US2655784A - Winding and setting mechanism for watch or clock movements - Google Patents

Winding and setting mechanism for watch or clock movements Download PDFInfo

- Publication number

- US2655784A US2655784A US250479A US25047951A US2655784A US 2655784 A US2655784 A US 2655784A US 250479 A US250479 A US 250479A US 25047951 A US25047951 A US 25047951A US 2655784 A US2655784 A US 2655784A

- Authority

- US

- United States

- Prior art keywords

- winding

- wheel

- rocking

- bar

- setting

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- G—PHYSICS

- G04—HOROLOGY

- G04B—MECHANICALLY-DRIVEN CLOCKS OR WATCHES; MECHANICAL PARTS OF CLOCKS OR WATCHES IN GENERAL; TIME PIECES USING THE POSITION OF THE SUN, MOON OR STARS

- G04B27/00—Mechanical devices for setting the time indicating means

- G04B27/02—Mechanical devices for setting the time indicating means by making use of the winding means

- G04B27/06—Mechanical devices for setting the time indicating means by making use of the winding means with rocking bar

Definitions

- the present invention provides a solution to the problem by the use of a construction in which the usual square head of the winding crown is shaped in such a manner that upon the return motion of the winding stem from the setting position into the winding position, the minute setting wheel pivoting on the rocking-bar does not actuate the hands of the watch or clock nor prevent the return motion of the rocking-bar.

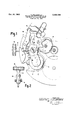

- Figure 1 is a plan view of a portion of a watch or clock mechanism illustrating one embodiment of the invention, the full lines showing the position of the parts in the winding position and the dash-dot lines indicating the position of the parts in the setting position.

- Figure 2 is a plan view of a winding stem made in accordance with another embodiment of the invention.

- a rocking-bar I is pivoted in a cap screw 2 carrying a minute setting wheel 3 and a winding wheel 4.

- the winding wheel 4 is meshed with a ratchet wheel 5 of the barrel, and the minute setting wheel 3 is out of engagement with a minute wheel 6.

- the setting position of the 4 Claims. (CI. 58-69) rocking-bar I the minute setting Wheel 3 is engaged with the minute wheel 5 and the winding wheel 4 is disengaged from the ratchet wheel 5.

- a transmission wheel I is pivoted coaxially with the rocking-bar I in fixed engagement with the setting wheel 3, the Wheel 4 and a winding pinion 8.

- a winding stem 9 has a square head I0 of helicoidal form adapted to fit an opening II of a corresponding shape made in the Winding pinion 8, the opening Il may also be made with flat walls to correspond with the walls of the head I (i. A rocking-bar spring I2 tends to maintain the rocking-bar I in the normal or Winding position.

- a setting lever I4 is held in one of two positions by the action of a jumper I5 positioned at one end of the setting lever. At its other end the setting lever has a pin engaged in a groove in the stem 9.

- the rocking-bar I is turned in the clockwise direction to bring the wheel 3 into engagement with the wheel 6

- the setting lever I4 is moved back into the position shown in full lines, and the rocking-bar I is turned in the counterclockwise direction under the action of its spring I2.

- Movement of the stem 9 through its helicoidal square head In causes the rotation of the pinion 8 to drive the transmission wheel I in the direction of the arrow A, and the minute wheel 3 is driven in the direction of the arrow B. Simultaneously, the rocking-bar I is returned into its normal position rotating the Wheel 3 on the transmission wheel I in the direction of the arrow C.

- the pitch of the helicoidal square head In is chosen so that the opposite rotational movements of the wheel 3 in the directions of the arrows B and C compensate each other. In this manner the lack of reaction of the transmission wheel I prevents any force transmission from the wheel 3 to the minute wheel 6.

- the rocking-bar is thus free to assume its normal position and the minute wheel 6 is not moved so as to eiiect the setting of the timepiece.

- the second embodiment of the invention differs from the first embodiment in that, while in the first embodiment the transmission wheel 1 is positively rotated as the crown I3 is moved inwardly, in the second embodiment the inward movement of the crown I3 permits a slight possible free rotation of the transmission wheel 1 providing the same result as obtained with the helicoidal square head.

- the square head I6 of the Winding stem 9 is made in the shape of a truncated pyramid with its small basis turned towards the crown l3. By reason of the shape of the head [6, and because of the fact that when the crown is pressed inwardly, the winding pinion 8 acquires a certain play with respect to the head It so that the transmission wheel is free to move without transmitting movement to the minute wheel 6.

- a winding and setting mechanism for a timepiece, a plate, a winding stem rotatably and reciprocally mounted on the plate, a winding pinion in contact with and rotatable by the winding stem, a rocking-bar pivotably mounted on the plate, a transmission Wheel rotatably mounted .on the rocking-bar and meshing with the winding pinion, a minute setting wheel rotatably mounted on the rocking-bar and permanently meshingwith the transmission wheel, a

- winding wheel rotatably mounted on the rockingbar and permanently meshing with the transmission wheel, and a hand-actuating minute wheel rotatably supported for engagement with the minute setting wheel, the improvement wherein the contact surfaces between the winding stem 'andthe-Winding pinion are shaped permitting relative movement therebetween as the stem is reciprocated.

- a-winding and setting mechanism for a timepiece, a plate, a winding stem rotatably and reciprocally mounted on the plate, a winding pinion in contact with and rotatable by the winding stem, a rocking-bar pivotably mounted on the'plate, a transmission wheel rotatably mounted on the rocking-bar and meshing with the winding -pinion, a minute setting wheel rotatably mounted on the rocking-bar and permanently meshing with the transmission wheel, a winding wheel rotatably mounted on the rocking-bar and.

- the winding stem is made of a shape at the position of contact with the winding pinion permitting relative movement therebetween as the stem is reciprocated.

- a plate In a winding and setting mechanism for a timepiece, a plate, a windin stem rotatably and reciprocallymounted on the plate, a winding pinion in contact with and rotatable by the winding stem, a rocking-bar pivotably mounted on the plate, a transmission wheel rotatably mounted on therocking-bar and meshing with i the winding pinion, a minute setting wheel rotatably mounted on the rocking-bar and permanently meshing with the transmission wheel, a

- winding wheel rotatably mounted on the rocking- .mounted on the rocking-bar and meshing with the winding pinion, a minute setting wheel rotatably mounted on the rocking-bar and permanently meshing with the transmission wheel, a winding wheel rotatably mounted on the rockingbar and permanently meshing with the trans- 'mission wheel, and a hand-actuating minute wheel rotatably supported for engagement with the minute setting wheel, the improvement wherein the winding stem is made in the form of atruncated pyramid at the position of contact with the winding pinion, the great base of the pyramid turned towards the end of the stem in engagement with the winding pinion permitting relative movement therebetween as the stem is reciprocated.

Landscapes

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Electromechanical Clocks (AREA)

- Electroplating And Plating Baths Therefor (AREA)

Description

G. DUCOMMUN 2,655,784 WIND AND SETTING MECHANISM FOR CH OR CLOCK MOVEMENTS Filed Oct. 9, 1951 Oct. 20, 1953 Patented Oct. 20, 1953 WINDING AND SETTING MECHANISM FOR WATCH OR CLOCK MOVEMENTS Georges Ducommun, Grenchen, Switzerland, assignor to Ebauches S. A., Grenchen, Switzerland Application October 9, 1951, Serial No. 250,479 In Switzerland March '7, 1951 The present invention relates to an improved winding and setting mechanism for watch or clock movements of the type including a rockingbar.

In prior timing devices the use of a rockingbar mechanism particularly in water-tight watches or clocks has not been entirely satisfactory because the Winding crown was retained by a water-tight packing which held the transmission wheel against free movement. In returning the stem to its normal winding position after it had been in the setting position, the minute setting wheel which was rotatably mounted on the rocking-bar tended to roll in the manner of a planet wheel on the transmission wheel resulting in the turning of the minute setting wheel so that either the rocking-bar remained in the setting position, or, if the rocking-bar returned to the winding position, the minute setting wheel rotated the minute wheel to slightly move the.

hands of the Watch or clock affecting the setting thereof.

Devices were provided to overcome the foregoing difiiculty by constructing the wheels of the mechanism with special teeth in the form of an involute of a circle. Such constructions were disadvantageous because of the difiicult and expensive manufacture, and. because the construction resulted in excessive pressures on the shafts, etc. The present invention provides a solution to the problem by the use of a construction in which the usual square head of the winding crown is shaped in such a manner that upon the return motion of the winding stem from the setting position into the winding position, the minute setting wheel pivoting on the rocking-bar does not actuate the hands of the watch or clock nor prevent the return motion of the rocking-bar.

In the drawings:

Figure 1 is a plan view of a portion of a watch or clock mechanism illustrating one embodiment of the invention, the full lines showing the position of the parts in the winding position and the dash-dot lines indicating the position of the parts in the setting position.

Figure 2 is a plan view of a winding stem made in accordance with another embodiment of the invention.

Referring to the drawings, a rocking-bar I is pivoted in a cap screw 2 carrying a minute setting wheel 3 and a winding wheel 4. In the winding position of the rocking-bar shown in full lines, the winding wheel 4 is meshed with a ratchet wheel 5 of the barrel, and the minute setting wheel 3 is out of engagement with a minute wheel 6. In the setting position of the 4 Claims. (CI. 58-69) rocking-bar I, the minute setting Wheel 3 is engaged with the minute wheel 5 and the winding wheel 4 is disengaged from the ratchet wheel 5. A transmission wheel I is pivoted coaxially with the rocking-bar I in fixed engagement with the setting wheel 3, the Wheel 4 and a winding pinion 8.

In accordance with the first embodiment of the invention a winding stem 9 has a square head I0 of helicoidal form adapted to fit an opening II of a corresponding shape made in the Winding pinion 8, the opening Il may also be made with flat walls to correspond with the walls of the head I (i. A rocking-bar spring I2 tends to maintain the rocking-bar I in the normal or Winding position.

A setting lever I4 is held in one of two positions by the action of a jumper I5 positioned at one end of the setting lever. At its other end the setting lever has a pin engaged in a groove in the stem 9. Upon the outward movement of the crown I3, the rocking-bar I is turned in the clockwise direction to bring the wheel 3 into engagement with the wheel 6 Upon the inward movement of the crown I3 into the winding position, the setting lever I4 is moved back into the position shown in full lines, and the rocking-bar I is turned in the counterclockwise direction under the action of its spring I2. Movement of the stem 9 through its helicoidal square head In causes the rotation of the pinion 8 to drive the transmission wheel I in the direction of the arrow A, and the minute wheel 3 is driven in the direction of the arrow B. Simultaneously, the rocking-bar I is returned into its normal position rotating the Wheel 3 on the transmission wheel I in the direction of the arrow C. The pitch of the helicoidal square head In is chosen so that the opposite rotational movements of the wheel 3 in the directions of the arrows B and C compensate each other. In this manner the lack of reaction of the transmission wheel I prevents any force transmission from the wheel 3 to the minute wheel 6. The rocking-bar is thus free to assume its normal position and the minute wheel 6 is not moved so as to eiiect the setting of the timepiece.

The second embodiment of the invention differs from the first embodiment in that, while in the first embodiment the transmission wheel 1 is positively rotated as the crown I3 is moved inwardly, in the second embodiment the inward movement of the crown I3 permits a slight possible free rotation of the transmission wheel 1 providing the same result as obtained with the helicoidal square head. In the construction of the second embodiment, the square head I6 of the Winding stem 9 is made in the shape of a truncated pyramid with its small basis turned towards the crown l3. By reason of the shape of the head [6, and because of the fact that when the crown is pressed inwardly, the winding pinion 8 acquires a certain play with respect to the head It so that the transmission wheel is free to move without transmitting movement to the minute wheel 6. Upon the return of the rocking-bar l to its normal winding position, the lack of reaction of the transmission wheel 1 prevents any movement through the whee1,.3-to the minute wheel 6. Therefore, the hands of the watch or clock remain at rest while the rocking-bar I is returned into the winding position.

While the invention has been described and illustrated with reference to specific embodiments thereof, it will be understood that other embodiments may be resorted to without departing from the invention. Therefore, the form of the invention set out above should be considered as illustrative and not as limiting the scope of the following claims.

I claim:

1. In a winding and setting mechanism'for a timepiece, a plate, a winding stem rotatably and reciprocally mounted on the plate, a winding pinion in contact with and rotatable by the winding stem, a rocking-bar pivotably mounted on the plate, a transmission Wheel rotatably mounted .on the rocking-bar and meshing with the winding pinion, a minute setting wheel rotatably mounted on the rocking-bar and permanently meshingwith the transmission wheel, a

winding wheel rotatably mounted on the rockingbar and permanently meshing with the transmission wheel, and a hand-actuating minute wheel rotatably supported for engagement with the minute setting wheel, the improvement wherein the contact surfaces between the winding stem 'andthe-Winding pinion are shaped permitting relative movement therebetween as the stem is reciprocated.

2. In a-winding and setting mechanism for a timepiece, a plate, a winding stem rotatably and reciprocally mounted on the plate, a winding pinion in contact with and rotatable by the winding stem, a rocking-bar pivotably mounted on the'plate, a transmission wheel rotatably mounted on the rocking-bar and meshing with the winding -pinion, a minute setting wheel rotatably mounted on the rocking-bar and permanently meshing with the transmission wheel, a winding wheel rotatably mounted on the rocking-bar and.

permanently meshing with the transmission wheel, and a hand-actuating minute wheel rotatably supported for engagement with the minute setting wheel, the improvement wherein the winding stem is made of a shape at the position of contact with the winding pinion permitting relative movement therebetween as the stem is reciprocated.

*3. In a winding and setting mechanism for a timepiece, a plate, a windin stem rotatably and reciprocallymounted on the plate, a winding pinion in contact with and rotatable by the winding stem, a rocking-bar pivotably mounted on the plate, a transmission wheel rotatably mounted on therocking-bar and meshing with i the winding pinion, a minute setting wheel rotatably mounted on the rocking-bar and permanently meshing with the transmission wheel, a

winding wheel rotatably mounted on the rocking- .mounted on the rocking-bar and meshing with the winding pinion, a minute setting wheel rotatably mounted on the rocking-bar and permanently meshing with the transmission wheel, a winding wheel rotatably mounted on the rockingbar and permanently meshing with the trans- 'mission wheel, and a hand-actuating minute wheel rotatably supported for engagement with the minute setting wheel, the improvement wherein the winding stem is made in the form of atruncated pyramid at the position of contact with the winding pinion, the great base of the pyramid turned towards the end of the stem in engagement with the winding pinion permitting relative movement therebetween as the stem is reciprocated.

GEORGES DUCOMMUN.

References Cited in the file of this patent UNITED STATES PATENTS Name Date sandoz June 4, 1907 Number

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CH290044T | 1951-03-07 | ||

| CH690464X | 1951-03-07 | ||

| CH2655784X | 1951-03-07 | ||

| CH867672X | 1951-03-07 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US2655784A true US2655784A (en) | 1953-10-20 |

Family

ID=61623845

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US250479A Expired - Lifetime US2655784A (en) | 1951-03-07 | 1951-10-09 | Winding and setting mechanism for watch or clock movements |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US2655784A (en) |

| CH (1) | CH290044A (en) |

| DE (1) | DE867672C (en) |

| GB (1) | GB690464A (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2982085A (en) * | 1957-03-01 | 1961-05-02 | Ebauches Sa | Winding and setting device for timepieces |

| US3104517A (en) * | 1962-01-29 | 1963-09-24 | United States Time Corp | Planetary gear winding mechanism |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1003654B (en) * | 1954-06-21 | 1957-02-28 | Friedrich Mauthe Ges Mit Besch | Clock winding and pointer setting device with rocker |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US856183A (en) * | 1905-09-05 | 1907-06-04 | Henri Sandoz | Winding and setting mechanism for watches. |

-

1951

- 1951-03-07 CH CH290044D patent/CH290044A/en unknown

- 1951-07-28 DE DEE4124A patent/DE867672C/en not_active Expired

- 1951-09-26 GB GB22481/51A patent/GB690464A/en not_active Expired

- 1951-10-09 US US250479A patent/US2655784A/en not_active Expired - Lifetime

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US856183A (en) * | 1905-09-05 | 1907-06-04 | Henri Sandoz | Winding and setting mechanism for watches. |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2982085A (en) * | 1957-03-01 | 1961-05-02 | Ebauches Sa | Winding and setting device for timepieces |

| US3104517A (en) * | 1962-01-29 | 1963-09-24 | United States Time Corp | Planetary gear winding mechanism |

Also Published As

| Publication number | Publication date |

|---|---|

| GB690464A (en) | 1953-04-22 |

| CH290044A (en) | 1953-04-15 |

| DE867672C (en) | 1953-02-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US5793708A (en) | Timepiece with a chronograph mechanism | |

| US3628325A (en) | Self-winding watch | |

| US11537080B2 (en) | Timepiece display mechanism with a resilient hand | |

| US3911667A (en) | Instantaneous feed mechanism for a day-date timepiece | |

| US3470688A (en) | Date and day correcting device of a calendar timepiece | |

| US2976672A (en) | Timepiece with date indicator | |

| GB1360543A (en) | Timepiece | |

| US4676659A (en) | Intermittent driving arrangement for a time indicator | |

| US2655784A (en) | Winding and setting mechanism for watch or clock movements | |

| US3104517A (en) | Planetary gear winding mechanism | |

| US5297112A (en) | Setting a double face watch | |

| US2650467A (en) | Calendar timepiece | |

| US3412550A (en) | Self-winding watch movement | |

| US3695029A (en) | Calendar day and date watch | |

| GB1385070A (en) | Calendar timepieces | |

| GB1397492A (en) | Timepiece | |

| GB1205962A (en) | Calendar timepiece setting mechanism | |

| US7813227B2 (en) | Musical module for a watch movement | |

| US3888077A (en) | Mechanical watch movement | |

| GB709774A (en) | Timepiece movement, with an automatic winding mechanism comprising a lockable oscillating weight | |

| US1973898A (en) | Winding mechanism for timepiece driving springs | |

| US3576100A (en) | Date-watch | |

| US3377795A (en) | Calendar setting mechanism for an electric watch | |

| GB706203A (en) | Automatic winding device for wristlet watches | |

| US548008A (en) | Bello |