CN103712416A - Method for controlling power of reboiler of crude krypton and xenon evaporating tower - Google Patents

Method for controlling power of reboiler of crude krypton and xenon evaporating tower Download PDFInfo

- Publication number

- CN103712416A CN103712416A CN201310743394.5A CN201310743394A CN103712416A CN 103712416 A CN103712416 A CN 103712416A CN 201310743394 A CN201310743394 A CN 201310743394A CN 103712416 A CN103712416 A CN 103712416A

- Authority

- CN

- China

- Prior art keywords

- power

- reboiler

- temperature

- rectifying tower

- krypton xenon

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Landscapes

- Separation By Low-Temperature Treatments (AREA)

Abstract

The invention discloses a method for controlling power of a reboiler of a crude krypton and xenon evaporating tower. The method is applied to a rectifying tower assembly. The method comprises the following steps that S1, it is tested that all temperature testing points of the rectifying tower assembly are T1, and liquid oxygen at the bottom of a rectifying tower is rapidly evaporated by regulating the power of the reboiler manually; S2, when temperature of the lower middle portion of the rectifying tower assembly gradually rises to about T2, power output of the reboiler is gradually reduced, and power output is continuously regulated, so that the temperature tends to be stable; S3, when the temperature ranges from T3 to T4, the power value of the reboiler at this moment is recorded to serve as a parameter of a power basic value, power control of the reboiler is changed into automatic regulation, the temperature of control points of the rectifying tower assembly is controlled, and meanwhile the regulating factor is modified according to changes of the power and the temperature value, so that the temperature becomes stable further. The method achieves the purposes that no liquid oxygen is residual, krypton and xenon can not go out, and the operation condition of the reboiler is stable.

Description

Technical field

The present invention relates to Deep Cooling Method technology, relate in particular to a kind of method of controlling crude krypton xenon concentration tower reboiler power.

Background technology

Deep Cooling Method is in liquid oxygen during concentrated krypton-xenon mixture, by the reboiler of rectifier bottoms is heated to the krypton xenon mixed liquor (Kr+Xe >=99.99%) making after liquid oxygen evaporation can be concentrated to liquid oxygen.Should guarantee that liquid oxygen evaporates completely, leave krypton xenon mixed liquor simultaneously, guarantee that krypton xenon is from rectifying tower top escape, so the power of tower bottom reboiler change on concentrated effect impact huge.If power is too large, krypton xenon mixture can gasify together along with liquid oxygen, rises to rectifying column top, and the rectifying column of finally escaping out causes high-purity krypton, high-purity xenon recovery rate to decline; Conversely, if power is too little, liquid oxygen evaporation not exclusively, enters follow-up rectifying column together with krypton-xenon concentrate, causes the final products purity cannot be up to standard.When practical operation, if manually controlled by operating personnel, need frequently to intervene the power stage of reboiler, too expend operating personnel's energy, if and manual control rectifying column temperature variation suddenly sometimes is not but found in time, is responded, make adjustment, can cause power, variations in temperature fluctuation range very large, to the operating mode of rectifying column is stable, bring inconvenience, even destroy the whole operating mode of rectifying column.

Summary of the invention

In view of this, the object of this invention is to provide a kind of method of controlling crude krypton xenon concentration tower reboiler power, for certain some temperature of krypton xenon concentration tower, carry out special control, reach liquid oxygen noresidue, krypton xenon is not escaped, reboiler operating condition is stable object.

In order to achieve the above object, the object of the invention is to be achieved through the following technical solutions:

Control a method for crude krypton xenon concentration tower reboiler power, be applied to, in rectifying tower group, wherein, comprise the following steps:

S1. record all temperature points of rectifying tower group and be T1, in the mode of manual adjustments reboiler power, evaporate rapidly the liquid oxygen of rectifier bottoms;

S2. when rectifying tower group middle and lower part temperature is increased to T2 left and right gradually, progressively reduce the output of reboiler power, constantly regulating power output, tends towards stability temperature;

S3. when temperature, between T3~T4, hover and record reboiler performance number now, parameter as power base value, the power of reboiler is controlled and changed automatic adjusting into, rectifying tower group control point temperature is carried out to temperature control, according to the modifications adjustment factor of power and temperature value, make temperature further stable simultaneously.

The method of above-mentioned crude krypton xenon concentration tower reboiler power, wherein, the computational methods of described reboiler power are carried out following formula:

P=P1+K*(0.5-P0);

Wherein P represents reboiler power, and P1 represents power base value, the basis changing to limit reboiler power; K represents adjustment factor, the step-length changing to limit reboiler power; P0 represents automatic regulating power.

The method of above-mentioned crude krypton xenon concentration tower reboiler power, wherein, described power base value P1 and described adjustment factor K are manual setting.

The method of above-mentioned crude krypton xenon concentration tower reboiler power, wherein, described automatic regulating power P0 adopts PID regulative mode.

The method of above-mentioned crude krypton xenon concentration tower reboiler power, wherein, described T1 is-165 ℃, and T2 is-133 ℃, and T3 is-132 ℃, and T4 is-135 ℃.

Compared with the prior art, beneficial effect of the present invention is:

Liquid oxygen noresidue, krypton xenon is not escaped, and reboiler operating condition is stable.

Accompanying drawing explanation

The accompanying drawing that forms a part of the present invention is used to provide a further understanding of the present invention, and schematic description and description of the present invention is used for explaining the present invention, does not form inappropriate limitation of the present invention.In the accompanying drawings:

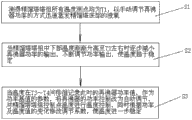

Fig. 1 is the schematic flow sheet of the method for crude krypton xenon concentration tower reboiler power of the present invention;

Fig. 2 is the structural representation of rectifying tower group in the method for crude krypton xenon concentration tower reboiler power of the present invention;

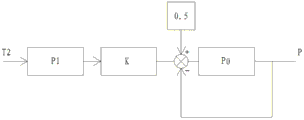

Fig. 3 is the formula schematic diagram of reboiler power calculation method in the method for crude krypton xenon concentration tower reboiler power of the present invention.

The specific embodiment

Below in conjunction with the accompanying drawing in the embodiment of the present invention, the technical scheme in the embodiment of the present invention is clearly and completely described, obviously, described embodiment is only the present invention's part embodiment, rather than whole embodiment.Embodiment based in the present invention, those of ordinary skills, not making the every other embodiment obtaining under creative work prerequisite, belong to the scope of protection of the invention.

It should be noted that, in the situation that not conflicting, embodiment and the feature in embodiment in the present invention can combine mutually.

The embodiment of the present invention provides a kind of method of controlling crude krypton xenon concentration tower reboiler power, is applied in rectifying tower group.

This control method is divided into manual intervention and automatically regulates two parts, and referring to Fig. 1 and Fig. 3, dominated formulate is as follows:

The automatic regulating power P0 of reboiler power output P=power base value P1+ adjustment factor K(0.5-), wherein P represents reboiler power, and P1 represents power base value, the basis changing to limit reboiler power; K represents adjustment factor, the step-length changing to limit reboiler power; P0 represents automatic regulating power.

Power base value P1 and adjustment factor K are manual setting, and visual different operating modes are changed.

Automatically regulating power P0 is the regulation output of PID adjuster, and the parameter that adjuster is controlled is chosen the temperature of a certain temperature point on rectifying column.

Power base value P1 defines the basis that reboiler power changes, and when carrying out temperature control and regulate, it is benchmark that the power output of reboiler all be take the numerical value of P1.

Adjustment factor K defines the step-length that reboiler power changes, and the stride that each temperature control regulates is X%*K.

Automatically regulating power P0 is the output of Power Regulation signal, and rectifying column middle and lower part point temperature is carried out to PID adjusting, and regulative mode is positive characteristic, (0.5-P0) the excursion of reboiler power has been limited in the scope of power base value P1 ± 0.5K.

In a preferred embodiment of the invention, according to following step, carry out:

Continuation is referring to Fig. 1 to Fig. 3, the adjusting initial stage, the all temperature points of rectifying tower group are-165 ℃ (T1), now in the mode of manual adjustments P, evaporate rapidly the liquid oxygen of rectifier bottoms, when being increased to-133 ℃ of (T2) left and right gradually, rectifying tower group middle and lower part temperature progressively reduces the output of P, now temperature ascendant trend slows down, constantly regulating power output, temperature is tended towards stability, when temperature, between-132 ℃ of (T3)~-135 ℃ (T4), hover and record reboiler power P value now, as the parameter of power base value P1.Now the power of reboiler is controlled and changed automatic adjusting into, rectifying tower group control point temperature is carried out to temperature control, simultaneously according to the variation of power and temperature value, revise adjustment factor K, make temperature further stable.Now, the value of P1 and K is the best setup parameter of operation, and the operation that can maintain a long-term stability.

Above specific embodiments of the invention be have been described in detail, but the present invention is not restricted to specific embodiment described above, it is just as example.To those skilled in the art, any equivalent modifications and alternative also all among category of the present invention.Therefore, equalization conversion and the modification done without departing from the spirit and scope of the invention, all should contain within the scope of the invention.

Claims (5)

1. control a method for crude krypton xenon concentration tower reboiler power, be applied to, in rectifying tower group, it is characterized in that, comprise the following steps:

S1. record all temperature points of rectifying tower group and be T1, in the mode of manual adjustments reboiler power, evaporate rapidly the liquid oxygen of rectifier bottoms;

S2. when rectifying tower group middle and lower part temperature is increased to T2 left and right gradually, progressively reduce the output of reboiler power, constantly regulating power output, tends towards stability temperature;

S3. when temperature, between T3~T4, hover and record reboiler performance number now, parameter as power base value, the power of reboiler is controlled and changed automatic adjusting into, rectifying tower group control point temperature is carried out to temperature control, according to the modifications adjustment factor of power and temperature value, make temperature further stable simultaneously.

2. the method for controlling according to claim 1 crude krypton xenon concentration tower reboiler power, is characterized in that, the computational methods of described reboiler power are carried out following formula:

P=P1+K*(0.5-P0);

Wherein P represents reboiler power, and P1 represents power base value, the basis changing to limit reboiler power; K represents adjustment factor, the step-length changing to limit reboiler power; P0 represents automatic regulating power.

3. the method for controlling according to claim 1 crude krypton xenon concentration tower reboiler power, is characterized in that, described power base value P1 and described adjustment factor K are manual setting.

4. the method for crude krypton xenon concentration tower reboiler power according to claim 1, is characterized in that, described automatic regulating power P0 adopts PID regulative mode.

5. according to the method for crude krypton xenon concentration tower reboiler power described in any one in claim 1 to 4, it is characterized in that, described T1 is-165 ℃, and T2 is-133 ℃, and T3 is-132 ℃, and T4 is-135 ℃.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201310743394.5A CN103712416B (en) | 2013-12-27 | 2013-12-27 | The method controlling crude krypton xenon concentration tower reboiler power |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201310743394.5A CN103712416B (en) | 2013-12-27 | 2013-12-27 | The method controlling crude krypton xenon concentration tower reboiler power |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN103712416A true CN103712416A (en) | 2014-04-09 |

| CN103712416B CN103712416B (en) | 2016-06-22 |

Family

ID=50405589

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201310743394.5A Active CN103712416B (en) | 2013-12-27 | 2013-12-27 | The method controlling crude krypton xenon concentration tower reboiler power |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN103712416B (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN108031138A (en) * | 2017-12-14 | 2018-05-15 | 浙江新锐空分设备有限公司 | A kind of krypton xenon concentration tower bottom heat of evaporation source system |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB927518A (en) * | 1959-11-23 | 1963-05-29 | British Oxygen Co Ltd | Process for the separation of krypton and xenon from mixture with oxygen |

| JPS5743185A (en) * | 1980-08-29 | 1982-03-11 | Nippon Oxygen Co Ltd | Production of krypton and xenon |

| CN1192423A (en) * | 1997-03-04 | 1998-09-09 | 林德股份公司 | Method for obtg. Kr and Xe |

| CN101726158A (en) * | 2009-11-12 | 2010-06-09 | 上海启元科技发展有限公司 | Method for removing oxygen and methane from concentrated krypton-xenon liquid |

| JP2012007990A (en) * | 2010-06-24 | 2012-01-12 | Taiyo Nippon Sanso Corp | Liquid level meter and measurement method of liquid level, and rectifying column and operation method of rectifying column |

| CN202216489U (en) * | 2011-07-21 | 2012-05-09 | 上海启元空分技术发展股份有限公司 | Containing CO2Device for separating krypton-xenon concentrate from methane |

-

2013

- 2013-12-27 CN CN201310743394.5A patent/CN103712416B/en active Active

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB927518A (en) * | 1959-11-23 | 1963-05-29 | British Oxygen Co Ltd | Process for the separation of krypton and xenon from mixture with oxygen |

| JPS5743185A (en) * | 1980-08-29 | 1982-03-11 | Nippon Oxygen Co Ltd | Production of krypton and xenon |

| CN1192423A (en) * | 1997-03-04 | 1998-09-09 | 林德股份公司 | Method for obtg. Kr and Xe |

| CN101726158A (en) * | 2009-11-12 | 2010-06-09 | 上海启元科技发展有限公司 | Method for removing oxygen and methane from concentrated krypton-xenon liquid |

| JP2012007990A (en) * | 2010-06-24 | 2012-01-12 | Taiyo Nippon Sanso Corp | Liquid level meter and measurement method of liquid level, and rectifying column and operation method of rectifying column |

| CN202216489U (en) * | 2011-07-21 | 2012-05-09 | 上海启元空分技术发展股份有限公司 | Containing CO2Device for separating krypton-xenon concentrate from methane |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN108031138A (en) * | 2017-12-14 | 2018-05-15 | 浙江新锐空分设备有限公司 | A kind of krypton xenon concentration tower bottom heat of evaporation source system |

Also Published As

| Publication number | Publication date |

|---|---|

| CN103712416B (en) | 2016-06-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN104808705B (en) | A kind of turbine governor system control parameter setting method of feature based parameter | |

| CN107096252B (en) | The method that the top of the distillation column cooling capacity automatically controls | |

| CN102758251A (en) | Method for controlling sapphire seeding form of Kyropoulos method | |

| PE20212099A1 (en) | SYSTEM AND METHOD TO CONTROL A MULTI-STATE ELECTROCHEMICAL CELL | |

| CN103712416A (en) | Method for controlling power of reboiler of crude krypton and xenon evaporating tower | |

| CN102707620A (en) | Backpressure control system of large air-cooler unit | |

| CN102860220B (en) | Cultivation method of bottle planted needle mushroom | |

| CN104868013B (en) | Solar crystalline silicon cell diffusion process | |

| CN105676922B (en) | A kind of greenhouse optimising and adjustment method | |

| CN103207562A (en) | Improved proportional integral derivative (PID) algorithm for glass heating under vacuum | |

| CN101364082B (en) | Human-simulated PID intelligent control method for industrial process | |

| CN111878964A (en) | Control method and device of electronic expansion valve, air conditioner and storage medium | |

| CN106873686A (en) | Intelligent strawberry hot-house culture system and control method | |

| CN113082759A (en) | Automatic control system and control method for bromine distillation tower | |

| CN101708379B (en) | System for high purity control in high-efficiency energy-saving rectifying process and method thereof | |

| CN103451729A (en) | Growth method of square sapphire | |

| CN107023816A (en) | The control method and control system of boiler centrum's temperature | |

| CN110211872A (en) | Diffusion process debugging method capable of improving over-temperature phenomenon of low-pressure diffusion furnace | |

| CN110879526B (en) | Fractional order controller and parameter setting method thereof | |

| CN103983085A (en) | Method for controlling temperature of krypton and xenon separation tower | |

| CN101881961B (en) | Nonlinear control system and method for internal thermally coupled distillation column | |

| Sun et al. | Coordination of bypass control and economic optimisation for heat exchanger network with stream splits | |

| CN201473435U (en) | Kiln pressure stabilizing system for glass production line waste heat power generation kiln | |

| CN114545865A (en) | Polycrystalline silicon growth control method | |

| CN113877231A (en) | Automatic load increasing and decreasing intelligent control method for methanol rectification device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| TR01 | Transfer of patent right | ||

| TR01 | Transfer of patent right |

Effective date of registration: 20210629 Address after: 201800 rooms 202 and 204, building 3, 150 Heyu Road, Jiading District, Shanghai Patentee after: SHANGHAI QIYUAN GAS DEVELOPMENT Co.,Ltd. Address before: 201800 150 Heyu Road, Jiading District, Shanghai Patentee before: SHANGHAI QIYUAN AIR SEPARATE TECHNOLOGY DEVELOPMENT Co.,Ltd. |