JP2004001705A - Movable carriage - Google Patents

Movable carriage Download PDFInfo

- Publication number

- JP2004001705A JP2004001705A JP2003074741A JP2003074741A JP2004001705A JP 2004001705 A JP2004001705 A JP 2004001705A JP 2003074741 A JP2003074741 A JP 2003074741A JP 2003074741 A JP2003074741 A JP 2003074741A JP 2004001705 A JP2004001705 A JP 2004001705A

- Authority

- JP

- Japan

- Prior art keywords

- wheel

- weight

- base

- moving

- center

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Landscapes

- Handcart (AREA)

- Automobile Manufacture Line, Endless Track Vehicle, Trailer (AREA)

Abstract

Description

【0001】

【発明の属する技術分野】

本発明は、安定して段差等を乗り越えることのできる自走式の移動台車に関するものである。

【0002】

【従来の技術】

階段等の段差を乗り越えることのできる自走式の移動台車(90)に、図33に示すように、台車の重心位置を錘部(91)の移動によって調整する手段(92)を具えたものがある。重心移動手段(92)により、台車(90)は、車輪径の1/2よりも高い段差を乗り越えることができ、また、段差乗り越え時の台車の転倒を防止することができる(例えば、特許文献1、特許文献2参照)。

【0003】

【特許文献1】

特開2000−102569号公報(全文)

【特許文献2】

特開2001−37816号公報(全文)

【0004】

【発明が解決しようとする課題】

より高い段差を乗り越えるには、乗り上げようとする車輪とは逆側、つまり、乗り上げようとする車輪が前輪のときは後輪側、乗り上げようとする車輪が後輪のときは前輪側に台車の重心を移動させる必要がある。

具体的には、図33に示すように、前輪(93)が段差(80)に乗り上げた状態で、後輪(94)を次に乗り上げるには、前輪側に重心を移動させなければならない。しかしながら、錘部(91)を前方に移動させても、台車(90)が段差(80)に乗り上げて全体として後ろに傾く。その結果、図33に示すように、前輪中心と後輪中心の夫々真下への投影位置を結ぶ仮想線に対し、台車全体の重心の真下への投影位置は、前記仮想線の後方にきてしまい、後輪(94)に重量がかかって、後輪(94)の乗り上げができない。

【0005】

また、重心の移動を効果的に行なうには、台車(90)の重量に占める錘部(91)の重量割合を大きくする必要があるが、台車(90)の重量増を伴う問題があった。

【0006】

本発明の目的は、重心移動手段の錘部に、車輪回転手段、電源手段、制御手段の重量を利用して、錘部の重量増を図ると共に、台車全体の重量増を抑えることにより、重心移動を効率的に行なえる移動台車を提供することである。

【0007】

【課題を解決するための手段】

上記課題を解決するために、本発明の移動台車は、

基台と、

該基台の下部に配備された前輪及び後輪と、

前輪及び後輪に連繋され、各車輪を回転駆動する車輪回転手段と、

該車輪回転手段の電源手段と、

基台の上部に配備された錘部と、該錘部を基台に対して移動させる移動機構部とを有し、移動機構部により錘部を移動させて基台の重心位置を変える重心移動手段と、

車輪回転手段及び移動機構部を制御する制御手段と、

を具えた移動台車において、

車輪回転手段、電源手段及び制御手段の内の少なくとも1つの手段を、重心移動手段の錘部として利用した。

【0008】

【作用及び効果】

台車に搭載される車輪回転手段、電源手段、制御手段の内の少なくとも1つの手段を重心移動手段の錘部に配置し、錘部の重量として利用することにより、台車の重量増を抑えつつ、錘部の重量化が図れる。

これにより、錘部の移動による台車の重心移動を効率的に行なうことができる。

【0009】

【発明の実施の形態】

<実施例1>

図1は、本発明の移動台車(10)の側面図である。

図示の通り、本発明の移動台車(10)は、基台(12)の下側に台車(10)を走行させる前輪(20)及び後輪(22)を具え、基台(12)の上面には、台車(10)の重心位置を調整する重心移動手段(30)と、搭載物(62)を載せるテーブル(60)を具える。

【0010】

車輪(20)(22)は、基台(12)の下部に配置される。なお、図示の実施例では、車輪数は4輪であるが、4輪に限定されるものではない。

各車輪(20)(22)の回転軸は、複数のギア(25)及びベルト(26)を介して後述する車輪回転手段(24)に連繋される。ベルト(26)は伸縮可能なものを用いることが望ましい。

【0011】

基台(12)の上面には、重心移動手段(30)を具える。重心移動手段(30)は、錘部(32)と、該錘部(32)を基台(12)に対して移動させる移動機構部(40)から構成される。

移動機構部(40)は、基台(12)に対して錘部(32)を水平面内で回転可能に支持する回転機構部(42)と、該回転機構部(42)に対して錘部(32)を水平方向に往復移動させる並進機構部(44)とを具える。

回転機構部(42)は、基台(12)に対して水平面内で回転可能な機構を具え、錘部(32)に配備されたモータ(27)と、ベルト(図示せず)を介して連繋される。

並進機構部(44)は、一端が回転機構部(42)に連繋され、他端が錘部(32)に連繋された一対の平行リンク(45)(45)から構成できる。平行リンク(45)(45)の上端には、ギア(図示せず)が刻設され、錘部(32)に配備されたモータ(27)に減速機構等を介して連繋される。

【0012】

錘部(32)は、前述の並進機構部(44)の平行リンク(45)(45)に支持されており、上部にテーブル(60)を支持している。テーブル(60)は、ギア(25)及びベルト(26)を介して錘部(32)に対して揺動可能に支持される。

錘部(32)には、上記車輪(20)(22)の車輪回転手段(24)(24)と、回転機構部(42)と並進機構部(44)の動力源となるモータ(27)(27)と、テーブル(60)を揺動させるモータ(27)とが含まれる。その他にも、移動台車(10)の制御手段や、バッテリー等の電源手段等が台車(10)に搭載される場合には、それらを錘部(32)に含めることができる。

【0013】

テーブル(60)は、上述のとおり、錘部(32)に揺動可能に支持され、上面に荷物、カメラ等の搭載物(62)を搭載することができ、テーブル(60)及び搭載物(62)の重量も錘部(32)として利用される。

【0014】

上記構成の移動台車(10)について、並進機構部(44)を作動させると、図2及び図3に示すように、錘部(32)は基台(12)に対して前方又は後方に移動し、基台(12)の重心が前後に移動する。

また、錘部(32)を前方又は後方に移動させた状態で、回転機構部(42)を作動させると、図4に示すように、錘部(32)を基台(12)に対して左右に移動させることができ、基台(12)の重心が左右に移動する。

【0015】

段差(80)を乗り越える場合には、図5の状態から並進機構部(44)を作動させて、図6に示すように、錘部(32)を基台(12)の後方に移動させる。これにより、台車(10)の重量は、基台(12)の段差(80)に近い前輪(20)に殆んど加わらなくなり、後輪(22)の推力と、前輪(20)の段差(80)との摩擦力により、図7に示すように、前輪(20)が段差(80)を乗り上げる。

前輪(20)が段差(80)に乗り上げた後、並進機構部(44)を作動させて、図8に示すように、錘部(32)を基台(12)の前方に移動させる。これにより、後輪(22)には台車(10)の重量が殆んど加わらなくなるため、前輪(20)の推力と、後輪(22)の段差(80)との摩擦力により、後輪(22)が段差を乗り上げる。

