JP6261847B2 - Wheel bearing device and method for manufacturing wheel bearing device - Google Patents

Wheel bearing device and method for manufacturing wheel bearing device Download PDFInfo

- Publication number

- JP6261847B2 JP6261847B2 JP2012106691A JP2012106691A JP6261847B2 JP 6261847 B2 JP6261847 B2 JP 6261847B2 JP 2012106691 A JP2012106691 A JP 2012106691A JP 2012106691 A JP2012106691 A JP 2012106691A JP 6261847 B2 JP6261847 B2 JP 6261847B2

- Authority

- JP

- Japan

- Prior art keywords

- wheel bearing

- wheel

- convex

- fitting

- joint member

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000004519 manufacturing process Methods 0.000 title claims description 4

- 238000000034 method Methods 0.000 title claims description 3

- 238000005096 rolling process Methods 0.000 claims description 14

- 238000005520 cutting process Methods 0.000 claims description 6

- 230000002093 peripheral effect Effects 0.000 description 43

- 230000005540 biological transmission Effects 0.000 description 6

- 239000000725 suspension Substances 0.000 description 6

- 238000006073 displacement reaction Methods 0.000 description 5

- 239000004519 grease Substances 0.000 description 4

- 238000003825 pressing Methods 0.000 description 4

- 239000000314 lubricant Substances 0.000 description 2

- 230000036316 preload Effects 0.000 description 2

- 239000011347 resin Substances 0.000 description 2

- 229920005989 resin Polymers 0.000 description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 2

- 229910000954 Medium-carbon steel Inorganic materials 0.000 description 1

- 230000004323 axial length Effects 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 230000008878 coupling Effects 0.000 description 1

- 238000010168 coupling process Methods 0.000 description 1

- 238000005859 coupling reaction Methods 0.000 description 1

- 238000002788 crimping Methods 0.000 description 1

- 238000002347 injection Methods 0.000 description 1

- 239000007924 injection Substances 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 230000013011 mating Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 230000001105 regulatory effect Effects 0.000 description 1

- 102220097517 rs876659265 Human genes 0.000 description 1

Images

Landscapes

- Mounting Of Bearings Or Others (AREA)

- Rolling Contact Bearings (AREA)

Description

本発明は、例えば自動車の懸架装置に対して駆動車輪(FF車の前輪、FR車の後輪、4WD車の全輪)を回転自在に支持する車輪用軸受装置および車輪用軸受装置の製造方法に関する。 The present invention provides, for example, a wheel bearing device that rotatably supports driving wheels (front wheels of FF vehicles, rear wheels of FR vehicles, and all wheels of 4WD vehicles) with respect to a suspension device of an automobile, and a method of manufacturing the wheel bearing device. About.

例えば、車輪用軸受のハブ輪と等速自在継手の外側継手部材との分離を可能としてメンテナンス性に優れた車輪用軸受装置が提案されている(例えば、特許文献1参照)。この特許文献1に開示された車輪用軸受装置は、図11に示すように、ハブ輪101、内輪102、複列の転動体103,104および外輪105からなる車輪用軸受120と固定式等速自在継手106とで主要部が構成されている。

For example, there has been proposed a wheel bearing device that can be separated from a hub wheel of a wheel bearing and an outer joint member of a constant velocity universal joint and has excellent maintainability (see, for example, Patent Document 1). As shown in FIG. 11, the wheel bearing device disclosed in

ハブ輪101は、その外周面にアウトボード側の内側軌道面107が形成されると共に、車輪(図示せず)を取り付けるための車輪取付フランジ109を備えている。この車輪取付フランジ109の円周方向等間隔に、ホイールディスクを固定するためのハブボルト110が植設されている。このハブ輪101のインボード側外周面に形成された小径段部112に内輪102を嵌合させ、この内輪102の外周面にインボード側の内側軌道面108が形成されている。

The

内輪102は、クリープを防ぐために適当な締め代をもって圧入されている。ハブ輪101の外周面に形成されたアウトボード側の内側軌道面107と、内輪102の外周面に形成されたインボード側の内側軌道面108とで複列の軌道面を構成する。この内輪102をハブ輪101の小径段部112に圧入し、その小径段部112の端部を外側に加締めることにより、加締め部111でもって内輪102を抜け止めしてハブ輪101と一体化し、車輪用軸受120に予圧を付与している。

The

外輪105は、内周面にハブ輪101および内輪102の内側軌道面107,108と対向する複列の外側軌道面113,114が形成されている。この外輪105の外周面を車体の懸架装置(図示せず)から延びるナックルに嵌合させて固定することにより、車輪用軸受装置を車体に取り付けるようにしている。

The

車輪用軸受120は、複列のアンギュラ玉軸受構造で、ハブ輪101および内輪102の外周面に形成された内側軌道面107,108と外輪105の内周面に形成された外側軌道面113,114との間に転動体103,104を介在させ、各列の転動体103,104を保持器115,116により円周方向等間隔に支持した構造を有する。

The wheel bearing 120 has a double-row angular contact ball bearing structure, and has

車輪用軸受120の両端開口部には、ハブ輪101と内輪102の外周面に摺接するように、外輪105とハブ輪101および内輪102との環状空間を密封する一対のシール117,118が外輪105の両端部内径に嵌合され、内部に充填されたグリースの漏洩ならびに外部からの水や異物の侵入を防止するようになっている。

A pair of

等速自在継手106は、ドライブシャフト121を構成する中間シャフト122の一端に設けられ、内周面にトラック溝123が形成された外側継手部材124と、その外側継手部材124のトラック溝123と対向するトラック溝125が外周面に形成された内側継手部材126と、外側継手部材124のトラック溝123と内側継手部材126のトラック溝125との間に組み込まれたボール127と、外側継手部材124の内周面と内側継手部材126の外周面との間に介在してボール127を保持するケージ128とで構成されている。

The constant velocity

外側継手部材124は、内側継手部材126、ボール127およびケージ128からなる内部部品を収容したマウス部129と、マウス部129から軸方向に一体的に延びるステム部130とで構成されている。内側継手部材126は、中間シャフト122の軸端が圧入されてスプライン嵌合によりトルク伝達可能に結合されている。

The outer

等速自在継手106の外側継手部材124と中間シャフト122との間に、継手内部に封入されたグリース等の潤滑剤の漏洩を防ぐと共に継手外部からの異物侵入を防止するための樹脂製の蛇腹状ブーツ131を装着して、外側継手部材124の開口部を閉塞した構造としている。

Between the outer

このブーツ131は、外側継手部材124の外周面にブーツバンド132により締め付け固定された大径端部133と、中間シャフト122の外周面にブーツバンド134により締め付け固定された小径端部135と、大径端部133と小径端部135とを繋ぎ、その大径端部133から小径端部135へ向けて縮径した可撓性の蛇腹部136とで構成されている。

The

図12は、外側継手部材124のステム部130をハブ輪101の軸孔138に圧入する前の状態を示す。同図に示すように、外側継手部材124のステム部130は、その外周面に軸方向に延びる複数の凸部137からなる雄スプラインが形成されている。これに対して、ハブ輪101の軸孔138は、その内周面に雌スプラインが形成されていない単純な円筒部139をなす。

FIG. 12 shows a state before the

図13は、外側継手部材124のステム部130をハブ輪101の軸孔138に圧入した後の状態を示す。この外側継手部材124のステム部130をハブ輪101の軸孔138に圧入し、そのステム部130の凸部137をハブ輪101の軸孔138の円筒部139の内周面に転写することにより、同図に示すように、ハブ輪101の軸孔138の内周面に凸部137と締め代をもって密着する凹部140を形成し、この凸部137と凹部140との嵌合接触部位全域で密着する凹凸嵌合構造を構成することで、外側継手部材124とハブ輪101とをトルク伝達可能に結合させている。

FIG. 13 shows a state after the

このようにして、外側継手部材124のステム部130をハブ輪101の軸孔138に圧入した上で、図11に示すように、外側継手部材124のステム部130の軸端に形成された雌ねじ141にボルト142を螺合させることにより、そのボルト142をハブ輪101の端面に係止させた状態で締め付けることで、等速自在継手106をハブ輪101に固定している。

In this way, after the

ところで、前述した車輪用軸受装置において、ハブ輪101、内輪102、複列の転動体103,104および外輪105からなる車輪用軸受120と結合される固定式等速自在継手106がドライブシャフト121の一部を構成している。自動車のエンジンから車輪に動力を伝達するドライブシャフト121は、図14に示すように、エンジンと車輪との相対的位置関係の変化による角度変位と軸方向変位に対応する必要があるため、一般的にエンジン側(インボード側)に摺動式等速自在継手151を、車輪側(アウトボード側)に固定式等速自在継手106をそれぞれ装備し、両者の等速自在継手106,151を中間シャフト122で連結した構造を具備する。

By the way, in the wheel bearing device described above, the fixed constant velocity

ここで、従来の車輪用軸受装置では、図12に示すように、ハブ輪101の軸孔138の内周面は雌スプラインが形成されていない単純な円筒部139をなすことから、外側継手部材124のステム部130をハブ輪101の軸孔138に圧入するに際して、そのステム部130の凸部137を軸孔138の内周面に転写するために大きな圧入荷重が必要なため作業性が悪く、プレス機などを用いる必要があった。そのため、車輪用軸受120にドライブシャフト121の等速自在継手106を組み付けた状態で車輪用軸受装置を車体に組み付けなければならないというのが現状であった。

Here, in the conventional wheel bearing device, as shown in FIG. 12, the inner peripheral surface of the

その結果、自動車メーカでの車両組み立て時には、車輪用軸受120とドライブシャフト121の等速自在継手106とを結合させた状態、つまり、車輪用軸受120とドライブシャフト121の二つの等速自在継手106,151とが一体化した状態で取り扱われる。車体の懸架装置から延びるナックル152(図14参照)の最小内径寸法を等速自在継手106,151の最大外径寸法よりも大きくしていることから、この車体への組み付けは、図14および図15に示すように、ドライブシャフト121の摺動式等速自在継手151と固定式等速自在継手106とを、車体の懸架装置から延びるナックル152に順次通した上で、車輪用軸受120の外輪105をナックル152に嵌合させて固定するようにしていた。

As a result, when the vehicle is assembled by an automobile manufacturer, the wheel bearing 120 and the constant velocity

このドライブシャフト121は車輪側とエンジン側とを繋ぐ長尺なアッセンブリ体であることから、前述したようにドライブシャフト121の摺動式等速自在継手151と固定式等速自在継手106とをナックル152に順次通す車体への組み付け方法では作業性が悪く、その組み付け時にドライブシャフト121を構成する部品を損傷させたりする可能性がある。

Since the

そこで、本発明は前述の問題点に鑑みて提案されたもので、その目的とするところは、車体への組み付けにおける作業性を向上させ、その組み付け時の部品の損傷を未然に防止し得る車輪用軸受装置を提供することにある。 Accordingly, the present invention has been proposed in view of the above-mentioned problems, and the object of the present invention is to improve the workability in assembling the vehicle body and prevent damage to the components during the assembly. It is to provide a bearing device for use.

本発明に係る車輪用軸受装置は、内周に複列の外側軌道面が形成された外方部材と、外周に外側軌道面と対向する複列の内側軌道面を有し、ハブ輪および内輪からなる内方部材と、外方部材の外側軌道面と内方部材の内側軌道面との間に介装された複列の転動体とからなる車輪用軸受を備え、ハブ輪の内径に等速自在継手の外側継手部材のステム部を嵌合することにより車輪用軸受に等速自在継手をねじ締め付け構造により分離可能に結合させた構造を具備する。以上のように、車輪用軸受装置は、車輪用軸受と等速自在継手とで構成されている。 A wheel bearing device according to the present invention includes an outer member having a double-row outer raceway formed on the inner periphery, and a double-row inner raceway facing the outer raceway on the outer periphery. And a bearing for a wheel comprising a double row rolling element interposed between the outer raceway surface of the outer member and the inner raceway surface of the inner member, and the like to the inner diameter of the hub wheel By fitting the stem portion of the outer joint member of the quick universal joint, the structure is such that the constant velocity universal joint is separably coupled to the wheel bearing by a screw tightening structure. As described above, the wheel bearing device includes the wheel bearing and the constant velocity universal joint.

前者の車輪用軸受は、内周に複列の外側軌道面が形成された外方部材と、外周に外側軌道面と対向する複列の内側軌道面を有し、ハブ輪および内輪からなる内方部材と、外方部材の外側軌道面と内方部材の内側軌道面との間に介装された複列の転動体とを備え、ハブ輪の内径に等速自在継手の外側継手部材のステム部を嵌合することにより等速自在継手がねじ締め付け構造により分離可能に結合される。 The former wheel bearing has an outer member having a double-row outer raceway formed on the inner periphery, and a double-row inner raceway facing the outer raceway on the outer periphery. And a double row rolling element interposed between the outer raceway surface of the outer member and the inner raceway surface of the inner member, and the outer joint member of the constant velocity universal joint is provided on the inner diameter of the hub ring. By fitting the stem portion, the constant velocity universal joint is detachably coupled by the screw tightening structure.

後者の等速自在継手は、ステム部を有する外側継手部材と、外側継手部材との間でトルク伝達部材を介して角度変位を許容しながらトルクを伝達する内側継手部材とを備え、外側継手部材のステム部を車輪用軸受のハブ輪の内径に嵌合することにより車輪用軸受がねじ締め付け構造により分離可能に結合される。 The latter constant velocity universal joint includes an outer joint member having a stem portion and an inner joint member that transmits torque while allowing angular displacement between the outer joint member and the outer joint member via the torque transmission member. The wheel bearing is separably coupled by the screw tightening structure by fitting the stem portion to the inner diameter of the hub ring of the wheel bearing.

