EP0603149B2 - Vacuum machine - Google Patents

Vacuum machine Download PDFInfo

- Publication number

- EP0603149B2 EP0603149B2 EP93890223A EP93890223A EP0603149B2 EP 0603149 B2 EP0603149 B2 EP 0603149B2 EP 93890223 A EP93890223 A EP 93890223A EP 93890223 A EP93890223 A EP 93890223A EP 0603149 B2 EP0603149 B2 EP 0603149B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- machine

- suction

- drive

- longitudinal direction

- suction nozzle

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000010276 construction Methods 0.000 claims 5

- 238000006073 displacement reaction Methods 0.000 claims 3

- 230000015572 biosynthetic process Effects 0.000 description 3

- 239000004575 stone Substances 0.000 description 3

- 239000013590 bulk material Substances 0.000 description 2

- 238000004140 cleaning Methods 0.000 description 2

- 230000006978 adaptation Effects 0.000 description 1

- 235000019504 cigarettes Nutrition 0.000 description 1

- 238000011109 contamination Methods 0.000 description 1

- 238000001914 filtration Methods 0.000 description 1

- 230000007115 recruitment Effects 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01B—PERMANENT WAY; PERMANENT-WAY TOOLS; MACHINES FOR MAKING RAILWAYS OF ALL KINDS

- E01B27/00—Placing, renewing, working, cleaning, or taking-up the ballast, with or without concurrent work on the track; Devices therefor; Packing sleepers

- E01B27/06—Renewing or cleaning the ballast in situ, with or without concurrent work on the track

- E01B27/10—Renewing or cleaning the ballast in situ, with or without concurrent work on the track without taking-up track

- E01B27/102—Removing unwanted material without removing the ballast

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01H—STREET CLEANING; CLEANING OF PERMANENT WAYS; CLEANING BEACHES; DISPERSING OR PREVENTING FOG IN GENERAL CLEANING STREET OR RAILWAY FURNITURE OR TUNNEL WALLS

- E01H1/00—Removing undesirable matter from roads or like surfaces, with or without moistening of the surface

- E01H1/08—Pneumatically dislodging or taking-up undesirable matter or small objects; Drying by heat only or by streams of gas; Cleaning by projecting abrasive particles

- E01H1/0827—Dislodging by suction; Mechanical dislodging-cleaning apparatus with independent or dependent exhaust, e.g. dislodging-sweeping machines with independent suction nozzles ; Mechanical loosening devices working under vacuum

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01H—STREET CLEANING; CLEANING OF PERMANENT WAYS; CLEANING BEACHES; DISPERSING OR PREVENTING FOG IN GENERAL CLEANING STREET OR RAILWAY FURNITURE OR TUNNEL WALLS

- E01H8/00—Removing undesirable matter from the permanent way of railways; Removing undesirable matter from tramway rails

Definitions

- the invention relates to a suction machine with a on rail bogies movable, a vacuum generator and a ballast storage Machine frame, one arranged on the end of this Driving cabin and a height-adjustable suction nozzle, which over the the driving cabin having machine end cantilevered and by a Exhaust pipe located above the cab connected to the ballast storage is, which on a connected to the machine frame Supported suction nozzle each with its own, independent drives of the supporting structure which can be acted upon from one another in accordance with a XYZ coordinate system in one in the machine longitudinal direction and in one is designed to be adjustable in the normal direction.

- Such a known suction machine has one on a wagon platform parked excavator with a rotatable around a vertical axis Crane boom on. This can be tilted and swiveled by additional drives

- the crane boom is equipped with a flexible suction nozzle Suction pipe connected.

- this known version has the Disadvantage that the suction of a threshold compartment from one to the other Threshold end to be moved suction nozzle describes an arc and therefore constant recruitment is required.

- Another suction machine is known from DE 21 36 306 A.

- the on The suction nozzle attached to the projecting suction tube is equipped with vibrators Loosening of the ballast stones to be extracted.

- the suction pipe itself is above by a rotating and swiveling boom supported a driving cabin.

- Another suction machine is already through the German utility model 90 00 529 known, two suction nozzles on one by auxiliary rail trolleys movable trucks are height-adjustable attached to the track.

- the two suction nozzles are at a fixed distance from each other in the cross-machine direction arranged and are used in the work at a constant low Distance to the surface of the track in order to prevent contamination, such as B. remains of cigarettes or the like.

- ballast Vacuum the track bed using cross-adjustable and height-adjustable suction nozzles. These are rotating tools for loosening encrusted Associated with crushed stone.

- the suction nozzles are relative to the machine frame arranged longitudinally displaceable. After centering over one Threshold compartment, the suction nozzles are lowered into the ballast, the Ballast also vacuumed in the adjacent areas below the sleepers becomes. The whole gravel extracted in this way Ballast bedding is fed to a cleaning system and then in cleaned state again thrown onto the exposed formation.

- the German utility model 82 36 650 is another suction machine known with a height-adjustable suction nozzle.

- the one about this Suction nozzle taken from the track grate or next to the track grate Ballast stones are led into a collecting container and from there placed on a vibrating floor for cleaning.

- the lower end of the suction nozzle is connected to a specially designed rubber apron.

- the object of the present invention is now to create a Suction machine of the type described in the introduction, which with unrestricted Visibility from the cab to the suction nozzle is as powerful as possible Evacuation especially of threshold subjects enabled.

- Such training allows for a relatively simple design improved control of the suction nozzle according to XYZ coordinates, so that with a faster and more targeted positioning of the suction nozzle a significant improvement in suction power can be achieved. This is especially for the suction of the ballast from a variety of narrow limited areas, such as B. threshold subjects, of great advantage.

- the Targeted control of the suction nozzle can be advantageous without any restriction Way to be done in the cab.

- the training of the support structure according to claims 4, 5 and 6 has an even better guidance and adaptation of the suction nozzle to during suction to avoid immediate obstacles.

- the ballast is also below Areas that are located in threshold areas can be extracted more specifically.

