WO2020044391A1 - Heat exchanger, heat exchanger unit, and refrigeration cycle device - Google Patents

Heat exchanger, heat exchanger unit, and refrigeration cycle device Download PDFInfo

- Publication number

- WO2020044391A1 WO2020044391A1 PCT/JP2018/031502 JP2018031502W WO2020044391A1 WO 2020044391 A1 WO2020044391 A1 WO 2020044391A1 JP 2018031502 W JP2018031502 W JP 2018031502W WO 2020044391 A1 WO2020044391 A1 WO 2020044391A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- heat exchanger

- flat tube

- flat

- tube

- pipe

- Prior art date

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28D—HEAT-EXCHANGE APPARATUS, NOT PROVIDED FOR IN ANOTHER SUBCLASS, IN WHICH THE HEAT-EXCHANGE MEDIA DO NOT COME INTO DIRECT CONTACT

- F28D1/00—Heat-exchange apparatus having stationary conduit assemblies for one heat-exchange medium only, the media being in contact with different sides of the conduit wall, in which the other heat-exchange medium is a large body of fluid, e.g. domestic or motor car radiators

- F28D1/02—Heat-exchange apparatus having stationary conduit assemblies for one heat-exchange medium only, the media being in contact with different sides of the conduit wall, in which the other heat-exchange medium is a large body of fluid, e.g. domestic or motor car radiators with heat-exchange conduits immersed in the body of fluid

- F28D1/04—Heat-exchange apparatus having stationary conduit assemblies for one heat-exchange medium only, the media being in contact with different sides of the conduit wall, in which the other heat-exchange medium is a large body of fluid, e.g. domestic or motor car radiators with heat-exchange conduits immersed in the body of fluid with tubular conduits

- F28D1/053—Heat-exchange apparatus having stationary conduit assemblies for one heat-exchange medium only, the media being in contact with different sides of the conduit wall, in which the other heat-exchange medium is a large body of fluid, e.g. domestic or motor car radiators with heat-exchange conduits immersed in the body of fluid with tubular conduits the conduits being straight

- F28D1/0535—Heat-exchange apparatus having stationary conduit assemblies for one heat-exchange medium only, the media being in contact with different sides of the conduit wall, in which the other heat-exchange medium is a large body of fluid, e.g. domestic or motor car radiators with heat-exchange conduits immersed in the body of fluid with tubular conduits the conduits being straight the conduits having a non-circular cross-section

- F28D1/05366—Assemblies of conduits connected to common headers, e.g. core type radiators

- F28D1/05383—Assemblies of conduits connected to common headers, e.g. core type radiators with multiple rows of conduits or with multi-channel conduits

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B13/00—Compression machines, plants or systems, with reversible cycle

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B39/00—Evaporators; Condensers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28D—HEAT-EXCHANGE APPARATUS, NOT PROVIDED FOR IN ANOTHER SUBCLASS, IN WHICH THE HEAT-EXCHANGE MEDIA DO NOT COME INTO DIRECT CONTACT

- F28D1/00—Heat-exchange apparatus having stationary conduit assemblies for one heat-exchange medium only, the media being in contact with different sides of the conduit wall, in which the other heat-exchange medium is a large body of fluid, e.g. domestic or motor car radiators

- F28D1/02—Heat-exchange apparatus having stationary conduit assemblies for one heat-exchange medium only, the media being in contact with different sides of the conduit wall, in which the other heat-exchange medium is a large body of fluid, e.g. domestic or motor car radiators with heat-exchange conduits immersed in the body of fluid

- F28D1/04—Heat-exchange apparatus having stationary conduit assemblies for one heat-exchange medium only, the media being in contact with different sides of the conduit wall, in which the other heat-exchange medium is a large body of fluid, e.g. domestic or motor car radiators with heat-exchange conduits immersed in the body of fluid with tubular conduits

- F28D1/0408—Multi-circuit heat exchangers, e.g. integrating different heat exchange sections in the same unit or heat exchangers for more than two fluids

- F28D1/0426—Multi-circuit heat exchangers, e.g. integrating different heat exchange sections in the same unit or heat exchangers for more than two fluids with units having particular arrangement relative to the large body of fluid, e.g. with interleaved units or with adjacent heat exchange units in common air flow or with units extending at an angle to each other or with units arranged around a central element

- F28D1/0435—Combination of units extending one behind the other

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28D—HEAT-EXCHANGE APPARATUS, NOT PROVIDED FOR IN ANOTHER SUBCLASS, IN WHICH THE HEAT-EXCHANGE MEDIA DO NOT COME INTO DIRECT CONTACT

- F28D1/00—Heat-exchange apparatus having stationary conduit assemblies for one heat-exchange medium only, the media being in contact with different sides of the conduit wall, in which the other heat-exchange medium is a large body of fluid, e.g. domestic or motor car radiators

- F28D1/02—Heat-exchange apparatus having stationary conduit assemblies for one heat-exchange medium only, the media being in contact with different sides of the conduit wall, in which the other heat-exchange medium is a large body of fluid, e.g. domestic or motor car radiators with heat-exchange conduits immersed in the body of fluid

- F28D1/04—Heat-exchange apparatus having stationary conduit assemblies for one heat-exchange medium only, the media being in contact with different sides of the conduit wall, in which the other heat-exchange medium is a large body of fluid, e.g. domestic or motor car radiators with heat-exchange conduits immersed in the body of fluid with tubular conduits

- F28D1/053—Heat-exchange apparatus having stationary conduit assemblies for one heat-exchange medium only, the media being in contact with different sides of the conduit wall, in which the other heat-exchange medium is a large body of fluid, e.g. domestic or motor car radiators with heat-exchange conduits immersed in the body of fluid with tubular conduits the conduits being straight

- F28D1/0535—Heat-exchange apparatus having stationary conduit assemblies for one heat-exchange medium only, the media being in contact with different sides of the conduit wall, in which the other heat-exchange medium is a large body of fluid, e.g. domestic or motor car radiators with heat-exchange conduits immersed in the body of fluid with tubular conduits the conduits being straight the conduits having a non-circular cross-section

- F28D1/05366—Assemblies of conduits connected to common headers, e.g. core type radiators

- F28D1/05391—Assemblies of conduits connected to common headers, e.g. core type radiators with multiple rows of conduits or with multi-channel conduits combined with a particular flow pattern, e.g. multi-row multi-stage radiators

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28F—DETAILS OF HEAT-EXCHANGE AND HEAT-TRANSFER APPARATUS, OF GENERAL APPLICATION

- F28F1/00—Tubular elements; Assemblies of tubular elements

- F28F1/10—Tubular elements and assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with projections, with recesses

- F28F1/12—Tubular elements and assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with projections, with recesses the means being only outside the tubular element

- F28F1/14—Tubular elements and assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with projections, with recesses the means being only outside the tubular element and extending longitudinally

- F28F1/20—Tubular elements and assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with projections, with recesses the means being only outside the tubular element and extending longitudinally the means being attachable to the element

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28F—DETAILS OF HEAT-EXCHANGE AND HEAT-TRANSFER APPARATUS, OF GENERAL APPLICATION

- F28F1/00—Tubular elements; Assemblies of tubular elements

- F28F1/10—Tubular elements and assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with projections, with recesses

- F28F1/12—Tubular elements and assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with projections, with recesses the means being only outside the tubular element

- F28F1/14—Tubular elements and assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with projections, with recesses the means being only outside the tubular element and extending longitudinally

- F28F1/22—Tubular elements and assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with projections, with recesses the means being only outside the tubular element and extending longitudinally the means having portions engaging further tubular elements

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28F—DETAILS OF HEAT-EXCHANGE AND HEAT-TRANSFER APPARATUS, OF GENERAL APPLICATION

- F28F1/00—Tubular elements; Assemblies of tubular elements

- F28F1/10—Tubular elements and assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with projections, with recesses

- F28F1/12—Tubular elements and assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with projections, with recesses the means being only outside the tubular element

- F28F1/24—Tubular elements and assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with projections, with recesses the means being only outside the tubular element and extending transversely

- F28F1/32—Tubular elements and assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with projections, with recesses the means being only outside the tubular element and extending transversely the means having portions engaging further tubular elements

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28F—DETAILS OF HEAT-EXCHANGE AND HEAT-TRANSFER APPARATUS, OF GENERAL APPLICATION

- F28F17/00—Removing ice or water from heat-exchange apparatus

- F28F17/005—Means for draining condensates from heat exchangers, e.g. from evaporators

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28D—HEAT-EXCHANGE APPARATUS, NOT PROVIDED FOR IN ANOTHER SUBCLASS, IN WHICH THE HEAT-EXCHANGE MEDIA DO NOT COME INTO DIRECT CONTACT

- F28D21/00—Heat-exchange apparatus not covered by any of the groups F28D1/00 - F28D20/00

- F28D2021/0019—Other heat exchangers for particular applications; Heat exchange systems not otherwise provided for

- F28D2021/0068—Other heat exchangers for particular applications; Heat exchange systems not otherwise provided for for refrigerant cycles

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28F—DETAILS OF HEAT-EXCHANGE AND HEAT-TRANSFER APPARATUS, OF GENERAL APPLICATION

- F28F2215/00—Fins

- F28F2215/02—Arrangements of fins common to different heat exchange sections, the fins being in contact with different heat exchange media

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28F—DETAILS OF HEAT-EXCHANGE AND HEAT-TRANSFER APPARATUS, OF GENERAL APPLICATION

- F28F2215/00—Fins

- F28F2215/10—Secondary fins, e.g. projections or recesses on main fins

Definitions

- the present invention relates to a heat exchanger, a heat exchanger unit including the heat exchanger, and a refrigeration cycle apparatus, and particularly to a fin structure attached to a flat tube.

- Tube heat exchangers are known. (See, for example, Patent Document 1).

- the present invention has been made to solve the above problems, and improves the pressure resistance of a pipe through which a refrigerant flows, reduces the weight of a heat transfer fin, and is easy to manufacture. It is an object to obtain a refrigerator unit and a refrigeration cycle device.

- the heat exchanger according to the present invention is provided with a first flat tube group including a plurality of flat tubes arranged in parallel with their tube axes parallel to each other, and is arranged adjacent to the first flat tube group to make the tube axes parallel.

- a second flat tube group including the plurality of flat tubes arranged in parallel, a first flat tube that is one of the plurality of flat tubes included in the first flat tube group, and the second flat tube

- a heat exchanger unit according to the present invention includes the above heat exchanger.

- a refrigeration cycle device includes the heat exchanger unit.

- the present invention since a plurality of flat tube groups constituted by a plurality of flat tubes are connected by fins, the pressure resistance of the tubes through which the refrigerant flows is improved, and the weight of the fins is reduced because the fins can be formed thin. Can be reduced. Further, it is possible to obtain a heat exchanger, a heat exchanger unit, and a refrigeration cycle device that have high heat exchange performance and are easy to manufacture.

- FIG. 2 is a front view showing the heat exchanger according to Embodiment 1.

- FIG. 2 is a side view showing the heat exchanger according to Embodiment 1.

- FIG. 2 is an explanatory diagram of a refrigeration cycle device to which the heat exchanger according to Embodiment 1 is applied. It is explanatory drawing of the cross-section of the heat exchanger of FIG. It is a side view of the heat exchanger of the modification of the heat exchanger which concerns on Embodiment 1.

- FIG. 4 is an explanatory diagram of a cross-sectional structure of a heat exchanger according to a modified example of the heat exchanger according to Embodiment 1. It is the enlarged view seen from the x direction of the slit.

- FIG. 4 is an explanatory diagram of a cross-sectional structure of a heat exchanger according to a modified example of the heat exchanger according to Embodiment 1.

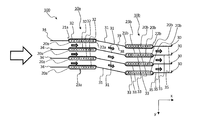

- FIG. 1 is a front view showing a heat exchanger 100 according to the first embodiment.

- FIG. 2 is a side view showing the heat exchanger 100 according to the first embodiment.

- FIG. 3 is an explanatory diagram of the refrigeration cycle apparatus 1 to which the heat exchanger 100 according to Embodiment 1 is applied.

- the heat exchanger 100 shown in FIGS. 1 and 2 is mounted on a refrigeration cycle device 1 such as an air conditioner or a refrigerator.

- a refrigeration cycle device 1 such as an air conditioner or a refrigerator.

- the compressor 3, the four-way valve 4, the outdoor heat exchanger 5, the expansion device 6, and the indoor heat exchanger 7 are connected by a refrigerant pipe 90 to form a refrigerant circuit. Things.

- the refrigeration cycle apparatus 1 when the refrigeration cycle apparatus 1 is an air conditioner, the refrigerant flows through the refrigerant pipe 90, and the flow of the refrigerant is switched by the four-way valve 4, thereby switching to the heating operation, the refrigeration operation, or the defrosting operation. be able to.

- the outdoor heat exchanger 5 mounted on the outdoor unit 8 and the indoor heat exchanger 7 mounted on the indoor unit 9 include the blower 2 in the vicinity.

- the blower 2 sends outside air to the outdoor heat exchanger 5, and performs heat exchange between the outside air and the refrigerant.

- the indoor unit 9 the blower 2 sends indoor air to the indoor heat exchanger 7, performs heat exchange between the indoor air and the refrigerant, and balances the temperature of the indoor air.

- the heat exchanger 100 can be used as the outdoor heat exchanger 5 mounted on the outdoor unit 8 and the indoor heat exchanger 7 mounted on the indoor unit 9 in the refrigeration cycle apparatus 1, and can be used as a condenser or an evaporator. Function. Note that devices such as the outdoor unit 8 and the indoor unit 9 on which the heat exchanger 100 is mounted are particularly referred to as a heat exchanger unit.

- the heat exchanger 100 shown in FIG. 1 includes two flat tube groups 10.

- One of the two flat tube groups 10 is called a first flat tube group 10a, and the other is called a second flat tube group 10b.

- the flat tube groups 10a and 10b may be collectively referred to as a flat tube group 10.

- the first flat tube group 10a and the second flat tube group 10b are arranged in parallel in the x direction.

- the flat tube group 10 includes a plurality of flat tubes 20.

- the plurality of flat tubes 20 are shown as 20a and 20b in FIGS.

- the plurality of flat tubes 20 of each flat tube group 10 are arranged in parallel in the y direction with their respective tube axes parallel to each other.

- the tube axes of the plurality of flat tubes 20 are oriented in the z direction.

- the reverse direction in the z direction coincides with the direction of gravity, but heat exchanger 100 may be arranged with the z axis inclined in the direction of gravity.

- the plurality of flat tubes 20a of the first flat tube group 10a are connected to the lower end header 50a at the lower end in the tube axis direction, and are connected to the upper end header 51a at the upper end in the tube axis direction. .

- the plurality of flat tubes 20b of the second flat tube group 10b are also connected to the lower end header 50b at the lower end in the tube axis direction, and are connected to the upper end header 51b at the upper end in the tube axis direction. It is connected.

- the heat exchanger 100 includes two flat tube groups 10a and 10b. However, the heat exchanger 100 may include more flat tube groups 10.

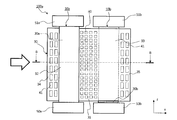

- FIG. 4 is an explanatory diagram of a cross-sectional structure of the heat exchanger 100 of FIG.

- FIG. 4 shows a cross section perpendicular to the tube axis of the plurality of flat tubes 20 included in each of the plurality of flat tube groups 10, and is an explanatory diagram of a cross-sectional structure corresponding to the AA cross section in FIG.

- a part of a plurality of flat tubes 20 constituting each flat tube group 10 is shown.

- the plurality of flat tubes 20a of the first flat tube group 10a and the plurality of flat tubes 20b of the second flat tube group 10b are arranged with the long axis in the x direction and the short axis in the y direction in a cross section perpendicular to the tube axis.

- the plurality of flat tubes 20a of the first flat tube group 10a and the plurality of flat tubes 20b of the second flat tube group 10b are arranged in a staggered manner. That is, the second flat tubes 20b constituting the second flat tube group 10b are arranged at positions displaced in the y-direction from an extension of the long axis of the first flat tubes 20a constituting the first flat tube group 10a. When viewed from the x direction, the second flat tube 20b is disposed on an extension of a gap between two adjacent first flat tubes 20a.

- the first flat tube 20a and the second flat tube 20b may be collectively referred to as a flat tube 20.

- fins 30 are installed on the first flat tubes 20a of the first flat tube group 10a and the second flat tubes 20b of the second flat tube group 10b.

- the fin 30 is formed by bending a single plate-like member, and is installed with its plate surface along the first flat tube 20a and the second flat tube 20b.

- the fins 30 since the tube axes of the first flat tube 20a and the second flat tube 20b coincide with the direction of gravity, the fins 30 have the plate surfaces arranged along the direction of gravity.

- the heat exchanger 100 when the heat exchanger 100 functions as an evaporator, the condensed water adhered to the fins 30 due to dew condensation or the frost melted water due to the defrost operation when frost is formed can be discharged from the fins 30 without delay. Thereby, the heat exchanger 100 maintains a high heat exchange performance.

- the fin 30 includes a first portion 31 disposed between the first flat tube 20a and the second flat tube 20b, a second portion 32 joined to the first flat tube 20a, and a second portion 32.

- the third portion 33 joined to the flat tube 20b, the fourth portion 34 extending in the x-direction from the end 21a of the first flat tube 20a, and the end of the second flat tube 20b

- a fifth portion 35 is provided extending in the x direction from the portion 22b.

- the fin 30 and the first flat tube 20a are in contact at the second portion 32 and are joined by brazing or the like.

- the second portion 32 has a concave shape formed by bending a plate-like member so as to follow the side surface shape of the first flat tube 20a, and the first flat tube 20a fits into the concave shape.

- the fin 30 and the second flat tube 20b are in contact with each other at the third portion 33, and are joined by brazing or the like.

- the third portion 33 is also formed with a concave shape along the side surface shape of the second flat tube 20b by bending the plate member, and the second flat tube 20b fits into the concave shape.

- the second portion 32 and the third portion 33 of the fin 30 face different directions of the concave shape.

- the concave shape of the second portion 32 is open in the y direction

- the concave shape of the third portion 33 is open in the opposite direction to the y direction. That is, the first flat tube 20a is attached to one plate surface 38 of the fin 30 facing the y direction, and the second flat tube 20b is attached to the other plate surface 39 of the fin 30 facing the y direction. Is attached.

- the first flat tube 20a and the second flat tube 20b are fitted in the concave shape of one fin 30.

- the fin 30, the first flat tube 20a, and the second flat tube 20b can be handled as an integral part during manufacturing. That is, before joining with the lower end headers 50a and 50b and the upper end headers 51a and 51b, the two flat tubes 20 can be fitted and integrated into the concave shape of one fin 30, so that the two flat tubes 20 are joined before joining. Can be easily positioned with each other, and the assembling workability can be improved.

- the fin 30 includes a first portion 31 located between the first flat tube group 10a and the second flat tube group 10b.

- the first portion 31 is arranged so as to connect the concave end where the first flat tube 20a fits and the concave end where the second flat tube 20b fits.

- the first portion 31 includes the end 22a of the end of the first flat tube 20a located on the second flat tube group 10b side and the first flat tube of the end of the second flat tube 20b. It is arranged so as to connect with the end 21b located on the group 10a side.

- the first portion 31 is arranged to be inclined with respect to the long axis of the first flat tube 20a and the second flat tube 20b.

- Embodiment 1 air flows into the heat exchanger 100 in the x direction.

- the air meanders through the gap between the first flat tube 20a, the second flat tube 20b, and the fin 30. Flowing. Therefore, the heat exchanger 100 has an increased heat transfer area and improved heat transfer performance.

- the air flowing on the side wall 23b of the second flat tube 20b collides as the wind is bent. Since the air flow between the second flat tubes 20b is disturbed by the collision of air, the temperature of the air that contacts each part of the second flat tubes 20b is easily averaged, and flows through the second flat tubes 20b. The dryness of the refrigerant is made uniform. Thereby, the heat exchanger 100 has improved heat exchange performance.

