JP4827905B2 - Plate type heat exchanger and air conditioner equipped with the same - Google Patents

Plate type heat exchanger and air conditioner equipped with the same Download PDFInfo

- Publication number

- JP4827905B2 JP4827905B2 JP2008250278A JP2008250278A JP4827905B2 JP 4827905 B2 JP4827905 B2 JP 4827905B2 JP 2008250278 A JP2008250278 A JP 2008250278A JP 2008250278 A JP2008250278 A JP 2008250278A JP 4827905 B2 JP4827905 B2 JP 4827905B2

- Authority

- JP

- Japan

- Prior art keywords

- heat transfer

- wave

- plate

- heat

- fluid

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Heat-Exchange Devices With Radiators And Conduit Assemblies (AREA)

Abstract

Description

本発明は、プレート式熱交換器、及びこれを搭載した空気調和機に関する。 The present invention relates to a plate heat exchanger and an air conditioner equipped with the plate heat exchanger.

従来、プレート式熱交換器は、流体が層流で流れるため熱伝達向上が難しく、また、流体の熱伝達向上には流速増加が伴うため圧力損失が大きくなるという問題があった。

このような問題を解決するために、伝熱プレートのアスペクト比(横方向長さWに対する縦方向長さHの比)を小さくしたもの(例えば、特許文献1参照)、あるいは、波角度や形状を変化させたものがあった(例えば、特許文献2参照)。

Conventionally, the plate heat exchanger has a problem that it is difficult to improve heat transfer because the fluid flows in a laminar flow, and the pressure loss increases because the increase in the flow velocity is accompanied by the improvement in heat transfer of the fluid.

In order to solve such a problem, the heat transfer plate having a reduced aspect ratio (ratio of the longitudinal length H to the lateral length W) (see, for example, Patent Document 1), or a wave angle or shape (For example, refer to Patent Document 2).

しかしながら、特許文献1記載の技術のように、アスペクト比を小さくすると流路断面積が大きくなり流速が低下するため、同一流量での熱交換効率が悪い。

熱伝達向上のため、波角度を大きくすると、流路を形成する隣接するプレート接合部のロウ付け面積が大きくなり流路が狭くなるため、圧力損失が増加し、加えて、隣接するプレートの接合点が減るため、強度不足になる。また、強度向上から隣接するプレートの接合点を増やすため波ピッチを小さくすると、接合点の増加により、圧力損失が増加する等の問題があった。

However, as in the technique described in

Increasing the wave angle to improve heat transfer increases the brazing area of adjacent plate joints that form the flow path and narrows the flow path, increasing pressure loss and, in addition, joining adjacent plates. Since the points are reduced, the strength is insufficient. In addition, if the wave pitch is reduced in order to increase the joint points of adjacent plates in order to improve the strength, there is a problem that the pressure loss increases due to the increase of the joint points.

このため、特許文献2記載の技術のように、波角度や形状を変化させることもできるが、波角度が大きいハードな刻み目の領域では隣接するプレート接合部のロウ付け面積が大きくなり、波角度が小さいソフトな刻み目の領域では隣接するプレートの接合点が増えるため、強度向上とともに圧力損失も増加する。

For this reason, the wave angle and shape can be changed as in the technique described in

本発明は、上記課題を解決するためになされたものであり、熱伝達向上のため、波角度を大きく、波ピッチを小さくしても、流体の圧力損失増加を抑制することができるプレート式熱交換器、及びこれを搭載した空気調和機を提供することを目的とする。 The present invention has been made in order to solve the above-mentioned problems, and in order to improve heat transfer, even if the wave angle is increased and the wave pitch is decreased, the plate type heat that can suppress the increase in the pressure loss of the fluid is achieved. An object is to provide an exchanger and an air conditioner equipped with the exchanger.