前述の目的を達成するための技術的手段として、本発明に係る車輪用軸受装置は、前記ハブ輪1と前記外側継手部材24のステム部30のうちのいずれか一方の部材に軸方向に延びる複数の凸部37が形成され、他方の部材に、前記凸部37の形状が転写された凹部40が形成され、前記凹部40に前記凸部37が圧入されており、前記凸部37の径方向先端部44と前記凹部40との間に隙間pがあり、前記他方の部材が、圧入した前記凸部37による切削で形成された切粉66を備え、前記切粉66が、前記凸部37の周方向側壁部43に対応する位置のみに形成され、前記凸部37と前記凹部40との嵌合接触部位全域Xが密着した凹凸嵌合構造Mを有し、前記凹凸嵌合構造Mにおける嵌合長さに対するピッチ円径の比を2.0〜3.0の範囲で規定したことを特徴とする。

As a technical means for achieving the above-described object, the wheel bearing device according to the present invention extends in the axial direction to one of the

本発明では、ハブ輪と外側継手部材のステム部のうちのいずれか一方に軸方向に延びる複数の凸部を形成すると共に他方に凸部に対して締め代を有する凹部を予め形成しておく。ハブ輪と外側継手部材のステム部のうちのいずれか一方を他方に圧入することにより、凸部と凹部との嵌合接触部位全域が密着する凹凸嵌合構造を構成する。ここで、本発明における凸部は外側継手部材のステム部に設けられ、凹部はハブ輪に設けられた構造が望ましい。このようにすれば、外側継手部材のステム部をハブ輪に圧入することにより、凸部と凹部との嵌合接触部位全域が密着する凹凸嵌合構造を容易に構成することができる。 In the present invention, a plurality of convex portions extending in the axial direction are formed on one of the hub portion and the stem portion of the outer joint member, and a concave portion having a tightening margin with respect to the convex portion is formed in advance on the other side. . By pressing any one of the hub wheel and the stem portion of the outer joint member into the other, an uneven fitting structure in which the entire fitting contact portion between the convex portion and the concave portion is in close contact is configured. Here, the convex part in this invention is provided in the stem part of an outer joint member, and the structure in which the recessed part was provided in the hub ring | wheel is desirable. In this way, by pressing the stem portion of the outer joint member into the hub wheel, it is possible to easily configure the concave-convex fitting structure in which the entire fitting contact portion between the convex portion and the concave portion is in close contact.

前述の圧入時、凸部が極僅かな塑性変形および切削加工を伴いながら、相手側の凹部形成面に凸部の形状を転写する。この時、凸部が相手側の凹部形成面に食い込んでいくことによってハブ輪の内径が僅かに拡径した状態となって、凸部の軸方向の相対的移動が許容される。凸部の軸方向相対移動が停止すれば、ハブ輪の内径が元の径に戻ろうとして縮径することになる。これによって、凸部と凹部との嵌合接触部位全域で密着し、外側継手部材とハブ輪を強固に結合一体化することができる。 At the time of the press-fitting described above, the shape of the convex portion is transferred to the concave portion forming surface on the other side while the convex portion is accompanied by a slight plastic deformation and cutting. At this time, the convex portion bites into the concave-part forming surface on the other side, so that the inner diameter of the hub wheel is slightly expanded, and relative movement in the axial direction of the convex portion is allowed. When the axial relative movement of the convex portion stops, the inner diameter of the hub wheel is reduced to return to the original diameter. Thereby, it can closely_contact | adhere in the fitting contact site | part whole area | region of a convex part and a recessed part, and an outer joint member and a hub ring can be combined firmly.

ここで、凸部に対して凹部を予め形成していることから、従来のように凸部を単純な円筒部に転写する場合よりも、凸部と凹部との嵌合接触部位全域で密着させるための圧入荷重を下げることができるので、車輪用軸受を車体に取り付けた後にその車輪用軸受のハブ輪に外側継手部材を圧入して等速自在継手を車輪用軸受に結合させることが容易となって作業性の向上が図れる。 Here, since the concave portion is formed in advance with respect to the convex portion, the convex portion and the concave portion are brought into close contact with each other as compared with the conventional case where the convex portion is transferred to a simple cylindrical portion. Therefore, it is easy to press the outer joint member into the hub wheel of the wheel bearing and to connect the constant velocity universal joint to the wheel bearing after the wheel bearing is attached to the vehicle body. Therefore, workability can be improved.

また、凹凸嵌合構造における嵌合長さに対するピッチ円径の比を2.0〜3.0の範囲で規定したことにより、ハブ輪と外側継手部材のステム部のうちのいずれか一方を他方に圧入する際の圧入荷重を確実に下げることができ、等速自在継手を車輪用軸受に結合させることが容易となって作業性の向上が図れる。また、凸部の剪断強度を高くすることができて凹凸嵌合構造において十分な強度を確保することができる。 Further, by defining the ratio of the pitch circle diameter to the fitting length in the concave-convex fitting structure in the range of 2.0 to 3.0, either one of the hub wheel and the stem portion of the outer joint member is used as the other. The press-fitting load during press-fitting into the wheel can be reliably reduced, and the constant velocity universal joint can be easily coupled to the wheel bearing, thereby improving workability. Moreover, the shear strength of the convex portion can be increased, and sufficient strength can be secured in the concave-convex fitting structure.

本発明における凹部は、凸部の周方向側壁部のみに対して締め代を有する構造が望ましい。ここで、「凸部の周方向側壁部のみ」とは、凸部の径方向先端部を除いた部位を意味する。この凸部の径方向先端部は、凹部と締め代を有さないことから、相手側の凹部形成面に凸部の径方向先端部の形状が転写されることはない。このように、凸部の周方向側壁部のみに対して締め代を有するように設定されていることから、凸部の全体に亘って凹部と締め代を有するように設定した場合よりも、さらに、圧入荷重を下げることができるので、等速自在継手を車輪用軸受に結合させる圧入作業がより一層容易になる。 The concave portion in the present invention preferably has a structure having a tightening margin only for the circumferential side wall portion of the convex portion. Here, “only the circumferential side wall portion of the convex portion” means a portion excluding the radial front end portion of the convex portion. Since the radial tip end portion of the convex portion does not have a recess and a fastening margin, the shape of the radial tip end portion of the convex portion is not transferred to the recess forming surface on the counterpart side. Thus, since it is set so as to have a tightening margin only for the circumferential side wall portion of the convex portion, it is further more than the case where the concave portion and the tightening margin are set over the entire convex portion. Since the press-fitting load can be reduced, the press-fitting work for coupling the constant velocity universal joint to the wheel bearing is further facilitated.

本発明では、凸部の表面硬度を凹部の表面硬度よりも大きくすることが望ましい。このようにすれば、ハブ輪と外側継手部材のステム部のうちのいずれか一方を他方に圧入するに際して、塑性変形および切削加工により、相手側の凹部形成面に凸部の形状を容易に転写することができる。 In the present invention, it is desirable to make the surface hardness of the convex portion larger than the surface hardness of the concave portion. In this way, when one of the hub wheel and the stem portion of the outer joint member is press-fitted into the other, the shape of the convex portion is easily transferred to the concave portion forming surface on the other side by plastic deformation and cutting. can do.

本発明では、ねじ締め付け構造により発生する軸力以下でハブ輪に対して外側継手部材を圧入可能とすることが望ましい。このようにすれば、車輪用軸受を車体に取り付けた後にその車輪用軸受のハブ輪に外側継手部材を圧入するに際して、専用の治具を別に用意する必要がなく、車輪用軸受装置を構成する部品であるねじ締め付け構造でもって等速自在継手を簡易に車輪用軸受に結合させることができる。 In the present invention, it is desirable that the outer joint member can be press-fitted into the hub wheel with an axial force generated by the screw tightening structure or less. In this way, when the outer joint member is press-fitted into the hub wheel of the wheel bearing after the wheel bearing is attached to the vehicle body, there is no need to prepare a dedicated jig, and the wheel bearing device is configured. The constant velocity universal joint can be easily coupled to the wheel bearing with a screw tightening structure as a part.