- the fin 30 includes a flat plate-shaped fourth portion 34 extending from the end 21a of the first flat tube 20a that is opposite to the x direction. That is, the fourth portion 34 extends from the end 21a of the end of the first flat tube 20a opposite to the end 22a from which the first portion 31 extends. Further, the fin 30 includes a fifth flat portion 35 extending from the end 22b of the second flat tube 20b facing in the x direction. That is, the fifth portion 35 extends from the end 22b of the end of the second flat tube 20b opposite to the end 21b where the first portion 31 extends. Since the fin 30 includes the fourth portion 34 and the fifth portion 35, the heat exchanger 100 has an increased heat transfer area and improved heat transfer performance.

- FIG. 5 is a side view of heat exchanger 100a as a modification of heat exchanger 100 according to Embodiment 1.

- FIG. 6 is an explanatory diagram of a cross-sectional structure of a heat exchanger 100a according to a modified example of the heat exchanger 100 according to Embodiment 1.

- FIG. 7 is an enlarged view of the slit 41 as viewed from the x direction.

- FIG. 6 is an explanatory diagram of a cross-sectional structure corresponding to the BB cross section of FIG.

- the heat exchanger 100a is located on the most windward side of the fin 30, and a slit 41 is provided in a fourth portion 34 extending from the end 21a of the first flat tube 20a.

- the slit 41 is formed by cutting and raising a part of the fourth portion 34 in a direction perpendicular to the plate surface. As shown in FIG. 7, the plate-shaped fourth portion 34 is partially cut and raised, and a parallel portion 45 positioned substantially parallel to the fourth portion 34 and a fourth portion from both ends of the parallel portion 45. A rising portion 44 that connects the plate surfaces of the portion 34 is formed.

- the heat exchanger 100a is located on the most leeward side of the fin 30, and the fifth portion 35 extending from the end 21b of the second flat tube 20b is also provided with a slit 41.

- the slit 41 is provided in the same structure as in the fourth portion 34. Therefore, the boundary layer of the flow of the air flowing parallel to the surface of the fifth portion 35 is reduced, and it is possible to suppress the increase in the ventilation resistance while improving the heat transfer performance.

- the heat exchanger 100a includes a louver 40 in the first portion 31 located between the first flat tube 20a and the second flat tube 20b.

- the louver 40 is formed by cutting and raising a part of the plate-shaped first portion 31, and extends in the x direction in parallel with the long axes of the first flat tube 20a and the second flat tube 20b. It is a tongue piece. Further, an opening is formed at the base of the louver 40 so as to penetrate the plate surface of the first portion 31.

- the louver 40 extends in parallel with the flow of air passing between the first flat tubes 20a. Therefore, the air passes through a hole formed in the plate surface of the first portion 31 where the louver 40 is provided.

- the heat exchangers 100 and 100a are manufactured by the following steps. First, the plurality of fins 30 are combined with the first flat tube group 10a and the second flat tube group 10b. Each flat tube 20 is fitted into the concave shape of the fin 30. In a state where the first flat tube 20a, the second flat tube 20b, and the fin 30 are integrated, the first flat tube 20a and the second flat tube 20b have ends in the tube axial direction at the lower end header 50a. , 50b or upper headers 51a, 51b. Thereafter, the fins 30 are pulled from the fourth portion 34 and the fifth portion 35 located at both ends in the x direction of FIGS.

- the fin 30 has the second portion 32 pressed against the first flat tube 20a, and the third portion 33 pressed against the second flat tube 20b.

- the plurality of flat tubes 20a, 20b are inserted into the lower end headers 50a, 50b and the upper end headers 51a, 51b.

- the brazing material is arranged at the joint between the plurality of flat tubes 20a, 20b and the lower headers 50a, 50b and the upper headers 51a, 51b, and at the joint between the plurality of flat tubes 20a, 20b and the fins 30. It is inserted and brazed. Since the heat exchangers 100 and 100a can handle the first flat tube group 10a and the second flat tube group 10b integrally by the plurality of fins 30, the heat exchangers 100 and 100a have an advantage that assembly is easy and manufacturing is easy. is there.

- the first flat tube 20a and the second flat tube 20b are arranged in a staggered manner with their long axes parallel to each other. Although arranged obliquely with respect to the tube 20a and the second flat tube 20b, the present invention is not limited to this embodiment. Further, as a modified example of the heat exchanger 100 according to Embodiment 1, the heat exchanger 100a in which both the louver 40 and the slit 41 are formed has been described, but one of the louver 40 and the slit 41 is formed. It may be a heat exchanger.

- FIG. 8 is an explanatory diagram of a cross-sectional structure of a heat exchanger 100b according to a modified example of the heat exchanger 100 according to Embodiment 1.

- FIG. 8 is an explanatory diagram of a cross section corresponding to the AA cross section of FIG.

- the first portion 31, the second portion 32 into which the first flat tube 20a fits, and the third portion 33 into which the second flat tube 20b fits become parallel.

- the fourth part 34 located at the most leeward side and the fifth part 35 located at the most leeward side are the first part 31, the second part 32 to which the first flat tube 20a fits, And the third portion 33 in which the second flat tube 20b fits.

- the air flowing into the heat exchanger 100 in the x direction collides with the side wall 23a of the first flat tube 20a. Since the air flow between the first flat tubes 20a is disturbed by the collision of air, the temperature of the air that contacts each part of the first flat tubes 20a is easily averaged, and flows through the first flat tubes 20a. The dryness of the refrigerant is made uniform. Thereby, the heat exchanger 100b has improved heat exchange performance.

- the heat exchangers 100, 100a, and 100b according to Embodiment 1 have high energy efficiency by being used in at least one of the outdoor heat exchanger 5 and the indoor heat exchanger 7 of the refrigeration cycle apparatus 1 shown in FIG.

- the refrigeration cycle device 1 can be provided.

- the effects can be achieved with refrigerants such as R410A, R32, and HFO1234yf. You can do it.

- refrigerants such as R410A, R32, and HFO1234yf. You can do it.

- air and a refrigerant are used as the working fluid, but the same effect can be obtained by using another gas, liquid, or gas-liquid mixed fluid.

- the structures of the heat exchangers 100, 100a, and 100b according to the first embodiment can be appropriately combined.

- both or one of the louver 40 and the slit 41 of the heat exchanger 100a can be applied to the heat exchanger 100b.

- Refrigeration cycle device 2 blower, 3 compressor, 4 four-way valve, 5 outdoor heat exchanger, 6 expansion device, 7 indoor heat exchanger, 8 outdoor unit, 9 indoor unit, 10 flat tube group, 10 a (first) Flat tube group, 10b (second) flat tube group, 20 flat tube, 20a (first) flat tube, 20b (second) flat tube, 21a end, 21b end, 22a end, 22b end , 23a side wall, 23b side wall, 30 fin, 31 first part, 32 second part, 33 3 third part, 34 fourth part, 35 fifth part, 38 plate surface, 39 plate surface, 40 louver , 41 slit, 44 rising section, 45 parallel section, 50 bottom header, 50a bottom header, 50b bottom header, 51 top header, 51a top header, 51b top header, 90 Refrigerant pipe, 100 heat exchanger, 100a heat exchanger, 100b heat exchanger.

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Geometry (AREA)

- Heat-Exchange Devices With Radiators And Conduit Assemblies (AREA)

Abstract

The purpose of the present invention is to provide a heat exchanger, a heat exchanger unit, and a refrigeration cycle device, in which the pressure-resistant properties of a pipe for allowing a refrigerant to flow therethrough are improved, and the weight of heat transfer fins is reduced, and which can be manufactured easily. The present invention comprises: a first flat pipe group provided with a plurality of flat pipes arranged side-by-side with the pipe axes thereof arranged parallel to each other; a second flat pipe group disposed adjacent to the first flat pipe group and provided with a plurality of flat pipes arranged side-by-side with the pipe axes thereof arranged parallel to each other; a first flat pipe, which is one of the plurality of flat pipes of the first flat pipe group; a second flat pipe, which is one of the plurality of flat pipes of the second flat pipe group; and a fin mounted on the first flat pipe and the second flat pipe. The fin has a first portion which connects an end of the long axis of a cross-section of the first flat pipe perpendicular to the pipe axis of the first flat pipe and an end of the long axis of a cross-section of the second flat pipe perpendicular to the pipe axis of the second flat pipe.

Description

本発明は、熱交換器、熱交換器を備えた熱交換器ユニット、及び冷凍サイクル装置に関し、特に扁平管に取り付けられたフィンの構造に関する。

The present invention relates to a heat exchanger, a heat exchanger unit including the heat exchanger, and a refrigeration cycle apparatus, and particularly to a fin structure attached to a flat tube.

従来の熱交換器において熱交換性能を向上させるために、2枚の板を貼り合わせ、細径の管体部を千鳥構造に配列し、管体部の間を伝熱フィンにより接続した多列管熱交換器が知られている。(例えば、特許文献1を参照)。

In order to improve the heat exchange performance in the conventional heat exchanger, two plates are stuck together, the small-diameter tubes are arranged in a staggered structure, and the tubes are connected by heat transfer fins. Tube heat exchangers are known. (See, for example, Patent Document 1).

しかし、特許文献1に示されている従来の熱交換器においては、2枚の板を貼り合わせて管体部を構成しているため、管体部の耐圧性能を確保するために伝熱フィンも肉厚になり重量が増加するという課題があった。また、2枚の板を貼り合わせ、接合するロウ材が管体部の内部の冷媒流路に浸入してしまうという課題があった。

However, in the conventional heat exchanger disclosed in Patent Literature 1, since the tube is formed by bonding two plates, the heat transfer fins are required to secure the pressure resistance of the tube. However, there has been a problem that the thickness of the tire also increases and the weight increases. In addition, there is a problem that the brazing material to be bonded and bonded to the two plates invades the refrigerant flow path inside the tubular body.

本発明は、上記のような課題を解決するためのものであり、冷媒が流通する管の耐圧性能を向上させ、伝熱フィンの重量も低減させ、かつ製造も容易な熱交換器、熱交換器ユニット、及び冷凍サイクル装置を得ることを目的とする。

SUMMARY OF THE INVENTION The present invention has been made to solve the above problems, and improves the pressure resistance of a pipe through which a refrigerant flows, reduces the weight of a heat transfer fin, and is easy to manufacture. It is an object to obtain a refrigerator unit and a refrigeration cycle device.