本発明に係るプレート式熱交換器は、積層されて接合された複数の伝熱プレートの間に第1流路及び第2流路が形成され、第1流路及び第2流路にそれぞれ第1流体及び第2流体を通して伝熱プレートの間に流通させ、第1流体と第2流体との間で熱交換するプレート式熱交換器であって、伝熱プレートの表面に、第1、第2流体の流れに乱れを与えて熱交換を促進する伝熱促進面が設けられ、伝熱促進面は山部と谷部が伝熱プレートの高さ方向に沿って交互に繰り返され、前記山部の高さを当該山部の長手方向に波状に変化させて波部が形成され、隣接する伝熱プレートの接合部における波部の接合長さが伝熱プレートの幅に対して30%を維持するように、前記波部が形成され、伝熱プレートの接合点数を調整したものである。

また、本発明に係る空気調和機は、上記のプレート式熱交換器を搭載したものである。

In the plate heat exchanger according to the present invention, a first flow path and a second flow path are formed between a plurality of heat transfer plates that are stacked and joined, and the first flow path and the second flow path respectively. A plate-type heat exchanger that circulates between a heat transfer plate through a first fluid and a second fluid, and exchanges heat between the first fluid and the second fluid. A heat transfer promotion surface that disturbs the flow of the two fluids to promote heat exchange, and the heat transfer promotion surface is alternately repeated in the height direction of the heat transfer plate at the peaks and valleys; The corrugation is formed by changing the height of the corrugation in the longitudinal direction of the peak portion, and the joining length of the corrugation at the joint of adjacent heat transfer plates is 30% of the width of the heat transfer plate. The wave portion is formed so as to maintain, and the number of junctions of the heat transfer plate is adjusted.

Moreover, the air conditioner which concerns on this invention mounts said plate type heat exchanger.

本発明に係るプレート式熱交換器によれば、隣接する伝熱プレートの接合部における波部の接合長さが伝熱プレートの幅に対し30%を維持するように波部の高さを長手方向に変化させて接合点数を調整したので、必要最小限度の接合点数で流体の流路を構成することができ、従来と同等の強度を維持したまま、圧力損失の増加を抑制し、熱交換率を向上させることができる。このため、伝熱プレートの波角度を70°〜80°とし、波ピッチをほぼ4mmとした場合であっても、圧力損失の増加の抑制、熱交換率の向上が可能となる。また、伝熱プレートの幅を縦横比4〜6の範囲内で狭くした場合は、伝熱プレート間に流入する流体の入口流速が大きくなり、伝熱プレート間の熱交換率がさらに向上する。

こうして、熱伝達が良く、強度を維持したまま、圧力損失の増加を最小限に抑制することができるので、安価で信頼性に優れたプレート式熱交換器、及びこれを搭載した空気調和機を得ることができる。

According to the plate heat exchanger according to the present invention, the height of the wave portion is set to be long so that the joining length of the wave portion at the joining portion of the adjacent heat transfer plates is maintained at 30% with respect to the width of the heat transfer plate. Since the number of junction points is adjusted by changing the direction, the fluid flow path can be configured with the minimum number of junction points, and while maintaining the same strength as before, the increase in pressure loss is suppressed and heat exchange is performed. The rate can be improved. For this reason, even when the wave angle of the heat transfer plate is set to 70 ° to 80 ° and the wave pitch is set to about 4 mm, an increase in pressure loss can be suppressed and the heat exchange rate can be improved. Moreover, when the width | variety of a heat exchanger plate is made narrow within the range of 4 to 6 aspect ratio, the inlet flow velocity of the fluid which flows in between heat exchanger plates becomes large, and the heat exchange rate between heat exchanger plates further improves.

In this way, heat transfer is good and the increase in pressure loss can be suppressed to a minimum while maintaining strength. Therefore, an inexpensive and reliable plate heat exchanger and an air conditioner equipped with the plate heat exchanger are provided. Obtainable.

実施の形態1.

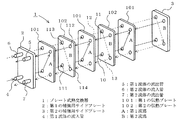

図1は本発明の実施の形態1に係るプレート式熱交換器を模式的に示した分解斜視図、図2は図1の組み立て状態の側面図、図3は図1の第1の補強用サイドプレートの正面図、図4は図1の第1の伝熱プレートの正面図、図5は図1の第2の伝熱プレートの正面図、図6は図1の第2の補強用サイドプレートの正面図である。

図1に示すように、プレート式熱交換器1において、最も外側に位置する2枚のプレート、すなわち第1の補強用サイドプレート2(図3参照)及び第2の補強用サイドプレート3(図6参照)の間に、2種類の伝熱プレート、すなわち第1の伝熱プレート101(図4参照)及び第2の伝熱プレート102(図5参照)が交互に積層され、それらがロウ付けによって一体的に接合されている。これら第1、第2の伝熱プレート101、102のあいだには、第1流体が流れる第1流路A、及び第2流体が流れる第2流路Bが交互に繰り返し形成されている。