台車(10)が段差(80)を乗り越えた後は、図9に示すように、基台(12)のほぼ中央に重心がくるように、錘部(32)を移動させる。

【0016】

傾斜した路面を走行する場合には、台車(10)の転倒を防止するために、路面の傾斜角度及び傾斜の向きに応じて、錘部(32)を移動させる。具体的には、斜面の上側(山側)にある車輪側に重心を移動させる。

例えば、図10に示すように、台車(10)の進行方向に対して、左右に傾斜した斜面を走行する場合には、山側(図中向かって左側)に錘部(32)を移動させる。錘部(32)を左右に移動させるには、上述の通り、並進機構部(44)と回転機構部(42)を作動させればよい。なお、重心の移動量については傾斜に合わせて適宜決定すればよい。

【0017】

<実施例2>

錘部(32)の移動機構部(40)の異なる実施例を示す。なお、その他の部分は、実施例1と同様である。

移動機構部(40)は、図11及び図12に示すように、錘部(32)と基台(12)とを接続する一対の杆体(49)(49)を具える。杆体(49)(49)は、錘部(32)に対して左右方向にスライド可能となるようにスライド機構(47)を介して連繋され、杆体(49)の下端は基台(12)にギア(図示せず)及びベルト(図示せず)を介して揺動可能な揺動機構(48)を介して連繋される。揺動機構(48)のベルトは、錘部(32)に配備されたモータ(図示せず)によって駆動する。

【0018】

スライド機構(47)を作動させると、図12に示すように、錘部(32)は基台(12)に対して左右にスライドし、基台(12)の重心位置を左右に移動させることができる。また、揺動機構(48)を作動させると、図13に示すように、錘部(32)が前後に並進し、基台(12)の重心を移動させることができる。なお、このとき、テーブル(60)は水平に維持するように制御することが望ましい。

【0019】

<実施例3>

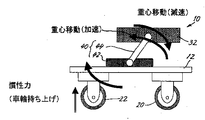

本実施例は、錘部(32)を移動させる際に生ずる慣性力を利用して、段差(80)を乗り越えるようにしたものである。

実施例1と共通する構成については説明を省略する。

【0020】

移動台車(10)は、図14に示すように基台(12)の下面には4つの車輪(20)(22)を具え、基台上面には、錘部(32)の移動機構部(40)が配備されている。移動機構部(40)は、回転機構部(42)と並進機構部(44)によって構成している。回転機構部(42)は、実施例1と同様であり、並進機構部(44)は、実施例1の平行リンク(45)(45)に代えて、端部を夫々錘部(32)と回転機構部(42)にベルト(図示せず)及びギア(図示せず)を介して揺動可能に支持した杆体(49)から構成している。

各車輪(20)(22)及び各機構は、錘部(32)に配備されたモータ(図示せず)に夫々ベルトやギア等を介して接続されて、駆動可能となっている。

【0021】

上記構成の移動台車(10)において、段差(80)を乗り越える場合には、図14の状態から並進機構部(44)を作動させて、図15に示すように、錘部(32)を基台(12)の前方に加速させつつ移動又は回転させる。錘部(32)を加速しつつ前方に移動又は回転させると、基台(12)の重心位置の動的な変化によって発生する慣性力は、基台(12)に錘部(32)の移動方向とは逆向きのトルクとして作用し、その結果、前輪(20)の負荷重量が軽減され、前輪(20)が持ち上げ可能となる。

なお、錘部(32)を減速させつつ後方に移動又は回転させても、前輪(20)が持ち上がる方向に慣性力が作用する。

逆に、錘部(32)を減速させつつ前方に移動又は回転させたり、錘部(32)を加速させつつ後方に移動又は回転させることにより、図16に示すように、後輪(22)が持ち上がる方向に慣性力が作用する。

上述のように、錘部(32)を加減速させつつ回転又は移動させることにより、車輪(20)(22)の持ち上げが可能となる。

【0022】

実施例3の移動台車(10)を用いた段差(80)の乗り越え工程について説明する。図17の状態で台車(10)を走行させ、前輪(20)が段差(80)に近づくと、並進機構部(44)を作動させて、図18に示すように、錘部(32)を前方に加速させつつ移動又は回転させる。これにより、前輪(20)にかかる重量が小さくなり、後輪(22)の推力と、前輪(20)の段差(80)との摩擦力により、図19に示すように、前輪(20)が段差(80)に乗り上げる。

前輪(20)が段差(80)に乗り上げると、上記とは逆に、図20に示すように、錘部(32)を後方に加速させつつ移動又は回転させる。これにより、後輪(22)にかかる重量が小さくなり、前輪(20)の推力と、後輪(22)の段差(80)との摩擦力により、後輪(22)が段差(80)が段差に乗り上げ、図21に示すように、台車(10)が段差(80)を乗り越える。

【0023】

<実施例4>

台車(10)が斜面を走行する際に、台車(10)の重心位置を移動させることは上述のように効果的であるが、重心位置が台車(10)の4つの車輪(20)(22)を順に結んだ仮想線よりも外側にくると、台車(10)が転倒することがある。特に、テーブルに載置した搭載物の重量バランスが偏っている場合には、転倒が起こりやすい。このため、重心位置の制御を行なう必要がある。

そこで、本実施例では、各車輪(20)(22)に荷重を検出可能な荷重センサ(14)を配備し、各荷重センサ(14)の値をフィードバックすることによって、台車(10)全体の重心位置を制御する。

なお、錘部の移動機構部については、本発明に示す各実施例を適用することができるし、その他の移動機構を用いてもよい。

【0024】

具体的には、図22に示すように、各車輪(20)(22)に荷重センサ(14)を配備し、各荷重センサ(14)の出力値を検出する。得られた荷重センサ(14)の出力値を、以下の式に代入することによって、重心位置の車輪接地平面への投影位置が車輪間距離の割合で検出される。

なお、図22では、台車(10)の4つの車輪(20)(22)の配列の中心(基台(12)の中心)を座標中心とし、前後方向にY軸、左右方向にX軸を採り、重心位置をPzm=(pzm x,pzm y)とする。また、各荷重センサ(14)の出力値は、右側前輪をFfr、左側前輪をFfl、右側後輪をFrr、左側後輪をFrlとし、検出範囲は、左右(X軸方向)に±0.5、前後(Y軸方向)に±0.5とする。

【0025】

【数1】

【0026】

上記数式に夫々各車輪(20)(22)の荷重センサ(14)の出力値を代入することにより、簡単に台車(10)の重心位置Pzmを知ることができ、基台全体つまり台車(10)の重心位置の制御に用いることができる。

【0027】

<実施例5>

本実施例は、基台(12)に対して、車輪(20)(22)を移動可能に配備することによって、車輪(20)(22)に対する重心位置を変えるようにしたものである。

車輪(20)(22)は、図23(a)に示すように、基台(12)に対して前後に独立してスライド可能に配備されており、錘部(32)は、基台(12)のほぼ中央に固定されている。

図23(b)及び図23(c)に示すように、後輪(22)を前方へ移動させたり、前輪(20)を後方へ移動させることにより、車輪(20)(22)に対する重心位置を変えることができる。

