durch Ausnehmungen 49, welche im wesentlichen von Langlöchern gebildet sind, hindurchgeführt ist und an der Achse 48 wiederum ein Bügel 50 für die Verbindung des Zwischenstückes 12 mit dem bandförmigen Zugglied 26 vorgesehen ist. Das Zwischenstück 12 weist weiters einen in Längsrichtung des Spanners und somit in Verschieberichtung weisenden Fortsatz 51 auf, welcher in ein entsprechendes Gegenprofil bzw. eine entsprechende Ausnehmung 52 des Spanners eintaucht, wobei in dieser Ausnehmung 52 weiters eine Feder 53, welche vom Fortsatz 51 zumindest teilweise übergriffen wird, angeordnet ist. Durch diese Feder wird das Zwischenstück, wie auch bei vorangehenden Ausführungsformen, wiederum entgegen der Zugrichtung belastet. Ein Entlasten der Spannschnalle erfolgt wiederum über den zweiarmigen Betätigungshebel 38 bei einem Lösen des Eingriffes der Verriegelungsglieder 40 in einer entsprechenden Ausnehmung 41 des Zwischenstückes 12.In the embodiment according to FIGS. 9 and 10, the

Bei der Explosionsdarstellung in Fig.10 sind anstelle der Achsen 39 bzw. 48 die diese Achsen aufnehmenden Öffnungen mit diesen Bezugszeichen versehen, um die Zuordnung der Position der einzelnen Bestandteile zu erleichtern.In the exploded view in FIG. 10, instead of

Bei der Ausführungsform gemäß Fig.11 ist das Zwischenstück 12 wiederum unmittelbar mit dem bandförmigen Zugglied 26 verbunden und in einer Ausnehmung 54 des wiederum um die Achse 8 schwenkbaren Spanners verschieblich geführt. Bei dieser Ausbildung ist das als zweiarmiger Hebel ausgebildete Betätigungsglied 38 wiederum um eine Achse 39 am Spanner schwenkbar angelenkt. Bei einer Ausübung einer Druckkraft auf das freie Ende 21 des zweiarmigen Hebels 38 erfolgt ein Anheben des Zwischenstückes 12 im Bereich des Endes 55 des Betätigungsgliedes 38, so daß ein wiederum von einem Haken gebildetes Verriegelungsglied 56 des Zwischenstückes 12 außer Eingriff mit der Achse 39 gelangt und eine Verschiebung des Zwischenstückes relativ zum Spanner 2 in Richtung einer Verlängerung der wirksamen Länge der gesamten Spannschnalle 1 erzielt wird.In the embodiment according to FIG. 11, the

Bei der Ausführungsform gemäß der Fig.12 ist die am Spanner vorgesehene Schwenkachse 39 für das Betätigungsglied 38 nahe der Schwenkachse 8 des Spanners am Lappen vorgesehen. Bei Ausübung einer Kraft auf das Ende 21 des Hebels 38 wirkt dieser Hebel auf Fortsätze 57 des mit dem Zugglied 26 verbundenen Zwischenstückes 12 ein und das Zwischenstück wird in einer gekröpften Bahn, welche in Fig.13 mit 58 bezeichnet ist, in Richtung einer Verlängerung der wirksamen Länge der gesamten Spannschnalle bewegt. Die in Fig.12 gezeigte Stellung der Fortsätze 57 ist dabei in Fig.13 voll eingezeichnet, während die entlastete Stellung strichliert mit 57′ angedeutet ist.In the embodiment according to FIG. 12, the

