JP4773395B2 - Static elimination performance detector - Google Patents

Static elimination performance detector Download PDFInfo

- Publication number

- JP4773395B2 JP4773395B2 JP2007099393A JP2007099393A JP4773395B2 JP 4773395 B2 JP4773395 B2 JP 4773395B2 JP 2007099393 A JP2007099393 A JP 2007099393A JP 2007099393 A JP2007099393 A JP 2007099393A JP 4773395 B2 JP4773395 B2 JP 4773395B2

- Authority

- JP

- Japan

- Prior art keywords

- electrode

- body case

- main body

- charging electrode

- external charging

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Testing Electric Properties And Detecting Electric Faults (AREA)

- Elimination Of Static Electricity (AREA)

Description

本発明は除電器の性能を検知する除電性能検知器に関する。 The present invention relates to a static elimination performance detector that detects the performance of a static eliminator.

従来、除電器の性能を調べる技術として次の特許文献1〜5に記載されたものがある。

<特許文献1(特開平11−271372号公報)>

プローブを先端に有するとともに、電荷量測定部を内蔵したプローブユニットと、その外部に接続された計算・表示部とからなり、プローブは、帯電物に接触して電荷を電荷量測定部に入力し、電荷量測定部は、スイッチと、このスイッチに接続された抵抗と、この抵抗に一方の入力端が接続されたオペアンプと、このオペアンプの一方の入力端と他方の入力端との間に接続されたコンデンサとを有し、計算・表示部は、オペアンプの他方の入力端に対する電圧として出力されたオペアンプの出力を基に電荷量を計算し、これを表示する。

Conventionally, there are techniques described in the following Patent Documents 1 to 5 as techniques for examining the performance of the static eliminator.

<Patent Document 1 (Japanese Patent Laid-Open No. 11-271372)>

It consists of a probe unit with a probe at the tip and a built-in charge amount measurement unit, and a calculation / display unit connected to the outside. The probe contacts the charged object and inputs the charge to the charge amount measurement unit. The charge measuring unit is connected between the switch, the resistor connected to the switch, the operational amplifier having one input connected to the resistor, and one input terminal and the other input terminal of the operational amplifier. The calculation / display unit calculates the charge amount based on the output of the operational amplifier output as a voltage with respect to the other input terminal of the operational amplifier, and displays this.

<特許文献2(特開2002−286776号公報)>

コロナ放電を利用した除電器の接地電極に取付けられ、導電性の帯電板および除電器と帯電板が所定の位置関係を保つよう帯電板を支持する支持装置とを有するセンサユニットと、電圧発生ユニットとから構成されている。導電性を有する帯電板は、正または負のどちらか一方あるいは両方の電圧を印加できるよう構成されており、支持装置は、除電器の接地電極に取付けられ、接地電極にスライド可能に保持されるよう構成されている。

<Patent Document 2 (Japanese Patent Application Laid-Open No. 2002-286776)>

A voltage generating unit, which is attached to a ground electrode of a static eliminator using corona discharge and has a conductive charging plate and a support device that supports the charging plate so that the static eliminator and the charging plate maintain a predetermined positional relationship; It consists of and. The conductive charging plate is configured to be able to apply either positive or negative voltage or both, and the support device is attached to the ground electrode of the static eliminator and is slidably held on the ground electrode. It is configured as follows.

<特許文献3(特開平5−264628号公報)>

高圧が印加される除電電極とアース極の間にコロナ放電を起こさせて静電気を除去する除電器の外側にプローブを取付ける。このプローブに、除電電極の外側に位置する金属製の検知板と、この検知板の外側に位置するシールド板を設ける。プローブに電気的に接続した判別装置により、検知板の誘導電位を基準電圧と比較して除電器の動作の良否を判別する。

<Patent Document 3 (JP-A-5-264628)>

A probe is attached to the outside of the static eliminator that removes static electricity by causing a corona discharge between the static elimination electrode to which a high voltage is applied and the ground electrode. The probe is provided with a metal detection plate located outside the static elimination electrode and a shield plate located outside the detection plate. A discrimination device electrically connected to the probe compares the induced potential of the detection plate with a reference voltage to determine whether the operation of the static eliminator is good or bad.

<特許文献4(特開2005−77348号公報)>

高電圧を出力する高電圧電源と、金属プレートと高電圧電源との通電/遮断を切り替えるスイッチと、金属プレートの電位を測定する電位計と、電位計の測定結果に基づいて、正・負イオンのバランスずれ値及び/又は金属プレートの電位減衰波形のスイングを考慮して除電時間等を求める演算処理をする演算部と、演算部の演算結果を外部出力する出力部とによって構成されている。記録部は、正・負イオンのバランスずれ値や除電時間等の演算部の演算結果を記録する。

<Patent Document 4 (Japanese Patent Laid-Open No. 2005-77348)>

Based on the measurement result of the high voltage power supply that outputs high voltage, the switch that switches between energization / cutoff of the metal plate and the high voltage power supply, the electrometer that measures the potential of the metal plate, and positive / negative ion The calculation unit is configured to perform a calculation process for obtaining a static elimination time in consideration of the balance deviation value and / or the swing of the potential decay waveform of the metal plate, and an output unit that outputs the calculation result of the calculation unit to the outside. The recording unit records the calculation result of the calculation unit such as the positive / negative ion balance deviation value and the static elimination time.

<特許文献5(特開2001−124812号公報)>

除電器により帯電される上金属プレートと下金属プレートとを絶縁体を介して対向させた第1のコンデンサと、これら上金属プレートと下金属プレートとの間にスイッチを介して接続された第2のコンデンサと、上・下金属プレートに高電圧を印加する高圧電源と、上金属プレートの表面電位を測定するために、この上金属プレートの表面上に離隔設置された表面電位センサと、その測定値をアナログデータとして表示・記録するオシロスコープなどの表示記録器とからなる。

<Patent Document 5 (Japanese Patent Laid-Open No. 2001-124812)>

A first capacitor in which an upper metal plate and a lower metal plate charged by a static eliminator are opposed to each other via an insulator, and a second capacitor connected between the upper metal plate and the lower metal plate via a switch. Capacitors, high-voltage power supply that applies high voltage to the upper and lower metal plates, surface potential sensors placed on the surface of the upper metal plate to measure the surface potential of the upper metal plate, and measurement It consists of a display recorder such as an oscilloscope that displays and records values as analog data.

しかし、これらはいずれも簡便かつ小型な構造とは言えない。また、周囲の電界や湿度、塵などの周囲環境による外乱を受けやすく、測定精度の変動が大きいなどの問題がある。

本発明の課題は、小型で、除電器の性能をそれとは非接触で簡便に測定できるとともに、周囲の電界や湿度、塵などの周囲環境による外乱を受けることが少なく、精度良く測定できる除電性能検知器を提供することにある。 The problem of the present invention is that it is small and can easily measure the performance of the static eliminator without contact with it, and is less susceptible to disturbance due to the surrounding environment such as the electric field, humidity, and dust, and can be accurately measured. It is to provide a detector.

請求項1に係る本発明による除電性能検知器は、表面電位センサを内蔵した本体ケースの外面上に、アース電極と外部帯電電極とがそれらの間に電極間絶縁部材を介在させて配設されているとともに、本体ケースの内部に表面電位センサと対向して内部帯電電極が設置され、この内部帯電電極と外部帯電電極とは、電荷を誘導するように本体ケースの内外を貫通する導通部材により電気的に導通されており、アース電極と外部帯電電極と電極間絶縁部材とは、本体ケースの外面上に、アース電極、電極間絶縁部材、外部帯電電極の順で重合され、アース電極と外部帯電電極とは、いずれも板状である。 In the static elimination performance detector according to the first aspect of the present invention, the ground electrode and the external charging electrode are disposed on the outer surface of the main body case incorporating the surface potential sensor with an interelectrode insulating member interposed therebetween. and with that, the internal charging electrode is disposed to face the front surface potential sensor in the interior of the main body case, and the internal charging electrode and the external charging electrodes, conductive member penetrating the inside and outside of the main body case so as to induce charge The ground electrode, the external charging electrode, and the interelectrode insulating member are polymerized on the outer surface of the main body case in the order of the ground electrode, the interelectrode insulating member, and the external charging electrode. the external charging electrode, both Ru plate der.

その好ましい構造である請求項2に係る発明は、導通部材は、電極間絶縁部材を貫通するとともに、アース電極及び本体ケースとは非接触にこれらを貫通して外部帯電電極と内部帯電電極とを導通させている。

As a preferred structure is the invention according to

同じく請求項3に係る発明では、電極間絶縁部材が板状になっている。

同じく請求項4に係る発明では、導通部材が導電性のスプリングとなっている。

Also in the invention according to

Similarly, in the invention according to

請求項5に係る発明は、本体ケースが角筒形で、アース電極が本体ケースの胴部の外面上に取り付けられ、該アース電極のL形に折曲形成された端部が、本体ケースの前端に添うアース線接続部となっている。

In the invention according to

本発明の除電性能検知器よると、本体ケース内の内部帯電電極に高電圧を印加してこれを帯電させると、その電荷が、本体ケースの内外を貫通する導通部材により本体ケース外の外部帯電電極に誘導される。外部帯電電極に除電器からのイオンを当てると、本体ケースの外面上において外部帯電電極とアース電極との間に電極間絶縁部材が介在されているので、アース電極を基準とした外部帯電電極の電位が除電器の性能により変化(具体的には、イオン電流等により変化)して、導通部材を介して内部帯電電極に反映され、その電位変化が本体ケース内で表面電位センサにより間接的に検出されるので、周囲の電界や湿度、塵などの周囲環境による外乱を受けにくく、除電器の性能を精度良く測定できる。本体ケースの外面上に、アース電極と外部帯電電極とを、それらの間に電極間絶縁部材を介在させて配設した単純な構造であるので、小型化でき、取り扱いも容易である。 According to the static elimination performance detector of the present invention, when a high voltage is applied to the internal charging electrode in the main body case to charge it, the charge is externally charged outside the main body case by the conductive member penetrating the inside and outside of the main body case. Induced to the electrode. When ions from the static eliminator are applied to the external charging electrode, an interelectrode insulating member is interposed between the external charging electrode and the earth electrode on the outer surface of the main body case. The potential changes depending on the performance of the static eliminator (specifically, changes due to ion current, etc.) and is reflected on the internal charging electrode through the conductive member. The potential change is indirectly detected by the surface potential sensor in the main body case. Because it is detected, it is less susceptible to disturbance due to the surrounding environment such as the surrounding electric field, humidity, and dust, and the performance of the static eliminator can be measured with high accuracy. Since the ground electrode and the external charging electrode are arranged on the outer surface of the main body case with an interelectrode insulating member interposed therebetween, the size can be reduced and the handling is easy.

請求項2に係る発明によると、本体ケースの外面上に、アース電極、電極間絶縁部材、外部帯電電極の順で重合され、導通部材は、電極間絶縁部材を貫通するとともに、アース電極及び本体ケースとは非接触にこれらを貫通しているので、構造が一層単純となる。

請求項3に係る発明によると、アース電極と外部帯電電極と電極間絶縁部材とがいずれも板状であるので、一層の小型化が可能である。

According to the invention of

According to the third aspect of the invention, since the ground electrode, the external charging electrode, and the interelectrode insulating member are all plate-shaped, further miniaturization is possible.

請求項4に係る発明によると、導通部材が導電性のスプリングであるので、帯電電極が外部帯電電極と内部帯電電極とに分かれていても、内外の組み立てが容易である。

請求項5に係る発明によると、内部帯電電極への高電圧の印加を、本体ケースの外側で簡単にオン・オフできる。

According to the fourth aspect of the present invention, since the conducting member is a conductive spring, it is easy to assemble the inside and outside even if the charging electrode is divided into the external charging electrode and the internal charging electrode.

According to the invention which concerns on

請求項6に係る発明によると、本体ケースが角筒形で、アース電極が本体ケースの胴部の外面上に取り付けられ、該アース電極のL形に折曲形成された端部が、本体ケースの前端に添うアース線接続部となっているので、アース電極を本体ケースの外面上に安定して取り付けることができるとともに、アース配線が容易である。

According to the invention of

次に、本発明の実施例を図面に基づいて詳細に説明する。 Next, embodiments of the present invention will be described in detail with reference to the drawings.

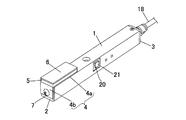

図1は本実施例の除電性能検知器の外観斜視図で、この除電性能検知器は、その本体ケース1がアルミニューム製の角筒形、つまり、アルミニューム製角パイプ材を加工したもので、その前端開口と後端開口とは、同じくアルミニューム製の前カバー片2及び後カバー片3を嵌合させることで閉じられている。

FIG. 1 is an external perspective view of a static elimination performance detector according to the present embodiment. This static elimination performance detector is obtained by processing a rectangular tube made of aluminum, that is, an aluminum square pipe material. The front end opening and the rear end opening are closed by fitting a

この本体ケース1の上面(外面)の前端部上には、いずれも板状のアース電極4と電極間絶縁部材5と外部帯電電極6とが、この順序で重合させて取り付けられている。

On the front end portion of the upper surface (outer surface) of the main body case 1, a plate-

アース電極4は、本体ケース1の幅員と同じ幅員のステンレス等の金属製板片で、先端部をL形に折曲してあり、本体ケース1の上面上に添う長方形の電極主部4aと、本体ケース1の前端面、つまり、前カバー片2の前面に添う配線用端部4bとからなる。この配線用端部4bには、図示しないアース線を接続するためのアース線接続ねじ7が設けられている。

The

電極間絶縁部材5は、アース電極4の電極主部4aと同じ大きさの長方形樹脂片で、外部帯電電極6は、電極間絶縁部材5と同じ大きさの長方形のステンレス等の金属製板片である。

The

図2及び図3にこの除電性能検知器の断面を示す。

アース電極4と電極間絶縁部材5と外部帯電電極6とは、外部帯電電極6の裏面(下面)の二箇所に固着されたナット8を、電極間絶縁部材5に形成された凹部5aに嵌め、これらナット8に、アース電極4の電極主部4aの裏側から、これに設けられた孔を通じて絶縁性のねじ9を螺合させることにより重合されている。

2 and 3 show a cross section of the static elimination performance detector.

The

一方、本体ケース1内には、ステンレス等の長方形金属板片である内部帯電電極10が、本体ケース1の上壁を挟んでアース電極4の電極主部4aと対向するように、本体ケース1の上壁内面に絶縁シール11を介して付設されている。その付設は、絶縁性のねじ12によるねじ止めにて本体ケース1の外側から行われている。

On the other hand, in the main body case 1, the main body case 1 is such that the

外部帯電電極6の裏面(下面)の中央には、ステンレス等の金属製小管であるスプリングガイド13が固着されている。このスプリングガイド13は、電極間絶縁部材5を貫通しているとともに、アース電極4及び本体ケース1に接触することなく、アース電極4の電極主部4aに設けられた孔14を通じて本体ケース1に設けられた孔15まで突入している。そして、これら外部帯電電極6と内部帯電電極10とを電気的に導通させる導電部材として、金属製のコイルスプリング16が、外部帯電電極6と内部帯電電極10とで挟んでこれらで圧縮した状態にしてスプリングガイド13内に挿入されている。

A

本体ケース1内には、回路基板16が、その両端を前カバー片2と後カバー片3とで保持して設置されている。この回路基板16には、表面電位センサ17のほかに各種の回路部品が実装されている。

A

表面電位センサ17は、例えば特許第3518809号公報に開示されているように、検出電極と、この検出電極と被測定物との間の電界をチョッピングする振動子とを、検出孔を有するセンサケースに内蔵し、振動子を振動子駆動回路にて振動させ、検出電極から生ずる交流電圧から被測定物の表面電位を検出する音叉型である。この表面電位センサ17は、その検出孔を内部帯電電極10と間隔をおいて対向させており、内部帯電電極10に帯電された電荷の電位を本体ケース1内で非接触で検出する。その出力は増幅器で増幅され、V/F変換器で周波数信号に変換されてから、後カバー片3に接続したケーブル18を通じて外部の表示器へ電送される。

For example, as disclosed in Japanese Patent No. 3518809, the surface

回路基板16上には、内部帯電電極10に配線接続されたリレー19と、本体ケース1の側面に設けられた小窓20から押しボタン21を突出させたスイッチ22も実装されている。このスイッチ22をオン・オフすると、リレー19がオン・オフし、内部帯電電極10への高電圧の印加を本体ケース1の外側でオン・オフ操作できるようになっている。

On the

さらに、回路基板16上には、動作表示ランプ(発光ダイオード)23や、内部帯電電極10へ印加する高電圧を調整する電圧調整ボリューム24や、表面電位センサ14による検出感度を調整する感度調整ボリューム25等も実装され、これらは本体ケース1に設けられたそれぞれのための孔に臨んでいる。

Further, on the

この除電性能検知器はこのような構造になっているので、スイッチ22をオンにして内部帯電電極10に正又は負の高電圧を印加すると、その電荷が導電部材であるコイルスプリング16を通じて外部帯電電極6に誘導され、これが帯電する。

Since this static elimination performance detector has such a structure, when the

そこで、除電器からのイオンを外部帯電電極6に当てると、外部帯電電極6及びこれと導通している内部帯電電極10の電位が除電器の性能に応じて変化し、内部帯電電極10の電位変化が、本体ケース1内で表面電位センサ14により非接触で検出される。その際、本体ケース1が密閉構造となっているので、周囲の電界や湿度、塵などの周囲環境による外乱を受けにくい。

Therefore, when ions from the static eliminator are applied to the

スイッチ22をオフにすると、内部帯電電極10へ高電圧が印加されなくなる。このとき、内部帯電電極10をアースする構成にすることができる。

When the

1 本体ケース

2 前カバー片

3 後カバー片

4 アース電極

4a 電極主部

4b 配線用端部

5 電極間絶縁部材

5a 凹部

6 外部帯電電極

7 アース線接続ねじ

8 ナット

9 ねじ

10 内部帯電電極

11 絶縁シール

12 ねじ

13 スプリングガイド

14 孔

15 孔

16 コイルスプリング

17 表面電位センサ

18 ケーブル

19 リレー

20 小窓

21 押しボタン

22 スイッチ

23 動作表示ランプ

24 電圧調整ボリューム

25 感度調整ボリューム

DESCRIPTION OF SYMBOLS 1

Claims (5)

前記アース電極と前記外部帯電電極と前記電極間絶縁部材とは、前記本体ケースの外面上に、前記アース電極、前記電極間絶縁部材、前記外部帯電電極の順で重合され、

前記アース電極と前記外部帯電電極とは、いずれも板状である

ことを特徴とする除電性能検知器。 On the outer surface of the body case with a built-in surface potential sensor, and the earth electrode and the external charging electrode electrode insulating member interposed therebetween together is disposed therebetween, before Symbol surface potential sensor in the interior of the main body case An internal charging electrode is installed opposite to the internal charging electrode, and the external charging electrode and the external charging electrode are electrically connected by a conductive member that penetrates the inside and outside of the main body case so as to induce charge ,

The ground electrode, the external charging electrode, and the interelectrode insulating member are polymerized in this order on the outer surface of the main body case, the ground electrode, the interelectrode insulating member, and the external charging electrode.

The grounding electrode and the external charging electrode are both plate-shaped, and a static elimination performance detector.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007099393A JP4773395B2 (en) | 2007-04-05 | 2007-04-05 | Static elimination performance detector |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007099393A JP4773395B2 (en) | 2007-04-05 | 2007-04-05 | Static elimination performance detector |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2008256545A JP2008256545A (en) | 2008-10-23 |

| JP4773395B2 true JP4773395B2 (en) | 2011-09-14 |

Family

ID=39980248

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2007099393A Active JP4773395B2 (en) | 2007-04-05 | 2007-04-05 | Static elimination performance detector |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4773395B2 (en) |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS59185840U (en) * | 1983-05-25 | 1984-12-10 | ティーディーケイ株式会社 | electronic equipment |

| JPH02231578A (en) * | 1989-03-06 | 1990-09-13 | Hitachi Ltd | Method and device for deciding destaticization effect |

| JPH0742167U (en) * | 1993-12-22 | 1995-07-21 | 八木アンテナ株式会社 | Electronic device housing |

| JP3069848B2 (en) * | 1997-10-09 | 2000-07-24 | 春日電機株式会社 | Static eliminator performance inspection device |

| JP2002025791A (en) * | 2000-07-12 | 2002-01-25 | Hugle Electronics Inc | Ac power source type ionizer |

| JP2003303695A (en) * | 2002-04-09 | 2003-10-24 | Kasuga Electric Works Ltd | Automatic charging amount control method and device of charged object |

| JP2003332096A (en) * | 2002-05-10 | 2003-11-21 | Kasuga Electric Works Ltd | Static electricity eliminating control device |

| JP4205375B2 (en) * | 2002-07-12 | 2009-01-07 | 九州日立マクセル株式会社 | hairbrush |

| JP2006156276A (en) * | 2004-12-01 | 2006-06-15 | Shishido Seidenki Kk | Air nozzle type ion generation device |

| JP2007048550A (en) * | 2005-08-09 | 2007-02-22 | Sharp Corp | Ion generating device |

-

2007

- 2007-04-05 JP JP2007099393A patent/JP4773395B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| JP2008256545A (en) | 2008-10-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2803055B1 (en) | Method and apparatus for detecting smoke in an ion chamber | |

| US4720682A (en) | Surface electric potential sensor | |

| CN110274641B (en) | Electromagnetic flowmeter | |

| JP4971504B2 (en) | Sensor device for capacitively detecting intervals | |

| EP2795598B1 (en) | Method and apparatus for detecting smoke in an ion chamber | |

| CN106610326A (en) | Tulip contact pressure electronic measuring instrument | |

| JP4410220B2 (en) | Ion generator performance measuring device | |

| JP4773395B2 (en) | Static elimination performance detector | |

| KR20220056408A (en) | Radon detector using pulsified alpha particle | |

| JP4130188B2 (en) | Surface electrometer | |

| JP5044336B2 (en) | Level gauge sensor | |

| CN104677484B (en) | Vibration and dynamic acceleration sensing using capacitors | |

| CN110567419A (en) | breaker contact engagement depth detection device | |

| JP4800908B2 (en) | Gas alarm with built-in electrochemical gas sensor | |

| JP6688257B2 (en) | Charged plate monitor | |

| US4231258A (en) | Method and apparatus for detecting foreign matters in gas sealed electric apparatus | |

| JP3269269B2 (en) | Vibration detection sensor | |

| US3714561A (en) | A transducer for measuring the displacement of an electrically conductive objective | |

| FR3115883B1 (en) | Device for detecting the capacitive coupling between an object and a detection surface | |

| SU690308A1 (en) | Level indicator | |

| JP3849516B2 (en) | Electromagnetic flow meter | |

| JPH03120761A (en) | Optical voltage detector for high voltage | |

| JP2018159708A (en) | Load detector | |

| JP2000121603A (en) | Dew condensation sensor | |

| JP5462648B2 (en) | Equipment for measuring ions in the atmosphere |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20100209 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100525 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100726 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20110614 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20110623 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20140701 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4773395 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| S531 | Written request for registration of change of domicile |

Free format text: JAPANESE INTERMEDIATE CODE: R313531 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20140701 Year of fee payment: 3 |

|

| R360 | Written notification for declining of transfer of rights |

Free format text: JAPANESE INTERMEDIATE CODE: R360 |

|

| R360 | Written notification for declining of transfer of rights |

Free format text: JAPANESE INTERMEDIATE CODE: R360 |

|

| R371 | Transfer withdrawn |

Free format text: JAPANESE INTERMEDIATE CODE: R371 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20140701 Year of fee payment: 3 |

|

| S531 | Written request for registration of change of domicile |

Free format text: JAPANESE INTERMEDIATE CODE: R313531 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20140701 Year of fee payment: 3 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |