US3472341A - Lift truck with telescopic mast - Google Patents

Lift truck with telescopic mast Download PDFInfo

- Publication number

- US3472341A US3472341A US691298A US3472341DA US3472341A US 3472341 A US3472341 A US 3472341A US 691298 A US691298 A US 691298A US 3472341D A US3472341D A US 3472341DA US 3472341 A US3472341 A US 3472341A

- Authority

- US

- United States

- Prior art keywords

- mast

- movable

- rollers

- mast member

- carriage

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B66—HOISTING; LIFTING; HAULING

- B66F—HOISTING, LIFTING, HAULING OR PUSHING, NOT OTHERWISE PROVIDED FOR, e.g. DEVICES WHICH APPLY A LIFTING OR PUSHING FORCE DIRECTLY TO THE SURFACE OF A LOAD

- B66F9/00—Devices for lifting or lowering bulky or heavy goods for loading or unloading purposes

- B66F9/06—Devices for lifting or lowering bulky or heavy goods for loading or unloading purposes movable, with their loads, on wheels or the like, e.g. fork-lift trucks

- B66F9/075—Constructional features or details

- B66F9/08—Masts; Guides; Chains

Definitions

- FIG-2 LRONT 2 L m m w M ,n mm m vA r W9 A A l D L 0, R A H V! a FIG-5 United States Patent 3,472,341 LIFT TRUCK WITH TELESCOPIC MAST Harold A. Stammen, New Bremen, Ohio, assignor to Crown Controls Corporation, New Bremen, Ohio, a corporation of Ohio Filed Dec. 18, 1967, Ser. No. 691,298 Int. Cl. B66b 9/20, 7/02 US. Cl.

- This invention relates to lift trucks and the like, either hand-propelled or self-propelled, which incorporate a socalled telescopic mast and lift structure.

- this lift structure incorporates a fixed mast member which extends generally vertical from the truck frame, and a vertically movable mast member which in turn carries the load supporting carriage.

- the carriage usually has forks or some equivalent structure for holding a load as it is lifted. In some instances, more than one movable mast member is employed, to obtain greater vertical extension.

- the load supported from the carriage is generally carried outwardly of the carriage and mast structure, thus as the load is lifted and particularly as the mast structure is extended, increasing deflection in the mast and its parts, tending to cause the mast and carriage to tilt somewhat.

- Various proposals have been made to compensate for this action, however most of them require some parts causing a tilting movement of the lower mast structure and making it movable with respect to the truck body and frame.

- the present invention provides a novel mast structure of the so-called telescopic type in which the parts supporting and guiding the movable mast member on the fixed mast member are so constructed and arranged that as the mast is extended the movable mast member automatically is caused to tilt in a direction opposite to any deflection caused by the load supported from the carriage, thereby assuring an essentially vertical lifting action, and overcoming any tendency for the load to shift or lean with respect to the mast as the mast is extended.

- the primary object of the invention is to provide a novel guiding and supporting arrangement between the fixed and movable mast members, which cause the movable mast member to tilt increasingly away from the vertical center line of the fixed mast member as the mast member is extended toward its full height; and to provide such an arrangement wherein this action is obtained by locating the axes of rotation of guiding and supporting rollers in the mast structure at such different distances from the vertical center line of the lower or fixed mast member that as the rollers move closer together, the offset of their respective axes of rotation is increasingly effective to tilt the movable mast member.

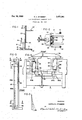

- FIG. 1 is an overall side view of a typical lift truck employing the present invention

- FIG. 2 is a plan view of the truck shown in FIG. 1, illustrating in a general way the arrangement of the telescopic mast and the lift carriage;

- FIG. 3 is an enlarged view of one side of the telescopic mast, with the mast members retracted to their lowered position;

- FIG. 4 is a view taken from the top of the mast structure shown in FIG. 3 with the left hand side in section, taken generally along the lines 4L-4L, and the right hand side shown in elevation taken generally along the line 4R-4R- in FIG. 3;

- FIG. 5 is a diagram illustrating the tiltback action of the mast structure as it is vertically extended.

- a self-propelled walking lift truck is illustrated, as one typical type of truck to which the present invention is applicable. It will be clear to those skilled in th art that the invention is likewise applicable to handpropelled trucks, to self-propelled trucks which carry an operator, and to similar types of vehicles.