本発明におけるねじ締め付け構造は、外側継手部材のステム部の軸端に形成された雌ねじ部と、その雌ねじ部に螺合した状態でハブ輪に係止される雄ねじ部とで構成された構造が可能である。この構造では、ステム部の雌ねじ部に雄ねじ部を螺合させることによりその雄ねじ部をハブ輪に係止させた状態で締め付けることで、等速自在継手をハブ輪に固定することになる。 The screw tightening structure according to the present invention includes a female screw portion formed at the shaft end of the stem portion of the outer joint member, and a male screw portion that is engaged with the female screw portion and locked to the hub wheel. Is possible. In this structure, the constant-velocity universal joint is fixed to the hub wheel by screwing the male screw part into the female screw part of the stem part and tightening the male screw part in a state where the male screw part is locked to the hub wheel.

本発明におけるねじ締め付け構造は、外側継手部材のステム部の軸端に形成された雄ねじ部と、その雄ねじ部に螺合した状態でハブ輪に係止される雌ねじ部とで構成された構造が可能である。この構造では、ステム部の雄ねじ部に雌ねじ部を螺合させることによりその雌ねじ部をハブ輪に係止させた状態で締め付けることで、等速自在継手をハブ輪に固定することになる。 The screw tightening structure according to the present invention has a structure composed of a male screw portion formed at the shaft end of the stem portion of the outer joint member and a female screw portion that is engaged with the male screw portion and locked to the hub wheel. Is possible. In this structure, the constant-velocity universal joint is fixed to the hub wheel by screwing the female screw portion into the male screw portion of the stem portion and tightening the female screw portion while being locked to the hub wheel.

本発明によれば、ハブ輪と外側継手部材のステム部のうちのいずれか一方に形成されて軸方向に延びる複数の凸部を、その凸部に対して締め代を有する複数の凹部が形成された他方に圧入し、その他方に凸部の形状を転写することで凸部と凹部との嵌合接触部位全域が密着する凹凸嵌合構造を構成したことにより、凸部に対して締め代を有する凹部を予め形成していることから、凸部と凹部との嵌合接触部位全域で密着させるための圧入荷重を下げることができるので、車輪用軸受を車体に取り付けた後にその車輪用軸受のハブ輪に外側継手部材を圧入して等速自在継手を車輪用軸受に結合させることが容易となり、車体への組み付けにおける作業性を向上させ、その組み付け時の部品の損傷を未然に防止することができる。 According to the present invention, a plurality of convex portions formed in any one of the hub wheel and the stem portion of the outer joint member and extending in the axial direction are formed into a plurality of concave portions having an allowance for the convex portion. By press-fitting into the other side and transferring the shape of the convex part to the other side, a concavity and convexity fitting structure is formed in which the whole contact area of the convex part and the concave part is in close contact with each other. Since the press-fit load for making it adhere in the fitting contact part whole region of a convex part and a recessed part can be lowered | hung, since it has previously formed the recessed part which has a wheel bearing after attaching a wheel bearing to a vehicle body It is easy to press-fit the outer joint member into the hub wheel and to connect the constant velocity universal joint to the wheel bearing, improve the workability in assembling to the vehicle body, and prevent the parts from being damaged during the assembling. be able to.

また、凹凸嵌合構造における嵌合長さに対するピッチ円径の比を2.0〜3.0の範囲で規定したことにより、ハブ輪と外側継手部材のステム部のうちのいずれか一方を他方に圧入する際の圧入荷重を確実に下げることができ、等速自在継手を車輪用軸受に結合させることが容易となって作業性の向上が図れる。また、凸部の剪断強度を高くすることができて凹凸嵌合構造において十分な強度を確保することができる。 Further, by defining the ratio of the pitch circle diameter to the fitting length in the concave-convex fitting structure in the range of 2.0 to 3.0, either one of the hub wheel and the stem portion of the outer joint member is used as the other. The press-fitting load during press-fitting into the wheel can be reliably reduced, and the constant velocity universal joint can be easily coupled to the wheel bearing, thereby improving workability. Moreover, the shear strength of the convex portion can be increased, and sufficient strength can be secured in the concave-convex fitting structure.

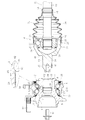

本発明に係る車輪用軸受装置の実施形態を以下に詳述する。図1および図2に示す車輪用軸受装置は、内方部材であるハブ輪1および内輪2、複列の転動体3,4、外輪5からなる車輪用軸受20と等速自在継手6とで主要部が構成されている。図1は車輪用軸受20に等速自在継手6を組み付ける前の状態を示し、図2は車輪用軸受20に等速自在継手6を組み付けた後の状態を示す。なお、以下の説明では、車体に組み付けた状態で、車体の外側寄りとなる側をアウトボード側(図面左側)と呼び、中央寄りとなる側をインボード側(図面右側)と呼ぶ。

An embodiment of a wheel bearing device according to the present invention will be described in detail below. The wheel bearing device shown in FIGS. 1 and 2 includes a

ハブ輪1は、その外周面にアウトボード側の内側軌道面7が形成されると共に、車輪(図示せず)を取り付けるための車輪取付フランジ9を備えている。この車輪取付フランジ9の円周方向等間隔に、ホイールディスクを固定するためのハブボルト10が植設されている。このハブ輪1のインボード側外周面に形成された小径段部12に内輪2を嵌合させ、この内輪2の外周面にインボード側の内側軌道面8が形成されている。

The

内輪2は、クリープを防ぐために適当な締め代をもって圧入されている。ハブ輪1の外周面に形成されたアウトボード側の内側軌道面7と、内輪2の外周面に形成されたインボード側の内側軌道面8とで複列の軌道面を構成する。この内輪2をハブ輪1の小径段部12に圧入し、その小径段部12の端部を揺動加締めにより外側に加締めることにより、加締め部11でもって内輪2を抜け止めしてハブ輪1と一体化し、車輪用軸受20に予圧を付与している。

The

外輪5は、内周面にハブ輪1および内輪2の軌道面7,8と対向する複列の外側軌道面13,14が形成され、車体(図示せず)の懸架装置から延びるナックルに取り付けるための車体取付フランジ19を備えている。後述するように、この車体取付フランジ19は、前述のナックル52に嵌合されてボルト63により固定される(図3参照)。

The

車輪用軸受20は、複列のアンギュラ玉軸受構造で、ハブ輪1および内輪2の外周面に形成された内側軌道面7,8と外輪5の内周面に形成された外側軌道面13,14との間に転動体3,4を介在させ、各列の転動体3,4を保持器15,16により円周方向等間隔に支持した構造を有する。

The

車輪用軸受20の両端開口部には、ハブ輪1と内輪2の外周面に摺接するように、外輪5とハブ輪1および内輪2との環状空間を密封する一対のシール17,18が外輪5の両端部内径に嵌合され、内部に充填されたグリースの漏洩ならびに外部からの水や異物の侵入を防止するようになっている。

A pair of

等速自在継手6は、ドライブシャフト21を構成する中間シャフト22の一端に設けられ、内周面にトラック溝23が形成された外側継手部材24と、その外側継手部材24のトラック溝23と対向するトラック溝25が外周面に形成された内側継手部材26と、外側継手部材24のトラック溝23と内側継手部材26のトラック溝25との間に組み込まれたボール27と、外側継手部材24の内周面と内側継手部材26の外周面との間に介在してボール27を保持するケージ28とで構成されている。

