明細書 布帛と加硫ゴムの結合体及びその製造法 技術分野 Description: Combined fabric and vulcanized rubber and method for producing the same

本発明は、 布帛と加硫ゴムの結合体及びその製造法、 更こ詳しくはゴム ·ゴム スポンジ/繊維の接着方法に関する。 背景技術 The present invention relates to a combination of a cloth and a vulcanized rubber and a method for producing the same, and more particularly, to a method for bonding rubber / rubber sponge / fiber. Background art

従来、 主にゴムと繊維の接着技術は、 タイヤ ·ベルト ·ホースなどの工業材料 製造業界より多くの特許が出願されている。 基本的にはタイヤ ·ベルト ·ホース などのゴムと繊維の複合体を得るもので、 例えばレゾルシンホルマリンラテック ス (R F L ) 処理による接着、 或いは練り込み型接着が行われている (例えば特 許文献 1〜2参照)。 Conventionally, many patents have been applied for the technology of bonding rubber and fiber, mainly from the manufacturing industry of industrial materials such as tires, belts and hoses. Basically, a composite of rubber and fiber such as tires, belts, hoses, etc. is obtained. For example, adhesion by resorcinol formalin latex (RFL) treatment or kneading-type adhesion is performed (for example, see Patent Document 1). 2).

〔特許文献 1〕 特開昭 5 4 _ 4 9 7 6号公報 (Patent Document 1) JP-A-54_4976

〔特許文献 2〕 特開平 6— 3 0 6 2 1 1号公報 [Patent Document 2] Japanese Patent Application Laid-Open No. Hei 6-306201

R F Lは、 主に以下の 3段階の工程でゴムと繊維の複合体を得る。 RFL mainly obtains a composite of rubber and fiber in the following three steps.

( 1 ) エポキシ化合物ゃィソシァネー卜化合物で繊維を処理して、 2 0 0〜2 5 0 °Cの高温で熱処理する、 (1) treating the fiber with an epoxy compound / diacid compound and heat treating at a high temperature of 200 to 250 ° C;

( 2 ) レゾルシン一ホルムアルデヒド初期縮合物とゴムラテックスの混合液 (R F L液) で繊維を処理し、 再度、 2 0 0〜2 5 O tの高温で熱処理する、 ( 3 ) 未加硫のゴム中に、 この処理した繊維材料を埋設して、 加硫接着する。 練り込み型接着は、 R F L処理にも用いられるレゾルシン一ホルムアルデヒド 縮合物など (加熱によりホルムアルデヒドを発生するホル厶アルデヒド発生剤) を、 ゴム加工工程中に、 ゴム側に配合し、 繊維側の接着剤処理の有無にかかわら ず、 未加硫のゴムの加硫工程において繊維との接着を行なレ 複合体を得る。 これらの加硫接着条件は、 一般的には、 加熱 ·加圧によるプレス成型で、 タイ

ャ ·ベルト ·ホースなどのゴムと繊維の複合体 (成形品) を得る加硫時間は、 2 0〜3 0分以上と長い。 これは用途に応じたもので、 得られる製品の厚み (略 1 0 mm以上) によるところが大きい。 ただし、 繊維自体をゴムの補強材とした複 合体 (成形品) とするために、 補強性 ·剛性の向上などを主な目的としている。 上記のような一般的なタイヤ ·ベルト ·ホースなどに見られる従来技術では、 繊維をゴムの補強材として使用するための技術であり、 本発明の繊維とゴムの接 着技術とは全く異なるものである。 即ち、 上記タイヤなどに見られる接着処理技 術における、 R F L処理や練り込み型接着は、 基本的に繊維がゴム中に埋設され る。 一方、 後者の接着においては繊維がゴム中に埋設されることに限定されない。 また R F L処理については、 繊維を高温で処理するため、 繊維の劣化、 老化が 懸念され、 繊維の強度低下を引き起こす。 また、 殆んどがカーボンブラックを添 加するものであり、 カラーが黒色に限定される。 (2) Treat the fiber with a mixture of resorcinol-formaldehyde precondensate and rubber latex (RFL solution) and heat treat again at a high temperature of 200 to 25 Ot. (3) In unvulcanized rubber Then, the treated fiber material is embedded and vulcanized and bonded. In the kneading-type bonding, a resorcinol-formaldehyde condensate (formaldehyde generating agent that generates formaldehyde by heating), which is also used for RFL treatment, is compounded on the rubber side during the rubber processing process, and the fiber side adhesive is used. Irrespective of the presence or absence of the treatment, the unvulcanized rubber is bonded to the fiber in the vulcanization step to obtain a composite. These vulcanization bonding conditions are generally press molding by heating and pressurizing. The vulcanization time to obtain rubber-fiber composites (molded products) such as rubber belts and hoses is as long as 20 to 30 minutes. This depends on the application and largely depends on the thickness of the product obtained (about 10 mm or more). However, the main purpose is to improve the reinforcing property and rigidity in order to make a composite (molded product) using the fiber itself as a rubber reinforcing material. The conventional technology found in general tires, belts, hoses, etc. as described above is a technology for using fibers as a reinforcing material for rubber, and is completely different from the fiber-rubber bonding technology of the present invention. It is. That is, in the RFL treatment and the kneading-type adhesion in the adhesion treatment technology found in the above-mentioned tires and the like, fibers are basically embedded in rubber. On the other hand, the latter bonding is not limited to embedding fibers in rubber. In the RFL treatment, since the fiber is treated at a high temperature, deterioration and aging of the fiber are feared, and the strength of the fiber is reduced. Most also add carbon black, and the color is limited to black.

練り込み型接着方法についてもホルムアルデヒドの影響により、 繊維やゴムの 変色の問題は避けることができず、 視覚的に露出される個所への適用は困難であ る。 また、 上記の R F Lおよび練り込み型接着方法は、 処理方法や成形に費やす 時間が長く、 量産化においては設備費用が莫大となる。 Even with the kneading-type bonding method, the problem of discoloration of fibers and rubber cannot be avoided due to the effect of formaldehyde, and it is difficult to apply it to visually exposed places. In addition, the above RFL and kneading-type bonding methods require a long time for processing methods and molding, and the equipment cost is enormous in mass production.

本発明の課題は高温での処理が必要でなく、 繊維の強度低下を引き起こすこと がなく、 エネルギー効率もよい布帛と加硫ゴムの結合体及びその製造法を提供す ることにある。 An object of the present invention is to provide a combination of a fabric and a vulcanized rubber which does not require high-temperature treatment, does not cause a decrease in fiber strength, and has high energy efficiency, and a method for producing the same.

本発明の目的は短時間で加硫が完了し生産性が高く、 必要な接着力が得られる 布帛と加硫ゴムの結合体及びその製造法を提供することにある。 An object of the present invention is to provide a combination of a cloth and a vulcanized rubber, which can complete vulcanization in a short time and has a high productivity and a required adhesive strength, and a method for producing the same.

本発明の目的はホルムアルデヒドを使用しないので、 ゴム ·ゴムスポンジゃ繊 維の変色がなく、 力ラー化が可能な布帛と加硫ゴムの結合体及びその製造法を提 供することにある。 発明の開示 An object of the present invention is to provide a composite of a fabric and a vulcanized rubber, which does not discolor rubber / rubber sponge / fiber because it does not use formaldehyde, and which can be made strong, and a method for producing the same. Disclosure of the invention

本発明は以下の発明に係る。

1 . 布帛にイソシァネート化合物を含浸、 乾燥させ、 次にこれにスチレン系ポ リマーを含む接着剤を含浸、 乾燥させ、 得られた布帛に未加硫ゴムを載せて、 加 熱プレスすることにより未加硫ゴムを加硫すると同時に布帛に接着させることに より得られる、 布帛と加硫ゴムの結合体。 The present invention relates to the following inventions. 1. Impregnate the fabric with an isocyanate compound, dry it, then impregnate it with an adhesive containing a styrene-based polymer, dry it, place the unvulcanized rubber on the resulting fabric, and press it by hot pressing. A combined fabric and vulcanized rubber obtained by vulcanizing a vulcanized rubber and simultaneously adhering it to a fabric.

2 . 布帛にイソシァネート化合物を含浸、 乾燥させる工程、 得られた布帛にス チレン系ポリマーを含む接着剤を含浸、 乾燥させる工程、 得られた布帛に未加硫 ゴムを載せて、 加熱プレスすることにより未加硫ゴムを加硫すると同時に布帛に 接着させる工程を含むことを特徴とする、 布帛と加硫ゴムの結合体の製造法。 3 . 布帛にイソシァネート化合物を含浸、 乾燥させる工程の前に、 布帛を予め 溶剤で前処理する、 上記布帛と加硫ゴムの結合体の製造法。 2. Impregnating and drying the fabric with an isocyanate compound, impregnating the obtained fabric with an adhesive containing a styrene-based polymer, and drying. Placing unvulcanized rubber on the obtained fabric and heating and pressing. And vulcanizing the unvulcanized rubber and simultaneously adhering the unvulcanized rubber to a fabric. 3. A method for producing a combined body of the above-mentioned cloth and vulcanized rubber, wherein the cloth is pre-treated with a solvent before the step of impregnating and drying the cloth with an isocyanate compound.

本発明の布帛と加硫ゴムの結合体、 布帛処理方法は、 従来技術とは根本的に異 なり、 全く新しいゴム ·ゴムスポンジ Z繊維の接着手法に関する発明である。 本発明において、 布帛としてはポリエステル繊維、 ポリアミド繊維、 アクリル 繊維、 ポリプロピレン繊維、 アセテート繊維、 ガラス繊維、 カーボン繊維、 ァラ ミド繊維、 ポリイミド繊維などの合成繊維、 綿、 絹、 麻などの天然繊維、 また他 の繊維より得られた織布、 不織布、 編み布、 一方これらを表面起毛させた布帛な どを例示することができる。 The bonded body of fabric and vulcanized rubber and the fabric treatment method of the present invention are fundamentally different from the prior art, and are an invention relating to a completely new rubber / rubber sponge Z fiber bonding method. In the present invention, as the fabric, synthetic fibers such as polyester fiber, polyamide fiber, acrylic fiber, polypropylene fiber, acetate fiber, glass fiber, carbon fiber, aramide fiber, and polyimide fiber; natural fibers such as cotton, silk, and hemp; In addition, woven fabrics, nonwoven fabrics, knitted fabrics obtained from other fibers, and fabrics obtained by raising the surface thereof on the other hand can be exemplified.

これら布帛はイソシァネート化合物を含浸させる前に、 予め溶剤で前処理する のが好ましい。 溶剤としては、 例えばトルエン、 酢酸ェチル、 メチルェチルケト ン、 アセトンなどを例示することができる。 These fabrics are preferably pre-treated with a solvent before impregnation with the isocyanate compound. Examples of the solvent include toluene, ethyl acetate, methyl ethyl ketone, acetone and the like.

イソシァネート化合物としては、 イソシァネート基を有する化合物なら特に限 定されず、 例えばフエ二レンジイソシァネート, 1、リレンジイソシァネ一卜 (T D I ) , キシリレンジイソシァネー卜 (X D I ), トリフエニルメタントリイソシ ァネート (T T I )、 ジフエニルメタンジイソシァネート (MD I )、 1、リス (フ ェニルイソシァネート) チ才フホスフエ一卜、 へキサメチレンジイソシァネー卜 などのポリイソシァネート化合物を例示することができる。 The isocyanate compound is not particularly limited as long as it has an isocyanate group. Examples thereof include phenylene diisocyanate, 1, reylene diisocyanate (TDI), xylylene diisocyanate (XDI), and triphenyl. Polyisocyanates such as methane triisocyanate (TTI), diphenyl methane diisocyanate (MDI), 1, squirrel (phenyl isocyanate), and hexamethylene diisocyanate Compounds can be exemplified.

布帛にイソシァネート化合物を含浸するには、 例えば布帛をイソシァネート溶

液に浸漬して含浸させる方法を例示することができるが、 これに限定されるもの ではない。 その際のイソシァネート溶液の固形分は 0. 5〜4. 2重量%が好まし く、 1〜3. 5重量%が特に好ましい。 イソシァネート化合物を含浸した後、 約 4 0〜1 0 0 ° (:、 好ましくは約 6 0〜8 0 °Cで乾燥させ、 次にこれにスチレン系 ポリマーを含む接着剤を含浸、 乾燥させる。 To impregnate the fabric with the isocyanate compound, for example, A method of immersing in a liquid for impregnation can be exemplified, but the method is not limited thereto. In this case, the solid content of the isocyanate solution is preferably 0.5 to 4.2% by weight, particularly preferably 1 to 3.5% by weight. After impregnating with the isocyanate compound, it is dried at about 40 to 100 ° (preferably at about 60 to 80 ° C), and then impregnated with an adhesive containing a styrene-based polymer and dried.

スチレン系ポリマーとしては、 例えばスチレンブ夕ジェンゴム ( S B R)、 ス チレンブタジエン系熱可塑性エラストマ一 ( S B S ) などを例示することができ る。 本発明の接着剤はスチレン系ポリマー以外に例えば天然ゴム、 ァクリロニト リルブタジエンゴムなどを含むことができる。 本発明の接着剤には、 更に加硫促 進剤、 可塑剤、 活性剤、 亜鉛華、 硫黄、 ホワイトカーボンなどの補強材などを配 合することができる。 Examples of the styrene polymer include styrene butene rubber (SBR) and styrene butadiene thermoplastic elastomer (SBS). The adhesive of the present invention can contain, for example, natural rubber, acrylonitrile butadiene rubber, and the like in addition to the styrene-based polymer. The adhesive of the present invention may further include a vulcanization accelerator, a plasticizer, an activator, a reinforcing material such as zinc white, sulfur, and white carbon.

本発明の接着剤の固形分中のスチレン含有量は 2〜4 7重量%が好ましく、 特 に 5〜4 0重量%が好ましい。 接着剤の布帛への含浸比率は布帛重量に対して 3 0重量%以上が好ましく、 特に 4 0〜1 0 0重量%が好ましい。 The styrene content in the solid content of the adhesive of the present invention is preferably 2 to 47% by weight, particularly preferably 5 to 40% by weight. The impregnating ratio of the adhesive to the fabric is preferably 30% by weight or more, and more preferably 40 to 100% by weight, based on the weight of the fabric.

接着剤を含浸するには、 例えば布帛を接着剤の溶液に浸漬して含浸させる方法 を例示することができるが、 これに限定されるものではない。 接着剤を含浸した 後、 約 4 0〜 1 0 0 °C、 好ましくは約 6 0〜 8 0 °Cで乾燥させる。 Examples of the method of impregnating the adhesive include, but are not limited to, a method of impregnating the cloth by immersing the cloth in a solution of the adhesive. After impregnating the adhesive, it is dried at about 40 to 100 ° C, preferably at about 60 to 80 ° C.

上記のようにイソシァネート化合物とスチレン系ポリマーを含む接着剤を含浸 して得られた布帛に未加硫ゴムを載せて (密着させて)、 加熱プレスすることに より未加硫ゴムを加硫すると同時に布帛に接着させ、 布帛と加硫ゴムの結合体を 得ることができる。 加熱プレスは約 1 4 0〜 1 8 0 ° (:、 好ましくは約 1 5 0〜 1 6 O で行うのが好ましい。 加熱プレスの時間は通常 3〜1 0分程度が好ましい。 未加硫ゴムのゴム成分としては、 例えば天然ゴム、 イソプレンゴム、 スチレンブ 夕ジェンゴム、 アクリロニトリルブタジエンゴム、 ブタジエンゴム、 クロロプレ ンゴム、 プチルゴムなどを例示することができる。 As described above, the unvulcanized rubber is placed on the fabric obtained by impregnating the adhesive containing the isocyanate compound and the styrene-based polymer (closely adhered), and then heated and pressed to vulcanize the unvulcanized rubber. At the same time, it is bonded to the fabric to obtain a combined body of the fabric and the vulcanized rubber. The heating press is performed at about 140 to 180 ° (:, preferably, at about 150 to 16 O. The heating press time is usually preferably about 3 to 10 minutes. Unvulcanized rubber Examples of the rubber component include natural rubber, isoprene rubber, styrene rubber, acrylonitrile butadiene rubber, butadiene rubber, chloroprene rubber, and butyl rubber.

本発明で得られた布帛と加硫ゴムの結合体は軽量性及び屈曲性において、 極め て優れている。 また擦り減りにくく耐久性 (耐摩耗性) に優れている。

本発明の布帛と加硫ゴムの結合体は、 例えば靴のソールの一部又は全部に用い ることができ、 好ましくはグリップ性を有するソール、 さらに好ましくはグ ッ プ性に優れたソールとして使用できる。 それ以外にも例えば軍手、 サッカー用グ ローブなどの手袋、 衣服のワンポイントマーク、 サポ一夕一、 バレーネット CD支 柱カバ一、 繊維強化ゴム (F i b e r Re i n f o r c e d Rub b e :r)、 各種用具のダリップ部分の滑り止めなどのテープ類、 さらには床材料などに用い ることができる。 図面の簡単な説明 The combination of the fabric and the vulcanized rubber obtained by the present invention is extremely excellent in lightness and flexibility. In addition, it is hard to be worn down and has excellent durability (wear resistance). The composite of the fabric and the vulcanized rubber of the present invention can be used, for example, for part or all of the sole of a shoe, and is preferably used as a sole having grip properties, more preferably as a sole having excellent grip properties. it can. Other than that, for example, gloves such as gloves, soccer gloves, one-point marks on clothes, one-off sapo, valet net CD support, fiber reinforced rubber (Fiber Reinforced Rub be: r), various equipment It can be used for tapes such as non-slip of the drip part, as well as floor materials. Brief Description of Drawings

【図 1】 布帛とゴムの引裂剥離強度の測定の概略図、 及び引裂試験における荷 重と変位を示すグラフである。 FIG. 1 is a schematic diagram of the measurement of the tear peel strength of a fabric and rubber, and a graph showing the load and displacement in a tear test.

【図 2】 接着剤中のスチレン量と引裂剥離強度の関係を示すグラフである。 FIG. 2 is a graph showing the relationship between the amount of styrene in the adhesive and the tear peel strength.

【図 3】 接着剤の布帛への含浸比率と引裂剥離強度の関係を示すグラフである。 FIG. 3 is a graph showing a relationship between an impregnation ratio of an adhesive into a fabric and a tear peel strength.

【図 4】 イソシァネート溶液の固形分の濃度と引裂剥離強度の関係を示すグラ フである。 FIG. 4 is a graph showing the relationship between the solid content of the isocyanate solution and the tear strength.

【図 5】 本発明の処理及び RFL処理の各処理後の布帛の引張強度、 伸び、 引 裂強度を未処理の布帛の強度と対比して示すグラフである。 FIG. 5 is a graph showing tensile strength, elongation, and tear strength of the fabric after each of the treatment of the present invention and the RFL treatment in comparison with the strength of an untreated fabric.

【図 6】 本発明の方法を用いて布帛と加硫ゴムの結合体をシューズのソ一 Jレの 一部に形成する模様を示す概略図である。 発明を実施するための最良の形態 FIG. 6 is a schematic view showing a pattern in which a combined body of a fabric and vulcanized rubber is formed on a part of a shoe J using the method of the present invention. BEST MODE FOR CARRYING OUT THE INVENTION

以下に参考例及び実施例を挙げ、 本発明を具体的に説明するが、 本発明は何ら これに限定されるものではない。 Hereinafter, the present invention will be described in detail with reference to Reference Examples and Examples, but the present invention is not limited thereto.

参考例 1 (イソシァネート溶液の作成) Reference Example 1 (Preparation of isocyanate solution)

トリス (フエ二ルイソシァネート) チオフホスフエ一卜 27重量%、 酢酸ェチ ル 7 1重量%、 モノクロ口ベンゼン 2重量%からなる住友バイエルウレタン Sumitomo Bayer Urethane composed of 27% by weight of tris (phenylisocyanate) thiophene phosphate, 71% by weight of ethyl acetate, and 2% by weight of benzene with monochromatic mouth

(株) 社製デスモジュール RFEをトルエンと 1 : 1 0で希釈して、 イソシァネ

—ト化合物の含有量を 2.45重量%のイソシァネート溶液を作成した。 Desmodule RFE manufactured by Co., Ltd. is diluted 1:10 with toluene and isocyanate -An isocyanate solution having a content of 2.45% by weight of the compound was prepared.

参考例 2 (接着剤溶液の作成) Reference Example 2 (Preparation of adhesive solution)

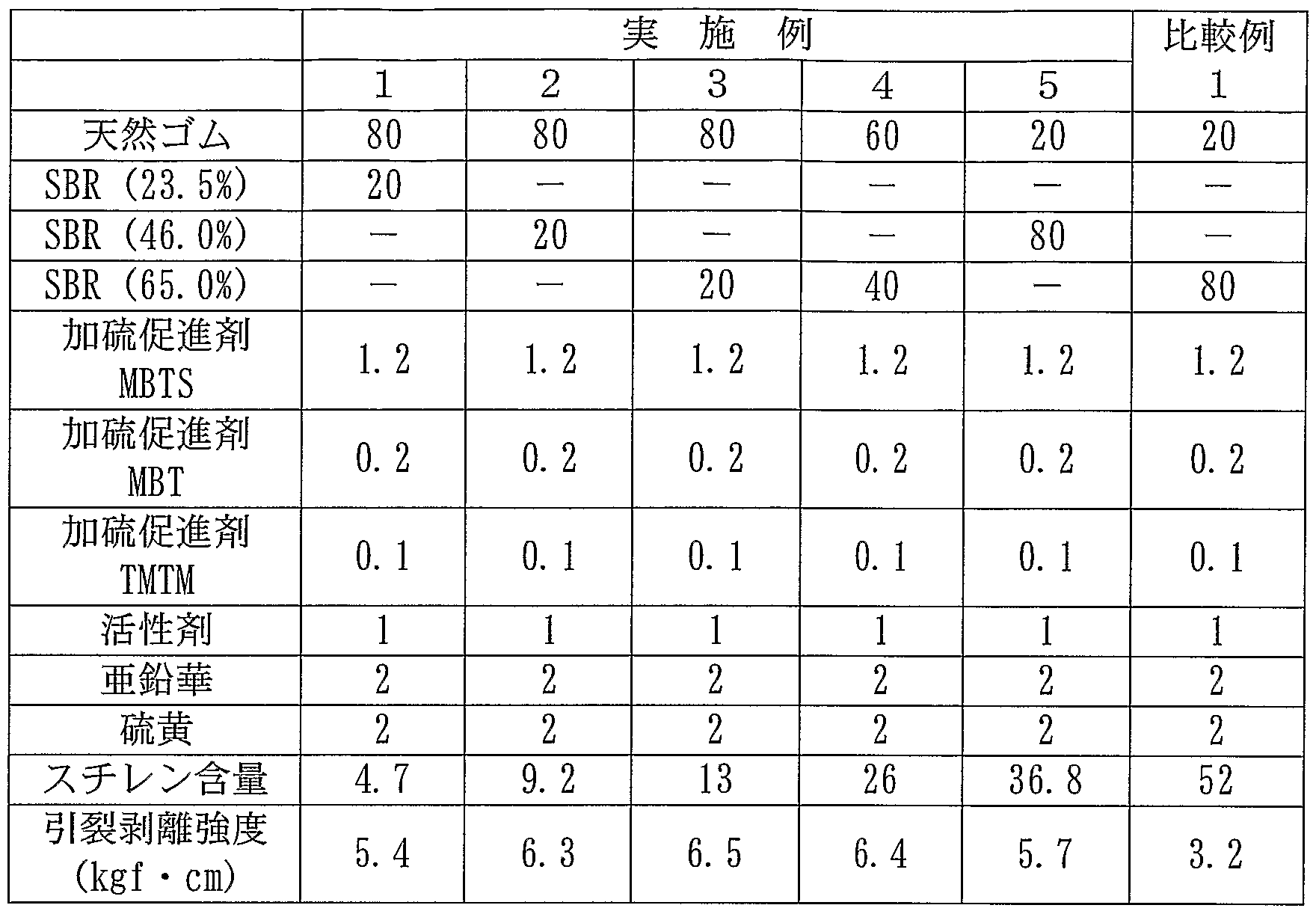

天然ゴムとスチレン含量 23. 5重量%のスチレンブタジエンゴム (SBR) を主成分とする表 1に示した組成から成る接着剤をトルエンと 5 : 95で希釈し、 接着剤溶液 (1) を作成した。 接着剤の固形分全体に対するスチレンの含量は 4. 7重量%であった。 An adhesive consisting of natural rubber and styrene butadiene rubber (SBR) with a styrene content of 23.5% by weight and having the composition shown in Table 1 was diluted with toluene at a ratio of 5:95 to prepare an adhesive solution (1). did. The content of styrene based on the total solid content of the adhesive was 4.7% by weight.

【表 1】 【table 1】

( ) 内は結合スチレン量 (重量%) を示す () Indicates bound styrene content (% by weight)

参考例 3 (未加硫ゴムの作成) Reference Example 3 (Preparation of unvulcanized rubber)

表 2に示した組成から成る未加硫ゴムをロール加工により作成し、 厚さ 4. 5 mmの未加硫ゴムのシートを作成した。 Unvulcanized rubber having the composition shown in Table 2 was prepared by rolling, and a 4.5 mm thick unvulcanized rubber sheet was prepared.

【表 2】 [Table 2]

天然ゴム 100 Natural rubber 100

ホワイ卜カーボン 40 White carbon 40

ステアリン酸 1. 8 Stearic acid 1.8

シランカツプリング剤 2 Silane coupling agent 2

プロセスオイル 10 Process oil 10

活性剤 0. 5 Activator 0.5

亜鉛華 3. 5 Zinc flower 3.5

加硫助剤 1. 2 Vulcanization aid 1.2

老化防止剤 1 Anti-aging agent 1

加硫促進剤 B G 0. 8 Vulcanization accelerator B G 0.8

加硫促進剤 MBTS 0. 15 Vulcanization accelerator MBTS 0.15

加硫促進剤 MBT 0. 9 Vulcanization accelerator MBT 0.9

加硫促進剤 TMTM 0. 1

実施例 1 Vulcanization accelerator TMTM 0.1 Example 1

ポリエステル繊維より得られた織布 (表面起毛 50 cmX 25 cm) をトルェ ン溶液に 1分浸潰して取出した後、 70°Cで 25分放置して乾燥後、 参考例 1の イソシァネート溶液に 3分浸漬して取出した後、 70°Cで 30分乾燥させ、 次い で参考例 2の接着剤溶液に 3分浸漬して取出した後、 70°Cで 30分乾燥させた。 接着剤の布帛への含浸比率は布帛重量に対して 45重量%であった。 得られた布 帛に参考例 3の未加硫ゴムのシートを載置し、 1 55 °Cで 5分加熱プレスして未 加硫ゴムを加硫すると同時に布帛に接着させて布帛と加硫ゴムの結合体を得た。 得られた結合体のゴムと布帛の間の引裂剥離強度を以下の方法により測定した。 その結果、 5.4kg f · cmの引裂剥離強度が得られた。 結果を表 3に示す。 測定方法 A woven cloth (surface raised 50 cm x 25 cm) obtained from polyester fiber is immersed in a toluene solution for 1 minute, taken out, left at 70 ° C for 25 minutes, dried, and then added to the isocyanate solution of Reference Example 1 for 3 minutes. After immersion for 3 minutes, the product was dried at 70 ° C. for 30 minutes, then immersed in the adhesive solution of Reference Example 3 for 3 minutes, taken out, and dried at 70 ° C. for 30 minutes. The impregnation ratio of the adhesive to the fabric was 45% by weight based on the weight of the fabric. The unvulcanized rubber sheet of Reference Example 3 was placed on the obtained fabric, and heated and pressed at 155 ° C for 5 minutes to vulcanize the unvulcanized rubber and simultaneously adhere to the fabric to vulcanize the fabric. A rubber conjugate was obtained. The tear peel strength between the rubber and the fabric of the obtained composite was measured by the following method. As a result, a tearing-off strength of 5.4 kgf · cm was obtained. Table 3 shows the results. Measuring method

引張試験機: (株) 東洋精機製作所製 STROGRAPH VI - B Tensile testing machine: STROGRAPH VI-B manufactured by Toyo Seiki Seisaku-sho, Ltd.

引裂試験方法:クロスへッドスピード 5 Omm/m i n.で一端はゴムを、 一 端は布帛をチャックし、 上記の条件により荷重と変位を計測した。 一端をチヤッ クするゴムの厚さは 4mm、 幅 2 cmとした。 Tear test method: At a crosshead speed of 5 Omm / min, rubber was chucked at one end and the fabric was chucked at one end, and the load and displacement were measured under the above conditions. The thickness of the rubber that checks one end was 4 mm and the width was 2 cm.

引裂試験強度:上記の試験により得られた荷重、 変位から、 チャックしたゴムの 単位幅あたりの剥離エネルギー E 1 (図 1) を布帛とゴムの引裂剥離強度とした。 実施例 2〜 5及び比較例 1 Tear test strength: From the load and displacement obtained in the above test, the peel energy per unit width of the chucked rubber E 1 (FIG. 1) was taken as the tear peel strength between the fabric and rubber. Examples 2 to 5 and Comparative Example 1

スチレン含量 23. 5重量%、 46. 0重量%、 65. 0重量%の 3種のスチレ ンブタジエンゴム (SBR) のいずれか 1種と、 天然ゴムを主成分とする表 3に 示した組成から成る接着剤を用いた以外は実施例 1と同様にして布帛と加硫ゴム の結合体を得た。 Styrene butadiene rubber (SBR) with a styrene content of 23.5% by weight, 46.0% by weight, and 65.0% by weight, and a composition shown in Table 3 mainly composed of natural rubber In the same manner as in Example 1 except that the adhesive consisting of

得られた結合体のゴムと布帛の間の引裂剥離強度を実施例 1と同様にして測定 した結果を表 3及び図 2に示す。

【表 3】 Table 3 and FIG. 2 show the results of measuring the tear-peeling strength between the rubber and the fabric of the obtained composite in the same manner as in Example 1. [Table 3]

( ) 内は結合スチレン量 (重量%) を示す 実施例 6〜 8及び比較例 2 () Indicates the amount of bound styrene (% by weight) Examples 6 to 8 and Comparative Example 2

参考例 2の接着剤溶液の作成時に、 トルエンの比率を変更して、 接着剤の布帛 への含浸比率が 20重量% (比較例 2)、 35重量%、 80重量%、 1 30重 量% (実施例 6〜8) となるようにした以外は実施例 1と同様にして布帛と加硫 ゴムの結合体を得た。 When preparing the adhesive solution of Reference Example 2, the ratio of toluene was changed so that the impregnation ratio of the adhesive into the fabric was 20% by weight (Comparative Example 2), 35% by weight, 80% by weight, and 130% by weight. A combined body of the cloth and the vulcanized rubber was obtained in the same manner as in Example 1 except that (Examples 6 to 8) were used.

得られた結合体のゴムと布帛の間の引裂剥離強度を実施例 1と同様にして測定 した結果を図 3に示す。 FIG. 3 shows the result of measuring the tear-peeling strength between the rubber and the fabric of the obtained combined body in the same manner as in Example 1.

実施例 9〜 12及び比較例 3〜 4 Examples 9 to 12 and Comparative Examples 3 to 4

参考例 1のイソシァネート溶液の作成時に、 トルエンの比率を変更して、 イソ シァネート溶液の固形分の濃度が 1. 2重量%、 2.0重量%、 2. 5重量%、 3. 7重量% (実施例 9〜12)、 0重量%、 4. 5重量% (比較例 3〜4) となるよ うにした以外は実施例 1と同様にして布帛と加硫ゴムの結合体を得た。

得られた結合体のゴムと布帛の間の引裂剥離強度を実施例 1と同様にして測定 した結果を図 4に示す。 When preparing the isocyanate solution of Reference Example 1, the concentration of the solids in the isocyanate solution was changed to 1.2%, 2.0%, 2.5%, and 3.7% by weight by changing the ratio of toluene. Examples 9 to 12), 0% by weight, and 4.5% by weight (Comparative Examples 3 to 4) were performed in the same manner as in Example 1 to obtain a conjugate of a cloth and a vulcanized rubber. FIG. 4 shows the results of measuring the tear-peeling strength between the rubber and the fabric of the obtained combined body in the same manner as in Example 1.

比較例 5 Comparative Example 5

実施例 1において接着剤を用いず、 イソシァネート溶液に浸漬、 乾燥させた布 帛を用いて、 その他は実施例 1と同様にして、 布帛と加硫ゴムの結合体を得た。 得られた結合体のゴムと布帛の間の引裂剥離強度は 1. 6 k g f · cmであった。 試験例 1 A bonded body of a vulcanized rubber and a fabric was obtained in the same manner as in Example 1 except that the fabric was immersed in an isocyanate solution and dried without using an adhesive in Example 1. The tear strength between the rubber and the fabric of the obtained conjugate was 1.6 kgf · cm. Test example 1

本発明の接着手法と一般的な R F L処理の剥離強度の比較を以下のように行つ た。 A comparison of the peel strength between the bonding method of the present invention and general RFL treatment was made as follows.

(1) 本発明接着剤および処理条件 (1) Adhesive of the present invention and processing conditions

接着剤の布帛への含浸比率は布帛重量に対して 30重量%とし、 未加硫ゴムと 布帛を 1 60°CX 6分の条件で加熱プレスした以外は、 実施例 1と同様にして布 帛と加硫ゴムの結合体を得た。 得られた結合体のゴムと布帛の間の引裂剥離強度 は 6. 5 k g f · cmであった。 また、 布帛の色は元の濃いグレイ色よりむしろ 明るいグレイ色に改良されていた。 The cloth was impregnated with the adhesive at a ratio of 30% by weight based on the weight of the cloth, and the uncured rubber and the cloth were heated and pressed at 160 ° C for 6 minutes, except that the cloth was heated in the same manner as in Example 1. And a composite of vulcanized rubber. The tear strength between the rubber and the fabric of the obtained composite was 6.5 kgf · cm. Also, the color of the fabric was improved to a light gray color rather than the original dark gray color.

(2) RFL処理 (2) RFL processing

実施例 1と同様に繊維を洗浄し、 イソシァネート化合物で処理した後、 25 0°CX 1分で熱処理し、 次いでレゾルシン一ホルムアルデヒド初期化合物とゴム ラテックスの混合液 (RFL) で繊維処理し、 250°CX 1分で熱処理して未加 硫ゴムと布帛を 160°CX 6分の条件で加熱プレスして布帛と加硫ゴムの結合体 を得た。 得られた結合体のゴムと布帛の間の引裂剥離強度は 2. 7 kg f · cm であった。 また、 布帛の色は元の濃いグレイ色が茶褐色に変色していた。 The fibers were washed and treated with the isocyanate compound in the same manner as in Example 1, heat-treated at 250 ° C for 1 minute, and then treated with a mixed solution (RFL) of the initial compound of resorcinol-formaldehyde and rubber latex (250 ° C). CX was heat-treated for 1 minute, and the unvulcanized rubber and the fabric were hot-pressed at 160 ° C. for 6 minutes to obtain a combined fabric and vulcanized rubber. The tear strength between the rubber and the fabric of the obtained bonded article was 2.7 kgf · cm. Further, the color of the fabric was changed from the original dark gray color to brown.

(3) 繊維の強度変化の測定 (3) Measurement of fiber strength change

上記 (1) 及び (2) の処理後の繊維の引張強度、 伸び、 引裂強度を未処理の 繊維の強度と併せて図 5に示す。 引張強度、 伸び、 引裂強度はそれぞれ J I S L 1 0 1 8により測定した。 Fig. 5 shows the tensile strength, elongation, and tear strength of the fiber after the treatments (1) and (2), together with the strength of the untreated fiber. Tensile strength, elongation, and tear strength were measured according to JIS L1018, respectively.

試験例 2

実施例 3の接着剤を含浸させたポリエステル布帛の上に加硫ゴムを図 6 ( c ) のようにパターン状に載せ、 実施例 1と同様にして布帛と加硫ゴムの結合体を得 た。 この結合体を図 6 ( d ) のように周囲を抜き型により所望の形状にカットし て、 図 6 ( b ) のシューズのツールの前足部にウレタン系接着剤により接着して 貼り付け図 6 ( a ) のソ一ルを得た。 産業上の利用可能性 Test example 2 A vulcanized rubber was placed in a pattern on the polyester cloth impregnated with the adhesive of Example 3 as shown in FIG. 6 (c), and a combined body of the cloth and the vulcanized rubber was obtained in the same manner as in Example 1. . As shown in Fig. 6 (d), the perimeter is cut into the desired shape using a punching die as shown in Fig. 6 (d), and glued to the forefoot of the shoe tool shown in Fig. 6 (b) with a urethane adhesive. (a) was obtained. Industrial applicability

本発明の方法では高温での処理が必要でなく、 繊維の強度低下を引き起こすこ とがなく、 エネルギー効率もよい布帛と加硫ゴムの結合体を得ることができる。 また本発明では短時間で加硫が完了し生産性が高く、 必要な接着力を有する布 帛と加硫ゴムの結合体が得られる。 The method of the present invention does not require high-temperature treatment, does not cause a decrease in fiber strength, and can provide a combination of a vulcanized rubber and a fabric with high energy efficiency. Further, in the present invention, vulcanization is completed in a short time, the productivity is high, and a bonded body of a cloth and a vulcanized rubber having a necessary adhesive strength can be obtained.

また本発明ではホルムアルデヒドを使用しないので、 ゴム ·ゴムスポンジスポ ンジゃ繊維の変色がなく、 力ラー化が可能な布帛と加硫ゴムの結合体を得ること ができる。

In addition, since formaldehyde is not used in the present invention, a rubber / rubber sponge sponge / fiber has no discoloration, and it is possible to obtain a composite of a fabric and a vulcanized rubber which can be made strong.