- the truck frame 10 supports the body 12, and includes rearwardly extending outriggers 14 which mount supporting wheels 15.

- a single front wheel 16 provides guidance and traction in this instance, being mounted for rotation within the frame and body under the control of a tiller arm 18, and being driven by a suitable electric motor (not shown) contained within the body 12, which also may house electric storage batteries as a suitable source of energy for the drive motor.

- This mast structure includes a fixed or stationary mast member including side channels 22 connected at their upper ends by a crosspiece 23. These channels are usually of the shape of an I-beam in cross-section, although of course they may be U-shaped or other configurations.

- a movable, vertically extensible mast member comprising a pair of side channels 25 which are connected by suitable crosspieces 26.

- the movable mast member is mounted in telescopic arrangement within the stationary mast member, as shown in FIGS. 2 and 4, although it is possible to reverse this arrangement and have the stationary mast member the innermost if so desired.

- a lift carriage 30 is suitably supported on the movable mast member, usually through one or more rollers 31 (FIG. 1) which are received within and guided by the members 25.

- the carriage is provided with outwardly extending load supporting forks 33, or in some cases with equivalent load supporting devices for handling articles that cannot be accommodated on the usual forks.

- Suitable lift structure (not shown in detail) is provided for moving the carriage 30' vertically along the inner mast member and also for moving the inner mast member vertically along the outer fixed mast member.

- the general location of this structure is shown at 35, however details are omitted since they form no part of this invention.

- a typical arrangement is shown in US. Patent No. 2,936,047, issued May 10, 1960 in the name of Quayle.

- the lift capacity of equipment of this type can be substantial, ranging for example anywhere from 2,000 to 6,000 pounds, and bearing in mind that the length of the forks 33 may vary anywhere from 30 to 52 inches in length, it is apparent that the load supported through the carriage 30 may be considerable and is located a substantial distance outwardly of the carriage.

- the center of the load is illustrated in FIG. 1 between arrow 37, and it is apparent that this load results in a bending moment on the mast structure and parts supported thereby, tending to tilt or deflect the entire mast structure in a direction rearward of the truck.

- the requirements on the mast structure to resist this deflection increase, particularly as to the mast members which are now moved apart as far as possible, thereby placing an increasing load upon their connecting structure to keep the mast members in desired alignment.

- the following guiding and supporting structure is provided on the fixed and movable mast members.

- the fixed mast beams 22 At the top of the fixed mast beams 22 are guiding rollers 49 which engage the adjacent flange 25a of the movable mast beams 25.

- the diameter of the rollers 40, and the location of their supporting pins 42 which define the axes of rotation, are so selected that the flange 25a is slightly spaced from the flange 22a of the stationary mast beam 22.

- This arrangement of course exists at both sides of the upper end of the mast, howev r it is shown in detail only on the right hand side of FIG. 4, in order to compare with the different arrangement provided at the bottom of the movable mast beams.

- roll rs 45 are mounted on supporting pins 46 adjacent the lower ends of the movable mast beams 25. In this region a portion of the flange 25a is cut away in order that the rim of the roller 45 can extend beyond and into contact with the flange 22a of the fixed mast beam.

- the size of the rollers 45 and/or the location of the pins 46 defining their axes of rotation, are so selected and arranged that the flange 25a of the mast beam 25 is in this location spaced a significant amount from the flange 22a. This spacing is indicated in FIG. 5, as the base 48 of a right triangle, with the solid lines indicating the general arrangement of the parts with the mast in its lowered or retracted position.

- the distances 48 remain the same.

- the clearance between the flanges of the masts at the region of the rollers 40 likewise is maintained, therefore as the mast is extended the movable mast member automatically is caused to tilt in a direction toward the front of the truck, and in a direction opposite to any deflection caused by the load supported by the carriage.

- the movable mast member automatically is caused to tilt in a direction toward the front of the truck, and in a direction opposite to any deflection caused by the load supported by the carriage.

- the distances between points on the respective fixed and movable mast parts corresponding to the axes of the rollers 40 and 45, with the mast fully retracted is seventy-seven inches. At full extension the distance between these points is increased to one hundred forty-one inches, and the distance between the rollers themselves is decreased to about thirteen inches.

- the centers or axes of rotation of these rollers are so arranged that the clearance space C-l between flanges of the mast members near the upper rollers 40 is about one-quarter inch.

- the clearance C-2 between these flanges adjacent the lower rollers 45 is about seven-sixteenths of an inch.

- a telescopic mast and lift structure comprising an upright first mast member attached to and extending upwardly from said body,

- a movable mast member vertically movable with respect to said first mast member

- a carriage mounted for vertical movement on said movable mast member and adapted to support a load generally outboard of the mast

- said guiding means includes parts carried by said fixed mast member and said movable mast member, respectively, and engaging the opposite one of said mast members maintaining them in slight misalignment in the lowered position and causing an increase in such misalignment in a direction away from said carriage as said movable mast member is raised.

- said guiding means includes first flanges on opposite sides of said first mast member and corresponding second flanges on opposite sides of said movable mast member, said flanges extending next to each other,

- first rollers mounted near the upper ends of said first flanges and in predetermined closely spaced relation thereto forming a space through which said second flanges move in contact with said first rollers as said movable mast member is raised and lowered,

- rollers being of such size and having their centers so located with respect to said second flanges that said first and second flanges are maintained farther apart in the region of said second rollers than in the region of said first rollers thereby defining a slight angular relation between said first and second flanges in the lowered position which increases in magnitude as said movable mast member is raised.

Landscapes

- Engineering & Computer Science (AREA)

- Transportation (AREA)

- Structural Engineering (AREA)

- Civil Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- Geology (AREA)

- Mechanical Engineering (AREA)

- Forklifts And Lifting Vehicles (AREA)

- Orthopedics, Nursing, And Contraception (AREA)

Description

Oct. 14, 1969 H. A. STAMMEN LIFT TRUCK WITH TELESCOPIC MAST Filed Dec, 18, 1967 FIG-2 LRONT 2 L m m w M ,n mm m vA r W9 A A l D L 0, R A H V! a FIG-5 United States Patent 3,472,341 LIFT TRUCK WITH TELESCOPIC MAST Harold A. Stammen, New Bremen, Ohio, assignor to Crown Controls Corporation, New Bremen, Ohio, a corporation of Ohio Filed Dec. 18, 1967, Ser. No. 691,298 Int. Cl. B66b 9/20, 7/02 US. Cl. 187-9 3 Claims ABSTRACT OF THE DISCLOSURE Background of the invention This invention relates to lift trucks and the like, either hand-propelled or self-propelled, which incorporate a socalled telescopic mast and lift structure. In generally, this lift structure incorporates a fixed mast member which extends generally vertical from the truck frame, and a vertically movable mast member which in turn carries the load supporting carriage. The carriage usually has forks or some equivalent structure for holding a load as it is lifted. In some instances, more than one movable mast member is employed, to obtain greater vertical extension. The load supported from the carriage is generally carried outwardly of the carriage and mast structure, thus as the load is lifted and particularly as the mast structure is extended, increasing deflection in the mast and its parts, tending to cause the mast and carriage to tilt somewhat. Various proposals have been made to compensate for this action, however most of them require some parts causing a tilting movement of the lower mast structure and making it movable with respect to the truck body and frame.

Brief description of the invention The present invention provides a novel mast structure of the so-called telescopic type in which the parts supporting and guiding the movable mast member on the fixed mast member are so constructed and arranged that as the mast is extended the movable mast member automatically is caused to tilt in a direction opposite to any deflection caused by the load supported from the carriage, thereby assuring an essentially vertical lifting action, and overcoming any tendency for the load to shift or lean with respect to the mast as the mast is extended.

Accordingly, the primary object of the invention is to provide a novel guiding and supporting arrangement between the fixed and movable mast members, which cause the movable mast member to tilt increasingly away from the vertical center line of the fixed mast member as the mast member is extended toward its full height; and to provide such an arrangement wherein this action is obtained by locating the axes of rotation of guiding and supporting rollers in the mast structure at such different distances from the vertical center line of the lower or fixed mast member that as the rollers move closer together, the offset of their respective axes of rotation is increasingly effective to tilt the movable mast member.

Other objects and advantages of the invention will be apparent from the following description, the accompanying drawings and the appended claims.