The constant velocity

外側継手部材24は、内側継手部材26、ボール27およびケージ28からなる内部部品を収容したマウス部29と、マウス部29から軸方向に一体的に延びるステム部30とで構成されている。内側継手部材26は、中間シャフト22の軸端が圧入されてスプライン嵌合によりトルク伝達可能に結合されている。

The outer

等速自在継手6の外側継手部材24と中間シャフト22との間に、継手内部に封入されたグリース等の潤滑剤の漏洩を防ぐと共に継手外部からの異物侵入を防止するための樹脂製の蛇腹状ブーツ31を装着して、外側継手部材24の開口部を閉塞した構造としている。

Between the outer

このブーツ31は、外側継手部材24の外周面にブーツバンド32により締め付け固定された大径端部33と、中間シャフト22の外周面にブーツバンド34により締め付け固定された小径端部35と、大径端部33と小径端部35とを繋ぎ、その大径端部33から小径端部35へ向けて縮径した可撓性の蛇腹部36とで構成されている。

The

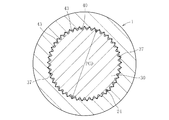

この車輪用軸受装置は、外側継手部材24のステム部30のインボード側外周面に円柱形状の嵌合面61を形成すると共に、ステム部30のアウトボード側外周面に軸方向に延びる複数の凸部37からなる雄スプラインを形成する。これに対して、ハブ輪1の軸孔38のインボード側内周面に円筒形状の嵌合面62を形成すると共に、その軸孔38のアウトボード側内周面に前述の凸部37の周方向側壁部43のみに対して締め代nを有する複数の凹部39(小凹部)を形成する〔図7(B)参照〕。なお、前述の凸部37は断面台形の歯形状としているが、インボリュート歯形状であってもよい。

The wheel bearing device has a cylindrical

この車輪用軸受装置では、外側継手部材24のステム部30をハブ輪1の軸孔38に圧入し、相手側の凹部形成面であるハブ輪1の軸孔38に凸部37の周方向側壁部43のみの形状を転写することにより凹部40を形成し〔図8(B)参照〕、凸部37と凹部40との嵌合接触部位全域Xが密着する凹凸嵌合構造Mを構成する(図2参照)。なお、外側継手部材24およびハブ輪1の材質としては、S53C等に代表される機械構造用の中炭素鋼が好適である。

In this wheel bearing device, the

この車輪用軸受装置は、以下のようなねじ締め付け構造N(図2参照)を具備する。このねじ締め付け構造Nは、外側継手部材24のステム部30の軸端に形成された雌ねじ部41と、その雌ねじ部41に螺合した状態でハブ輪1に係止される雄ねじ部であるボルト42とで構成されている。この構造では、ステム部30の雌ねじ部41にボルト42を螺合させることによりそのボルト42をハブ輪1に係止させた状態で締め付けることで、等速自在継手6をハブ輪1に固定する。なお、車輪用軸受20は、加締め部11でもって内輪2を抜け止めしてハブ輪1と一体化した構造となっていることから、等速自在継手6の外側継手部材24と分離可能となっている。

This wheel bearing device includes a screw tightening structure N (see FIG. 2) as follows. The screw tightening structure N includes a

ところで、この車輪用軸受装置では、車輪用軸受20のハブ輪1の加締め部11と外側継手部材24の肩部45とが突き合わされた接触状態にあることから、例えば、車両発進時、ハブ輪1の加締め部11と外側継手部材24の肩部45との間で、カッキン音と通称されるスティックスリップ音が発生するおそれがある。このスティックスリップ音は、車両発進時、静止状態にある車輪用軸受20のハブ輪1に対して等速自在継手6の外側継手部材24から回転トルクが負荷されると、外側継手部材24からハブ輪1へ回転トルクを伝達しようとするが、外側継手部材24と車輪用軸受20との間の伝達トルク変動と外側継手部材24のねじれにより、ハブ輪1の加締め部11と外側継手部材24の肩部45との当接面で急激な滑りが発生する。この急激な滑りが原因となってスティックスリップ音が発生する。

By the way, in this wheel bearing device, the

このスティックスリップ音を未然に防止する手段として、以上で説明したねじ締め付け構造Nでは、ハブ輪1に対する外側継手部材24の圧入時の締め付けトルクよりも低い締め付けトルクに設定されている。つまり、ハブ輪1に対する外側継手部材24の圧入後、ねじ締め状態を一端緩めて、再度、その圧入時の締め付けトルクよりも低い締め付けトルクに設定する。これにより、ハブ輪1の加締め部11と外側継手部材24の肩部45との当接面に発生する面圧を最適に管理することができ、その当接面で急激な滑りによるスティックスリップ音の発生を未然に防止することができる。

In the screw tightening structure N described above, as a means for preventing the stick-slip noise, the tightening torque is set lower than the tightening torque when the outer

この車輪用軸受装置において、ハブ輪1、内輪2、複列の転動体3,4および外輪5からなる車輪用軸受20と結合される固定式等速自在継手6はドライブシャフト21の一部を構成している。自動車のエンジンから車輪に動力を伝達するドライブシャフト21は、図3に示すように、エンジンと車輪との相対的位置関係の変化による角度変位と軸方向変位に対応する必要があるため、一般的にエンジン側(インボード側)に摺動式等速自在継手51を、車輪側(アウトボード側)に固定式等速自在継手6をそれぞれ装備し、両者の等速自在継手6,51を中間シャフト22で連結した構造を具備する。

In this wheel bearing device, a fixed type constant velocity

図4に示すように、外側継手部材24のステム部30をハブ輪1の軸孔38に圧入するに先立って、ステム部30のインボード側外周面に円柱形状の嵌合面61を形成すると共に、ハブ輪1の軸孔38のインボード側内周面に円筒形状の嵌合面62を形成していることから、ハブ輪1の軸孔38の嵌合面62にステム部30の嵌合面61を嵌合させることで、ハブ輪1に対するステム部30の軸芯合わせを容易に行うことができる。

As shown in FIG. 4, prior to press-fitting the

また、図6(A)(B)に示すように、ハブ輪1のインボード側に位置する嵌合面62とアウトボード側に位置する凹部39との間に、圧入の開始をガイドするガイド部64を設けている。このガイド部64はステム部30の凸部37よりも大きめの凹部65が前述の凹部39と連続するように形成されている(図1の拡大部分参照)。つまり、凸部37と凹部65との間に隙間mが形成されている〔図7(B)参照〕。ガイド部64により、外側継手部材24のステム部30をハブ輪1に圧入するに際して、ステム部30の凸部37がハブ輪1の凹部39に確実に圧入するように誘導することができるので、凸部37と凹部39との位相合わせが容易で安定した圧入が可能となって圧入時の芯ずれや芯傾きなどを防止することができる。

6A and 6B, a guide for guiding the start of press-fitting between the

ステム部30のハブ輪1への圧入時、図7(A)(B)および図8(A)(B)に示すように、ハブ輪1の軸孔38に凸部37の周方向側壁部43のみの形状を転写することにより凹部40を形成する。この時、凸部37に対して凹部39を予め形成していることから、従来のように凸部137を円筒部139に転写する場合(図12参照)よりも、凸部37と凹部40との嵌合接触部位全域X(図2参照)で密着させるための圧入荷重を下げることができる。