In Fig.14 ist eine abgewandelte Ausführungsform dargestellt, wobei das mit dem Zugglied 26 verbundenen Zwischenstück von einem Bügel 59 gebildet ist, welcher relativ zum Spanner 60, welcher wiederum um die Achse 8 schwenkbar am Skischuhlappen befestigt ist, verlagerbar ist. Das von dem Bügel 59 gebildete Zwischenstück wirkt über eine Achse 61 mit dem Spanner 60 zusammen, wobei diese Achse 61 in zwei, der verriegelten und der entspannten Position entsprechenden Stellungen mit Rastelementen 62 des Spanners zusammenwirkt. Das Betätigungsglied ist bei dieser Ausführungsform mit 63 bezeichnet und ist um die Achse 8, um welche der Spanner 60 am Auflagerelement 7 schwenkbar ist, in einer Ausnehmung 64 des Spanners schwenkbar. Das Betätigungsglied 63 weist dabei eine in Verschieberichtung verlaufende, längliche Ausnehmung 65 auf, welche von der Achse 61 des Zwischenstückes 59 im zusammengebauten Zustand durchsetzt wird. Über eine Feder 66 wird das Betätigungsglied 63 in eine Lage vorgespannt, in welcher die Achse 61 in einer definierten Stellung relativ zu den Rastelementen 62 gehalten ist. In der in Fig.14 gezeigten Stellung wird dabei die entspannte Position eingenommen, wobei zur Verdeutlichung der Darstellung der Spanner 60 leicht angehoben ausgebildet ist. Bei einer Ausübung eines Druckes auf das Betätigungsglied 63 wird die in der Ausnehmung 65 geführte Achse 61 des Zwischenstückes außer Eingriff mit dem der Schwenkachse 8 entfernteren Rastelement 62 gebracht und durch eine Führung in der Ausnehmung 65 kann die in Fig.14 dargestellte Position eingenommen werden.FIG. 14 shows a modified embodiment, the intermediate piece connected to the

Bei einer weiteren Ausbildung gemäß den Fig.15 bis 18 ist in Fig.15 und 16 die Spannschnalle in den zwei möglichen Positionen des wiederum von einem Bügel 59 gebildeten Zwischenstückes relativ zum Spanner 60 dargestellt. Zur Verdeutlichung ist der Spanner 60 wiederum teilweise vom Auflagerelement 7 abgehoben dargestellt, wobei nochmals darauf hingewiesen wird, daß die Verlagerung des Zwischenstückes in Richtung einer vergrößerten wirksamen Länge der gesamten Spannschnalle in der anliegenden Position des Spanners 60 am Skischuhlappen bzw. Auflagerteil 7 vorgenommen wird. Der Spanner 60 weist wiederum Rastelemente 62 auf, in welche die quer zur Verschieberichtung verlaufende Achse 61 des Zwischenstückes 59 eingreift. Dabei ist in Fig.15 die erste verriegelte Position des Zwischenstückes 59 am Spanner 60 und in Fig.16 die entspannte Position dargestellt, in welcher die Spannschnalle eine vergrößerte wirksame Länge aufweist. Bei dieser Ausführungsform ist ein mit im wesentlichen U-förmigem Querschnitt ausgebildetes Betätigungsglied 67 in einer Ausnehmung 68 im Spanner 60 normal auf die Verschieberichtung des Zwischenstückes verschiebbar geführt, wie dies aus Fig.17 und 18 deutlicher ersichtlich ist. Das Betätigungsglied 67 weist in Verschieberichtung verlaufende Langlöcher 69 auf, welche auch als Längsnuten ausgebildet sein können, in welchen die Achse 61 des als Bügel 59 ausgebildeten verlagerbaren Zwischenstückes verschiebbar gelagert ist. Die entsprechend den Rastelementen 62 am Spanner 60 möglichen Positionen der Achse 61 sind in Fig.17 mit 61′ und 61˝ angedeutet, wobei Position 61′ die verriegelte Stellung entsprechend Fig.15 und die Position 61˝ die entspannte Stellung entsprechend Fig.16 darstellt. Das Betätigungsglied 67 ist durch eine Blattfeder 70 vorgespannt, um die in den Langlöchern 69 verschiebbare Achse 61 in einer definierten Anlagestellung an den sägezahnförmigen Rastelementen 62 in Anlage zu halten. Ausgehend von einer Lage entsprechend der Position 61′ gelangt die Achse 61 bei einer Aufbringung einer im wesentlichen normalen Kraft auf das Betätigungsglied 67 außer Eingriff mit dem der Schwenkachse 8 abgewandten sägezahnförmigen Rastelement 62 und wird in Richtung einer vergrößerten wirksamen Länge der gesamten Spannschnalle in den Langlochführungen 69 des Betätigungsgliedes geführt in die mit 61˝ bezeichnete Position übergeführt. Die Verriegelung der Lage der Achse 61 des Zwischenstückes 59 erfolgt dabei derart im Zusammenwirken der Rastelemente 62 mit den über eine begrenzte Länge sich erstreckenden Langlöchern 69.In a further embodiment according to FIGS. 15 to 18, the tensioning buckle is shown in FIGS. 15 and 16 in the two possible positions of the intermediate piece, again formed by a

Bei sämtlichen Ausführungsformen erfolgt nach einer Entlastung, d.h. nach einer Verlängerung der wirksamen Länge der gesamten Spannschnalle die Verriegelung in der ursprünglich eingestellten Position durch ein kurzes Verschwenken des Spanners um die Schwenkachse am Skischuhlappen, wodurch die Verriegelungsglieder wieder miteinander in Eingriff gelangen und derart die verkürzte Länge der Spannschnalle wiederum eingestellt wird.In all embodiments, after relieving, ie after extending the effective length of the entire tensioning buckle, the locking in the originally set position takes place by briefly pivoting the tensioner about the pivot axis on the ski boot flap, as a result of which the locking members come into engagement with one another again and in this way the shortened length of the tensioning buckle is set again.

Claims (9)

- A clamping fastening (1) for ski boots, having a tightener (2, 60) which is pivotable transversely to the direction of traction and can via an intermediate piece (12, 59) be connected in a length-changing manner to a tension member (11, 26), characterised in that the intermediate piece (12, 59) is connected to the tightener (2, 60) so as to be movable in the direction of traction (16) and in a first position is detachably lockable to the tightener (2, 60) and in an unlocked position is guided in a manner so as to be movable to a limited extent in the direction of an increased active length of the clamping fastening (1).

- A clamping fastening in accordance with Claim 1, characterised in that the movable intermediate piece (12, 59) is displaceable in or on the tightener (2, 60).

- A clamping fastening in accordance with Claim 1 or 2, characterized in that the intermediate piece (12, 59) is articulated on the tightener (2, 60) so as to be pivotable parallel to the axis of pivot (8) of the tightener (2, 60).

- A clamping fastening in accordance with any one of Claims 1, 2 or 3, characterised in that the tightener (2) has a recess (23) for receiving the intermediate piece (12).

- A clamping fastening in accordance with any one of Claims 1 to 4, characterised in that a spindle (13) running parallel to the axis of pivot (8) of the tightener (2) is arranged in or on the tightener (2) and passes through an oblong hole (22) which is in the intermediate piece (12) and which extends transversely to this axis (8).

- A clamping fastening in accordance with any one of Claims 1 to 5, characterised in that in or on the intermediate piece (12, 59) or the tightener (2, 60) there is an operating member ( 17, 28, 38) - bearing at least one locking member (19, 29, 34, 40, 57) for the intermediate piece (12, 59) - arranged so as to be pivotable about a spindle (18, 27, 39) extending transversely to the displacement direction of the intermediate piece (12, 59) or so as to be displaceable transversely to the displacement direction.

- A clamping fastening in accordance with Claim 6, characterised in that the operating member (17, 28, 38) is in the form of a two-armed lever pivotable about the spindle (18, 27, 39), one arm of this lever bearing a locking member (19, 29, 34, 40, 57) which is in particular hook-shaped and which in the locking position co-operates with an appropriate counterprofile (13, 30, 35, 41) of the tightener (2) or of the intermediate piece (12).

- A clamping fastening in accordance with Claim 6 or 7, characterised in that the operating member is resiliently pressed into the locking position of the intermediate piece (12).

- A clamping fastening in accordance with any one of Claims 1 to 8, characterised in that the intermediate piece (12, 59) has - in a plane running transversely to the displacement direction - a spindle (61) or coaxial prolongations which engage(s) into grooves or oblong holes (65) running in the displacement direction or into catch elements (62), saw-tooth-shaped in particular, of the tightener (60) and/or of the operating member (63).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT1350/89 | 1989-06-02 | ||

| AT135089A AT397603B (en) | 1989-06-02 | 1989-06-02 | TENSION BUCKLE |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0401202A2 EP0401202A2 (en) | 1990-12-05 |

| EP0401202A3 EP0401202A3 (en) | 1991-07-31 |

| EP0401202B1 true EP0401202B1 (en) | 1994-07-13 |

Family

ID=3511995

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19900890168 Expired - Lifetime EP0401202B1 (en) | 1989-06-02 | 1990-05-30 | Clamp fastening |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0401202B1 (en) |

| AT (1) | AT397603B (en) |

| DE (1) | DE59006404D1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8060990B2 (en) | 2006-01-27 | 2011-11-22 | Skis Rossignol | Binding buckle with secure docking element |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| IT1257572B (en) * | 1992-01-16 | 1996-02-01 | Nordica Spa | TIGHTENING LEVER STRUCTURE PARTICULARLY FOR SPORT SHOES |

| IT226867Z2 (en) * | 1992-08-13 | 1997-07-22 | Canstar Italia | LACING OF SKI BOOTS WITH LACING VOLTAGE ADJUSTMENT DEVICE |

| EP0705545B1 (en) | 1994-10-07 | 1999-05-06 | Lange International S.A. | Closing- and clamping device for a ski boot |

| FR2729547A1 (en) * | 1995-01-19 | 1996-07-26 | Salomon Sa | LOCKING AND TIGHTENING DEVICE |

| IT239590Y1 (en) * | 1995-10-04 | 2001-03-05 | Tecnica Spa | CLOSING DEVICE FOR SPORTS FOOTWEAR, IN PARTICULAR SKI BOOTS WITH AN EXTENDABLE RACK ELEMENT |

| IT242084Y1 (en) * | 1996-02-05 | 2001-06-04 | Nordica Spa | CLAMPING DEVICE FOR SPORT SHOES |

| US5720084A (en) * | 1996-12-31 | 1998-02-24 | Chen; Chin Chu | Securing device for footwear |

| FR2784554B1 (en) | 1998-10-20 | 2000-12-15 | Salomon Sa | ADJUSTING / CLOSING DEVICE OF A SPORTS SHOE |

| DE10155922B4 (en) * | 2000-11-17 | 2010-04-01 | Benetton Group S.P.A., Ponzano Veneto | Lever closure device |

| ITPN20030012U1 (en) * | 2003-04-23 | 2004-10-24 | Luigi Sa Societe Anonyme Holding | CLAMPING DEVICE, ESPECIALLY FOR SPORTS FOOTWEAR. |

| IT1392758B1 (en) * | 2009-01-27 | 2012-03-16 | Premec Spa | LEVER CLOSING DEVICE FOR SPORTS SHOES. |

| IT1399820B1 (en) * | 2010-03-23 | 2013-05-03 | Premec Spa | CLOSING DEVICE, PARTICULARLY FOR SPORTS SHOES. |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3363288A (en) * | 1966-08-29 | 1968-01-16 | Robert B. Lange | Boot buckle |

| AT370595B (en) * | 1980-06-27 | 1983-04-11 | Koeflach Sportgeraete Gmbh | BUCKLE TO CLOSE SHOES |

| US4470175A (en) * | 1981-06-16 | 1984-09-11 | Warrington Inc. | Fastening device for ski-boots |

-

1989

- 1989-06-02 AT AT135089A patent/AT397603B/en not_active IP Right Cessation

-

1990

- 1990-05-30 EP EP19900890168 patent/EP0401202B1/en not_active Expired - Lifetime

- 1990-05-30 DE DE59006404T patent/DE59006404D1/en not_active Expired - Fee Related

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8060990B2 (en) | 2006-01-27 | 2011-11-22 | Skis Rossignol | Binding buckle with secure docking element |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0401202A2 (en) | 1990-12-05 |

| ATA135089A (en) | 1993-10-15 |