JP6734504B2 - Remote operated drain plug device - Google Patents

Remote operated drain plug device Download PDFInfo

- Publication number

- JP6734504B2 JP6734504B2 JP2016016724A JP2016016724A JP6734504B2 JP 6734504 B2 JP6734504 B2 JP 6734504B2 JP 2016016724 A JP2016016724 A JP 2016016724A JP 2016016724 A JP2016016724 A JP 2016016724A JP 6734504 B2 JP6734504 B2 JP 6734504B2

- Authority

- JP

- Japan

- Prior art keywords

- shaft

- operating

- plug device

- valve member

- drain plug

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E03—WATER SUPPLY; SEWERAGE

- E03C—DOMESTIC PLUMBING INSTALLATIONS FOR FRESH WATER OR WASTE WATER; SINKS

- E03C1/00—Domestic plumbing installations for fresh water or waste water; Sinks

- E03C1/12—Plumbing installations for waste water; Basins or fountains connected thereto; Sinks

- E03C1/22—Outlet devices mounted in basins, baths, or sinks

- E03C1/23—Outlet devices mounted in basins, baths, or sinks with mechanical closure mechanisms

- E03C1/2304—Outlet devices mounted in basins, baths, or sinks with mechanical closure mechanisms the actuation force being transmitted to the plug via flexible elements, e.g. chain, Bowden cable

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Environmental & Geological Engineering (AREA)

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Hydrology & Water Resources (AREA)

- Public Health (AREA)

- Water Supply & Treatment (AREA)

- Sink And Installation For Waste Water (AREA)

Description

本発明は、遠隔操作式排水栓装置に関し、更に詳しくは、施工性の向上、また設計レイアウトの自由度を高めると共に、故障が発生しにくい遠隔操作式排水栓装置を提供するものである。 The present invention relates to a remote-operated drain tap device, and more specifically, to provide a remote-operated drain tap device that improves workability and flexibility in design layout and is resistant to failure.

従来より、浴槽や洗面ボウルなどの槽体の内部に生じた排水を処理するため、槽体の底面等に排水口を設け、この排水口から配管部材を介し、下水側に排水を排出する方法が広く知られている。また、槽体内に水を溜める場合に、弁部材の昇降を利用して排水口を開閉する方法があるが、この弁部材による排水口の開閉を、弁部材や排水口から離間した位置、例えば槽体の縁部や槽体側面の上方に設けた操作部への操作によって行う遠隔操作式排水栓装置が知られている。

広く知られた遠隔操作式排水栓装置としては、特許文献1に記載のような、槽体の底面に設けられた排水口と、排水口を上下動することによって閉塞する弁部材と、槽体の側面上方に備えられた、操作体を有する操作部と、操作部に加えられた操作を排水口に備えられた弁部材に伝達するレリースワイヤと、から構成されるものがある。この特許文献1に記載された遠隔操作式排水栓装置では、弁部材の上昇状態を維持するため、段落0009に記載されているように排水口または操作部のいずれかにロック機構(スラストロック機構)が備えられてなる。

このような遠隔操作式排水栓装置において、操作体に押し込み操作を加えると、操作体の動作に対応して、インナーワイヤが弁部材側に移動する。

特許文献1には詳述されていないが、操作部側にロック機構が配置された場合には、ロック機構の一端に操作体が、他端にレリースワイヤが接続され、操作体に操作を加えてロック機構が作動することでレリースワイヤの動作が固定されて、レリースワイヤが弁部材を押し上げ、排水口を開口した状態を維持固定する。再度操作体に操作を加えるとロック機構によるレリースワイヤの動作の固定が解除されて弁部材が降下し排水口を閉口する。

また、排水口側にロック機構が配置された場合には、ロック機構の一端に弁部材が、他端にレリースワイヤが接続され、操作体に操作を加えるとレリースワイヤを介して操作がロック機構に伝達され、ロック機構が弁部材を押し上げ、排水口を開口した状態を維持固定する。再度操作体に操作を加えると、再びレリースワイヤを介してロック機構に操作が伝達され、ロック機構の固定が解除されて弁が降下し排水口を閉口する。

As a widely known remote control type drain plug device, as described in

In such a remote control type drain plug device, when a pushing operation is applied to the operating body, the inner wire moves to the valve member side in response to the operation of the operating body.

Although not described in detail in

Further, when the lock mechanism is arranged on the drain port side, the valve member is connected to one end of the lock mechanism and the release wire is connected to the other end, and when the operation body is operated, the operation is performed via the release wire. The lock mechanism pushes up the valve member to maintain and fix the state in which the drain port is opened. When the operation body is operated again, the operation is again transmitted to the lock mechanism via the release wire, the lock mechanism is released from the fixed state, the valve descends, and the drain port is closed.

上記のように構成した遠隔操作式排水栓装置には、以下のような問題点があった。

上記遠隔操作式排水栓装置のレリースワイヤは、軸方向には剛性を、側面方向にはある程度の可撓性を備えて側面方向に屈曲可能に構成されているが、屈曲の半径が極端に小さいと、座屈と呼ばれる復元不可能な折れ曲がりを生じる。この座屈を防ぐため、レリースワイヤを配置する経路には、レリースワイヤの最小曲がり半径(座屈が発生しない範囲での最小の半径)よりも大きな半径で屈曲が行える空間を確保する必要がある。

遠隔操作式排水栓装置の配置に際して特にレリースワイヤの曲がり半径が小さくなる部分としては、槽体側面に配置した操作部近傍部分の空間、また排水口近傍部分の空間がある。

The remote-operated drain plug device configured as described above has the following problems.

The release wire of the remote-operated drain plug device is configured to be rigid in the axial direction and flexible to some extent in the lateral direction so that it can be bent in the lateral direction, but the bending radius is extremely small. And an unrecoverable bend called buckling occurs. In order to prevent this buckling, it is necessary to secure a space for bending the release wire with a radius larger than the minimum bending radius of the release wire (the minimum radius in the range where buckling does not occur). ..

When arranging the remote-operated drain plug device, as a portion where the bending radius of the release wire becomes particularly small, there is a space near the operation portion arranged on the side surface of the tank body and a space near the drain port.

操作部近傍部分について説明すると、浴槽等槽体の側面と、槽体が設置される部屋の側面との隙間部分を広くすると、その分槽体内が狭くなり、浴槽であれば入浴の快適さが失われ、洗面台や流し台では槽体の容量が減少して使い勝手が悪くなるため、なるべく槽体の側面との隙間部分を狭くし、その分槽体内を大きくするように構成される。このため、槽体の側面と槽体を設置した部屋の側面との隙間部分が狭くなる。

特許文献1に記載の遠隔操作式排水栓装置の場合、操作部は槽体である浴槽の側面に配置され、レリースワイヤは水平方向から浴槽の側面と浴室の側面との隙間部分にて垂直方向に屈曲するように配置される。上記のように、浴槽の側面と浴室の側面との隙間部分が狭く、しかも屈曲の開始部分となるレリースワイヤの端部の接続部分は、操作体を進退させる軸体(操作軸)の端部に接続されるか、またはロック機構が操作部に配置された場合はロック機構の端部に接続されるか、であり、軸体やロック機構の長さ分、レリースワイヤの屈曲の為の半径を更に小さくしなければならず、小さな半径での屈曲によりレリースワイヤに負担が掛かり、座屈を生じやすくなっていた。

Explaining the part near the operation part, if you widen the gap between the side of the bath such as a bath and the side of the room where the bath is installed, the inside of the bath will be narrower by that amount, and if it is a bath, comfort of bathing will be improved. It is lost, and the capacity of the tank body decreases in the wash basin and the sink, and the usability is deteriorated. Therefore, the gap between the side surface of the tank body is narrowed as much as possible, and the tank body is enlarged accordingly. Therefore, the gap between the side surface of the tank body and the side surface of the room in which the tank body is installed becomes narrow.