When the

この凹凸嵌合構造Mでは、凸部37の周方向側壁部43のみに対して締め代nを有するように、その凹部39の周方向寸法を凸部37よりも小さく設定している。この凸部37の周方向側壁部43を除く部位、つまり、凸部37の径方向先端部44は、凹部39と締め代を有さないことから、その形状が凹部39に転写されることなく、また、凹部39の径方向寸法を凸部37よりも大きく設定することから、凹部39との間に隙間pを有する。このように、凸部37の周方向側壁部43のみに対して締め代nを有するように設定されていることから、凸部37の全体に亘って凹部39と締め代を有するように設定した場合よりも、圧入荷重をより一層下げることができる。

In the concave / convex fitting structure M, the circumferential dimension of the

その結果、図5に示すように、ボルト42の締め付けにより発生する軸力以下でハブ輪1に対して外側継手部材24を圧入可能とすることができる。つまり、自動車メーカでの車両組み立て時、車輪用軸受20を車体の懸架装置から延びるナックル52にボルト63で取り付けた後、ねじ締め付け構造Nのボルト42による引き込み力でもって、車輪用軸受20のハブ輪1の軸孔38に等速自在継手6の外側継手部材24のステム部30を容易に圧入することができ、車輪用軸受20にドライブシャフト21の等速自在継手6を簡易に組み付けることが可能となって車体への組み付け時の作業性を向上させ、その組み付け時の部品の損傷を未然に防止することができる。

As a result, as shown in FIG. 5, the outer

このように、車輪用軸受20を車体のナックル52に取り付けた後にその車輪用軸受20のハブ輪1に外側継手部材24を圧入するに際して、専用の治具を別に用意する必要がなく、車輪用軸受装置を構成する部品であるボルト42でもって等速自在継手6を簡易に車輪用軸受20に結合させることができる。また、ボルト42の締め付けにより発生する軸力以下という比較的小さな引き込み力の付与で圧入することができるので、ボルト42による引き込み作業性の向上が図れる。さらに、大きな圧入荷重を付与しないので済むことから、凹凸嵌合構造Mでの凹凸が損傷する(むしれる)ことを防止でき、高品質で長寿命の凹凸嵌合構造Mを実現できる。

Thus, when the outer

この外側継手部材24のステム部30をハブ輪1の軸孔38に圧入するに際して、凸部37の周方向側壁部43による凹部形成面の極僅かな塑性変形および切削加工を伴いながら、その凹部形成面に凸部37の周方向側壁部43の形状を転写することになる。この時、凸部37の周方向側壁部43が凹部形成面に食い込んでいくことによってハブ輪1の内径が僅かに拡径した状態となって、凸部37の軸方向の相対的移動が許容される。この凸部37の軸方向相対移動が停止すれば、ハブ輪1の内径が元の径に戻ろうとして縮径することになる。これによって、凸部37と凹部40との嵌合接触部位全域Xで密着し、外側継手部材24とハブ輪1を強固に結合一体化することができる。

When the

このような低コストで信頼性の高い結合により、ステム部30とハブ輪1の嵌合部分の径方向および周方向においてガタが生じる隙間が形成されないので、嵌合接触部位全域Xが回転トルク伝達に寄与して安定したトルク伝達が可能であり、耳障りな歯打ち音を長期に亘り防止できる。このように嵌合接触部位全域Xで密着していることから、トルク伝達部位の強度が向上するため、車両用軸受装置の軽量コンパクト化が図れる。

Such a low-cost and highly reliable connection does not form gaps that cause play in the radial direction and circumferential direction of the fitting portion of the

外側継手部材24のステム部30をハブ輪1の軸孔38に圧入するに際して、凸部37の表面硬度を凹部39の表面硬度よりも大きくする。その場合、凸部37の表面硬度と凹部39の表面硬度との差をHRCで20以上とする。これにより、圧入時における塑性変形および切削加工により、相手側の凹部形成面に凸部37の周方向側壁部43の形状を容易に転写することができる。なお、凸部37の表面硬度としてはHRCで50〜65、また、凹部39の表面硬度としてはHRCで10〜30が好適である。

When the

ハブ輪1の軸孔38と外側継手部材24のステム部30との間に、圧入による凸部形状の転写によって生じる食み出し部66(切粉)を収容する収容部67を設けている〔図7(A)および図8(A)参照〕。これにより、圧入による凸部形状の転写によって生じる食み出し部66を収容部67に保持することができ、その食み出し部66が装置外の車両内などへ入り込んだりすることを阻止できる。その食み出し部66を収容部67に保持することで、食み出し部66の除去処理が不要となり、作業工数の削減を図ることができ、作業性の向上およびコスト低減を図ることができる。

Between the

以上で説明した凹凸嵌合構造Mでは、図8(A)および図9に示すように、嵌合接触部位全域Xの軸方向長さ(以下、単に嵌合長さと称す)に対するピッチ円径(PCD)の比を2.0〜3.0の範囲で規定している。ここで、嵌合長さに対するピッチ円径の比は、ピッチ円径を嵌合長さで除算した値(PCD/X)を意味する。凸部137を円筒部139に転写する従来の凹凸嵌合構造(図12参照)では、嵌合長さに対するピッチ円径の比を1.0より小さく設定していたのに対して、この実施形態における凹凸嵌合構造Mでは、嵌合長さに対するピッチ円径の比を2.0〜3.0の範囲で規定する。

In the concave-convex fitting structure M described above, as shown in FIGS. 8A and 9, the pitch circle diameter (with respect to the axial length (hereinafter simply referred to as the fitting length) of the fitting contact region X is ( (PCD) ratio is specified in the range of 2.0 to 3.0. Here, the ratio of the pitch circle diameter to the fitting length means a value (PCD / X) obtained by dividing the pitch circle diameter by the fitting length. In the conventional concave / convex fitting structure (see FIG. 12) for transferring the

このように、嵌合長さに対するピッチ円径の比を2.0〜3.0の範囲で規定することにより、ハブ輪1の軸孔38に外側継手部材24のステム部30を圧入する際の圧入荷重を確実に下げることができ、ねじ締め付け構造Nのボルト42による引き込み力でもって、ハブ輪1の軸孔38に外側継手部材24のステム部30を容易に圧入することができる。また、外側継手部材24のステム部30の破損強度よりも凸部37の剪断強度を高くすることができ、凹凸嵌合構造Mにおいて十分な強度を確保することができる。

In this way, when the ratio of the pitch circle diameter to the fitting length is defined in the range of 2.0 to 3.0, when the

なお、嵌合長さに対するピッチ円径の比が2.0よりも小さいと、ピッチ円径に対して嵌合長さが大きくなり過ぎることから、ねじ締め付け構造Nのボルト42による引き込み力でもって、ハブ輪1の軸孔38に外側継手部材24のステム部30を圧入する際の圧入荷重を下げることが難しくなり、ハブ輪1の軸孔38に外側継手部材24のステム部30を圧入することが困難となる。また、装置のコンパクト化および軽量化が困難となる。逆に、嵌合長さに対するピッチ円径の比が3.0よりも大きいと、ピッチ円径に対して嵌合長さが小さくなり過ぎることから、外側継手部材24のステム部30の破損強度よりも凸部37の剪断強度が低くなり、凹凸嵌合構造Mにおいて十分な強度を確保することが困難となる。