1 is an exploded perspective view schematically showing a plate heat exchanger according to

As shown in FIG. 1, in the

第1、第2の補強サイドプレート2、3、及び第1、第2の伝熱プレート101、102は金属製のほぼ矩形状の平板からなり、少なくとも伝熱プレート101、102の縦横比は4〜6の範囲内となっている。縦横比とは、伝熱プレート101、102の幅Wに対する高さの比であり、縦横比を4〜6にすることにより、流体の圧力損失増加を抑制してプレート式熱交換器1の熱伝達を向上させることができる。

The first and second reinforcing

第1の補強用サイドプレート2の左下部分及び右上部分にはそれぞれ第1流体の流入管4及び第1流体の流出管5が設けられており、左上部分及び右下部分にはそれぞれ第2流体の流入管6及び第2流体の流出管7が設けられている。

A first

そして、第1の伝熱プレート101及び第2の伝熱プレート102には、第2の補強サイドプレート2の第1流体の流入管4、第1流体の流出管5、第2流体の流入管6、第2流体の流出管7に対応する位置に、それぞれ、第1開口111、第2開口112、第3開口113、第4開口114が形成されており、これら第1開口〜第4開口111〜114は、それぞれ、各第1流路の流入口、各第1流路の流出口、各第2流路の流入口、各第2流路の流出口を形成している。

The first

第1開口111〜第4開口114の周りには、その周囲を覆い、かつ第1、第2の伝熱プレート101、102の表側または裏側に膨出する平坦なシール部(図示せず)が設けられている。このシール部は、第1流体が流れる第1流路Aにおいては、第3開口113、第4開口114がシールされており、第2流体が流れる第2流路Bにおいては、第1開口111、第2開口112がシールされている。こうして、第1流路Aへの第2流体の流入が阻止されると共に、第2流路Bへの第1流体の流入が阻止される。

Around the first opening 111 to the

第1の伝熱プレート101と第2の伝熱プレート102は交互に積層されており、第1開口111によって区画される第1流入空間10、第2開口112によって区画される第1流出空間11、第3開口113によって区画される第2流入空間12、第4開口114によって区画される第2流出空間13がそれぞれ形成される。

The first

図4、図5に示すように、第1、第2の伝熱プレート101、102には、その表面に互いに反対方向に傾斜する伝熱促進面115、117が形成されている。この伝熱促進面115、117は、各流体の流れに乱れを与えて熱交換を促進する部分であり、その高さ方向(図の上下方向)に沿って波部116、118が交互に繰り返して形成されている。この第1、第2の伝熱プレート101、102に設けた波部116、118は、図8、図9に示すように、幅方向(図の左右方向)の中央部が低く、両側に向かって波形に傾斜してそれぞれ両側の中央部が高い実線で示す波部と、この波部に隣接し、中央部が高く、両側に向かって波形に傾斜してそれぞれ両側の中央部が低い破線で示す波部とが交互に形成されている。

As shown in FIGS. 4 and 5, the first and second

そして、この伝熱促進面115、117はその長手方向イ(幅方向の中央部から一方の側)に波部116、118の高さを波状に変化させることにより、第1、第2の伝熱プレート101、102の波部116、118の頂部同士を接合して接合点数を減少させ、流体の圧力損失増加を抑制するようにしてある。ただし、図7に示すように、波部116、118の接合部におけるロウ付け130の長さLは、第1、第2の伝熱プレート101、102の幅W(図4参照)に対して30%を維持するようにする。

The heat

また、第1、第2の伝熱プレート101、102の高さ方向に対して波部116、118の長手方向イのなす角度θ(鋭角側の角度θ、以下波角度θという)は、例えば70°〜80°のように大きく形成され、隣接する波部116、118のピッチPは例えばほぼ4mmになるように小さくして、熱伝達がよくなるようにしてある。

In addition, an angle θ formed by the longitudinal direction A of the

そして、第1伝熱プレート101と第2伝熱プレート102との互い波部116、118の頂部同士が接合され、各伝熱プレート101、102の間に、曲がりくねったジグザグの流路となる第1、第2の流路A、Bが形成される。

Then, the top portions of the

第1、第2の伝熱プレート101、102の周縁部は折り曲げられており、これらの伝熱プレート101、102を積層した際に、周縁部同士が重なり合ってプレート式熱交換器1の側面を形成するようにしてある。そして、これらの側面部に囲まれて、第1の伝熱プレート101の表側と第2の伝熱プレート102の裏側との間には、第1流体が流通する第1流路Aが形成され、第1伝熱プレート101の裏側と第2伝熱プレート102の表側との間には、第2流体が流通する第2流路Bが形成されている。

The peripheral portions of the first and second

次に、第1、第2の伝熱プレート101、102に設けられた波部116、118の構成について説明する。

図8は、第1の伝熱プレート101の波部116の流路の概略説明図で、波部116が波形状をなし、その高さを長手方向イに変化させている。波部116の高さは、C面を基準とした場合、頂部がH1であり、頂部以外の部分がH2であって、H1>H2となる。なお、破線は隣接する波部116を示す。

Next, the structure of the

FIG. 8 is a schematic explanatory view of the flow path of the

図9は、第1の伝熱プレート101の上に、さらに第2の伝熱プレート102を重ね合わせた場合の流路の概略説明図である。こうして積層されたプレート式熱交換器1では、第1の伝熱プレート101の実線の波部116の頂部が第2の伝熱プレート102の破線の波部118の底部と、2点D、Eで接合する。

この場合、波部116、118の高さが0.2mm以下であれば、伝熱プレート101、102間のロウ材130のフィレット形成を抑制することができ、接合点数を調整することができる。

FIG. 9 is a schematic explanatory diagram of the flow path when the second

In this case, if the

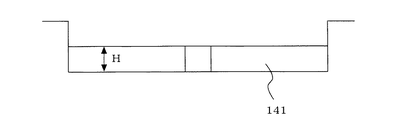

図10は図8との比較のための第1の伝熱プレート141の伝熱促進面の流路の概略を示し、図11は図9との比較のための第1の伝熱プレート141と第2の伝熱プレート142を重ね合わせた場合の伝熱促進面の流路の概略を示す。このプレート式熱交換器では、図8、図9の場合と異なり、伝熱促進面は高さH1が一定であるため、第1、第2の伝熱プレート141、142間で多くの接点ができることになる。しかしながら、この比較例では、接合点が増えると、圧力損失が悪化するため、空調機器の消費電力が増加する。また、ゴミ詰まり等の信頼性も低下する。さらに、水、炭化水素、低GWP冷媒といった圧力損失の大きな流体の使用が不可能となる。

10 schematically shows the flow path of the heat transfer promoting surface of the first

図12は、波部116、118の角度θ(以下、波角度という)と熱通過率、圧力損失との関係を示す線図であり、図13は、波角度θと接合部で形成されるフィレットのロウ材長さlとの関係を示す線図である。

波角度θが70°〜80°である場合は、図12から分かるように、波角度θが例えば66°である場合に比べて、熱通過率は1.1倍となるが、圧力損失も大きくなる。また、図13からわかるように、波角度θが大きくなると、隣接する伝熱プレートの接合部における1フィレットのロウ材の長さL(図7参照)が大きくなり、フィレット間で形成する流体の流路が狭まるため、圧力損失が大きくなる。

しかしながら、本発明では、波角度θが70°〜80°であっても圧力損失を少なくすることができる。

12 is a diagram showing the relationship between the angle θ of the

When the wave angle θ is 70 ° to 80 °, as can be seen from FIG. 12, the heat passage rate is 1.1 times as compared with the case where the wave angle θ is 66 °, for example, but the pressure loss also increases. growing. Further, as can be seen from FIG. 13, as the wave angle θ increases, the length L (see FIG. 7) of one fillet brazing material at the joint between adjacent heat transfer plates increases, and the fluid formed between the fillets increases. Since the flow path is narrowed, the pressure loss is increased.

However, in the present invention, the pressure loss can be reduced even if the wave angle θ is 70 ° to 80 °.

図14は、波部116、118のピッチPと熱通過率、圧力損失の関係を示す線図である。図14からわかるように、波部116、118のピッチPが4mm程度にまで小さくなっていくと、流体の乱れ効果により熱通過率が増加し、面積拡大率も増加するため、熱交換器の性能が向上するが、接合点の増加(図15参照)により圧力損失も大きくなる。

しかしながら、本発明では、波部のピッチLが4mm程度であっても圧力損失を少なくすることができる。

FIG. 14 is a diagram showing the relationship between the pitch P of the

However, in the present invention, the pressure loss can be reduced even if the wave portion pitch L is about 4 mm.

図16は、伝熱プレートの幅Wと熱通過率、圧力損失の関係を示す線図、図17は伝熱プレートの縦横比と熱通過率、圧力損失の関係を示す線図である。

図16より、伝熱プレートの幅Wを小さくすると、流路断面積が小さくなるため、流体の速度が増加し、熱通過率が向上するが、圧力損失も大きくなる。

この幅Wに関連して、図17は、伝熱プレート1枚当りの伝熱面積を一定とし、縦横比(高さH/幅W)をパラメータとして、熱通過率、圧力損失、プレート式熱交換器の重量の関係を示している。縦横比が大きくなると、熱通過率が増加し、能力に必要な伝熱面積を小さくできるため、プレート式熱交換器の重量も小さくなる。しかしながら、圧力損失も増加する。

本発明では、縦横比を4〜6としたので、圧力損失を少なくすることができる。

FIG. 16 is a diagram showing the relationship between the width W of the heat transfer plate, the heat passage rate, and the pressure loss, and FIG. 17 is a diagram showing the relationship between the aspect ratio of the heat transfer plate, the heat passage rate, and the pressure loss.

As shown in FIG. 16, when the width W of the heat transfer plate is reduced, the cross-sectional area of the flow path is reduced, so that the speed of the fluid is increased and the heat passage rate is improved, but the pressure loss is also increased.

In relation to this width W, FIG. 17 shows that the heat transfer area per one heat transfer plate is constant, and the aspect ratio (height H / width W) is a parameter, and the heat transfer rate, pressure loss, plate heat It shows the weight relationship of the exchanger. As the aspect ratio increases, the heat transfer rate increases and the heat transfer area required for capacity can be reduced, so the weight of the plate heat exchanger is also reduced. However, pressure loss also increases.

In the present invention, since the aspect ratio is 4 to 6, the pressure loss can be reduced.

図18は、波角度θと伝熱プレートの幅Wから、強度確保に最低限必要な上下の伝熱プレートの接合点数をまとめた説明図である。

この接合点数は、隣接する伝熱プレートの波部の接合部におけるロウ付け長さL(図7参照)が伝熱プレートの幅Wに対し30%以上になるものであり、一般的に使用されるプレート式熱交換器の幅Wに対するロウ付け長さLの割合である。本発明は、この割合を満たすよう接合点数を決定した。この接合点数になるよう波部の波高さを調整すれば、接合点数が減っても、強度を維持した状態で流体の圧力損失を低減することができる。

FIG. 18 is an explanatory diagram summarizing the number of joining points of the upper and lower heat transfer plates necessary for ensuring the strength based on the wave angle θ and the width W of the heat transfer plate.

The number of joining points is such that the brazing length L (see FIG. 7) at the joining portion of the wave portion of the adjacent heat transfer plate is 30% or more with respect to the width W of the heat transfer plate, and is generally used. This is the ratio of the brazing length L to the width W of the plate heat exchanger. In the present invention, the number of junction points is determined so as to satisfy this ratio. If the wave height of the wave portion is adjusted so that the number of junction points is obtained, the pressure loss of the fluid can be reduced while maintaining the strength even if the number of junction points is reduced.

一例として、幅Wが100mm、高さHが300mm(縦横比3)、波ピッチが7mm、角度θが66°の伝熱プレートの伝熱性能を上げるため、伝熱プレート1枚当りの伝熱面積を一定にして、幅Wを77mm、高さHを390mm(縦横比5)、波ピッチを4mm、角度θを80°にすると、熱通過率は30%上昇するため、同等能力においてプレート式熱交換器の重量は30%低減できる。一方、圧力損失は、接合点を減らさなければ3.6倍に増えるが、接合点を減らした本発明では1.8倍と半分に抑制することができる。 As an example, in order to increase the heat transfer performance of a heat transfer plate having a width W of 100 mm, a height H of 300 mm (aspect ratio 3), a wave pitch of 7 mm, and an angle θ of 66 °, heat transfer per heat transfer plate If the area is constant, the width W is 77 mm, the height H is 390 mm (aspect ratio 5), the wave pitch is 4 mm, and the angle θ is 80 °, the heat transfer rate increases by 30%. The weight of the heat exchanger can be reduced by 30%. On the other hand, the pressure loss increases 3.6 times if the junction point is not reduced, but can be suppressed to 1.8 times and half in the present invention in which the junction point is reduced.

本発明では、第1、第2の伝熱プレート101、102の接合点数は、隣接する伝熱プレート101、102の波部116、118の高さを流体の流れ方向に1波毎に変化させて調整しても良い。

この場合、接合点を持つ波の高さに対し、接合点を持たない波の高さは0.2mm以下とし、隣接する伝熱プレートの接合点を調整する。これにより、波高さの変化が流れの乱れを起こすため、伝熱性能に優れ、接合点減少により圧力損失が小さくなる。

In the present invention, the number of joining points of the first and second

In this case, the height of the wave having no junction point is 0.2 mm or less with respect to the height of the wave having the junction point, and the junction point of the adjacent heat transfer plates is adjusted. As a result, the change in the wave height causes the flow disturbance, so that the heat transfer performance is excellent, and the pressure loss is reduced by reducing the junction points.

また、本発明では、第1、第2の伝熱プレート101、102の接合点数は、隣接する伝熱プレート101、102の波部のピッチPを流体の流れ方向に1波毎に変化させて調整しても良い。

この場合、波部116、118のピッチPの大きな領域は接合点数を減らせ、波部116、118のピッチPの小さな領域は接合点数を増やすことができる。波部116、118のピッチPの変化による流れの乱れが伝熱性能を向上し、接合点減少により圧力損失を小さくする。

Further, in the present invention, the number of junctions of the first and second

In this case, the number of junction points can be reduced in the region where the pitch P of the

さらに、上記の説明では、第1、第2の伝熱プレート101、102の波部116、118の高さを長手方向イに波状に変化させて接合点数を調整した場合を示したが、波部116、118の一方の面の長手方向イに所定間隔で溝部116a、118aを設けて高さを変化させ、接合点数を調整するようにしてもよく、図19、図20はその場合の流路の概略説明図である。

図19は第1の伝熱プレート101aに第2の伝熱プレート102aを重ね合わせたものである。溝部116a、118aでない部分116b、118bのみが高くなり、この部分のみが接合点D、Eとなるので、流体の流れ方向の圧力損失が小さく抑えられ、波角度θや縦横比の伝熱促進効果が得られる。

Furthermore, in the above description, the case where the number of junction points is adjusted by changing the height of the

In FIG. 19, the second

次に、本発明の作用を図1を用いて説明する。

上記のように構成したプレート式熱交換器における第1流体と第2流体との熱交換動作は、次のようにして行われる。

図1に実線矢印で示すように、低温の気液二相状態の第1の冷媒は、第1の流入管4から流入し、第1流入空間8を通じて各第1流路A、A・・・に流入する。一方、高温ガス状態の第2冷媒は、破線で示すように、第2流入管6から流入し、第2流入空間10を通じて各第2流路B、B・・・に流入する。

Next, the operation of the present invention will be described with reference to FIG.

The heat exchange operation between the first fluid and the second fluid in the plate heat exchanger configured as described above is performed as follows.

As shown by solid line arrows in FIG. 1, the first refrigerant in the low-temperature gas-liquid two-phase state flows from the

第1流路Aを流れる第1冷媒と第2流路Bを流れる第2冷媒とは、第1、第2の伝熱プレート101、102を介して互いに熱交換を行い、第1冷媒は蒸発し、第2冷媒は凝縮する。そして、蒸発してガス状態となった第1冷媒は、第1流出空間11を経て、第1流出管5から流出する。一方、凝縮して液状態になった第2冷媒は、第2流出空間13を経て、第2流出管7から流出する。

The first refrigerant flowing through the first flow path A and the second refrigerant flowing through the second flow path B exchange heat with each other via the first and second

第1流路Aを流れる第1冷媒と第2流路Bを流れる第2冷媒とが、第1、第2の伝熱プレート101、102を介して互いに熱交換を行う際、伝熱促進面115、117に設けられた波部116、118を通過し、ここで、熱交換が効率よく行われる。

When the first refrigerant flowing through the first flow path A and the second refrigerant flowing through the second flow path B exchange heat with each other via the first and second

実施の形態1によれば、伝熱プレート101、102の波角度θを大きくして70°〜80°とし、波ピッチPを小さくしてほぼ4mmとしても、隣接する伝熱プレート101、102の波部116、118の接合部におけるロウ付け長さLが幅Wに対し30%を維持するように波部116、118の高さを長手方向イに変化させて接合点数を調整したので、必要最小限度の接合点数で流体の流路を構成することができ、従来のプレート式熱交換器と同等の強度を維持したまま、圧力損失の増加を抑制し、熱交換率を向上させることができる。そして、従来と同等の強度を維持したまま圧力損失の増加を抑制することができるので、伝熱プレート101、102へのスケール等の異物が詰まり難くなり、長期に渡り伝熱性能を維持することができ、信頼性が高くなる。

According to the first embodiment, even if the wave angle θ of the

また、上記の場合において、伝熱プレート101、102の幅を縦横比4〜6の範囲内で小さくしたので、伝熱プレート101、102間に流入する流体の入口流速が大きくなり、このため、伝熱プレート101、102間の熱伝達がさらに向上し、積層する伝熱プレート102、103の枚数が低減でき、材料費や加工費等の製造コストが削減できる。

In the above case, since the width of the

こうして、熱伝達が良く、強度を維持したまま、圧力損失の増加が最小限に抑制できるので、安価で信頼性に優れたプレート式熱交換器1を提供することができる。

Thus, since heat transfer is good and the increase in pressure loss can be minimized while maintaining strength, the

実施の形態2.

本発明の実施の形態2は、実施の形態1に係るプレート式熱交換器1を搭載した空調機器に関するものである(図示せず)。

実施の形態2に係る空気調和機は、実施の形態1に係るプレート式熱交換器1を搭載したので、消費電力量が少なくて済む。

The second embodiment of the present invention relates to an air conditioner equipped with the

Since the air conditioner according to the second embodiment is equipped with the

1 プレート式熱交換器 、2 第1の補強用サイドプレート、 3 第2の補強用サイドプレート、4 第1流体の流入管、5 第1流体の流出管、6 第2流体の流入管、7 第2流体の流出管、101 第1の伝熱プレート、102 第2の伝熱プレート、115、117 伝熱促進面、116、118 波部、130 波部の接合部(ロウ材)、A 第1流路、B 第2流路、H 高さ、W 幅、L ロウ付け長さ、P 波部のピッチ、θ 波角度。

DESCRIPTION OF

Claims (7)

前記伝熱プレートの表面に、前記第1、第2流体の流れに乱れを与えて熱交換を促進する伝熱促進面が設けられ、

前記伝熱促進面は山部と谷部が前記伝熱プレートの高さ方向に沿って交互に繰り返され、

前記山部の高さを当該山部の長手方向に波状に変化させて波部が形成され、

隣接する前記伝熱プレートの接合部における前記波部の接合長さが前記伝熱プレートの幅に対して30%を維持するように、前記波部が形成され、前記伝熱プレートの接合点数を調整したことを特徴とするプレート式熱交換器。 A first flow path and a second flow path are formed between the plurality of heat transfer plates that are stacked and joined, and the first fluid and the second fluid are passed through the first flow path and the second flow path, respectively. A plate-type heat exchanger that circulates between the heat plates and exchanges heat between the first fluid and the second fluid,

On the surface of the heat transfer plate, there is provided a heat transfer promoting surface that disturbs the flow of the first and second fluids to promote heat exchange,

The heat transfer promotion surface is alternately repeated with the ridges and valleys along the height direction of the heat transfer plate ,

A wave portion is formed by changing the height of the peak portion in a wave shape in the longitudinal direction of the peak portion,

The wave portions are formed so that the joining length of the wave portions at the joining portions of the adjacent heat transfer plates is maintained at 30% with respect to the width of the heat transfer plate, and the number of joining points of the heat transfer plates is determined. A plate heat exchanger characterized by adjustment.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008250278A JP4827905B2 (en) | 2008-09-29 | 2008-09-29 | Plate type heat exchanger and air conditioner equipped with the same |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008250278A JP4827905B2 (en) | 2008-09-29 | 2008-09-29 | Plate type heat exchanger and air conditioner equipped with the same |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2010078286A JP2010078286A (en) | 2010-04-08 |

| JP4827905B2 true JP4827905B2 (en) | 2011-11-30 |

Family

ID=42208937

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008250278A Active JP4827905B2 (en) | 2008-09-29 | 2008-09-29 | Plate type heat exchanger and air conditioner equipped with the same |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4827905B2 (en) |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5932777B2 (en) | 2011-04-18 | 2016-06-08 | 三菱電機株式会社 | Plate heat exchanger and heat pump device |

| WO2013076751A1 (en) * | 2011-11-21 | 2013-05-30 | 三菱電機株式会社 | Plate-type heat exchanger and refrigeration cycle device using same |

| JPWO2013076751A1 (en) * | 2011-11-21 | 2015-04-02 | 三菱電機株式会社 | Plate heat exchanger and refrigeration cycle apparatus using the same |

| WO2013080256A1 (en) * | 2011-11-30 | 2013-06-06 | 三菱電機株式会社 | Plate-type heat exchanger and refrigeration cycle equipment including this heat exchanger |

| JP6094261B2 (en) * | 2013-02-27 | 2017-03-15 | 株式会社デンソー | Laminate heat exchanger |

| DE112014001028T5 (en) * | 2013-02-27 | 2016-01-07 | Denso Corporation | Stack heat exchanger |

| JP6160385B2 (en) * | 2013-09-17 | 2017-07-12 | 株式会社デンソー | Laminate heat exchanger |

| EP3077753B1 (en) * | 2013-12-05 | 2017-11-08 | SWEP International AB | Heat exchanging plate with varying pitch |

| JP2018179340A (en) * | 2017-04-06 | 2018-11-15 | 東京電力ホールディングス株式会社 | Plate heat exchanger |

| WO2024185671A1 (en) * | 2023-03-09 | 2024-09-12 | 株式会社ティラド | Stacked-plate-type evaporator |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS52105352A (en) * | 1976-02-28 | 1977-09-03 | Hisaka Works Ltd | Condenser |

| DE4020735A1 (en) * | 1990-06-29 | 1992-01-02 | Schmidt Bretten W Gmbh | HEAT EXCHANGER |

| JPH10232093A (en) * | 1997-02-19 | 1998-09-02 | Daikin Ind Ltd | Heat storage device |

| JP3292128B2 (en) * | 1998-02-27 | 2002-06-17 | ダイキン工業株式会社 | Plate heat exchanger |

| PT1630510E (en) * | 2004-08-28 | 2007-04-30 | Swep Int Ab | A plate heat exchanger |

| SE528879C2 (en) * | 2005-07-04 | 2007-03-06 | Alfa Laval Corp Ab | Heat exchanger plate, pair of two heat exchanger plates and plate package for plate heat exchanger |

-

2008

- 2008-09-29 JP JP2008250278A patent/JP4827905B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| JP2010078286A (en) | 2010-04-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4827905B2 (en) | Plate type heat exchanger and air conditioner equipped with the same | |

| JP6567097B2 (en) | Plate heat exchanger and heat pump heating / hot water system equipped with the same | |

| US9618280B2 (en) | Plate-type heat exchanger, particularly for motor vehicles | |

| JP5553828B2 (en) | Heat exchanger | |

| EP1070928B1 (en) | Plate type heat exchanger | |

| KR101445474B1 (en) | A heat exchanger plate and a plate heat exchanger | |

| JP6163190B2 (en) | Heat exchanger | |

| JP2007500836A (en) | Heat exchanger and manufacturing method thereof | |

| JP5872859B2 (en) | Heat exchanger | |

| JP2006322698A (en) | Heat exchanger | |

| JP5077926B2 (en) | Heat exchanger | |

| JPWO2014147804A1 (en) | Plate heat exchanger and refrigeration cycle apparatus equipped with the same | |

| JP2010114174A (en) | Core structure for heat sink | |

| WO2011062118A1 (en) | Plate-type heat exchanger and heat pump device | |

| WO2013001744A1 (en) | Fin tube heat exchanger | |

| JP4879258B2 (en) | Plate heat exchanger and air conditioner equipped with the same | |

| JP5538344B2 (en) | Plate heat exchanger and heat pump device | |

| JP5419719B2 (en) | Plate heat exchanger and heat pump device | |

| JP2009186142A (en) | Brazed plate type heat exchanger | |

| JP2002048491A (en) | Heat exchanger for cooling | |

| JP2017101904A (en) | Fin for heat exchanger | |

| CN211903861U (en) | Plate heat exchanger | |

| JP5595064B2 (en) | Plate heat exchanger and heat pump device | |

| JP2006112732A (en) | Small-diameter heat transfer tube unit of small-diameter multitubular heat exchanger | |

| JP2021081158A (en) | Heat exchanger |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20110310 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20110315 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110511 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20110816 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20110913 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20140922 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 Ref document number: 4827905 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |