WO2019196598A1 - Package structure, electronic device and packaging method - Google Patents

Package structure, electronic device and packaging method Download PDFInfo

- Publication number

- WO2019196598A1 WO2019196598A1 PCT/CN2019/078509 CN2019078509W WO2019196598A1 WO 2019196598 A1 WO2019196598 A1 WO 2019196598A1 CN 2019078509 W CN2019078509 W CN 2019078509W WO 2019196598 A1 WO2019196598 A1 WO 2019196598A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- substrate

- package structure

- bonding

- antenna

- region

- Prior art date

Links

- 238000000034 method Methods 0.000 title claims abstract description 24

- 238000004806 packaging method and process Methods 0.000 title claims abstract description 19

- 239000000758 substrate Substances 0.000 claims abstract description 228

- 238000004891 communication Methods 0.000 claims abstract description 7

- 239000000853 adhesive Substances 0.000 claims description 40

- 230000001070 adhesive effect Effects 0.000 claims description 40

- 239000000084 colloidal system Substances 0.000 claims description 39

- 230000002093 peripheral effect Effects 0.000 claims description 10

- 239000011241 protective layer Substances 0.000 claims description 10

- 238000003825 pressing Methods 0.000 claims description 5

- 230000008054 signal transmission Effects 0.000 claims description 5

- 230000000149 penetrating effect Effects 0.000 claims description 4

- 230000005855 radiation Effects 0.000 claims 1

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 12

- 229910052802 copper Inorganic materials 0.000 description 12

- 239000010949 copper Substances 0.000 description 12

- 229910000679 solder Inorganic materials 0.000 description 10

- 239000003292 glue Substances 0.000 description 8

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 description 4

- 239000010410 layer Substances 0.000 description 4

- 229910052709 silver Inorganic materials 0.000 description 4

- 239000004332 silver Substances 0.000 description 4

- 230000000903 blocking effect Effects 0.000 description 3

- 238000002788 crimping Methods 0.000 description 3

- 238000005516 engineering process Methods 0.000 description 3

- 230000002708 enhancing effect Effects 0.000 description 3

- 239000007788 liquid Substances 0.000 description 3

- 239000011345 viscous material Substances 0.000 description 3

- 239000004840 adhesive resin Substances 0.000 description 2

- 229920006223 adhesive resin Polymers 0.000 description 2

- 238000011109 contamination Methods 0.000 description 2

- 238000000206 photolithography Methods 0.000 description 2

- 238000007789 sealing Methods 0.000 description 2

- 238000001179 sorption measurement Methods 0.000 description 2

- 230000006641 stabilisation Effects 0.000 description 2

- 238000011105 stabilization Methods 0.000 description 2

- 238000005728 strengthening Methods 0.000 description 2

- 238000003466 welding Methods 0.000 description 2

- NIXOWILDQLNWCW-UHFFFAOYSA-N acrylic acid group Chemical group C(C=C)(=O)O NIXOWILDQLNWCW-UHFFFAOYSA-N 0.000 description 1

- 239000012790 adhesive layer Substances 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 239000003990 capacitor Substances 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 238000001125 extrusion Methods 0.000 description 1

- 238000001914 filtration Methods 0.000 description 1

- 230000004907 flux Effects 0.000 description 1

- 238000002347 injection Methods 0.000 description 1

- 239000007924 injection Substances 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000003973 paint Substances 0.000 description 1

- 238000007639 printing Methods 0.000 description 1

- 230000003014 reinforcing effect Effects 0.000 description 1

- 239000011347 resin Substances 0.000 description 1

- 229920005989 resin Polymers 0.000 description 1

- 238000005476 soldering Methods 0.000 description 1

- 239000000243 solution Substances 0.000 description 1

- 230000000087 stabilizing effect Effects 0.000 description 1

- 238000006467 substitution reaction Methods 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/50—Assembly of semiconductor devices using processes or apparatus not provided for in a single one of the subgroups H01L21/06 - H01L21/326, e.g. sealing of a cap to a base of a container

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L23/00—Details of semiconductor or other solid state devices

- H01L23/48—Arrangements for conducting electric current to or from the solid state body in operation, e.g. leads, terminal arrangements ; Selection of materials therefor

- H01L23/488—Arrangements for conducting electric current to or from the solid state body in operation, e.g. leads, terminal arrangements ; Selection of materials therefor consisting of soldered or bonded constructions

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L23/00—Details of semiconductor or other solid state devices

- H01L23/58—Structural electrical arrangements for semiconductor devices not otherwise provided for, e.g. in combination with batteries

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01Q—ANTENNAS, i.e. RADIO AERIALS

- H01Q1/00—Details of, or arrangements associated with, antennas

- H01Q1/12—Supports; Mounting means

- H01Q1/22—Supports; Mounting means by structural association with other equipment or articles

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01Q—ANTENNAS, i.e. RADIO AERIALS

- H01Q1/00—Details of, or arrangements associated with, antennas

- H01Q1/12—Supports; Mounting means

- H01Q1/22—Supports; Mounting means by structural association with other equipment or articles

- H01Q1/2283—Supports; Mounting means by structural association with other equipment or articles mounted in or on the surface of a semiconductor substrate as a chip-type antenna or integrated with other components into an IC package

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/10—Bump connectors; Manufacturing methods related thereto

- H01L2224/15—Structure, shape, material or disposition of the bump connectors after the connecting process

- H01L2224/16—Structure, shape, material or disposition of the bump connectors after the connecting process of an individual bump connector

- H01L2224/161—Disposition

- H01L2224/16151—Disposition the bump connector connecting between a semiconductor or solid-state body and an item not being a semiconductor or solid-state body, e.g. chip-to-substrate, chip-to-passive

- H01L2224/16221—Disposition the bump connector connecting between a semiconductor or solid-state body and an item not being a semiconductor or solid-state body, e.g. chip-to-substrate, chip-to-passive the body and the item being stacked

- H01L2224/16225—Disposition the bump connector connecting between a semiconductor or solid-state body and an item not being a semiconductor or solid-state body, e.g. chip-to-substrate, chip-to-passive the body and the item being stacked the item being non-metallic, e.g. insulating substrate with or without metallisation

Definitions

- the present application relates to the field of wireless communications technologies, and in particular, to a package structure, an electronic device, and a packaging method.

- AiP Antenna in Package

- EIRP Equivalent Isotropic Radiated Power

- the technical problem to be solved by the embodiments of the present application is to provide a package structure and a packaging method thereof for improving reliability.

- an embodiment of the present application provides a package structure including a first substrate, a second substrate, and a chip, the second substrate being mounted on an upper surface of the first substrate, the chip being mounted on the first substrate

- the upper surface of the first substrate is provided with spaced protrusions

- the lower surface of the second substrate is provided with spaced protrusions

- the convex portions on the second substrate are opposite to each other and surround the bonding region between the first substrate and the second substrate and an antenna region for accommodating the antenna radiator

- on the second substrate a through hole penetrating through the upper and lower surfaces of the second substrate, the through hole communicating with the bonding region, wherein the through hole and the bonding region are filled with an adhesive colloid

- the bonding area overflows into the through hole, and the adhesive colloid is condensed into a rivet structure in the bonding area and the through hole.

- the second substrate includes at least one through hole penetrating the upper and lower surfaces of the second substrate, and the through hole communicates with the bonding region, and the first substrate and the second substrate are When the substrate is bonded, the pressure of the first substrate is pressed by the second substrate, and the blocking action of the convex portion of the first substrate and the convex portion of the second substrate, excess adhesive colloid (viscous material) Filling into the through hole, the adhesive colloid is condensed in the bonding area and the through hole to form a rivet structure capable of firmly connecting the first substrate and the second substrate.

- the rivet structure strengthens the connection strength between the first substrate and the second substrate, thereby improving the reliability of the package structure.

- the convex portion of the first substrate can effectively control the amount of dispensing at the solder joint of the first substrate, thereby effectively improving the packaging efficiency of the package structure.

- an upper surface of the second substrate is also provided with an antenna radiator, and an antenna radiator of an upper surface of the second substrate corresponds to an antenna radiator in the antenna region.

- the sidewall of the through hole includes an uneven microstructure, and the microstructure can increase a contact surface of the sidewall of the through hole with the adhesive colloid, thereby improving the adhesion. The reliability of bonding the colloid to the sidewall of the through hole.

- the convex portion of the first substrate and the corresponding convex portion of the second substrate are seamlessly bonded together.

- the convex portion of the first substrate and the corresponding convex portion of the second substrate serve to support the first substrate and the second substrate, and the first substrate and the first substrate can be effectively maintained.

- the spacing of the second substrate ensures stability of a gap between the antenna radiator on the first substrate and the second substrate, thereby ensuring antenna performance.

- the width of the gap between the antenna radiator and the second substrate is between 0 and 100 um, and the package structure is used to implement a frequency band of 40 G or more, for example, a frequency band of 40 G to 70 G. Millimeter wave.

- the package structure further includes a peripheral region disposed adjacent to an edge of the package structure, wherein a width of a cross section of the protrusion portion of the first substrate in the peripheral region is smaller than a width of the second substrate at the periphery

- the cross-sectional width of the raised portion of the region is such that the bonding interface between the adhesive colloid and the first substrate in the peripheral region becomes larger, enhancing the connection strength between the first substrate and the second substrate And the sealing property, thereby improving the reliability of the package structure.

- the first substrate includes a first plate body and a protective layer

- the protective layer is disposed on a lower surface of the first plate body

- the protrusion portion is disposed on the first plate body

- the upper surface of the chip is disposed adjacent to the protective layer, and the protective layer is used to protect a line in the first board.