If the ratio of the pitch circle diameter to the fitting length is smaller than 2.0, the fitting length becomes too large with respect to the pitch circle diameter. It becomes difficult to lower the press-fit load when the

また、この凹凸嵌合構造Mでは、モジュールを0.3〜0.75の範囲で規定している。ここで、モジュールとは、図8(B)および図9に示すように、外側継手部材24のステム部30の外周面に形成された凸部37とハブ輪1の軸孔38の内周面に形成された凹部40との嵌合構造におけるピッチ円径(PCD)を凸部37の数Z(歯数)で除した値(PCD/Z)を意味する。凸部137を円筒部139に転写する従来の凹凸嵌合構造(図12参照)では、その凹凸嵌合構造におけるモジュールを1.0程度に設定していたのに対して、この実施形態における凹凸嵌合構造Mでは、モジュールを0.3〜0.75の範囲で規定する。

Moreover, in this uneven | corrugated fitting structure M, the module is prescribed | regulated in the range of 0.3-0.75. Here, as shown in FIG. 8B and FIG. 9, the module refers to the

このように、凹凸嵌合構造Mにおけるモジュールを0.3〜0.75の範囲で規定することにより、外側継手部材24のステム部30の凸部37とハブ輪1の軸孔38の凹部40とが確実に噛み合うことから、車輪用軸受20と等速自在継手6との間でのトルク伝達容量を十分に確保することができる。また、ハブ輪1の軸孔38に外側継手部材24のステム部30を圧入する際の圧入荷重を確実に下げることができ、ねじ締め付け構造Nのボルト42による引き込み力でもって、ハブ輪1の軸孔38に外側継手部材24のステム部30を容易に圧入することができる。

Thus, by defining the module in the concave-convex fitting structure M in the range of 0.3 to 0.75, the

なお、凹凸嵌合構造Mにおけるモジュールが0.3よりも小さいと、凸部37に対する凹部39の嵌合代が小さくなり過ぎることから、車輪用軸受20と等速自在継手6との間で十分なトルク伝達容量を確保することが困難となる。逆に、凹凸嵌合構造Mにおけるモジュールが0.75よりも大きいと、凸部37に対する凹部39の嵌合代が大きくなり過ぎることから、ハブ輪1の軸孔38に外側継手部材24のステム部30を圧入する際の圧入荷重を下げることが難しくなり、ねじ締め付け構造Nのボルト42による引き込み力でもって、ハブ輪1の軸孔38に外側継手部材24のステム部30を圧入することが困難となる。

If the module in the concave-convex fitting structure M is smaller than 0.3, the fitting margin of the

以上の実施形態では、ステム部30の雌ねじ部41にボルト42を螺合させることによりボルト42をハブ輪1の端面に係止させた状態で締め付ける構造を例示したが、他のねじ締め付け構造として、図10に示すように、外側継手部材24のステム部30の軸端に形成された雄ねじ部68と、その雄ねじ部68に螺合した状態でハブ輪1の端面に係止される雌ねじ部であるナット69とで構成することも可能である。この構造では、ステム部30の雄ねじ部68にナット69を螺合させることによりナット69をハブ輪1に係止させた状態で締め付けることで、等速自在継手6をハブ輪1に固定することになる。

In the above embodiment, the structure in which the

また、以上の実施形態では、ハブ輪1および内輪2からなる内方部材に形成された複列の内側軌道面7,8の一方、つまり、アウトボード側の内側軌道面7をハブ輪1の外周に形成した(第三世代と称される)タイプの駆動車輪用軸受装置に適用した場合を例示したが、本発明はこれに限定されることなく、ハブ輪の外周に一対の内輪を圧入し、アウトボード側の軌道面7を一方の内輪の外周に形成すると共にインボード側の軌道面8を他方の内輪の外周に形成した(第一、第二世代と称される)タイプの駆動車輪用軸受装置にも適用可能である。

Further, in the above embodiment, one of the double-row

本発明は前述した実施形態に何ら限定されるものではなく、本発明の要旨を逸脱しない範囲内において、さらに種々なる形態で実施し得ることは勿論のことであり、本発明の範囲は、特許請求の範囲によって示され、さらに特許請求の範囲に記載の均等の意味、および範囲内のすべての変更を含む。 The present invention is not limited to the above-described embodiments, and can of course be implemented in various forms without departing from the gist of the present invention. It includes the equivalent meanings recited in the claims and the equivalents recited in the claims, and all modifications within the scope.

1 内方部材(ハブ輪)

2 内方部材(内輪)

3,4 転動体

5 外方部材(外輪)

6 等速自在継手

7,8 内側軌道面

13,14 外側軌道面

20 車輪用軸受

24 外側継手部材

30 ステム部

37 凸部(雄スプライン)

39,40 凹部

41 雌ねじ部

42 雄ねじ部(ボルト)

43 凸部の周方向側壁部

68 雄ねじ部

69 雌ねじ部(ナット)

n 締め代

M 凹凸嵌合構造

N ねじ締め付け構造

X 嵌合接触部位全域

1 Inner member (hub ring)

2 Inner member (inner ring)

3, 4

6 Constant velocity

39, 40

43 Circumferential side wall portion of

n Tightening allowance M Concave / concave fitting structure N Screw tightening structure X Fitting contact area

Claims (6)

前記ハブ輪1と前記外側継手部材24のステム部30のうちのいずれか一方の部材に軸方向に延びる複数の凸部37が形成され、

他方の部材に、前記凸部37の形状が転写された凹部40が形成され、

前記凹部40に前記凸部37が圧入されており、

前記凸部37の径方向先端部44と前記凹部40との間に隙間pがあり、

前記他方の部材が、圧入した前記凸部37による切削で形成された切粉66を備え、

前記切粉66が、前記凸部37の周方向側壁部43に対応する位置のみに形成され、

前記凸部37と前記凹部40との嵌合接触部位全域Xが密着した凹凸嵌合構造Mを有し、

前記凹凸嵌合構造Mにおける嵌合長さに対するピッチ円径の比を2.0〜3.0の範囲で規定したことを特徴とする車輪用軸受装置。 An outer member 5 having double-row outer raceways 13 and 14 formed on the inner periphery, and double-row inner raceways 7 and 8 facing the outer raceways 13 and 14 on the outer periphery, And an inner member composed of the inner ring 2 and a double row rolling element 3 interposed between the outer raceway surfaces 13 and 14 of the outer member 5 and the inner raceway surfaces 7 and 8 of the inner members 1 and 2. , 4, and a stem portion 30 of the outer joint member 24 of the constant velocity universal joint 6 is fitted to the inner diameter of the hub wheel 1 of the wheel bearing 20 so that the wheel bearing 20 is In the wheel bearing device in which the quick universal joint 6 is detachably coupled by the screw tightening structure N,

A plurality of convex portions 37 extending in the axial direction is formed on any one of the hub wheel 1 and the stem portion 30 of the outer joint member 24,

The other member is formed with a concave portion 40 to which the shape of the convex portion 37 is transferred,

The convex portion 37 is press-fitted into the concave portion 40,

There is a gap p between the radial tip 44 of the convex portion 37 and the concave portion 40,

The other member includes a chip 66 formed by cutting with the press-fitted convex portion 37;

The chip 66 is formed only at a position corresponding to the circumferential side wall portion 43 of the convex portion 37,

It has a concavo-convex fitting structure M in which the fitting contact region X of the convex portion 37 and the concave portion 40 is in close contact,

A wheel bearing device characterized in that a ratio of a pitch circle diameter to a fitting length in the uneven fitting structure M is defined in a range of 2.0 to 3.0.