In the drawing FIG. 1 is an overall side view of a typical lift truck employing the present invention;

FIG. 2 is a plan view of the truck shown in FIG. 1, illustrating in a general way the arrangement of the telescopic mast and the lift carriage;

FIG. 3 is an enlarged view of one side of the telescopic mast, with the mast members retracted to their lowered position;

FIG. 4 is a view taken from the top of the mast structure shown in FIG. 3 with the left hand side in section, taken generally along the lines 4L-4L, and the right hand side shown in elevation taken generally along the line 4R-4R- in FIG. 3; and

FIG. 5 is a diagram illustrating the tiltback action of the mast structure as it is vertically extended.

Description of the preferred embodiment Referring to the drawings, and particularly with reference to FIG. 1, a self-propelled walking lift truck is illustrated, as one typical type of truck to which the present invention is applicable. It will be clear to those skilled in th art that the invention is likewise applicable to handpropelled trucks, to self-propelled trucks which carry an operator, and to similar types of vehicles. The truck frame 10 supports the body 12, and includes rearwardly extending outriggers 14 which mount supporting wheels 15. A single front wheel 16 provides guidance and traction in this instance, being mounted for rotation within the frame and body under the control of a tiller arm 18, and being driven by a suitable electric motor (not shown) contained within the body 12, which also may house electric storage batteries as a suitable source of energy for the drive motor.

At the rear of the body 12, and generally at the forward end of the Outriggers 14, there is a vertically extending mast structur indicated by the general reference numeral 20. This mast structure includes a fixed or stationary mast member including side channels 22 connected at their upper ends by a crosspiece 23. These channels are usually of the shape of an I-beam in cross-section, although of course they may be U-shaped or other configurations. On this stationary mast member there is supported a movable, vertically extensible mast member comprising a pair of side channels 25 which are connected by suitable crosspieces 26. In a typical arrangement the movable mast member is mounted in telescopic arrangement within the stationary mast member, as shown in FIGS. 2 and 4, although it is possible to reverse this arrangement and have the stationary mast member the innermost if so desired.

A lift carriage 30 is suitably supported on the movable mast member, usually through one or more rollers 31 (FIG. 1) which are received within and guided by the members 25. The carriage is provided with outwardly extending load supporting forks 33, or in some cases with equivalent load supporting devices for handling articles that cannot be accommodated on the usual forks.

Suitable lift structure (not shown in detail) is provided for moving the carriage 30' vertically along the inner mast member and also for moving the inner mast member vertically along the outer fixed mast member. The general location of this structure is shown at 35, however details are omitted since they form no part of this invention. A typical arrangement is shown in US. Patent No. 2,936,047, issued May 10, 1960 in the name of Quayle.

Bearing in mind that the lift capacity of equipment of this type can be substantial, ranging for example anywhere from 2,000 to 6,000 pounds, and bearing in mind that the length of the forks 33 may vary anywhere from 30 to 52 inches in length, it is apparent that the load supported through the carriage 30 may be considerable and is located a substantial distance outwardly of the carriage. By way of example, the center of the load is illustrated in FIG. 1 between arrow 37, and it is apparent that this load results in a bending moment on the mast structure and parts supported thereby, tending to tilt or deflect the entire mast structure in a direction rearward of the truck. As the load is lifted to greater height, the requirements on the mast structure to resist this deflection increase, particularly as to the mast members which are now moved apart as far as possible, thereby placing an increasing load upon their connecting structure to keep the mast members in desired alignment.

In accordance with the invention, in order to overcome this tendency the following guiding and supporting structure is provided on the fixed and movable mast members. At the top of the fixed mast beams 22 are guiding rollers 49 which engage the adjacent flange 25a of the movable mast beams 25. The diameter of the rollers 40, and the location of their supporting pins 42 which define the axes of rotation, are so selected that the flange 25a is slightly spaced from the flange 22a of the stationary mast beam 22. This arrangement of course exists at both sides of the upper end of the mast, howev r it is shown in detail only on the right hand side of FIG. 4, in order to compare with the different arrangement provided at the bottom of the movable mast beams.

As shown at the left hand side of FIG. 4, roll rs 45 are mounted on supporting pins 46 adjacent the lower ends of the movable mast beams 25. In this region a portion of the flange 25a is cut away in order that the rim of the roller 45 can extend beyond and into contact with the flange 22a of the fixed mast beam. The size of the rollers 45 and/or the location of the pins 46 defining their axes of rotation, are so selected and arranged that the flange 25a of the mast beam 25 is in this location spaced a significant amount from the flange 22a. This spacing is indicated in FIG. 5, as the base 48 of a right triangle, with the solid lines indicating the general arrangement of the parts with the mast in its lowered or retracted position.

As the mast is extended, the distances 48 remain the same. The clearance between the flanges of the masts at the region of the rollers 40 likewise is maintained, therefore as the mast is extended the movable mast member automatically is caused to tilt in a direction toward the front of the truck, and in a direction opposite to any deflection caused by the load supported by the carriage. Obviously the further the extension of the movable mast member, the more the angle of tilt increases.

By way of a typical example, in one mast structure constructed according to the invention the distances between points on the respective fixed and movable mast parts corresponding to the axes of the rollers 40 and 45, with the mast fully retracted is seventy-seven inches. At full extension the distance between these points is increased to one hundred forty-one inches, and the distance between the rollers themselves is decreased to about thirteen inches. Using rollers of the same diameter, for example three inches, the centers or axes of rotation of these rollers are so arranged that the clearance space C-l between flanges of the mast members near the upper rollers 40 is about one-quarter inch. The clearance C-2 between these flanges adjacent the lower rollers 45 is about seven-sixteenths of an inch.

While the form of apparatus herein described constitutes a preferred embodiment of the invention, it is to be understood that the invention is not limited to this precise form of apparatus, and that changes may be made therein.

What is claimed is:

1. In a lift truck or the like having a body, a telescopic mast and lift structure comprising an upright first mast member attached to and extending upwardly from said body,

a movable mast member vertically movable with respect to said first mast member,

a carriage mounted for vertical movement on said movable mast member and adapted to support a load generally outboard of the mast,

power means connected to move said carriage and said movable mast member between raised and lowered positions,

and guiding means operatively connected between said first and movable mast members in such a manner so as to cause limited angular movement of said movable mast member automatically with respect to said first mast member and in a direction opposite to the load supported by said carriage as said movable mast member is extended to the raised position.

2. Apparatus as defined in claim 1, wherein said guiding means includes parts carried by said fixed mast member and said movable mast member, respectively, and engaging the opposite one of said mast members maintaining them in slight misalignment in the lowered position and causing an increase in such misalignment in a direction away from said carriage as said movable mast member is raised.

3. The mast and lift structure defined in claim 1 wherein said guiding means includes first flanges on opposite sides of said first mast member and corresponding second flanges on opposite sides of said movable mast member, said flanges extending next to each other,

first rollers mounted near the upper ends of said first flanges and in predetermined closely spaced relation thereto forming a space through which said second flanges move in contact with said first rollers as said movable mast member is raised and lowered,

second rollers carried on the lower end of said movable mast member and adapted to roll along said first flanges,

said rollers being of such size and having their centers so located with respect to said second flanges that said first and second flanges are maintained farther apart in the region of said second rollers than in the region of said first rollers thereby defining a slight angular relation between said first and second flanges in the lowered position which increases in magnitude as said movable mast member is raised.

References Cited UNITED STATES PATENTS 2,918,143 12/1959 Schaffer 187-9 3,358,791 12/1967 Goodacre l87-9 HARVEY C. HORNSBY, Primary Examiner US. Cl. X.R. 187-95

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US69129867A | 1967-12-18 | 1967-12-18 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US3472341A true US3472341A (en) | 1969-10-14 |

Family

ID=24775980

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US691298A Expired - Lifetime US3472341A (en) | 1967-12-18 | 1967-12-18 | Lift truck with telescopic mast |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US3472341A (en) |

| DE (1) | DE1800002B2 (en) |

| FR (1) | FR1590357A (en) |

| GB (1) | GB1242254A (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4572479A (en) * | 1983-06-23 | 1986-02-25 | Film-Gerate-Verieith Schmidle & Fritz | Camera truck |

| US20100065377A1 (en) * | 2008-09-12 | 2010-03-18 | Crown Equipment Corporation | Monomast for a materials handling vehicle |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4503935A (en) * | 1982-03-15 | 1985-03-12 | Towmotor Corporation | Lift jack retention bracket |

| DE9303538U1 (en) * | 1993-03-11 | 1994-07-21 | Winkel GmbH, 75428 Illingen | Lifting device for electric pallet trucks |

| DE19503981A1 (en) * | 1995-02-07 | 1996-08-08 | Linde Ag | Lifting frame for lifting truck |

| DE102007015485A1 (en) * | 2007-03-30 | 2008-10-02 | Linde Material Handling Gmbh | Reach truck for picking object located in region of pallet has electronic control apparatus designed to drive actuating element so that lifting mast moves automatically in direction of side facing away from load while load is picked up |

| GB2528833A (en) * | 2014-06-10 | 2016-02-10 | Walter Stephen Weston | Pedestrian stacker truck |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2918143A (en) * | 1957-12-19 | 1959-12-22 | Towmotor Corp | Triple telescopic high free lift truck |

| US3358791A (en) * | 1965-06-01 | 1967-12-19 | Lansing Bagnall Ltd | Industrial lift trucks |

-

1967

- 1967-12-18 US US691298A patent/US3472341A/en not_active Expired - Lifetime

-

1968

- 1968-10-01 DE DE1800002A patent/DE1800002B2/en not_active Ceased

- 1968-10-15 GB GB48793/68A patent/GB1242254A/en not_active Expired

- 1968-10-30 FR FR1590357D patent/FR1590357A/fr not_active Expired

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2918143A (en) * | 1957-12-19 | 1959-12-22 | Towmotor Corp | Triple telescopic high free lift truck |

| US3358791A (en) * | 1965-06-01 | 1967-12-19 | Lansing Bagnall Ltd | Industrial lift trucks |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4572479A (en) * | 1983-06-23 | 1986-02-25 | Film-Gerate-Verieith Schmidle & Fritz | Camera truck |

| US20100065377A1 (en) * | 2008-09-12 | 2010-03-18 | Crown Equipment Corporation | Monomast for a materials handling vehicle |

| US20100068023A1 (en) * | 2008-09-12 | 2010-03-18 | Crown Equipment Corporation | Fork carriage apparatus for a materials handling vehicle |

| US8714311B2 (en) | 2008-09-12 | 2014-05-06 | Crown Equipment Corporation | Monomast for a materials handling vehicle |

| US8851825B2 (en) | 2008-09-12 | 2014-10-07 | Crown Equipment Corporation | Fork carriage apparatus for a materials handling vehicle |

| US10144626B2 (en) | 2008-09-12 | 2018-12-04 | Crown Equipment Corporation | Fork carriage apparatus for a materials handling vehicle |

Also Published As

| Publication number | Publication date |

|---|---|

| DE1800002A1 (en) | 1969-08-07 |

| DE1800002B2 (en) | 1978-10-26 |

| GB1242254A (en) | 1971-08-11 |

| FR1590357A (en) | 1970-04-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US3561628A (en) | Load handling in fork-lift trucks movable fork cover for forklift truck | |

| US3747789A (en) | Load handling vehicle | |

| US3930587A (en) | Retractable chain lifting device | |

| USRE24958E (en) | G ehmann | |

| US3998346A (en) | Material handling apparatus | |

| US2806618A (en) | Overhead guard for industrial lift trucks | |

| EP3313773B1 (en) | An improved linkage system for a forklift truck | |

| US3762588A (en) | Front and lateral loading mechanism | |

| GB2104052A (en) | Handling storage units, e.g. pallets | |

| US3472341A (en) | Lift truck with telescopic mast | |

| US2877868A (en) | Hydraulic lift for industrial trucks and tractors | |

| US3836031A (en) | Material handling truck apparatus | |

| US3335879A (en) | Side carrying lift truck | |

| US3616953A (en) | Narrow-aisle truck with retractable arms | |

| US3515233A (en) | Articulated industrial truck | |

| US3521779A (en) | Lift truck with a rotating mast mounted on a suberame | |

| US2855071A (en) | Industrial trucks | |

| US3512672A (en) | Stacker crane with pivotal fork and extension means thereon | |

| US2492608A (en) | Industrial truck | |

| US3608761A (en) | Forklift truck with swinging mast | |

| US3684114A (en) | Fork lift load handling devices | |

| US3235034A (en) | Triple lift truck with continuous lift chain | |

| US3240372A (en) | Extensible mounting apparatus for hoists | |

| US3542227A (en) | Lift truck with ground-engaging means for supporting base of mast | |

| US3484851A (en) | Industrial lift truck |