- the package structure further includes a ball grid array mounted on a lower surface of the first substrate, the ball grid array being disposed adjacent to the chip. After the information received by the antenna of the package structure is processed, the ball grid array ball is sent to the main board of the electronic device to realize signal transmission.

- the adhesive colloid comprises at least one of copper paste, solder paste, silver paste, and low flow adhesive resin glue.

- the chip includes at least one of a radio frequency chip, a digital chip, a filter chip, and a power chip.

- an embodiment of the present application further provides an electronic device including a main board and a package structure as described above, wherein the main board and the package structure have signal transmission.

- an embodiment of the present application further provides a packaging method, including the following steps:

- the first bonding zone corresponds to the bonding zone

- the bonding gel overflows from the bonding zone to the second a through hole of the substrate, wherein the adhesive colloid is condensed into a rivet structure in the bonding region and the through hole.

- the packaging method further comprises the step of mounting a chip on a lower surface of the first substrate.

- the packaging method further includes the step of: implanting the ball grid array on the lower surface of the first substrate, The ball grid array is disposed adjacent to the chip.

- the information received by the antenna of the package structure is processed and sent to the main board of the electronic device through the ball grid array ball to realize signal transmission.

- the second substrate in the step of “pressing the second substrate on the first substrate”, the second substrate is vacuum-adsorbed by the upper sheet device and the second substrate is crimped to the The first substrate.

- the top sheet device adopts vacuum adsorption of the second substrate, in the process of crimping the second substrate to the first substrate, almost no adhesive colloid due to the action of vacuum Entering between the convex portion of the first substrate and the convex portion of the corresponding second substrate, thereby facilitating stabilization of the width of the gap between the antenna radiator and the second substrate to ensure antenna performance.

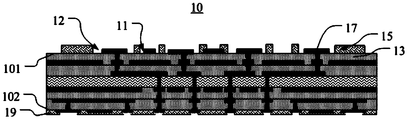

- FIG. 1 is a cross-sectional view of a package structure according to an embodiment of the present invention.

- FIG. 2 is a schematic cross-sectional view of a first substrate according to an embodiment of the present invention.

- FIG 3 is a schematic cross-sectional view of a second substrate according to an embodiment of the present invention.

- FIG. 4 is a schematic cross-sectional view of a through hole according to an embodiment of the present invention.

- FIG. 5 is a schematic flowchart diagram of a packaging method according to an embodiment of the present invention.

- FIG. 6 is a schematic cross-sectional view showing the injection of the first adhesive region of the first substrate into the adhesive.

- FIG. 7 is a schematic cross-sectional view showing the second substrate being crimped onto the first substrate.

- FIG. 8 is a schematic cross-sectional view showing the chip mounted on the first substrate.

- an embodiment of the present application provides a package structure 100 including a first substrate 10 , a second substrate 30 , and a chip 50 .

- the first substrate 10 includes an upper surface 101 and a lower surface 102 which are oppositely disposed.

- the second substrate 30 is mounted on the upper surface 101 of the first substrate 10, and the chip 50 is fixed on the lower surface. 102.

- the second substrate 30 includes an upper surface 103 and a lower surface 104 disposed opposite to each other, and a lower surface 104 of the second substrate 30 is disposed toward the first substrate 10 .

- the chip 50 is not limited to be fixed on the lower surface 102 of the first substrate 10, and the chip 50 can be fixed to the receiving slot/hole by the receiving hole/hole in the first substrate 10. Not limited.

- the upper surface 101 of the first substrate 10 is provided with spaced protrusions 15

- the lower surface 104 of the second substrate 30 is provided with spaced protrusions 35

- the convex portions 15 on the second substrate 30 are opposed to each other and surround the bonding region 107 and the antenna region 108 for accommodating the antenna radiator 17 between the first substrate 10 and the second substrate 30.

- the second substrate 30 further includes at least one through hole 31 penetrating through the upper surface 103 and the lower surface 104 of the second substrate 30, each through hole 31 communicating with a bonding region 107, the through hole 31 and the The bonding area 107 is filled with an adhesive colloid 60, and the adhesive colloid 60 overflows from the bonding area 107 into the through hole 31, and the adhesive colloid 60 is in the bonding area 107 and

- the condensed structure in the through hole 31 is a rivet structure.

- each of the through holes 31 is disposed in communication with one of the bonding regions 107, when the first substrate 10 and the second substrate 20 are bonded, the first substrate 10 is crimped by the second substrate 30.

- the pressure, and the blocking action of the boss 15 and the boss 35, the excess adhesive colloid 60 (viscous material) is squeezed into the through hole 31 to condense to form the rivet structure, the rivet structure reinforcing the first

- the strength of the connection between the substrate 10 and the second substrate 30 improves the reliability of the package structure 100.

- the first substrate 10 is a multi-layer structure, which can be adjusted according to wiring and performance requirements, and is not limited to the laminated structure shown in FIGS. Further, the convex portion 15 on the first substrate 10 surrounds the first bonding region 11 and the first antenna region 12.

- the at least one antenna radiator 17 is attached to the upper surface 101 of the first substrate 10, and each of the antenna radiators 17 is disposed in a first antenna region 12.

- the first substrate 10 is provided with a line.

- the antenna radiator 17 and the chip 50 are fed through a line in the first substrate 10.

- the upper surface 101 of the first substrate 10 is a soldering surface.

- a non-solder resist layer defining pad NON-SOLDER MASK DEFINE PAD, NSMD

- a solder resist layer defining pad SOLDER MASK DEFINE PAD, SMD

- a copper-free pad may be used, for example, in a first paste.

- the junction region 11 is NSMD

- a first bonding region 11 is made of SMD

- a first bonding region 11 is made of a copper-free pad.

- the raised portion 35 of the second substrate 30 surrounds at least one second bonding region 32 and at least one second antenna region 34.

- Each of the second bonding regions 32 corresponds to a first bonding region 11.

- Each of the second antenna regions 34 corresponds to a first antenna region 12.

- Each of the bosses 35 is disposed opposite to and attached to one of the bosses 15. The raised portion 35 can effectively prevent the adhesive colloid 60 in the second bonding region 32 from overflowing into the second bonding region 32 into the second antenna region 34 during packaging, thereby causing contamination of the second antenna region 34.

- the raised portion 15 and the raised portion 35 are made of a liquid photo-resistance flux, which is an acrylic oligomer, also known as green oil/green paint.

- a liquid photo solder resist to the upper surface 101 of the first substrate 10, forming a plurality of protrusions 15 on the first substrate 10 by a photolithography process; applying a liquid photo solder resist to the second substrate 30

- the lower surface 104 is formed with a plurality of convex portions 35 on the second substrate 30 by a photolithography process.

- the bonding area 107 and the antenna area 108 are alternately arranged. It can be understood that the bonding area 107 and the antenna area 108 are not alternately arranged. The number and arrangement of the bonding area 107 and the antenna area 108 are set according to actual needs.

- An antenna cavity for accommodating the antenna radiator 17 is surrounded by the convex portion 15, the corresponding convex portion 35, the first plate body 13, and the second plate body 33.

- the cavity of the antenna cavity is the antenna region 107. region.

- a convex cavity for accommodating the adhesive body 60 is formed by the convex portion 15, the convex portion 35, the first plate body 13, and the second plate body 33.

- the cavity of the bonding cavity is a bonding region. 108 area.

- a bank-shaped convex portion 15 is formed on the upper surface 101 of the first substrate 10, and a bank-shaped convex portion 35 is formed on the lower surface 104 of the second substrate 30, which is advantageous for controlling the amount of the adhesive colloid 60 to avoid bonding.

- the colloid 60 enters the first antenna region 12 and the second antenna region 34 due to excessive usage, resulting in contamination.

- each of the protrusions 35 is disposed corresponding to one of the protrusions 15 to facilitate the alignment of the first substrate 10 and the second substrate 30, thereby improving packaging efficiency.

- a gap 170 is formed between the antenna radiator 17 and the second substrate 30.

- the width d of the slit 170 is between 0 and 100 ⁇ m, and the package structure 100 is used to realize a millimeter wave of a frequency band of 40 G or more, for example, a band millimeter wave of a range of 40 G to 70 G.

- the antenna radiator 37 is provided on the upper surface 103 of the second substrate 30. Each of the antenna radiators 37 is disposed corresponding to the antenna radiator 17 of one antenna region 108.

- the second substrate 30 is vacuum-adsorbed by a top sheet device, and then the second substrate 30 is pressure-bonded to the first substrate 10.

- the adhesive colloid 60 is self-sufficient due to the action of pressing and the action of vacuum.

- the bonding region 107 overflows to the through hole 31, and only a small amount, or the non-adhesive colloid 60 enters between the convex portion 15 and the convex portion 35. It can be understood that, in an embodiment, the convex portion 15 of the first substrate 10 and the convex portion 35 of the second substrate 30 are seamlessly bonded together.

- the convex portion 151 and the convex portion 35 are provided with the stabilizing slit 170 while the thickness of the convex portion 151 and the convex portion 35 serves to support the first substrate 10 and the second substrate 30, and the package structure 100 is ensured. Antenna performance.

- the antenna radiator 17 and the antenna radiator 37 are both metal layers, and the antenna radiator 17 and the antenna radiator 37 are used to radiate electromagnetic wave signals.

- the package structure 100 further includes a peripheral region 105 disposed adjacent to an edge of the package structure 100, and a convex portion 15 located in the peripheral region 105 has a smaller cross-sectional width than a convex portion 35 of the peripheral region 105.

- the cross-sectional width increases the bonding interface between the adhesive colloid 60 of the peripheral region 105 and the first substrate 10, enhancing the connection strength and sealing between the first substrate 10 and the second substrate 30. Thereby improving the reliability of the package structure 100.

- the chip 50 is a radio frequency chip, and the antenna radiator 17 is communicatively connected with the chip 50.

- the package structure 100 is an integrated antenna package structure (AiP, Antenna in Package).

- the chip 50 can also be a digital chip, a filter chip, a power chip, or the like.

- the manner in which the chip 50 is connected to the first substrate 10 can be connected by flip chip bonding. In one embodiment, the number of chips 50 may be two, three or more.

- the package structure 100 may also include passive components (eg, resistors, capacitors, inductors, etc.), control chips, and the like.

- the control chip is electrically connected to the RF chip and is used to process signals transmitted by the RF chip. Passive devices are used to provide filtering or noise reduction for the RF chip.

- the adhesive colloid 60 includes at least one of copper paste, solder paste, silver paste, and low flow adhesive resin glue. It can be understood that the applicable adhesive colloid 60 can be selected according to the structure/material of the first substrate 10 disposed in the first bonding region 11, thereby strengthening the bonding strength between the adhesive colloid 60 and the first substrate 10. For example, in the present embodiment, the first bonding region 11 designed by NSMD and SMD is used. Since the copper pad is provided, the adhesive colloid 60 is selected from a solder paste, and the copper paste and the silver paste are also suitable for the copper pad. The first bonding region 11; for the first bonding region 11 without the copper pad, at least one of resin glue, copper paste and silver glue may be used.

- the package structure 100 further includes a Ball Grid Array (BGA) 70 that is implanted on the lower surface 102 of the first substrate 10, the ball grid array 70 being disposed adjacent to the chip 50.

- the ball grid array 70 is used to transmit information received by the antenna to the motherboard of the device/device.

- the first substrate 10 includes a first plate body 13 and a protective layer 19.

- the first plate body 13 is provided with a line.

- the protective layer 19 is disposed on a lower surface of the first board 13 for protecting a line in the first substrate 10.

- the protruding portion 15 is disposed on an upper surface of the first plate body 13 , and the chip 50 and the ball grid array 70 are disposed adjacent to the protective layer 19 .

- the first plate 13 comprises a copper clad laminate (CCL) and a prepreg (PPG).

- the number of the copper clad laminates is four, the number of the prepregs is one, and the two prepregs are respectively provided with two copper clad laminates.

- a circuit is disposed in the copper clad laminate and the prepreg.

- the second substrate 30 is made of a copper clad laminate.

- the first plate body 13 may be other laminated structures, which is not limited herein.

- the sidewall of the through hole 31 includes an uneven microstructure 311, which can increase the contact surface between the sidewall of the through hole 31 and the adhesive colloid 60. The reliability of bonding of the adhesive colloid 60 to the sidewall of the through hole 31 can be improved.

- the embodiment of the present application further provides an electronic device including a main board (not shown) and the package structure 100 as described above. There is signal transmission between the main board and the package structure 100.

- the embodiment of the present application further provides a packaging method. Referring to FIG. 5, the method includes the following steps:

- Step 401 referring to FIG. 6, the adhesive layer 60 is injected into the first bonding region 11 surrounded by the convex portion 15 of the first substrate 10.

- the glue may be applied to the first bonding region 11 of the first substrate 10 by a dispensing device (not shown) or by a stencil printing process.

- the second substrate 30 is crimped onto the first substrate 10, and the convex portion 15 on the first substrate 10 and the convex portion 35 on the second substrate 30 are mutually connected to each other.

- the first bonding area 11 corresponds to the bonding In the region 107

- the adhesive colloid 60 overflows from the bonding region 107 to the through hole 31 of the second substrate 30, and the adhesive colloid 60 is in the bonding region 107 and the through hole 31.

- the condensate structure becomes a rivet structure.

- the top sheet device is a vacuum adsorption device, and the top sheet device adsorbs the second substrate 30 by vacuum.

- the adhesive colloid 60 is extruded into the through hole 31 to form a rivet structure, and the rivet structure

- the first substrate 10 and the second substrate 30 can be firmly connected together, thereby enhancing the connection strength between the first substrate 10 and the second substrate 30.

- the top sheet device vacuum-adsorbs the second substrate 30, in the process of crimping the second substrate 30 to the first substrate 10, the second substrate 30 is adsorbed by the vacuum.

- the non-adhesive colloid 60 enters between the convex portion 15 and the convex portion 35, thereby facilitating the stabilization of the slit 170 between the antenna radiator 17 and the second substrate 37, ensuring the antenna. performance.

- Step 403 referring to FIG. 8, the chip 50 is fixed to the first substrate 10.

- the chip 50 is attached to the lower surface 102 of the first substrate 10 by a conventional flip chip process.

- the chip 50 is fed into a line within the first substrate 10.

- Step 404 referring again to FIG. 1, the ball grid array 70 is implanted on the lower surface 102 of the first substrate 10, and the ball grid array 70 is disposed adjacent to the chip 50.

- the ball grid array 70 is connected to the line of the first substrate 10.

- the package structure, the electronic device, and the packaging method provided by the embodiment of the present application because the second substrate 30 is provided with the through hole 31 corresponding to the first bonding region 11, so that the adhesive colloid 60 in the bonding region 107 is encapsulated at the time of packaging. Extrusion into the through hole 31 to form a rivet structure connecting the first substrate 10 and the second substrate 30 to prevent the adhesive colloid 60 from entering the antenna region 108, and strengthening the first substrate 10 The strength of the connection with the second substrate 30. Further, the convex portion 15 and the convex portion 35 can effectively control the amount of the adhesive colloid 60, and further prevent the adhesive colloid 60 from entering the antenna region 108.

- the thickness of the convex portion 15 and the convex portion 35 serves to support the first substrate 10 and the second substrate 30, the first substrate 10 and the second substrate 30 can be effectively maintained.

- the spacing ensures the stability of the gap 170 between the antenna radiator 17 and the second substrate 30, ensuring the antenna performance of the package structure 100.

- the height of the slit 170 between the first substrate 10 and the second substrate 30 is stable, and good stability can be maintained even after a plurality of high-temperature heat cycles.

- the through hole 31 of the second substrate 30 effectively absorbs excess overflow glue, and effectively solves the technical problem that the overflow of the antenna area and the thickness of the viscous material are difficult to control.

- the glue overflows with the glue of the welding surface to form a rivet structure, which plays a good role in welding the first substrate 10 and the second substrate 30.

Landscapes

- Engineering & Computer Science (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Computer Hardware Design (AREA)

- Power Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Combinations Of Printed Boards (AREA)

- Details Of Aerials (AREA)

Abstract

Provided in the embodiments of the present application are a package structure, comprising a first substrate, a second substrate and a chip, wherein the second substrate is mounted on the upper surface of the first substrate, and the chip is mounted on the first substrate; the upper surface of the first substrate is provided with spaced protrusions thereon, and a lower surface of the second substrate is provided with spaced protrusions; the protrusions on the first substrate and the second substrate are opposite to each other and form a bonding region and an antenna region used for accommodating an antenna radiator between the first substrate and the second substrate; the second substrate is provided thereon with a through hole which is in communication with the bonding region; and bonding gel in the through hole and the bonding region overflows from the bonding region into the through hole and is solidified into a rivet structure. The described through hole prevents the bonding gel from overflowing and contaminating the antenna region during packaging, thereby ensuring the antenna performance of the package structure, and thus improving the reliability of the package structure. Also provided in the present invention are an electronic device and a packaging method.

Description

本申请要求在2018年4月8日提交中国国家知识产权局、申请号为2018103070786、发明名称为“封装结构、电子装置及封装方法”的中国专利申请的优先权,其全部内容通过引用结合在本申请中。This application claims priority to Chinese Patent Application No. 2018103070786, entitled "Package Structure, Electronic Device, and Packaging Method", filed on April 8, 2018, the entire contents of which are incorporated by reference. In this application.

本申请涉及无线通信技术领域,尤其涉及一种封装结构、电子装置及封装方法。The present application relates to the field of wireless communications technologies, and in particular, to a package structure, an electronic device, and a packaging method.

随着5G等高速率通信时代的来临,毫米波通信逐步成为主流,毫米波天线的设计和应用需求也越来越旺盛。由于毫米波频段传输路径长短对信号幅度损耗影响非常大,传统天线的架构模式已经慢慢无法满足高性能需求。封装天线集成(Antenna in Package,AiP)架构由于天线馈线路径极短,使得无线系统的等效全向辐射功率(Equivalent Isotropic Radiated Power,EIRP)值可以最大化,有利于更宽范围的覆盖,因此AiP技术逐步成为5G和毫米波高速通信系统的主流天线技术,具备广阔的应用空间和市场空间前景。而如何解决AiP的可靠性问题是业界所研究的重点。With the advent of the era of high-speed communication such as 5G, millimeter-wave communication has gradually become the mainstream, and the design and application requirements of millimeter-wave antennas are becoming more and more vigorous. Since the length of the transmission path of the millimeter wave band has a great influence on the signal amplitude loss, the architecture mode of the conventional antenna has been slowly unable to meet the high performance requirement. The Antenna in Package (AiP) architecture maximizes the Equivalent Isotropic Radiated Power (EIRP) value of the wireless system due to the extremely short antenna feeder path, which facilitates a wider range of coverage. AiP technology has gradually become the mainstream antenna technology for 5G and millimeter wave high-speed communication systems, with broad application space and market space prospects. How to solve the reliability problem of AiP is the focus of research in the industry.