【0028】

実施例5の移動台車(10)を用いた段差(80)の乗り越え工程について説明する。前輪(20)が段差(80)に近づくと、図24(a)に示すように、後輪(22)を前方に移動して、後輪側に重心を移動させる。これにより、前輪(20)にかかる重量が小さくなり、後輪(22)の推力と、前輪(20)の段差(80)との摩擦力により、図24(b)に示すように、前輪(20)が持ち上がり、図24(c)に示すように、前輪(20)が段差(80)に乗り上げる。

前輪(20)が段差(80)に乗り上げると、上記とは逆に、図24(d)に示すように、前輪(20)及び後輪(22)を後方に移動させて、前輪側に重心を移動させる。これにより、後輪(22)にかかる重量が小さくなり、前輪(20)の推力と、後輪(22)の段差(80)との摩擦力により、図24(e)に示すように後輪(22)が持ち上がり、後輪(22)が段差(80)に乗り上げて、図24(f)に示すように、台車(10)が段差(80)を乗り越える。

【0029】

なお、図25(a)乃至図25(c)に示すように、車輪(20)(22)を、基台(12)に対して揺動可能に支持された車輪取付脚(28)(28)に配備してもよい。この場合、車輪取付脚(28)(28)を基台(12)に対して揺動させることによって、図25(b)及び図25(c)に示すように、車輪(20)(22)に対する重心位置を変えることができる。

【0030】

<実施例6>

以下、搭載物(62)を搭載するテーブル(60)の他の実施例について説明する。

図26は、本実施例の移動台車(10)を示している。なお、テーブル(60)以外については、実施例2の移動台車(10)と同様であるため説明を省略する。

テーブル(60)は、錘部(32)から上向きに突設された支持杆(70)と、該支持杆(70)の上端に取り付けられた凹球状の水平支持部(72)と、該水平支持部(72)の凹球状内面に沿って揺動可能な半球状の水平維持部材(74)とを具える。水平維持部材(74)は、上面が搭載物(62)を搭載する面となっており、水平支持部(72)に対して、ギア(図示せず)等の駆動によって揺動する。

【0031】

上記構成の移動台車(10)において、図27に示すように、錘部(32)を前方に移動させると、支持杆(70)及び水平支持部(72)は、錘部(32)と共に前方に傾く。このとき、水平維持部材(74)を前方に移動させると共に、水平維持部材(74)の上面が水平を維持するように揺動させる。その結果、搭載物(62)の転倒及び脱落が防止されると共に、搭載物(62)の重心も前方に移動するから、重心移動を大きく採ることができる。

【0032】

なお、図28に示すように、テーブル(60)は、支持杆(70)に対して水平支持部(72)を揺動させる構成としてもよいが、図27と図28を比較してわかるとおり、図27の方が、錘部(32)を傾斜させたときに、搭載物(62)の重心の移動量を大きく採ることができ、台車(10)の重心移動を促進させることができる。

【0033】

<実施例7>

次に、前輪(20)又は後輪(22)を持ち上げて、溝(82)や凹み、段差等の障害物を乗り越えることのできる移動台車(10)について説明する。

図29乃至図32は、本実施例の溝(82)の乗越え手順を時系列的に並べて示す説明図である。台車(10)は、図29(a)に示すように、基台(12)の上面に、錘部(32)を基台(12)に対して前後に傾動させる回転機構部(42)と、該回転機構部(42)に接続された杆体(49)の上端に配備され、錘部(32)を前後に平行移動させる移動機構部(40)を具える。

その他、実施例1又は実施例2と同様の構成については説明を省略する。

【0034】

以下、実施例7の台車(10)の溝乗越えについて、図面を参照しながら説明する。

台車(10)の重心(図29(a)中の重心位置マーク)が略中央にある状態から、台車(10)を前進させたときに、前方に溝(82)があることをセンサ等で認識すると、まず、図29(a)に示すように、前輪(20)が溝(82)の縁に到達するまで台車(10)を前進させる。

次に、図29(b)に示すように、移動機構部(40)を動作して、錘部(32)を後方に移動させ、台車(10)の重心を後輪(22)の上方まで移動させる。この状態で、図29(c)に示すように、回転機構部(42)を前輪(20)が持ち上がる方向(図29(c)中矢印Aで示す)に動作させると、重心が後輪(22)上にあるため、前輪(20)が持ち上がる(倒立制御)。

前輪(20)が持ち上がった状態(倒立状態)を維持したままで後輪(22)を駆動させ、台車(10)を前進させる(後輪倒立走行)。このとき、台車(10)の重心位置が多少ずれたとしても(図29(d)及び図30(a)の状態)、倒立制御を行なうことにより、倒立状態を維持したまま前進する。台車(10)が前進し、前輪(20)が溝(82)を越えたことを検知、後輪(22)が溝(82)の縁に到達したことを検知、又は、台車(10)が所定距離前進したことを検知すると、図30(b)に矢印A’で示すように、回転機構部(42)を上記とは逆に動作させて、前輪(20)を着地させる(図30(c)参照)。

前輪(20)が着地した後、図30(c)に示すように、移動機構部(40)を動作して、図30(d)に示すように、錘部(32)を後方から前方に移動させて、以下の後輪(22)の溝乗越え動作に移る。

【0035】

前輪(20)が着地した後に、図31(a)に示すように、錘部(32)を前方に移動させ、図31(b)に示すように、重心を後輪(22)の上方まで移動させる。この状態で、図31(c)に示すように、回転機構部(42)を後輪(22)が持ち上がる方向(図31(c)中矢印Bで示す)に動作させると、重心が前輪(20)の上にあるため、後輪(22)が持ち上がる(倒立制御)。

後輪(22)が持ち上がった状態(倒立状態)を維持したままで前輪(20)を駆動させ、台車(10)を前進させる(前輪倒立走行)。このとき、台車(10)の重心位置が多少ずれたとしても(図31(d)及び図32(a)の状態)、倒立制御を行なうことにより、倒立状態を維持したまま前進する。台車(10)が前進し、後輪(22)が溝(82)を越えたことを検知、又は、台車(10)が所定距離前進したことを検知すると、図32(b)に矢印B’で示すように、回転機構部(42)を上記とは逆に動作させて、後輪(22)を着地させる(図32(c)参照)。

後輪(22)が着地した後、図32(c)に示すように、移動機構部(40)を動作して、図32(d)に示すように、前方に移動していた錘部(32)を台車(10)の中央に戻す。

これにより、台車(10)は、溝(82)を乗り越えて、通常の走行状態に戻る。

【0036】

なお、上記要領により、同様に段差等の障害物を乗り越えることもできる。

また、上記倒立制御を行なって、前輪(20)又は後輪(22)を浮上させた状態で、接地している車輪(20)又は(22)を回転させると、倒立走行を行なうことができる。

【0037】

上記実施例の説明は、本発明を説明するためのものであって、特許請求の範囲に記載の発明を限定し、或は範囲を減縮する様に解すべきではない。又、本発明の各部構成は上記実施例に限らず、特許請求の範囲に記載の技術的範囲内で種々の変形が可能である。