本発明に係る熱交換器は、管軸を平行にして並列された複数の扁平管を備える第1扁平管群と、前記第1扁平管群に隣合って配置され、前記管軸を平行にして並列された前記複数の扁平管を備える、第2扁平管群と、前記第1扁平管群が備える前記複数の扁平管のうちの1つである第1の扁平管と、前記第2扁平管群が備える前記複数の扁平管のうちの1つである第2の扁平管と、前記第1の扁平管と前記第2の扁平管とに設置されるフィンと、を備え、前記フィンは、前記第1の扁平管の前記管軸に垂直な断面における長軸の端部と、前記第2の扁平管の前記管軸に垂直な断面における前記長軸の端部と、を接続する第1の部分を備える。

The heat exchanger according to the present invention is provided with a first flat tube group including a plurality of flat tubes arranged in parallel with their tube axes parallel to each other, and is arranged adjacent to the first flat tube group to make the tube axes parallel. A second flat tube group including the plurality of flat tubes arranged in parallel, a first flat tube that is one of the plurality of flat tubes included in the first flat tube group, and the second flat tube A second flat tube that is one of the plurality of flat tubes included in the tube group; and fins installed on the first flat tube and the second flat tube. A second end connecting the end of the long axis in a cross section perpendicular to the tube axis of the first flat tube and the end of the long axis in a cross section perpendicular to the tube axis of the second flat tube; 1 part.

本発明に係る熱交換器ユニットは、上記熱交換器を備える。

熱 A heat exchanger unit according to the present invention includes the above heat exchanger.

本発明に係る冷凍サイクル装置は、上記熱交換器ユニットを備える。

冷凍 A refrigeration cycle device according to the present invention includes the heat exchanger unit.

本発明によれば、複数の扁平管により構成された複数の扁平管群をフィンにより接続したため、冷媒を流通させる管の耐圧性能が向上し、かつ、フィンを肉薄に形成できるためフィンの重量も低減させることができる。また、熱交換性能が高く製造も容易な熱交換器、熱交換器ユニット、及び冷凍サイクル装置を得ることができる。

According to the present invention, since a plurality of flat tube groups constituted by a plurality of flat tubes are connected by fins, the pressure resistance of the tubes through which the refrigerant flows is improved, and the weight of the fins is reduced because the fins can be formed thin. Can be reduced. Further, it is possible to obtain a heat exchanger, a heat exchanger unit, and a refrigeration cycle device that have high heat exchange performance and are easy to manufacture.

以下に、熱交換器及び熱交換器ユニットの実施の形態について説明する。なお、図面の形態は一例であり、本発明を限定するものではない。また、各図において同一の符号を付したものは、同一のまたはこれに相当するものであり、これは明細書の全文において共通している。さらに、以下の図面では各構成部材の大きさの関係が実際のものとは異なる場合がある。

Hereinafter, embodiments of the heat exchanger and the heat exchanger unit will be described. In addition, the form of the drawings is an example, and does not limit the present invention. In the drawings, the same reference numerals denote the same or corresponding components, which are common throughout the entire specification. Further, in the following drawings, the size relationship of each component may be different from the actual one.

実施の形態1.

図1は、実施の形態1に係る熱交換器100を示す正面図である。図2は、実施の形態1に係る熱交換器100を示す側面図である。図3は、実施の形態1に係る熱交換器100が適用された冷凍サイクル装置1の説明図である。図1及び図2に示された熱交換器100は、空気調和装置又は冷蔵庫等の冷凍サイクル装置1に搭載されるものである。図3に示される様に冷凍サイクル装置1は、圧縮機3、四方弁4、室外熱交換器5、膨張装置6、及び室内熱交換器7を冷媒配管90により接続し、冷媒回路を構成したものである。例えば冷凍サイクル装置1が空気調和装置である場合には、冷媒配管90内には冷媒が流通し、四方弁4により冷媒の流れを切り換えることにより、暖房運転、冷凍運転、又は除霜運転に切り換えることができる。Embodiment 1 FIG.

FIG. 1 is a front view showing aheat exchanger 100 according to the first embodiment. FIG. 2 is a side view showing the heat exchanger 100 according to the first embodiment. FIG. 3 is an explanatory diagram of the refrigeration cycle apparatus 1 to which the heat exchanger 100 according to Embodiment 1 is applied. The heat exchanger 100 shown in FIGS. 1 and 2 is mounted on a refrigeration cycle device 1 such as an air conditioner or a refrigerator. As shown in FIG. 3, in the refrigeration cycle apparatus 1, the compressor 3, the four-way valve 4, the outdoor heat exchanger 5, the expansion device 6, and the indoor heat exchanger 7 are connected by a refrigerant pipe 90 to form a refrigerant circuit. Things. For example, when the refrigeration cycle apparatus 1 is an air conditioner, the refrigerant flows through the refrigerant pipe 90, and the flow of the refrigerant is switched by the four-way valve 4, thereby switching to the heating operation, the refrigeration operation, or the defrosting operation. be able to.

図1は、実施の形態1に係る熱交換器100を示す正面図である。図2は、実施の形態1に係る熱交換器100を示す側面図である。図3は、実施の形態1に係る熱交換器100が適用された冷凍サイクル装置1の説明図である。図1及び図2に示された熱交換器100は、空気調和装置又は冷蔵庫等の冷凍サイクル装置1に搭載されるものである。図3に示される様に冷凍サイクル装置1は、圧縮機3、四方弁4、室外熱交換器5、膨張装置6、及び室内熱交換器7を冷媒配管90により接続し、冷媒回路を構成したものである。例えば冷凍サイクル装置1が空気調和装置である場合には、冷媒配管90内には冷媒が流通し、四方弁4により冷媒の流れを切り換えることにより、暖房運転、冷凍運転、又は除霜運転に切り換えることができる。

FIG. 1 is a front view showing a

室外機8に搭載された室外熱交換器5及び室内機9に搭載された室内熱交換器7は、近傍に送風機2を備える。室外機8において送風機2は、室外熱交換器5に外気を送り込み、外気と冷媒との間で熱交換を行う。また、室内機9において送風機2は、室内熱交換器7に室内の空気を送り込み、室内の空気と冷媒との間で熱交換を行い、室内の空気の温度を調和する。また、熱交換器100は、冷凍サイクル装置1において室外機8に搭載された室外熱交換器5及び室内機9に搭載された室内熱交換器7として用いることができ、凝縮器又は蒸発器として機能する。なお、熱交換器100が搭載された室外機8及び室内機9等の機器を、特に熱交換器ユニットと呼ぶ。

The outdoor heat exchanger 5 mounted on the outdoor unit 8 and the indoor heat exchanger 7 mounted on the indoor unit 9 include the blower 2 in the vicinity. In the outdoor unit 8, the blower 2 sends outside air to the outdoor heat exchanger 5, and performs heat exchange between the outside air and the refrigerant. In the indoor unit 9, the blower 2 sends indoor air to the indoor heat exchanger 7, performs heat exchange between the indoor air and the refrigerant, and balances the temperature of the indoor air. Further, the heat exchanger 100 can be used as the outdoor heat exchanger 5 mounted on the outdoor unit 8 and the indoor heat exchanger 7 mounted on the indoor unit 9 in the refrigeration cycle apparatus 1, and can be used as a condenser or an evaporator. Function. Note that devices such as the outdoor unit 8 and the indoor unit 9 on which the heat exchanger 100 is mounted are particularly referred to as a heat exchanger unit.

図1に示される熱交換器100は、2つの扁平管群10を備える。2つの扁平管群10のうち、一方を第1扁平管群10aと呼び、他方を第2扁平管群10bと呼ぶ。また、各扁平管群10a、10bを総称して扁平管群10と呼ぶ場合がある。第1扁平管群10aと第2扁平管群10bとは、x方向に並列されている。扁平管群10は、複数の扁平管20を備える。複数の扁平管20は、図1及び図2においては20a及び20bとして示されるものである。各扁平管群10の複数の扁平管20は、それぞれの管軸を互いに平行にしてy方向に並列されている。実施の形態1において、複数の扁平管20の管軸は、z方向に向けられている。実施の形態1においては、z方向逆向きが重力方向に一致しているが、熱交換器100は、z軸を重力方向に傾斜させて配置されていても良い。第1扁平管群10aの複数の扁平管20aは、管軸方向の下側の端部において下端ヘッダ50aと接続されており、管軸方向の上側の端部において上端ヘッダ51aと接続されている。また、第2扁平管群10bの複数の扁平管20bも同様に、管軸方向の下側の端部において下端ヘッダ50bと接続されており、管軸方向の上側の端部において上端ヘッダ51bと接続されている。なお、実施の形態1においては、熱交換器100は、2つの扁平管群10a、10bを備えるが、さらに多くの扁平管群10を備えていても良い。

熱 The heat exchanger 100 shown in FIG. 1 includes two flat tube groups 10. One of the two flat tube groups 10 is called a first flat tube group 10a, and the other is called a second flat tube group 10b. Further, the flat tube groups 10a and 10b may be collectively referred to as a flat tube group 10. The first flat tube group 10a and the second flat tube group 10b are arranged in parallel in the x direction. The flat tube group 10 includes a plurality of flat tubes 20. The plurality of flat tubes 20 are shown as 20a and 20b in FIGS. The plurality of flat tubes 20 of each flat tube group 10 are arranged in parallel in the y direction with their respective tube axes parallel to each other. In the first embodiment, the tube axes of the plurality of flat tubes 20 are oriented in the z direction. In the first embodiment, the reverse direction in the z direction coincides with the direction of gravity, but heat exchanger 100 may be arranged with the z axis inclined in the direction of gravity. The plurality of flat tubes 20a of the first flat tube group 10a are connected to the lower end header 50a at the lower end in the tube axis direction, and are connected to the upper end header 51a at the upper end in the tube axis direction. . Similarly, the plurality of flat tubes 20b of the second flat tube group 10b are also connected to the lower end header 50b at the lower end in the tube axis direction, and are connected to the upper end header 51b at the upper end in the tube axis direction. It is connected. In the first embodiment, the heat exchanger 100 includes two flat tube groups 10a and 10b. However, the heat exchanger 100 may include more flat tube groups 10.

図4は、図2の熱交換器100の断面構造の説明図である。図4は、複数の扁平管群10のそれぞれが備える複数の扁平管20の管軸に垂直な断面を示しており、図2のA-A断面に対応する断面の構造の説明図である。なお、図4においては、各扁平管群10を構成する複数の扁平管20のうち一部を表示している。第1扁平管群10aの複数の扁平管20a及び第2扁平管群10bの複数の扁平管20bは、管軸に垂直な断面において長軸をx方向に、短軸をy方向に沿って配置されている。また、第1扁平管群10aの複数の扁平管20aと第2扁平管群10bの複数の扁平管20bとは、千鳥に配置されている。つまり、第2扁平管群10bを構成する第2の扁平管20bは、第1扁平管群10aを構成する第1の扁平管20aの長軸の延長線上からy方向にずれた位置に配置されており、x方向から見た時に、隣合う2つの第1の扁平管20aの間の隙間の延長線上に第2の扁平管20bが配置されている。以下、第1の扁平管20a及び第2の扁平管20bを総称して扁平管20と呼ぶ場合がある。

FIG. 4 is an explanatory diagram of a cross-sectional structure of the heat exchanger 100 of FIG. FIG. 4 shows a cross section perpendicular to the tube axis of the plurality of flat tubes 20 included in each of the plurality of flat tube groups 10, and is an explanatory diagram of a cross-sectional structure corresponding to the AA cross section in FIG. In FIG. 4, a part of a plurality of flat tubes 20 constituting each flat tube group 10 is shown. The plurality of flat tubes 20a of the first flat tube group 10a and the plurality of flat tubes 20b of the second flat tube group 10b are arranged with the long axis in the x direction and the short axis in the y direction in a cross section perpendicular to the tube axis. Have been. The plurality of flat tubes 20a of the first flat tube group 10a and the plurality of flat tubes 20b of the second flat tube group 10b are arranged in a staggered manner. That is, the second flat tubes 20b constituting the second flat tube group 10b are arranged at positions displaced in the y-direction from an extension of the long axis of the first flat tubes 20a constituting the first flat tube group 10a. When viewed from the x direction, the second flat tube 20b is disposed on an extension of a gap between two adjacent first flat tubes 20a. Hereinafter, the first flat tube 20a and the second flat tube 20b may be collectively referred to as a flat tube 20.

図4に示される様に、第1扁平管群10aの第1の扁平管20a及び第2扁平管群10bの第2の扁平管20bには、フィン30が設置されている。フィン30は、1枚の板状部材を曲げて形成され、板面を第1の扁平管20a及び第2の扁平管20bに沿わせて設置されている。実施の形態1においては、第1の扁平管20a及び第2の扁平管20bの管軸が重力方向と一致しているため、フィン30は、板面が重力方向に沿って配置されている。そのため、熱交換器100は、蒸発器として機能する場合に結露によりフィン30に付着した凝縮水や着霜した場合にデフロスト運転による霜の融解水を、フィン30から滞りなく排出することができる。これにより、熱交換器100は、熱交換性能が高く維持される。

フ ィ ン As shown in FIG. 4, fins 30 are installed on the first flat tubes 20a of the first flat tube group 10a and the second flat tubes 20b of the second flat tube group 10b. The fin 30 is formed by bending a single plate-like member, and is installed with its plate surface along the first flat tube 20a and the second flat tube 20b. In the first embodiment, since the tube axes of the first flat tube 20a and the second flat tube 20b coincide with the direction of gravity, the fins 30 have the plate surfaces arranged along the direction of gravity. Therefore, when the heat exchanger 100 functions as an evaporator, the condensed water adhered to the fins 30 due to dew condensation or the frost melted water due to the defrost operation when frost is formed can be discharged from the fins 30 without delay. Thereby, the heat exchanger 100 maintains a high heat exchange performance.

フィン30は、第1の扁平管20aと第2の扁平管20bとの間に配置される第1の部分31、第1の扁平管20aと接合されている第2の部分32、第2の扁平管20bと接合されている第3の部分33、第1の扁平管20aの端部21aからx方向逆向きに延設されている第4の部分34、及び第2の扁平管20bの端部22bからx方向に延設されている第5の部分35を備える。

The fin 30 includes a first portion 31 disposed between the first flat tube 20a and the second flat tube 20b, a second portion 32 joined to the first flat tube 20a, and a second portion 32. The third portion 33 joined to the flat tube 20b, the fourth portion 34 extending in the x-direction from the end 21a of the first flat tube 20a, and the end of the second flat tube 20b A fifth portion 35 is provided extending in the x direction from the portion 22b.

フィン30と第1の扁平管20aとは、第2の部分32において接しており、ロウ付け等により接合されている。第2の部分32は、板状部材を曲げることにより第1の扁平管20aの側面形状に沿うように凹形状が形成されており、その凹形状に第1の扁平管20aが嵌る。また、フィン30と第2の扁平管20bとは、第3の部分33において接しており、ロウ付け等により接合されている。第3の部分33も板状部材を曲げることにより第2の扁平管20bの側面形状に沿うように凹形状が形成されており、その凹形状に第2の扁平管20bが嵌る。フィン30の第2の部分32と第3の部分33とは、凹形状が異なる方向を向いている。第2の部分32の凹形状は、y方向に凹形状が開いており、第3の部分33の凹形状はy方向逆向きに凹形状が開いている。つまり、フィン30のy方向を向いた一方の板面38に第1の扁平管20aが取り付けられており、フィン30のy方向逆向きを向いた他方の板面39に第2の扁平管20bが取り付けられている。

The fin 30 and the first flat tube 20a are in contact at the second portion 32 and are joined by brazing or the like. The second portion 32 has a concave shape formed by bending a plate-like member so as to follow the side surface shape of the first flat tube 20a, and the first flat tube 20a fits into the concave shape. The fin 30 and the second flat tube 20b are in contact with each other at the third portion 33, and are joined by brazing or the like. The third portion 33 is also formed with a concave shape along the side surface shape of the second flat tube 20b by bending the plate member, and the second flat tube 20b fits into the concave shape. The second portion 32 and the third portion 33 of the fin 30 face different directions of the concave shape. The concave shape of the second portion 32 is open in the y direction, and the concave shape of the third portion 33 is open in the opposite direction to the y direction. That is, the first flat tube 20a is attached to one plate surface 38 of the fin 30 facing the y direction, and the second flat tube 20b is attached to the other plate surface 39 of the fin 30 facing the y direction. Is attached.

図4に示される様に、第1の扁平管20aと第2の扁平管20bとは、1つのフィン30の凹形状に嵌っている。このような形態により、製造時においてフィン30と第1の扁平管20aと第2の扁平管20bとは、一体の部品として取り扱うことができる。つまり、下端ヘッダ50a、50b及び上端ヘッダ51a、51bとの接合前に、2つの扁平管20を1つのフィン30の凹形状に嵌め込み一体にすることができるため、接合前に2つの扁平管20の互いの位置決めが容易になり、組立作業性を向上させることができる。

As shown in FIG. 4, the first flat tube 20a and the second flat tube 20b are fitted in the concave shape of one fin 30. With such a configuration, the fin 30, the first flat tube 20a, and the second flat tube 20b can be handled as an integral part during manufacturing. That is, before joining with the lower end headers 50a and 50b and the upper end headers 51a and 51b, the two flat tubes 20 can be fitted and integrated into the concave shape of one fin 30, so that the two flat tubes 20 are joined before joining. Can be easily positioned with each other, and the assembling workability can be improved.

フィン30は、第1扁平管群10aと第2扁平管群10bとの間に位置する第1の部分31を備える。第1の部分31は、第1の扁平管20aが嵌っている凹形状の端部と第2の扁平管20bが嵌っている凹形状の端部とを接続するように配置されている。言い換えると、第1の部分31は、第1の扁平管20aの端部のうち第2扁平管群10b側に位置する端部22aと第2の扁平管20bの端部のうち第1扁平管群10a側に位置する端部21bとを接続するように配置されている。また、実施の形態1において、第1の部分31は、第1の扁平管20a及び第2の扁平管20bの長軸に対し傾斜して配置されている。

The fin 30 includes a first portion 31 located between the first flat tube group 10a and the second flat tube group 10b. The first portion 31 is arranged so as to connect the concave end where the first flat tube 20a fits and the concave end where the second flat tube 20b fits. In other words, the first portion 31 includes the end 22a of the end of the first flat tube 20a located on the second flat tube group 10b side and the first flat tube of the end of the second flat tube 20b. It is arranged so as to connect with the end 21b located on the group 10a side. In the first embodiment, the first portion 31 is arranged to be inclined with respect to the long axis of the first flat tube 20a and the second flat tube 20b.

図4に示される様に、実施の形態1において空気は熱交換器100に対しx方向に流入する。上述したように、フィン30の第1の部分31が傾斜して配置されていることにより、第1の扁平管20a、第2の扁平管20b、及びフィン30の間の隙間を空気が蛇行して流れる。そのため、熱交換器100は、伝熱面積が拡大すると共に伝熱性能が向上する。また、フィン30の第1の部分31において、風が曲げられることで第2の扁平管20bの側壁23bに流れる空気が衝突する。空気の衝突により第2の扁平管20bの間の空気の流れが乱れるため、第2の扁平管20bの各部に接触する空気の温度が平均化されやすくなり、第2の扁平管20b内を流れる冷媒の乾き度が均一化される。これにより、熱交換器100は、熱交換性能が向上する。

空 気 As shown in FIG. 4, in Embodiment 1, air flows into the heat exchanger 100 in the x direction. As described above, since the first portion 31 of the fin 30 is arranged obliquely, the air meanders through the gap between the first flat tube 20a, the second flat tube 20b, and the fin 30. Flowing. Therefore, the heat exchanger 100 has an increased heat transfer area and improved heat transfer performance. Further, in the first portion 31 of the fin 30, the air flowing on the side wall 23b of the second flat tube 20b collides as the wind is bent. Since the air flow between the second flat tubes 20b is disturbed by the collision of air, the temperature of the air that contacts each part of the second flat tubes 20b is easily averaged, and flows through the second flat tubes 20b. The dryness of the refrigerant is made uniform. Thereby, the heat exchanger 100 has improved heat exchange performance.

また、フィン30は、第1の扁平管20aの端部のうちx方向逆向きを向いた端部21aから延設される平板状の第4の部分34を備える。つまり、第4の部分34は、第1の扁平管20aの端部のうち第1の部分31が延設されている端部22aと反対側の端部21aから延設されている。さらに、フィン30は、第2の扁平管20bの端部のうちx方向を向いた端部22bから延設される平板状の第5の部分35を備える。つまり、第5の部分35は、第2の扁平管20bの端部のうち第1の部分31が延設されている端部21bと反対側の端部22bから延設されている。フィン30が第4の部分34及び第5の部分35を備えることにより、熱交換器100は、伝熱面積が拡大すると共に伝熱性能が向上する。

フ ィ ン The fin 30 includes a flat plate-shaped fourth portion 34 extending from the end 21a of the first flat tube 20a that is opposite to the x direction. That is, the fourth portion 34 extends from the end 21a of the end of the first flat tube 20a opposite to the end 22a from which the first portion 31 extends. Further, the fin 30 includes a fifth flat portion 35 extending from the end 22b of the second flat tube 20b facing in the x direction. That is, the fifth portion 35 extends from the end 22b of the end of the second flat tube 20b opposite to the end 21b where the first portion 31 extends. Since the fin 30 includes the fourth portion 34 and the fifth portion 35, the heat exchanger 100 has an increased heat transfer area and improved heat transfer performance.

図5は、実施の形態1に係る熱交換器100の変形例の熱交換器100aの側面図である。図6は、実施の形態1に係る熱交換器100の変形例の熱交換器100aの断面構造の説明図である。図7は、スリット41のx方向から見た拡大図である。図6は、図5のB-B断面に対応する断面構造の説明図である。熱交換器100aは、フィン30の最も風上側にあり、第1の扁平管20aの端部21aから延設される第4の部分34にスリット41が設けられている。スリット41は、第4の部分34の一部を板面に垂直な方向に切り起こして形成される。図7に示される様に、板状の第4の部分34は、一部が切り起こされ、第4の部分34に略平行に位置する平行部45と、平行部45の両端から第4の部分34の板面を繋ぐ部分である立ち上がり部44とが形成されている。フィン30の第4の部分34の板面と平行に平行部45を設けることにより、第4の部分34の表面に対し平行に流れる空気の流れの境界層を小さくすることができ、伝熱性能を向上させつつ通風抵抗の増加を抑制できる。

FIG. 5 is a side view of heat exchanger 100a as a modification of heat exchanger 100 according to Embodiment 1. FIG. 6 is an explanatory diagram of a cross-sectional structure of a heat exchanger 100a according to a modified example of the heat exchanger 100 according to Embodiment 1. FIG. 7 is an enlarged view of the slit 41 as viewed from the x direction. FIG. 6 is an explanatory diagram of a cross-sectional structure corresponding to the BB cross section of FIG. The heat exchanger 100a is located on the most windward side of the fin 30, and a slit 41 is provided in a fourth portion 34 extending from the end 21a of the first flat tube 20a. The slit 41 is formed by cutting and raising a part of the fourth portion 34 in a direction perpendicular to the plate surface. As shown in FIG. 7, the plate-shaped fourth portion 34 is partially cut and raised, and a parallel portion 45 positioned substantially parallel to the fourth portion 34 and a fourth portion from both ends of the parallel portion 45. A rising portion 44 that connects the plate surfaces of the portion 34 is formed. By providing the parallel portion 45 parallel to the plate surface of the fourth portion 34 of the fin 30, the boundary layer of the flow of air flowing parallel to the surface of the fourth portion 34 can be reduced, and the heat transfer performance can be reduced. And the increase in ventilation resistance can be suppressed.

また、熱交換器100aは、フィン30の最も風下側にあり、第2の扁平管20bの端部21bから延設される第5の部分35にもスリット41が設けられている。第5の部分35においても、スリット41は第4の部分34と同様な構造で設置されている。そのため、第5の部分35の表面に対し平行に流れる空気の流れの境界層が小さくなり、伝熱性能を向上させつつ通風抵抗の増加を抑えることができる。

The heat exchanger 100a is located on the most leeward side of the fin 30, and the fifth portion 35 extending from the end 21b of the second flat tube 20b is also provided with a slit 41. In the fifth portion 35 as well, the slit 41 is provided in the same structure as in the fourth portion 34. Therefore, the boundary layer of the flow of the air flowing parallel to the surface of the fifth portion 35 is reduced, and it is possible to suppress the increase in the ventilation resistance while improving the heat transfer performance.

さらに、熱交換器100aは、第1の扁平管20aと第2の扁平管20bとの間に位置する第1の部分31にルーバー40を備える。ルーバー40は、板状の第1の部分31の一部を切り起して形成され、第1の扁平管20a及び第2の扁平管20bの長軸と平行にしてx方向に延設される舌状片である。また、ルーバー40の根元部には、第1の部分31の板面を貫通する開口部が形成されている。ルーバー40は、第1の扁平管20aの間を通過する空気の流れと平行に延設されている。そのため、ルーバー40が設けられている部分の第1の部分31の板面に形成された穴を空気が通過する。これにより、第1の扁平管20aに対して傾斜している第1の部分31が設けられている部位においても、扁平管20の長軸と平行な空気の流れを形成できる。従って、ルーバー40により伝熱性能を向上させつつ熱交換器100aの通風抵抗の増加を抑制できる。

Furthermore, the heat exchanger 100a includes a louver 40 in the first portion 31 located between the first flat tube 20a and the second flat tube 20b. The louver 40 is formed by cutting and raising a part of the plate-shaped first portion 31, and extends in the x direction in parallel with the long axes of the first flat tube 20a and the second flat tube 20b. It is a tongue piece. Further, an opening is formed at the base of the louver 40 so as to penetrate the plate surface of the first portion 31. The louver 40 extends in parallel with the flow of air passing between the first flat tubes 20a. Therefore, the air passes through a hole formed in the plate surface of the first portion 31 where the louver 40 is provided. Thereby, even at a portion where the first portion 31 inclined with respect to the first flat tube 20a is provided, an air flow parallel to the long axis of the flat tube 20 can be formed. Therefore, an increase in ventilation resistance of the heat exchanger 100a can be suppressed while improving the heat transfer performance by the louver 40.

熱交換器100、100aは、以下のような工程で製造される。まず、複数のフィン30と第1扁平管群10a及び第2扁平管群10bとを組み合わせる。各扁平管20は、フィン30の凹形状に嵌め込まれる。第1の扁平管20a、第2の扁平管20b、及びフィン30が一体になった状態で第1の扁平管20aと第2の扁平管20bとは、管軸方向の端部を下端ヘッダ50a、50b又は上端ヘッダ51a、51bに差し込まれる。その後、フィン30は図4及び図6のx方向の両端に位置する第4の部分34及び第5の部分35から引っ張られる。これにより、フィン30は、第1の扁平管20aに第2の部分32が押し付けられ、第2の扁平管20bに第3の部分33が押し付けられる。これにより、フィン30と複数の扁平管20とがより接触するため、フィン30の扁平管20に対する取り付け精度が向上する。この状態のまま、複数の扁平管20a、20bは、下端ヘッダ50a、50b及び上端ヘッダ51a、51bに挿入される。そして複数の扁平管20a、20bと下端ヘッダ50a、50b及び上端ヘッダ51a、51bとの接合部、及び複数の扁平管20a、20bとフィン30との接合部にロウ材が配置され、炉中に入れられロウ付けが行われる。熱交換器100、100aは、複数のフィン30により第1扁平管群10a及び第2扁平管群10bとを一体にして取り扱うことができるため、組立が容易で、製造が容易になるという利点がある。

The heat exchangers 100 and 100a are manufactured by the following steps. First, the plurality of fins 30 are combined with the first flat tube group 10a and the second flat tube group 10b. Each flat tube 20 is fitted into the concave shape of the fin 30. In a state where the first flat tube 20a, the second flat tube 20b, and the fin 30 are integrated, the first flat tube 20a and the second flat tube 20b have ends in the tube axial direction at the lower end header 50a. , 50b or upper headers 51a, 51b. Thereafter, the fins 30 are pulled from the fourth portion 34 and the fifth portion 35 located at both ends in the x direction of FIGS. Thereby, the fin 30 has the second portion 32 pressed against the first flat tube 20a, and the third portion 33 pressed against the second flat tube 20b. Thereby, since the fin 30 and the plurality of flat tubes 20 are in more contact with each other, the mounting accuracy of the fin 30 to the flat tube 20 is improved. In this state, the plurality of flat tubes 20a, 20b are inserted into the lower end headers 50a, 50b and the upper end headers 51a, 51b. The brazing material is arranged at the joint between the plurality of flat tubes 20a, 20b and the lower headers 50a, 50b and the upper headers 51a, 51b, and at the joint between the plurality of flat tubes 20a, 20b and the fins 30. It is inserted and brazed. Since the heat exchangers 100 and 100a can handle the first flat tube group 10a and the second flat tube group 10b integrally by the plurality of fins 30, the heat exchangers 100 and 100a have an advantage that assembly is easy and manufacturing is easy. is there.

なお、実施の形態1においては、第1の扁平管20aと第2の扁平管20bとは、長軸を平行にして千鳥状に配置されているため、第1の部分31が第1の扁平管20a及び第2の扁平管20bに対し傾斜して配置されているが、この形態だけに限定されるものではない。また、実施の形態1に係る熱交換器100の変形例として、ルーバー40とスリット41の両方が形成された熱交換器100aを説明したが、ルーバー40とスリット41のいずれか一方が形成された熱交換器であってもよい。

In the first embodiment, the first flat tube 20a and the second flat tube 20b are arranged in a staggered manner with their long axes parallel to each other. Although arranged obliquely with respect to the tube 20a and the second flat tube 20b, the present invention is not limited to this embodiment. Further, as a modified example of the heat exchanger 100 according to Embodiment 1, the heat exchanger 100a in which both the louver 40 and the slit 41 are formed has been described, but one of the louver 40 and the slit 41 is formed. It may be a heat exchanger.

図8は、実施の形態1に係る熱交換器100の変形例の熱交換器100bの断面構造の説明図である。図8は、図2のA-A断面に相当する断面の説明図である。変形例の熱交換器100bは、フィン30の第1の部分31、第1の扁平管20aが嵌る第2の部分32、及び第2の扁平管20bが嵌る第3の部分33が平行になっている。フィン30のうち、最も風上側に位置する第4の部分34及び最も風下側に位置する第5の部分35が、第1の部分31、第1の扁平管20aが嵌る第2の部分32、及び第2の扁平管20bが嵌る第3の部分33に対し傾斜している。そのため、熱交換器100に対しx方向に向かって流入した空気は、第1の扁平管20aの側壁23aに衝突する。空気の衝突により第1の扁平管20aの間の空気の流れが乱れるため、第1の扁平管20aの各部に接触する空気の温度が平均化されやすくなり、第1の扁平管20a内を流れる冷媒の乾き度が均一化される。これにより、熱交換器100bは、熱交換性能が向上する。

FIG. 8 is an explanatory diagram of a cross-sectional structure of a heat exchanger 100b according to a modified example of the heat exchanger 100 according to Embodiment 1. FIG. 8 is an explanatory diagram of a cross section corresponding to the AA cross section of FIG. In the heat exchanger 100b of the modified example, the first portion 31, the second portion 32 into which the first flat tube 20a fits, and the third portion 33 into which the second flat tube 20b fits become parallel. ing. Of the fins 30, the fourth part 34 located at the most leeward side and the fifth part 35 located at the most leeward side are the first part 31, the second part 32 to which the first flat tube 20a fits, And the third portion 33 in which the second flat tube 20b fits. Therefore, the air flowing into the heat exchanger 100 in the x direction collides with the side wall 23a of the first flat tube 20a. Since the air flow between the first flat tubes 20a is disturbed by the collision of air, the temperature of the air that contacts each part of the first flat tubes 20a is easily averaged, and flows through the first flat tubes 20a. The dryness of the refrigerant is made uniform. Thereby, the heat exchanger 100b has improved heat exchange performance.

実施の形態1に係る熱交換器100、100a、100bは、図3に示される冷凍サイクル装置1の室外熱交換器5及び室内熱交換器7の少なくとも一方に用いられることにより、エネルギ効率の高い冷凍サイクル装置1を提供することができる。ここで、エネルギ効率は、「暖房エネルギ効率=室内熱交換器(凝縮器)能力/全入力」、及び「冷房エネルギ効率=室内熱交換器(蒸発器)能力/全入力」で定義されるものである。

The heat exchangers 100, 100a, and 100b according to Embodiment 1 have high energy efficiency by being used in at least one of the outdoor heat exchanger 5 and the indoor heat exchanger 7 of the refrigeration cycle apparatus 1 shown in FIG. The refrigeration cycle device 1 can be provided. Here, the energy efficiency is defined by “heating energy efficiency = indoor heat exchanger (condenser) capacity / all inputs” and “cooling energy efficiency = indoor heat exchanger (evaporator) capacity / all inputs”. It is.

また、上述の実施の形態1で述べた熱交換器100、100a、100b、熱交換器ユニット、及びそれを用いた冷凍サイクル装置1については、R410A、R32、HFO1234yf等の冷媒においてその効果を達成することが出来る。さらに、実施の形態1においては、作動流体として、空気と冷媒の例を示したが、他の気体、液体、気液混合流体を用いても、同様の効果を奏する。

Further, with respect to the heat exchangers 100, 100a, 100b, the heat exchanger units, and the refrigeration cycle apparatus 1 using the same as described in the first embodiment, the effects can be achieved with refrigerants such as R410A, R32, and HFO1234yf. You can do it. Furthermore, in the first embodiment, an example has been described in which air and a refrigerant are used as the working fluid, but the same effect can be obtained by using another gas, liquid, or gas-liquid mixed fluid.

実施の形態1に係る熱交換器100、100a、100bのそれぞれの構造は、適宜組み合わせることも出来る。例えば、熱交換器100aのルーバー40およびスリット41の両方又はどちらか一方を熱交換器100bに適用することも可能である。

構造 The structures of the heat exchangers 100, 100a, and 100b according to the first embodiment can be appropriately combined. For example, both or one of the louver 40 and the slit 41 of the heat exchanger 100a can be applied to the heat exchanger 100b.

1 冷凍サイクル装置、2 送風機、3 圧縮機、4 四方弁、5 室外熱交換器、6 膨張装置、7 室内熱交換器、8 室外機、9 室内機、10 扁平管群、10a (第1)扁平管群、10b (第2)扁平管群、20 扁平管、20a (第1の)扁平管、20b (第2の)扁平管、21a 端部、21b 端部、22a 端部、22b 端部、23a 側壁、23b 側壁、30 フィン、31 第1の部分、32 第2の部分、33 第3の部分、34 第4の部分、35 第5の部分、38 板面、39 板面、40 ルーバー、41 スリット、44 立ち上がり部、45 平行部、50 下端ヘッダ、50a 下端ヘッダ、50b 下端ヘッダ、51 上端ヘッダ、51a 上端ヘッダ、51b 上端ヘッダ、90 冷媒配管、100 熱交換器、100a 熱交換器、100b 熱交換器。

1 Refrigeration cycle device, 2 blower, 3 compressor, 4 four-way valve, 5 outdoor heat exchanger, 6 expansion device, 7 indoor heat exchanger, 8 outdoor unit, 9 indoor unit, 10 flat tube group, 10 a (first) Flat tube group, 10b (second) flat tube group, 20 flat tube, 20a (first) flat tube, 20b (second) flat tube, 21a end, 21b end, 22a end, 22b end , 23a side wall, 23b side wall, 30 fin, 31 first part, 32 second part, 33 3 third part, 34 fourth part, 35 fifth part, 38 plate surface, 39 plate surface, 40 louver , 41 slit, 44 rising section, 45 parallel section, 50 bottom header, 50a bottom header, 50b bottom header, 51 top header, 51a top header, 51b top header, 90 Refrigerant pipe, 100 heat exchanger, 100a heat exchanger, 100b heat exchanger.

Claims (9)

- 管軸を平行にして並列された複数の扁平管を備える第1扁平管群と、

前記第1扁平管群に隣合って配置され、前記管軸を平行にして並列された前記複数の扁平管を備える、第2扁平管群と、

前記第1扁平管群が備える前記複数の扁平管のうちの1つである第1の扁平管と、前記第2扁平管群が備える前記複数の扁平管のうちの1つである第2の扁平管と、

前記第1の扁平管と前記第2の扁平管とに設置されるフィンと、を備え、

前記フィンは、

前記第1の扁平管の前記管軸に垂直な断面における長軸の端部と、前記第2の扁平管の前記管軸に垂直な断面における前記長軸の端部と、を接続する第1の部分を備える、熱交換器。 A first flat tube group including a plurality of flat tubes arranged in parallel with their tube axes parallel to each other;

A second flat tube group, which is arranged adjacent to the first flat tube group and includes the plurality of flat tubes arranged in parallel with the tube axes parallel to each other;

A first flat tube which is one of the plurality of flat tubes provided in the first flat tube group, and a second flat tube which is one of the plurality of flat tubes provided in the second flat tube group. A flat tube,

Fins installed on the first flat tube and the second flat tube,

The fins

A first connecting end of a long axis in a cross section perpendicular to the tube axis of the first flat tube and an end of the long axis in a cross section perpendicular to the tube axis of the second flat tube. A heat exchanger comprising: - 前記第1扁平管群の前記複数の扁平管と前記第2扁平管群の前記複数の扁平管とは、

千鳥状に配置される、請求項1に記載の熱交換器。 The plurality of flat tubes of the first flat tube group and the plurality of flat tubes of the second flat tube group,

The heat exchanger according to claim 1, wherein the heat exchanger is arranged in a staggered manner. - 前記フィンは、

前記第1の扁平管の側壁と接合される第2の部分と、

前記第2の扁平管の側壁と接合される第3の部分と、を備え、

前記第2の部分は、

前記第1の扁平管と当該フィンの板面の一方の面側で接合され、

前記第3の部分は、

前記第2の扁平管と前記板面の他方の面側で接合される、請求項1又は2に記載の熱交換器。 The fins

A second portion joined to a side wall of the first flat tube;

A third portion joined to a side wall of the second flat tube,

The second part is

The first flat tube and one of the plate surfaces of the fin are joined together,

The third part is

3. The heat exchanger according to claim 1, wherein the second flat tube is joined to the other side of the plate surface. 4. - 隣合う前記複数の扁平管群の間に位置する前記フィンの前記第1の部分は、

前記複数の扁平管の前記長軸に対し傾斜している、請求項1~3の何れか1項に記載の熱交換器。 The first portion of the fin located between the adjacent flat tube groups,

4. The heat exchanger according to claim 1, wherein the heat exchanger is inclined with respect to the long axis of the plurality of flat tubes. - 前記第1の部分は、

前記板面から前記管軸に交わる方向に延設されるルーバーと、

前記ルーバーの前記板面側の根元部に形成される前記板面を貫通する開口部と、を備える、請求項4に記載の熱交換器。 The first part is

A louver extending from the plate surface in a direction crossing the tube axis,

5. The heat exchanger according to claim 4, further comprising: an opening formed at a root portion of the louver on the plate surface side and penetrating the plate surface. 6. - 前記ルーバーは、

前記複数の扁平管の前記長軸と平行である、請求項5に記載の熱交換器。 The louver is

The heat exchanger according to claim 5, wherein the heat exchanger is parallel to the long axis of the plurality of flat tubes. - 前記フィンは、

前記第1の扁平管の前記長軸の端部のうち、前記第1の部分が延設される端部と反対側の端部から延設される第4の部分と、

前記第2の扁平管の前記長軸の端部のうち、前記第1の部分が延設される端部と反対側の端部から延設される第5の部分と、を備え、

前記第4の部分及び前記第5の部分の少なくとも一方は、

前記板面にスリットが形成されている、請求項1~6の何れか1項に記載の熱交換器。 The fins

A fourth portion extending from an end of the long axis of the first flat tube opposite to an end at which the first portion extends;

A fifth portion extending from an end opposite to the end at which the first portion extends, of the end of the long axis of the second flat tube,

At least one of the fourth part and the fifth part is

The heat exchanger according to any one of claims 1 to 6, wherein a slit is formed in the plate surface. - 請求項1~7の何れか1項に記載の熱交換器を備える、熱交換器ユニット。 A heat exchanger unit comprising the heat exchanger according to any one of claims 1 to 7.

- 請求項8に記載の熱交換器ユニットを備える、冷凍サイクル装置。 A refrigeration cycle apparatus comprising the heat exchanger unit according to claim 8.

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP18932105.2A EP3845851B1 (en) | 2018-08-27 | 2018-08-27 | Heat exchanger, heat exchanger unit, and refrigeration cycle device |

| PCT/JP2018/031502 WO2020044391A1 (en) | 2018-08-27 | 2018-08-27 | Heat exchanger, heat exchanger unit, and refrigeration cycle device |

| CN201880095774.3A CN112567192A (en) | 2018-08-27 | 2018-08-27 | Heat exchanger, heat exchanger unit, and refrigeration cycle device |

| JP2020539169A JP6980117B2 (en) | 2018-08-27 | 2018-08-27 | Heat exchanger, heat exchanger unit, and refrigeration cycle device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PCT/JP2018/031502 WO2020044391A1 (en) | 2018-08-27 | 2018-08-27 | Heat exchanger, heat exchanger unit, and refrigeration cycle device |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2020044391A1 true WO2020044391A1 (en) | 2020-03-05 |

Family

ID=69643578

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2018/031502 WO2020044391A1 (en) | 2018-08-27 | 2018-08-27 | Heat exchanger, heat exchanger unit, and refrigeration cycle device |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP3845851B1 (en) |

| JP (1) | JP6980117B2 (en) |

| CN (1) | CN112567192A (en) |

| WO (1) | WO2020044391A1 (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112277570A (en) * | 2020-10-30 | 2021-01-29 | 安徽江淮汽车集团股份有限公司 | Warm air core and automobile air conditioner |

| WO2022085067A1 (en) * | 2020-10-20 | 2022-04-28 | 三菱電機株式会社 | Heat exchanger and refrigeration cycle device |

| WO2023105566A1 (en) * | 2021-12-06 | 2023-06-15 | 三菱電機株式会社 | Heat exchanger |

Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1124526B (en) * | 1959-04-16 | 1962-03-01 | Licentia Gmbh | Coiled tube heat exchanger with heat conducting plates arranged between the tubes, in particular condensers for refrigeration machines |

| DE1927605A1 (en) * | 1969-05-30 | 1970-12-03 | Hans Henting | Weather cooler for mining, especially face cooler |

| JPH0396574U (en) * | 1989-12-29 | 1991-10-02 | ||

| JPH07305986A (en) * | 1994-05-16 | 1995-11-21 | Sanden Corp | Multitubular type heat exchanger |

| JP2000088297A (en) * | 1998-09-17 | 2000-03-31 | Hitachi Ltd | Ice heat storage type air-conditioning device and ice heat storage tank |

| WO2002016834A2 (en) * | 2000-08-21 | 2002-02-28 | Engineered Dynamics Corporation | Heat exchanger assembly and a method for efficiently transferring heat |

| JP2006084078A (en) | 2004-09-15 | 2006-03-30 | Daikin Ind Ltd | Thin heat transfer tube unit of thin multitubular heat exchanger |

| US20140027098A1 (en) * | 2011-04-14 | 2014-01-30 | Carrier Corporation | Heat exchanger |

| WO2018064696A1 (en) * | 2016-10-07 | 2018-04-12 | Euler Rolle Thomas | Heat exchanger |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2154366A1 (en) * | 1971-11-02 | 1973-05-10 | Folle Willi | AIR INLET BLINDS |

| HU184377B (en) * | 1981-02-05 | 1984-08-28 | Huetoegepgyar | Motor cooler |

| JP4540839B2 (en) * | 2000-12-13 | 2010-09-08 | 株式会社日本クライメイトシステムズ | Combined heat exchanger |

| JP2004251554A (en) * | 2003-02-20 | 2004-09-09 | Matsushita Electric Ind Co Ltd | Exterior heat exchanger for heat pump |

| JP2006162141A (en) * | 2004-12-06 | 2006-06-22 | Matsushita Electric Ind Co Ltd | Heat exchanger |

| JP4338667B2 (en) * | 2005-04-01 | 2009-10-07 | カルソニックカンセイ株式会社 | Heat exchanger |

| CN107218822B (en) * | 2016-03-21 | 2019-04-19 | 丹佛斯微通道换热器(嘉兴)有限公司 | Heat exchanger and air-conditioning system |

| WO2018185824A1 (en) * | 2017-04-04 | 2018-10-11 | 三菱電機株式会社 | Heat exchanger and refrigeration cycle device |

| ES2866323T3 (en) * | 2017-08-03 | 2021-10-19 | Mitsubishi Electric Corp | Heat exchanger and refrigeration cycle apparatus |

| CN110998201B (en) * | 2017-08-03 | 2022-02-11 | 三菱电机株式会社 | Heat exchanger and refrigeration cycle device |

| CN208238599U (en) * | 2018-05-18 | 2018-12-14 | 广东美的制冷设备有限公司 | Heat exchanger and heat exchange equipment |

-

2018

- 2018-08-27 CN CN201880095774.3A patent/CN112567192A/en active Pending

- 2018-08-27 EP EP18932105.2A patent/EP3845851B1/en active Active

- 2018-08-27 JP JP2020539169A patent/JP6980117B2/en active Active

- 2018-08-27 WO PCT/JP2018/031502 patent/WO2020044391A1/en unknown

Patent Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1124526B (en) * | 1959-04-16 | 1962-03-01 | Licentia Gmbh | Coiled tube heat exchanger with heat conducting plates arranged between the tubes, in particular condensers for refrigeration machines |

| DE1927605A1 (en) * | 1969-05-30 | 1970-12-03 | Hans Henting | Weather cooler for mining, especially face cooler |

| JPH0396574U (en) * | 1989-12-29 | 1991-10-02 | ||

| JPH07305986A (en) * | 1994-05-16 | 1995-11-21 | Sanden Corp | Multitubular type heat exchanger |

| JP2000088297A (en) * | 1998-09-17 | 2000-03-31 | Hitachi Ltd | Ice heat storage type air-conditioning device and ice heat storage tank |

| WO2002016834A2 (en) * | 2000-08-21 | 2002-02-28 | Engineered Dynamics Corporation | Heat exchanger assembly and a method for efficiently transferring heat |

| JP2006084078A (en) | 2004-09-15 | 2006-03-30 | Daikin Ind Ltd | Thin heat transfer tube unit of thin multitubular heat exchanger |

| US20140027098A1 (en) * | 2011-04-14 | 2014-01-30 | Carrier Corporation | Heat exchanger |

| WO2018064696A1 (en) * | 2016-10-07 | 2018-04-12 | Euler Rolle Thomas | Heat exchanger |

Non-Patent Citations (1)

| Title |

|---|

| See also references of EP3845851A4 |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2022085067A1 (en) * | 2020-10-20 | 2022-04-28 | 三菱電機株式会社 | Heat exchanger and refrigeration cycle device |

| CN112277570A (en) * | 2020-10-30 | 2021-01-29 | 安徽江淮汽车集团股份有限公司 | Warm air core and automobile air conditioner |

| CN112277570B (en) * | 2020-10-30 | 2022-05-20 | 安徽江淮汽车集团股份有限公司 | Warm braw core and vehicle air conditioner |

| WO2023105566A1 (en) * | 2021-12-06 | 2023-06-15 | 三菱電機株式会社 | Heat exchanger |

Also Published As

| Publication number | Publication date |

|---|---|

| EP3845851A1 (en) | 2021-07-07 |

| CN112567192A (en) | 2021-03-26 |

| JPWO2020044391A1 (en) | 2021-05-13 |

| EP3845851A4 (en) | 2021-09-01 |

| JP6980117B2 (en) | 2021-12-15 |

| EP3845851B1 (en) | 2023-03-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2015081765A (en) | Heat pump | |

| WO2020044391A1 (en) | Heat exchanger, heat exchanger unit, and refrigeration cycle device | |

| US20190049185A1 (en) | Heat exchanger | |

| US20110120177A1 (en) | Heat exchanger for shedding water | |

| US11175053B2 (en) | Heat exchanger, refrigeration cycle device, and air-conditioning apparatus | |

| JP6318371B2 (en) | Outdoor unit and refrigeration cycle apparatus using the same | |

| WO2020012549A1 (en) | Heat exchanger, heat exchange device, heat exchanger unit, and refrigeration system | |

| JP6997722B2 (en) | Heat exchanger and air conditioner | |

| JP7118279B2 (en) | HEAT EXCHANGER, MANUFACTURING METHOD THEREOF, AND AIR CONDITIONER | |

| WO2018185824A1 (en) | Heat exchanger and refrigeration cycle device | |

| JP6198976B2 (en) | Heat exchanger and refrigeration cycle apparatus | |

| WO2018207321A1 (en) | Heat exchanger and refrigeration cycle device | |

| WO2020178977A1 (en) | Heat exchanger, heat exchanger unit, and refrigeration cycle device | |

| US11578930B2 (en) | Heat exchanger, heat exchanger unit, and refrigeration cycle apparatus | |

| WO2020012577A1 (en) | Heat exchanger, heat exchanger unit, and refrigeration cycle device | |

| CN107850358B (en) | Heat exchanger and refrigeration cycle device | |

| JP7130116B2 (en) | air conditioner | |

| JP6621928B2 (en) | Heat exchanger and air conditioner | |

| WO2020178966A1 (en) | Gas header, heat exchanger, and refrigeration cycle device | |

| JP5664272B2 (en) | Heat exchanger and air conditioner | |

| WO2017154175A1 (en) | Heat exchanger | |

| JP7106814B2 (en) | Heat exchanger | |

| WO2020225845A1 (en) | Heat exchanger and refrigeration cycle device | |

| WO2020012548A1 (en) | Heat exchanger, heat exchanger unit, and refrigeration cycle device | |

| WO2019239554A1 (en) | Heat exchanger, heat exchanger unit, and refrigeration cycle device |