发明内容Summary of the invention

本申请实施例所要解决的技术问题在于提供一种提高可靠性的封装结构及其封装方法。The technical problem to be solved by the embodiments of the present application is to provide a package structure and a packaging method thereof for improving reliability.

为了实现上述目的,本申请实施方式采用如下技术方案:In order to achieve the above object, the implementation of the present application adopts the following technical solutions:

第一方面,本申请实施例提供了一种封装结构,包括第一基板、第二基板及芯片,所述第二基板被安装在所述第一基板的上表面上,所述芯片被安装在所述第一基板上,所述第一基板的上表面上设有间隔的凸起部,所述第二基板的下表面设置有间隔的凸起部,所述第一基板上的凸起部和所述第二基板上的凸起部彼此相对并在所述第一基板和所述第二基板之间围绕出粘结区以及用于收容天线辐射体的天线区,所述第二基板上设置有贯穿所述第二基板的上下表面的通孔,所述通孔与所述粘结区相通,所述通孔和所述粘结区中注有粘结胶体,所述粘结胶体自所述粘结区满溢至所述通孔中,所述粘结胶体在所述粘结区和所述通孔中凝结构成了铆钉结构。In a first aspect, an embodiment of the present application provides a package structure including a first substrate, a second substrate, and a chip, the second substrate being mounted on an upper surface of the first substrate, the chip being mounted on the first substrate On the first substrate, the upper surface of the first substrate is provided with spaced protrusions, and the lower surface of the second substrate is provided with spaced protrusions, and the protrusions on the first substrate And the convex portions on the second substrate are opposite to each other and surround the bonding region between the first substrate and the second substrate and an antenna region for accommodating the antenna radiator, on the second substrate a through hole penetrating through the upper and lower surfaces of the second substrate, the through hole communicating with the bonding region, wherein the through hole and the bonding region are filled with an adhesive colloid The bonding area overflows into the through hole, and the adhesive colloid is condensed into a rivet structure in the bonding area and the through hole.

本实施方式中,所述第二基板包括至少一个贯穿所述第二基板上下表面的通孔,所述通孔与所述粘结区相连通,在将所述第一基板与所述第二基板粘接时,利用所述第二基板压接所述第一基板的压力,以及第一基板的凸起部及第二基板的凸起部的阻挡作用,多余的粘结胶体(粘性材料)满溢至所述通孔内,粘结胶体在所述粘结区及所述通孔凝结构成了一个能够很好地将所述第一基板与所述第二基板牢固连接的铆钉结构,换句话说,所述铆钉结构加强所述第一基板与所述第二基板之间的连接强度,从而提高了所述封装结构的可靠性。In this embodiment, the second substrate includes at least one through hole penetrating the upper and lower surfaces of the second substrate, and the through hole communicates with the bonding region, and the first substrate and the second substrate are When the substrate is bonded, the pressure of the first substrate is pressed by the second substrate, and the blocking action of the convex portion of the first substrate and the convex portion of the second substrate, excess adhesive colloid (viscous material) Filling into the through hole, the adhesive colloid is condensed in the bonding area and the through hole to form a rivet structure capable of firmly connecting the first substrate and the second substrate. In other words, the rivet structure strengthens the connection strength between the first substrate and the second substrate, thereby improving the reliability of the package structure.

另外,所述第一基板的凸起部,能够有效控制在对所述第一基板的焊接点点胶时的用量,有效提高封装结构的封装效率。In addition, the convex portion of the first substrate can effectively control the amount of dispensing at the solder joint of the first substrate, thereby effectively improving the packaging efficiency of the package structure.

在一实施方式中,所述第二基板的上表面也设有天线辐射体,所述第二基板的上表面的天线辐射体与所述天线区中的天线辐射体相对应。In an embodiment, an upper surface of the second substrate is also provided with an antenna radiator, and an antenna radiator of an upper surface of the second substrate corresponds to an antenna radiator in the antenna region.

在一实施方式中,所述通孔的侧壁包括凹凸不平的微结构,所述微结构能够增大所述通孔的侧壁与所述粘结胶体的接触面,进而能够提高所述粘结胶体与所述通孔的侧壁结合的可靠性。In an embodiment, the sidewall of the through hole includes an uneven microstructure, and the microstructure can increase a contact surface of the sidewall of the through hole with the adhesive colloid, thereby improving the adhesion. The reliability of bonding the colloid to the sidewall of the through hole.

在一实施方式中,所述第一基板的凸起部与对应的所述第二基板的凸起部无缝隙贴合于一起。In one embodiment, the convex portion of the first substrate and the corresponding convex portion of the second substrate are seamlessly bonded together.

本实施方式中,所述第一基板的凸起部与对应的所述第二基板的凸起部起到支撑第一基板及第二基板的作用的同时,能够有效保持所述第一基板与所述第二基板的间距,确保所述第一基板上的天线辐射体与所述第二基板之间缝隙的稳定性,从而确保天线性能。In this embodiment, the convex portion of the first substrate and the corresponding convex portion of the second substrate serve to support the first substrate and the second substrate, and the first substrate and the first substrate can be effectively maintained. The spacing of the second substrate ensures stability of a gap between the antenna radiator on the first substrate and the second substrate, thereby ensuring antenna performance.

在一实施方式中,所述天线辐射体与所述第二基板之间缝隙的宽度位于0~100um之间,所述封装结构用于实现40G以上的频带毫米波,例如40G~70G范围的频带毫米波。In one embodiment, the width of the gap between the antenna radiator and the second substrate is between 0 and 100 um, and the package structure is used to implement a frequency band of 40 G or more, for example, a frequency band of 40 G to 70 G. Millimeter wave.

在一实施方式中,所述封装结构还包括邻近所述封装结构边缘设置的外围区域,所述第一基板位于所述外围区域的凸起部的截面宽度小于所述第二基板位于所述外围区域的凸起部的截面宽度,使得在所述外围区域的粘结胶体与所述第一基板的粘接界面变大,增强了所述第一基板与所述第二基板之间的连接强度以及密封性,进而提高了所述封装结构的可靠性。In an embodiment, the package structure further includes a peripheral region disposed adjacent to an edge of the package structure, wherein a width of a cross section of the protrusion portion of the first substrate in the peripheral region is smaller than a width of the second substrate at the periphery The cross-sectional width of the raised portion of the region is such that the bonding interface between the adhesive colloid and the first substrate in the peripheral region becomes larger, enhancing the connection strength between the first substrate and the second substrate And the sealing property, thereby improving the reliability of the package structure.

在一实施方式中,所述第一基板包括第一板体及保护层,所述保护层设于所述第一板体的下表面上,所述凸起部设于所述第一板体的上表面,所述芯片与所述保护层相邻设置,所述保护层用于保护所述第一板体内的线路。In one embodiment, the first substrate includes a first plate body and a protective layer, the protective layer is disposed on a lower surface of the first plate body, and the protrusion portion is disposed on the first plate body The upper surface of the chip is disposed adjacent to the protective layer, and the protective layer is used to protect a line in the first board.

在一实施方式中,所述封装结构还包括球栅阵列,所述球栅阵列安装于所述第一基板的下表面,所述球栅阵列与所述芯片相邻设置。封装结构的天线接收到的信息处理后,再通过所述球栅阵列球发送到电子装置的主板,实现信号的传输。In one embodiment, the package structure further includes a ball grid array mounted on a lower surface of the first substrate, the ball grid array being disposed adjacent to the chip. After the information received by the antenna of the package structure is processed, the ball grid array ball is sent to the main board of the electronic device to realize signal transmission.

在一实施方式中,所述粘结胶体包括铜膏、锡膏、银胶、低流动性粘性树脂胶水中的至少一种。In one embodiment, the adhesive colloid comprises at least one of copper paste, solder paste, silver paste, and low flow adhesive resin glue.

在一实施方式中,所述芯片包括射频芯片、数字芯片、滤波器芯片、电源芯片中的至少一种。In an embodiment, the chip includes at least one of a radio frequency chip, a digital chip, a filter chip, and a power chip.

第二方面,本申请实施方式还提供了一种电子装置,包括主板和如上所述的封装结构,所述主板与所述封装结构之间具有信号传输。In a second aspect, an embodiment of the present application further provides an electronic device including a main board and a package structure as described above, wherein the main board and the package structure have signal transmission.

第三方面,本申请实施方式还提供一种封装方法,其包括以下步骤:In a third aspect, an embodiment of the present application further provides a packaging method, including the following steps:

在第一基板的凸起部围绕出的第一粘结区注入粘结胶体;Injecting an adhesive colloid at a first bonding region surrounded by the convex portion of the first substrate;

将第二基板压接于所述第一基板上,所述第一基板上的凸起部和所述第二基板上的凸起部彼此相对并在所述第一基板和所述第二基板之间围绕出粘结区以及用于收容天线辐射体的天线区,所述第一粘结区对应所述粘结区,所述粘结胶体自所述粘结区满溢至所述第二基板的通孔,所述粘结胶体在所述粘结区和所述通孔中凝结构成了铆钉结构。Pressing a second substrate on the first substrate, the convex portion on the first substrate and the convex portion on the second substrate facing each other and on the first substrate and the second substrate Between the bonding zone and the antenna zone for receiving the antenna radiator, the first bonding zone corresponds to the bonding zone, and the bonding gel overflows from the bonding zone to the second a through hole of the substrate, wherein the adhesive colloid is condensed into a rivet structure in the bonding region and the through hole.

在一实施方式中,所述“将所述第二基板压接于所述第一基板上”的步骤后,所述封 装方法还包括步骤:将芯片安装于所述第一基板的下表面。In one embodiment, after the step of “compressing the second substrate on the first substrate”, the packaging method further comprises the step of mounting a chip on a lower surface of the first substrate.

在一实施方式中,所述“将芯片安装于所述第一基板的下表面”的步骤后,所述封装方法还包括步骤:将球栅阵列植球于所述第一基板的下表面,所述球栅阵列与所述芯片相邻设置。封装结构的天线接收到的信息,经处理后再通过所述球栅阵列球发送到电子装置的主板,实现信号的传输。In an embodiment, after the step of “mounting the chip on the lower surface of the first substrate”, the packaging method further includes the step of: implanting the ball grid array on the lower surface of the first substrate, The ball grid array is disposed adjacent to the chip. The information received by the antenna of the package structure is processed and sent to the main board of the electronic device through the ball grid array ball to realize signal transmission.

在一实施方式中,所述“将第二基板压接于所述第一基板上”的步骤中,通过上片设备真空吸附所述第二基板并将所述第二基板压接于所述第一基板。In one embodiment, in the step of “pressing the second substrate on the first substrate”, the second substrate is vacuum-adsorbed by the upper sheet device and the second substrate is crimped to the The first substrate.

本实施方式中,由于所述上片设备采用真空吸附所述第二基板,使得在将所述第二基板压接于所述第一基板的过程中,因真空的作用,几乎无粘结胶体进入第一基板的凸起部与对应的第二基板的凸起部之间,因此,有利于稳定天线辐射体与所述第二基板之间的缝隙的宽度,确保天线性能。In this embodiment, since the top sheet device adopts vacuum adsorption of the second substrate, in the process of crimping the second substrate to the first substrate, almost no adhesive colloid due to the action of vacuum Entering between the convex portion of the first substrate and the convex portion of the corresponding second substrate, thereby facilitating stabilization of the width of the gap between the antenna radiator and the second substrate to ensure antenna performance.

图1为本发明实施方式提供的封装结构的剖面示意图。FIG. 1 is a cross-sectional view of a package structure according to an embodiment of the present invention.

图2为本发明实施方式提供的第一基板的剖面示意图。2 is a schematic cross-sectional view of a first substrate according to an embodiment of the present invention.

图3为本发明实施方式提供的第二基板的剖面示意图。3 is a schematic cross-sectional view of a second substrate according to an embodiment of the present invention.

图4为本发明一实施方式提供的通孔剖面示意图。4 is a schematic cross-sectional view of a through hole according to an embodiment of the present invention.

图5为本发明实施方式提供的封装方法的流程示意图。FIG. 5 is a schematic flowchart diagram of a packaging method according to an embodiment of the present invention.

图6为第一基板的第一粘结区注入粘结胶体的剖面示意图。6 is a schematic cross-sectional view showing the injection of the first adhesive region of the first substrate into the adhesive.

图7为第二基板压接于第一基板上的剖面示意图。7 is a schematic cross-sectional view showing the second substrate being crimped onto the first substrate.

图8为芯片安装于第一基板的剖面示意图。FIG. 8 is a schematic cross-sectional view showing the chip mounted on the first substrate.

请参阅图1,本申请实施例提供了一种封装结构100,包括第一基板10、第二基板30及芯片50。所述第一基板10包括相对设置的上表面101及下表面102,所述第二基板30被安装在所述第一基板10的上表面101上,所述芯片50被固定在所述下表面102上。所述第二基板30包括相对设置的上表面103及下表面104,第二基板30的下表面104朝向所述第一基板10设置。可以理解,芯片50不限定固定在所述第一基板10的下表面102上,其可以通过于第一基板10挖设收容槽/孔,将芯片50固定于所述收容槽/孔,在此不作限定。Referring to FIG. 1 , an embodiment of the present application provides a package structure 100 including a first substrate 10 , a second substrate 30 , and a chip 50 . The first substrate 10 includes an upper surface 101 and a lower surface 102 which are oppositely disposed. The second substrate 30 is mounted on the upper surface 101 of the first substrate 10, and the chip 50 is fixed on the lower surface. 102. The second substrate 30 includes an upper surface 103 and a lower surface 104 disposed opposite to each other, and a lower surface 104 of the second substrate 30 is disposed toward the first substrate 10 . It can be understood that the chip 50 is not limited to be fixed on the lower surface 102 of the first substrate 10, and the chip 50 can be fixed to the receiving slot/hole by the receiving hole/hole in the first substrate 10. Not limited.

所述第一基板10的上表面101设有间隔的凸起部15,所述第二基板30的下表面104设有间隔的凸起部35,所述第一基板10上的凸起部15和所述第二基板30上的凸起部15彼此相对并在所述第一基板10和所述第二基板30之间围绕出粘结区107以及用于收容天线辐射体17的天线区108。The upper surface 101 of the first substrate 10 is provided with spaced protrusions 15 , and the lower surface 104 of the second substrate 30 is provided with spaced protrusions 35 , and the protrusions 15 on the first substrate 10 And the convex portions 15 on the second substrate 30 are opposed to each other and surround the bonding region 107 and the antenna region 108 for accommodating the antenna radiator 17 between the first substrate 10 and the second substrate 30. .

所述第二基板30还包括至少一个贯穿所述第二基板30的上表面103与下表面104的通孔31,每个通孔31与一个粘结区107相通,所述通孔31和所述粘结区107中注有粘结胶体60,所述粘结胶体60自所述粘结区107满溢至所述通孔31中,所述粘结胶体60在所述粘结区107和所述通孔31中凝结构成了铆钉结构。The second substrate 30 further includes at least one through hole 31 penetrating through the upper surface 103 and the lower surface 104 of the second substrate 30, each through hole 31 communicating with a bonding region 107, the through hole 31 and the The bonding area 107 is filled with an adhesive colloid 60, and the adhesive colloid 60 overflows from the bonding area 107 into the through hole 31, and the adhesive colloid 60 is in the bonding area 107 and The condensed structure in the through hole 31 is a rivet structure.

由于每个通孔31与一个粘结区107相通设置,在将所述第一基板10与所述第二基板20粘接时,利用所述第二基板30压接所述第一基板10的压力,以及凸起部15和凸起部35的阻挡作用,多余的粘结胶体60(粘性材料)被挤入通孔31内从而凝结形成所述铆钉结构,所述铆钉结构加强了所述第一基板10与所述第二基板30之间的连接强度,提高了所述封装结构100的可靠性。Since each of the through holes 31 is disposed in communication with one of the bonding regions 107, when the first substrate 10 and the second substrate 20 are bonded, the first substrate 10 is crimped by the second substrate 30. The pressure, and the blocking action of the boss 15 and the boss 35, the excess adhesive colloid 60 (viscous material) is squeezed into the through hole 31 to condense to form the rivet structure, the rivet structure reinforcing the first The strength of the connection between the substrate 10 and the second substrate 30 improves the reliability of the package structure 100.

在一具体实施例中,请结合参阅图2,第一基板10为多层结构,实际可以根据布线和性能需要进行调整,而不限于图1-图2所示的叠层结构。进一步地,第一基板10上的凸起部15围绕出第一粘结区11及第一天线区12。In a specific embodiment, referring to FIG. 2, the first substrate 10 is a multi-layer structure, which can be adjusted according to wiring and performance requirements, and is not limited to the laminated structure shown in FIGS. Further, the convex portion 15 on the first substrate 10 surrounds the first bonding region 11 and the first antenna region 12.

所述至少一个天线辐射体17贴设于所述第一基板10的上表面101,每个天线辐射体17设于一个第一天线区12。第一基板10设有线路。天线辐射体17与芯片50通过第一基板10内的线路馈接。The at least one antenna radiator 17 is attached to the upper surface 101 of the first substrate 10, and each of the antenna radiators 17 is disposed in a first antenna region 12. The first substrate 10 is provided with a line. The antenna radiator 17 and the chip 50 are fed through a line in the first substrate 10.

进一步地,所述第一基板10的上表面101为焊接面。具体可以采用非防焊层界定垫(NON-SOLDER MASK DEFINE PAD,NSMD)、防焊层界定垫(SOLDER MASK DEFINE PAD,SMD)、无铜垫中的至少一种,例如,在一个第一粘结区11采用NSMD,一个第一粘结区11采用SMD,一个第一粘结区11采用无铜垫。Further, the upper surface 101 of the first substrate 10 is a soldering surface. Specifically, at least one of a non-solder resist layer defining pad (NON-SOLDER MASK DEFINE PAD, NSMD), a solder resist layer defining pad (SOLDER MASK DEFINE PAD, SMD), and a copper-free pad may be used, for example, in a first paste. The junction region 11 is NSMD, a first bonding region 11 is made of SMD, and a first bonding region 11 is made of a copper-free pad.

请结合参阅图3,第二基板30的凸起部35围绕出至少一个第二粘结区32及至少一个第二天线区34。每个第二粘结区32对应一个第一粘结区11。每个第二天线区34对应一个第一天线区12。每个凸起部35与一个凸起部15相对设置并贴合于一起。凸起部35能够有效避免封装时所述第二粘结区32内的粘结胶体60溢出所述第二粘结区32进入第二天线区34,而对第二天线区34造成污染。Referring to FIG. 3, the raised portion 35 of the second substrate 30 surrounds at least one second bonding region 32 and at least one second antenna region 34. Each of the second bonding regions 32 corresponds to a first bonding region 11. Each of the second antenna regions 34 corresponds to a first antenna region 12. Each of the bosses 35 is disposed opposite to and attached to one of the bosses 15. The raised portion 35 can effectively prevent the adhesive colloid 60 in the second bonding region 32 from overflowing into the second bonding region 32 into the second antenna region 34 during packaging, thereby causing contamination of the second antenna region 34.