【図面の簡単な説明】

【図1】本発明の実施例1の移動台車の側面図である。

【図2】錘部を前後に移動させた状態を示す実施例1の移動台車の側面図である。

【図3】図2の平面図である。

【図4】錘部を左右に移動させた状態を示す実施例1の移動台車の平面図である。

【図5】実施例1の移動台車の段差乗り越え工程を示す側面図である。

【図6】実施例1の移動台車の段差乗り越え工程を示す側面図である。

【図7】実施例1の移動台車の段差乗り越え工程を示す側面図である。

【図8】実施例1の移動台車の段差乗り越え工程を示す側面図である。

【図9】実施例1の移動台車の段差乗り越え工程を示す側面図である。

【図10】実施例1の移動台車の斜面走行状態を示す正面図である。

【図11】本発明の実施例2の移動台車の側面図である。

【図12】図11の線XII−XIIに沿う断面図である。

【図13】錘部を前後に移動させた状態を示す実施例2の移動台車の側面図である。

【図14】本発明の実施例3の移動台車の側面図である。

【図15】錘部を加速前方回転させた状態を示す実施例3の移動台車の側面図である。

【図16】錘部を加速後方回転又は減速前方回転させた状態を示す実施例3の移動台車の側面図である。

【図17】実施例3の移動台車の段差乗り越え工程を示す側面図である。

【図18】実施例3の移動台車の段差乗り越え工程を示す側面図である。

【図19】実施例3の移動台車の段差乗り越え工程を示す側面図である。

【図20】実施例3の移動台車の段差乗り越え工程を示す側面図である。

【図21】実施例3の移動台車の段差乗り越え工程を示す側面図である。

【図22】実施例4の重心位置測定に用いられる仮想座標を示す説明図である。

【図23】本発明の実施例5の移動台車の側面図である。

【図24】実施例5の移動台車の段差乗り越え工程を示す側面図である。

【図25】実施例5の異なる実施例を示す移動台車の側面図である。

【図26】本発明の実施例6の移動台車を示す側面図である。

【図27】錘部を前後に移動させた状態を示す実施例6の移動台車の側面図である。

【図28】実施例6の異なる実施例を示す移動台車の側面図である。

【図29】実施例7の移動台車の溝乗越え手順を示す説明図である。

【図30】実施例7の移動台車の溝乗越え手順を示す説明図である。

【図31】実施例7の移動台車の溝乗越え手順を示す説明図である。

【図32】実施例7の移動台車の溝乗越え手順を示す説明図である。

【図33】従来の移動台車の側面図である。

【符号の説明】

(10) 移動台車

(12) 基台

(20) 前輪

(22) 後輪

(30) 重心移動手段

(32) 錘部

(60) テーブル[0001]

TECHNICAL FIELD OF THE INVENTION

The present invention relates to a self-propelled mobile trolley that can stably climb over a step or the like.

[0002]

[Prior art]

As shown in FIG. 33, a self-propelled movable trolley (90) capable of overcoming steps such as stairs is provided with means (92) for adjusting the position of the center of gravity of the trolley by moving the weight (91). There is. By the center of gravity moving means (92), the bogie (90) can get over a step higher than 1/2 of the wheel diameter, and can prevent the bogie from tipping over the step. 1, see Patent Document 2).

[0003]

[Patent Document 1]

JP-A-2000-102569 (full text)

[Patent Document 2]

JP 2001-37816 A (full text)

[0004]

[Problems to be solved by the invention]

To get over a higher step, the bogie must be on the opposite side of the wheel to be climbed, that is, on the rear wheel side when the wheel to be climbed is the front wheel, and on the front wheel side when the wheel to be climbed is the rear wheel. It is necessary to move the center of gravity.

Specifically, as shown in FIG. 33, when the front wheel (93) rides on the step (80) and the rear wheel (94) rides next, the center of gravity must be moved to the front wheel side. However, even when the weight (91) is moved forward, the bogie (90) rides on the step (80) and leans backward as a whole. As a result, as shown in FIG. 33, the projected position directly below the center of gravity of the entire bogie is behind the virtual line connecting the projected positions directly below the front wheel center and the rear wheel center respectively. As a result, the rear wheel (94) is heavy and cannot ride on the rear wheel (94).

[0005]

Further, in order to move the center of gravity effectively, it is necessary to increase the weight ratio of the weight portion (91) to the weight of the bogie (90), but there is a problem that the weight of the bogie (90) increases. .

[0006]

An object of the present invention is to increase the weight of the weight portion by using the weights of the wheel rotating means, the power supply means, and the control means in the weight portion of the center of gravity moving means, and to suppress the increase in the weight of the entire bogie. An object of the present invention is to provide a mobile trolley capable of efficiently moving.

[0007]

[Means for Solving the Problems]

In order to solve the above-mentioned problems, the movable trolley of the present invention is

A base,

A front wheel and a rear wheel arranged under the base,

Wheel rotating means connected to the front wheels and the rear wheels, for rotating and driving each wheel,

Power supply means for the wheel rotating means;

A weight portion disposed on an upper portion of the base, and a moving mechanism portion for moving the weight portion with respect to the base, and moving the weight portion by the moving mechanism portion to change the position of the center of gravity of the base. Means,

Control means for controlling the wheel rotating means and the moving mechanism,

In the mobile trolley equipped with

At least one of the wheel rotating means, the power supply means and the control means was used as the weight of the center of gravity moving means.

[0008]

[Action and effect]

By arranging at least one of the wheel rotating means, the power supply means, and the control means mounted on the trolley on the weight of the center of gravity moving means and using the weight as the weight of the trolley, while suppressing the weight increase of the trolley, The weight of the weight can be increased.

Thereby, the movement of the center of gravity of the bogie due to the movement of the weight portion can be performed efficiently.

[0009]

BEST MODE FOR CARRYING OUT THE INVENTION

<Example 1>

FIG. 1 is a side view of a movable trolley (10) of the present invention.

As shown in the drawing, the mobile trolley (10) of the present invention includes a front wheel (20) and a rear wheel (22) for running the trolley (10) under the base (12), and the upper surface of the base (12). Includes a center-of-gravity moving means (30) for adjusting the position of the center of gravity of the cart (10), and a table (60) on which the load (62) is placed.

[0010]

The wheels (20) and (22) are arranged below the base (12). Although the number of wheels is four in the illustrated embodiment, the number of wheels is not limited to four.

The rotating shaft of each wheel (20) (22) is connected to a wheel rotating means (24) described later via a plurality of gears (25) and a belt (26). It is desirable to use a belt that can be extended and contracted.

[0011]

A center of gravity moving means (30) is provided on the upper surface of the base (12). The center of gravity moving means (30) includes a weight (32) and a moving mechanism (40) for moving the weight (32) with respect to the base (12).

The moving mechanism section (40) includes a rotating mechanism section (42) that supports the weight section (32) rotatably in a horizontal plane with respect to the base (12), and a weight section section with respect to the rotating mechanism section (42). A translation mechanism (44) for reciprocating the (32) horizontally.

The rotation mechanism (42) includes a mechanism rotatable in a horizontal plane with respect to the base (12), and via a motor (27) provided on the weight (32) and a belt (not shown). Connected.

The translation mechanism (44) can be composed of a pair of parallel links (45) (45), one end of which is connected to the rotation mechanism (42) and the other end of which is connected to the weight (32). A gear (not shown) is engraved on the upper end of the parallel link (45) (45), and is connected to a motor (27) provided on the weight (32) via a speed reduction mechanism or the like.

[0012]

The weight (32) is supported by the parallel links (45) and (45) of the translation mechanism (44), and supports the table (60) at the upper part. The table (60) is swingably supported by the weight (32) via the gear (25) and the belt (26).

The weight (32) includes a wheel rotating means (24) (24) for the wheels (20) and (22), and a motor (27) serving as a power source for the rotating mechanism (42) and the translation mechanism (44). (27) and a motor (27) for swinging the table (60). In addition, when the control means of the movable trolley (10) and the power supply means such as a battery are mounted on the trolley (10), they can be included in the weight portion (32).

[0013]

As described above, the table (60) is swingably supported by the weight portion (32), and can carry a load (62) such as luggage and a camera on the upper surface. The weight of 62) is also used as the weight (32).

[0014]

When the translation mechanism (44) of the movable carriage (10) having the above configuration is operated, the weight (32) moves forward or backward with respect to the base (12) as shown in FIGS. Then, the center of gravity of the base (12) moves back and forth.

When the rotating mechanism (42) is operated with the weight (32) moved forward or backward, the weight (32) is moved relative to the base (12) as shown in FIG. The center of gravity of the base (12) moves left and right.

[0015]

When the vehicle climbs over the step (80), the translation mechanism (44) is operated from the state shown in FIG. 5 to move the weight (32) to the rear of the base (12) as shown in FIG. As a result, the weight of the bogie (10) hardly applies to the front wheel (20) near the step (80) of the base (12), and the thrust of the rear wheel (22) and the step ( The front wheel (20) rides on the step (80) due to the frictional force with the front wheel (80), as shown in FIG.

After the front wheel (20) rides on the step (80), the translation mechanism (44) is operated to move the weight (32) forward of the base (12) as shown in FIG. As a result, the weight of the bogie (10) is hardly added to the rear wheel (22), and the thrust of the front wheel (20) and the frictional force between the step (80) of the rear wheel (22) cause the rear wheel. (22) runs over the step.

After the carriage (10) has passed over the step (80), as shown in FIG. 9, the weight (32) is moved so that the center of gravity is substantially at the center of the base (12).

[0016]

When traveling on an inclined road surface, the weight (32) is moved according to the inclination angle and the inclination direction of the road surface in order to prevent the cart (10) from falling over. Specifically, the center of gravity is moved to the wheel side above the slope (mountain side).

For example, as shown in FIG. 10, when traveling on a slope inclined left and right with respect to the traveling direction of the bogie (10), the weight portion (32) is moved to the mountain side (the left side in the figure). To move the weight (32) to the left or right, the translation mechanism (44) and the rotation mechanism (42) may be operated as described above. The amount of movement of the center of gravity may be appropriately determined according to the inclination.

[0017]

<Example 2>

The different Example of the moving mechanism part (40) of a weight part (32) is shown. The other parts are the same as in the first embodiment.

As shown in FIGS. 11 and 12, the moving mechanism (40) includes a pair of rods (49) (49) connecting the weight (32) and the base (12). The rods (49) and (49) are linked via a slide mechanism (47) so as to be slidable in the left-right direction with respect to the weight (32), and the lower end of the rod (49) is connected to the base (12). It is linked via a swing mechanism (48) that can swing via a gear (not shown) and a belt (not shown). The belt of the swing mechanism (48) is driven by a motor (not shown) provided in the weight portion (32).

[0018]

When the slide mechanism (47) is operated, as shown in FIG. 12, the weight portion (32) slides left and right with respect to the base (12) to move the center of gravity of the base (12) left and right. Can be. When the swing mechanism (48) is operated, as shown in FIG. 13, the weight (32) translates back and forth, and can move the center of gravity of the base (12). At this time, it is desirable to control the table (60) to be kept horizontal.

[0019]

<Example 3>

In the present embodiment, the step (80) is overcome using the inertial force generated when the weight (32) is moved.

The description of the configuration common to the first embodiment is omitted.

[0020]

The moving trolley (10) is provided with four wheels (20) and (22) on the lower surface of the base (12) as shown in FIG. 14, and on the upper surface of the base, a moving mechanism portion (32) of the weight (32) is provided. 40) is deployed. The moving mechanism (40) includes a rotation mechanism (42) and a translation mechanism (44). The rotation mechanism (42) is the same as that of the first embodiment, and the translation mechanism (44) has ends each of which has a weight (32) instead of the parallel links (45) and (45) of the first embodiment. It is constituted by a rod (49) swingably supported by a rotation mechanism (42) via a belt (not shown) and a gear (not shown).

Each wheel (20) (22) and each mechanism are connected to a motor (not shown) provided on the weight portion (32) via a belt, a gear, or the like, and can be driven.

[0021]

In the mobile trolley (10) having the above configuration, when the vehicle goes over the step (80), the translation mechanism (44) is operated from the state shown in FIG. It is moved or rotated while being accelerated in front of the table (12). When the weight (32) is moved forward or rotated while accelerating, the inertial force generated by the dynamic change of the position of the center of gravity of the base (12) causes the movement of the weight (32) on the base (12). Acts as a torque in a direction opposite to the direction, so that the load weight of the front wheel (20) is reduced, and the front wheel (20) can be lifted.

Even if the weight portion (32) is moved backward or rotated while being decelerated, inertial force acts in the direction in which the front wheel (20) is lifted.

Conversely, by moving forward or rotating the weight portion (32) while decelerating it, or moving or rotating the weight portion (32) backward while accelerating the weight portion (32), as shown in FIG. The inertial force acts in the direction in which is lifted.

As described above, the wheels (20) and (22) can be lifted by rotating or moving the weight portion (32) while accelerating and decelerating.

[0022]

The step of climbing over the step (80) using the moving vehicle (10) of the third embodiment will be described. When the trolley (10) runs in the state of FIG. 17 and the front wheel (20) approaches the step (80), the translation mechanism (44) is operated to move the weight (32) as shown in FIG. Move or rotate while accelerating forward. As a result, the weight applied to the front wheel (20) is reduced, and the thrust of the rear wheel (22) and the frictional force between the step (80) of the front wheel (20) cause the front wheel (20) to move as shown in FIG. Get on the step (80).

When the front wheel (20) rides on the step (80), the weight (32) is moved or rotated while accelerating backward as shown in FIG. As a result, the weight applied to the rear wheel (22) is reduced, and the rear wheel (22) has a step (80) due to the thrust of the front wheel (20) and the frictional force between the step (80) of the rear wheel (22). After climbing over the step, as shown in FIG. 21, the trolley (10) gets over the step (80).

[0023]

<Example 4>

It is effective to move the position of the center of gravity of the truck (10) when the truck (10) travels on a slope, as described above. However, the position of the center of gravity of the truck (10) is the four wheels (20) (22). ), The truck (10) may fall over when it comes outside the imaginary line connecting the) in order. In particular, if the weight balance of the load placed on the table is uneven, the fall is likely to occur. Therefore, it is necessary to control the position of the center of gravity.

Therefore, in the present embodiment, a load sensor (14) capable of detecting a load is provided on each wheel (20) (22), and the value of each load sensor (14) is fed back, so that the entire bogie (10) is fed back. Control the position of the center of gravity.

It should be noted that each embodiment shown in the present invention can be applied to the moving mechanism of the weight portion, and other moving mechanisms may be used.

[0024]

Specifically, as shown in FIG. 22, a load sensor (14) is provided on each wheel (20) (22), and the output value of each load sensor (14) is detected. By substituting the obtained output value of the load sensor (14) into the following equation, the projection position of the position of the center of gravity on the wheel ground plane is detected as the ratio of the distance between the wheels.

In FIG. 22, the center of the arrangement of the four wheels (20) and (22) of the truck (10) (the center of the base (12)) is the coordinate center, and the Y axis is in the front-rear direction and the X axis is in the left and right direction. And take the position of the center of gravity as Pzm = (pzm x, pzm y). The output value of each load sensor (14) is Ffr for the right front wheel, Ffl for the left front wheel, Frr for the right rear wheel, and Frl for the left rear wheel. The detection range is ± 0. 5, ± 0.5 before and after (Y-axis direction).

[0025]

(Equation 1)

[0026]

By substituting the output values of the load sensors (14) of the wheels (20) and (22) into the above equations, the center of gravity Pzm of the truck (10) can be easily known, and the entire base, that is, the truck (10) ) Can be used for controlling the position of the center of gravity.

[0027]

<Example 5>

In the present embodiment, the position of the center of gravity with respect to the wheels (20) and (22) is changed by disposing the wheels (20) and (22) movably with respect to the base (12).

As shown in FIG. 23A, the wheels (20) and (22) are provided so as to be independently slidable back and forth with respect to the base (12). 12) is fixed substantially at the center.

As shown in FIGS. 23 (b) and 23 (c), by moving the rear wheel (22) forward or moving the front wheel (20) backward, the center of gravity position with respect to the wheels (20) and (22) is obtained. Can be changed.

[0028]

A step of climbing over a step (80) using the movable cart (10) of the fifth embodiment will be described. When the front wheel (20) approaches the step (80), the rear wheel (22) is moved forward and the center of gravity is moved to the rear wheel side, as shown in FIG. As a result, the weight applied to the front wheel (20) decreases, and the thrust of the rear wheel (22) and the frictional force between the step (80) of the front wheel (20) as shown in FIG. The front wheel (20) rides on the step (80) as shown in FIG. 24 (c).

When the front wheel (20) rides on the step (80), the front wheel (20) and the rear wheel (22) are moved backward, as shown in FIG. To move. As a result, the weight applied to the rear wheel (22) is reduced, and the thrust of the front wheel (20) and the frictional force between the step (80) of the rear wheel (22) as shown in FIG. (22) is lifted, the rear wheel (22) rides on the step (80), and as shown in FIG. 24 (f), the trolley (10) gets over the step (80).

[0029]

As shown in FIGS. 25 (a) to 25 (c), the wheels (20) and (22) are supported by the wheel mounting legs (28) and (28) which are swingably supported with respect to the base (12). ) May be deployed. In this case, by swinging the wheel mounting legs (28) and (28) with respect to the base (12), the wheels (20) and (22) as shown in FIGS. 25 (b) and 25 (c). Can be changed.

[0030]

<Example 6>

Hereinafter, another embodiment of the table (60) on which the load (62) is mounted will be described.

FIG. 26 shows the mobile trolley (10) of the present embodiment. The components other than the table (60) are the same as those of the mobile trolley (10) according to the second embodiment, and a description thereof will be omitted.

The table (60) includes a support rod (70) projecting upward from the weight part (32), a concave spherical horizontal support part (72) attached to the upper end of the support rod (70), A hemispherical horizontal holding member (74) swingable along the concave spherical inner surface of the support portion (72). The horizontal maintaining member (74) has a top surface on which the load (62) is mounted, and swings with respect to the horizontal support portion (72) by driving a gear (not shown) or the like.

[0031]

When the weight (32) is moved forward as shown in FIG. 27 in the movable trolley (10) having the above configuration, the support rod (70) and the horizontal support (72) move forward together with the weight (32). Lean on. At this time, the horizontal maintenance member (74) is moved forward, and is swung so that the upper surface of the horizontal maintenance member (74) is maintained horizontal. As a result, the load (62) is prevented from falling over and falling off, and the center of gravity of the load (62) also moves forward, so that the movement of the center of gravity can be made large.

[0032]

As shown in FIG. 28, the table (60) may be configured to swing the horizontal support portion (72) with respect to the support rod (70), but as can be seen by comparing FIGS. 27 and 28. 27, when the weight portion (32) is inclined, the amount of movement of the center of gravity of the load (62) can be increased, and the movement of the center of gravity of the bogie (10) can be promoted.

[0033]

<Example 7>

Next, the mobile trolley (10) capable of lifting the front wheel (20) or the rear wheel (22) and overcoming obstacles such as grooves (82), dents, and steps will be described.

FIG. 29 to FIG. 32 are explanatory diagrams showing a procedure for climbing over the groove (82) of this embodiment in a time-series manner. The cart (10) includes, as shown in FIG. 29 (a), a rotating mechanism (42) for tilting the weight (32) back and forth with respect to the base (12) on the upper surface of the base (12). A moving mechanism (40) disposed at an upper end of a rod (49) connected to the rotating mechanism (42), for moving the weight (32) in parallel back and forth.

In addition, the description of the same configuration as the first embodiment or the second embodiment is omitted.

[0034]

Hereinafter, the movement of the bogie (10) of the seventh embodiment over the groove will be described with reference to the drawings.

When the bogie (10) is advanced from a state where the center of gravity of the bogie (10) (the center of gravity position mark in FIG. 29 (a)) is substantially at the center, the presence of the groove (82) ahead is detected by a sensor or the like. Upon recognition, first, the bogie (10) is advanced until the front wheel (20) reaches the edge of the groove (82), as shown in FIG.

Next, as shown in FIG. 29 (b), the moving mechanism (40) is operated to move the weight (32) rearward, and the center of gravity of the bogie (10) is raised above the rear wheel (22). Move. In this state, as shown in FIG. 29 (c), when the rotating mechanism (42) is operated in a direction in which the front wheel (20) is lifted (indicated by an arrow A in FIG. 29 (c)), the center of gravity is shifted to the rear wheel ( 22) Since it is above, the front wheel (20) is lifted (inverted control).

The rear wheel (22) is driven while the front wheel (20) is held up (inverted state), and the bogie (10) is advanced (rear wheel inverted traveling). At this time, even if the position of the center of gravity of the carriage (10) is slightly shifted (the state of FIGS. 29 (d) and 30 (a)), the carriage moves forward while maintaining the inverted state by performing the inverted control. The trolley (10) moves forward and detects that the front wheel (20) has crossed the groove (82), detects that the rear wheel (22) has reached the edge of the groove (82), or detects the trolley (10). When it is detected that the vehicle has moved forward by a predetermined distance, as shown by an arrow A ′ in FIG. 30 (b), the rotation mechanism (42) is operated in the opposite direction to the above to land the front wheel (20) (FIG. c)).

After the front wheel (20) lands, the moving mechanism (40) is operated as shown in FIG. 30 (c), and the weight (32) is moved from the rear to the front as shown in FIG. 30 (d). By moving the rear wheel (22), the operation proceeds to the following over-groove operation of the rear wheel (22).

[0035]

After the front wheel (20) lands, the weight (32) is moved forward as shown in FIG. 31 (a), and the center of gravity is raised to above the rear wheel (22) as shown in FIG. 31 (b). Move. In this state, as shown in FIG. 31 (c), when the rotating mechanism (42) is operated in a direction in which the rear wheel (22) is lifted (indicated by an arrow B in FIG. 31 (c)), the center of gravity of the front wheel ( 20), the rear wheel (22) is lifted (inverted control).

The front wheel (20) is driven while the rear wheel (22) is maintained in a raised state (inverted state), and the bogie (10) is advanced (front wheel inverted traveling). At this time, even if the position of the center of gravity of the bogie (10) is slightly shifted (the state shown in FIGS. 31 (d) and 32 (a)), the vehicle moves forward while maintaining the inverted state by performing the inverted control. When the bogie (10) moves forward and detects that the rear wheel (22) has passed the groove (82) or detects that the bogie (10) has moved forward by a predetermined distance, an arrow B 'in FIG. As shown by, the rotation mechanism (42) is operated in the reverse of the above to land the rear wheel (22) (see FIG. 32 (c)).

After the rear wheel (22) lands, the moving mechanism (40) is operated as shown in FIG. 32 (c), and as shown in FIG. 32 (d), the weight ( 32) is returned to the center of the cart (10).

Thereby, the carriage (10) gets over the groove (82) and returns to the normal running state.

[0036]

In addition, according to the above-mentioned point, it is also possible to get over obstacles such as steps.

In addition, by performing the above-described inverted control and rotating the grounded wheel (20) or (22) in a state where the front wheel (20) or the rear wheel (22) is levitated, the inverted traveling can be performed. .

[0037]

The description of the above embodiments is intended to explain the present invention, and should not be construed as limiting the invention described in the claims or reducing the scope thereof. Further, the configuration of each part of the present invention is not limited to the above embodiment, and various modifications can be made within the technical scope described in the claims.

[Brief description of the drawings]

FIG. 1 is a side view of a mobile trolley according to a first embodiment of the present invention.

FIG. 2 is a side view of the movable trolley according to the first embodiment, showing a state in which the weight is moved back and forth.

FIG. 3 is a plan view of FIG. 2;

FIG. 4 is a plan view of the movable trolley according to the first embodiment, showing a state in which the weight is moved right and left.

FIG. 5 is a side view showing a step over the step of the movable trolley according to the first embodiment.

FIG. 6 is a side view showing a step over the step of the movable trolley according to the first embodiment.

FIG. 7 is a side view showing a step over the step of the movable trolley according to the first embodiment.

FIG. 8 is a side view showing a step over the step of the movable trolley according to the first embodiment.

FIG. 9 is a side view showing a step over the step of the movable trolley according to the first embodiment.

FIG. 10 is a front view showing a traveling state of the mobile trolley according to the first embodiment on a slope.

FIG. 11 is a side view of the movable trolley according to the second embodiment of the present invention.

FIG. 12 is a sectional view taken along lines XII-XII in FIG. 11;

FIG. 13 is a side view of the movable trolley according to the second embodiment, showing a state in which the weight is moved back and forth.

FIG. 14 is a side view of the movable trolley according to the third embodiment of the present invention.

FIG. 15 is a side view of the movable trolley according to the third embodiment, showing a state where the weight portion is rotated forward with acceleration.

FIG. 16 is a side view of the movable trolley according to the third embodiment, showing a state where the weight portion is rotated backward in acceleration or forward in deceleration.

FIG. 17 is a side view illustrating a step over a step of the movable trolley according to the third embodiment.

FIG. 18 is a side view illustrating a step over a step of the movable trolley according to the third embodiment.

FIG. 19 is a side view illustrating a step over a step of the movable trolley according to the third embodiment.

FIG. 20 is a side view showing a step over a step of the movable trolley according to the third embodiment.

FIG. 21 is a side view showing a step of overcoming a step of a movable trolley according to the third embodiment.

FIG. 22 is an explanatory diagram showing virtual coordinates used for measuring the center of gravity of the fourth embodiment.

FIG. 23 is a side view of the movable trolley according to the fifth embodiment of the present invention.

FIG. 24 is a side view showing a step of stepping over a step of the movable trolley according to the fifth embodiment.

FIG. 25 is a side view of a mobile trolley showing a fifth embodiment different from the fifth embodiment.

FIG. 26 is a side view illustrating a movable trolley according to a sixth embodiment of the present invention.

FIG. 27 is a side view of the movable trolley according to the sixth embodiment, showing a state where the weight is moved back and forth.

FIG. 28 is a side view of a movable trolley showing a sixth embodiment different from the sixth embodiment.

FIG. 29 is an explanatory diagram showing a procedure for moving over the groove of the movable cart according to the seventh embodiment.

FIG. 30 is an explanatory view showing a procedure for moving over the groove of the movable trolley according to the seventh embodiment.

FIG. 31 is an explanatory diagram showing a procedure for moving over a groove of a movable trolley according to the seventh embodiment.

FIG. 32 is an explanatory diagram showing a procedure for moving over the groove of the movable trolley according to the seventh embodiment.

FIG. 33 is a side view of a conventional mobile trolley.

[Explanation of symbols]

(10) Moving trolley (12) Base (20) Front wheel (22) Rear wheel (30) Center of gravity moving means (32) Weight part (60) Table

Claims (14)

該基台の下部に配備された前輪及び後輪と、

前輪及び後輪に連繋され、各車輪を回転駆動する車輪回転手段と、

該車輪回転手段の電源手段と、

基台の上部に配備された錘部と、該錘部を基台に対して移動させる移動機構部とを有し、移動機構部により錘部を移動させて基台の重心位置を変える重心移動手段と、

車輪回転手段及び移動機構部を制御する制御手段と、

を具えた移動台車において、

車輪回転手段、電源手段及び制御手段の内の少なくとも1つの手段を、重心移動手段の錘部として利用していることを特徴とする移動台車。A base,

A front wheel and a rear wheel arranged under the base,

Wheel rotating means connected to the front wheels and the rear wheels, for rotating and driving each wheel,

Power supply means for the wheel rotating means;

A weight portion disposed on an upper portion of the base, and a moving mechanism portion for moving the weight portion with respect to the base, and moving the weight portion by the moving mechanism portion to change the position of the center of gravity of the base. Means,

Control means for controlling the wheel rotating means and the moving mechanism,

In the mobile trolley equipped with

A movable trolley, wherein at least one of the wheel rotating means, the power supply means and the control means is used as a weight of the center of gravity moving means.

該基台の下部に配備された前輪及び後輪と、

前輪及び後輪に連繋され、各車輪を回転駆動する車輪回転手段と、

基台の上部に配備された錘部と、該錘部を基台に対して移動させる移動機構部とを有し、錘部を移動させることにより基台の重心位置を移動させる重心移動手段と、

を具えた移動台車において、

車輪回転手段の重量を、重心移動手段の錘部に利用していることを特徴とする移動台車。A base,

A front wheel and a rear wheel arranged under the base,

Wheel rotating means connected to the front wheels and the rear wheels, for rotating and driving each wheel,

A weight portion disposed on an upper portion of the base, and a moving mechanism for moving the weight portion with respect to the base, and a center of gravity moving means for moving the position of the center of gravity of the base by moving the weight portion; ,

In the mobile trolley equipped with

A moving trolley, wherein the weight of the wheel rotating means is used for the weight of the center of gravity moving means.

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2003074741A JP2004001705A (en) | 2002-03-29 | 2003-03-19 | Movable carriage |

| US10/397,195 US7152882B2 (en) | 2002-03-28 | 2003-03-27 | Mobile carriage |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2002093457 | 2002-03-29 | ||

| JP2003074741A JP2004001705A (en) | 2002-03-29 | 2003-03-19 | Movable carriage |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| JP2004001705A true JP2004001705A (en) | 2004-01-08 |

Family

ID=30446299

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2003074741A Pending JP2004001705A (en) | 2002-03-28 | 2003-03-19 | Movable carriage |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2004001705A (en) |

Cited By (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2006341709A (en) * | 2005-06-08 | 2006-12-21 | Toin Gakuen | Stairlift |

| KR100702188B1 (en) * | 2006-04-18 | 2007-04-02 | 유제우 | Apparatus for shifting the center of gravity of a vehicle having three wheels or more |

| JP2013519588A (en) * | 2010-02-17 | 2013-05-30 | ズームアビリティー アーベー | Vehicle having a horizontal compensation system |

| WO2014002275A1 (en) * | 2012-06-29 | 2014-01-03 | 株式会社安川電機 | Moving body and moving body system |

| CN104129446A (en) * | 2014-05-21 | 2014-11-05 | 潍坊泰阳座椅系统有限公司 | Claw type stair climbing machine |

| CN106741298A (en) * | 2016-12-10 | 2017-05-31 | 徐州乐泰机电科技有限公司 | A kind of obstacle detouring dual drive moving trolley |

| JP2017537283A (en) * | 2014-07-09 | 2017-12-14 | ウ ベ,ソク | Equilibrium maintenance device for transport equipment and transport equipment equipped with the balance maintenance device |

| JPWO2016181627A1 (en) * | 2015-05-13 | 2018-03-01 | パナソニックIpマネジメント株式会社 | Transport device and rack mounted on the same |

| CN107757750A (en) * | 2017-10-26 | 2018-03-06 | 青岛大学 | Obstacle-detouring method and its implementation based on adjustment position of centre of gravity |

| CN107856759A (en) * | 2017-10-26 | 2018-03-30 | 青岛大学 | Telecontrol equipment and its application using changeable wheelbase as driving |

| JP2019182177A (en) * | 2018-04-09 | 2019-10-24 | Thk株式会社 | Transport cart |

| CN111301560A (en) * | 2020-03-26 | 2020-06-19 | 行星算力(深圳)科技有限公司 | Transport robot |

| CN111688835A (en) * | 2020-06-12 | 2020-09-22 | 行星算力(深圳)科技有限公司 | Carrying robot |

| JP2021062793A (en) * | 2019-10-16 | 2021-04-22 | トヨタ自動車株式会社 | Traveling body |

| WO2021153411A1 (en) * | 2020-01-27 | 2021-08-05 | 株式会社Preferred Networks | Moving trolley |

| WO2022138694A1 (en) * | 2020-12-24 | 2022-06-30 | 川崎重工業株式会社 | Robot |

| CN115520291A (en) * | 2021-06-25 | 2022-12-27 | 中国农业机械化科学研究院 | Crawler-type transportation robot and gravity center control method thereof |

| JP7577534B2 (en) | 2020-12-24 | 2024-11-05 | 川崎重工業株式会社 | robot |

-

2003

- 2003-03-19 JP JP2003074741A patent/JP2004001705A/en active Pending

Cited By (22)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4734038B2 (en) * | 2005-06-08 | 2011-07-27 | 学校法人千葉工業大学 | Stair lifting device |

| JP2006341709A (en) * | 2005-06-08 | 2006-12-21 | Toin Gakuen | Stairlift |

| KR100702188B1 (en) * | 2006-04-18 | 2007-04-02 | 유제우 | Apparatus for shifting the center of gravity of a vehicle having three wheels or more |

| JP2013519588A (en) * | 2010-02-17 | 2013-05-30 | ズームアビリティー アーベー | Vehicle having a horizontal compensation system |

| WO2014002275A1 (en) * | 2012-06-29 | 2014-01-03 | 株式会社安川電機 | Moving body and moving body system |

| CN104412191A (en) * | 2012-06-29 | 2015-03-11 | 株式会社安川电机 | Moving body and moving body system |

| JPWO2014002275A1 (en) * | 2012-06-29 | 2016-05-30 | 株式会社安川電機 | Mobile body and mobile system |

| CN104129446A (en) * | 2014-05-21 | 2014-11-05 | 潍坊泰阳座椅系统有限公司 | Claw type stair climbing machine |

| JP2017537283A (en) * | 2014-07-09 | 2017-12-14 | ウ ベ,ソク | Equilibrium maintenance device for transport equipment and transport equipment equipped with the balance maintenance device |

| JPWO2016181627A1 (en) * | 2015-05-13 | 2018-03-01 | パナソニックIpマネジメント株式会社 | Transport device and rack mounted on the same |

| CN106741298A (en) * | 2016-12-10 | 2017-05-31 | 徐州乐泰机电科技有限公司 | A kind of obstacle detouring dual drive moving trolley |

| CN107757750A (en) * | 2017-10-26 | 2018-03-06 | 青岛大学 | Obstacle-detouring method and its implementation based on adjustment position of centre of gravity |

| CN107856759A (en) * | 2017-10-26 | 2018-03-30 | 青岛大学 | Telecontrol equipment and its application using changeable wheelbase as driving |

| JP2019182177A (en) * | 2018-04-09 | 2019-10-24 | Thk株式会社 | Transport cart |

| JP2021062793A (en) * | 2019-10-16 | 2021-04-22 | トヨタ自動車株式会社 | Traveling body |

| WO2021153411A1 (en) * | 2020-01-27 | 2021-08-05 | 株式会社Preferred Networks | Moving trolley |

| CN111301560A (en) * | 2020-03-26 | 2020-06-19 | 行星算力(深圳)科技有限公司 | Transport robot |

| CN111688835A (en) * | 2020-06-12 | 2020-09-22 | 行星算力(深圳)科技有限公司 | Carrying robot |

| CN111688835B (en) * | 2020-06-12 | 2023-09-15 | 行星算力(深圳)科技有限公司 | Carrying robot |

| WO2022138694A1 (en) * | 2020-12-24 | 2022-06-30 | 川崎重工業株式会社 | Robot |

| JP7577534B2 (en) | 2020-12-24 | 2024-11-05 | 川崎重工業株式会社 | robot |

| CN115520291A (en) * | 2021-06-25 | 2022-12-27 | 中国农业机械化科学研究院 | Crawler-type transportation robot and gravity center control method thereof |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2004001705A (en) | Movable carriage | |

| JP4867823B2 (en) | Inverted wheel type moving body and control method thereof | |

| US7152882B2 (en) | Mobile carriage | |

| EP2356016B1 (en) | Apparatus and method for control of a dynamically self-balancing vehicle | |

| JP4735598B2 (en) | Inverted wheel type moving body and control method thereof | |

| KR100950953B1 (en) | Moving robot | |

| CN112334383B (en) | Moving body | |

| JP6400174B1 (en) | Traveling device | |

| JP2006256401A (en) | Three-wheel type riding movable carriage | |

| JP2008126936A (en) | Moving device | |

| KR20180086001A (en) | Moving flatform self-maintaining horizontal posture | |

| CN109677535A (en) | Method for transporting the stand-type vehicle of the electric drive of personnel and for running stand-type vehicle | |

| JP2008131821A (en) | Vehicle | |

| JP2004291799A (en) | Movable carriage | |

| JP2009101899A (en) | Inverted wheel type moving body and control method thereof | |

| JP5511523B2 (en) | Bipod type moving device | |

| JP2009035157A (en) | Inverted wheel type mobile body, and method of controlling the same | |

| JP2003285743A (en) | Mobile carriage | |

| JP4877120B2 (en) | vehicle | |

| JP2007237996A (en) | Inverted pendulum type moving body | |

| JP2012224250A (en) | Wheel type moving body | |

| KR20210053315A (en) | Low-billing prevention monowheel vehicle | |

| KR101272604B1 (en) | Riding robot and operating system comprising the same | |

| KR101613451B1 (en) | Apparatus and methods for control of a vehicle by gyroscope | |

| JP2000203419A (en) | Single-rail carrying device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20040903 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20060323 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20060411 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20060822 |