前記ハブ輪1と前記外側継手部材24のステム部30のうちのいずれか一方の部材に軸方向に延びる複数の凸部37を形成すると共に、他方の部材に前記凸部37の周方向側壁部43のみに対して締め代nを有する複数の小凹部39を形成し、

前記ねじ締め付け構造Nの軸力で前記凸部37を前記小凹部39に圧入して前記凸部37の周方向側壁部43のみで前記締め代nを切削し、

これによって、他方の部材に凹部40を形成して前記凸部37と前記凹部40の嵌合接触部位全域Xが密着する凹凸嵌合構造Mを構成すると共に、凸部37の径方向先端部44と前記凹部40との間に隙間pを設け、かつ前記凹部40の嵌合長さに対する前記凸部37のピッチ円径の比を2.0〜3.0の範囲としたことを特徴とする車輪用軸受装置の製造方法。 An outer member 5 having double-row outer raceways 13 and 14 formed on the inner periphery, and double-row inner raceways 7 and 8 facing the outer raceways 13 and 14 on the outer periphery, And an inner member composed of the inner ring 2 and a double row rolling element 3 interposed between the outer raceway surfaces 13 and 14 of the outer member 5 and the inner raceway surfaces 7 and 8 of the inner members 1 and 2. , 4, and the wheel bearing 20 by fitting the stem portion 30 of the outer joint member 24 of the constant velocity universal joint 6 to the inner diameter of the hub wheel 1 of the wheel bearing 20. A method for manufacturing a wheel bearing device in which a constant velocity universal joint 6 is detachably coupled via a screw tightening structure N,

A plurality of convex portions 37 extending in the axial direction are formed on one member of the hub wheel 1 and the stem portion 30 of the outer joint member 24, and the circumferential side wall portion of the convex portion 37 is formed on the other member. A plurality of small recesses 39 having a tightening allowance n with respect to 43 only ,

The convex portion 37 is press-fitted into the small concave portion 39 by the axial force of the screw tightening structure N, and the tightening margin n is cut only by the circumferential side wall portion 43 of the convex portion 37,

Thus, the concave portion 40 is formed in the other member to form the concave-convex fitting structure M in which the convex portion 37 and the fitting contact region X of the concave portion 40 are in close contact with each other, and the radial tip 44 of the convex portion 37 is formed. A gap p is provided between the concave portion 40 and the ratio of the pitch circle diameter of the convex portion 37 to the fitting length of the concave portion 40 is in the range of 2.0 to 3.0. Manufacturing method of wheel bearing device.

Priority Applications (6)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2012103578A JP5829173B2 (en) | 2012-04-27 | 2012-04-27 | Manufacturing method of wheel bearing device |

| JP2012106691A JP6261847B2 (en) | 2012-05-08 | 2012-05-08 | Wheel bearing device and method for manufacturing wheel bearing device |

| EP13782148.4A EP2857224B1 (en) | 2012-04-27 | 2013-04-24 | Bearing device for wheel and manufacturing method thereof |

| PCT/JP2013/062083 WO2013161880A1 (en) | 2012-04-27 | 2013-04-24 | Bearing device for wheel |

| US14/396,263 US9829048B2 (en) | 2012-04-27 | 2013-04-24 | Bearing device for wheel |

| CN201380022003.9A CN104271358B (en) | 2012-04-27 | 2013-04-24 | The manufacture method of bearing apparatus for wheel and bearing apparatus for wheel |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2012106691A JP6261847B2 (en) | 2012-05-08 | 2012-05-08 | Wheel bearing device and method for manufacturing wheel bearing device |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2013233843A JP2013233843A (en) | 2013-11-21 |

| JP6261847B2 true JP6261847B2 (en) | 2018-01-17 |

Family

ID=49760323

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2012106691A Active JP6261847B2 (en) | 2012-04-27 | 2012-05-08 | Wheel bearing device and method for manufacturing wheel bearing device |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP6261847B2 (en) |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2008111525A1 (en) * | 2007-03-07 | 2008-09-18 | Ntn Corporation | Bearing device for driving wheel, and its assembling method |

| JP5323337B2 (en) * | 2007-10-15 | 2013-10-23 | Ntn株式会社 | Wheel bearing device |

| DE112009000812B4 (en) * | 2008-04-04 | 2024-03-07 | Ntn Corp. | Wheel bearing device and axle module |

| WO2009125657A1 (en) * | 2008-04-10 | 2009-10-15 | Ntn株式会社 | Bearing device for wheel |

| JP2010144902A (en) * | 2008-12-22 | 2010-07-01 | Jtekt Corp | Spline fitting structure, sliding type tripod constant velocity joint, and ball-type constant velocity joint |

-

2012

- 2012-05-08 JP JP2012106691A patent/JP6261847B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| JP2013233843A (en) | 2013-11-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5829173B2 (en) | Manufacturing method of wheel bearing device | |

| WO2013042595A1 (en) | Wheel bearing and bearing device | |

| JP4394736B2 (en) | Drive wheel bearing device and assembly method thereof | |

| JP6320695B2 (en) | Wheel bearing device and assembly method thereof | |

| JP6253909B2 (en) | Wheel bearing device | |

| JP6042142B2 (en) | WHEEL BEARING, WHEEL BEARING DEVICE, AND METHOD FOR MANUFACTURING WHEEL BEARING DEVICE | |

| WO2015015992A1 (en) | Bearing device for wheel | |

| JP5752542B2 (en) | Wheel bearing device | |

| JP6261846B2 (en) | Wheel bearing device and method for manufacturing wheel bearing device | |

| JP6109786B2 (en) | Wheel bearing device and method for manufacturing wheel bearing device | |

| JP6239310B2 (en) | Wheel bearing device | |

| JP2007321903A (en) | Bearing device for wheel | |

| JP6261847B2 (en) | Wheel bearing device and method for manufacturing wheel bearing device | |

| JP6253906B2 (en) | Wheel bearing device | |

| JP6009495B2 (en) | Manufacturing method of wheel bearing device | |

| JP6279237B2 (en) | Wheel bearing device | |

| JP2008247274A (en) | Wheel bearing device | |

| JP6239315B2 (en) | Wheel bearing device | |

| JP2017116108A (en) | Bearing device for vehicle and manufacturing method of bearing device for vehicle | |

| JP2008184051A (en) | Bearing device for wheel | |

| JP5101051B2 (en) | Drive wheel bearing unit | |

| JP2016107873A (en) | Wheel bearing device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20150309 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20160105 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20160302 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20160902 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20161202 |

|

| A911 | Transfer to examiner for re-examination before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20161209 |

|

| A912 | Re-examination (zenchi) completed and case transferred to appeal board |

Free format text: JAPANESE INTERMEDIATE CODE: A912 Effective date: 20170127 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20171023 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20171213 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6261847 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |