EP0312843A1 - Procédé d'échange de chaleur et son application en refroidissement contrôlé de produits laminés - Google Patents

Procédé d'échange de chaleur et son application en refroidissement contrôlé de produits laminés Download PDFInfo

- Publication number

- EP0312843A1 EP0312843A1 EP88116561A EP88116561A EP0312843A1 EP 0312843 A1 EP0312843 A1 EP 0312843A1 EP 88116561 A EP88116561 A EP 88116561A EP 88116561 A EP88116561 A EP 88116561A EP 0312843 A1 EP0312843 A1 EP 0312843A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- rolling stock

- section

- water

- tube

- pipe

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000000034 method Methods 0.000 title claims abstract description 34

- 238000001816 cooling Methods 0.000 title claims abstract description 21

- 230000008569 process Effects 0.000 title abstract description 7

- 238000005096 rolling process Methods 0.000 claims abstract description 92

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims abstract description 43

- 239000007788 liquid Substances 0.000 claims abstract description 20

- 239000000203 mixture Substances 0.000 claims abstract description 17

- 239000007787 solid Substances 0.000 claims abstract description 9

- 238000002347 injection Methods 0.000 claims abstract description 3

- 239000007924 injection Substances 0.000 claims abstract description 3

- 238000012546 transfer Methods 0.000 claims description 15

- 238000013459 approach Methods 0.000 claims description 4

- 230000000694 effects Effects 0.000 abstract description 5

- 239000000498 cooling water Substances 0.000 description 9

- 230000008859 change Effects 0.000 description 4

- 238000010586 diagram Methods 0.000 description 4

- 230000007257 malfunction Effects 0.000 description 3

- 239000000463 material Substances 0.000 description 3

- 238000013461 design Methods 0.000 description 2

- 230000002093 peripheral effect Effects 0.000 description 2

- 238000012549 training Methods 0.000 description 2

- 238000005276 aerator Methods 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 239000002826 coolant Substances 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 238000000605 extraction Methods 0.000 description 1

- 239000007789 gas Substances 0.000 description 1

- 229910000734 martensite Inorganic materials 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 230000000284 resting effect Effects 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 230000001360 synchronised effect Effects 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D9/00—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor

- C21D9/52—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor for wires; for strips ; for rods of unlimited length

- C21D9/54—Furnaces for treating strips or wire

- C21D9/56—Continuous furnaces for strip or wire

- C21D9/573—Continuous furnaces for strip or wire with cooling

- C21D9/5732—Continuous furnaces for strip or wire with cooling of wires; of rods

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B45/00—Devices for surface or other treatment of work, specially combined with or arranged in, or specially adapted for use in connection with, metal-rolling mills

- B21B45/02—Devices for surface or other treatment of work, specially combined with or arranged in, or specially adapted for use in connection with, metal-rolling mills for lubricating, cooling, or cleaning

- B21B45/0203—Cooling

- B21B45/0209—Cooling devices, e.g. using gaseous coolants

- B21B45/0215—Cooling devices, e.g. using gaseous coolants using liquid coolants, e.g. for sections, for tubes

- B21B45/0224—Cooling devices, e.g. using gaseous coolants using liquid coolants, e.g. for sections, for tubes for wire, rods, rounds, bars

Definitions

- the invention relates to a method for heat transfer between liquid media, on the one hand, and also liquid media or solid bodies, on the other hand, and to the use of the method for temperature-controlled cooling of rolling stock during and after the rolling deformation in rolling stock guide pipes through which water flows and which the water flows from with a presettable inlet pressure one which is fed to a ring nozzle with a variable outlet cross section and fitted in a feed pipe.

- the invention has for its object to provide such a possibility with relatively little technical effort.

- a container holding the liquid medium or a conduit for the flowing liquid medium or the solid body is acted upon on all sides by a flowing liquid medium to which a predetermined proportion of a gaseous medium is constantly mixed.

- water can advantageously be used as the liquid medium and air can advantageously be used as the admixing gaseous medium.

- the pressure of the flowing medium changeable and definable or, insofar as the heat transfer is to take place on a solid body, to move it at a variable and definable speed.

- a suitable device for carrying out these methods is a cylindrical outer tube which coaxially comprises an inner cylinder tube which receives the flowing medium.

- a nozzle head is expediently arranged at the open entrance of the outer cylinder tube, to which the liquid flowing medium can be fed, and which has an inlet pipe which can be axially displaced therein, with which together the nozzle head has an annular nozzle which surrounds the inner cylinder tube and for the outlet of the liquid medium with simultaneous suction form the gaseous medium through the open entrance of the outer cylinder tube.

- the method can be used, for example, for temperature-controlled cooling of rolling stock in such a way that, for example, water is introduced into the nozzle head and emerges from the ring nozzle formed by the nozzle head and inlet pipe.

- the negative pressure which arises behind the outlet cross section of the nozzle formed in this way sucks air out of the well-known manner open entrance of the outer cylinder tube, so that a water-air mixture arises behind the nozzle, its composition can be changed within wide limits according to the invention by axial displacement of the inlet pipe.

- the water-air mixture acts on all sides of the inner cylinder tube, in which the liquid medium is guided, which is supposed to either absorb or release heat.

- a rod-shaped solid body for example in wire form, can also be moved directly through the center of the outer cylinder tube at the desired speed, the periphery of this rod being acted upon directly by the water-air mixture.

- the inlet pipe of the nozzle head and possibly the discharge pressure and rod speed can be controlled in a manner known per se with the aid of sensors and control devices, in accordance with values calculated on the basis of the sensor measurement results.

- Working methods and devices are known (DE-B-16 02 356) in which, here the wire passing through at high speed of a wire rolling mill before it enters the wire reel and subsequent treatment devices working with air or other coolants in the same way Water is cooled so that the wire is completely enclosed by the water introduced into the wire guide tube through the ring nozzle and thereby releases its heat to the water.

- the primary purpose of the working methods and devices was to cool the wire down to a greater or lesser extent from the rolling heat and to prepare it for subsequent placement by means of a reel on horizontal conveyors, on which the wire was then further treated. It was tried to ver the cooling effect by increasing the inflow pressure of the water and / or by extending the wire guide tubes strengthen.

- these known, known working methods and devices used for this purpose are to be improved so that the possibility is created for the rolling stock within the rolling stock guide tubes to be given predetermined or precalculated amounts of heat over a large setting range, with the aim, for example, of a permissible temperature difference between the core and to maintain the circumferential surface of the rolling stock or a defined surface temperature, for example the martensite point not to fall below.

- the invention further provides, when the rolling stock is guided through a plurality of rolling stock guide tubes arranged one behind the other, each having ring nozzles with an adjustable outlet cross section, the cooling of the rolling stock in the individual successive guide tubes with definable different settings of the respective outlet cross section of the ring nozzles and / or of the inlet pressure of the water is effected.

- an elastically supported deflection cover which can be brought into and out of the cover position and which deflects the cooling water jet emerging from the exit downwards if arranged no rolling stock is moved through the rolling stock guide tube during breaks.

- the deflection cover prevents the cooling water jet from acting on the rolling stock behind the outlet of the cooling tube, the cooling water jet the opposite wiper jet of the wiper nozzle head breaks through and may cause malfunctions.

- the respective output and input of these partial tubes would be coaxially opposite each other at the front, the input of the second partial tube in a known manner as an inlet funnel and the output of the first partial tube from a tube section which tapers conically in the flow direction and which is in a cylindrical shape Pipe section merges, are formed, the tapered pipe section and the cylindrical pipe section have longitudinal recesses open to the pipe center axis. The total cross section of these longitudinal recesses is dimensioned such that the through cross section of these two pipe sections is approximately equal to the through cross section of the first partial pipe.

- the division of the rolling stock guide tube has the further advantage that, in the event of any malfunctions during the cooling operation, the sections of the rolling stock located in the guide tubes can be more easily removed from these shorter tubes.

- the setting of the outlet cross section of the ring nozzles can be effected with a remotely controllable actuator for setting this outlet cross section.

- a device for performing the above-described method according to the invention which consists of a stationary nozzle head connected to the water supply with a conical funnel attachment and a conically tapered beginning projecting and axially displaceable rolling stock inlet pipe, as is known from DE-U-71 34 676 be designed such that the inlet pipe is connected to the nozzle head by a screw thread and carries a worm wheel outside the nozzle head which can be driven by a worm shaft.

- levers connected to an actuator are articulated at the end of the rolling stock inlet pipe located outside the funnel attachment of the nozzle head and are rotatably mounted about an axis running at a distance transversely to the center axis of the rolling stock inlet pipe.

- the levers can engage as a pair of levers with a sliding cam arranged at their free end in an annular groove arranged at the end of the rolling stock inlet pipe and with their other end can be fixedly connected to the axle mounted above or below the rolling stock inlet pipe, which at one free end has one on one Piston cylinder unit carries the actuated lever.

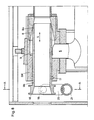

- a rolling stock guide tube FR consisting of partial tubes 2a and 2b is arranged in a fixed manner in the housing 1 in a housing 1.

- the nozzle head DK is placed on the input side E of the partial tube 2a and a centering projection ZA on the output side A of the partial tube 2b, behind which a deflection cover 4 is articulated in the housing 1 outside the tube part 2b.

- a wiping nozzle head ADK is also arranged in a stationary manner in the housing 1.

- the nozzle head DK and the scraper nozzle head ADK are connected to the water supply line ZL with a distribution pipe 5.

- a collecting trough 6, which leads to a drain 7, is arranged below the partial pipes 2a and 2b and the nozzle head DK of the centering projection ZA and the wiping nozzle head ADK.

- the nozzle head DK forms with a conical funnel attachment 8 and a thread-guided rolling stock inlet pipe 9, the conical tip 9a of which projects into the conical funnel attachment 8, an annular nozzle whose outlet cross section extends by turning the rolling stock inlet pipe 9 in the thread 8a of the nozzle head DK is changeable.

- the rotary drive consists of a worm wheel 10 placed on the rolling stock inlet pipe 9 and the worm shaft 11 meshing therewith, the drive of which is not shown.

- the water is fed to the nozzle head DK in the direction of arrow R4 from the distribution pipe 5 (FIG. 1).

- the conical funnel attachment 8 of the nozzle head DK is connected to the inlet E of the guide tube FR.

- the deflection cover 4 is arranged behind the output A of the wire guide tube FR in a manner not shown on the housing 1 about a pivot bearing DL, which is supported by springs or other elements, not shown, from the dash-dotted lines Deflection position in the passage position shown in full lines is pivotable.

- a pipe extension 14 is arranged at the outlet A of the rolling stock guide pipe, which has a pipe section 14a which tapers conically in the flow direction and an adjoining cylindrical outlet pipe section 14b (cf. . 4 and 5).

- Both pipe sections 14a and 14b have longitudinal grooves 16 open towards the pipe center axis, here with a cross section in the form of a circular section. The total passage cross-section of these longitudinal grooves 16 is approximately as large as the passage cross-section of the partial pipe 2a to be fed.

- the device is operated according to the working method according to the invention as follows:

- the rolling stock (the wire rod) D is brought from a feed tube, not shown, in the direction of arrow R6 (FIGS. 1 and 2) into the inlet tube of the nozzle head DK and further into the input side E of the wire guide tube FR.

- the cooling water passed through the distribution pipe 5 into the nozzle head DK passes through the outlet cross section of the ring nozzle formed by the conical tip 9a of the rolling stock inlet pipe 9 and the inner wall of the conical funnel attachment 8 into the considerably larger cross section behind this conical funnel attachment 8 a.

- the resulting water-air mixture is then carried on in the rolling stock guide pipe FR, enclosing the outer circumference of the wire rod D, cools it down during the passage through the rolling stock guide pipe FR and, after leaving the rolling stock guide pipe FR in the outlet A, in a known manner through one of the direction of travel R6 inclined opposite water jet from the ring nozzle of the wiper nozzle head ADK from the peripheral surface of the wire rod D removed.

- the baffle cover 4 is in this operating phase in the passage position shown in full lines in FIG. 3.

- the baffle cover 4 moves into the deflection position shown in dash-dot lines and causes the cooling water jet emerging from the output A of the rolling stock guide tube FR to be deflected downwards, while at the same time maintains or stabilizes the pressure conditions necessary for the passage of rolling stock through the rolling stock guide pipe FR.

- deflecting the cooling water jet with the aid of the deflecting cover 4 prevents the cooling water jet from breaking through the opposing water jet of the wiping nozzle head ADK and thereby causing malfunctions or making it necessary for the water jet from the wiping nozzle head ADK to be considerably strengthened. which would result in a large additional water consumption.

- the rolling stock guide pipe FR is, as can be seen from FIG. 1, divided into two partial pipes 2a and 2b.

- the outlet and the inlet of the two partial tubes 2a, 2b are coaxially opposite each other at the separation point at the front.

- the inlet of the second pipe section 2b is designed in a known manner as an inlet funnel and the outlet of the first pipe section 2a (see FIGS. 4 and 5) has pipe sections 14a and 14b which taper conically or cylindrically in the flow direction for centering the rolled material strand run.

- FIG. 6 An example of the cooling process when the wire rod passes through the rolling stock guide tube FR is indicated in a diagram in FIG. 6.

- the diagram shows the temperature profile of the outer circumference of the wire rod with curve 1, the average with curve 2 and the core with curve 3 and shows that the wire rod has already been cooled for 8 seconds after leaving the rolling stock guide tube FR so that one of the entire wire rod cross-section comprehensive reduction in temperature to 600 ° C has been achieved.

- the required low heat transfer coefficient can only be achieved with a water-air mixture with a high proportion of air and requires a very long cooling tube that is not suitable for rolling operation.

- the end 9b of the rolling stock inlet pipe 9 located outside the funnel attachment 8 of the nozzle head DK is mounted in the nozzle head DK so as to be longitudinally displaceable and secured against rotation by a locking bolt 17. It has an annular groove 18, into which slide cams 19 engage, which are arranged at the free ends of a pair of levers 20 which is seated on an axis 21 which is supported in bearings 22 in the housing 1 of the device.

- the axis 21 runs below the rolling stock inlet pipe 9 transversely to its central axis. With the axis 21, an adjusting lever 23 is fixedly connected to the piston-cylinder unit, not shown, by means of the longitudinal connection 25.

- the pair of levers 20 pivots in the same sense and by the same pivot angle.

- the rolling stock inlet pipe 9 is displaced in one direction or the other of the arrow F in the nozzle head DK via the sliding cams 19 engaging in the annular groove 18 and thus the outlet cross section of the nozzle head formed between the funnel neck 8 and the conical tip 9 of the rolling stock inlet pipe 9 DK changed.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Mechanical Engineering (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Crystallography & Structural Chemistry (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Metal Rolling (AREA)

- Heat Treatment Of Articles (AREA)

- Heat Treatments In General, Especially Conveying And Cooling (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT88116561T ATE83405T1 (de) | 1987-10-22 | 1988-10-06 | Verfahren zur waermeuebertragung und dessen anwendung zum temperaturkontrollierten kuehlen von walzgut. |

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3735789 | 1987-10-22 | ||

| DE19873735789 DE3735789A1 (de) | 1987-10-22 | 1987-10-22 | Verfahren zur waermeuebertragung |

| DE19873735790 DE3735790A1 (de) | 1987-10-22 | 1987-10-22 | Arbeitsverfahren und vorrichtungen zum temperaturkontrollierten kuehlen von walzgut |

| DE3735790 | 1987-10-22 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0312843A1 true EP0312843A1 (fr) | 1989-04-26 |

| EP0312843B1 EP0312843B1 (fr) | 1992-12-16 |

Family

ID=25861010

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP88116561A Expired - Lifetime EP0312843B1 (fr) | 1987-10-22 | 1988-10-06 | Procédé d'échange de chaleur et son application en refroidissement contrôlé de produits laminés |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0312843B1 (fr) |

| JP (1) | JPH01138012A (fr) |

| DE (1) | DE3876747D1 (fr) |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0737524A1 (fr) * | 1995-04-12 | 1996-10-16 | DANIELI & C. OFFICINE MECCANICHE S.p.A. | Chambre de refroidissement pour produits laminés |

| EP0882804A1 (fr) * | 1997-06-05 | 1998-12-09 | DANIELI & C. OFFICINE MECCANICHE S.p.A. | Procédé et dispositif pour le traitement thermique de produits laminés |

| CN101947564A (zh) * | 2010-09-01 | 2011-01-19 | 莱芜钢铁股份有限公司 | 一种组合式穿水冷却器 |

| CN103252366A (zh) * | 2013-05-07 | 2013-08-21 | 攀钢集团江油长城特殊钢有限公司 | 一种冷却喷嘴及穿水冷却装置 |

| CN113070354A (zh) * | 2021-03-11 | 2021-07-06 | 青岛雷霆重工股份有限公司 | 一种线材轧制的冷却设备的反扑装置 |

Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2624178A (en) * | 1948-06-07 | 1953-01-06 | Blaw Knox Co | Cooling of the rod in rod rolling mills |

| US3323586A (en) * | 1964-10-14 | 1967-06-06 | Olin Mathieson | Concentric tube heat exchanger with sintered metal matrix |

| US3339373A (en) * | 1964-12-21 | 1967-09-05 | Mobins Hans Eberhard | Process and device for cooling wire coils |

| FR1552711A (fr) * | 1967-02-08 | 1969-01-03 | ||

| DE7134676U (de) * | 1971-09-11 | 1973-09-13 | Kueppers K | Einrichtung zum Entfernen von Kühl wasser in einer Wasserkuhleinrichtung für schnellaufenden Walzdraht |

| BE807884A (fr) * | 1973-11-27 | 1974-05-27 | Centre Rech Metallurgique | Dispositif pour refroidir des produits en acier lamines |

| BE807882A (fr) * | 1973-09-27 | 1974-05-27 | Centre Rech Metallurgique | Dispositif de refroidissement |

| FR2305248A1 (fr) * | 1975-03-25 | 1976-10-22 | Wennberg Ab C J | Procede et dispositif pour nettoyer, laver et secher la surface d'objets allonges tels que des bandes, des fils, des tiges, des fibres, etc. |

| FR2385459A1 (fr) * | 1977-03-30 | 1978-10-27 | Schloemann Siemag Ag | Procede et dispositif de refroidissement d'un produit lamine circulant rapidement |

| DE3309171A1 (de) * | 1983-03-15 | 1984-09-20 | Mannesmann AG, 4000 Düsseldorf | Wasserkuehlstrecke fuer walzwarmes walzgut |

| EP0132249A2 (fr) * | 1983-07-18 | 1985-01-23 | CENTRE DE RECHERCHES METALLURGIQUES CENTRUM VOOR RESEARCH IN DE METALLURGIE Association sans but lucratif | Procédé et dispositifs pour la fabrication d'armatures à béton en acier sur train à fil à grande vitesse |

-

1988

- 1988-10-06 DE DE8888116561T patent/DE3876747D1/de not_active Expired - Fee Related

- 1988-10-06 EP EP88116561A patent/EP0312843B1/fr not_active Expired - Lifetime

- 1988-10-20 JP JP63263024A patent/JPH01138012A/ja active Pending

Patent Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2624178A (en) * | 1948-06-07 | 1953-01-06 | Blaw Knox Co | Cooling of the rod in rod rolling mills |

| US3323586A (en) * | 1964-10-14 | 1967-06-06 | Olin Mathieson | Concentric tube heat exchanger with sintered metal matrix |

| US3339373A (en) * | 1964-12-21 | 1967-09-05 | Mobins Hans Eberhard | Process and device for cooling wire coils |

| FR1552711A (fr) * | 1967-02-08 | 1969-01-03 | ||

| DE7134676U (de) * | 1971-09-11 | 1973-09-13 | Kueppers K | Einrichtung zum Entfernen von Kühl wasser in einer Wasserkuhleinrichtung für schnellaufenden Walzdraht |

| BE807882A (fr) * | 1973-09-27 | 1974-05-27 | Centre Rech Metallurgique | Dispositif de refroidissement |

| BE807884A (fr) * | 1973-11-27 | 1974-05-27 | Centre Rech Metallurgique | Dispositif pour refroidir des produits en acier lamines |

| FR2305248A1 (fr) * | 1975-03-25 | 1976-10-22 | Wennberg Ab C J | Procede et dispositif pour nettoyer, laver et secher la surface d'objets allonges tels que des bandes, des fils, des tiges, des fibres, etc. |

| FR2385459A1 (fr) * | 1977-03-30 | 1978-10-27 | Schloemann Siemag Ag | Procede et dispositif de refroidissement d'un produit lamine circulant rapidement |

| DE3309171A1 (de) * | 1983-03-15 | 1984-09-20 | Mannesmann AG, 4000 Düsseldorf | Wasserkuehlstrecke fuer walzwarmes walzgut |

| EP0132249A2 (fr) * | 1983-07-18 | 1985-01-23 | CENTRE DE RECHERCHES METALLURGIQUES CENTRUM VOOR RESEARCH IN DE METALLURGIE Association sans but lucratif | Procédé et dispositifs pour la fabrication d'armatures à béton en acier sur train à fil à grande vitesse |

Non-Patent Citations (4)

| Title |

|---|

| SOVIET INVENTIONS ILLUSTRATED, Woche 84/07, Klasse M21 P51, 28. März 1984, Nr. 84-041759/07, Derwent Publications Ltd, London, GB; & SU-A-1 010 142 (FERROUS METALLURGY INST.) 07-04-1983 * |

| SOVIET INVENTIONS ILLUSTRATED, Woche 8606, Klasse P51, 18. Februar 1986, Nr. 84-041759/07, Derwent Publications Ltd, London, GB; & SU-A-1 142 515 (FERROUS METALLURGY INST.) 28-02-1985 * |

| SOVIET INVENTIONS ILLUSTRATED, Woche 8607, Klasse M22, 25. Februar 1986, Nr. 86-047165/07, Derwent Publications Ltd, London, GB; & SU-A-1 168 609 (FERR METAL EFFL PURIF) 23-07-1985 * |

| SOVIET INVENTIONS ILLUSTRATED, Woche J48, Klasse M21 P51, 19. Januar 1983, Nr. 039797/48, Derwent Publications Ltd, London, GB; & SU-A-900 916 (DON FERROUS METAL) 30-01-1982 * |

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0737524A1 (fr) * | 1995-04-12 | 1996-10-16 | DANIELI & C. OFFICINE MECCANICHE S.p.A. | Chambre de refroidissement pour produits laminés |

| US5617735A (en) * | 1995-04-12 | 1997-04-08 | Danieli & C. Officine Meccaniche Spa | Cooling chamber for rolled products |

| AU702427B2 (en) * | 1995-04-12 | 1999-02-18 | Danieli & C. Officine Meccaniche S.P.A. | Cooling chamber for rolled products |

| EP0882804A1 (fr) * | 1997-06-05 | 1998-12-09 | DANIELI & C. OFFICINE MECCANICHE S.p.A. | Procédé et dispositif pour le traitement thermique de produits laminés |

| US6096146A (en) * | 1997-06-05 | 2000-08-01 | Danieli & C. Officine Meccanichi Spa | Method for heat treating rolled stock and device to achieve the method |

| CN101947564A (zh) * | 2010-09-01 | 2011-01-19 | 莱芜钢铁股份有限公司 | 一种组合式穿水冷却器 |

| CN101947564B (zh) * | 2010-09-01 | 2012-11-21 | 山东钢铁股份有限公司 | 一种组合式穿水冷却器 |

| CN103252366A (zh) * | 2013-05-07 | 2013-08-21 | 攀钢集团江油长城特殊钢有限公司 | 一种冷却喷嘴及穿水冷却装置 |

| CN113070354A (zh) * | 2021-03-11 | 2021-07-06 | 青岛雷霆重工股份有限公司 | 一种线材轧制的冷却设备的反扑装置 |

Also Published As

| Publication number | Publication date |

|---|---|

| DE3876747D1 (de) | 1993-01-28 |

| JPH01138012A (ja) | 1989-05-30 |

| EP0312843B1 (fr) | 1992-12-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69311436T2 (de) | Verfahren zur Behandlung von Kunstgarnen hauptsächlich während eines Texturiervorganges und Vorrichtung zur Durchführung dieses Verfahrens | |

| DE69309101T2 (de) | Extrudereinrichtung mit mitteln zur anpassung des abgabenendes einer extrusionsdüse relativ zu einem extruder zur ausrichtung einer stromabwärts liegenden vorrichtung | |

| DE1290112B (de) | Vorrichtung zum Kuehlen von Warmband | |

| EP1215291B1 (fr) | Installation pour le refroidissement et le traitement de corps métalliques chauffés à symétrie de révolution | |

| EP0001391A1 (fr) | Dispositif de refroidissement des profilés continus, en forme d'un tube à double-paroi | |

| DE3149647C2 (fr) | ||

| EP0943435A1 (fr) | Cylindre réfrigérant | |

| EP0931600B1 (fr) | Dispositif pour le décalaminage de produits laminés | |

| EP0312843A1 (fr) | Procédé d'échange de chaleur et son application en refroidissement contrôlé de produits laminés | |

| EP1314491B1 (fr) | Mode d'opération d'un laminoir étireur-réducteur et laminoir étireur-réducteur | |

| DE1930979A1 (de) | Drehbank | |

| DE3735790A1 (de) | Arbeitsverfahren und vorrichtungen zum temperaturkontrollierten kuehlen von walzgut | |

| DE19934557C2 (de) | Vorrichtung zum Kühlen von auf einer Förderstrecke geförderten Metallbändern oder -blechen | |

| DE2039389B2 (de) | Vorkuhleinnchtung fur eine Ultraschallmeßeinrichtung | |

| DE2135220C3 (de) | Verfahren und Vorrichtung zum thermochemischen Flämmen der Außenfläche eines zylindrischen metallischen Werkstückes | |

| DE862139C (de) | Walzwerk zum Walzen von nahtlosen Rohren aus Hohlbloecken | |

| DE2822582B2 (de) | Kühlmittelleit- und Walzgutführungseinrichtung für die intermittierende Kühlung von Walzgut, insbesondere von Draht, Feineisen o.dgl | |

| DE19606361C2 (de) | Vorrichtung zum Führen einer Luppe | |

| WO2000077513A9 (fr) | Dispositif pour l'essai non destructif de materiaux de laminage, en particulier en forme de barres, a chaud | |

| DE2648218C3 (de) | Verfahren zur Regelung der Waschleistung eines Venturirohres und Vorrichtungen zur Durchführung dieses Verfahrens | |

| DE2314077B2 (de) | Vorrichtung zum Transportieren von Rohren durch eine Wärmebehandlungseinrichtung | |

| EP0380827A2 (fr) | Installation de compacter pour pulvériser horizontalement | |

| DE3933930A1 (de) | Anordnung zur steuerung der walgutabkuehlung | |

| DE10295852B4 (de) | Vorrichtung zur regelbaren Kühlung von Walzgut | |

| DD159610A1 (de) | Kuehlrohr in walzwerken |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19881031 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT DE IT SE |

|

| 17Q | First examination report despatched |

Effective date: 19901031 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT DE IT SE |

|

| REF | Corresponds to: |

Ref document number: 83405 Country of ref document: AT Date of ref document: 19930115 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3876747 Country of ref document: DE Date of ref document: 19930128 |

|

| ITF | It: translation for a ep patent filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| EAL | Se: european patent in force in sweden |

Ref document number: 88116561.7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20010925 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20011001 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20011005 Year of fee payment: 14 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20021006 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20021007 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030501 |

|

| EUG | Se: european patent has lapsed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20051006 |