JP2016125175A - Sleeve structure - Google Patents

Sleeve structure Download PDFInfo

- Publication number

- JP2016125175A JP2016125175A JP2015001774A JP2015001774A JP2016125175A JP 2016125175 A JP2016125175 A JP 2016125175A JP 2015001774 A JP2015001774 A JP 2015001774A JP 2015001774 A JP2015001774 A JP 2015001774A JP 2016125175 A JP2016125175 A JP 2016125175A

- Authority

- JP

- Japan

- Prior art keywords

- sleeve

- sleeve member

- small

- cuff

- upper side

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Landscapes

- Details Of Garments (AREA)

Abstract

Description

本発明は、少なくとも着用者の腕部を覆う長さを有する袖の構造体に関するものである。 The present invention relates to a sleeve structure having a length covering at least a wearer's arm.

従来より、気温が低い環境下で、手袋を使わずに手元を保温するために、上衣の袖口を引き伸ばして手元を収納することが行われていた。そこで、袖口の構造や形状を工夫し、手元を保温する上衣について、従来より提案されている。例えば特許文献1には、手袋体を衣服体の袖部に沿設状態に設けた収納袋部に出し入れ自在に収納する構成とすることで、手袋体不使用時(収納時)の体裁も良好となる手袋付衣服について開示されている。

また特許文献2には、袖口及び裾口部に袋状部を設け、表裏反転させて被覆する事により手足を保温できる乳幼児用衣服について開示されている。

Conventionally, in order to keep a hand warm without using gloves in an environment where the temperature is low, the cuff of the upper garment is stretched and the hand is stored. In view of this, an upper garment that keeps the hand warm by contriving the structure and shape of the cuffs has been proposed. For example, in Patent Document 1, the glove body is stored in a storage bag portion that is provided along the sleeve portion of the garment body so that the glove body can be inserted and removed freely, so that the appearance when the glove body is not used (when stored) is also good. Gloved clothing is disclosed.

Further,

しかし、特許文献1では、手袋体を収納袋部に収納させるが、手袋体を別途費用と手間をかけて作成する必要があり、さらには収納部には手袋体のみならず、他の用品を収納したり、保温性を高めるために携帯用カイロ等を収納することが開示されているが、収納できる物品に限りがあった。

また、特許文献2では、袖口及び裾口部の袋状部を表裏反転させて被覆し、手足を保温できるが、袋状部とその付近の構造におけるその他の活用用途については言及されていない。

However, in Patent Document 1, the glove body is stored in the storage bag portion, but it is necessary to create the glove body at an additional cost and effort. Further, not only the glove body but also other items are included in the storage portion. Although it has been disclosed to store portable warmers or the like in order to store or improve heat retention, there is a limit to the items that can be stored.

Moreover, in

本発明は、上記従来の課題を解決するため、袖の構造体において、複数の生地を配置させて縫製することにより、保温性を高める以外の便利な用途をもつ機能を、簡易に費用をかけずに実現させるものである。 In order to solve the above-described conventional problems, the present invention easily and cost-effectively has a function having a convenient use other than improving heat retention by arranging a plurality of fabrics and sewing in a sleeve structure. It will be realized without.

本発明の袖の構造体は、少なくとも着用者の腕部を覆う長さを有する袖の構造体であり、

上袖1、下袖2、大袖部材3、小袖部材4、を縫着して形成し、

上袖1の下に下袖2を重ねて、上袖元12と下袖元22が一致するように上袖1と下袖2の左右の側部同士を縫着し、

上袖1の下に大袖部材3を重ねて、上袖口11と大袖部材袖口31が一致するように、左右の側部同士を縫着し、

大袖部材3の下に小袖部材4を重ねて、大袖部材袖口31と小袖部材袖口41、更には左右の側部同士を縫着したことを特徴とする。

The sleeve structure of the present invention is a sleeve structure having a length covering at least the wearer's arm,

The upper sleeve 1, the

The

The

The

本発明の袖の構造体は、着用者の腕部を覆う長さを有する袖の構造体であって、複数の生地を配置させて縫製することにより、保温性を高めるための手袋としての機能を、指の出し入れ等の機能でさらに充実させ、それ以外の小物を収納したり、袖部分もしくは衣服本体までも収納する等の機能を、簡易な構造で費用をかけずに実現させることができる。 The sleeve structure of the present invention is a sleeve structure having a length covering the arm portion of the wearer, and functions as a glove for improving heat retention by arranging and sewing a plurality of fabrics. With functions such as putting in and out of fingers, functions such as storing other small items and storing even the sleeve part or clothing body can be realized with a simple structure without cost. .

従来までの袖の構造体は、手袋等を使用せずに手元の保温機能を実現するために、袖口に別部材や袋状部材を設けることで、その効果を得ていたが、本発明における袖の構造体は、簡単な部材と構造で手元の保温機能に加え、付加的な使用方法を提供することができる。 The conventional sleeve structure has obtained its effect by providing a separate member or bag-like member at the cuffs in order to realize the heat retaining function at hand without using gloves or the like, but in the present invention The sleeve structure can provide an additional method of use in addition to the thermal insulation function at hand with a simple member and structure.

上記手元の保温機能とは、具体的には、袖部と袖部材を組み合わせて、袖部材を折り返して袋状部を形成し、手袋として使用する機能をいう。 The above-mentioned heat-retaining function refers to a function of combining a sleeve part and a sleeve member, folding the sleeve member to form a bag-like part, and using it as a glove.

上記付加的な使用方法とは、具体的には、袖部と袖部材を組み合わせることにより、親指等を出し入れすることが可能になり、指を使った作業をしやすくしたり、

また、上記袋状部が設けられることで、その部分に小物を収納したり、

更には、上記袋状部に袖を含め衣服本体までもを収納し、

更には、補助部材を組み合わせることで、上記付加的な機能を使用しやすくするものをいう。

Specifically, the additional usage method described above is to combine the sleeve part and the sleeve member, so that the thumb can be taken in and out, making it easier to work with fingers,

In addition, by providing the bag-like part, small parts can be stored in that part,

In addition, the bag-shaped part contains the sleeves and even the clothing body,

Furthermore, the auxiliary member is used to facilitate the use of the additional function.

以下、図面に基づいて、本発明の袖の構造体について説明する。 Hereinafter, the sleeve structure of the present invention will be described with reference to the drawings.

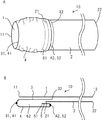

図1Aは、本発明の袖の構造体10の一実施態様であり、袖を下側から見た場合を示した図である。

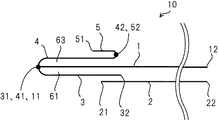

図1Bは、図1Aを横から見た場合の各生地の構成を示す断面図である。本発明の袖の構造体10は、上袖1、下袖2、大袖部材3、小袖部材4、及び補助部材5からなる。図1A、及び図1Bにおいて、重なる各部材の端部については、破線にて示している。また、図1B中、黒丸は生地の縫着部を表している。

上袖1、下袖2は、上下に構成された袖の構造体10を主として構成する部材である。

大袖部材3は、下袖2の袖口側に配置し、袖口までの下袖2の足りない部分の袖を補い、さらには小袖部材4の袖口と側部同士を縫着することで形成される手袋や小物の収納部、袖または衣服全体を収納する袋部を形成する目的で配置する部材である。

小袖部材4は、上記大袖部材3と対となり、上記のとおり大袖部材3の外側に配置し、袖口と側部同士を縫着することで、袋部を形成する目的で配置する部材である。

補助部材5は、上記小袖部材4の上辺に配置し、上辺と側部同士を縫着することで、上記手袋をフィットさせる目的でに引き上げるつまみにしたり、袋部に小物をいれる場合のストッパーにしたり、袖または衣服全体を収納する袋部の蓋を構成する目的で配置する部材である。

FIG. 1A is an embodiment of a

FIG. 1B is a cross-sectional view showing the configuration of each fabric when FIG. 1A is viewed from the side. The

The upper sleeve 1 and the

The

The

The

図2Aは本発明における袖の構造体10の上袖1、図2Bは下袖2、図2Cは大袖部材3、図2Dは小袖部材4、図2Eは補助部材5のパターンを表した図である。

下袖2は、上袖1よりも長手方向に短く、上袖1と袖元で位置合わせをした際に、下袖口21が上袖口11よりも袖元側に位置する。

上袖1と下袖2の各々袖口と、大袖部材3、及び小袖部材4とは、略同一幅である。

大袖部材3、小袖部材4の長さは任意とすることができるが、本実施の形態では大袖部材3が小袖部材4よりも長く、下袖2の上に重なり、下袖口21を袖元側へ越えて長くなるように形成している。

大袖部材4は下袖2の下に重なり、下袖口21を袖元側へ越えて長くなるように形成している。

2A is an upper sleeve 1 of a

The

The cuffs of the upper sleeve 1 and the

The lengths of the

The

図1A、Bに示すように、本発明の袖の構造体10の一実施態様は、上袖1の下に下袖2を重ねて、上袖元12と下袖元22とが一致するように上袖1と下袖2の左右の側部同士を縫着し、

上袖1の下に大袖部材3を重ねて、上袖口11と大袖部材袖口31が一致するように、左右の側部同士を縫着することで、本発明の袖構造10の袖元と袖口とを連通する筒状空隙が形成され、

小袖部材4の下に大袖部材3を重ねて、大袖部材袖口31と小袖部材袖口41、更には左右の側部同士を縫着することで、大袖部材袖口31と小袖部材41を底面とする第二袋部62が形成され、

補助部材5を、小袖部材4の上に重ねて、補助部材上辺52と小袖部材上辺42、更には左右の側部同士を縫着し、

上袖1と小袖部材4の左右側部は、大きめに作成して縫い縮めて、構成されている。

As shown in FIGS. 1A and 1B, in one embodiment of the

The sleeve portion of the

The

The

The left and right side portions of the upper sleeve 1 and the

上記本発明の袖の構造体10の作成方法の一例としては、下記の通りであるが、下記の作成方法に限定されない。

補助部材5を、小袖部材4の上に重ねて、補助部材上辺52と大袖部材上辺42を縫着し上袖1と小袖部材4の左右側部を、大きめに作成して縫い縮め、

上袖1、大袖部材3、前記補助部材5を縫着した小袖部材4、下袖部材2を上から各々の袖口を重ねて、側部のみを同時に縫製している。

また、ここでは同時に縫製を行っているが、上記各部材の縫製を別々に行っても良い。

An example of a method for producing the

The

The upper sleeve 1, the

Further, although the sewing is performed at the same time here, the respective members may be sewn separately.

図3Aは、本発明における袖の構造体10を、そのまま手元を外に出して着用した、使用方法1を示す図である。

FIG. 3A is a diagram showing a method of use 1 in which the

図3Bは、本発明における袖の構造体10を、大袖部材上辺32と下袖口21との間に設けられた隙間、更には小袖部材上辺42と下袖口21との間に設けられた隙間から指を出して着用した、使用方法2を示す図である。このように指を出して使用することで、指先以外の部分を保温しながら、指先を使った作業が容易になる。上記隙間から出す指としては、親指が一般的であり、袖口から出した他の指と同時に作業することを容易にするが、特に親指に限定されない。

FIG. 3B shows a structure in which the

図3Cは、本発明における袖の構造体10を、図3Bにおける小袖部材上辺42を手先方向に折り返して、連動する大袖部材3と上袖1も含めて裏返し、大袖部材3と上袖1が形成する第一袋部61に指先を入れて着用した、使用方法3を示す図である。

また、図3Cを横から見た場合の各生地の構成を示す断面図を、図4に示している。ここで図4中、黒丸は生地の縫着部を表している。このように使用することで、指先を完全に覆うことができる保温もしくは防護目的の手袋となり、さらには大袖部材上辺32と下袖口21との間に設けられた隙間から指を出すことにより、温まりすぎた第一袋部61内もしくは袖、衣服本体に空気を導入することが可能になり、衣服内の温度を下げることが可能になる。もしくは親指等を出すことにより、指先を使った作業が容易に行うことができる。ここで隙間から出す指についてはどの指でも任意であり、特に親指に限定されない。

FIG. 3C shows the

FIG. 4 is a cross-sectional view showing the configuration of each fabric when FIG. 3C is viewed from the side. Here, in FIG. 4, black circles represent the sewn portion of the fabric. By using it in this way, it becomes a glove for heat insulation or protection purpose that can completely cover the fingertip, and further by taking out the finger from the gap provided between the

図3Dは、本発明における袖の構造体10において、大袖部材3と小袖部材4が形成する第二袋部62に小物を入れて収納する使用方法4を示す図である。このように第二袋部62に小物を入れて収納することで、カイロを入れて手元をさらに温めたり、運動時にはタオルを入れて、汗をかいた場合に手早くタオルにてふき取ることが可能となる。このように第二袋部62に小物を入れることについては、上記カイロやタオルに限定されず、任意に選択できる。

FIG. 3D is a diagram illustrating a

図3Eは、本発明における袖の構造体10において、図3Cにおける第一袋部61と、第一袋部61を形成したときに上袖1と小袖部材4にて同時に形成される第三袋部63と本発明における各々の袖、袖部材を含め、衣服本体までも収納する使用方法5を示す図である。

図3Cにおける第一袋部61を形成する際には、図4に示すように、第三袋部63が同時に形成されることになる。この第一袋部61と第三袋部63を一つの袋体とすると、いずれか一方の袋体では収納することが困難な袖、更には衣服本体を収納することを容易にする。

FIG. 3E shows the first bag portion 61 in FIG. 3C and the third bag formed simultaneously with the upper sleeve 1 and the

When the first bag portion 61 in FIG. 3C is formed, the

次に、図1Bに示すように下袖2が、大袖部材3の下に重なるように、下袖口21が大袖部材上辺32を、大袖部材袖口31側に超えて長く形成されていることが好ましい。

このように形成されていることで図3Dに示す第二袋部62に小物を入れて収納する使用方法4において、大袖部材上辺32に小物が引っ掛からずに、スムーズに小物を入れることが可能となる。

Next, as shown in FIG. 1B, the

In the

又、下袖口21は大袖部材上辺32を、大袖部材袖口31側に超えて0.5〜4cm長く形成されていることが好ましい。0.5cmより短く形成されると、図3Dに示す使用方法4において、大袖部材上辺32に小物が引っ掛かる可能性が増すからである。また、4cmより長く形成されると、図3Bに示す使用方法2において、親指等を出す時に、下袖口21が邪魔になることがあり、親指等を出す動作が困難になる。

Moreover, it is preferable that the

次に、図1Bに示すように小袖部材4が、下袖2の下に重なるように、小袖部材上辺42が、下袖口21を、下袖元22側に超えて長く形成されていることが好ましい。

このように形成されていることで図3Aに示す通常使用である使用方法1において、下袖口21と小袖部材上辺42間に形成された隙間から、運動時等に進行方向に対して風を受けずに、袖部もしくは衣服全体内部の温度低下を防止することができる。

さらには、図3Bに示す使用方法2において、親指等を出す時に、小袖部材上辺42が蓋となり、余分な風を入れることがない。

さらには、図3Dに示す使用方法4において、第二袋部62の上辺である小袖部材上辺42が小物を受け入れる形状となるため、小袖部材上辺42を無理に開かずともスムーズに小物を入れることが可能となる。

Next, as shown in FIG. 1B, the small sleeve member

In the usage method 1 which is the normal use shown in FIG. 3A by being formed in this way, the wind is received from the gap formed between the

Furthermore, in the method of

Furthermore, in the

又、小袖部材上辺42が、下袖口21を、下袖元22側に超えて0.5〜3cm長く形成されていることが好ましい。0.5cmより短く形成されると、図3Dに示す使用方法4において、第二袋部62の上辺である小袖部材上辺42を開くときに下袖口21が邪魔になることがあり、第二袋部62の上辺をスムーズに開くことができない。また、3cmより長く形成されると、図3Bに示す使用方法2において、親指等を出す時に、小袖部材上辺42が邪魔になり、親指等を出す動作が困難になる。

Moreover, it is preferable that the small sleeve member

次に、図1A、Bに示すように、補助部材5を、小袖部材4の上に重ねて、補助部材上辺52と小袖部材上辺42、更には左右の側部同士を縫着することが好ましい。

補助部材5については、小袖部材上辺42を所定の長さに折り返して、折り返し部分を縫製して形成しても良い。

このように形成されていることで、図3Dに示す使用方法4において、補助部材5が第二袋部62に小物を入れる際のつまみになり、第二袋部62の上辺を引き上げたり、開いたりする際の操作性が良好となる。また、第二袋部62に小物を入れる際、補助部材5と小袖部材4の間に小物を入れるようにすれば、激しい動作にて腕を振ったときにも、小物が脱落しないストッパーの役割となる。

さらには、図3Cに示す使用方法3において、補助部材5が第一袋部61に連結する第三袋部63の上端のつまみとなり、第一袋部61に入れた手元のフィット感を調節することが容易になる。

さらには、図3Eに示す使用方法5において、第一袋部61、第三袋部63に袖、衣服本体を収納する際に、折り返して蓋にすることが出来、収納した袖部、衣服本体が袋から脱落することを防止できる。

Next, as shown in FIGS. 1A and 1B, the

The

In this way, in the

Furthermore, in the

Furthermore, in the

又、上袖1と小袖部材4の左右側部は、大きめに作成し、縫い縮めて縫製されていることが好ましい。

このように形成することで、図3Dにおける使用方法4において、第二袋部62が長手方向の中央部が幅方向に長い立体形状に形成されることで、入れられる小物の大きさの許容範囲を大きくすることができ、第二袋部62の入り口が狭く形成されていることで、激しい動作にて腕を振ったときにも入れた小物が脱落しにくくなる。

さらには、図3Eにおける使用方法5において、第一袋部61、第三袋部63が長手方向の中央部が幅方向に長い立体形状に形成されることで、袖部、衣服本体部を入れられる大きさの許容範囲を大きくすることができ、ある程度嵩があり、こわばった素材で作成されていても収納することが可能となる。

尚、縫い縮める場合は、小袖部材4にて縫い縮め分量を25〜50%とすることが好ましく、縫い縮め分量25〜50%とは、小袖部材4の元の左右側部長さより、25〜50%の長さを縫い縮めることをいう。また、上袖1の縫い縮め分量は、小袖部材4の縫い縮め分量に合わせることでよい。

この範囲であれば、第二袋部62、第三袋部63に収納される小物や、収納した袖部、衣服本体部の大きさに好適である。

さらに、ここでいう縫い縮めとは、ギャザー、タック、ダーツ、プリーツ等の縫製技術を指し、特定の技術に限定されない。

Moreover, it is preferable that the left and right side portions of the upper sleeve 1 and the

By forming in this way, in the

Furthermore, in the

In the case of sewing shrinkage, it is preferable that the amount of shrinkage in the

If it is this range, it is suitable for the magnitude | size of the accessory accommodated in the

Furthermore, the term “sewing shrinkage” as used herein refers to sewing techniques such as gathers, tacks, darts, and pleats, and is not limited to specific techniques.

次に、大袖部材3の長手方向の平均長さは、8〜15cmであることが好ましい。この長さはサイズ展開や性別、子供用など、様々なサイズに適合するように決定しており、最小のサイズを想定した場合、8cmより短くなると、図3Bにおける使用方法2、もしくは図3Cにおける使用方法3において、特に親指を出そうとしたときに、適切に出せないことになる。

さらに図3Cにおける使用方法3において、第一袋部61が手のサイズに合わず、きつく感じることになる。

また最大のサイズを想定した場合、15cmより長く形成されても、上記図3Bにおける使用方法2、もしくは図3Cにおける使用方法3において、親指の位置が同様に適切でないこととなり、図3Cにおける使用方法3において、第一袋部61が手のサイズに合わず、大きすぎて違和感を生むこととなる。

Next, the average length in the longitudinal direction of the

Furthermore, in the

Also, assuming the maximum size, even if the length is longer than 15 cm, the position of the thumb is not appropriate in the

次に、小袖部材4の長手方向の平均長さが、7〜14cmであることが好ましい。この長さは大袖部材3と同様、様々なサイズに適合するように決定しており、最小のサイズを想定した場合、7cmより短くなると、図3Bにおける使用方法2において、特に親指を出そうとしたときに、適切に出せないことになる。また図3Dにおける使用方法3において、入れられる小物の大きさの許容量が小さくなりすぎる。

また最大のサイズを想定した場合、14cmより長く形成されても、図3Bにおける使用方法2において、同様に親指の位置が適切でないこととなる。

また、左右の側部を縫い縮める場合は、縫い縮め分量が25%であれば、小袖部材4の長手方向の平均長さが、10〜19cmに、縫い縮め分量が50%であれば、小袖部材4の長手方向の平均長さが14〜28cmとなるように追加することとなる。

Next, the average length in the longitudinal direction of the

If the maximum size is assumed, even if the length is longer than 14 cm, the position of the thumb is not appropriate in the

Further, when the right and left sides are shrunk, if the amount of shrinkage is 25%, the average length in the longitudinal direction of the

次に、上記補助部材5の袖(上下)方向の平均長さが、3〜7cmであることが好ましい。3cmより短くなると、図3Dにおける使用方法4において、小物のストッパーの役目を十分に果たさない。また、図3Eにおける使用方法5において、第一袋部61、第三袋部63の蓋の役割を十分に果たさない。

さらに、7cmより長くなると、図3Dにおける使用方法4において、小物のストッパーの役目を果たすが、小物を取り出しにくくなる。また、図3Eにおける使用方法5において、第一袋部61、第三袋部63の蓋の役割は果たすが、袋部から蓋を外す際に、外しにくくなる。そしてコストが増大する。

Next, it is preferable that the average length of the

Furthermore, when it becomes longer than 7 cm, it serves as a small stopper in the method of

また、本発明の袖の構造体10を構成する部材の各々の袖口、上辺については、縁止めとして、別途長方形の生地を短辺の中央で折り返して縫製し、部材の袖口、上辺の生地のほつれを防いだり、意匠性を高めることが好ましい。さらには、伸縮性のある生地を用い、各々の袖口から出した手首や、上辺から出した指へフィットさせることが好ましい。

縁止めを用いる場合は、本発明の衣服の袖構造10を形成する各々袖部、袖部材を形成する長手方向の生地長さは、縁止めを含めた長さとする。

また、縁止め部材を折り返して縫製した片側の上下方向の幅は、1〜2cm程度が好ましいが、特に限定はされない。

Further, as for the cuffs and upper sides of the members constituting the

When the edge stopper is used, the length of the fabric in the longitudinal direction forming the sleeve portion and the sleeve member forming the

Moreover, although the width | variety of the up-down direction of the one side which turned the edge stop member and sewed is preferable, about 1-2 cm is not specifically limited.

本発明の袖の構造体10を形成する各々袖部、袖部材を形成する生地については、同じでも良いし、異なっていても良い。素材については、特に限定されないが、ポリエステルが好適であり、布帛素材のみの構成の場合、袖単体の質量としては12g〜15g程度となり、衣服全体としては85〜100g程度となる。

また、ニット素材のみの構成の場合は、袖単体の質量としては17〜20g程度となり、衣服全体としては130〜150g程度となる。

上記生地を構成する繊維としては、特に限定されず、ポリエステル繊維であれば、例えばポリエチレンテレフタレート、ポリトリメチレンテレフタレート、ポリブチレンテレフタレートなど、その他にはポリウレタン繊維、ポリアミド繊維、アセテート繊維、コットン繊維、レーヨン繊維、エチレンビニルアルコール繊維、ナイロン繊維などを用いることができる。

The sleeve portions and the fabrics forming the sleeve members that form the

Further, in the case of the configuration of only the knit material, the mass of the sleeve alone is about 17 to 20 g, and the overall clothing is about 130 to 150 g.

The fiber constituting the fabric is not particularly limited, and if it is a polyester fiber, for example, polyethylene terephthalate, polytrimethylene terephthalate, polybutylene terephthalate, etc., other than that, polyurethane fiber, polyamide fiber, acetate fiber, cotton fiber, rayon Fiber, ethylene vinyl alcohol fiber, nylon fiber, or the like can be used.

本発明の袖の構造体は、登山、トレッキング、ハイキング、スキー、スノーボード、スケート、野球、ゴルフ、ホッケー、サッカー、ジョギング、マラソン、テニス、バドミントン、スカッシュ、卓球などあらゆるスポーツにおける衣服に好適であるほか、一般の衣服にも有用である。 The sleeve structure of the present invention is suitable for clothes in all sports such as mountain climbing, trekking, hiking, skiing, snowboarding, skating, baseball, golf, hockey, soccer, jogging, marathon, tennis, badminton, squash, table tennis, etc. It is also useful for general clothing.

又、本発明が適用可能な袖の構造体の種類としては、ティーシャツ、ポロシャツ、ウインドブレーカー、ウォームアップ、ブルゾン、レインウェア等が挙げられ、さらには袖単体で使用するアームウォーマーや簡易な手袋構造体等も挙げられる。 The types of sleeve structures to which the present invention can be applied include tea shirts, polo shirts, windbreakers, warm-ups, blousons, rainwear, and the like, and arm warmers and simple gloves used alone. Examples include structures.

1 上袖

2 下袖

3 大袖部材

4 小袖部材

5 補助部材

10 袖の構造体

11 上袖口

12 上袖元

21 下袖口

22 下袖元

31 大袖部材袖口

32 大袖部材上辺

41 小袖部材袖口

42 小袖部材上辺

51 補助部材下辺

52 補助部材上辺

61 第一袋部

62 第二袋部

63 第三袋部

DESCRIPTION OF SYMBOLS 1

Claims (11)

上袖(1)の下に下袖(2)を重ねて、上袖元(12)と下袖元(22)が一致するように上袖(1)と下袖(2)の左右の側部同士を縫着し、

上袖(1)の下に大袖部材(3)を重ねて、上袖口(11)と大袖部材袖口(31)とが一致するように、上袖(1)と大袖部材(3)の左右の側部同士を縫着し、

大袖部材(3)の下に小袖部材(4)を重ねて、大袖部材袖口(31)と小袖部材袖口(41)とを縫着し、かつ大袖部材袖口(31)と小袖部材袖口(41)の左右の側部同士を縫着したことを特徴とする袖の構造体。 A sleeve structure having a length that covers at least a wearer's arm and is formed by sewing an upper sleeve (1), a lower sleeve (2), a large sleeve member (3), and a small sleeve member (4). In

Put the lower sleeve (2) under the upper sleeve (1), and the left and right sides of the upper sleeve (1) and the lower sleeve (2) so that the upper sleeve base (12) and the lower sleeve base (22) match. Sewing parts together,

The large sleeve member (3) is placed under the upper sleeve (1), and the upper sleeve (1) and the large sleeve member (3) are arranged so that the upper sleeve cuff (11) and the large sleeve member cuff (31) coincide with each other. Sewing the left and right sides of the

The large sleeve member cuff (31) and the small sleeve member cuff (41) are sewn on the large sleeve member cuff (31) and the small sleeve member cuff (41). A sleeve structure characterized in that the left and right sides of (41) are sewn together.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2015001774A JP2016125175A (en) | 2015-01-07 | 2015-01-07 | Sleeve structure |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2015001774A JP2016125175A (en) | 2015-01-07 | 2015-01-07 | Sleeve structure |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| JP2016125175A true JP2016125175A (en) | 2016-07-11 |

Family

ID=56356771

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2015001774A Pending JP2016125175A (en) | 2015-01-07 | 2015-01-07 | Sleeve structure |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2016125175A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20190001682U (en) * | 2017-12-26 | 2019-07-04 | 손기승 | Street clothes with sealed sleeves |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2004060134A (en) * | 2002-07-31 | 2004-02-26 | As Corp | Supporter |

| JP3105088U (en) * | 2004-05-10 | 2004-10-21 | 株式会社サンベビー大島屋 | Baby clothes |

| JP2005517828A (en) * | 2002-02-20 | 2005-06-16 | ロキ エルエルシー | Multipurpose clothing |

| JP3146166U (en) * | 2008-08-26 | 2008-11-06 | 株式会社イチーナ | Driving gloves |

| JP3159402U (en) * | 2010-02-26 | 2010-05-20 | 彦辰商事株式会社 | Cuff structure with glove function |

-

2015

- 2015-01-07 JP JP2015001774A patent/JP2016125175A/en active Pending

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2005517828A (en) * | 2002-02-20 | 2005-06-16 | ロキ エルエルシー | Multipurpose clothing |

| JP2004060134A (en) * | 2002-07-31 | 2004-02-26 | As Corp | Supporter |

| JP3105088U (en) * | 2004-05-10 | 2004-10-21 | 株式会社サンベビー大島屋 | Baby clothes |

| JP3146166U (en) * | 2008-08-26 | 2008-11-06 | 株式会社イチーナ | Driving gloves |

| JP3159402U (en) * | 2010-02-26 | 2010-05-20 | 彦辰商事株式会社 | Cuff structure with glove function |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20190001682U (en) * | 2017-12-26 | 2019-07-04 | 손기승 | Street clothes with sealed sleeves |

| KR200489723Y1 (en) | 2017-12-26 | 2019-07-26 | 손기승 | Street clothes with sealed sleeves |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US20120060256A1 (en) | Outerwear with retractably-tethered hand covering | |

| US10362817B2 (en) | Multi-use garment | |

| US20150181960A1 (en) | Pull-over pouch | |

| US20140317824A1 (en) | Rella | |

| JP2021528576A (en) | Gamer hoodie | |

| US20200093245A1 (en) | Articles incorporated into an attached pouch | |

| US20140373246A1 (en) | Article of clothing facilitating its own storage during use | |

| US20210127761A1 (en) | Single-piece garment | |

| US20150096097A1 (en) | Convertible Child Care Garment | |

| US10070671B2 (en) | Article of clothing | |

| US20170056735A1 (en) | Pocketed towel made of a plurality of fabrics | |

| JP2016125175A (en) | Sleeve structure | |

| JP3186427U (en) | socks | |

| US20170295858A1 (en) | Lightweight Portable Changing Garment | |

| US20080222768A1 (en) | Nursing privacy screen | |

| US20200221799A1 (en) | Multi-functional tubular garment with internal components | |

| CN208354632U (en) | A kind of clothes suit | |

| KR200453528Y1 (en) | Hand back towel | |

| JP6467228B2 (en) | Hood structure | |

| KR20220007676A (en) | upper body clothing | |

| JP3229887U (en) | Golf wear | |

| JP6370973B2 (en) | Pockets and clothes with pockets | |

| JP3188126U (en) | Clothing with hood | |

| US20170164666A1 (en) | Nursing cover and infinity scarf | |

| JP3209635U (en) | Clothing with hood |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20171006 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20180919 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20180928 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20190322 |