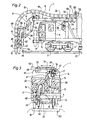

- the suction machine 1 shown in Fig. 1 is with a on rail bogies 2 movable machine frame having a vacuum generator 3 4 provided. This has driver cabs 5 arranged at the ends a central control device 6. Furthermore, the suction machine 1 equipped with a motor 7 for the energy supply and a travel drive 8.

- support structure 11 For guiding and supporting one machine end 9 projecting suction nozzle 10 is on the machine frame 4 attached support structure 11 is provided. This consists of two in the machine longitudinal direction arranged in a row and under formation a joint with a vertical swivel axis 12 and a swivel drive 13 articulated with each other connected parts 14.15 together. This The supporting structure is described in more detail in FIG. 2.

- the Suction nozzle 10 opposite end 49 vertically is slidably mounted to the machine longitudinal direction.

- Ballast storage 17.18 each with an unloading opening 19 provided.

- filter chambers 20 with closable discharge openings 21 are located between these ballast stores 17, 18 and the vacuum generator 3 .

- a machine longitudinal direction Conveyor belt 22 is provided with a rotary drive 23.

- An end further distanced from the suction nozzle 10 24 of this conveyor belt 22 is above the end rail chassis attached to the machine frame 4 2 and positioned below the cab 5.

- the End 24 of the conveyor belt 22 is one with a Receiving end 25 below the conveyor belt 22 arranged transfer conveyor 26 assigned. This is on a by a rotary drive 27 by one vertical axis of rotation 28 rotatable on the machine frame 4 attached support 29 stored and in relation to this by a drive 30 in the machine longitudinal direction - In one shown in dash-dotted lines Transfer position - designed to be displaceable.

- One of those Transfer conveyor belt 26 assigned conveyor drive 31 can be loaded in either direction of rotation.

- a Drive 32 telescopically extendable in the machine longitudinal direction Main beam 33 formed.

- This is in his from the suction nozzle 10 more distant end region by a drive 34 transversely to the machine longitudinal direction horizontal cross guides 35 slidably mounted and points in its other End area the joint point with the pivot axis 12 on.

- Support structure 11 consists essentially of one through the pivot axis 12 articulated with the Main carrier 33 connected support body 36 and one at this fixed parallelogram linkage 37 together. This is in turn with a height guide 38 connected on which a second support body 39 through a first height adjustment drive 40 adjustable in height is stored. The height adjustment of the parallelogram linkage 37 together with the suction nozzle 10 takes place through a second height adjustment drive 41.

- the lower end of the second support body 39 is provided with a rotator 42 connected, through the one connected to the suction nozzle 10 Support plate 43 about a vertical axis of rotation 44 is rotatable.

- the suction nozzle 10 is vertical to the nozzle or machine longitudinal direction or horizontally extending pivot axis 45 pivotable with the support plate 43 connected.

- a Nozzle swivel drive 46 is provided to pivot the Suction nozzle around said pivot axis 45 .

- each of the two Ballast store 17, 18 has its own intake opening 47.48.

- the end facing away from the suction nozzle 10 49 of the suction pipe 16 is by a drive 50 from the first to the second suction opening 47,48 stored.

- This is one with the end 49 of the suction tube 16 and flange connected to the drive 50 51 in one of the two suction openings 47, 48 with one another connecting link guide 52 stored.

- All on the supporting structure supporting the suction nozzle 10 11 drives are by the in the control device 6 located in the driving cabin 5 can be controlled.

- the suction nozzle 10 can Central control device 6 directly from the cab 5 off correctly positioned and lowered for suction become. It is conveniently done with the help of second height adjustment drive 41 a first, approximate Lowering the suction nozzle 10 into the desired one Height, which is then using the first height adjustment drive 40 is exactly adjustable.

- the rotator 42 is the suction nozzle by a total of 180 ° about the axis of rotation 44 pivotable, which means in particular in connection with an additional swivel by the nozzle swivel drive 46 also below a threshold 54 located gravel can be extracted.

- the positioning the suction nozzle 10 can by means of the drives 33, 34 and 40 and 41 in a simple manner according to XYZ coordinates be performed.

- Swivel drives 13 is the suction nozzle 10 in a side area adjacent to track 53 can be pivoted.

- the end 49 of the suction tube 16 to the neighboring Ballast storage 17 or 18 moves. Subsequently takes place parallel to the ballast intake in the empty ballast store emptying the filled one Ballast storage 17 or 18 by opening the corresponding Discharge opening 19. That way emptied gravel is applied to the drive 23 via the conveyor belt 22 and the transfer conveyor belt 26 to one connected to the suction machine 1 Loading car 55 transported and stored. Simultaneously with the automatic loading the drive 50 is also automatic Reversal of the intake flow from one of the first Filter chamber 20 associated suction opening 56 to a the second filter chamber 20 associated suction opening 57 or vice versa. The emptying of the two Filter chambers 20 are carried out in the same way as those of the ballast stores 17, 18 via the conveyor belt 22 and the transfer conveyor belt 26.

- the transfer conveyor belt is moved 26 with the help of the drive 30 in the Transfer position shown in dash-dotted lines.

- the conveyor drive 31 is in the opposite direction acted on, so that of the ballast storage 17 or 18 gravel thrown onto the conveyor belt 22 from this to the retracted transfer conveyor 26 is transported, this the gravel in the direction indicated by an arrow 58 the track 53 sheds.

- the projecting part becomes 15 for the transfer journey the support structure 11 in the dash-dotted in Fig. 2 Lines indicated position to the side of the Driving cabin 5 spent within the clearance prototype. This is for those in the cab 5 Operator an unobstructed view of the track ensures.

Landscapes

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Engineering & Computer Science (AREA)

- Machines For Laying And Maintaining Railways (AREA)

- Massaging Devices (AREA)

- Magnetic Bearings And Hydrostatic Bearings (AREA)

- Separation By Low-Temperature Treatments (AREA)

- Cleaning In General (AREA)

- Motor Or Generator Cooling System (AREA)

- Details Of Reciprocating Pumps (AREA)

- Medicines That Contain Protein Lipid Enzymes And Other Medicines (AREA)

- Medicines Containing Material From Animals Or Micro-Organisms (AREA)

- Disintegrating Or Milling (AREA)

Abstract

Description

Die Erfindung betrifft eine Saugmaschine mit einem auf Schienenfahrwerken verfahrbaren, einen Unterdruckerzeuger sowie einen Schotterspeicher aufweisenden Maschinenrahmen, einer endseitig auf diesem angeordneten Fahrkabine und einer höhenverstellbaren Saugdüse, die über das die Fahrkabine aufweisende Maschinenende vorkragend angeordnet und durch ein über der Fahrkabine befindliches Absaugrohr mit dem Schotterspeicher verbunden ist, wobei die auf einer mit dem Maschinenrahmen verbundenen Tragkonstruktion abgestützte Saugdüse jeweils mittels eigener, unabhängig voneinander beaufschlagbarer Antriebe der Tragkonstruktion gemäß einem XYZ-Korrdinatensystem in einer in Maschinenlängsrichtung sowie in einer normal dazu verlaufenden Richtung verstellbar ausgebildet ist.The invention relates to a suction machine with a on rail bogies movable, a vacuum generator and a ballast storage Machine frame, one arranged on the end of this Driving cabin and a height-adjustable suction nozzle, which over the the driving cabin having machine end cantilevered and by a Exhaust pipe located above the cab connected to the ballast storage is, which on a connected to the machine frame Supported suction nozzle each with its own, independent drives of the supporting structure which can be acted upon from one another in accordance with a XYZ coordinate system in one in the machine longitudinal direction and in one is designed to be adjustable in the normal direction.

Eine derartige bekannte Saugmaschine weist einen auf einer Waggonplattform abgestellten Kleinbagger mit einem um eine vertikale Achse drehbaren Kranausleger auf. Dieser durch zusätzliche Antriebe höhen- und seitenverschwenkbare Kranausleger ist mit einem eine Saugdüse aufweisenden flexiblen Absaugrohr verbunden. Diese bekannte Ausführung hat allerdings den Nachteil, daß die zum Aussaugen eines Schwellenfaches von einem zum anderen Schwellenende zu bewegende Saugdüse dabei einen Kreisbogen beschreibt und daher eine ständige Neueinstellung erforderlich ist.Such a known suction machine has one on a wagon platform parked excavator with a rotatable around a vertical axis Crane boom on. This can be tilted and swiveled by additional drives The crane boom is equipped with a flexible suction nozzle Suction pipe connected. However, this known version has the Disadvantage that the suction of a threshold compartment from one to the other Threshold end to be moved suction nozzle describes an arc and therefore constant recruitment is required.

Eine weitere Saugmaschine ist durch die DE 21 36 306 A bekannt. Die auf dem vorkragenden Absaugrohr befestigte Saugdüse ist mit Vibratoren zur Lockerung der abzusaugenden Schottersteine ausgestattet. Das Absaugrohr selbst ist durch einen verdreh- und verschwenkbaren Ausleger oberhalb einer Fahrkabine abgestützt.Another suction machine is known from DE 21 36 306 A. The on The suction nozzle attached to the projecting suction tube is equipped with vibrators Loosening of the ballast stones to be extracted. The suction pipe itself is above by a rotating and swiveling boom supported a driving cabin.

Eine andere Saugmaschine ist bereits durch das Deutsche Gebrauchsmuster 90 00 529 bekannt, wobei zwei Saugdüsen auf einem durch Hilfsschienenfahrwerke am Gleis verfahrbaren Lastkraftwagen höhenverstellbar befestigt sind. Die beiden Saugdüsen sind in Maschinenquerrichtung im fixen Abstand zueinander angeordnet und werden im Arbeitseinsatz in einem konstanten geringen Abstand zur Gleisoberfläche geführt, um von dieser Verunreinigungen, wie z. B. Zigaretten reste oder dergleichen, abzusaugen. Another suction machine is already through the German utility model 90 00 529 known, two suction nozzles on one by auxiliary rail trolleys movable trucks are height-adjustable attached to the track. The two suction nozzles are at a fixed distance from each other in the cross-machine direction arranged and are used in the work at a constant low Distance to the surface of the track in order to prevent contamination, such as B. remains of cigarettes or the like.

Durch die GB 2 172 326 A ist es auch bereits bekannt, den Schotter einer

Gleisbettung mit Hilfe von quer- und höhenverstellbaren Saugdüsen abzusaugen.

Diesen sind jeweils rotierende Werkzeuge zur Auflockerung von verkrustetem

Schotter zugeordnet. Um eine kontinuierliche Vorwärtsbewegung

der Saugmaschine zu ermöglichen, sind die Saugdüsen relativ zum Maschinenrahmen

längsverschiebbar angeordnet. Nach Zentrierung über einem

Schwellenfach werden die Saugdüsen in den Schotter abgesenkt, wobei der

Schotter auch in den angrenzenden Bereichen unterhalb der Schwellen abgesaugt

wird. Der auf diese Weise zur Gänze abgesaugte Schotter einer

Schotterbettung wird einer Reinigungsanlage zugeführt und anschließend im

gereinigten Zustand wiederum auf das freigelegte Planum abgeworfen.From

Durch das Deutsche Gebrauchsmuster 82 36 650 ist eine weitere Saugmaschine mit einer höhenverstellbaren Saugdüse bekannt. Die über diese Saugdüse aus dem Gleisrost oder neben dem Gleisrost aufgenommenen Schottersteine werden in einen Sammelbehälter geführt und von diesem aus auf einen Rüttelboden zur Reinigung abgegeben. Das untere Ende der Saugdüse ist mit einer speziell gestalteten Gummischürze verbunden.The German utility model 82 36 650 is another suction machine known with a height-adjustable suction nozzle. The one about this Suction nozzle taken from the track grate or next to the track grate Ballast stones are led into a collecting container and from there placed on a vibrating floor for cleaning. The lower end of the suction nozzle is connected to a specially designed rubber apron.

Weitere Saugmaschinen sind noch durch die US 4 741 072, DE 41 08 673 und das Deutsche Gebrauchsmuster 89 13 731.0 bekannt.Further suction machines are also known from US 4,741,072, DE 41 08 673 and the German utility model 89 13 731.0 known.

Die Aufgabe der vorliegenden Erfindung besteht nun in der Schaffung einer Saugmaschine der eingangs beschriebenen Art, die bei uneingeschränkter Einsehbarkeit von der Fahrkabine auf die Saugdüse eine möglichst leistungsfähige Räumung insbesondere von Schwellenfächern ermöglicht.The object of the present invention is now to create a Suction machine of the type described in the introduction, which with unrestricted Visibility from the cab to the suction nozzle is as powerful as possible Evacuation especially of threshold subjects enabled.

Diese Aufgabe wird erfindungsgemäß mit der eingangs genannten Saugmaschine dadurch gelöst, daß die Tragkonstruktion einen in Maschinenlängsrichtung verlaufenden, durch den Antrieb teleskopisch verlängerbaren Hauptträger aufweist, der in seinem von der Saugdüse weiter entfernten Endbereich durch den Antrieb auf quer zur Maschinenlängsrichtung verlaufenden horizontalen Querführungen verschiebbar gelagert ist. This object is achieved with the suction machine mentioned at the beginning solved in that the support structure one in the machine longitudinal direction extending main beam which can be extended telescopically by the drive has in its end region further away from the suction nozzle thanks to the drive on horizontal lines running transversely to the machine longitudinal direction Cross guides is slidably mounted.

Eine derartige Ausbildung ermöglicht bei relativ einfacher konstruktiver Gestaltung eine verbesserte Steuerung der Saugdüse gemäß XYZ-Koordinaten, so daß mit einer rascheren und gezielteren Positionierung der Saugdüse eine wesentliche Verbesserung der Saugleistung erzielbar ist. Dies ist insbesondere für die Absaugung des Schotters aus einer Vielzahl von eng begrenzten Bereichen, wie z. B. Schwellenfächern, von großem Vorteil. Die gezielte Steuerung der Saugdüse kann ohne jedwede Einschränkung in vorteilhafter Weise in der Fahrkabine durchgeführt werden.Such training allows for a relatively simple design improved control of the suction nozzle according to XYZ coordinates, so that with a faster and more targeted positioning of the suction nozzle a significant improvement in suction power can be achieved. This is especially for the suction of the ballast from a variety of narrow limited areas, such as B. threshold subjects, of great advantage. The Targeted control of the suction nozzle can be advantageous without any restriction Way to be done in the cab.

Die Ausbildung der Tragkonstruktion gemäß den Ansprüchen 2 und 3 ermöglicht

auch eine problemlose Verschwenkung der Saugdüse in den Schwellenvorkopfbereich,

wobei weiterhin eine uneingeschränkte Verstellung gemäß

den XYZ-Koordinaten durchführbar ist.The formation of the support structure according to

Die Weiterbildung der Tragkonstruktion nach den Ansprüchen 4, 5 und 6 hat

eine noch bessere Führung und Anpassung der Saugdüse an bei der Absaugung

zu umgehende Hindernisse zur Folge. Durch eine Schrägstellung der

Saugdüse mit Hilfe des Rotators ist der Schotter auch in unterhalb der

Schwellen gelegenen Bereichen gezielter absaugbar.The training of the support structure according to

Die Weiterbildung der Saugmaschine nach den Ansprüchen 7 und 8 hat den

besonderen Vorteil, daß die beiden Schotterspeicher unter Erzielung einer

kontinuierlichen Ansaugung abwechselnd entleerbar sind.The development of the suction machine according to

Schließlich ermöglicht die Weiterbildung nach den Ansprüchen 9, 10, und 11

einen leistungsfähigen Abtransport des angesaugten Schüttgutes auf nachfolgende

Speicherwagen. Mit der wahlweisen Beaufschlagbarkeit des Förderantriebes

in beiden Drehrichtungen ist das angesaugte Schüttgut bedarfsweise

mit Hilfe des Übergabeförderbandes wiederum auf das Gleis abwerfbar.Finally, the training according to

Im folgenden wird die Erfindung anhand in der Zeichnung dargestellter Ausführungsbeispiele näher beschrieben. In the following the invention with reference to exemplary embodiments shown in the drawing described in more detail.

Es zeigen:

Die in Fig. 1 ersichtliche Saugmaschine 1 ist mit einem auf Schienenfahrwerken

2 verfahrbaren, einen Unterdruckerzeuger 3 aufweisenden Maschinenrahmen

4 versehen. Dieser weist endseitig angeordnete Fahrkabinen 5 mit

einer zentralen Steuereinrichtung 6 auf. Desweiteren ist die Saugmaschine

1 mit einem Motor 7 für die Energieversorgung und einem Fahrantrieb 8 ausgestattet. The

Zur Führung und Abstützung einer über ein Maschinenende

9 vorkragenden Saugdüse 10 ist eine am Maschinenrahmen

4 befestigte Tragkonstruktion 11 vorgesehen.

Diese setzt sich aus zwei in Maschinenlängsrichtung

hintereinander angeordneten und unter Bildung

einer Gelenkstelle mit einer vertikalen Schwenkachse

12 und einem Schwenkantrieb 13 gelenkig miteinander

verbundenen Teilen 14,15 zusammen. Diese

Tragkonstruktion wird in Fig. 2 noch näher beschrieben.For guiding and supporting one machine end

9 projecting

An die mit dem Teil 15 verbundene Saugdüse 10

schließt ein flexibles Absaugrohr 16 an, dessen der

Saugdüse 10 gegenüberliegendes Ende 49 senkrecht

zur Maschinenlängsrichtung verschiebbar gelagert ist.

Zur Speicherung des angesaugten Schotters sind zwei

in Maschinenquerrichtung einander gegenüberliegende

Schotterspeicher 17,18 mit jeweils einer Entladeöffnung

19 vorgesehen. Zwischen diesen Schotterspeichern

17,18 und dem Unterdruckerzeuger 3 befinden sich

zwei Filterkammern 20 mit verschließbaren Entladeöffnungen

21.To the

Unterhalb der Entladeöffnungen 19 der beiden

Schotterspeicher 17,18 und der Entladeöffnungen 21

der Filterkammern 20 sowie unterhalb des Maschinenrahmens

4 ist ein in Maschinenlängsrichtung verlaufendes

Förderband 22 mit einem Drehantrieb 23 vorgesehen.

Ein von der Saugdüse 10 weiter distanziertes Ende

24 dieses Förderbandes 22 ist oberhalb des endseitig

am Maschinenrahmen 4 befestigten Schienenfahrwerkes

2 und unterhalb der Fahrkabine 5 positioniert. Dem

genannten Ende 24 des Förderbandes 22 ist ein mit einem

Aufnahmeende 25 unterhalb des Förderbandes 22

angeordnetes Übergabeförderband 26 zugeordnet.

Dieses ist auf einer durch einen Drehantrieb 27 um eine

vertikale Drehachse 28 drehbar am Maschinenrahmen

4 befestigten Abstützung 29 gelagert und in bezug auf

diese durch einen Antrieb 30 in Maschinenlängsrichtung

- in eine in strichpunktierten Linien dargestellte

Überstellposition - verschiebbar ausgebildet. Ein dem

Übergabeförderband 26 zugeordneter Förderantrieb 31

ist wahlweise in beiden Drehrichtungen beaufschlagbar.Below the

Wie in Fig. 2 ersichtlich, ist der über der Fahrkabine

5 befindliche Teil 14 der Tragkonstruktion 11 aus einem

in Maschinenlängsrichtung verlaufenden, durch einen

Antrieb 32 in Maschinenlängsrichtung teleskopisch verlängerbaren

Hauptträger 33 gebildet. Dieser ist in seinem

von der Saugdüse 10 weiter entfernten Endbereich

durch einen Antrieb 34 auf quer zur Maschinenlängsrichtung

verlaufenden horizontalen Querführungen 35

verschiebbar gelagert und weist in seinem anderen

Endbereich die Gelenkstelle mit der Schwenkachse 12

auf.As can be seen in Fig. 2, that is above the

Der vor der Fahrkabine 5 befindliche Teil 15 der

Tragkonstruktion 11 setzt sich im wesentlichen aus einem

durch die Schwenkachse 12 gelenkig mit dem

Hauptträger 33 verbundenen Tragkörper 36 und einer

an diesem fixierten Parallelogrammanlenkung 37 zusammen.

Diese ist wiederum mit einer Höhenführung

38 verbunden, auf der ein zweiter Tragkörper 39 durch

einen ersten Höhenverstellantrieb 40 höhenverstellbar

gelagert ist. Die Höhenverstellung der Parallelogrammanlenkung

37 mitsamt der Saugdüse 10 erfolgt durch

einen zweiten Höhenverstellantrieb 41. Das untere Ende

des zweiten Tragkörpers 39 ist mit einem Rotator 42

verbunden, durch den eine mit der Saugdüse 10 verbundene

Tragplatte 43 um eine vertikale Drehachse 44

verdrehbar ist. Die Saugdüse 10 ist über eine senkrecht

zur Düsen- oder Maschinenlängsrichtung bzw. horizontal

verlaufende Schwenkachse 45 verschwenkbar mit

der Tragplatte 43 verbunden. Zur Verschwenkung der

Saugdüse um die genannte Schwenkachse 45 ist ein

Düsenschwenkantrieb 46 vorgesehen.The

Wie in Fig. 3 ersichtlich, weist jeder der beiden

Schotterspeicher 17,18 eine eigene Ansaugöffnung

47,48 auf. Das von der Saugdüse 10 abgewandte Ende

49 des Absaugrohres 16 ist durch einen Antrieb 50 von

der ersten zur zweiten Ansaugöffnung 47,48 verschiebbar

gelagert. Dazu ist ein mit dem Ende 49 des Absaugrohres

16 und mit dem Antrieb 50 verbundener Flansch

51 in einer die beiden Ansaugöffnungen 47,48 miteinander

verbindenden Kulissenführung 52 gelagert.

Sämtliche auf der die Saugdüse 10 abstützenden Tragkonstruktion

11 befindlichen Antriebe sind durch die in

der Fahrkabine 5 befindliche Steuereinrichtung 6 steuerbar.As can be seen in Fig. 3, each of the two

Ballast

Wie in Fig. 4 ersichtlich, ergibt sich aus der speziellen

Tragkonstruktion 11 ein sehr weiter, durch eine

strichpunktierte Begrenzungslinie angedeuteter Einsatzbereich,

in dem problemlos auch seitlich neben einem

Gleis 53 befindlicher Schotter absaugbar ist.As can be seen in Fig. 4, the special

Support structure 11 a very wide, by a

dash-dotted boundary line indicated area of application,

in the side and next to one

Im Arbeitseinsatz kann die Saugdüse 10 über die

zentrale Steuereinrichtung 6 direkt von der Fahrkabine

5 aus richtig positioniert und zur Absaugung abgesenkt

werden. Dabei erfolgt zweckmäßigerweise mit Hilfe des

zweiten Höhenverstellantriebes 41 eine erste, annähernde

Absenkung der Saugdüse 10 in die gewünschte

Höhe, die dann mit Hilfe des ersten Höhenverstellantriebes

40 exakt einstellbar ist. Durch den Rotator 42 ist

die Saugdüse um insgesamt 180° um die Drehachse 44

verschwenkbar, wodurch insbesondere in Verbindung

mit einer zusätzlichen Verschwenkung durch den Düsenschwenkantrieb

46 auch unterhalb einer Schwelle

54 befindlicher Schotter absaugbar ist. Die Positionierung

der Saugdüse 10 kann mit Hilfe der Antriebe 33, 34

und 40 bzw. 41 in einfacher Weise entsprechend XYZ-Koordinaten

durchgeführt werden. Mit Hilfe der

Schwenkantriebe 13 ist die Saugdüse 10 in einen seitlich

neben dem Gleis 53 befindlichen Bereich verschwenkbar.In work, the

Sobald einer der beiden Schotterspeicher 17 bzw.

18 gefüllt ist, erfolgt durch einen entsprechenden Sensor

eine automatische Beaufschlagung des Antriebes

50, der das Ende 49 des Absaugrohres 16 zum benachbarten

Schotterspeicher 17 bzw. 18 verschiebt. Anschließend

erfolgt parallel zur Schotteransaugung in

den leeren Schotterspeicher eine Entleerung des gefüllten

Schotterspeichers 17 bzw. 18 durch Öffnen der entsprechenden

Entladeöffnung 19. Der auf diese Weise

entleerte Schotter wird unter Beaufschlagung des Antriebes

23 über das Förderband 22 und das Übergabeförderband

26 auf einen an die Saugmaschine 1 angeschlossenen

Verladewagen 55 transportiert und gespeichert.

Gleichzeitig mit der automatischen Beaufschlagung

des Antriebes 50 erfolgt auch eine automatische

Umsteuerung des Ansaugstromes von einer der ersten

Filterkammer 20 zugeordneten Ansaugöffnung 56 zu einer

der zweiten Filterkammer 20 zugeordneten Ansaugöffnung

57 bzw. umgekehrt. Die Entleerung der beiden

Filterkammern 20 erfolgt ebenso wie jene der Schotterspeicher

17,18 über das Förderband 22 und das Übergabeförderband

26.As soon as one of the two

Für den Fall, daß der angesaugte und infolge der

Filterung der Absaugluft gegebenenfalls auch gereinigte

Schotter zur Einschotterung eines Gleisabschnittes

benötigt wird, erfolgt eine Verschiebung des Übergabeförderbandes

26 mit Hilfe des Antriebes 30 in die mit

strichpunktierten Linien dargestellte Überstellposition.

Parallel dazu wird der Förderantrieb 31 in die Gegenrichtung

beaufschlagt, so daß der vom Schotterspeicher

17 bzw. 18 auf das Förderband 22 abgeworfene Schotter

von diesem auf das eingefahrene Übergabeförderband

26 transportiert wird, wobei dieses den Schotter

in der durch einen Pfeil 58 angedeuteten Richtung auf

das Gleis 53 abwirft.In the event that the intake and as a result of

Filtering of the suction air, if necessary, also cleaned

Ballast for ballasting a section of track

is needed, the transfer conveyor belt is moved

26 with the help of the

Für die Überstellfahrt wird der vorkragende Teil 15

der Tragkonstruktion 11 in die in Fig. 2 mit strichpunktierten

Linien angedeutete Position seitlich neben der

Fahrkabine 5 innerhalb des Lichtraumprotiles verbracht.

Damit ist für die in der Fahrkabine 5 befindliche

Bedienungsperson eine uneingeschränkte Sicht auf

das Gleis gewährleistet.The projecting part becomes 15 for the transfer journey

the

Claims (11)

- A suction machine comprising a machine frame (4), designed for travelling on on-track undercarriages (2) and having a vacuum generator (3) and a ballast store (17,18), a driver's cab (5) arranged at the end of the said machine frame and a vertically adjustable suction nozzle (10) which is arranged so as to project over the machine end (9) having the driver's cab (5) and which is connected to the ballast store (17,18) by a suction pipe (16) located above the driver's cab (5), with the suction nozzle (10), supported on a supporting construction (11) connected to the machine frame (4), being designed for adjustment by means of respective separate drives (32,34,40) of the supporting construction (11), operable independently of one another, in accordance with an XYZ coordinate system in a direction running in the longitudinal direction of the machine and in a direction running perpendicularly thereto, characterized in that the supporting construction (11) has a main beam (33), extending in the longitudinal direction of the machine and extendable telescopically by means of the drive (32), which in its end region further away from the suction nozzle (10) is mounted for displacement by means of the drive (34) on horizontal transverse guides (35) extending transversely to the longitudinal direction of the machine.

- A machine according to claim 1, characterized in that the supporting construction (11) is composed of two parts (14,15), arranged one following the other in the longitudinal direction of the machine and joined together in an articulated manner, forming an articulation point with a vertical pivot axis (12) and a pivot drive (13).

- A machine according to claim 1 or 2, characterized in that the main beam (33), extending in the longitudinal direction of the machine, is arranged above the driver's cab (5).

- A machine according to claim 1, 2 or 3, characterized in that the suction nozzle (10) is vertically adjustable on the one hand by means of a parallel linkage (37) with a vertical adjustment drive (41) and on the other hand by means of a vertical guide (38), fixed to the parallelogram linkage (37), with a further vertical adjustment drive (40).

- A machine according to one of claims 1 to 4, characterized in that the suction nozzle (10) is pivotable in its region adjoining the suction pipe (16) by means of a rotator (42) about a vertical axis of rotation (44).

- A machine according to claim 5, characterized in that the rotator (42) is attached to a support plate (43), connected to the supporting construction (11), on which the suction nozzle (10) is mounted for rotation by means of a nozzle pivot drive (46) about a pivot axis (45) extending horizontally or perpendicularly to the longitudinal direction of the nozzle.

- A machine according to one of claims 1 to 6, characterized in that two ballast stores (17,18) are provided, arranged side by side in a direction extending perpendicularly to the longitudinal direction of the machine, one end (49) of the suction pipe (16) facing away from the suction nozzle (10) being mounted for displacement by means of a drive (50) from a suction opening (47) associated with the first ballast store (17) to a second suction opening (48), remote from the said first suction opening, associated with the second ballast store (18).

- A machine according to claim 7, characterized by a connecting link guide (52) interconnecting the two suction openings (47,48), in which a flange (51) connected to the end (49) of the suction pipe (16) and to the drive (50) is mounted for displacement transversely to the longitudinal direction of the machine.

- A machine according to one of claims 1 to 8, characterized in that arranged underneath discharge openings (19) of the ballast stores (17,18) and underneath the machine frame (4) is a conveyor belt (22), running in the longitudinal direction of the machine, whose end (24) situated further away from the suction nozzle (10) is positioned above the on-track undercarriage (2), attached to the end of the machine frame (4), and underneath a further driver's cab (5).

- A machine according to claim 9, characterized in that associated with the end (24) of the conveyor belt (22) is a transfer conveyor belt (26), arranged with its intake end (25) underneath the conveyor belt (22), which is mounted on a support (29) attached to the machine frame (4) for rotation by means of a rotary drive (27) about a vertical axis of rotation (28), and which is designed to be displaceable with respect to this support by means of a drive (30) in the longitudinal direction of the machine.

- A machine according to claim 10, characterized in that a conveyor drive (31) associated with the transfer conveyor belt (26) may be operated in either direction of rotation, as desired.

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT249592 | 1992-12-16 | ||

| AT2495/92 | 1993-01-29 | ||

| AT174993 | 1993-08-31 | ||

| AT1749/93 | 1993-08-31 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0603149A1 EP0603149A1 (en) | 1994-06-22 |

| EP0603149B1 EP0603149B1 (en) | 1996-08-28 |

| EP0603149B2 true EP0603149B2 (en) | 1999-04-07 |

Family

ID=25596708

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP93890223A Expired - Lifetime EP0603149B2 (en) | 1992-12-16 | 1993-11-12 | Vacuum machine |

Country Status (10)

| Country | Link |

|---|---|

| EP (1) | EP0603149B2 (en) |

| JP (1) | JP3188575B2 (en) |

| CN (1) | CN1052772C (en) |

| AT (1) | ATE141979T1 (en) |

| AU (1) | AU667591B2 (en) |

| CZ (1) | CZ279012B6 (en) |

| DE (2) | DE9320980U1 (en) |

| FI (1) | FI107822B (en) |

| HU (1) | HU215742B (en) |

| SK (1) | SK280231B6 (en) |

Families Citing this family (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE59504300D1 (en) * | 1994-04-18 | 1999-01-07 | Plasser Bahnbaumasch Franz | Suction machine |

| AT406060B (en) * | 1997-12-19 | 2000-02-25 | Plasser Bahnbaumasch Franz | MACHINE FOR SUCTIONING GRAVEL |

| DE10059729A1 (en) * | 2000-11-30 | 2002-06-13 | Stefan Mattes | Process for cleaning stones |

| CN101421461A (en) * | 2006-04-10 | 2009-04-29 | 马蒂萨材料工业股份有限公司 | Storage car |

| AU2007335261A1 (en) * | 2006-12-21 | 2008-06-26 | J.D. Rail Machines Australia Pty Ltd | Rail ballast servicing vehicle |

| AT508931B1 (en) * | 2010-03-30 | 2011-05-15 | Plasser Bahnbaumasch Franz | SUCTION MACHINE FOR SUCTION OF BREATHING GRILL OF A TRAIL |

| DE102010055722B4 (en) * | 2010-12-22 | 2015-10-22 | Continental Automotive Gmbh | cleaning device |

| CN102363954B (en) * | 2011-11-19 | 2013-08-21 | 昆明中铁大型养路机械集团有限公司 | Railway ballast bed side dirt blowing and sucking device |

| CN103334398B (en) * | 2013-07-25 | 2016-01-13 | 武汉优力汽车技术发展有限公司 | There is the road-sweeper of floated nozzle unit |

| TR201810302T4 (en) | 2014-05-20 | 2018-08-27 | Plasser & Theurer Export Von Bahnbaumaschinen Gmbh | Bulk material loading wagon. |

| AT516471B1 (en) * | 2014-10-27 | 2017-02-15 | Hp3 Real Gmbh | Device for conveying material for track construction |

| CN105290869B (en) * | 2015-05-29 | 2017-10-24 | 中国铁建高新装备股份有限公司 | The iron filings milling collection system of rail row rail milling grinding machine |

| CN109731649B (en) * | 2019-01-17 | 2021-04-27 | 徐州专用汽车有限责任公司 | Intelligent automatic classification garbage cleaning vehicle |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4741072A (en) * | 1987-02-17 | 1988-05-03 | Wilkerson Kenneth R | Railroad track cleaner |

| DE4101489A1 (en) * | 1990-02-20 | 1991-08-22 | Josef Nusser | Cleaning machine for surface cleaning appliances - has swivel mounted tool holders to adapt to surface contours |

| US5142732A (en) * | 1990-09-28 | 1992-09-01 | Davis Henry J | Bulk separator for industrial vacuum machine |

| DE4108673A1 (en) * | 1991-03-16 | 1992-09-17 | Helmar Haas | Process for continuous cleaning of railway ballast - involves using hood equipped with compressed air and high pressure water jets, attached to constantly moving vehicle |

-

1993

- 1993-11-12 DE DE9320980U patent/DE9320980U1/en not_active Expired - Lifetime

- 1993-11-12 DE DE59303574T patent/DE59303574D1/en not_active Expired - Fee Related

- 1993-11-12 AT AT93890223T patent/ATE141979T1/en not_active IP Right Cessation

- 1993-11-12 EP EP93890223A patent/EP0603149B2/en not_active Expired - Lifetime

- 1993-11-29 CZ CZ932573A patent/CZ279012B6/en not_active IP Right Cessation

- 1993-12-08 SK SK1383-93A patent/SK280231B6/en unknown

- 1993-12-14 HU HU9303569A patent/HU215742B/en not_active IP Right Cessation

- 1993-12-15 FI FI935649A patent/FI107822B/en not_active IP Right Cessation

- 1993-12-15 AU AU52427/93A patent/AU667591B2/en not_active Ceased

- 1993-12-15 JP JP31496393A patent/JP3188575B2/en not_active Expired - Fee Related

- 1993-12-16 CN CN93112757.2A patent/CN1052772C/en not_active Expired - Fee Related

Non-Patent Citations (1)

| Title |

|---|

| Prospekt "RAILVAC 16000" der Fa. NORDVAC AB, 1991 † |

Also Published As

| Publication number | Publication date |

|---|---|

| SK280231B6 (en) | 1999-10-08 |

| HU215742B (en) | 1999-02-01 |

| HUT66364A (en) | 1994-11-28 |

| CN1052772C (en) | 2000-05-24 |

| AU5242793A (en) | 1994-06-30 |

| ATE141979T1 (en) | 1996-09-15 |

| AU667591B2 (en) | 1996-03-28 |

| SK138393A3 (en) | 1994-07-06 |

| JPH06212603A (en) | 1994-08-02 |

| CZ257393A3 (en) | 1994-07-13 |

| DE59303574D1 (en) | 1996-10-02 |

| CZ279012B6 (en) | 1994-11-16 |

| FI107822B (en) | 2001-10-15 |

| FI935649A (en) | 1994-06-17 |

| EP0603149B1 (en) | 1996-08-28 |

| JP3188575B2 (en) | 2001-07-16 |

| CN1088649A (en) | 1994-06-29 |

| EP0603149A1 (en) | 1994-06-22 |

| DE9320980U1 (en) | 1995-07-20 |

| FI935649A0 (en) | 1993-12-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0426004B1 (en) | Machine for collecting and redistributing ballast | |

| EP0613980B1 (en) | Ballast levelling machine | |

| EP0635082B1 (en) | Machine for sucking up rail ballast | |

| DE2023931C2 (en) | Track renewal train for continuously changing sleepers and / or rails on a track | |

| EP0621371B1 (en) | Railway track renewing or laying machine | |

| EP0603149B2 (en) | Vacuum machine | |

| EP1162311B1 (en) | Apparatus and method for removing an existing railway track and laying a new track | |

| EP1162312B1 (en) | Machine for renewing a railway track | |

| AT400341B (en) | THRESHOLDING MACHINE | |

| DE4127383A1 (en) | MACHINE FOR REPLACING THE SILLS OF A TRACK | |

| SK336692A3 (en) | Device for production of protected layer of plain and method of maintenance of plain | |

| EP0811721B1 (en) | Device for laying railway track | |

| DE4108673A1 (en) | Process for continuous cleaning of railway ballast - involves using hood equipped with compressed air and high pressure water jets, attached to constantly moving vehicle | |

| EP1195468B1 (en) | Machine for renewing a railway track | |

| DE4108743C2 (en) | Track-moving machine for distributing and leveling ballast ballast | |

| DE4341240C2 (en) | Suction machine for suctioning ballast from a ballast bed | |

| EP0663472B1 (en) | Machine for cleaning the ballast of a railway track | |

| DE9213041U1 (en) | Gravel plow | |

| EP0761880B1 (en) | Machine for working the ballast bed of a track | |

| AT404947B (en) | TROLLEYS FOR THE GRADUATION OF A TRACK | |

| EP1081293A2 (en) | Rail-road excavator | |

| DE3607245A1 (en) | Working method and finisher for producing a ballast bed for railway tracks on a formation | |

| AT406060B (en) | MACHINE FOR SUCTIONING GRAVEL | |

| DE202007004544U1 (en) | Rail transporting vehicle, has crawler tracks fastened at longitudinal end of supporting frame that is connected with vehicle frame by rotary drive, where supporting frame is adjustable relative to longitudinal direction of vehicle frame | |

| CH633598A5 (en) | Track-mounted mobile device for taking up the ballast from track skeletons |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT CH DE FR GB IT LI SE |

|

| 17P | Request for examination filed |

Effective date: 19940708 |

|

| 17Q | First examination report despatched |

Effective date: 19940808 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT CH DE FR GB IT LI SE |

|

| REF | Corresponds to: |

Ref document number: 141979 Country of ref document: AT Date of ref document: 19960915 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: DIPL.-ING. ETH H. R. WERFFELI PATENTANWALT |

|

| ITF | It: translation for a ep patent filed | ||

| REF | Corresponds to: |

Ref document number: 59303574 Country of ref document: DE Date of ref document: 19961002 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19960917 |

|

| ET | Fr: translation filed | ||

| PLBQ | Unpublished change to opponent data |

Free format text: ORIGINAL CODE: EPIDOS OPPO |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLBF | Reply of patent proprietor to notice(s) of opposition |

Free format text: ORIGINAL CODE: EPIDOS OBSO |

|

| 26 | Opposition filed |

Opponent name: KROLL-DISAB AB Effective date: 19970526 |

|

| PLBF | Reply of patent proprietor to notice(s) of opposition |

Free format text: ORIGINAL CODE: EPIDOS OBSO |

|

| PLAW | Interlocutory decision in opposition |

Free format text: ORIGINAL CODE: EPIDOS IDOP |

|

| PLAW | Interlocutory decision in opposition |

Free format text: ORIGINAL CODE: EPIDOS IDOP |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 19990407 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AT CH DE FR GB IT LI SE |

|

| GBTA | Gb: translation of amended ep patent filed (gb section 77(6)(b)/1977) | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: AEN Free format text: AUFRECHTERHALTUNG DES PATENTES IN GEAENDERTER FORM |

|

| ITF | It: translation for a ep patent filed | ||

| ET3 | Fr: translation filed ** decision concerning opposition | ||

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20041008 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20041029 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20041118 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20041123 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20041125 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20050121 Year of fee payment: 12 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20051112 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20051112 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20051112 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20051113 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20051130 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20051130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060601 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| EUG | Se: european patent has lapsed | ||

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20051112 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060731 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20060731 |