In the case of the remote-operated drain plug device described in

排水口近傍部分について説明すると、排水口近傍の部材についてはできるだけ高さ幅を狭くできるほうが好適である。槽体の排水は重力による自然排水のため、排水口は槽体の底面の、更に最も低い個所に設けられる。浴槽のように排水口からの排水配管が床下空間に配置される場合、排水口近傍の部材の高さ幅が狭くなれば、その分床下空間を狭くし、代わりに居住空間を上下方向に幅広にし、使用者の生活空間を快適にできる。また洗面台や流し台のように、排水口近傍の排水配管が屋内の居住空間に配置される場合、排水口の下方にはキャビネット等が配置されて洗剤やタオルなどの収納に利用されるため、排水口近傍の部材の高さ幅が狭くなれば、その分収納空間を上下に広くし、収納量を増加させることができる。

このように排水口近傍の部材は、できるだけ高さ幅を狭くしたほうが好適である。

特許文献1に記載の遠隔操作式排水栓装置の場合、排水口は槽体である浴槽の底面に配置され、レリースワイヤは、排水口の直下に配置された継手部材の内部にて、垂直から水平方向に屈曲するように配置される。上記のように、排水口近傍の部材、特に排水口の下方に配置された部材は上下方向に狭く、しかも遠隔操作式排水栓装置の場合、排水口には弁部材の上下動をガイドする軸体(押上軸)が備えられ、レリースワイヤはこの軸体の下端に接続されるため、レリースワイヤの屈曲が可能な空間もこの軸体よりも下方に限られて屈曲可能な範囲がより狭くなる。

また、ロック機構が排水口側に配置された場合、レリースワイヤが接続されるのはこのロック機構の下端端部であり、軸体やロック機構の長さ分、レリースワイヤの屈曲の為の半径を小さくしなければならず、小さな半径での屈曲によりレリースワイヤに負担が掛かり、座屈を生じやすくなっていた。

本発明は上記問題点に鑑み発明されたものであって、遠隔操作式排水栓装置において、レリースワイヤ等に故障が発生しにくいものとすると共に、設計レイアウトの自由度を高め、また施工性を向上させた遠隔操作式排水栓装置を提供するものである。

Explaining the vicinity of the drainage port, it is preferable that the height width of the members near the drainage port can be made as narrow as possible. Since the drainage of the tank body is natural drainage due to gravity, the drain port is provided at the lowest point on the bottom surface of the tank body. When the drainage pipe from the drainage port is placed in the underfloor space like a bathtub, if the height width of the members near the drainage port becomes narrower, the underfloor space is narrowed by that amount, and instead the living space is widened vertically. The user's living space can be made comfortable. Also, when the drainage pipe near the drainage outlet is placed in the indoor living space, like a washbasin or sink, a cabinet or the like is placed below the drainage outlet and is used for storing detergent, towels, etc. If the height width of the member in the vicinity of the drainage port is narrowed, the storage space can be widened in the vertical direction and the storage amount can be increased.

As described above, it is preferable that the height and width of the member near the drain port be as narrow as possible.

In the case of the remote-operated drain plug device described in

When the lock mechanism is placed on the drain side, it is the lower end of this lock mechanism that connects the release wire, and the radius for bending the release wire is the length of the shaft and lock mechanism. Had to be made small, and the release wire was burdened by bending with a small radius, and buckling was likely to occur.

The present invention has been invented in view of the above problems, in the remote-operated drainage plug device, the release wire and the like is less likely to cause a failure, the flexibility of the design layout is increased, and the workability is improved. An improved remote operated drain plug device is provided.

請求項1に記載の本発明は、槽体に設けた排水口と、上下動によって排水口を開閉する弁部材と、弁部材の上下動を操作する操作部と、操作部に加えられた操作を弁部材に伝達する、筒状のアウターチューブ、該アウターチューブ内を摺動するインナーワイヤ、からなるレリースワイヤと、からなる遠隔操作式排水栓装置において、

操作部に、使用者の操作によって進退する操作軸と、操作軸の一端に備えられた、使用者が操作を加える操作体と、操作軸の操作体側端部又は操作軸の途中の位置に接続された枝部と、を備え、操作軸の動作が枝部によって操作軸の進退方向に対して角度を有した方向に変換され、枝部からインナーワイヤを介することで、操作軸に加えられた操作が弁部材に伝達されるように構成したことを特徴とする遠隔操作式排水栓装置である。

The present invention according to

Connected to the operation part, which is operated by the user to move back and forth in the operation part, the operation body provided at one end of the operation shaft to be operated by the user, and the operation body side end part of the operation shaft or a position in the middle of the operation shaft. And a branch portion provided with a branch portion, and the operation of the operation shaft is converted by the branch portion into a direction having an angle with respect to the advancing/retreating direction of the operation shaft, and is applied to the operation shaft through the inner wire from the branch portion. A remote-operated drain plug device characterized in that an operation is transmitted to a valve member.

請求項2に記載の本発明は、槽体に設けた排水口と、上下動によって排水口を開閉する弁部材と、弁部材の上下動を操作する操作部と、操作部に加えられた操作を弁部材に伝達する、筒状のアウターチューブ、該アウターチューブ内を摺動するインナーワイヤ、からなるレリースワイヤと、からなる遠隔操作式排水栓装置において、

操作部に、使用者の操作によって進退する操作軸と、操作軸の一端に備えられた、使用者が操作を加える操作体と、を備え、インナーワイヤ端部を、操作軸の操作体側端部又は操作軸の途中の位置に接続し、インナーワイヤを介して操作軸に加えられた操作が弁部材に伝達されるように構成したことを特徴とする遠隔操作式排水栓装置である。

The present invention according to

The operation unit includes an operation shaft that moves forward and backward by a user's operation, and an operation body that is provided at one end of the operation shaft and is operated by the user, and the inner wire end portion is the operation body side end portion of the operation shaft. Alternatively, the remote-operated drain plug device is characterized in that it is connected to a position in the middle of the operation shaft so that an operation applied to the operation shaft is transmitted to the valve member via an inner wire.

請求項3に記載の本発明は、上記遠隔操作式排水栓装置において、

操作軸の一端に、弁部材の上昇状態又は下降状態を維持するロック機構を備えたことを特徴とする、請求項1又は請求項2に記載の遠隔操作式排水栓装置である。

The present invention according to claim 3 provides the remote-operated drain plug device,

The remote-operated drain plug device according to

請求項4に記載の本発明は、上記遠隔操作式排水栓装置において、

操作軸が槽体の内側に配置され、操作軸の進退方向が槽体の内側面に沿う方向であると共に、槽体の側面に貫通孔が設けられ、該貫通孔を介して枝部またはレリースワイヤが槽体の裏面側に配置されることを特徴とする、請求項1乃至請求項3のいずれか一つに記載の遠隔操作式排水栓装置である。

The present invention according to

The operation shaft is arranged inside the tank body, and the advancing/retreating direction of the operation shaft is along the inner side surface of the tank body, and a through hole is provided in the side surface of the tank body, and a branch portion or a release is provided through the through hole. The remote operated drain plug device according to any one of

請求項1に記載の本発明では、遠隔操作式排水栓装置において、操作軸の途中または操作体側の端部に枝部を備え、枝部を利用して操作軸の進退方向とレリースワイヤの方向を異なる方向とすることで、操作部近傍におけるレリースワイヤの曲がり半径を大きな半径とすることができ、座屈が生じにくく、また設計レイアウトの自由度を高めた構成とすることができる。

請求項2に記載の本発明では、遠隔操作式排水栓装置において、インナーワイヤ端部を、操作軸の操作体側端部又は操作軸の途中の位置に接続したことによって、操作部近傍におけるレリースワイヤの曲がり半径を大きな半径とすることができ、座屈が生じにくく、また設計レイアウトの自由度を高めた構成とすることができる。

請求項3に記載の本発明では、ロック機構の端部にはレリースワイヤが接続されない構成としたことで、従来のロック機構の端部にレリースワイヤが接続される構成の遠隔操作式排水栓装置と同じ機能を有するようにしつつ、且つ操作部近傍におけるレリースワイヤの曲がり半径を大きな半径とすることができる。

請求項4に記載の本発明においては、操作部側の主な可動部分である操作軸が、槽体の内側に配置されるため、メンテナンス等を容易にすることができる。

According to the first aspect of the present invention, in the remote control type drain plug device, a branch portion is provided in the middle of the operation shaft or at an end portion on the side of the operating body, and the branch portion is used to advance and retreat the operation shaft and release wire direction. By setting the directions different from each other, the bending radius of the release wire in the vicinity of the operation portion can be set to a large radius, buckling hardly occurs, and the degree of freedom in design layout can be increased.

According to the second aspect of the present invention, in the remote operated drain plug device, the inner wire end portion is connected to the operation body side end portion of the operation shaft or a position in the middle of the operation shaft, so that the release wire near the operation portion is formed. The bending radius can be set to a large radius, buckling is unlikely to occur, and the degree of freedom in design layout can be increased.

According to the third aspect of the present invention, the release wire is not connected to the end of the lock mechanism, so that the release wire is connected to the end of the conventional lock mechanism. While having the same function as described above, the bending radius of the release wire in the vicinity of the operating portion can be made large.

According to the fourth aspect of the present invention, since the operation shaft, which is a main movable portion on the operation portion side, is arranged inside the tank body, maintenance and the like can be facilitated.

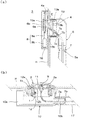

以下に本発明の第一実施例を、図面を参照しつつ説明する。

尚、以下の説明に記載した図2、図3において、(a)は操作部近傍を、(b)は排水口近傍を、それぞれ示すものである。

図1乃至図3に示した、本発明の第一実施例の遠隔操作式排水栓装置は、以下に記載する、槽体を備えた排水機器である浴槽Bに施工されるものであって、以下に記載する、排水口本体1、継手部材10、操作伝達部材としてのレリースワイヤ7、弁部材2、支持部材12、操作部3、ガイド管17、より構成されてなる。

浴槽Bは、上方が開口した箱体であって、底面には排水口本体1を取り付ける取付孔を、側面には操作部3を取り付ける操作部取付孔を、それぞれ備えてなる。

排水口本体1は、内部に排水流路を形成する略円筒形状の部材であって、その内部に排水口1aを、上縁に外方向に突出したフランジ部1bを、フランジ部1b下方の側面に雄ネジを、それぞれ備えてなる。また排水口1a内部には周縁方向に沿って凸部が複数設けられてなる。

継手部材10は、上記排水口本体1が接続される、略90度に屈曲した管体であって、上方の開口には排水口本体1の雄ネジと螺合する雌ネジを備えてなり、側面方向には下水側の配管と接続するための排出口10aを備えてなる。また、継手部材10の側面には、後述するレリースワイヤ7を挿入するための枝管部10bを備えてなる。

レリースワイヤ7は、操作部3に加えられた操作を、弁部材2に伝達するための部材であって、筒状にして軸方向に剛性を、側面方向に可撓性を備えたアウターチューブ7aと、上記アウターチューブ7a内を摺動自在に動作する、軸方向に剛性を、側面方向に可撓性を備えたインナーワイヤ7bと、インナーワイヤ7bを操作部3側に付勢する戻りスプリング7cと、インナーワイヤ7bの排水口1a側端部に備えた、弁部材2の昇降をガイドする為の押上軸9と、から構成される。

弁部材2は、略円盤状を成す部材であって、その下面中央はレリースワイヤ7の押上軸9と嵌合するように構成され、側面部には排水口1aと水密に接続する為のパッキングを備え、レリースワイヤ7のインナーワイヤ7bの進退に対応して、排水口1aに対して上下動するように構成され、上昇時には排水口1aを開口し、下降時においては排水口1aの上端部分を覆うことで排水口1aを閉口する。

支持部材12は、排水口本体1内部の凸部と嵌合することで、排水口1aに配置固定される部材であって、レリースワイヤ7のアウターチューブ7a端部を固定するワイヤ固定部11と、リング状にして排水口1a内部の凸部と嵌合する第一リング部12aと、第一リング部12aとワイヤ固定部11を連絡するアーム部12bと、から構成される。ワイヤ固定部11は、第一リング部12aの中央に配置され、施工が完了した場合には、レリースワイヤ7の押上軸9が排水口1aの中央に配置されて上下動するように構成される。

操作部3は、浴槽Bの操作部取付孔に取り付けられ、弁部材2の上下動を操作する部材であって、以下に記載する、操作部本体4、エルボ部材5、ロック機構8、操作軸6a、操作体6b、操作部側支持部材13から構成される。

操作部本体4は、略円筒形状にして端部外側面に鍔部4aを、筒部分の外側面に雄ネジを、それぞれ備えてなり、更に内部にレリースワイヤ7を挿通する開口を形成してなる。また開口の内部には周縁方向に沿って凸部が複数設けられてなる。

エルボ部材5は、上記操作部本体4が接続される、略90度に屈曲した管体であって、上流の開口には操作部本体4の雄ネジと螺合する雌ネジを備えてなり、下流にはレリースワイヤ7が挿通される接続管部5aを備えてなる。

ロック機構8は、回動自在な歯車を備えた、棒状の部材であるロック軸8aと、該ロック軸8aをその内部に進退自在に挿通させる、内部に溝部を備えた形状のロック機構本体部8bと、ロック機構8本体内部に収納配置されて、ロック軸8aをロック機構8に対し図 における上方に付勢するスプリングからなる弾性部材と、からなる(内部構造の図示は省略するものとし、これに伴い歯車、溝部、弾性部材の図示も省略)。このロック機構8は、ロック軸8aに対して下方に向け押し込み操作を行う都度、ロック軸8aを下方に降下した状態で固定/固定を解除して弾性部材の付勢によりロック軸8aを上方に上昇、を交互に繰り返す部材である。

操作軸6aは略円柱形状を成す部材であって、操作体6bが備えられる上端部分の近傍側面に、ヒンジ部を介して操作軸6aに回動自在に接続される枝部Eを備えてなる。

また、ネジ接続を利用して、ロック軸8aの上端と操作軸6aの下端とを固定接続することができるように構成されてなる。

操作体6bは、裏面側(施工完了時、槽体である浴槽Bの内側面を向く面)と下面が開放された略箱体形状を成す部材であって、施工完了時その内部に操作軸6a及びロック機構8が配置されると共に、その上壁面の下面に、操作軸6aの上端部分と嵌合接続する突起を備えてなる。

操作部側支持部材13は、操作部本体4内部の凸部と嵌合することで、操作部本体4内に配置固定される部材であって、リング状にして操作部本体4内部の凸部と嵌合する第二リング部13aと、施工完了時操作軸6aを上下動自在に収納するガイド筒部14と、第二リング部13aとガイド筒部14を連絡する連結部13bと、ロック機構本体部8bを接続固定するホルダー部16を備えてなる。

ガイド筒部14は、施工完了時操作軸6aを収納する操作軸収納部15aと、操作軸収納部15aの上端近傍から枝分かれした、枝部Eを収納する枝収納部15bとからなり、図1乃至図3に示したように、施工完了時操作軸収納部15aは槽体である浴槽Bの内側面に沿って上下方向に配置され、また枝収納部15bはこの浴槽Bの内側から外側に向かって下方に下る傾斜を備えて構成される。この時、操作軸収納部15a下端−枝分かれ部分−枝収納部15b下端は鋭角、即ち90度よりも小さい角度を成すように構成される。

また、枝収納部15bの下端は、施工完了時浴槽Bの壁面を貫通してエルボ部材5内に達すると共に、レリースワイヤ7のアウターチューブ7a端部が接続される。

また、操作軸収納部15aは、上方の開口は操作軸6aと下方を向いた枝部Eとを挿通可能な内径を有し、枝収納部15bとの交差部分にて縮径して、枝収納部15bよりも下方では操作軸6aのみを挿通する径を有している。このため、操作軸収納部15aの上方から操作軸6aを挿通すると、枝部Eは枝収納部15bとの交差部分から枝収納部15b側に向かって配置される。

ホルダー部16は、操作軸6aの直下位置に配置され、施工完了時操作軸6aとロック機構8のロック軸8aとが同軸上に配置されるように、ロック機構本体部8bを固定する。即ち、施工完了時、このロック機構8も槽体である浴槽Bの内側に配置される。

ガイド管17は軟質樹脂から構成される、可撓性を備えたチューブ管であって、一端は継手部材10の枝管部10bに、他端はエルボ部材5の接続管部5aに、それぞれ接続される。

A first embodiment of the present invention will be described below with reference to the drawings.

2 and 3 described below, (a) shows the vicinity of the operation portion, and (b) shows the vicinity of the drainage port.

The remote-operated drain plug device according to the first embodiment of the present invention shown in FIGS. 1 to 3 is to be installed in a bathtub B which is a drainage device including a tank body, which will be described below. It is composed of a

The bathtub B is a box body having an upper opening, and has a bottom surface provided with an attachment hole for attaching the

The

The

The

The

The

The operation unit 3 is a member that is attached to the operation unit attachment hole of the bathtub B and operates the vertical movement of the

The operation portion

The

The

The

Moreover, the upper end of the

The

The operation portion

The

Further, the lower end of the

In addition, the operation

The

The

上記のように構成した第一実施例の遠隔操作式排水栓装置は、以下のようにして、槽体である浴槽Bに施工される。尚、特に記載しない場合でも、必要に応じて接着剤やパッキングを用いたネジ接続などにより、各部材の接続箇所は水密的に接続される。

まず、事前に、ガイド管17の一端を継手部材10の枝管部10bに、他端をエルボ部材5の接続管部5aに、それぞれ接続しておく。

次に、排水口本体1を、浴槽B底面に設けられた取付孔に挿通し、フランジ部1bの下面を、取付孔の周縁上面に当接した状態とする。

次に、継手部材10の排出口10aを下水側配管に接続した上で、浴槽Bの下方から配置し、排水口本体1の雄ネジを、継手部材10の雌ネジと螺合させ、取付孔周縁をフランジ部1b下面と継手部材10の雌ネジの開口の上端部分とで挟持させて、浴槽Bに固定する。

次に、操作部本体4を、浴槽B側面に設けられた操作部取付孔に挿通し、鍔部4aの背面を、操作部取付孔の周縁に当接した状態とする。

次に、エルボ部材5を浴槽Bの背面に配置し、操作部本体4の雄ネジを、エルボ部材5の雌ネジと螺合させ、操作部取付孔周縁を鍔部4a背面とエルボ部材5の雌ネジの開口の端部部分とで挟持させて、浴槽Bに固定する。

次に、レリースワイヤ7のアウターチューブ7aの操作部3側端部を、操作部側支持部材13のガイド筒部14の枝部E収納部の下端に接続固定する。

次に、操作部側支持部材13のガイド筒部14内に操作軸6a及び枝部Eを収納した上で、操作軸6aの下端とロック軸8a上端とをネジ固定した上で、ホルダー部16にロック機構本体部8bを固定する。この時、操作軸6aは操作軸収納部15a内に、枝部Eは枝収納部15b内に、それぞれ配置される。

次に、レリースワイヤ7の排水口1a側端部を操作部本体4の開口に挿通し、操作部本体4、エルボ部材5、ガイド管17、枝管部10b、継手部材10、の順に挿通した上で、操作部側支持部材13の第二リング部13aを操作部本体4の凸部に嵌合させて、操作部側支持部材13を操作部本体4に固定する。

これにより、槽体である浴槽Bの側面に開口した貫通孔である操作部取付孔(または操作部本体4内の開口)を貫通してレリースワイヤ7が浴槽Bの裏面側に配置される。この実施例では、図1等により明らかなように貫通孔である浴槽Bの操作部取付孔の位置には、枝部Eが配置されてなる。

次に、操作体6bの突起を操作軸6aの上端に嵌合させて操作体6bを操作軸6aに接続する。

次に、継手部材10内部のレリースワイヤ7端部を排水口1aから浴槽B内に引き上げ、排水口1a側のアウターチューブ7a端部を、支持部材12のワイヤ固定部11に接続固定する。

次に、支持部材12の第一リング部12aを排水口1a内部の凸部に嵌合させて、支持部材12を排水口本体1に固定し、更に弁部材2の下面中央にインナーワイヤ7b端部の押上軸9先端を嵌合固定させて、本実施例の遠隔操作式排水栓装置の施工が完了する。

The remote-operated drain plug device of the first embodiment configured as described above is installed in the bathtub B which is a tank body as follows. In addition, even if not particularly described, the connection points of the respective members are water-tightly connected by screw connection using an adhesive or packing as necessary.

First, one end of the

Next, the drain port

Next, after connecting the

Next, the operation portion

Next, the

Next, the end portion of the

Next, after accommodating the

Next, the

As a result, the

Next, the protrusion of the operating

Next, the end portion of the

Next, the

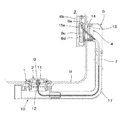

以下に、上記第一実施例の遠隔操作式排水栓装置の動作について説明する。

上記第一実施例の遠隔操作式排水栓装置を使用する場合、図2のように、まず操作部3の操作体6bに操作を加え、排水口1aを弁部材2が覆って排水口1aを閉口した状態とする。この時にはロック機構8のロック軸8aは固定されていないため、操作軸6a、ロック軸8a、及び操作体6b(以下「操作軸6a等」と記載)は、ロック機構8の弾性部材とレリースワイヤ7の戻りスプリング7cの作用によって上昇した状態となっている。

この状態において、浴槽B内に吐水を行うと、排水口1aが閉口しているために、浴槽B内に吐水を溜めることができる。

この状態から操作体6bに押し込み操作を行うと、図3に示したように、ロック機構8が作用し、操作軸6a等を下方に移動した状態で固定する。

これにより、操作軸6aに対して回動自在に接続されている枝部Eは、操作軸6aとの角度を鋭角の範囲で変化させながらガイド管17の枝収納部15b内を枝収納部15bの端部方向に向かって突出し、枝収納部15b端部内に配置されているインナーワイヤ7bを、排水口1a側に前進させた状態を維持して停止する。

そして、排水口1a側に前進したインナーワイヤ7bによって、押上軸9と共に弁部材2が上昇して排水口1aより弁部材2が離間し、排水口1aを開口させる。即ち、本実施例の遠隔操作式排水栓装置では、操作軸6aの下端に、レリースワイヤ7の前進した状態を維持するロック機構8を備えたことで、弁部材2の上昇状態を維持するように構成されてなる。

この弁部材2が上昇し、排水口1aが開口した状態において、浴槽B内に浴湯が溜まっていたり、または浴槽B内に吐水を行うと、浴槽B内の水は、排水口1aから、継手部材10を介し、継手部材10の排出口10aより下水側に排出される。

この状態より操作体6bに再び押し込み操作を行うと、ロック機構8が作用し、操作軸6a等の固定が解除される。固定が解除された操作軸6a等は、ロック機構8の弾性部材とレリースワイヤ7の戻りスプリング7cの作用によって上昇し、ロック軸8aの上昇に伴って枝部Eもガイド管17の枝収納部15b内を後退する。枝部Eに押されるようにして排水口1a側に前進していたインナーワイヤ7bは、弁部材2の自重及び戻りスプリング7cの作用により、操作部3側に後退し、図2示した、浴槽Bの排水口1aが閉口した状態に戻る。

以降、上記したように、操作体6bに押し込み操作を繰り返す毎に、インナーワイヤ7bが弁部材2を押し上げて排水口1aを開口/インナーワイヤ7b端部の後退に伴って自重等により弁部材2が降下し排水口1aを閉口、を交互に行い、排水口1aを遠隔操作式排水栓装置により自在に開閉することができる。

The operation of the remote-operated drain plug device of the first embodiment will be described below.

When using the remote operated drain plug device of the first embodiment, first, as shown in FIG. 2, the

When water is discharged into the bathtub B in this state, the water discharge can be collected in the bathtub B because the

When the push-in operation is performed on the

As a result, the branch E, which is rotatably connected to the

Then, the

When the hot water is stored in the bathtub B or the water is discharged into the bathtub B while the

When the push-in operation is performed again on the

Thereafter, as described above, every time the pushing operation is repeated on the

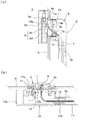

次に本発明の第二実施例を、図面を参照しつつ説明する。

尚、以下の説明に記載した図5、図6において、(a)は操作部近傍を、(b)は排水口近傍を、それぞれ示すものである。

図4乃至図6に示した、本発明の第二実施例の遠隔操作式排水栓装置は、排水口本体1、継手部材10、操作伝達部材としてのレリースワイヤ7、弁部材2、支持部材12、操作部3、ガイド管17、より構成されてなる。

これらの各部材の内、操作部3以外の、排水口本体1、継手部材10、操作伝達部材としてのレリースワイヤ7、弁部材2、支持部材12、ガイド管17、の各部材は、段落0015に記載された第一実施例の部材と同じ構成のため省略する。

また、操作部3は、操作部本体4、エルボ部材5、ロック機構8、操作軸6a、操作体6b、操作部側支持部材13から構成される部材であるが、これら操作部3の各部材の内、ロック機構8、操作軸6a、操作部側支持部材13以外の、操作部本体4、エルボ部材5、の各部材は、やはり段落0015に記載された第一実施例と同じ構成のため省略し、以下に、第一実施例と異なる、操作軸6a、操作体6b、ロック機構8、操作部側支持部材13について説明する。

操作軸6aは略円筒形状を成す部材であって、操作軸6aの軸方向の中間部分から下端に達するまで、側面上に切り欠きを備えてなる。更に円周方向に沿って、上下二か所に環状溝部8cを備えてなる。

操作体6bは、裏面側(施工完了時、槽体である浴槽Bの内側面を向く面)と下面が開放された略箱体形状を成す部材であって、施工完了時その内部に操作軸6a及びロック機構8が配置されると共に、上面の壁の上方からビス部材を挿通して操作軸6aにネジ接続することで、操作軸6aに対して上方、下方のいずれの方向に応力を加えても外れることのないように接続固定される。

操作部側支持部材13は、操作部本体4内部の凸部と嵌合することで、操作部本体4に配置固定される部材であって、リング状にして操作部本体4内部の凸部と嵌合する第二リング部13aと、施工完了時操作軸6aを上下動自在に収納する操作軸収納部15aと、操作軸収納部15a内に備えられた、操作軸6aの環状溝部8cと係合する弾性爪8dと、レリースワイヤ7を配置固定するガイド筒部14を備えてなる。

更に操作部側支持部材13について詳述すると、図5又は図6に示したように、施工完了時、操作軸収納部15aは槽体である浴槽Bの内側面に沿って上下方向に配置され、更に操作軸収納部15aの、浴槽B壁面を向く方向は切り欠きが設けられて上端から下端の近傍まで開放されてなる。そして、この開放された切り欠きの部分を介してガイド筒部14が配置されている。

ガイド筒部14は管体を側面視円弧形状に屈曲させたような形状の部材であって、施工完了時、レリースワイヤ7の操作部3側端部の内、インナーワイヤ7bはガイド筒部14内を挿通されて、操作軸6aの内部であり、且つ操作軸6aの軸方向途中の位置(但し、図より明らかなように、操作体6bに近い上端近傍部分の位置)で、操作軸6aの動作方向である上下方向と同じ上方向を向いて配置固定されるように構成される。また、アウターチューブ7a端部はガイド筒部14の端部に接続固定される。

また、ガイド筒部14の上端の周囲に、上下動自在に操作軸6aが配置され、更に操作軸6aの周囲には操作軸収納部15aが配置されて操作軸6aが上下動するようにガイドしてなる。ガイド筒部14は、操作軸6a及び操作軸収納部15aの切り欠きの部分を介して、操作軸6a及び操作軸収納部15aの側面より操作部本体4内を挿通する。この時、図5、図6に示したように、側面視切り欠きの部分から延出されるガイド筒部14は、操作軸6aに対し鋭角、即ち90度よりも小さい角度を成すように構成される。

また、アウターチューブ7a内部に進退自在に挿通されるインナーワイヤ7b端部は、施工完了時、操作軸6aの内部上端に当接するように構成されてなる。

ロック機構8は、操作軸6aに設けられた上下二か所の環状溝部8cと、操作軸収納部15a内に備えられた、操作軸6aの環状溝部8cと係合する弾性爪8dによって構成される。

Next, a second embodiment of the present invention will be described with reference to the drawings.

5 and 6 described below, (a) shows the vicinity of the operating portion, and (b) shows the vicinity of the drainage port.

The remote-operated drain plug device according to the second embodiment of the present invention shown in FIGS. 4 to 6 is a

Among these members, the

The operation unit 3 is a member including the operation unit

The operating

The

The operation portion

More specifically, the operation portion

The

Further, an

Further, the end portion of the

The

上記のように構成した第二実施例の遠隔操作式排水栓装置は、以下のようにして、槽体である浴槽Bに施工される。尚、特に記載しない場合でも、必要に応じて接着剤やパッキングを用いたネジ接続などにより、各部材の接続箇所は水密的に接続される。

まず、事前に、ガイド管17の一端を継手部材10の枝管部10bに、他端をエルボ部材5の接続管部5aに、それぞれ接続しておく。

次に、排水口本体1を、浴槽B底面に設けられた取付孔に挿通し、フランジ部1bの下面を、取付孔の周縁上面に当接した状態とする。

次に、継手部材10の排出口10aを下水側配管に接続した上で、浴槽Bの下方から配置し、排水口本体1の雄ネジを、継手部材10の雌ネジと螺合させ、取付孔周縁をフランジ部1b下面と継手部材10の雌ネジの開口の上端部分とで挟持させて、浴槽Bに固定する。

次に、操作部本体4を、浴槽B側面に設けられた操作部取付孔に挿通し、鍔部4aの背面を、操作部取付孔の周縁に当接した状態とする。

次に、エルボ部材5を浴槽Bの背面に配置し、操作部本体4の雄ネジを、エルボ部材5の雌ネジと螺合させ、操作部取付孔周縁を鍔部4a背面とエルボ部材5の雌ネジの開口の端部部分とで挟持させて、浴槽Bに固定する。

次に、操作部3側端部となるレリースワイヤ7の内、インナーワイヤ7b端部を操作部側支持部材13のガイド筒部14に挿通した上で、アウターチューブ7a端部を、ガイド筒部14の端部に接続固定する。

次に、操作軸6aの切り欠きの部分が、ガイド筒部14と合致するようにして、操作軸6aを上方より操作軸収納部15a内に挿通する。この挿通は、弾性爪8dが、操作軸6aの下方の環状溝部8cに弾性嵌合するまで挿通する。これによって、ガイド筒部14に固定されたアウターチューブ7a部端部の外周に、上下動自在に操作軸6aが配置され、更に操作軸6aの周囲には操作軸収納部15aが配置される。

次に、レリースワイヤ7の排水口1a側端部を操作部本体4の開口に挿通し、操作部本体4、エルボ部材5、ガイド管17、枝管部10b、継手部材10、の順に挿通した上で、操作部側支持部材13の第二リング部13aを操作部本体4の凸部に嵌合させて、操作部側支持部材13を操作部本体4に固定する。

これにより、槽体である浴槽Bの側面に開口した貫通孔である操作部取付孔(または操作部本体4内の開口)を貫通してレリースワイヤ7が浴槽Bの裏面側に配置される。更にビス部材を用いて、操作体6bを操作軸6aの上端にネジ接続する。

次に、継手部材10内部のレリースワイヤ7端部を排水口1aから浴槽B内に引き上げ、排水口1a側のアウターチューブ7a端部を、支持部材12のワイヤ固定部11に接続固定する。

次に、支持部材12の第一リング部12aを排水口1a内部の凸部に嵌合させて、支持部材12を排水口本体1に固定し、更に弁部材2の下面中央にインナーワイヤ7b端部の押上軸9先端を嵌合固定させて、本実施例の遠隔操作式排水栓装置の施工が完了する。

The remote-operated drain plug device of the second embodiment configured as described above is installed in the bathtub B which is the tank body as follows. In addition, even if not particularly described, the connection points of the respective members are water-tightly connected by screw connection using an adhesive or packing as necessary.

First, one end of the

Next, the drain port

Next, after connecting the

Next, the operation portion

Next, the

Next, after the

Next, the cutout portion of the

Next, the

As a result, the

Next, the end portion of the

Next, the

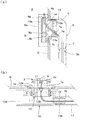

以下に、上記第二実施例の遠隔操作式排水栓装置の動作について説明する。

上記第二実施例の遠隔操作式排水栓装置を使用する場合、図5のように、まず操作部3の操作体6bに操作を加え、排水口1aを弁部材2が覆って排水口1aを閉口した状態とする。この時には操作軸6aの上下二つある環状溝部8cの内、下方の環状溝部8cが操作軸収納部15aの弾性爪8dと弾性嵌合してなる。この環状溝部8cと弾性爪8dとの嵌合により操作軸6aは上昇した位置で保持され、インナーワイヤ7bは戻りスプリング7cの付勢によって操作部3側に後退してなる。

この状態において、浴槽B内に吐水を行うと、排水口1aが閉口しているために、浴槽B内に吐水を溜めることができる。

この状態から操作体6bに押し込み操作を行うと、操作軸6aの、下方の環状溝部8cと弾性爪8dとの弾性嵌合が解除されて操作軸6aが降下する。その後、図6に示したように、操作軸6aの上方の環状溝部8cと弾性爪8dとが嵌合する位置まで操作軸6aを降下させて両者を嵌合させ、操作軸6a等を下方に移動した状態で固定する。

これにより、操作軸6aの内部上端に当接されているインナーワイヤ7bは、操作軸6aの内部上端に押されるようにして排水口1a側に前進する。そして、排水口1a側に前進したインナーワイヤ7bによって、押上軸9と共に弁部材2が上昇して排水口1aより弁部材2が離間し、排水口1aを開口させる。

即ち、本実施例の遠隔操作式排水栓装置では、操作軸6aに、レリースワイヤ7の前進した状態を維持するロック機構8(操作軸6aの環状溝部8cと操作軸収納部15aの弾性爪8d)を備えたことで、弁部材2の上昇状態を維持するように構成されてなる。

この弁部材2が上昇し、排水口1aが開口した状態において、浴槽B内に浴湯が溜まっていたり、または浴槽B内に吐水を行うと、浴槽B内の水は、排水口1aから、継手部材10を介し、継手部材10の排出口10aより下水側に排出される。

この状態から操作体6bを把持し、操作体6bを上昇させると、操作軸6aの、上方の環状溝部8cと弾性爪8dとの弾性嵌合が解除されて操作軸6aが上昇する。その後、再び図5に示したように、操作軸6aの下方の環状溝部8cと弾性爪8dとが嵌合する位置まで操作軸6aを上昇させて両者を嵌合させ、操作軸6a等を上方に移動した状態で固定する。

操作軸6aの内部上端に当接されているインナーワイヤ7bは、操作軸6aが上昇すると、戻りスプリング7cの作用によって操作部3側に後退し、図5に示した、浴槽Bの排水口1aが閉口した状態に戻る。

以降、上記したように、操作体6bに押し込み操作/引き上げ操作を繰り返す毎に、インナーワイヤ7bが弁部材2を押し上げて排水口1aを開口/インナーワイヤ7b端部の後退に伴って自重等により弁部材2が降下し排水口1aを閉口、を交互に行い、排水口1aを遠隔操作式排水栓装置により自在に開閉することができる。

The operation of the remote operated drain plug device of the second embodiment will be described below.

