EP4139527B1 - Photographic paper - Google Patents

Photographic paper Download PDFInfo

- Publication number

- EP4139527B1 EP4139527B1 EP21715208.1A EP21715208A EP4139527B1 EP 4139527 B1 EP4139527 B1 EP 4139527B1 EP 21715208 A EP21715208 A EP 21715208A EP 4139527 B1 EP4139527 B1 EP 4139527B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- layer

- colloidal silica

- base layer

- photographic paper

- composition

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 claims description 56

- 239000000839 emulsion Substances 0.000 claims description 48

- 239000000203 mixture Substances 0.000 claims description 48

- 239000008119 colloidal silica Substances 0.000 claims description 44

- 239000000084 colloidal system Substances 0.000 claims description 41

- 239000011230 binding agent Substances 0.000 claims description 38

- 239000003795 chemical substances by application Substances 0.000 claims description 31

- 238000000034 method Methods 0.000 claims description 31

- 229920000642 polymer Polymers 0.000 claims description 17

- 230000003746 surface roughness Effects 0.000 claims description 17

- 239000002245 particle Substances 0.000 claims description 16

- 238000000576 coating method Methods 0.000 claims description 11

- 239000011248 coating agent Substances 0.000 claims description 10

- VQLYBLABXAHUDN-UHFFFAOYSA-N bis(4-fluorophenyl)-methyl-(1,2,4-triazol-1-ylmethyl)silane;methyl n-(1h-benzimidazol-2-yl)carbamate Chemical compound C1=CC=C2NC(NC(=O)OC)=NC2=C1.C=1C=C(F)C=CC=1[Si](C=1C=CC(F)=CC=1)(C)CN1C=NC=N1 VQLYBLABXAHUDN-UHFFFAOYSA-N 0.000 claims description 8

- 239000000758 substrate Substances 0.000 claims description 4

- 239000011888 foil Substances 0.000 claims description 3

- 239000002585 base Substances 0.000 description 60

- -1 silver halide Chemical class 0.000 description 45

- 108010010803 Gelatin Proteins 0.000 description 44

- 229920000159 gelatin Polymers 0.000 description 44

- 235000019322 gelatine Nutrition 0.000 description 44

- 235000011852 gelatine desserts Nutrition 0.000 description 44

- 239000008273 gelatin Substances 0.000 description 38

- 239000003381 stabilizer Substances 0.000 description 37

- 150000001875 compounds Chemical class 0.000 description 31

- 229910052709 silver Inorganic materials 0.000 description 24

- 239000004332 silver Substances 0.000 description 24

- 239000004094 surface-active agent Substances 0.000 description 15

- 238000012360 testing method Methods 0.000 description 15

- 150000003839 salts Chemical class 0.000 description 14

- 239000002253 acid Substances 0.000 description 13

- 239000002904 solvent Substances 0.000 description 12

- 230000000903 blocking effect Effects 0.000 description 11

- 239000000463 material Substances 0.000 description 10

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 10

- 230000000052 comparative effect Effects 0.000 description 9

- 238000002156 mixing Methods 0.000 description 9

- 239000006097 ultraviolet radiation absorber Substances 0.000 description 9

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 description 8

- 239000000243 solution Substances 0.000 description 7

- HEMHJVSKTPXQMS-UHFFFAOYSA-M Sodium hydroxide Chemical compound [OH-].[Na+] HEMHJVSKTPXQMS-UHFFFAOYSA-M 0.000 description 6

- 239000002250 absorbent Substances 0.000 description 6

- 230000002745 absorbent Effects 0.000 description 6

- 239000004333 gold (food color) Substances 0.000 description 6

- 239000000975 dye Substances 0.000 description 5

- 238000005259 measurement Methods 0.000 description 5

- 229920003229 poly(methyl methacrylate) Polymers 0.000 description 5

- 239000004926 polymethyl methacrylate Substances 0.000 description 5

- 230000008569 process Effects 0.000 description 5

- 238000012545 processing Methods 0.000 description 5

- 239000000126 substance Substances 0.000 description 5

- QGZKDVFQNNGYKY-UHFFFAOYSA-N Ammonia Chemical compound N QGZKDVFQNNGYKY-UHFFFAOYSA-N 0.000 description 4

- OKKJLVBELUTLKV-UHFFFAOYSA-N Methanol Chemical compound OC OKKJLVBELUTLKV-UHFFFAOYSA-N 0.000 description 4

- 206010070834 Sensitisation Diseases 0.000 description 4

- 239000007844 bleaching agent Substances 0.000 description 4

- 238000001125 extrusion Methods 0.000 description 4

- 150000002344 gold compounds Chemical class 0.000 description 4

- 239000007788 liquid Substances 0.000 description 4

- 238000004519 manufacturing process Methods 0.000 description 4

- IOLCXVTUBQKXJR-UHFFFAOYSA-M potassium bromide Chemical compound [K+].[Br-] IOLCXVTUBQKXJR-UHFFFAOYSA-M 0.000 description 4

- FGIUAXJPYTZDNR-UHFFFAOYSA-N potassium nitrate Chemical compound [K+].[O-][N+]([O-])=O FGIUAXJPYTZDNR-UHFFFAOYSA-N 0.000 description 4

- 238000002360 preparation method Methods 0.000 description 4

- 239000000047 product Substances 0.000 description 4

- 230000008313 sensitization Effects 0.000 description 4

- SQGYOTSLMSWVJD-UHFFFAOYSA-N silver(1+) nitrate Chemical compound [Ag+].[O-]N(=O)=O SQGYOTSLMSWVJD-UHFFFAOYSA-N 0.000 description 4

- QTBSBXVTEAMEQO-UHFFFAOYSA-N Acetic acid Chemical compound CC(O)=O QTBSBXVTEAMEQO-UHFFFAOYSA-N 0.000 description 3

- CSCPPACGZOOCGX-UHFFFAOYSA-N Acetone Chemical compound CC(C)=O CSCPPACGZOOCGX-UHFFFAOYSA-N 0.000 description 3

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 3

- XEKOWRVHYACXOJ-UHFFFAOYSA-N Ethyl acetate Chemical compound CCOC(C)=O XEKOWRVHYACXOJ-UHFFFAOYSA-N 0.000 description 3

- WSFSSNUMVMOOMR-UHFFFAOYSA-N Formaldehyde Chemical compound O=C WSFSSNUMVMOOMR-UHFFFAOYSA-N 0.000 description 3

- PEDCQBHIVMGVHV-UHFFFAOYSA-N Glycerine Chemical compound OCC(O)CO PEDCQBHIVMGVHV-UHFFFAOYSA-N 0.000 description 3

- WMFOQBRAJBCJND-UHFFFAOYSA-M Lithium hydroxide Chemical compound [Li+].[OH-] WMFOQBRAJBCJND-UHFFFAOYSA-M 0.000 description 3

- 101100221809 Neurospora crassa (strain ATCC 24698 / 74-OR23-1A / CBS 708.71 / DSM 1257 / FGSC 987) cpd-7 gene Proteins 0.000 description 3

- 239000004698 Polyethylene Substances 0.000 description 3

- 239000004372 Polyvinyl alcohol Substances 0.000 description 3

- KWYUFKZDYYNOTN-UHFFFAOYSA-M Potassium hydroxide Chemical compound [OH-].[K+] KWYUFKZDYYNOTN-UHFFFAOYSA-M 0.000 description 3

- JUJWROOIHBZHMG-UHFFFAOYSA-N Pyridine Chemical class C1=CC=NC=C1 JUJWROOIHBZHMG-UHFFFAOYSA-N 0.000 description 3

- XEIPQVVAVOUIOP-UHFFFAOYSA-N [Au]=S Chemical compound [Au]=S XEIPQVVAVOUIOP-UHFFFAOYSA-N 0.000 description 3

- 230000015572 biosynthetic process Effects 0.000 description 3

- 229920001577 copolymer Polymers 0.000 description 3

- 238000011161 development Methods 0.000 description 3

- 238000001035 drying Methods 0.000 description 3

- 150000002148 esters Chemical class 0.000 description 3

- 125000000524 functional group Chemical group 0.000 description 3

- BASFCYQUMIYNBI-UHFFFAOYSA-N platinum Chemical compound [Pt] BASFCYQUMIYNBI-UHFFFAOYSA-N 0.000 description 3

- 229920000573 polyethylene Polymers 0.000 description 3

- 229920002451 polyvinyl alcohol Polymers 0.000 description 3

- 239000011347 resin Substances 0.000 description 3

- 229920005989 resin Polymers 0.000 description 3

- 239000000377 silicon dioxide Substances 0.000 description 3

- 235000012239 silicon dioxide Nutrition 0.000 description 3

- 229920002554 vinyl polymer Polymers 0.000 description 3

- QGKMIGUHVLGJBR-UHFFFAOYSA-M (4z)-1-(3-methylbutyl)-4-[[1-(3-methylbutyl)quinolin-1-ium-4-yl]methylidene]quinoline;iodide Chemical compound [I-].C12=CC=CC=C2N(CCC(C)C)C=CC1=CC1=CC=[N+](CCC(C)C)C2=CC=CC=C12 QGKMIGUHVLGJBR-UHFFFAOYSA-M 0.000 description 2

- NPOMAIJXMCXWGP-UHFFFAOYSA-N (cyanatodisulfanyl) cyanate Chemical class N#COSSOC#N NPOMAIJXMCXWGP-UHFFFAOYSA-N 0.000 description 2

- GGZHVNZHFYCSEV-UHFFFAOYSA-N 1-Phenyl-5-mercaptotetrazole Chemical compound SC1=NN=NN1C1=CC=CC=C1 GGZHVNZHFYCSEV-UHFFFAOYSA-N 0.000 description 2

- IXPNQXFRVYWDDI-UHFFFAOYSA-N 1-methyl-2,4-dioxo-1,3-diazinane-5-carboximidamide Chemical compound CN1CC(C(N)=N)C(=O)NC1=O IXPNQXFRVYWDDI-UHFFFAOYSA-N 0.000 description 2

- HZAXFHJVJLSVMW-UHFFFAOYSA-N 2-Aminoethan-1-ol Chemical compound NCCO HZAXFHJVJLSVMW-UHFFFAOYSA-N 0.000 description 2

- 229920001817 Agar Polymers 0.000 description 2

- 102000009027 Albumins Human genes 0.000 description 2

- 108010088751 Albumins Proteins 0.000 description 2

- LSNNMFCWUKXFEE-UHFFFAOYSA-M Bisulfite Chemical compound OS([O-])=O LSNNMFCWUKXFEE-UHFFFAOYSA-M 0.000 description 2

- KAKZBPTYRLMSJV-UHFFFAOYSA-N Butadiene Chemical compound C=CC=C KAKZBPTYRLMSJV-UHFFFAOYSA-N 0.000 description 2

- 101100501963 Caenorhabditis elegans exc-4 gene Proteins 0.000 description 2

- VYZAMTAEIAYCRO-UHFFFAOYSA-N Chromium Chemical compound [Cr] VYZAMTAEIAYCRO-UHFFFAOYSA-N 0.000 description 2

- JPVYNHNXODAKFH-UHFFFAOYSA-N Cu2+ Chemical class [Cu+2] JPVYNHNXODAKFH-UHFFFAOYSA-N 0.000 description 2

- 239000004593 Epoxy Substances 0.000 description 2

- 241000206672 Gelidium Species 0.000 description 2

- VEXZGXHMUGYJMC-UHFFFAOYSA-N Hydrochloric acid Chemical compound Cl VEXZGXHMUGYJMC-UHFFFAOYSA-N 0.000 description 2

- MHAJPDPJQMAIIY-UHFFFAOYSA-N Hydrogen peroxide Chemical compound OO MHAJPDPJQMAIIY-UHFFFAOYSA-N 0.000 description 2

- 239000004354 Hydroxyethyl cellulose Substances 0.000 description 2

- WTDHULULXKLSOZ-UHFFFAOYSA-N Hydroxylamine hydrochloride Chemical compound Cl.ON WTDHULULXKLSOZ-UHFFFAOYSA-N 0.000 description 2

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 2

- OFOBLEOULBTSOW-UHFFFAOYSA-N Malonic acid Chemical compound OC(=O)CC(O)=O OFOBLEOULBTSOW-UHFFFAOYSA-N 0.000 description 2

- 229920000881 Modified starch Polymers 0.000 description 2

- LRHPLDYGYMQRHN-UHFFFAOYSA-N N-Butanol Chemical compound CCCCO LRHPLDYGYMQRHN-UHFFFAOYSA-N 0.000 description 2

- CBENFWSGALASAD-UHFFFAOYSA-N Ozone Chemical compound [O-][O+]=O CBENFWSGALASAD-UHFFFAOYSA-N 0.000 description 2

- KDLHZDBZIXYQEI-UHFFFAOYSA-N Palladium Chemical compound [Pd] KDLHZDBZIXYQEI-UHFFFAOYSA-N 0.000 description 2

- NBIIXXVUZAFLBC-UHFFFAOYSA-N Phosphoric acid Chemical compound OP(O)(O)=O NBIIXXVUZAFLBC-UHFFFAOYSA-N 0.000 description 2

- FAPWRFPIFSIZLT-UHFFFAOYSA-M Sodium chloride Chemical compound [Na+].[Cl-] FAPWRFPIFSIZLT-UHFFFAOYSA-M 0.000 description 2

- 229920002125 Sokalan® Polymers 0.000 description 2

- PPBRXRYQALVLMV-UHFFFAOYSA-N Styrene Chemical compound C=CC1=CC=CC=C1 PPBRXRYQALVLMV-UHFFFAOYSA-N 0.000 description 2

- LSNNMFCWUKXFEE-UHFFFAOYSA-N Sulfurous acid Chemical class OS(O)=O LSNNMFCWUKXFEE-UHFFFAOYSA-N 0.000 description 2

- 150000008065 acid anhydrides Chemical class 0.000 description 2

- 150000007513 acids Chemical class 0.000 description 2

- 235000010419 agar Nutrition 0.000 description 2

- 150000001412 amines Chemical class 0.000 description 2

- 125000003277 amino group Chemical group 0.000 description 2

- 229910021529 ammonia Inorganic materials 0.000 description 2

- 239000007864 aqueous solution Substances 0.000 description 2

- 230000008901 benefit Effects 0.000 description 2

- 125000003178 carboxy group Chemical group [H]OC(*)=O 0.000 description 2

- 229920003090 carboxymethyl hydroxyethyl cellulose Polymers 0.000 description 2

- 239000005018 casein Substances 0.000 description 2

- BECPQYXYKAMYBN-UHFFFAOYSA-N casein, tech. Chemical compound NCCCCC(C(O)=O)N=C(O)C(CC(O)=O)N=C(O)C(CCC(O)=N)N=C(O)C(CC(C)C)N=C(O)C(CCC(O)=O)N=C(O)C(CC(O)=O)N=C(O)C(CCC(O)=O)N=C(O)C(C(C)O)N=C(O)C(CCC(O)=N)N=C(O)C(CCC(O)=N)N=C(O)C(CCC(O)=N)N=C(O)C(CCC(O)=O)N=C(O)C(CCC(O)=O)N=C(O)C(COP(O)(O)=O)N=C(O)C(CCC(O)=N)N=C(O)C(N)CC1=CC=CC=C1 BECPQYXYKAMYBN-UHFFFAOYSA-N 0.000 description 2

- 235000021240 caseins Nutrition 0.000 description 2

- 239000001913 cellulose Substances 0.000 description 2

- 229920002678 cellulose Polymers 0.000 description 2

- 239000003638 chemical reducing agent Substances 0.000 description 2

- JAWGVVJVYSANRY-UHFFFAOYSA-N cobalt(3+) Chemical class [Co+3] JAWGVVJVYSANRY-UHFFFAOYSA-N 0.000 description 2

- 230000001143 conditioned effect Effects 0.000 description 2

- AFOSIXZFDONLBT-UHFFFAOYSA-N divinyl sulfone Chemical class C=CS(=O)(=O)C=C AFOSIXZFDONLBT-UHFFFAOYSA-N 0.000 description 2

- 238000007765 extrusion coating Methods 0.000 description 2

- 150000004676 glycans Chemical class 0.000 description 2

- PCHJSUWPFVWCPO-UHFFFAOYSA-N gold Chemical compound [Au] PCHJSUWPFVWCPO-UHFFFAOYSA-N 0.000 description 2

- 239000010931 gold Substances 0.000 description 2

- 229910052737 gold Inorganic materials 0.000 description 2

- VKYKSIONXSXAKP-UHFFFAOYSA-N hexamethylenetetramine Chemical compound C1N(C2)CN3CN1CN2C3 VKYKSIONXSXAKP-UHFFFAOYSA-N 0.000 description 2

- 150000003840 hydrochlorides Chemical class 0.000 description 2

- 125000002887 hydroxy group Chemical group [H]O* 0.000 description 2

- 235000019447 hydroxyethyl cellulose Nutrition 0.000 description 2

- 239000004615 ingredient Substances 0.000 description 2

- 239000003112 inhibitor Substances 0.000 description 2

- 230000002401 inhibitory effect Effects 0.000 description 2

- 229910052741 iridium Inorganic materials 0.000 description 2

- GKOZUEZYRPOHIO-UHFFFAOYSA-N iridium atom Chemical compound [Ir] GKOZUEZYRPOHIO-UHFFFAOYSA-N 0.000 description 2

- 239000012948 isocyanate Substances 0.000 description 2

- 150000002513 isocyanates Chemical class 0.000 description 2

- 238000003475 lamination Methods 0.000 description 2

- 229920000126 latex Polymers 0.000 description 2

- 239000003446 ligand Substances 0.000 description 2

- 229940057995 liquid paraffin Drugs 0.000 description 2

- 239000000314 lubricant Substances 0.000 description 2

- 239000006224 matting agent Substances 0.000 description 2

- 235000019426 modified starch Nutrition 0.000 description 2

- 239000003960 organic solvent Substances 0.000 description 2

- 239000000049 pigment Substances 0.000 description 2

- 229920000191 poly(N-vinyl pyrrolidone) Polymers 0.000 description 2

- 229920002401 polyacrylamide Polymers 0.000 description 2

- 239000004584 polyacrylic acid Substances 0.000 description 2

- 229920001282 polysaccharide Polymers 0.000 description 2

- 239000005017 polysaccharide Substances 0.000 description 2

- 239000004323 potassium nitrate Substances 0.000 description 2

- 235000010333 potassium nitrate Nutrition 0.000 description 2

- 238000005488 sandblasting Methods 0.000 description 2

- 230000035945 sensitivity Effects 0.000 description 2

- ADZWSOLPGZMUMY-UHFFFAOYSA-M silver bromide Chemical compound [Ag]Br ADZWSOLPGZMUMY-UHFFFAOYSA-M 0.000 description 2

- 229910001961 silver nitrate Inorganic materials 0.000 description 2

- 235000010413 sodium alginate Nutrition 0.000 description 2

- 239000000661 sodium alginate Substances 0.000 description 2

- 229940005550 sodium alginate Drugs 0.000 description 2

- CDBYLPFSWZWCQE-UHFFFAOYSA-L sodium carbonate Substances [Na+].[Na+].[O-]C([O-])=O CDBYLPFSWZWCQE-UHFFFAOYSA-L 0.000 description 2

- VWDWKYIASSYTQR-UHFFFAOYSA-N sodium nitrate Chemical compound [Na+].[O-][N+]([O-])=O VWDWKYIASSYTQR-UHFFFAOYSA-N 0.000 description 2

- AKHNMLFCWUSKQB-UHFFFAOYSA-L sodium thiosulfate Chemical compound [Na+].[Na+].[O-]S([O-])(=O)=S AKHNMLFCWUSKQB-UHFFFAOYSA-L 0.000 description 2

- 235000019345 sodium thiosulphate Nutrition 0.000 description 2

- GGCZERPQGJTIQP-UHFFFAOYSA-N sodium;9,10-dioxoanthracene-2-sulfonic acid Chemical compound [Na+].C1=CC=C2C(=O)C3=CC(S(=O)(=O)O)=CC=C3C(=O)C2=C1 GGCZERPQGJTIQP-UHFFFAOYSA-N 0.000 description 2

- 239000007787 solid Substances 0.000 description 2

- 230000003068 static effect Effects 0.000 description 2

- 238000003860 storage Methods 0.000 description 2

- TXUICONDJPYNPY-UHFFFAOYSA-N (1,10,13-trimethyl-3-oxo-4,5,6,7,8,9,11,12,14,15,16,17-dodecahydrocyclopenta[a]phenanthren-17-yl) heptanoate Chemical compound C1CC2CC(=O)C=C(C)C2(C)C2C1C1CCC(OC(=O)CCCCCC)C1(C)CC2 TXUICONDJPYNPY-UHFFFAOYSA-N 0.000 description 1

- BJEPYKJPYRNKOW-REOHCLBHSA-N (S)-malic acid Chemical compound OC(=O)[C@@H](O)CC(O)=O BJEPYKJPYRNKOW-REOHCLBHSA-N 0.000 description 1

- LUMLZKVIXLWTCI-NSCUHMNNSA-N (e)-2,3-dichloro-4-oxobut-2-enoic acid Chemical compound OC(=O)C(\Cl)=C(/Cl)C=O LUMLZKVIXLWTCI-NSCUHMNNSA-N 0.000 description 1

- JAEZSIYNWDWMMN-UHFFFAOYSA-N 1,1,3-trimethylthiourea Chemical compound CNC(=S)N(C)C JAEZSIYNWDWMMN-UHFFFAOYSA-N 0.000 description 1

- YHMYGUUIMTVXNW-UHFFFAOYSA-N 1,3-dihydrobenzimidazole-2-thione Chemical compound C1=CC=C2NC(S)=NC2=C1 YHMYGUUIMTVXNW-UHFFFAOYSA-N 0.000 description 1

- 150000005208 1,4-dihydroxybenzenes Chemical class 0.000 description 1

- FCTDKZOUZXYHNA-UHFFFAOYSA-N 1,4-dioxane-2,2-diol Chemical compound OC1(O)COCCO1 FCTDKZOUZXYHNA-UHFFFAOYSA-N 0.000 description 1

- MZFSRQQVIKFYON-UHFFFAOYSA-N 1-(3-acetyl-5-prop-2-enoyl-1,3,5-triazinan-1-yl)prop-2-en-1-one Chemical compound CC(=O)N1CN(C(=O)C=C)CN(C(=O)C=C)C1 MZFSRQQVIKFYON-UHFFFAOYSA-N 0.000 description 1

- PRAJOOPKIIUZRM-UHFFFAOYSA-N 2,2-dichloro-1,4-dioxane Chemical compound ClC1(Cl)COCCO1 PRAJOOPKIIUZRM-UHFFFAOYSA-N 0.000 description 1

- VZYDKJOUEPFKMW-UHFFFAOYSA-N 2,3-dihydroxybenzenesulfonic acid Chemical compound OC1=CC=CC(S(O)(=O)=O)=C1O VZYDKJOUEPFKMW-UHFFFAOYSA-N 0.000 description 1

- IKQCSJBQLWJEPU-UHFFFAOYSA-N 2,5-dihydroxybenzenesulfonic acid Chemical compound OC1=CC=C(O)C(S(O)(=O)=O)=C1 IKQCSJBQLWJEPU-UHFFFAOYSA-N 0.000 description 1

- YKUDHBLDJYZZQS-UHFFFAOYSA-N 2,6-dichloro-1h-1,3,5-triazin-4-one Chemical compound OC1=NC(Cl)=NC(Cl)=N1 YKUDHBLDJYZZQS-UHFFFAOYSA-N 0.000 description 1

- SMZOUWXMTYCWNB-UHFFFAOYSA-N 2-(2-methoxy-5-methylphenyl)ethanamine Chemical compound COC1=CC=C(C)C=C1CCN SMZOUWXMTYCWNB-UHFFFAOYSA-N 0.000 description 1

- OEPOKWHJYJXUGD-UHFFFAOYSA-N 2-(3-phenylmethoxyphenyl)-1,3-thiazole-4-carbaldehyde Chemical compound O=CC1=CSC(C=2C=C(OCC=3C=CC=CC=3)C=CC=2)=N1 OEPOKWHJYJXUGD-UHFFFAOYSA-N 0.000 description 1

- NIXOWILDQLNWCW-UHFFFAOYSA-N 2-Propenoic acid Natural products OC(=O)C=C NIXOWILDQLNWCW-UHFFFAOYSA-N 0.000 description 1

- URDCARMUOSMFFI-UHFFFAOYSA-N 2-[2-[bis(carboxymethyl)amino]ethyl-(2-hydroxyethyl)amino]acetic acid Chemical compound OCCN(CC(O)=O)CCN(CC(O)=O)CC(O)=O URDCARMUOSMFFI-UHFFFAOYSA-N 0.000 description 1

- BITBMHVXCILUEX-UHFFFAOYSA-N 2-chloroethylurea Chemical compound NC(=O)NCCCl BITBMHVXCILUEX-UHFFFAOYSA-N 0.000 description 1

- NEAQRZUHTPSBBM-UHFFFAOYSA-N 2-hydroxy-3,3-dimethyl-7-nitro-4h-isoquinolin-1-one Chemical compound C1=C([N+]([O-])=O)C=C2C(=O)N(O)C(C)(C)CC2=C1 NEAQRZUHTPSBBM-UHFFFAOYSA-N 0.000 description 1

- KRTDQDCPEZRVGC-UHFFFAOYSA-N 2-nitro-1h-benzimidazole Chemical class C1=CC=C2NC([N+](=O)[O-])=NC2=C1 KRTDQDCPEZRVGC-UHFFFAOYSA-N 0.000 description 1

- SEEZWGFVHCMHJF-UHFFFAOYSA-N 2-nitrosophenol Chemical class OC1=CC=CC=C1N=O SEEZWGFVHCMHJF-UHFFFAOYSA-N 0.000 description 1

- VCNCOKVOWKMRGJ-UHFFFAOYSA-N 3,4,5-trihydroxybenzenesulfonic acid Chemical compound OC1=CC(S(O)(=O)=O)=CC(O)=C1O VCNCOKVOWKMRGJ-UHFFFAOYSA-N 0.000 description 1

- LTPDITOEDOAWRU-UHFFFAOYSA-N 3,4-dihydroxybenzenesulfonic acid Chemical compound OC1=CC=C(S(O)(=O)=O)C=C1O LTPDITOEDOAWRU-UHFFFAOYSA-N 0.000 description 1

- PXDAXYDMZCYZNH-UHFFFAOYSA-N 3-methyl-2h-1,3-benzothiazole Chemical compound C1=CC=C2N(C)CSC2=C1 PXDAXYDMZCYZNH-UHFFFAOYSA-N 0.000 description 1

- OFNISBHGPNMTMS-UHFFFAOYSA-N 3-methylideneoxolane-2,5-dione Chemical compound C=C1CC(=O)OC1=O OFNISBHGPNMTMS-UHFFFAOYSA-N 0.000 description 1

- QNGVNLMMEQUVQK-UHFFFAOYSA-N 4-n,4-n-diethylbenzene-1,4-diamine Chemical compound CCN(CC)C1=CC=C(N)C=C1 QNGVNLMMEQUVQK-UHFFFAOYSA-N 0.000 description 1

- LRUDIIUSNGCQKF-UHFFFAOYSA-N 5-methyl-1H-benzotriazole Chemical compound C1=C(C)C=CC2=NNN=C21 LRUDIIUSNGCQKF-UHFFFAOYSA-N 0.000 description 1

- INVVMIXYILXINW-UHFFFAOYSA-N 5-methyl-1h-[1,2,4]triazolo[1,5-a]pyrimidin-7-one Chemical compound CC1=CC(=O)N2NC=NC2=N1 INVVMIXYILXINW-UHFFFAOYSA-N 0.000 description 1

- FFISWZPYNKWIRR-UHFFFAOYSA-N 5-oxidophenazin-5-ium Chemical class C1=CC=C2[N+]([O-])=C(C=CC=C3)C3=NC2=C1 FFISWZPYNKWIRR-UHFFFAOYSA-N 0.000 description 1

- OWNRRUFOJXFKCU-UHFFFAOYSA-N Bromadiolone Chemical compound C=1C=C(C=2C=CC(Br)=CC=2)C=CC=1C(O)CC(C=1C(OC2=CC=CC=C2C=1O)=O)C1=CC=CC=C1 OWNRRUFOJXFKCU-UHFFFAOYSA-N 0.000 description 1

- WKBOTKDWSSQWDR-UHFFFAOYSA-N Bromine atom Chemical compound [Br] WKBOTKDWSSQWDR-UHFFFAOYSA-N 0.000 description 1

- DKPFZGUDAPQIHT-UHFFFAOYSA-N Butyl acetate Natural products CCCCOC(C)=O DKPFZGUDAPQIHT-UHFFFAOYSA-N 0.000 description 1

- 239000004215 Carbon black (E152) Substances 0.000 description 1

- 229920002134 Carboxymethyl cellulose Polymers 0.000 description 1

- ZAMOUSCENKQFHK-UHFFFAOYSA-N Chlorine atom Chemical compound [Cl] ZAMOUSCENKQFHK-UHFFFAOYSA-N 0.000 description 1

- XXAXVMUWHZHZMJ-UHFFFAOYSA-N Chymopapain Chemical compound OC1=CC(S(O)(=O)=O)=CC(S(O)(=O)=O)=C1O XXAXVMUWHZHZMJ-UHFFFAOYSA-N 0.000 description 1

- 102000008186 Collagen Human genes 0.000 description 1

- 108010035532 Collagen Proteins 0.000 description 1

- 229920002307 Dextran Polymers 0.000 description 1

- FEWJPZIEWOKRBE-JCYAYHJZSA-N Dextrotartaric acid Chemical compound OC(=O)[C@H](O)[C@@H](O)C(O)=O FEWJPZIEWOKRBE-JCYAYHJZSA-N 0.000 description 1

- QSJXEFYPDANLFS-UHFFFAOYSA-N Diacetyl Chemical group CC(=O)C(C)=O QSJXEFYPDANLFS-UHFFFAOYSA-N 0.000 description 1

- QEVGZEDELICMKH-UHFFFAOYSA-N Diglycolic acid Chemical compound OC(=O)COCC(O)=O QEVGZEDELICMKH-UHFFFAOYSA-N 0.000 description 1

- KCXVZYZYPLLWCC-UHFFFAOYSA-N EDTA Chemical compound OC(=O)CN(CC(O)=O)CCN(CC(O)=O)CC(O)=O KCXVZYZYPLLWCC-UHFFFAOYSA-N 0.000 description 1

- VTLYFUHAOXGGBS-UHFFFAOYSA-N Fe3+ Chemical class [Fe+3] VTLYFUHAOXGGBS-UHFFFAOYSA-N 0.000 description 1

- SXRSQZLOMIGNAQ-UHFFFAOYSA-N Glutaraldehyde Chemical compound O=CCCCC=O SXRSQZLOMIGNAQ-UHFFFAOYSA-N 0.000 description 1

- CTKINSOISVBQLD-UHFFFAOYSA-N Glycidol Chemical compound OCC1CO1 CTKINSOISVBQLD-UHFFFAOYSA-N 0.000 description 1

- 229920000084 Gum arabic Polymers 0.000 description 1

- DGAQECJNVWCQMB-PUAWFVPOSA-M Ilexoside XXIX Chemical compound C[C@@H]1CC[C@@]2(CC[C@@]3(C(=CC[C@H]4[C@]3(CC[C@@H]5[C@@]4(CC[C@@H](C5(C)C)OS(=O)(=O)[O-])C)C)[C@@H]2[C@]1(C)O)C)C(=O)O[C@H]6[C@@H]([C@H]([C@@H]([C@H](O6)CO)O)O)O.[Na+] DGAQECJNVWCQMB-PUAWFVPOSA-M 0.000 description 1

- PEEHTFAAVSWFBL-UHFFFAOYSA-N Maleimide Chemical class O=C1NC(=O)C=C1 PEEHTFAAVSWFBL-UHFFFAOYSA-N 0.000 description 1

- CERQOIWHTDAKMF-UHFFFAOYSA-N Methacrylic acid Chemical compound CC(=C)C(O)=O CERQOIWHTDAKMF-UHFFFAOYSA-N 0.000 description 1

- MNSGOOCAMMSKGI-UHFFFAOYSA-N N-(hydroxymethyl)phthalimide Chemical compound C1=CC=C2C(=O)N(CO)C(=O)C2=C1 MNSGOOCAMMSKGI-UHFFFAOYSA-N 0.000 description 1

- BPQQTUXANYXVAA-UHFFFAOYSA-N Orthosilicate Chemical compound [O-][Si]([O-])([O-])[O-] BPQQTUXANYXVAA-UHFFFAOYSA-N 0.000 description 1

- FQYUMYWMJTYZTK-UHFFFAOYSA-N Phenyl glycidyl ether Chemical class C1OC1COC1=CC=CC=C1 FQYUMYWMJTYZTK-UHFFFAOYSA-N 0.000 description 1

- 229920002845 Poly(methacrylic acid) Polymers 0.000 description 1

- 229920002319 Poly(methyl acrylate) Polymers 0.000 description 1

- 239000002202 Polyethylene glycol Substances 0.000 description 1

- 239000004743 Polypropylene Substances 0.000 description 1

- 239000004793 Polystyrene Substances 0.000 description 1

- ZLMJMSJWJFRBEC-UHFFFAOYSA-N Potassium Chemical compound [K] ZLMJMSJWJFRBEC-UHFFFAOYSA-N 0.000 description 1

- KJTLSVCANCCWHF-UHFFFAOYSA-N Ruthenium Chemical compound [Ru] KJTLSVCANCCWHF-UHFFFAOYSA-N 0.000 description 1

- 241000978776 Senegalia senegal Species 0.000 description 1

- 229910021607 Silver chloride Inorganic materials 0.000 description 1

- PMZURENOXWZQFD-UHFFFAOYSA-L Sodium Sulfate Chemical compound [Na+].[Na+].[O-]S([O-])(=O)=O PMZURENOXWZQFD-UHFFFAOYSA-L 0.000 description 1

- UCKMPCXJQFINFW-UHFFFAOYSA-N Sulphide Chemical compound [S-2] UCKMPCXJQFINFW-UHFFFAOYSA-N 0.000 description 1

- FEWJPZIEWOKRBE-UHFFFAOYSA-N Tartaric acid Natural products [H+].[H+].[O-]C(=O)C(O)C(O)C([O-])=O FEWJPZIEWOKRBE-UHFFFAOYSA-N 0.000 description 1

- 229910021626 Tin(II) chloride Inorganic materials 0.000 description 1

- GWEVSGVZZGPLCZ-UHFFFAOYSA-N Titan oxide Chemical compound O=[Ti]=O GWEVSGVZZGPLCZ-UHFFFAOYSA-N 0.000 description 1

- BZHJMEDXRYGGRV-UHFFFAOYSA-N Vinyl chloride Chemical compound ClC=C BZHJMEDXRYGGRV-UHFFFAOYSA-N 0.000 description 1

- SJOOOZPMQAWAOP-UHFFFAOYSA-N [Ag].BrCl Chemical compound [Ag].BrCl SJOOOZPMQAWAOP-UHFFFAOYSA-N 0.000 description 1

- 235000010489 acacia gum Nutrition 0.000 description 1

- 239000000205 acacia gum Substances 0.000 description 1

- 229910052946 acanthite Inorganic materials 0.000 description 1

- 159000000021 acetate salts Chemical class 0.000 description 1

- VJHCJDRQFCCTHL-UHFFFAOYSA-N acetic acid 2,3,4,5,6-pentahydroxyhexanal Chemical compound CC(O)=O.OCC(O)C(O)C(O)C(O)C=O VJHCJDRQFCCTHL-UHFFFAOYSA-N 0.000 description 1

- 150000008360 acrylonitriles Chemical class 0.000 description 1

- 239000000654 additive Substances 0.000 description 1

- 230000001070 adhesive effect Effects 0.000 description 1

- 238000007754 air knife coating Methods 0.000 description 1

- 229910052783 alkali metal Inorganic materials 0.000 description 1

- 229910001513 alkali metal bromide Inorganic materials 0.000 description 1

- 229910001516 alkali metal iodide Inorganic materials 0.000 description 1

- 150000001340 alkali metals Chemical class 0.000 description 1

- 125000005250 alkyl acrylate group Chemical group 0.000 description 1

- 150000003973 alkyl amines Chemical class 0.000 description 1

- 125000002947 alkylene group Chemical group 0.000 description 1

- BJEPYKJPYRNKOW-UHFFFAOYSA-N alpha-hydroxysuccinic acid Natural products OC(=O)C(O)CC(O)=O BJEPYKJPYRNKOW-UHFFFAOYSA-N 0.000 description 1

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 1

- 229910000147 aluminium phosphate Inorganic materials 0.000 description 1

- 235000011126 aluminium potassium sulphate Nutrition 0.000 description 1

- ANBBXQWFNXMHLD-UHFFFAOYSA-N aluminum;sodium;oxygen(2-) Chemical compound [O-2].[O-2].[Na+].[Al+3] ANBBXQWFNXMHLD-UHFFFAOYSA-N 0.000 description 1

- 150000001413 amino acids Chemical class 0.000 description 1

- 150000001414 amino alcohols Chemical class 0.000 description 1

- XYXNTHIYBIDHGM-UHFFFAOYSA-N ammonium thiosulfate Chemical compound [NH4+].[NH4+].[O-]S([O-])(=O)=S XYXNTHIYBIDHGM-UHFFFAOYSA-N 0.000 description 1

- 125000000129 anionic group Chemical group 0.000 description 1

- 239000003963 antioxidant agent Substances 0.000 description 1

- 230000003078 antioxidant effect Effects 0.000 description 1

- 150000001541 aziridines Chemical class 0.000 description 1

- 230000004888 barrier function Effects 0.000 description 1

- 230000006399 behavior Effects 0.000 description 1

- 238000005452 bending Methods 0.000 description 1

- 238000004061 bleaching Methods 0.000 description 1

- KGBXLFKZBHKPEV-UHFFFAOYSA-N boric acid Chemical compound OB(O)O KGBXLFKZBHKPEV-UHFFFAOYSA-N 0.000 description 1

- 239000004327 boric acid Substances 0.000 description 1

- 150000001642 boronic acid derivatives Chemical class 0.000 description 1

- GDTBXPJZTBHREO-UHFFFAOYSA-N bromine Substances BrBr GDTBXPJZTBHREO-UHFFFAOYSA-N 0.000 description 1

- 229910052794 bromium Inorganic materials 0.000 description 1

- KDPAWGWELVVRCH-UHFFFAOYSA-N bromoacetic acid Chemical class OC(=O)CBr KDPAWGWELVVRCH-UHFFFAOYSA-N 0.000 description 1

- 239000000872 buffer Substances 0.000 description 1

- 239000006227 byproduct Substances 0.000 description 1

- 239000000298 carbocyanine Substances 0.000 description 1

- 125000004432 carbon atom Chemical group C* 0.000 description 1

- 125000002915 carbonyl group Chemical group [*:2]C([*:1])=O 0.000 description 1

- 239000001768 carboxy methyl cellulose Substances 0.000 description 1

- 235000010948 carboxy methyl cellulose Nutrition 0.000 description 1

- 150000001732 carboxylic acid derivatives Chemical class 0.000 description 1

- 239000008112 carboxymethyl-cellulose Substances 0.000 description 1

- 150000001767 cationic compounds Chemical class 0.000 description 1

- 125000002091 cationic group Chemical group 0.000 description 1

- 150000001768 cations Chemical class 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 239000000460 chlorine Substances 0.000 description 1

- 229910052801 chlorine Inorganic materials 0.000 description 1

- 150000001805 chlorine compounds Chemical class 0.000 description 1

- OIDPCXKPHYRNKH-UHFFFAOYSA-J chrome alum Chemical compound [K]OS(=O)(=O)O[Cr]1OS(=O)(=O)O1 OIDPCXKPHYRNKH-UHFFFAOYSA-J 0.000 description 1

- 239000008199 coating composition Substances 0.000 description 1

- 229920001436 collagen Polymers 0.000 description 1

- 238000001246 colloidal dispersion Methods 0.000 description 1

- 239000003086 colorant Substances 0.000 description 1

- 238000007796 conventional method Methods 0.000 description 1

- 238000003851 corona treatment Methods 0.000 description 1

- 239000013078 crystal Substances 0.000 description 1

- 238000007766 curtain coating Methods 0.000 description 1

- 150000003997 cyclic ketones Chemical class 0.000 description 1

- CIISBNCSMVCNIP-UHFFFAOYSA-N cyclopentane-1,2-dione Chemical compound O=C1CCCC1=O CIISBNCSMVCNIP-UHFFFAOYSA-N 0.000 description 1

- SOCTUWSJJQCPFX-UHFFFAOYSA-N dichromate(2-) Chemical class [O-][Cr](=O)(=O)O[Cr]([O-])(=O)=O SOCTUWSJJQCPFX-UHFFFAOYSA-N 0.000 description 1

- 235000014113 dietary fatty acids Nutrition 0.000 description 1

- 150000002012 dioxanes Chemical class 0.000 description 1

- OGTYNHUNAXSYEF-UHFFFAOYSA-L dioxido-oxo-sulfanylidene-$l^{6}-sulfane;gold(1+) Chemical compound [Au+].[Au+].[O-]S([O-])(=O)=S OGTYNHUNAXSYEF-UHFFFAOYSA-L 0.000 description 1

- 238000003618 dip coating Methods 0.000 description 1

- FGRVOLIFQGXPCT-UHFFFAOYSA-L dipotassium;dioxido-oxo-sulfanylidene-$l^{6}-sulfane Chemical compound [K+].[K+].[O-]S([O-])(=O)=S FGRVOLIFQGXPCT-UHFFFAOYSA-L 0.000 description 1

- 239000006185 dispersion Substances 0.000 description 1

- WBZKQQHYRPRKNJ-UHFFFAOYSA-L disulfite Chemical class [O-]S(=O)S([O-])(=O)=O WBZKQQHYRPRKNJ-UHFFFAOYSA-L 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000004945 emulsification Methods 0.000 description 1

- 238000007720 emulsion polymerization reaction Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 125000004185 ester group Chemical group 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 238000002474 experimental method Methods 0.000 description 1

- 239000000194 fatty acid Substances 0.000 description 1

- 229930195729 fatty acid Natural products 0.000 description 1

- YAGKRVSRTSUGEY-UHFFFAOYSA-N ferricyanide Chemical class [Fe+3].N#[C-].N#[C-].N#[C-].N#[C-].N#[C-].N#[C-] YAGKRVSRTSUGEY-UHFFFAOYSA-N 0.000 description 1

- 238000001914 filtration Methods 0.000 description 1

- 239000010419 fine particle Substances 0.000 description 1

- 230000006870 function Effects 0.000 description 1

- VOZRXNHHFUQHIL-UHFFFAOYSA-N glycidyl methacrylate Chemical compound CC(=C)C(=O)OCC1CO1 VOZRXNHHFUQHIL-UHFFFAOYSA-N 0.000 description 1

- RJHLTVSLYWWTEF-UHFFFAOYSA-K gold trichloride Chemical compound Cl[Au](Cl)Cl RJHLTVSLYWWTEF-UHFFFAOYSA-K 0.000 description 1

- RQVOBHDSEHUCDG-UHFFFAOYSA-M gold(1+);thiocyanate Chemical compound [Au]SC#N RQVOBHDSEHUCDG-UHFFFAOYSA-M 0.000 description 1

- 239000008187 granular material Substances 0.000 description 1

- 150000004820 halides Chemical class 0.000 description 1

- 229910052736 halogen Inorganic materials 0.000 description 1

- 150000002367 halogens Chemical class 0.000 description 1

- 150000002391 heterocyclic compounds Chemical class 0.000 description 1

- 125000000623 heterocyclic group Chemical group 0.000 description 1

- 239000004312 hexamethylene tetramine Substances 0.000 description 1

- 235000010299 hexamethylene tetramine Nutrition 0.000 description 1

- FUZZWVXGSFPDMH-UHFFFAOYSA-N hexanoic acid Chemical compound CCCCCC(O)=O FUZZWVXGSFPDMH-UHFFFAOYSA-N 0.000 description 1

- 229920001519 homopolymer Polymers 0.000 description 1

- 229930195733 hydrocarbon Natural products 0.000 description 1

- 150000002430 hydrocarbons Chemical class 0.000 description 1

- 229940079826 hydrogen sulfite Drugs 0.000 description 1

- 150000002443 hydroxylamines Chemical class 0.000 description 1

- 238000005286 illumination Methods 0.000 description 1

- 125000001841 imino group Chemical group [H]N=* 0.000 description 1

- NBZBKCUXIYYUSX-UHFFFAOYSA-N iminodiacetic acid Chemical compound OC(=O)CNCC(O)=O NBZBKCUXIYYUSX-UHFFFAOYSA-N 0.000 description 1

- 150000007529 inorganic bases Chemical class 0.000 description 1

- 150000002484 inorganic compounds Chemical class 0.000 description 1

- 229910010272 inorganic material Inorganic materials 0.000 description 1

- 238000005305 interferometry Methods 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- CTAPFRYPJLPFDF-UHFFFAOYSA-N isoxazole Chemical class C=1C=NOC=1 CTAPFRYPJLPFDF-UHFFFAOYSA-N 0.000 description 1

- 239000004816 latex Substances 0.000 description 1

- 230000000670 limiting effect Effects 0.000 description 1

- 238000011068 loading method Methods 0.000 description 1

- 239000002932 luster Substances 0.000 description 1

- 239000000395 magnesium oxide Substances 0.000 description 1

- CPLXHLVBOLITMK-UHFFFAOYSA-N magnesium oxide Inorganic materials [Mg]=O CPLXHLVBOLITMK-UHFFFAOYSA-N 0.000 description 1

- AXZKOIWUVFPNLO-UHFFFAOYSA-N magnesium;oxygen(2-) Chemical compound [O-2].[Mg+2] AXZKOIWUVFPNLO-UHFFFAOYSA-N 0.000 description 1

- FPYJFEHAWHCUMM-UHFFFAOYSA-N maleic anhydride Chemical compound O=C1OC(=O)C=C1 FPYJFEHAWHCUMM-UHFFFAOYSA-N 0.000 description 1

- 239000001630 malic acid Substances 0.000 description 1

- 235000011090 malic acid Nutrition 0.000 description 1

- QSHDDOUJBYECFT-UHFFFAOYSA-N mercury Chemical compound [Hg] QSHDDOUJBYECFT-UHFFFAOYSA-N 0.000 description 1

- 229910052753 mercury Inorganic materials 0.000 description 1

- DZVCFNFOPIZQKX-LTHRDKTGSA-M merocyanine Chemical compound [Na+].O=C1N(CCCC)C(=O)N(CCCC)C(=O)C1=C\C=C\C=C/1N(CCCS([O-])(=O)=O)C2=CC=CC=C2O\1 DZVCFNFOPIZQKX-LTHRDKTGSA-M 0.000 description 1

- 239000002184 metal Chemical class 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- ZAKLKBFCSHJIRI-UHFFFAOYSA-N mucochloric acid Natural products OC1OC(=O)C(Cl)=C1Cl ZAKLKBFCSHJIRI-UHFFFAOYSA-N 0.000 description 1

- NPKFETRYYSUTEC-UHFFFAOYSA-N n-[2-(4-amino-n-ethyl-3-methylanilino)ethyl]methanesulfonamide Chemical compound CS(=O)(=O)NCCN(CC)C1=CC=C(N)C(C)=C1 NPKFETRYYSUTEC-UHFFFAOYSA-N 0.000 description 1

- 230000007935 neutral effect Effects 0.000 description 1

- MGFYIUFZLHCRTH-UHFFFAOYSA-N nitrilotriacetic acid Chemical compound OC(=O)CN(CC(O)=O)CC(O)=O MGFYIUFZLHCRTH-UHFFFAOYSA-N 0.000 description 1

- 229910000510 noble metal Inorganic materials 0.000 description 1

- JRZJOMJEPLMPRA-UHFFFAOYSA-N olefin Natural products CCCCCCCC=C JRZJOMJEPLMPRA-UHFFFAOYSA-N 0.000 description 1

- 150000007524 organic acids Chemical class 0.000 description 1

- 150000007530 organic bases Chemical class 0.000 description 1

- 150000002894 organic compounds Chemical class 0.000 description 1

- 239000013110 organic ligand Substances 0.000 description 1

- RPQRDASANLAFCM-UHFFFAOYSA-N oxiran-2-ylmethyl prop-2-enoate Chemical compound C=CC(=O)OCC1CO1 RPQRDASANLAFCM-UHFFFAOYSA-N 0.000 description 1

- 150000004989 p-phenylenediamines Chemical class 0.000 description 1

- 239000003002 pH adjusting agent Substances 0.000 description 1

- 239000006174 pH buffer Substances 0.000 description 1

- 229910052763 palladium Inorganic materials 0.000 description 1

- 150000004965 peroxy acids Chemical class 0.000 description 1

- JRKICGRDRMAZLK-UHFFFAOYSA-L peroxydisulfate Chemical class [O-]S(=O)(=O)OOS([O-])(=O)=O JRKICGRDRMAZLK-UHFFFAOYSA-L 0.000 description 1

- 125000005496 phosphonium group Chemical group 0.000 description 1

- QWYZFXLSWMXLDM-UHFFFAOYSA-M pinacyanol iodide Chemical compound [I-].C1=CC2=CC=CC=C2N(CC)C1=CC=CC1=CC=C(C=CC=C2)C2=[N+]1CC QWYZFXLSWMXLDM-UHFFFAOYSA-M 0.000 description 1

- 238000007747 plating Methods 0.000 description 1

- 229910052697 platinum Inorganic materials 0.000 description 1

- 229920000233 poly(alkylene oxides) Polymers 0.000 description 1

- 229920000728 polyester Polymers 0.000 description 1

- 229920001223 polyethylene glycol Polymers 0.000 description 1

- 229920013716 polyethylene resin Polymers 0.000 description 1

- 229920006254 polymer film Polymers 0.000 description 1

- 229920001155 polypropylene Polymers 0.000 description 1

- 229920001296 polysiloxane Polymers 0.000 description 1

- 229920002223 polystyrene Polymers 0.000 description 1

- 229920006295 polythiol Polymers 0.000 description 1

- 229910052700 potassium Inorganic materials 0.000 description 1

- 239000011591 potassium Substances 0.000 description 1

- 229940050271 potassium alum Drugs 0.000 description 1

- GRLPQNLYRHEGIJ-UHFFFAOYSA-J potassium aluminium sulfate Chemical compound [Al+3].[K+].[O-]S([O-])(=O)=O.[O-]S([O-])(=O)=O GRLPQNLYRHEGIJ-UHFFFAOYSA-J 0.000 description 1

- 239000000843 powder Substances 0.000 description 1

- 239000002243 precursor Substances 0.000 description 1

- 238000002203 pretreatment Methods 0.000 description 1

- 238000003672 processing method Methods 0.000 description 1

- BDERNNFJNOPAEC-UHFFFAOYSA-N propan-1-ol Chemical compound CCCO BDERNNFJNOPAEC-UHFFFAOYSA-N 0.000 description 1

- 230000001681 protective effect Effects 0.000 description 1

- 235000018102 proteins Nutrition 0.000 description 1

- 108090000623 proteins and genes Proteins 0.000 description 1

- 102000004169 proteins and genes Human genes 0.000 description 1

- UMJSCPRVCHMLSP-UHFFFAOYSA-N pyridine Natural products COC1=CC=CN=C1 UMJSCPRVCHMLSP-UHFFFAOYSA-N 0.000 description 1

- JUJWROOIHBZHMG-UHFFFAOYSA-O pyridinium Chemical compound C1=CC=[NH+]C=C1 JUJWROOIHBZHMG-UHFFFAOYSA-O 0.000 description 1

- 238000011002 quantification Methods 0.000 description 1

- 150000003242 quaternary ammonium salts Chemical class 0.000 description 1

- 239000001397 quillaja saponaria molina bark Substances 0.000 description 1

- 150000004053 quinones Chemical class 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 229910052703 rhodium Inorganic materials 0.000 description 1

- 239000010948 rhodium Substances 0.000 description 1

- MHOVAHRLVXNVSD-UHFFFAOYSA-N rhodium atom Chemical compound [Rh] MHOVAHRLVXNVSD-UHFFFAOYSA-N 0.000 description 1

- 229910052707 ruthenium Inorganic materials 0.000 description 1

- 229930182490 saponin Natural products 0.000 description 1

- 150000007949 saponins Chemical class 0.000 description 1

- 230000001235 sensitizing effect Effects 0.000 description 1

- RMAQACBXLXPBSY-UHFFFAOYSA-N silicic acid Chemical compound O[Si](O)(O)O RMAQACBXLXPBSY-UHFFFAOYSA-N 0.000 description 1

- ZUNKMNLKJXRCDM-UHFFFAOYSA-N silver bromoiodide Chemical compound [Ag].IBr ZUNKMNLKJXRCDM-UHFFFAOYSA-N 0.000 description 1

- HKZLPVFGJNLROG-UHFFFAOYSA-M silver monochloride Chemical compound [Cl-].[Ag+] HKZLPVFGJNLROG-UHFFFAOYSA-M 0.000 description 1

- XUARKZBEFFVFRG-UHFFFAOYSA-N silver sulfide Chemical compound [S-2].[Ag+].[Ag+] XUARKZBEFFVFRG-UHFFFAOYSA-N 0.000 description 1

- 229940056910 silver sulfide Drugs 0.000 description 1

- 229910052708 sodium Inorganic materials 0.000 description 1

- 239000011734 sodium Substances 0.000 description 1

- 229910001388 sodium aluminate Inorganic materials 0.000 description 1

- 229910000029 sodium carbonate Inorganic materials 0.000 description 1

- 239000011780 sodium chloride Substances 0.000 description 1

- 239000004317 sodium nitrate Substances 0.000 description 1

- 235000010344 sodium nitrate Nutrition 0.000 description 1

- 239000001488 sodium phosphate Substances 0.000 description 1

- 229910000162 sodium phosphate Inorganic materials 0.000 description 1

- 159000000000 sodium salts Chemical class 0.000 description 1

- 229910052938 sodium sulfate Inorganic materials 0.000 description 1

- 235000011152 sodium sulphate Nutrition 0.000 description 1

- 230000000087 stabilizing effect Effects 0.000 description 1

- 239000001119 stannous chloride Substances 0.000 description 1

- 235000011150 stannous chloride Nutrition 0.000 description 1

- HMNUYYJYMOXWTN-UHFFFAOYSA-J strontium;barium(2+);disulfate Chemical compound [Sr+2].[Ba+2].[O-]S([O-])(=O)=O.[O-]S([O-])(=O)=O HMNUYYJYMOXWTN-UHFFFAOYSA-J 0.000 description 1

- 125000005504 styryl group Chemical group 0.000 description 1

- IIACRCGMVDHOTQ-UHFFFAOYSA-N sulfamic acid Chemical class NS(O)(=O)=O IIACRCGMVDHOTQ-UHFFFAOYSA-N 0.000 description 1

- LSNNMFCWUKXFEE-UHFFFAOYSA-L sulfite Chemical class [O-]S([O-])=O LSNNMFCWUKXFEE-UHFFFAOYSA-L 0.000 description 1

- 125000004964 sulfoalkyl group Chemical group 0.000 description 1

- RWSOTUBLDIXVET-UHFFFAOYSA-O sulfonium group Chemical group [SH3+] RWSOTUBLDIXVET-UHFFFAOYSA-O 0.000 description 1

- 150000003464 sulfur compounds Chemical class 0.000 description 1

- 150000003467 sulfuric acid derivatives Chemical class 0.000 description 1

- 238000003786 synthesis reaction Methods 0.000 description 1

- 229920001059 synthetic polymer Polymers 0.000 description 1

- 229920003002 synthetic resin Polymers 0.000 description 1

- 239000000057 synthetic resin Substances 0.000 description 1

- 239000011975 tartaric acid Substances 0.000 description 1

- 235000002906 tartaric acid Nutrition 0.000 description 1

- CBXCPBUEXACCNR-UHFFFAOYSA-N tetraethylammonium Chemical class CC[N+](CC)(CC)CC CBXCPBUEXACCNR-UHFFFAOYSA-N 0.000 description 1

- OGIDPMRJRNCKJF-UHFFFAOYSA-N titanium oxide Inorganic materials [Ti]=O OGIDPMRJRNCKJF-UHFFFAOYSA-N 0.000 description 1

- RYFMWSXOAZQYPI-UHFFFAOYSA-K trisodium phosphate Chemical compound [Na+].[Na+].[Na+].[O-]P([O-])([O-])=O RYFMWSXOAZQYPI-UHFFFAOYSA-K 0.000 description 1

- SOBHUZYZLFQYFK-UHFFFAOYSA-K trisodium;hydroxy-[[phosphonatomethyl(phosphonomethyl)amino]methyl]phosphinate Chemical compound [Na+].[Na+].[Na+].OP(O)(=O)CN(CP(O)([O-])=O)CP([O-])([O-])=O SOBHUZYZLFQYFK-UHFFFAOYSA-K 0.000 description 1

- 125000000391 vinyl group Chemical group [H]C([*])=C([H])[H] 0.000 description 1

- 238000005406 washing Methods 0.000 description 1

- 239000001993 wax Substances 0.000 description 1

- ZXAUZSQITFJWPS-UHFFFAOYSA-J zirconium(4+);disulfate Chemical compound [Zr+4].[O-]S([O-])(=O)=O.[O-]S([O-])(=O)=O ZXAUZSQITFJWPS-UHFFFAOYSA-J 0.000 description 1

- 239000004711 α-olefin Substances 0.000 description 1

Classifications

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03C—PHOTOSENSITIVE MATERIALS FOR PHOTOGRAPHIC PURPOSES; PHOTOGRAPHIC PROCESSES, e.g. CINE, X-RAY, COLOUR, STEREO-PHOTOGRAPHIC PROCESSES; AUXILIARY PROCESSES IN PHOTOGRAPHY

- G03C1/00—Photosensitive materials

- G03C1/76—Photosensitive materials characterised by the base or auxiliary layers

- G03C1/85—Photosensitive materials characterised by the base or auxiliary layers characterised by antistatic additives or coatings

- G03C1/853—Inorganic compounds, e.g. metals

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H19/00—Coated paper; Coating material

- D21H19/36—Coatings with pigments

- D21H19/38—Coatings with pigments characterised by the pigments

- D21H19/40—Coatings with pigments characterised by the pigments siliceous, e.g. clays

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H19/00—Coated paper; Coating material

- D21H19/72—Coated paper characterised by the paper substrate

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H27/00—Special paper not otherwise provided for, e.g. made by multi-step processes

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03C—PHOTOSENSITIVE MATERIALS FOR PHOTOGRAPHIC PURPOSES; PHOTOGRAPHIC PROCESSES, e.g. CINE, X-RAY, COLOUR, STEREO-PHOTOGRAPHIC PROCESSES; AUXILIARY PROCESSES IN PHOTOGRAPHY

- G03C1/00—Photosensitive materials

- G03C1/76—Photosensitive materials characterised by the base or auxiliary layers

- G03C1/775—Photosensitive materials characterised by the base or auxiliary layers the base being of paper

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03C—PHOTOSENSITIVE MATERIALS FOR PHOTOGRAPHIC PURPOSES; PHOTOGRAPHIC PROCESSES, e.g. CINE, X-RAY, COLOUR, STEREO-PHOTOGRAPHIC PROCESSES; AUXILIARY PROCESSES IN PHOTOGRAPHY

- G03C1/00—Photosensitive materials

- G03C1/76—Photosensitive materials characterised by the base or auxiliary layers

- G03C1/775—Photosensitive materials characterised by the base or auxiliary layers the base being of paper

- G03C1/79—Macromolecular coatings or impregnations therefor, e.g. varnishes

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03C—PHOTOSENSITIVE MATERIALS FOR PHOTOGRAPHIC PURPOSES; PHOTOGRAPHIC PROCESSES, e.g. CINE, X-RAY, COLOUR, STEREO-PHOTOGRAPHIC PROCESSES; AUXILIARY PROCESSES IN PHOTOGRAPHY

- G03C1/00—Photosensitive materials

- G03C1/76—Photosensitive materials characterised by the base or auxiliary layers

- G03C1/95—Photosensitive materials characterised by the base or auxiliary layers rendered opaque or writable, e.g. with inert particulate additives

Definitions

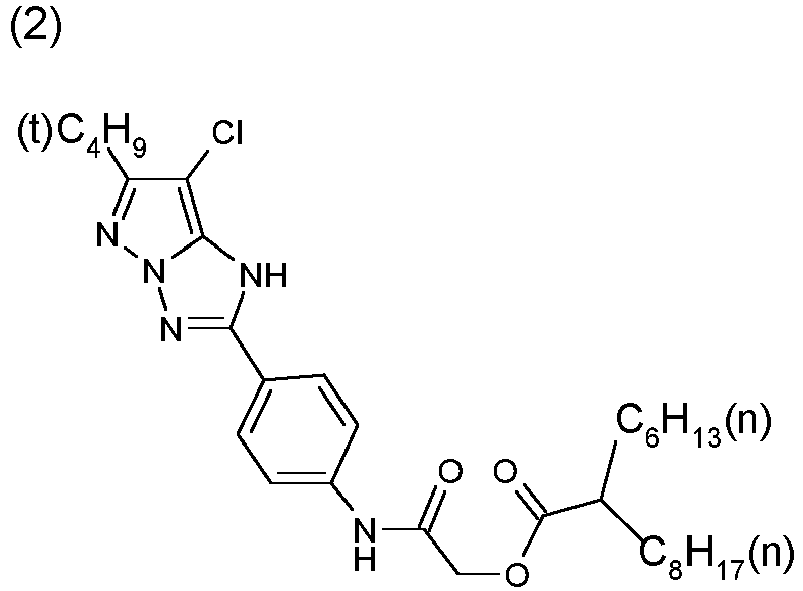

- This invention relates to a photographic paper, its preparation and use for making album-books.

- photographic paper typically comprises a base layer coated with one or more layers of light-sensitive chemicals.

- the paper will typically comprise three light-sensitive emulsion layers (yellow, magenta and cyan) to provide a full colour image, optionally with other layers.

- photographic papers can suffer from the problem of sticking together, due to the inherent stickiness of their outer-most layer.

- photographic paper In use, photographic paper is exposed to light in a controlled manner to generate an image thereon, for example using an image obtained on a camera film or using a digital image.

- the desired image then develops and the resultant photographic paper carrying the desired image is often referred to as a photograph.

- the photograph may be stacked along with other photographs, 'back-to-back', and handed or posted to the photographer.

- the photograph i.e. the photographic paper carrying the desired image

- the photograph i.e. the photographic paper carrying the desired image

- the photograph i.e. the photographic paper carrying the desired image

- album-book where the photographs contact each other in a 'face-to-face' manner as a result of being on opposite pages.

- This 'face-to-face' contact can cause problems, particularly when the album-book is stored under hot and/or humid conditions.

- the photographs are prone to sticking together, causing them damage when pages of the album-book are opened, sometimes spoiling irreplaceable family pictures.

- EP2619628 addressed the problem of photographic paper sticking together, especially photographic paper carrying images stored in album-books or other environments.

- Photobooks comprising a rough base layer suffer from the problem of a noise (e.g. a squeaking sound) being generated when pages are turned, bent and/or moved.

- a noise e.g. a squeaking sound

- the noise problem does not usually occur when the base layer is smooth (e.g. as is used for producing glossy photobooks) but when rough base layers are used to prepare photobooks having a silk, lustre or matte finish the noise during page turning can be distracting and disliked by customers.

- the present invention addresses the problem of reducing the volume of such noises in non-glossy photobooks or eliminating them entirely.

- photographic paper comprising a base layer having an average surface roughness (Sa) of at least 0.7 ⁇ m and an outer-most layer comprising a hydrophilic colloid binder and colloidal silica, wherein:

- the components of the photographic paper depend to some extent on whether an image has been developed thereon, i.e. whether or not the photographic paper has been used.

- a base layer e.g. polyester or resin-coated paper

- one or more light-sensitive emulsion layers e.g. layers which generate yellow, magenta or cyan colours

- the photographic paper typically comprises the same components except that the light-sensitive layers are no longer light sensitive, having been exposed to light in a controlled manner to develop the desired image thereon.

- the mean particle size of the colloidal silica is in the range 2 to 70nm, more preferably 2.5 to 9nm, especially 3 to 7nm. This preference arises because colloidal silica having a mean particle size below 2nm can increase the viscosity of coating solutions, leading to longer manufacturing times for the photographic paper or the requirement for expensive viscosity reducing agents to be included in coating compositions.

- the outer-most layer comprises 40mg/m 2 to 225mg/m 2 , especially about 150mg/m 2 of the colloidal silica.

- the photographic papers of the present invention have a low or no tendency to stick together and may be prepared conveniently at high speeds above 200m/min using, for example, a slide coater or a curtain coater.

- the outer-most layer of the present invention As the function of the outer-most layer of the present invention is to reduce the noise made when turning, bending and/or moving pages of the photographic paper in a photobook, the outer-most layer generally does not include any silver halide.

- the colloidal silica preferably consists essentially of silicon dioxide.

- the colloidal silica may contain, as a minor component, alumina or sodium aluminate, e.g. in an amount of 0 to 0.1g per g of the silicon dioxide.

- the colloidal silica optionally comprises, as a stabilizer, an inorganic base, for example sodium hydroxide, potassium hydroxide, lithium hydroxide or ammonia, or an organic base such as a tetraethylammonium salt.

- the colloidal silica can be employed in the form of a colloidal dispersion of fine particles of silica in a medium such as water or an organic liquid, for example, methanol, ethanol, propanol, butanol, acetone, ethyl acetate or butyl acetate.

- a medium such as water or an organic liquid, for example, methanol, ethanol, propanol, butanol, acetone, ethyl acetate or butyl acetate.

- Preferred in this invention is the use of silicate sol or silicic acid sol in a water environment.

- weight of other components e.g. water, organic liquid etc.

- colloidal silica to hydrophilic colloid binder are not taken into account when calculating the weight ratio of colloidal silica to hydrophilic colloid binder.

- colloidal silica examples include Levasil TM 300 and Levasil TM 500 from H.C. Starck. According to the manufacturer's catalogue these products contain colloidal silica having mean particle sizes of 9nm and 6nm respectively and surface areas of 300 g/m 2 and 450 g/m 2 respectively. Also Bindzil TM 30/360 may be used (7nm). Other commercially available colloidal silicas include NexSil TM 5 (6nm) and NexSil TM 8 (8nm) from Nyacol Nano Technologies, Inc. The colloidal silicas may be surface-treated if desired.

- the weight ratio of colloidal silica to hydrophilic colloid binder in said outer-most layer is (0.06:1 to 0.10:1) to (0.13:1 to 0.27:1).

- the outer-most layer provides photographic papers having silk, lustre or matte finish which are much less noisy when used in a photobook without detracting from the physical appearance of the images they carry.

- the viscosity of compositions required to provide the above colloidal silica loadings are generally low enough at high shear rates to be applied to a base layer carrying one or more light-sensitive emulsion layers in one step in a multi-layer coating method, e.g. at speeds higher than 150m/min using a slide coater or curtain coater. Speeds higher than 200m/min (i.e. for example 300m/min or 350m/min) may even be achieved.

- the photographic papers of the present invention also have good writability. In other words, the papers are receptive to subsequent marking with ink and even with pencil.

- the hydrophilic colloid binder preferably is or comprises a gelatin.

- Preferred gelatins include acid-processed gelatin, mixtures comprising acid-processed gelatin and alkali-processed gelatin and optionally other hydrophilic binders.

- Preferred acid-processed gelatins include gelatins produced by treating collagen with hydrochloric acid, etc., and differ from the typical alkali-processed gelatins used in the photographic industry. Details of the processes for producing acid- and alkali-processed gelatins and the properties thereof are described in Arthus Veis, The Macromolecular Chemistry of Gelatin, pages 187-217, Academic Press (1964 ). Preferred acid-processed gelatins have an isoelectric point at a pH of about 6.0 to 9.5, whereas alkali-processed gelatin typically have an isoelectric point at a pH of about 4.5 to 5.3.

- the hydrophilic colloid binder preferably comprises an acid-processed gelatin and a further hydrophilic binder other than an acid-processed gelatin, e.g. an alkali-processed gelatin, an enzyme-processed gelatin or a gelatin derivative.

- Gelatin derivatives may be prepared by treating and modifying the functional groups contained in the gelatin molecule with chemicals other than simple acids and alkalis. For example, amino groups, imino groups, hydroxyl groups or carboxyl groups normally present in gelatin may be reacted with a compound having a group capable of reacting with such a functional group.

- One may also graft a polymer or another high molecular weight material to gelatin in order to make a gelatin derivative.

- Compounds having groups capable of reacting the functional groups in gelatin include, for example, isocyanates, acid chlorides and acid anhydrides, e.g. as described in US 2,614,928 ; acid anhydrides as described in US 3,118,766 ; bromoacetic acids; phenylglycidyl ethers; vinylsulfone compounds, e.g. as described in US 3,132,945 ; N-allylvinylsulfonamides, e.g. as described in GB 861,414 ; maleinimide compounds, e.g. as described in US 3,186,846 ; acrylonitriles, e.g.

- suitable hydrophilic colloid binders include proteins, e.g. colloidal albumin and casein; cellulose derivatives, e.g. carboxymethyl cellulose and hydroxyethyl cellulose; polysaccharides, e.g. agar-agar, sodium alginate, dextran, gum arabic and starch derivatives; and synthetic hydrophilic colloids, e.g. polyvinyl alcohol, poly-N-vinylpyrrolidone, polyacrylic acid copolymer, polymethacrylic acid copolymer, polyacrylamide and polymethacrylamide; and mixures and derivatives thereof. If desired, a compatible mixture comprising two or more of these hydrophilic colloid binders can be used.

- proteins e.g. colloidal albumin and casein

- cellulose derivatives e.g. carboxymethyl cellulose and hydroxyethyl cellulose

- polysaccharides e.g. agar-agar, sodium alginate, dextran, gum arabic and

- hydrophilic colloid binder preferably comprises at least 20wt%, more preferably at least 40wt% acid-processed gelatin.

- hydrophilic colloid binder comprises at least 20wt% of acid-processed gelatin is less than about 20wt%, and alkali-processed gelatin, enzyme-processed gelatin or a gelatin derivative is not present as part of the hydrophilic colloid binder, compositions used to apply the outer-most layer to the substrate set (solidify) particularly well, improving the likelihood that a uniform and smoothly coated surface will result.

- the said outer-most layer preferably comprises 0.2 to 1.5g/m 2 of hydrophilic colloid binder.

- the photographic paper of the present invention preferably comprises 4 to 10g/m 2 , preferably 5 to 8g/m 2 , of hydrophilic colloid binder.

- the outer-most layer comprises one or more further ingredients, for example a matting agent, hardening agent, lubricant, surface active agent and/or or pH-regulator.

- a matting agent for example a matting agent, hardening agent, lubricant, surface active agent and/or or pH-regulator.

- suitable matting agents include certain organic compounds, e.g. water-dispersible vinyl polymers, e.g. polymethylacrylate, polymethylmethacrylate and/or polystyrene, and certain inorganic compounds, e.g. silver halide, strontium barium sulphate, magnesium oxide and/or titanium oxide.

- organic compounds e.g. water-dispersible vinyl polymers, e.g. polymethylacrylate, polymethylmethacrylate and/or polystyrene

- inorganic compounds e.g. silver halide, strontium barium sulphate, magnesium oxide and/or titanium oxide.

- the outer-most layer further comprises polymethyl methacrylate (PMMA), especially PMMA having a mean size of 3 to 10 microns (e.g. 4 microns), preferably in an amount of 2 to 50mg/m 2 (e.g. 10mg/m 2 ).

- PMMA polymethyl methacrylate

- lubricants one may use, for example, a wax, liquid paraffin, a higher fatty acid esters, a polyfluorinated hydrocarbon or derivative thereof, a silicone such as polyalkylpolysiloxane, polyarylsiloxane, polyalkylarylpolysiloxane and/or an alkyleneoxide adduct thereof.

- the outer-most layer comprises one or more hardening agents.

- hardening agents may be included to enhance the physical strength of an outer-most layer.

- suitable hardening agents include aldehyde compounds, e.g. formaldehyde and glutaraldehyde; ketone compounds, e.g. diacetyl and cyclopentanedione; compounds containing reactive halogens, e.g.

- N-hydroxymethylphthalimide and compounds described in US 2,732,316 and US 2,586,168 are isocyanates, e.g. as described in US 3,103,437 ; aziridine compounds, e.g. as described in US 3,017,280 and US 2,983,611 ; the acid derivatives described in US 2,725,294 and US 2,725,295 ; carbodiimide compounds, e.g. as described in US 3,100,704 ; epoxy compounds, e.g. as described in US 3,091,537 ; isooxazole compounds, e.g. as described in US 3,321,313 and US 3,543,292 ; halocarboxyaldehydes, e.g.

- mucochloric acid dioxane derivatives, e.g. dihydroxydioxane and dichlorodioxane; and inorganic hardening agents, e.g. chrome alum and zirconium sulfate.

- hardening agent precursors such as alkali metal bisulfite-aldehyde adducts, methylol derivatives of hydantoin and primary aliphatic nitroalcohols can be used.

- a particularly preferred hardening agent is 1-oxy-3,5-dichloro-s-triazine and salts thereof, e.g. the sodium salt.

- R is particularly so when the outer-most layer comprises a hardening agent. While the above preference is expressed in terms of the outer-most layer, there is also a preference for the photographic paper as a whole (i.e. not just the outer-most layer) to have a ratio (R) of hardening agent to hydrophilic colloid binder as defined above.

- the weight of hydrophilic colloid binder is in grams on a 100% solids basis.

- the hydrophilic colloid binder is a gelatin, as is preferred, the weight of any water present in the binder is not included when calculating the weight of hydrophilic colloid binder in grams.

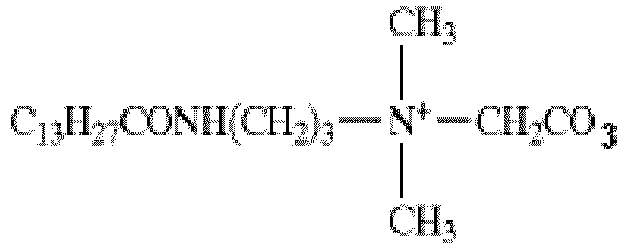

- R has a value of 0.00014 to 0.00018.

- Surface active agents can also be included in the outer-most layer, individually or as a mixture thereof, e.g., in an amount of from about 0.5 to 50mg, preferably 1 to 20mg, per g of hydrophilic colloidal binder. They are generally used as a coating aid for preventing the occurrence of difficulties such as unevenness in coating, but they are sometimes employed for other purposes, for example, for improving emulsification and dispersion, for preventing the formation of static charges. These surface active agents can be classified as natural surface active agents, e.g. such as saponin; nonionic surface active agents, e.g. such as alkylene oxide, glycerol and glycidol nonionic surface active agents; cationic surface active agents, e.g.

- anionic surface active agents containing acid groups e.g. such as carboxylic acid, sulfonic acid, phosphoric acid, sulfuric ester or phosphoric ester groups

- amphoteric surface active agents e.g. such as amino acids, aminosulfonic acids, or sulfuric or phosphoric esters of aminoalcohols.

- the surface active agents which can be used are described in, for example, US 2,271,623 , 2,240,472 , 3,441,413 , 3,442,654 , 3,475,174 and 3,545,974 , German Patent Application (OLS) No. 1,942,665 and GB 1,077,317 and GB 1,198,450 , as well as in Ryohei Oda et al., Synthesis and Applications of Surface Active Agents, Maki Publisher (1964 ), A.M. Schwartz et al., Surface Active Agents, Interscience Publications In. (1958 ), and J.P. Sisley et al., Encyclopedia of Surface Active Agents, Vol. 2, Chemical Publishing Company (1964 ).

- the photographic paper of this invention optionally contains the following components and can be prepared by the production methods described below.

- Silver halide emulsions for light-sensitive emulsion layer(s) are usually prepared by mixing a solution of a water-soluble silver salt (such as silver nitrate) with a solution of a water-soluble halide (such as potassium bromide or sodium chloride) in the presence of a solution of a water-soluble high molecular weight material such as gelatin.

- a water-soluble silver salt such as silver nitrate

- a water-soluble halide such as potassium bromide or sodium chloride

- Silver halides which can be used include silver chloride, silver bromide, as well as mixed silver halides such as silver chlorobromide, silver bromoiodide or silver chlorobromoiodide.

- the silver halide grains can be prepared using conventional methods. Of course, the grains can be advantageously prepared using the so-called single or double jet method, controlled double jet method, and the like. Moreover, two or more of silver halide photographic emulsions, separately prepared, can be mixed,

- the crystal structure of the silver halide grains can optionally be uniform throughout the grain, can have a stratified structure in which the interior and outer portion are different, or can be of the so-called conversion type as described in British Pat. No. 635,841 and US Pat. No. 622,318 .

- the silver halides can be of the type in which a latent image is formed mainly on the surface of the grains or of the type in which a latent image is formed in the interior of the grains thereof.

- the silver halide grains may, after the formation thereof, be washed with water to remove the water-soluble salts produced as by-products (for example, potassium nitrate when silver bromide is prepared using silver nitrate and potassium bromide) from the system and then heat treated in the presence of a chemical sensitizer such as sodium thiosulfate, N,N,N'-trimethylthiourea, gold(I) thiocyanate complex, gold(I) thiosulfate complex, stannous chloride or hexamethylenetetramine to increase the sensitivity without coarsening the grains.

- a chemical sensitizer such as sodium thiosulfate, N,N,N'-trimethylthiourea, gold(I) thiocyanate complex, gold(I) thiosulfate complex, stannous chloride or hexamethylenetetramine to increase the sensitivity without coarsening the grains.

- Conventional sensitizing methods are described in Mees and James

- Hydrophilic colloids which can be used as a vehicle for silver halide include gelatin, colloidal albumin, casein, cellulose derivatives such as carboxymethyl cellulose or hydroxyethyl cellulose, polysaccharides such as agar-agar, sodium alginate or starch derivatives, and synthetic hydrophilic colloids such as polyvinyl alcohol, poly-N-vinylpyrrolidone, polyacrylic acid copolymers or polyacrylamide, and the derivatives thereof and the partially hydrolyzed products thereof. If desired, a compatible mixture of two or more of these hydrophilic colloids can be used.

- gelatin is most generally used, but gelatin can be, partially or completely, replaced with a synthetic high molecular weight material. Furthermore, the gelatin can be replaced with a so-called gelatin derivative, e.g. as described above.

- synthetic polymer compounds such as a latex of water-dispersible vinyl compound polymers, particularly, compounds increasing the dimensional stability of the photographic material can be incorporated as such or as a mixture (e.g., of different polymers), or in combination with hydrophilic colloids which are permeable to water.

- synthetic polymer compounds are known, and are described, e.g., in US Pat. Nos. 2,375,005 , 3,607,290 and 3,645,740 , British Pat. Nos. 1,186,699 and 1,307,373 , etc.

- the so-called graft-type emulsionpolymerized latices of these vinyl compounds which are prepared by subjecting such a vinyl compound to emulsion polymerization in the presence of a hydrophilic protective colloid high molecular weight material can be used.

- the photographic papers of the present invention generally contain one or more light-sensitive, silver halide emulsion layers between the outer-most layer and a base layer.

- the silver halide emulsion layer(s) can be sensitized in a conventional manner.

- Suitable chemical sensitizers include, e.g., gold compounds, e.g. such as chloroaurate or auric trichloride as described in US Pat. Nos. 2,399,083 , 2,540,085 , 2,597,856 , 2,597,915 and 6,949,334 ; salts of noble metals, e.g. such as platinum, palladium, iridium, rhodium or ruthenium as described in US Pat. Nos.

- auro (I) complex having inorganic ligands auro dithiocyanate compounds such as potassium auro (I) dithiocyanate and auro dithiosulfate compound such as trisodium auro (I) dithiosulfate can be used, for example.

- auro (I) thiolate compound described in US 3,503,749 gold compounds described in JP-A Nos. 8-69074 , 8-69075 , and 9-269554 , US Pat. Nos. 5,620,841 , 5,912,112 , 5,620,841 , 5,939,245 and 5,912,111 can also be used.

- Various compounds can be added to the emulsion layer(s) of the photographic paper in order to prevent a reduction in sensitivity and the occurrence of fog during production of the photographic paper, during storage, and during processing.

- Many such compounds are known, for example, 4-hydroxy-6-methyl-1,3,3a, 7-tetraazaindene, 3-methylbenzothiazole, 1-phenyl-5-mercaptotetrazole, 5-arylamino-1,2,3,4-thiatriazole, as well as a large number of heterocyclic compounds, mercury-containing compounds, mercapto compounds, metal salts, and the like. Examples of such compounds which can be used are described in C.E.K. Mees & T.H.

- 11-327094 (particularly, those represented by the general formula (S1); descriptions in column Nos. 0036 to 0071 can be incorporated in the present specification), sulfo-substituted cathecol or hydroquinones described in JP-A No. 11-143011 (for example, 4,5-dihydroxy-1,3-benzenedisulfonic acid, 2,5-hydroxy 1,4-benzenedisulfonic acid, 3,4-dihydroxybenzenesulfonic acid, 2,3-dihydroxybenzenesulfonic acid, 2,5-dihydroxybenzenesulfonic acid, 3,4,5-trihydroxybenzenesulfonic acid and salts thereof), hydroxylamines represented by the general formula (A) in the specification US Pat. No.

- the light-sensitive emulsion layer(s) can be, if desired, spectrally sensitized or supersensitized using cyanine dyes such as cyanine, merocyanine or carbocyanine individually or in admixture, or in combination with, e.g., styryl dyes.

- cyanine dyes such as cyanine, merocyanine or carbocyanine individually or in admixture, or in combination with, e.g., styryl dyes.

- cyanine dyes such as cyanine, merocyanine or carbocyanine individually or in admixture, or in combination with, e.g., styryl dyes.

- the light-sensitive emulsion layers can be hardened if desired using a hardening agent.

- a hardening agent examples include acrylic, acrylic, and styrene.

- the emulsion layer(s) optionally contain surface active agents, individually or in admixture.

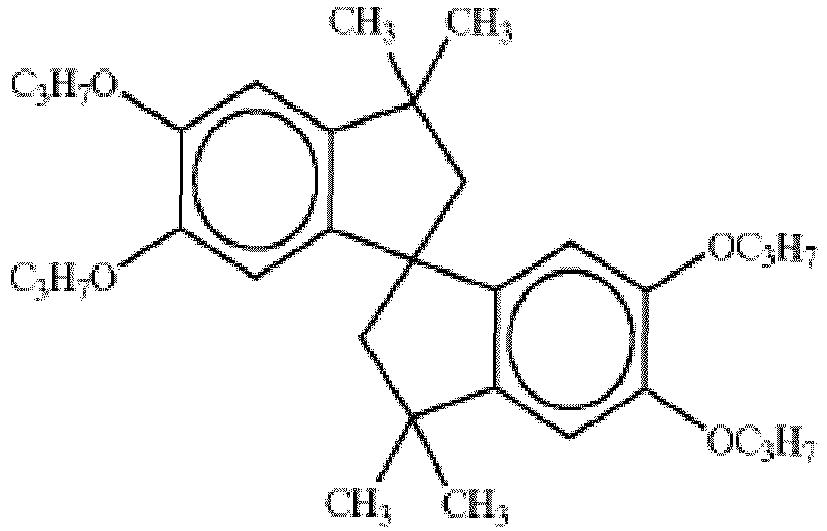

- the base layer has a silky, luster or matt appearance.

- the base layer has a specular gloss of less than 60%, more preferably from 20 to 50%, when measured at an angle of 60 degrees by the method of JIS Z8741.

- base layer comprises a paper, especially a laminated paper.

- base layer comprises a structured, laminated paper.

- the base layer comprises multiple pits and/or peaks.

- the base layer will have a non-glossy appearance (e.g. a silky, lustre or matte appearance).

- a suitable base layer e.g. a base layer having the desired specular gloss, roughness, pits, structure or lamination

- extrusion material i.e. the polymer

- the extrusion material which is typically in the form of granules, grains or powder, may be compacted, melted and homogenized in an extruder.

- the molten extrusion material may then be applied to a paper substrate by means of an extrusion die, which is adapted to the width of a paper web.

- the paper may be pretreated to achieve good bonding strength with the polymer. Flame pretreatment, corona treatment, an ozone shower or primer application may also be used to improve adhesion of the polymer to the paper.

- the extruded polymer film may then be cooled by means of a chill roll.

- the surface profile of this chill roll also has a significant influence on the surface of the resultant base layer and one may use surface rollers having a rough surface profile in order to obtain a base layer having the desired roughness, specular gloss and so forth.

- the structure of the surface of the base layer can be made "highly structured” (i.e. low gloss and high roughness) in a controlled manner simply by selecting a chill roll having the desired surface profile.

- the structured surface of the resultant base layer is a mirror image of the surface of the chill roll.

- Chill rolls having a rough surface profile may be produced by chrome plating a chill roll body and then sandblasting the chrome surface to create surface roughness. This forms a multitude of recesses, usually very fine, on the surface of the chill roll. Depending on the type and size of the sandblasting material and the duration of the treatment, silky, lustre or matte surface can be produced.

- the base layer preferably comprises a paper substrate and a polymer wherein the polymer is bonded to the paper and provides a textured surface profile thereon.

- the base layer has an average surface roughness (Sa) of from 0.9 to 5 ⁇ m, more preferably 1.0 to 4 ⁇ m and especially 1.1 to 3.9 ⁇ m, wherein the average surface roughness (Sa) is as determined by the method of ISO 25178-1-2016.

- Sa average surface roughness

- Preferred base layers are not glossy photographic paper derived from glossy supports generally do not make a noise when turned in a photo album, for example they have a silk, lustre or matte finish.

- the base layer is optionally coated or laminated with a polymer of an alpha-olefin, particularly having 2 to 10 carbon atoms, for example, polyethylene, polypropylene, ethylene-butene copolymers, etc., or synthetic resin films the surface of which has been roughened to improve the adhesion to other high molecular weight materials and improve printability.

- the lamination of the polymer on the paper is done via a multi-layer using a co-extrusion technique having pigment in an intermediate polymer layer.

- Preferred base layers are photographic grade base papers, optionally laminated on one or both sides with a polyethylene resin, preferably with a ratio of resin weight of top-side resin to back-side ranging from 0.70:1 to 1.30:1 and even more preferably between 0.85:1 and 1.15:1.

- the base layer preferably has a thickness of 70 to 250 microns (e.g. 130 or 147 or 160 or 227 microns).

- the base layer can be further coloured with a dye or a pigment if desired.

- the surface of the base layer can be subjected to a pre-treatment such as a corona discharge, an ultraviolet irradiation, an ozone treatment, a flame treatment, and the like.

- Examples of commercially available paper base layers from Schoeller having the required surface roughness Sa ( ⁇ m) and the standard deviation SD ( ⁇ m) in include the lustre, matte and pyramid papers described in Table 1 below (obtained from Schoeller): Table 1 Surface Commercial name (depending on thickness) Sa ( ⁇ m) Thickness ( ⁇ m) Laminated top side (g/m 2 ) Laminated back side (g/m 2 ) Lustre SALLF 1.90 70-240 18-24 18-24 SPFLG STLLH SULLF Matte SAMLF 0.99 70-240 18-24 18-24 SPFME SULMF Pyram id SPFSH 3.78 227 17-24 17-24 In Table 1:

- the average surface roughness (Sa) of the base layer is measured by the method of ISO 25178-1-2016, e.g. using interferometry. Sa may be determined by calculating the arithmetic average of the absolute values of the height values z of all in the x, y-plane of the viewing area lying between measured points. In each case three measurements may be performed and the mean value of the individual measurements given in ⁇ m.

- a suitable device for measuring average surface roughness (Sa) is a Bruker Contour GT-K 3D profilometer in combination with "Vision 64" software. An area of 2mm x 2mm of the paper base layer may be examined at a magnification of 10.9 x, optionally using the conditions described in the Examples below.

- the outer-most layer and light-sensitive emulsion layer(s) may be applied to a base layer by any suitable technique, including dip coating, air-knife coating, curtain coating, and extrusion coating. If desired, two or more layers can be coated at the same time using the techniques as described in US Pat. Nos. 2,761,791 , 3,508,947 , 2,941,898 and 3,526,528 .

- the outer-most layer and the underlying light-sensitive emulsion layer(s) are applied to the base layer simultaneously, preferably using a slide coater or curtain coater, preferably at a coating speed higher than 200 m/min.

- the photographic papers optionally further comprise an intermediate layer, a filter layer, a subbing layer, an antihalation layer, etc.

- the photographic papers of this invention may be developed, after exposure, to form colour images, to give what are often referred to as photographs.

- Development processing may include several steps (for example, a combination of bleaching, fixing, bleach-fixing, stabilizing, washing, etc.) and can be effected at a temperature below about 20°C, or higher temperatures, and, if desired, at above about 30°C, and preferably at about 32°C to 60°C. Again, the steps need not always be effected at the same temperature, and they can be carried out at higher or lower temperatures.

- Colour developers are alkaline aqueous solutions containing a compound whose oxidized product reacts with a colour coupler to form a dye, that is, containing, as a developing agent, p-phenylenediamines such as N,N-diethyl-p-phenylenediamine, N,N-diethy-3-methyl-p-phenylenediamine, 4-amino-3-methyl-N-ethyl-N-methanesulfonamidoethylaniline, 4-amino-3-methyl-N-ethyl-N-.beta.-hydroxyethylaniline and N-ethyl-N-.beta.-hydroxyethyl-p-phenylenediamine, or salts thereof such as the hydrochlorides, sulfates and sulfites thereof.

- p-phenylenediamines such as N,N-diethyl-p-phenylenediamine, N,N-

- the alkaline aqueous solution has a pH higher than about 8, preferably from 9 to 12.

- the compounds as described in US Pat. Nos. 2,193,015 and 2,592,364 can also been used as a developing agent.