本实施方式中,凸起部15及凸起部35由液态光致阻焊剂制成,所述液态光致阻焊剂是一种丙烯酸低聚物,亦称为绿油/绿漆。将液态光致阻焊剂涂覆于第一基板10的上表面101,通过光刻蚀工艺在第一基板10上形成多个凸起部15;将液态光致阻焊剂涂覆于第二基板30的下表面104,通过光刻蚀工艺在第二基板30上形成多个凸起部35。In the present embodiment, the raised portion 15 and the raised portion 35 are made of a liquid photo-resistance flux, which is an acrylic oligomer, also known as green oil/green paint. Applying a liquid photo solder resist to the upper surface 101 of the first substrate 10, forming a plurality of protrusions 15 on the first substrate 10 by a photolithography process; applying a liquid photo solder resist to the second substrate 30 The lower surface 104 is formed with a plurality of convex portions 35 on the second substrate 30 by a photolithography process.

粘结区107与天线区108交替设置,可以理解,不限定粘结区107与天线区108交替设置,粘结区107与天线区108两者的数量及排布方式依据实际需要进行设置。The bonding area 107 and the antenna area 108 are alternately arranged. It can be understood that the bonding area 107 and the antenna area 108 are not alternately arranged. The number and arrangement of the bonding area 107 and the antenna area 108 are set according to actual needs.

通过凸起部15、对应的凸起部35、第一板体13及第二板体33围成一个收容天线辐射体17的天线腔体,所述天线腔体的空腔即天线区107所在区域。通过凸起部15、凸起部35、第一板体13及第二板体33围成一个容纳粘结胶体60的粘结腔体,所述粘结腔体的空腔即为粘结区108所在区域。An antenna cavity for accommodating the antenna radiator 17 is surrounded by the convex portion 15, the corresponding convex portion 35, the first plate body 13, and the second plate body 33. The cavity of the antenna cavity is the antenna region 107. region. A convex cavity for accommodating the adhesive body 60 is formed by the convex portion 15, the convex portion 35, the first plate body 13, and the second plate body 33. The cavity of the bonding cavity is a bonding region. 108 area.

在第一基板10的上表面101形成堤坝状的凸起部15,以及在第二基板30的下表面104形成堤坝状的凸起部35,有利于控制粘结胶体60的用量,避免粘结胶体60因用量过大进入第一天线区12及第二天线区34造成污染。另外,每个凸起部35对应一个凸起部15设置,有利于封装所述第一基板10与所述第二基板30时对位,进而提高封装效率。A bank-shaped convex portion 15 is formed on the upper surface 101 of the first substrate 10, and a bank-shaped convex portion 35 is formed on the lower surface 104 of the second substrate 30, which is advantageous for controlling the amount of the adhesive colloid 60 to avoid bonding. The colloid 60 enters the first antenna region 12 and the second antenna region 34 due to excessive usage, resulting in contamination. In addition, each of the protrusions 35 is disposed corresponding to one of the protrusions 15 to facilitate the alignment of the first substrate 10 and the second substrate 30, thereby improving packaging efficiency.

所述天线辐射体17与所述第二基板30之间形成缝隙170。所述缝隙170的宽度d在0~100μm之间,所述封装结构100用于实现40G以上的频带毫米波,例如40G~70G范围的频带毫米波。天线辐射体37设于第二基板30的上表面103上。每个天线辐射体37对应一个天线区108的天线辐射体17设置。本实施方式中,通过一上片设备采用真空吸 附所述第二基板30,后将所述第二基板30压接于第一基板10上。在将第二基板30压接于第一基板10上的过程中,若某一粘合区107的点胶量过多时,由于挤压的作用以及真空的作用,所述粘结胶体60自所述粘结区107满溢至通孔31,仅有微量,或者无粘结胶体60进入凸起部15与凸起部35之间。可以理解,在一实施方式中,所述第一基板10的凸起部15与第二基板30的凸起部35之间无缝隙贴合于一起。利用凸起部151、凸起部35的厚度起到支撑第一基板10及第二基板30的作用的同时,凸起部151、凸起部35具备稳定缝隙170作用,确保了封装结构100的天线性能。A gap 170 is formed between the antenna radiator 17 and the second substrate 30. The width d of the slit 170 is between 0 and 100 μm, and the package structure 100 is used to realize a millimeter wave of a frequency band of 40 G or more, for example, a band millimeter wave of a range of 40 G to 70 G. The antenna radiator 37 is provided on the upper surface 103 of the second substrate 30. Each of the antenna radiators 37 is disposed corresponding to the antenna radiator 17 of one antenna region 108. In this embodiment, the second substrate 30 is vacuum-adsorbed by a top sheet device, and then the second substrate 30 is pressure-bonded to the first substrate 10. In the process of crimping the second substrate 30 onto the first substrate 10, if the amount of dispensing of a certain bonding area 107 is excessive, the adhesive colloid 60 is self-sufficient due to the action of pressing and the action of vacuum. The bonding region 107 overflows to the through hole 31, and only a small amount, or the non-adhesive colloid 60 enters between the convex portion 15 and the convex portion 35. It can be understood that, in an embodiment, the convex portion 15 of the first substrate 10 and the convex portion 35 of the second substrate 30 are seamlessly bonded together. The convex portion 151 and the convex portion 35 are provided with the stabilizing slit 170 while the thickness of the convex portion 151 and the convex portion 35 serves to support the first substrate 10 and the second substrate 30, and the package structure 100 is ensured. Antenna performance.

进一步地,天线辐射体17与天线辐射体37均为金属层,天线辐射体17与天线辐射体37用于辐射电磁波信号。Further, the antenna radiator 17 and the antenna radiator 37 are both metal layers, and the antenna radiator 17 and the antenna radiator 37 are used to radiate electromagnetic wave signals.

进一步地,所述封装结构100还包括邻近所述封装结构100边缘设置的外围区域105,位于所述外围区域105的凸起部15的截面宽度小于位于所述外围区域105的凸起部35的截面宽度,使得在所述外围区域105的粘结胶体60与第一基板10的粘接界面增大,增强了所述第一基板10与所述第二基板30的之间连接强度以及密封性,进而提高了所述封装结构100的可靠性。Further, the package structure 100 further includes a peripheral region 105 disposed adjacent to an edge of the package structure 100, and a convex portion 15 located in the peripheral region 105 has a smaller cross-sectional width than a convex portion 35 of the peripheral region 105. The cross-sectional width increases the bonding interface between the adhesive colloid 60 of the peripheral region 105 and the first substrate 10, enhancing the connection strength and sealing between the first substrate 10 and the second substrate 30. Thereby improving the reliability of the package structure 100.

本实施方式中,所述芯片50为射频芯片,所述天线辐射体17与所述芯片50之间通信连接。具体而言,所述封装结构100为集成天线封装结构100(AiP,Antenna in Package)。所述芯片50还可以为数字芯片、滤波器芯片、电源芯片等。芯片50与第一基板10的连接方式,可以通过倒装焊接方式连接。一种实施方式中,芯片50的数量可以为两个、三个或多个。封装结构100还可以包括无源器件(例如电阻、电容、电感等)、控制芯片等。控制芯片与射频芯片电连接,用于处理射频芯片所传送的信号。无源器件用于为射频芯片提供滤波或降噪等。In this embodiment, the chip 50 is a radio frequency chip, and the antenna radiator 17 is communicatively connected with the chip 50. Specifically, the package structure 100 is an integrated antenna package structure (AiP, Antenna in Package). The chip 50 can also be a digital chip, a filter chip, a power chip, or the like. The manner in which the chip 50 is connected to the first substrate 10 can be connected by flip chip bonding. In one embodiment, the number of chips 50 may be two, three or more. The package structure 100 may also include passive components (eg, resistors, capacitors, inductors, etc.), control chips, and the like. The control chip is electrically connected to the RF chip and is used to process signals transmitted by the RF chip. Passive devices are used to provide filtering or noise reduction for the RF chip.

所述粘结胶体60包括铜膏、锡膏、银胶、低流动性粘性树脂胶水中的至少一种。可以理解,可以根据第一基板10设在第一粘结区11的结构/材质选择适用的粘结胶体60,进而加强所述粘结胶体60与第一基板10的连接强度。例如,本实施方式中,采用NSMD及SMD设计的第一粘结区11,由于设有铜垫,所述粘结胶体60选用锡膏,而铜膏、银胶亦比较适用于设有铜垫的第一粘结区11;对于无铜垫的第一粘结区11,可以选用树脂胶水,铜膏、银胶中的至少一种。The adhesive colloid 60 includes at least one of copper paste, solder paste, silver paste, and low flow adhesive resin glue. It can be understood that the applicable adhesive colloid 60 can be selected according to the structure/material of the first substrate 10 disposed in the first bonding region 11, thereby strengthening the bonding strength between the adhesive colloid 60 and the first substrate 10. For example, in the present embodiment, the first bonding region 11 designed by NSMD and SMD is used. Since the copper pad is provided, the adhesive colloid 60 is selected from a solder paste, and the copper paste and the silver paste are also suitable for the copper pad. The first bonding region 11; for the first bonding region 11 without the copper pad, at least one of resin glue, copper paste and silver glue may be used.

封装结构100还包括球栅阵列(Ball Grid Array,BGA)70,所述球栅阵列70植球于第一基板10的下表面102,所述球栅阵列70与芯片50相邻设置。所述球栅阵列70用于将天线接收到的信息传送到设备/装置的主板。The package structure 100 further includes a Ball Grid Array (BGA) 70 that is implanted on the lower surface 102 of the first substrate 10, the ball grid array 70 being disposed adjacent to the chip 50. The ball grid array 70 is used to transmit information received by the antenna to the motherboard of the device/device.

进一步地,所述第一基板10包括第一板体13及保护层19。所述第一板体13设有线路。所述保护层19设于所述第一板体13的下表面上,用于保护第一基板10内的线路。所述凸起部15设于所述第一板体13的上表面,所述芯片50、所述球栅阵列70与所述保护层19相邻设置。Further, the first substrate 10 includes a first plate body 13 and a protective layer 19. The first plate body 13 is provided with a line. The protective layer 19 is disposed on a lower surface of the first board 13 for protecting a line in the first substrate 10. The protruding portion 15 is disposed on an upper surface of the first plate body 13 , and the chip 50 and the ball grid array 70 are disposed adjacent to the protective layer 19 .

进一步地,第一板体13包括覆铜板(Copper Clad Laminate,CCL)及半固化片(Prepreg,PPG)。本实施方式中,所述覆铜板的数量为四个,所述半固化片的数量为一个,所述半固化片的两侧分别设有两个覆铜板。所述覆铜板及所述半固化片内设有线路。第二基板30由覆铜板制成。当然,第一板体13可以为其他叠层结构,在此不作限定。Further, the first plate 13 comprises a copper clad laminate (CCL) and a prepreg (PPG). In this embodiment, the number of the copper clad laminates is four, the number of the prepregs is one, and the two prepregs are respectively provided with two copper clad laminates. A circuit is disposed in the copper clad laminate and the prepreg. The second substrate 30 is made of a copper clad laminate. Of course, the first plate body 13 may be other laminated structures, which is not limited herein.

在一实施方式中,请参阅图4,所述通孔31的侧壁包括凹凸不平的微结构311,能够增大所述通孔31的侧壁与所述粘结胶体60的接触面,进而能够提高所述粘结胶体60与所述通孔31的侧壁结合的可靠性。In an embodiment, referring to FIG. 4, the sidewall of the through hole 31 includes an uneven microstructure 311, which can increase the contact surface between the sidewall of the through hole 31 and the adhesive colloid 60. The reliability of bonding of the adhesive colloid 60 to the sidewall of the through hole 31 can be improved.

本申请实施方式还提供了一种电子装置,包括主板(图未示)及如上所述的封装结构100。所述主板与所述封装结构100之间具有信号传输。The embodiment of the present application further provides an electronic device including a main board (not shown) and the package structure 100 as described above. There is signal transmission between the main board and the package structure 100.

本申请实施方式还提供一种封装方法,请参阅图5,其包括以下步骤:The embodiment of the present application further provides a packaging method. Referring to FIG. 5, the method includes the following steps:

步骤401,请参阅图6,在第一基板10的凸起部15围绕出的第一粘结区11注入粘结胶体60。 Step 401, referring to FIG. 6, the adhesive layer 60 is injected into the first bonding region 11 surrounded by the convex portion 15 of the first substrate 10.

可以通过点胶设备(图未示)在第一基板10的第一粘结区11进行点胶,或者采用钢网印刷工艺在第一粘结区11涂胶。The glue may be applied to the first bonding region 11 of the first substrate 10 by a dispensing device (not shown) or by a stencil printing process.

步骤402,请参阅图7,将第二基板30压接于所述第一基板10上,所述第一基板10上的凸起部15和所述第二基板30上的凸起部35彼此相对并在所述第一基板10和所述第二基板30之间围绕出粘结区107以及用于收容天线辐射体17的天线区108,所述第一粘结区11对应所述粘结区107,所述粘结胶体60自所述粘结区107满溢至所述第二基板30的通孔31,所述粘结胶体60在所述粘结区107和所述通孔31中凝结构成了铆钉结构。本实施方式中,所述上片设备为一真空吸附设备,所述上片设备利用真空吸附所述第二基板30。 Step 402, referring to FIG. 7, the second substrate 30 is crimped onto the first substrate 10, and the convex portion 15 on the first substrate 10 and the convex portion 35 on the second substrate 30 are mutually connected to each other. Opposite and surrounding the bonding area 107 between the first substrate 10 and the second substrate 30 and the antenna area 108 for accommodating the antenna radiator 17, the first bonding area 11 corresponds to the bonding In the region 107, the adhesive colloid 60 overflows from the bonding region 107 to the through hole 31 of the second substrate 30, and the adhesive colloid 60 is in the bonding region 107 and the through hole 31. The condensate structure becomes a rivet structure. In this embodiment, the top sheet device is a vacuum adsorption device, and the top sheet device adsorbs the second substrate 30 by vacuum.

由于所述第二基板30压接所述第一基板10的压力作用,以及凸起部15与凸起部35的阻挡作用,粘结胶体60挤入通孔31形成铆钉结构,所述铆钉结构能够将第一基板10与第二基板30牢固连接于一起,进而加强了第一基板10与第二基板30的连接强度。此外,由于所述上片设备采用真空吸附所述第二基板30,使得在将所述第二基板30压接于所述第一基板10的过程中,因真空向上吸附第二基板30的作用,仅有微量,或者无粘结胶体60进入凸起部15与凸起部35之间,因此,有利于稳定天线辐射体17与所述第二基板37之间的缝隙170的作用,确保天线性能。Because the second substrate 30 is pressed against the pressure of the first substrate 10, and the blocking action of the convex portion 15 and the convex portion 35, the adhesive colloid 60 is extruded into the through hole 31 to form a rivet structure, and the rivet structure The first substrate 10 and the second substrate 30 can be firmly connected together, thereby enhancing the connection strength between the first substrate 10 and the second substrate 30. In addition, since the top sheet device vacuum-adsorbs the second substrate 30, in the process of crimping the second substrate 30 to the first substrate 10, the second substrate 30 is adsorbed by the vacuum. There is only a trace amount, or the non-adhesive colloid 60 enters between the convex portion 15 and the convex portion 35, thereby facilitating the stabilization of the slit 170 between the antenna radiator 17 and the second substrate 37, ensuring the antenna. performance.

步骤403,请参阅图8,将芯片50固定于所述第一基板10。 Step 403, referring to FIG. 8, the chip 50 is fixed to the first substrate 10.

本实施方式中,采用常规覆晶工艺贴芯片50于第一基板10的下表面102。芯片50与所述第一基板10内的线路馈接。In the embodiment, the chip 50 is attached to the lower surface 102 of the first substrate 10 by a conventional flip chip process. The chip 50 is fed into a line within the first substrate 10.

步骤404,请再次参阅图1,将球栅阵列70植球于所述第一基板10的下表面102,所述球栅阵列70与所述芯片50相邻设置。球栅阵列70与第一基板10的线路连接。 Step 404, referring again to FIG. 1, the ball grid array 70 is implanted on the lower surface 102 of the first substrate 10, and the ball grid array 70 is disposed adjacent to the chip 50. The ball grid array 70 is connected to the line of the first substrate 10.

本申请实施方式提供的封装结构、电子装置及封装方法,由于第二基板30对应第一粘结区11设有通孔31,使得在封装时所述粘结区107内的粘结胶体60因挤压进入所述通孔31,进而形成连接所述第一基板10与所述第二基板30的铆钉结构,避免粘结胶体60进入天线区108的同时,亦加强了所述第一基板10与所述第二基板30之间的连接强度。进一步地,凸起部15与凸起部35,能够有效控制粘结胶体60的用量,进一步避免粘结胶体60进入天线区108。更甚者,利用凸起部15与凸起部35的厚度起到支撑第一基板10及第二基板30的作用的同时,能够有效保持所述第一基板10与所述第二基板30的间距,确保所述天线辐射体17与所述第二基板30之间缝隙170的稳定性,确保封装结构100的天线性能。The package structure, the electronic device, and the packaging method provided by the embodiment of the present application, because the second substrate 30 is provided with the through hole 31 corresponding to the first bonding region 11, so that the adhesive colloid 60 in the bonding region 107 is encapsulated at the time of packaging. Extrusion into the through hole 31 to form a rivet structure connecting the first substrate 10 and the second substrate 30 to prevent the adhesive colloid 60 from entering the antenna region 108, and strengthening the first substrate 10 The strength of the connection with the second substrate 30. Further, the convex portion 15 and the convex portion 35 can effectively control the amount of the adhesive colloid 60, and further prevent the adhesive colloid 60 from entering the antenna region 108. Moreover, while the thickness of the convex portion 15 and the convex portion 35 serves to support the first substrate 10 and the second substrate 30, the first substrate 10 and the second substrate 30 can be effectively maintained. The spacing ensures the stability of the gap 170 between the antenna radiator 17 and the second substrate 30, ensuring the antenna performance of the package structure 100.

第一基板10、第二基板30之间的缝隙170的高度稳定,即使经过多次高温热循环,仍然能够保持较好的稳定性。第二基板30的通孔31有效吸收多余的溢胶,有效解决了溢胶污染天线区和粘性物质厚度控制困难的工艺问题。同时溢胶与焊接面的胶一起形成铆钉结构,起到很好的焊接第一基板10、第二基板30的作用。The height of the slit 170 between the first substrate 10 and the second substrate 30 is stable, and good stability can be maintained even after a plurality of high-temperature heat cycles. The through hole 31 of the second substrate 30 effectively absorbs excess overflow glue, and effectively solves the technical problem that the overflow of the antenna area and the thickness of the viscous material are difficult to control. At the same time, the glue overflows with the glue of the welding surface to form a rivet structure, which plays a good role in welding the first substrate 10 and the second substrate 30.

以上所述,仅为本发明的具体实施方式,但本发明的保护范围并不局限于此,任何熟悉本技术领域的技术人员在本发明揭露的技术范围内,可轻易想到变化或替换,都应涵盖在本发明的保护范围之内。因此,本发明的保护范围应以所述权利要求的保护范围为准。The above is only a specific embodiment of the present invention, but the scope of the present invention is not limited thereto, and any person skilled in the art can easily think of changes or substitutions within the technical scope of the present invention. It should be covered by the scope of the present invention. Therefore, the scope of the invention should be determined by the scope of the appended claims.

Claims (11)

- 一种封装结构,其特征在于,包括第一基板、第二基板及芯片,所述第二基板被安装在所述第一基板的上表面上,所述芯片被安装在所述第一基板上,A package structure, comprising: a first substrate, a second substrate, and a chip, the second substrate being mounted on an upper surface of the first substrate, the chip being mounted on the first substrate ,所述第一基板的上表面上设有间隔的凸起部,所述第二基板的下表面设置有间隔的凸起部,所述第一基板上的凸起部和所述第二基板上的凸起部彼此相对并在所述第一基板和所述第二基板之间围绕出粘结区以及用于收容天线辐射体的天线区,The upper surface of the first substrate is provided with spaced protrusions, and the lower surface of the second substrate is provided with spaced protrusions, the protrusions on the first substrate and the second substrate The raised portions are opposed to each other and surround the bonding region between the first substrate and the second substrate and an antenna region for receiving the antenna radiator.所述第二基板上设置有贯穿所述第二基板的上下表面的通孔,所述通孔与所述粘结区相通,所述通孔和所述粘结区中注有粘结胶体,所述粘结胶体自所述粘结区满溢至所述通孔中,所述粘结胶体在所述粘结区和所述通孔中凝结构成了铆钉结构。The second substrate is provided with a through hole penetrating through the upper and lower surfaces of the second substrate, the through hole is in communication with the bonding region, and the through hole and the bonding region are filled with a bonding gel. The adhesive colloid overflows from the bonding region into the through hole, and the adhesive colloid is condensed into a rivet structure in the bonding region and the through hole.

- 根据权利要求1所述的封装结构,其特征在于,所述第二基板的上表面也设有天线辐射体,所述第二基板的上表面的天线辐射体与所述天线区中的天线辐射体相对应。The package structure according to claim 1, wherein an upper surface of the second substrate is also provided with an antenna radiator, an antenna radiator of an upper surface of the second substrate and an antenna radiation in the antenna region The body corresponds.

- 根据权利要求1所述的封装结构,其特征在于,所述通孔的侧壁包括凹凸不平的微结构。The package structure according to claim 1, wherein the sidewall of the through hole comprises an uneven microstructure.

- 根据权利要求1所述的封装结构,其特征在于,所述第一基板的凸起部与对应的所述第二基板的凸起部无缝隙贴合于一起。The package structure according to claim 1, wherein the convex portion of the first substrate and the corresponding convex portion of the second substrate are seamlessly bonded together.

- 根据权利要求1所述的封装结构,其特征在于,所述天线区中的天线辐射体与所述第二基板之间缝隙的宽度位于0~100um之间。The package structure according to claim 1, wherein a width of a gap between the antenna radiator and the second substrate in the antenna region is between 0 and 100 um.

- 根据权利要求1所述的封装结构,其特征在于,所述封装结构还包括邻近所述封装结构边缘设置的外围区域,所述第一基板位于所述外围区域的凸起部的截面宽度小于所述第二基板位于所述外围区域的凸起部的截面宽度。The package structure according to claim 1, wherein the package structure further comprises a peripheral region disposed adjacent to an edge of the package structure, wherein a width of a section of the protrusion of the first substrate located in the peripheral region is smaller than The second substrate is located at a cross-sectional width of the convex portion of the peripheral region.

- 根据权利要求1所述的封装结构,其特征在于,所述第一基板包括第一板体及保护层,所述保护层设于所述第一板体的下表面上,所述凸起部设于所述第一板体的上表面,所述芯片与所述保护层相邻设置。The package structure according to claim 1, wherein the first substrate comprises a first plate body and a protective layer, and the protective layer is disposed on a lower surface of the first plate body, the convex portion The chip is disposed adjacent to the protective layer on the upper surface of the first plate.

- 根据权利要求1-7项任意一项所述的封装结构,其特征在于,所述封装结构还包括球栅阵列,所述球栅阵列安装于所述第一基板的下表面,所述球栅阵列与所述芯片相邻设置。The package structure according to any one of claims 1 to 7, wherein the package structure further comprises a ball grid array, the ball grid array being mounted on a lower surface of the first substrate, the ball grid The array is disposed adjacent to the chip.

- 一种电子装置,其特征在于,所述电子装置包括主板和根据权利要求1-8任意一项所述的封装结构,所述主板与所述封装结构之间具有信号传输。An electronic device, comprising: a main board and a package structure according to any one of claims 1-8, wherein the main board and the package structure have signal transmission.

- 一种封装方法,其特征在于,所述封装方法包括以下步骤:A packaging method, characterized in that the packaging method comprises the following steps:在第一基板的凸起部围绕出的第一粘结区注入粘结胶体;Injecting an adhesive colloid at a first bonding region surrounded by the convex portion of the first substrate;将第二基板压接于所述第一基板上,所述第一基板上的凸起部和所述第二基板上的凸起部彼此相对并在所述第一基板和所述第二基板之间围绕出粘结区以及用于收容天线辐射体的天线区,所述第一粘结区对应所述粘结区,所述粘结胶体自所述粘结区满溢至所述第二基板的通孔,所述粘结胶体在所述粘结区和所述通孔中凝结构成了铆钉结构。Pressing a second substrate on the first substrate, the convex portion on the first substrate and the convex portion on the second substrate facing each other and on the first substrate and the second substrate Between the bonding zone and the antenna zone for receiving the antenna radiator, the first bonding zone corresponds to the bonding zone, and the bonding gel overflows from the bonding zone to the second a through hole of the substrate, wherein the adhesive colloid is condensed into a rivet structure in the bonding region and the through hole.

- 根据权利要求10所述的封装方法,其特征在于,所述“将第二基板压接于所述第一基板上”的步骤中,通过上片设备真空吸附所述第二基板并将所述第二基板压接于所述第一基板上。The packaging method according to claim 10, wherein in the step of "pressing the second substrate onto the first substrate", the second substrate is vacuum-adsorbed by the upper sheet device and the The second substrate is crimped onto the first substrate.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201810307078.6 | 2018-04-08 | ||

| CN201810307078.6A CN110349931B (en) | 2018-04-08 | 2018-04-08 | Packaging structure, electronic device and packaging method |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2019196598A1 true WO2019196598A1 (en) | 2019-10-17 |

Family

ID=68163931

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/CN2019/078509 WO2019196598A1 (en) | 2018-04-08 | 2019-03-18 | Package structure, electronic device and packaging method |

Country Status (2)

| Country | Link |

|---|---|

| CN (1) | CN110349931B (en) |

| WO (1) | WO2019196598A1 (en) |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101785097A (en) * | 2008-07-01 | 2010-07-21 | 欧姆龙株式会社 | Electronic component |

| CN102007519A (en) * | 2008-04-14 | 2011-04-06 | 国际商业机器公司 | Radio frequency (rf) integrated circuit (ic) packages with integrated aperture-coupled patch antenna(s) in ring and/or offset cavities |

| CN102197475A (en) * | 2009-03-12 | 2011-09-21 | 爱信艾达株式会社 | Semiconductor module |

| US9620464B2 (en) * | 2014-08-13 | 2017-04-11 | International Business Machines Corporation | Wireless communications package with integrated antennas and air cavity |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH088293A (en) * | 1994-06-16 | 1996-01-12 | Casio Comput Co Ltd | Structure for connecting electronic parts and connection method therefor |

| JP3426589B2 (en) * | 2001-07-16 | 2003-07-14 | 沖電気工業株式会社 | Surface mount type semiconductor package and method of manufacturing the same |

| JP2004288826A (en) * | 2003-03-20 | 2004-10-14 | Murata Mfg Co Ltd | Package element |

| CN1319159C (en) * | 2003-03-26 | 2007-05-30 | 矽品精密工业股份有限公司 | Semiconductor package part with radiation fin |

| US7012326B1 (en) * | 2003-08-25 | 2006-03-14 | Xilinx, Inc. | Lid and method of employing a lid on an integrated circuit |

| US9520352B2 (en) * | 2014-12-10 | 2016-12-13 | Shinko Electric Industries Co., Ltd. | Wiring board and semiconductor device |

-

2018

- 2018-04-08 CN CN201810307078.6A patent/CN110349931B/en active Active

-

2019

- 2019-03-18 WO PCT/CN2019/078509 patent/WO2019196598A1/en active Application Filing

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102007519A (en) * | 2008-04-14 | 2011-04-06 | 国际商业机器公司 | Radio frequency (rf) integrated circuit (ic) packages with integrated aperture-coupled patch antenna(s) in ring and/or offset cavities |

| CN101785097A (en) * | 2008-07-01 | 2010-07-21 | 欧姆龙株式会社 | Electronic component |

| CN102197475A (en) * | 2009-03-12 | 2011-09-21 | 爱信艾达株式会社 | Semiconductor module |

| US9620464B2 (en) * | 2014-08-13 | 2017-04-11 | International Business Machines Corporation | Wireless communications package with integrated antennas and air cavity |

Also Published As

| Publication number | Publication date |

|---|---|