When using the remote operated drain plug device of the second embodiment, as shown in FIG. 5, first, the

When water is discharged into the bathtub B in this state, the water discharge can be collected in the bathtub B because the

When the push-in operation is performed on the

As a result, the

That is, in the remote control type drain plug device of the present embodiment, the lock mechanism 8 (the

When the hot water is stored in the bathtub B or the water is discharged into the bathtub B while the

When the operating

The

Thereafter, as described above, every time the pushing operation/pulling-up operation is repeated on the

上記第一実施例においては、操作軸6aの操作体6b近傍側に枝部Eを設け、この枝部Eを介してレリースワイヤ7での操作伝達を行うようにしたことで、また第二実施例操作軸6aにおいては操作軸6aの途中部分の位置においてレリースワイヤ7を接続して操作伝達を行うようにしたことで、従来の操作軸6aにレリースワイヤ7を接続した遠隔操作式排水栓装置や、操作軸6aにロック軸8aを接続して、ロック機構8の端部にレリースワイヤ7を接続するような遠隔操作式排水栓装置と比べ、操作部3近傍におけるレリースワイヤ7の曲がり半径を大きな半径とすることができ、設計レイアウトの自由度を高め、また故障が発生しにくい構成とすることができる。

また、ロック機構8が槽体である浴槽Bの内側に配置されたため、操作体6bを外せばロック機構8を確認し、故障などした場合は交換等の対応を行うことができる。ロック機構8は貫通孔である操作部取付孔や操作部本体4内から出し入れを行うには大きな部材で、貫通孔や槽体の外側に配置すると槽体の内側から取り出すことは困難であり、第一実施例、第二実施例のように、槽体の内側に配置されていると施工やメンテナンスが容易となる。

In the first embodiment described above, the branch portion E is provided near the operating

Further, since the

本発明の実施例は以上のようであるが、本発明は上記実施例に限定される物ではなく、主旨を変更しない範囲において自由に変更が可能である。

例えば上記実施例では遠隔操作式排水栓装置は全て浴槽Bに施工されてなるが、本発明は上記実施例に限定されるものでは無く、槽体としての洗面ボウルを備えた洗面台、槽体としてのシンクを備えた流し台等、排水口1aを備えた槽体であれば、どのような排水機器のどのような槽体に採用しても構わない。

Although the embodiments of the present invention have been described above, the present invention is not limited to the above-mentioned embodiments and can be freely modified within the scope of not changing the gist.

For example, in the above-mentioned embodiment, the remote-operated drain plug device is constructed entirely in the bathtub B, but the present invention is not limited to the above-mentioned embodiment, and a washbasin equipped with a washbasin as a tank, a tank body As long as it is a tank provided with the

また、上記第一実施例ではロック軸8aとロック機構本体部8bとからなるロック機構8を、第二実施例では操作軸6aに設けた上下二つの環状溝部8cと弾性爪8dとからなるロック機構8を構成しているが、本発明は上記実施例に限定されるものでは無く、第一実施例の遠隔操作式排水栓装置において、第二実施例のロック機構8のように操作軸6aに設けた上下二つの環状溝部8cと弾性爪8dとからなるロック機構8を採用したり、第二実施例の遠隔操作式排水栓装置において、第一実施例のロック機構8のようにロック軸8aとロック機構本体部8bとからなるロック機構8を採用しても構わない。また上記以外のロック機構8、例えばロック軸8a又は操作軸6aの側面にパッキングを配置しパッキングと他の部材との摩擦により位置を保持するようなロック機構8等、機能的に支障が無いのであればどのようなロック機構8を用いて構成しても構わない。

また、操作部3の取り付けについて、上記実施例では、全て槽体の内側面としたが、本発明は上記実施例に限定されるものではなく、必要に応じて、槽体の上縁から水平方向に延出された天板部分に操作体3bを配置し、操作体3bが上下に移動するように構成したり、逆に洗面台のカウンター下面に操作体3bを配置し、操作体3bを上下に押し引きするような構成としても良い。この場合、レリースワイヤは、操作体3bの上端近傍から下方に下り傾斜するように配置すれば好適である。

また、上記実施例の枝部Eはヒンジによって操作体6bや押上軸9に接続されてなるが、本発明は上記実施例に限定されるものではなく、例えば操作軸6bや押上軸9を樹脂素材にて構成し、これに樹脂弾性を利用して軸方向に剛性を、側面方向に可撓性を持たせた枝部Eを一体に構成しても良い。

Further, in the first embodiment, the

Further, with respect to the attachment of the operation portion 3, in the above-mentioned embodiment, the inner side surface of the tank body is used as a whole, but the present invention is not limited to the above-mentioned embodiment, and if necessary, the operation may be performed horizontally from the upper edge of the tank body. The operating body 3b is arranged on the top plate portion extending in the direction, and the operating body 3b is configured to move up and down, or conversely, the operating body 3b is arranged on the lower surface of the counter of the wash basin to move the operating body 3b. It may be configured to push and pull up and down. In this case, the release wire is preferably arranged so as to incline downward from the vicinity of the upper end of the operating body 3b.

The branch E of the above-described embodiment is connected to the

1 排水口本体 1a 排水口

1b フランジ部 2 弁部材

3 操作部 4 操作部本体

4a 鍔部 5 エルボ部材

5a 接続管部 6a 操作軸

6b 操作体 7 レリースワイヤ

7a アウターチューブ 7b インナーワイヤ

7c 戻りスプリング 8 ロック機構

8a ロック軸 8b ロック機構本体部

8c 環状溝部 8d 弾性爪

9 押上軸 10 継手部材

10a 排出口 10b 枝管部

11 ワイヤ固定部 12 支持部材

12a 第一リング部 12b アーム部

13 操作部側支持部材 13a 第二リング部

13b 連結部 14 ガイド筒部

15a 操作軸収納部 15b 枝収納部

16 ホルダー部 17 ガイド管

B 浴槽 E 枝部

1 Drain

Claims (4)

上下動によって排水口を開閉する弁部材と、

弁部材の上下動を操作する操作部と、

操作部に加えられた操作を弁部材に伝達する、筒状のアウターチューブ、該アウターチューブ内を摺動するインナーワイヤ、からなるレリースワイヤと、

からなる遠隔操作式排水栓装置において、

操作部に、

使用者の操作によって進退する操作軸と、

操作軸の一端に備えられた、使用者が操作を加える操作体と、

操作軸の操作体側端部又は操作軸の途中の位置に接続された枝部と、を備え、

操作軸の動作が枝部によって操作軸の進退方向に対して角度を有した方向に変換され、枝部からインナーワイヤを介することで、操作軸に加えられた操作が弁部材に伝達されるように構成したことを特徴とする遠隔操作式排水栓装置。 Drainage port provided in the tank body,

A valve member that opens and closes the drainage port by vertical movement,

An operating portion for operating the vertical movement of the valve member,

A release wire composed of a cylindrical outer tube for transmitting an operation applied to the operation portion to the valve member, and an inner wire sliding in the outer tube,

In the remote operated drain plug device consisting of

In the operation part,

An operation axis that moves back and forth according to the user's operation,

An operating body provided on one end of the operating shaft for the user to operate,

A branch portion connected to an end portion of the operating shaft on the operating body side or a position in the middle of the operating shaft;

The operation of the operation shaft is converted by the branch portion into a direction having an angle with respect to the advancing/retreating direction of the operation shaft, and the operation applied to the operation shaft is transmitted to the valve member through the inner wire from the branch portion. A remote-operated drain plug device characterized in that

上下動によって排水口を開閉する弁部材と、

弁部材の上下動を操作する操作部と、

操作部に加えられた操作を弁部材に伝達する、筒状のアウターチューブ、該アウターチューブ内を摺動するインナーワイヤ、からなるレリースワイヤと、

からなる遠隔操作式排水栓装置において、

操作部に、

使用者の操作によって進退する操作軸と、

操作軸の一端に備えられた、使用者が操作を加える操作体と、を備え、

インナーワイヤ端部を、操作軸の操作体側端部又は操作軸の途中の位置に接続し、

インナーワイヤを介して操作軸に加えられた操作が弁部材に伝達されるように構成したことを特徴とする遠隔操作式排水栓装置。 Drainage port provided in the tank body,

A valve member that opens and closes the drainage port by vertical movement,

An operating portion for operating the vertical movement of the valve member,

A release wire composed of a cylindrical outer tube for transmitting an operation applied to the operation portion to the valve member, and an inner wire sliding in the outer tube,

In the remote operated drain plug device consisting of

In the operation part,

An operation axis that moves back and forth according to the user's operation,

An operating body provided on one end of the operating shaft for the user to operate,

Connect the end of the inner wire to the end of the operating shaft on the operating body side or to a position in the middle of the operating shaft,

A remote-operated drain plug device, characterized in that an operation applied to an operation shaft is transmitted to a valve member via an inner wire.

操作軸の一端に、弁部材の上昇状態又は下降状態を維持するロック機構を備えたことを特徴とする、請求項1又は請求項2に記載の遠隔操作式排水栓装置。 In the remote operated drain plug device,

The remote-operated drain plug device according to claim 1 or 2, wherein a lock mechanism for maintaining a raised state or a lowered state of the valve member is provided at one end of the operation shaft.

操作軸が槽体の内側に配置され、

操作軸の進退方向が槽体の内側面に沿う方向であると共に、

槽体の側面に貫通孔が設けられ、該貫通孔を介して枝部またはレリースワイヤが槽体の裏面側に配置されることを特徴とする、請求項1乃至請求項3のいずれか一つに記載の遠隔操作式排水栓装置。 In the remote operated drain plug device,

The operating axis is located inside the tank,

The direction of movement of the operating shaft is along the inner surface of the tank,

4. A through hole is provided on a side surface of the tank body, and a branch portion or a release wire is arranged on the back surface side of the tank body through the through hole. Remotely operated drain plug device described in.

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2016016724A JP6734504B2 (en) | 2016-01-29 | 2016-01-29 | Remote operated drain plug device |

| CN201610885399.5A CN106759702B (en) | 2016-01-29 | 2016-10-10 | Remote operated drainage bolt |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2016016724A JP6734504B2 (en) | 2016-01-29 | 2016-01-29 | Remote operated drain plug device |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2017133333A JP2017133333A (en) | 2017-08-03 |

| JP6734504B2 true JP6734504B2 (en) | 2020-08-05 |

Family

ID=58972323

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2016016724A Active JP6734504B2 (en) | 2016-01-29 | 2016-01-29 | Remote operated drain plug device |

Country Status (2)

| Country | Link |

|---|---|

| JP (1) | JP6734504B2 (en) |

| CN (1) | CN106759702B (en) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP7266231B2 (en) * | 2017-12-28 | 2023-04-28 | 丸一株式会社 | drain plug device |

| CN110359527A (en) * | 2018-03-26 | 2019-10-22 | 宁波艾尚环保科技股份有限公司 | A kind of spinner |

| WO2020043056A1 (en) * | 2018-08-31 | 2020-03-05 | 宁波搏盛阀门管件有限公司 | Pressing plate-type kitchen and bath water drainage switch and water drainage device |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4596057A (en) * | 1984-01-31 | 1986-06-24 | Ikumi Ohta | Draining plug device |

| JPH111949A (en) * | 1997-06-12 | 1999-01-06 | Hashimoto Kinzoku Kogyo Kk | Remote control type drain plug for bathtub |

| JP2000220190A (en) * | 1999-01-29 | 2000-08-08 | Inax Corp | Drain plug device |

| JP2003293416A (en) * | 2002-03-28 | 2003-10-15 | Yasumi Ota | Drainage tap device |

| JP4214189B2 (en) * | 2002-06-20 | 2009-01-28 | 丸一株式会社 | Remote-controlled drain plug device |

| CN201125430Y (en) * | 2007-08-17 | 2008-10-01 | 冯伯安 | Drain apparatus of washing basin |

| CN201679053U (en) * | 2010-04-02 | 2010-12-22 | 宁波德利福洁具有限公司 | Bathtub water remover with water yielding and overflowing functions |

| CN102535599B (en) * | 2010-12-28 | 2015-01-14 | 丸一株式会社 | Remote operation type drainage stopper device |

| JP5663403B2 (en) * | 2011-05-24 | 2015-02-04 | 株式会社Lixil | Drain plug device |

| JP2014167251A (en) * | 2014-04-18 | 2014-09-11 | Maruichi Corp | Remote control type drain plug device |

| CN204385828U (en) * | 2014-12-17 | 2015-06-10 | 宁波威霖住宅设施有限公司 | Water assembly under the bathtub line traffic control of a kind of counnter attack pine |

| CN104818750B (en) * | 2015-05-18 | 2016-04-27 | 慈溪市南盾电器有限公司 | Dewatering installation |

| CN104831787B (en) * | 2015-05-18 | 2016-04-27 | 慈溪市南盾电器有限公司 | Reservoir spinner |

-

2016

- 2016-01-29 JP JP2016016724A patent/JP6734504B2/en active Active

- 2016-10-10 CN CN201610885399.5A patent/CN106759702B/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| CN106759702A (en) | 2017-05-31 |

| JP2017133333A (en) | 2017-08-03 |

| CN106759702B (en) | 2019-05-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6734504B2 (en) | Remote operated drain plug device | |

| JP2014167251A (en) | Remote control type drain plug device | |

| JP5412632B2 (en) | Remote control drain plug device and its construction method | |

| JP5756937B2 (en) | Remote-controlled drain plug device | |

| JP6596635B2 (en) | Remote-controlled drain plug device | |

| JP6682072B2 (en) | Remote operated drain plug device | |

| JP2018044280A (en) | Remote-controlled drain plug device | |

| JP2016176285A (en) | Remote control type drain plug device | |

| JP6734503B2 (en) | Remote operated drain plug device | |

| JP5948733B2 (en) | Remote-controlled drain plug device | |

| JP6630902B2 (en) | Remotely operated drain valve | |

| JP6936424B2 (en) | Remote-controlled drain plug device | |

| JP2012251315A (en) | Remotely-operated drain plug system and positioning jig for the system | |

| JP5793747B2 (en) | Remote-controlled drain plug device | |

| JP2017057561A (en) | Water cut-off structure of drain port | |

| JP2022139278A (en) | Remote-operated drain plug device | |

| JP2013213326A (en) | Release wire insertion fixture | |

| JP2017155447A (en) | Drain plug device | |

| JP6734509B2 (en) | Remote operated drain plug device | |

| JP3458307B2 (en) | Remote-controlled drain plug device | |

| JP5597834B2 (en) | Remote control drain plug device and its construction method | |

| JP2015190205A (en) | Water supply and drainage facility unit and water supply and drainage method | |

| JP2022050167A (en) | Remote control-type drain plug device | |

| JP2015200081A (en) | Drainage system | |

| JP4572271B2 (en) | Remote-operated drain plug device and its construction method |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20181207 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20190927 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20191015 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20191210 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20200512 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20200518 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6734504 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |