EP2643220B1 - Method and machine for the robot wrapping of a palletized load with a cover made of flexible plastics material - Google Patents

Method and machine for the robot wrapping of a palletized load with a cover made of flexible plastics material Download PDFInfo

- Publication number

- EP2643220B1 EP2643220B1 EP11804717.4A EP11804717A EP2643220B1 EP 2643220 B1 EP2643220 B1 EP 2643220B1 EP 11804717 A EP11804717 A EP 11804717A EP 2643220 B1 EP2643220 B1 EP 2643220B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- load

- cover

- transfer

- axis

- dta

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000000034 method Methods 0.000 title claims description 12

- 229920002457 flexible plastic Polymers 0.000 title claims description 5

- 239000000463 material Substances 0.000 title claims description 3

- 238000012546 transfer Methods 0.000 claims description 38

- 238000009825 accumulation Methods 0.000 claims description 31

- 230000007246 mechanism Effects 0.000 claims description 17

- 238000004806 packaging method and process Methods 0.000 claims description 11

- 238000005259 measurement Methods 0.000 claims description 8

- 238000000151 deposition Methods 0.000 claims description 5

- 230000007480 spreading Effects 0.000 claims description 3

- 238000005187 foaming Methods 0.000 description 9

- 238000002360 preparation method Methods 0.000 description 5

- 238000012423 maintenance Methods 0.000 description 4

- 238000007493 shaping process Methods 0.000 description 4

- 229920006257 Heat-shrinkable film Polymers 0.000 description 3

- 230000008021 deposition Effects 0.000 description 3

- 238000002513 implantation Methods 0.000 description 3

- 229920003023 plastic Polymers 0.000 description 3

- 239000004033 plastic Substances 0.000 description 3

- 239000002985 plastic film Substances 0.000 description 2

- 229920006302 stretch film Polymers 0.000 description 2

- 239000004698 Polyethylene Substances 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000005693 optoelectronics Effects 0.000 description 1

- 210000000056 organ Anatomy 0.000 description 1

- 238000012858 packaging process Methods 0.000 description 1

- -1 polyethylene Polymers 0.000 description 1

- 229920000573 polyethylene Polymers 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 125000006850 spacer group Chemical group 0.000 description 1

- 238000013519 translation Methods 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

- 238000004804 winding Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B11/00—Wrapping, e.g. partially or wholly enclosing, articles or quantities of material, in strips, sheets or blanks, of flexible material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B57/00—Automatic control, checking, warning, or safety devices

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B9/00—Enclosing successive articles, or quantities of material, e.g. liquids or semiliquids, in flat, folded, or tubular webs of flexible sheet material; Subdividing filled flexible tubes to form packages

- B65B9/10—Enclosing successive articles, or quantities of material, in preformed tubular webs, or in webs formed into tubes around filling nozzles, e.g. extruded tubular webs

- B65B9/13—Enclosing successive articles, or quantities of material, in preformed tubular webs, or in webs formed into tubes around filling nozzles, e.g. extruded tubular webs the preformed tubular webs being supplied in a flattened state

- B65B9/135—Enclosing successive articles, or quantities of material, in preformed tubular webs, or in webs formed into tubes around filling nozzles, e.g. extruded tubular webs the preformed tubular webs being supplied in a flattened state for palletised loads

Definitions

- a storage reel of the sheath is placed not far from the ground, and its axis extends parallel or at another angle to the transfer conveyor of the load to be packaged.

- the unrolled sheath rises vertically along the machine to position its open end above the load to be packaged.

- the unrolled sheath passes through a device of angle returns, before or after being mounted vertically along the machine to position its opening above the load to be packaged.

- the transverse axis of supply of the sheath is merged with the transverse axis of the transfer and accumulation device, and the transverse axis of the load, and is fixed independently of the loads.

- the documents EP1060988 and EP1574433B1 each describe a device for overpacking a palletized load by means of a cover prepared from a gusseted sleeve wound flat on a storage spool.

- a gripper comprises an accumulation system on which is accumulated a portion of the sheath, a transfer arm of the roller towards the filling station, and a mechanism of separation of the cover during the downward movement around the load .

- the sheath previously welded in the transverse direction is held in vertical position with the bellows solicited in opening by a positioning member.

- the arm of the robot is animated by at least one horizontal translational movement to the filling station which runs perpendicularly to the filling station.

- the document EP-A-395919 relates to a machine for packaging a palletized load by means of a heat-shrinkable film, comprising four vertical bars equipped with film grippers able to move up and down in the frame. It further includes an annular retraction furnace, a pair of horizontal sleepers and two trolleys that can move horizontally along the sleepers. The bars come closer when the carriage moves to the dispensing section, and move apart as the carriage moves over the load to be packaged. This mechanism also ensures the houssage. The movement of the carriage also runs perpendicularly to the filling station.

- the transverse axis of the filling station is necessarily coincident with the axis of supply of the sheath. from the storage coil. This sometimes results in constraints of implantation of the storage reel of the sheath with respect to the positional constraints of the conveyor for feeding the load to be packaged.

- the longitudinal axis of the packaged load is necessarily fixed and corresponds by construction to the longitudinal axis of the transfer and accumulation device. This requires positioning the load to be packaged at the filling station precisely along both axes. In most cases, the use of a device for transverse and / or longitudinal centering of the load to be packaged is used at the filling station or upstream of it.

- a first object of the invention is to improve the method of preparing and removing a cover on a load to be packaged, to limit the constraints of implantation of the storage reel of the sheath with respect to the positional constraints of the carrier supply of the load to be packaged.

- the positioning of the load can be either measured to define said position of the median transverse axis, or programmed in advance.

- the robot is thus positioned according to a specific measurement or parameterization, and the load can be anywhere on the conveyor.

- the position of the longitudinal axis of the load to be packaged is measured and / or programmed to allow longitudinal positioning of the transfer device and accumulation of the cover. This results in the possibility of removing the longitudinal centering device used in the prior art.

- the perimeter of the sheath is calculated according to the largest perimeter of the load (union of the ground projection of the perimeters of the different planes of the load to be packaged).

- the positioning of the transfer device and accumulation of the cover according to the axes of the upper plane of the load makes it possible to balance the functional clearance during the descent of the covering mechanism around the load. It also allows to work with a sheath whose perimeter is adjusted to that of the load to be packaged and therefore to reduce the amount of cover used.

- the cover mechanism positions the gripping elements and spacing according to the position of the transfer device and accumulation of the cover.

- the foaming mechanism controls the position of its gripping and spacing elements according to the position of the load to be packaged.

- the load to be packaged may not be stopped in the foaming area.

- the position of the transverse axis of the load is measured while it is being transported, so that the overshoot mechanism controls the position of its gripping and spreading elements of the cover so that they also follow the position of the load continuously.

- the device can rotate relative to a vertical axis of a suitable angle, to ensure the proper introduction of the film on the gripping fingers and spacing. This results in the possibility of using a film adapted to the load to be packaged by limiting the impact of the size of the gripping fingers and spacing.

- the device performs a combination of movements and rotations with respect to a horizontal axis of a suitable angle to ensure the proper introduction of the film on the grasping and spreading fingers. This results in the possibility of using a film adapted to the load to be packaged by limiting the impact of the size of the gripping fingers and spacing.

- a second object of the invention is to provide a machine for shaping and removing a packaging cover on a palletized load, limiting the constraints of implantation of the storage reel of the sheath with respect to the constraints. position of the conveyor for bringing the load to be packaged and can use either a sheath with or without bellows and made of plastic or not.

- the machine comprises a transfer and accumulation device comprising an accumulator element on which is wound a portion of the sheath, and a spacing mechanism of the open end of the sheath after transfer to the filling station.

- a device for controlling and / or measuring the position and the angle of inclination of the load feed axis enables synchronization of the positioning control of the transfer device with the data of the load. measuring the position of the load, positioning said transfer device according to the position, in space, of the load to be packaged.

- the transfer device may be configured to allow a new bellows duct to be positioned on the positioner members using the first reel, while continuing to operate using the second reel.

- the reels can be located perfectly free in position, but also along an axis parallel, perpendicular or indifferent to the carrier.

- the gripper can be positioned at a defined height level and in a space dedicated to maintenance allowing good accessibility for maintenance operations.

- the gripper can prepare a new cover and anticipate the feeding of other foaming frames located in the accessible envelope.

- a packaging machine 10 for a palletised CH load is composed of a first station 11 for preparing and shaping a cover 12 from a flexible plastic film, a second position 13 for the cover for removing the cover 12 on the load CH, and a transfer device 14 between the two positions 11, 13.

- a conveyor 32 makes it possible to bring the charges CH into the second stuffing station 13 at a predetermined rate.

- the control of the transfer device 14 is provided by a robot 15 having a multidirectional actuating arm 16 of the 4 or 5-axis type, for example a FANUC robot (registered trademark), controlled by a programmable processor control circuit.

- a robot 15 having a multidirectional actuating arm 16 of the 4 or 5-axis type for example a FANUC robot (registered trademark), controlled by a programmable processor control circuit.

- the packaging cover 12 is formed by a tubular sheath made of a flexible plastic film, for example polyethylene or any other flexible heat-shrinkable plastic material, or stretchable.

- the plastic sheath has double V gussets, and is folded flat after winding around one or two reels 17, 18 for storage in the first station 11.

- the sheath is unwound from one of the reels 17 passing through rollers 19, and is held in a vertical position in the first station 11, with the bellows solicited in spacing.

- the gusseted film can also be replaced by a simple tubular sheath without gussets, and also folded flat on the coils 17, 18.

- the organs of the first preparation station 11 are identical, only change the fingers of the deposition arm.

- the removal arm is provided with shaping fingers and pinching.

- the removal arm has pleating fingers and drawing associated with motorized rollers to ensure the accordion pleating of the cover on the lower part of the fingers.

- a transfer and accumulation device DTA formed by an accumulator element 20 and a spacing mechanism 21 with four swinging arms 22 is rotatably mounted.

- the accumulator element 20 comprises, for example, a motorized rotary roller 31 on which is wound a portion of the sheath, which is held by a retaining clip integrated in the roller 31.

- the four swing arms 22 of the spacer mechanism 21 are equipped with grippers 23 for guiding and grasping the cover 12.

- the sheath is welded transversely to form a heat-sealed connection, and a predetermined length of sheath is stored on the accumulator element 20 to constitute the cover 12.

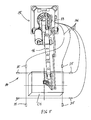

- FIGS. 1 to 4 illustrate a few operating cycles during the preparation, the transfer of the cover 12, and the cover on the load CH. These figures relate by way of example, a packaging machine with a stretch film sheath.

- the first preparation station 11 comprises two storage coils 17, 18, and the robot 15 is placed on a support 24 between the two coils 17, 18 and facing the second stuffing station 13.

- the actuating arm 16 of the robot 15 is rotatably mounted 360 ° about a vertical axis 25 on a rotatable base 26 of the support 24.

- the actuating arm 16 can also pivot about a horizontal axis 27 to allow up and down movements . The travel The direction of the actuating arm 16 is thus possible above the two stations 11, 13.

- the figure 2 illustrates the transfer of the cover 12 wound on the accumulator element 20 to the second filling station 13.

- the four rocking arms 22 are actuated to the spaced apart position to cause the opening of the lower free end of the cover 12.

- the fingers 28 can move horizontally along the removal arm 29 to be placed under the clamps 23 of the rocking arms 22.

- the removal arm 29 is movable in the upward and downward direction by means of a control mechanism 30 in vertical translation.

- the figure 4 shows the end of the foaming operation, the load CH being totally packed by the cover 12.

- the deposition arm 29 is in the low position, and the robot 15 has moved the accumulator element 20 towards the first preparation station. a new cover.

- the load CH to be packaged is transported by the conveyor to the area of foaming.

- a control system 34 measures the position of the load CH when it is stopped.

- the control system 34 is provided with a plurality of optoelectronic sensors distributed along a certain grid covering a surface greater than that of the top of the charge CH.

- the different sensors 35 are electrically connected by connecting wires 36 to the control circuit 33 of the robot 15.

- the positioning of the load (CH) can be programmed in advance after memory of certain parameters in the control circuit.

- the load stops in a predetermined position, and the robot is placed in a programmed position, without requiring any prior measurement.

- transverse center axis a1 of the load CH is perpendicular to the longitudinal axis a2 of the conveyor 32, and is separated by a distance D1 from the supply axis a3 of the sheath from the spool 17 This latter is placed parallel to the direction of movement of the conveyor 32.

- the sensors 35 measure the position of the median transverse axis a1 of the load to be packaged with respect to the supply axis a2 of the sheath.

- the control circuit 33 of the robot 15 causes the transfer and accumulation device DTA of the cover to move over the charge CH, synchronizing the positioning control of said device with the data of the measurement of the position of the load to pack.

- the spool 17 is moved 90 ° extending parallel to the conveyor 32.

- a return 37 redirects the sheath to the preparation station 38, and the direction of the supply axis a3 of the sheath is identical to the figure 6 .

- the longitudinal median axis a4 of the load CH is different from the longitudinal axis a2 of the conveyor 32.

- the control system 34 measures the position of the longitudinal central axis a4 of the load CH to be packaged to allow longitudinal positioning of the DTA transfer and accumulation device of the cover 12. This results in the possibility of removing the longitudinal centering device used in the prior art.

- the longitudinal axis a2 of the conveyor 32 forms an angle A different from 90 ° with the supply axis a3 of the sheath.

- the sensors then perform a measurement of the angular position of the two axes a1 and a2 of the charge CH to enable the device to be rotated. of transfer and accumulation DTA with respect to a vertical axis of a suitable angle.

- the figures 10 and 11 show a load CH with a deformation which generally results from an offset of the upper plane of the load relative to the lower plane.

- the control system 34 performs a measurement of the position of the two axes (transverse and longitudinal) of the upper plane of the load CH.

- the transfer and accumulation device DTA of the cover 12 can then be positioned along these axes, and makes it possible to better balance the functional clearance during the descent of the covering mechanism around the load. It also allows to work with a sheath whose perimeter is adjusted to that of the load to be packaged and therefore to reduce the amount of cover used.

- the CTA transfer and accumulation device can be positioned by the arm 16 of the robot 15 at a defined height level and in a space dedicated to maintenance allowing good accessibility for maintenance operations.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Basic Packing Technique (AREA)

Description

L'invention est relative à un procédé et un dispositif de mise en forme et de dépose d'une housse d'emballage sur une charge palettisée, ladite housse étant préparée à partir d'une gaine en matière plastique souple enroulée sur au moins une bobine de stockage, procédé consistant à :

- stocker sur un dispositif de transfert et d'accumulation une longueur prédéterminée de gaine pour constituer une housse fermée à une extrémité,

- reprendre l'extrémité ouverte opposée, et descendre la housse autour de la charge à emballer, en la maintenant écartée par ses quatre angles.

- storing on a transfer and accumulation device a predetermined length of sheath to form a cover closed at one end,

- take the opposite open end, and lower the cover around the load to be wrapped, keeping it separated by its four corners.

La plupart des machines connues possèdent un dispositif d'ouverture de la gaine placé, pendant l'opération de houssage, au-dessus de la charge à emballer, celle-ci étant introduite selon un cycle séquentiel automatisé dans la machine par l'intermédiaire d'un transporteur à rouleaux ou à chaînes et positionnée avec précision sous le dispositif d'ouverture de la gaine.Most known machines have a device for opening the sheath placed, during the foaming operation, above the load to be packaged, the latter being introduced in an automated sequential cycle into the machine via a roller or chain conveyor and accurately positioned under the opening device of the sheath.

Dans ces machines, une bobine de stockage de la gaine est placée non loin du sol, et son axe s'étend parallèlement ou selon un autre angle au transporteur de transfert de la charge à emballer.In these machines, a storage reel of the sheath is placed not far from the ground, and its axis extends parallel or at another angle to the transfer conveyor of the load to be packaged.

Dans la version où la bobine est parallèle au transporteur, la gaine déroulée monte verticalement le long de la machine pour positionner son extrémité ouverte au-dessus de la charge à emballer.In the version where the coil is parallel to the conveyor, the unrolled sheath rises vertically along the machine to position its open end above the load to be packaged.

Dans la version où l'axe de la bobine est positionné selon un autre angle non parallèle au transporteur, la gaine déroulée passe par un dispositif de renvoie d'angle, avant ou après être montée verticalement le long de la machine pour positionner son ouverture au-dessus de la charge à emballer. Dans ces deux cas, l'axe transversal d'amenée de la gaine est confondu avec l'axe transversal du dispositif de transfert et d'accumulation, et l'axe transversal de la charge, et est fixe indépendamment des charges.In the version where the axis of the coil is positioned at another angle not parallel to the conveyor, the unrolled sheath passes through a device of angle returns, before or after being mounted vertically along the machine to position its opening above the load to be packaged. In these two cases, the transverse axis of supply of the sheath is merged with the transverse axis of the transfer and accumulation device, and the transverse axis of the load, and is fixed independently of the loads.

Les documents

Le document

Dans des systèmes connus de ce type, l'axe transversal du poste de houssage est obligatoirement confondu avec l'axe d'amenée de la gaine en provenance de la bobine de stockage. Il en résulte parfois des contraintes d'implantation de la bobine de stockage de la gaine par rapport aux contraintes de position du transporteur d'amenée de la charge à emballer.In known systems of this type, the transverse axis of the filling station is necessarily coincident with the axis of supply of the sheath. from the storage coil. This sometimes results in constraints of implantation of the storage reel of the sheath with respect to the positional constraints of the conveyor for feeding the load to be packaged.

De plus l'axe longitudinal de la charge à emballée est obligatoirement fixe et correspond par construction à l'axe longitudinal du dispositif de transfert et d'accumulation. Ceci impose de positionner la charge à emballer au poste de houssage avec précision selon les deux axes. Dans la plupart des cas, l'utilisation d'un dispositif de centrage transversal et/ou longitudinal de la charge à emballer est utilisé au poste de houssage ou en amont de celui-ci.In addition, the longitudinal axis of the packaged load is necessarily fixed and corresponds by construction to the longitudinal axis of the transfer and accumulation device. This requires positioning the load to be packaged at the filling station precisely along both axes. In most cases, the use of a device for transverse and / or longitudinal centering of the load to be packaged is used at the filling station or upstream of it.

Un premier objet de l'invention consiste à améliorer le procédé de préparation et de dépose d'une housse sur une charge à emballer, pour limiter les contraintes d'implantation de la bobine de stockage de la gaine par rapport aux contraintes de position du transporteur d'amenée de la charge à emballer.A first object of the invention is to improve the method of preparing and removing a cover on a load to be packaged, to limit the constraints of implantation of the storage reel of the sheath with respect to the positional constraints of the carrier supply of the load to be packaged.

Le procédé d'emballage selon l'invention est caractérisé par les étapes intermédiaires suivantes :

- déterminer la position de l'axe transversal médian de la charge à emballer par rapport à l'axe d'amenée de la gaine,

- déplacer le dispositif de transfert et d'accumulation de la housse au-dessus de la charge à emballer, en synchronisant la commande de positionnement dudit dispositif avec les données de la position de la charge à emballer.

- determine the position of the median transverse axis of the load to be packaged relative to the axis of supply of the sheath,

- moving the transfer and accumulation device of the cover over the load to be packaged, by synchronizing the positioning control of said device with the data of the position of the load to be packaged.

Le positionnement de la charge peut être soit mesuré pour définir ladite position de l'axe transversal médian, soit programmé d'avance. Le robot est ainsi positionné selon une mesure ou un paramétrage spécifique, et la charge peut se trouver n'importe où sur le convoyeur.The positioning of the load can be either measured to define said position of the median transverse axis, or programmed in advance. The robot is thus positioned according to a specific measurement or parameterization, and the load can be anywhere on the conveyor.

Pendant l'étape de positionnement de la charge à emballer, la position de l'axe longitudinal de la charge à emballer est mesurée et/ou programmée pour permettre un positionnement longitudinal du dispositif de transfert et d'accumulation de la housse. Il en résulte la possibilité de supprimer le dispositif de centrage longitudinal utilisé dans l'art antérieur.During the step of positioning the load to be packaged, the position of the longitudinal axis of the load to be packaged is measured and / or programmed to allow longitudinal positioning of the transfer device and accumulation of the cover. This results in the possibility of removing the longitudinal centering device used in the prior art.

Il est également possible de mesurer et/ou de programmée la position des deux axes transversal et longitudinal du plan supérieur de la charge à emballer. Le dispositif de transfert et d'accumulation de la housse peut alors être positionné selon ces axes. Il en résulte la possibilité d'utiliser des gaines ayant un périmètre ajusté au périmètre de la charge à emballer. En effet dans cette version le périmètre d'une gaine est calculé en fonction d'un jeu fonctionnel nécessaire entre le périmètre de la charge à emballer et celui de la housse. Dans la plupart des cas, les charges à emballer présentent une déformation qui résulte généralement d'un décalage du plan supérieur de la charge par rapport au plan inférieur. Afin de préserver le film des frottements sur la charge à emballer, le périmètre de la gaine est calculé en fonction du plus grand périmètre de la charge (union de la projection au sol des périmètres des différents plans de la charge à emballer). Le positionnement du dispositif de transfert et d'accumulation de la housse selon les axes du plan supérieur de la charge permet d'équilibrer au mieux le jeu fonctionnel pendant la descente du mécanisme de houssage autour de la charge. Il permet également de travailler avec une gaine dont le périmètre est ajusté à celui de la charge à emballer et donc de diminuer la quantité de housse utilisée.It is also possible to measure and / or programmed the position of the two transverse and longitudinal axes of the upper plane of the load to be packaged. The transfer device and accumulation of the cover can then be positioned along these axes. This results in the possibility of using sheaths having a perimeter adjusted to the perimeter of the load to be packaged. Indeed in this version the perimeter of a sheath is calculated based on a necessary functional clearance between the perimeter of the load to be packaged and that of the cover. In most cases, the loads to be packaged have a deformation which generally results from a shift of the upper plane of the load relative to the lower plane. In order to preserve the film friction on the load to be packaged, the perimeter of the sheath is calculated according to the largest perimeter of the load (union of the ground projection of the perimeters of the different planes of the load to be packaged). The positioning of the transfer device and accumulation of the cover according to the axes of the upper plane of the load makes it possible to balance the functional clearance during the descent of the covering mechanism around the load. It also allows to work with a sheath whose perimeter is adjusted to that of the load to be packaged and therefore to reduce the amount of cover used.

Durant l'étape de prise de la housse et d'écartement de celle-ci, le mécanisme de houssage positionne les éléments de prise et d'écartement en fonction de la position du dispositif de transfert et d'accumulation de la housse.During the step of taking the cover and spacing thereof, the cover mechanism positions the gripping elements and spacing according to the position of the transfer device and accumulation of the cover.

Durant l'étape de descente autour de la charge, le mécanisme de houssage commande la position de ses éléments de prise et d'écartement en fonction de la position de la charge à emballée.During the descent step around the load, the foaming mechanism controls the position of its gripping and spacing elements according to the position of the load to be packaged.

La charge à emballer peut ne pas être arrêtée dans la zone de houssage. La mesure de la position de l'axe transversal de la charge se fait pendant qu'elle est transportée, afin que le mécanisme de houssage commande la position de ses éléments de prise et d'écartement de la housse pour qu'ils suivent également la position de la charge en continu.The load to be packaged may not be stopped in the foaming area. The position of the transverse axis of the load is measured while it is being transported, so that the overshoot mechanism controls the position of its gripping and spreading elements of the cover so that they also follow the position of the load continuously.

Il est également possible de mesurer et/ou de programmer la position angulaire des deux axes transversal et longitudinal de la charge à emballer. Durant l'étape de transfert et de prise de la housse par le mécanisme de houssage, intervient une rotation par rapport à un axe vertical d'un angle adapté afin d'assurer une bonne position par rapport à la charge.It is also possible to measure and / or program the angular position of the two transverse and longitudinal axes of the load to be packaged. During the step of transferring and taking the cover by the shading mechanism, rotates relative to a vertical axis of a suitable angle to ensure a good position relative to the load.

Il en résulte la possibilité de positionner la housse dans le meilleur sens en fonction de la charge à emballer, mais également de s'adapter à un axe d'amenée de la charge qui ne serait pas perpendiculaire à l'axe d'amenée de la gaine.This results in the possibility of positioning the cover in the best direction according to the load to be packaged, but also to adapt to an axis of supply of the load which would not be perpendicular to the axis of supply of the sheath.

Durant l'étape de transfert et de prise de la housse par le mécanisme de houssage, le dispositif peut effectuer une rotation par rapport à un axe vertical d'un angle adapté, afin d'assurer la bonne introduction du film sur les doigts de prise et d'écartement. Il en résulte la possibilité d'utiliser un film adapté à la charge à emballer en limitant l'impact de l'encombrement des doigts de prise et d'écartement.During the step of transferring and taking the cover by the foaming mechanism, the device can rotate relative to a vertical axis of a suitable angle, to ensure the proper introduction of the film on the gripping fingers and spacing. This results in the possibility of using a film adapted to the load to be packaged by limiting the impact of the size of the gripping fingers and spacing.

Durant l'étape de transfert et de prise de la housse par le mécanisme de houssage, le dispositif effectue une combinaison de mouvements et de rotations par rapport à un axe horizontal d'un angle adapté afin d'assurer la bonne introduction du film sur les doigts de prise et d'écartement. Il en résulte la possibilité d'utiliser un film adapté à la charge à emballer en limitant l'impacte de l'encombrement des doigts de prise et d'écartement.During the step of transferring and gripping the cover by the cover mechanism, the device performs a combination of movements and rotations with respect to a horizontal axis of a suitable angle to ensure the proper introduction of the film on the grasping and spreading fingers. This results in the possibility of using a film adapted to the load to be packaged by limiting the impact of the size of the gripping fingers and spacing.

Le dispositif d'ouverture et de débit de la housse est positionné sur un plan vertical à une hauteur calculée en fonction de plusieurs paramètres, notamment la hauteur de la charge, afin d'assurer le bon guidage du film :

- pendant l'étape de descente du mécanisme de houssage autour de la charge pour une première version. Il en résulte une meilleure maîtrise de la dépose de la housse afin d'éliminer les frottements de la housse sur la charge à emballer ;

- pendant l'étape de plissage de la housse sur les doigts pour une autre version. Il en résulte une meilleure maîtrise des frottements sur les doigts de plissage.

- during the descent step of the foaming mechanism around the load for a first version. This results in better control of the removal of the cover to eliminate the friction of the cover on the load to be packaged;

- during the pleating step of the cover on the fingers for another version. This results in better control of the friction on the pleating fingers.

Un deuxième objet de l'invention consiste à réaliser une machine pour la mise en forme et la dépose d'une housse d'emballage sur une charge palettisée, limitant les contraintes d'implantation de la bobine de stockage de la gaine par rapport aux contraintes de position du transporteur d'amenée de la charge à emballer et pouvant utiliser indifféremment une gaine avec ou sans soufflet et réalisée en matière plastique ou non.A second object of the invention is to provide a machine for shaping and removing a packaging cover on a palletized load, limiting the constraints of implantation of the storage reel of the sheath with respect to the constraints. position of the conveyor for bringing the load to be packaged and can use either a sheath with or without bellows and made of plastic or not.

La machine comporte un dispositif de transfert et d'accumulation comprenant un élément accumulateur sur lequel est enroulée une partie de la gaine, et un mécanisme d'écartement de l'extrémité ouverte de la gaine après transfert vers le poste de houssage. Selon l'invention, un dispositif de contrôle et/ou de mesure de la position et de l'angle d'inclinaison de l'axe d'amenée de la charge permet en synchronisant la commande de positionnement du dispositif de transfert avec les données de la mesure de la position de la charge, d'effectuer un positionnement dudit dispositif de transfert en fonction de la position, dans l'espace, de la charge à emballer.The machine comprises a transfer and accumulation device comprising an accumulator element on which is wound a portion of the sheath, and a spacing mechanism of the open end of the sheath after transfer to the filling station. According to the invention, a device for controlling and / or measuring the position and the angle of inclination of the load feed axis enables synchronization of the positioning control of the transfer device with the data of the load. measuring the position of the load, positioning said transfer device according to the position, in space, of the load to be packaged.

D'autres caractéristiques peuvent être utilisées en combinaison :Other features can be used in combination:

Le dispositif de transfert peut être configuré pour permettre la mise en place d'une nouvelle gaine à soufflet sur les organes positionneur en utilisant le premier dévidoir, alors qu'il continu de fonctionner en utilisant le deuxième dévidoir.The transfer device may be configured to allow a new bellows duct to be positioned on the positioner members using the first reel, while continuing to operate using the second reel.

Les dévidoirs peuvent être implantés de manière parfaitement libres en position, mais également selon un axe parallèle, perpendiculaire ou indifférent par rapport au transporteur.The reels can be located perfectly free in position, but also along an axis parallel, perpendicular or indifferent to the carrier.

Le préhenseur peut être positionné à un niveau de hauteur défini et dans un espace dédié à la maintenance permettant une bonne accessibilité pour les opérations de maintenance.The gripper can be positioned at a defined height level and in a space dedicated to maintenance allowing good accessibility for maintenance operations.

Pendant la phase de houssage, le préhenseur peut préparer une nouvelle housse et anticiper l'alimentation d'autres cadres de houssage implantés dans l'enveloppe accessible.During the foaming phase, the gripper can prepare a new cover and anticipate the feeding of other foaming frames located in the accessible envelope.

D'autres avantages et caractéristiques ressortiront plus clairement de la description qui va suivre d'un mode de réalisation de l'invention donné à titre d'exemple non limitatif et représenté aux dessins annexés, dans lesquels :

- Les

figures 1 à 4 décrivent la machine d'emballage selon l'invention avec différents cycles de fonctionnement ; - La

figure 5 représente une vue en plan du robot et du système de contrôle de la position de la charge ; - Les

figures 6 à 9 sont des vues en plan de la machine avec différentes configurations de l'amenée de la gaine par rapport au convoyeur ; - Les

figures 10 et11 montrent des vues en élévation et de profil du dispositif de transfert et d'accumulation avec une charge déformée à emballer ; - Les

figures 12 et13 représentent des vues du dispositif de transfert et d'accumulation positionné par le bras du robot à deux niveaux de hauteur.

- The

Figures 1 to 4 describe the packaging machine according to the invention with different operating cycles; - The

figure 5 represents a plan view of the robot and the position control system of the load; - The

Figures 6 to 9 are plan views of the machine with different configurations of the supply of the sheath relative to the conveyor; - The

figures 10 and11 show elevational and side views of the transfer and accumulation device with a deformed load to be packaged; - The

figures 12 and13 represent views of the transfer and accumulation device positioned by the robot arm at two levels of height.

Sur les figures, une machine d'emballage 10 d'une charge CH palettisée, est composée d'un premier poste 11 de préparation et de mise en forme d'une housse 12 à partir d'un film en matière plastique souple, d'un deuxième poste 13 de houssage pour la dépose de la housse 12 sur la charge CH, et d'un dispositif de transfert 14 entre les deux postes 11, 13.In the figures, a

Un convoyeur 32 permet d'amener les charges CH dans le deuxième poste de houssage 13 selon une cadence prédéterminée.A

La commande du dispositif de transfert 14 est assurée par un robot 15 à bras d'actionnement 16 multidirectionnel du type 4 ou 5 axes, par exemple un robot FANUC (marque déposée), piloté par un circuit de commande à processeur programmable.The control of the

La housse 12 d'emballage est formée par une gaine tubulaire constituée par un film en matière plastique souple, par exemple en polyéthylène ou toute autre matière plastique souple thermorétractable, ou étirable. La gaine plastique comporte des soufflets en double V, et est pliée à plat après enroulement autour d'une ou deux bobines 17, 18 de stockage dans le premier poste 11. La gaine est déroulée de l'une des bobines 17 en passant par des galets 19, et est maintenue en position verticale dans le premier poste 11, avec les soufflets sollicités en écartement.The

Le film à soufflets peut aussi être remplacé par une simple gaine tubulaire sans soufflets, et également pliée à plat sur les bobines 17, 18.The gusseted film can also be replaced by a simple tubular sheath without gussets, and also folded flat on the

Dans les deux versions de machines d'emballage avec une housse à film thermorétractable, ou étirable, les organes du premier poste de préparation 11 sont identiques, seuls changent les doigts du bras de dépose. Dans le cas de film thermorétractable, le bras de dépose est muni de doigts de conformation et de pincement. Dans le cas de film étirable, le bras de dépose comporte des doigts de plissage et d'étirage associés à des galets motorisés pour assurer le plissage en accordéon de la housse sur la partie basse des doigts.In both versions of packaging machines with a heat-shrinkable film cover, or stretchable, the organs of the

Au bras d'actionnement 16 du robot 15, est monté à rotation un dispositif de transfert et d'accumulation DTA formé par un élément accumulateur 20 et un mécanisme d'écartement 21 à quatre bras balanciers 22. L'élément accumulateur 20 comprend à titre d'exemple, un rouleau 31 rotatif motorisé sur lequel est enroulée une partie de la gaine, laquelle est maintenue par une pince de retenue intégrée dans le rouleau 31. Les quatre bras balanciers 22 du mécanisme d'écartement 21 sont équipés de pinces de préhension 23 pour guider et saisir la housse 12. On soude transversalement la gaine pour former une liaison thermosoudée, et on stocke sur l'élément accumulateur 20 une longueur prédéterminée de gaine pour constituer la housse 12.At the

Les

Sur la

La

Dans la

La

Sur la

Selon une variante, le positionnement de la charge (CH) peut être programmé d'avance après mise mémoire de certains paramètres dans le circuit de commande. La charge s'arrête dans une position prédéterminée, et le robot vient se placer dans une position programmée, sans nécessiter de mesure préalable.According to one variant, the positioning of the load (CH) can be programmed in advance after memory of certain parameters in the control circuit. The load stops in a predetermined position, and the robot is placed in a programmed position, without requiring any prior measurement.

Dans la

Dans ce cas, les capteurs 35 mesurent la position de l'axe transversal médian a1 de la charge à emballer par rapport à l'axe d'amenée a2 de la gaine. Le circuit de contrôle 33 du robot 15 provoque le déplacement du dispositif de transfert et d'accumulation DTA de la housse au-dessus de la charge CH, en synchronisant la commande de positionnement dudit dispositif avec les données de la mesure de la position de la charge à emballer.In this case, the

Sur la

Sur la

Sur la

Il en résulte la possibilité de positionner la housse 12 dans le meilleur sens en fonction de la charge CH à emballer, mais également de s'adapter à un axe d'amené de la charge qui ne serait pas perpendiculaire à l'axe d'amené de la gaine.This results in the possibility of positioning the

Les

Sur les

Claims (9)

- A method for forming and depositing a packaging cover (12) on a palletized load (CH), said cover being prepared from a sleeve made from flexible plastic material wound on at least one storage reel (17, 18), a method consisting in:- storing a predefined length of sleeve on a transfer and accumulation device (DTA) to constitute a cover (12) closed at one end,- taking up the opposite open end, and moving the cover (12) down around the load (CH) to be packaged, keeping it spread open via its four corners.characterized by the following intermediate steps:- determining the position of the transverse mid-axis (a1) of the load (CH) with respect to the feed axis (a3) of the sleeve,- and moving the transfer and accumulation device (DTA) of the cover (12) above the load (CH), synchronizing the positioning control of said transfer and accumulation device (DTA) with the position data of the load (CH).

- The method according to claim 1, characterized in that positioning of the load (CH) is performed by measurement of said position of the transverse mid-axis (a1).

- The method according to claim 1, characterized in that positioning of the load (CH) is programmed to place the robot in a predefined position.

- The method according to claim 1, characterized in that the position of the longitudinal mid-axis (a4) of the load (CH) is measured and/or programmed to adjust a longitudinal positioning of the transfer and accumulation device (DTA) of the cover (12).

- The method according to claim 4, characterized in that the position of the transverse mid axis (a1) and of the longitudinal mid-axis (a4) of the top plane of the load (CH) is measured and/or programmed to adjust the position of the transfer and accumulation device (DTA) of the cover (12).

- The method according to claim 4, characterized by measurement and/or programming of the angular position of the two transverse (a1) and longitudinal (a4) axes of the load (CH) to be packaged.

- The method according to one of the previous claims, characterized in that the covering mechanism adjusts the fingers (28) of the depositing arm (29) to the transfer position of the transfer and accumulation device (DTA) and the position of the load (CH).

- A packaging machine controlled by a robot (15) and comprising:- a transfer and accumulation device (DTA) on which a cover (12) is wound,- a mechanism (21) for separating the open end of the cover (12) after transfer to a covering station (13),characterized in that it comprises a control system (34) with sensors (35) designed to measure the position and inclination angle of the feed axis of the load synchronizing positioning control of the transfer and accumulation device (DTA) with the position measurement data of the load (CH).

- The packaging machine according to claim 8, characterized in that the transfer and accumulation device (DTA) performs a combination of movements and rotations through a suitable angle with respect to a horizontal axis in order to ensure correct introduction of the film on the take-up and spreading fingers (28).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR1004538A FR2967648B1 (en) | 2010-11-22 | 2010-11-22 | ROBOT PACKAGING METHOD AND MACHINE OF A PALLETIZED LOAD USING A SOFT PLASTIC COVER |

| PCT/FR2011/000612 WO2012069712A1 (en) | 2010-11-22 | 2011-11-22 | Method and machine for the robot wrapping of a palletized load with a cover made of flexible plastics material |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2643220A1 EP2643220A1 (en) | 2013-10-02 |

| EP2643220B1 true EP2643220B1 (en) | 2014-11-05 |

Family

ID=44140715

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP11804717.4A Active EP2643220B1 (en) | 2010-11-22 | 2011-11-22 | Method and machine for the robot wrapping of a palletized load with a cover made of flexible plastics material |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US10343798B2 (en) |

| EP (1) | EP2643220B1 (en) |

| CN (1) | CN103370260B (en) |

| DK (1) | DK2643220T3 (en) |

| ES (1) | ES2527818T3 (en) |

| FR (1) | FR2967648B1 (en) |

| WO (1) | WO2012069712A1 (en) |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ITMI20121689A1 (en) * | 2012-10-09 | 2014-04-10 | Sestese Off Mec | PACKAGING PACKING MACHINE PERFECTED, WITH AUTOMATIC CHANGE OF COILS. |

| SMP201500193B (en) * | 2015-08-07 | 2017-03-08 | Busca Andrea Ing | SELF PROPELLED WINDING MACHINE AND SYSTEM AND WINDING METHOD |

| US11370128B2 (en) | 2015-09-01 | 2022-06-28 | Berkshire Grey Operating Company, Inc. | Systems and methods for providing dynamic robotic control systems |

| US10647002B2 (en) | 2015-09-01 | 2020-05-12 | Berkshire Grey, Inc. | Systems and methods for providing dynamic robotic control systems |

| CA3156178C (en) | 2015-09-08 | 2023-10-31 | Berkshire Grey Operating Company, Inc. | Systems and methods for providing dynamic vacuum pressure in an articulated arm end effector |

| CA3045522C (en) | 2016-12-06 | 2023-10-03 | Berkshire Grey, Inc. | Systems and methods for providing for the processing of objects in vehicles |

| EP3592510B1 (en) | 2017-03-06 | 2023-09-06 | Berkshire Grey Operating Company, Inc. | Systems and methods for efficiently moving a variety of objects |

| CN113748000B (en) | 2019-04-25 | 2024-04-05 | 伯克希尔格雷营业股份有限公司 | System and method for maintaining vacuum hose life in a hose routing system in a programmable motion system |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1923672B2 (en) * | 1969-05-09 | 1976-02-26 | Nütro Hirsch & Co, 8500 Nürnberg; Intra Maschinenbau- und Handels-GmbH, 4720 Beckum | DEVICE FOR COVERING A FLAT LAYED FILM TUBE OVER A LOADED PALLET |

| US3897674A (en) * | 1973-08-31 | 1975-08-05 | Comptex | Bagging machine |

| DE3011264A1 (en) * | 1980-03-24 | 1981-10-01 | Ing. Paul Joosten Verpackungstechnik, 4180 Goch | FILM COVER |

| JPS6132113A (en) * | 1984-07-23 | 1986-02-14 | Seiko Instr & Electronics Ltd | Robot control system |

| IT1229317B (en) | 1989-05-02 | 1991-08-08 | Sestese Off Mec | AUTOMATIC WRAPPING MACHINE FOR THE PACKAGING OF PRODUCTS, IN PARTICULAR OF PALLETIZED UNITS, WITH HEAT-SHRINKABLE TUBULAR FILM. |

| US5761881A (en) * | 1995-05-10 | 1998-06-09 | Wall; Benjamin | Process and apparatus for wrapping paper rolls |

| FR2794720B1 (en) * | 1999-06-10 | 2001-08-31 | Thimon | METHOD AND DEVICE FOR FORMING AND DEPOSITING A FLEXIBLE HEAT SHRINK COVER ON A PALLETIZED LOAD |

| DE10020856B9 (en) * | 2000-04-28 | 2007-10-04 | MSK-Verpackungs-Systeme Gesellschaft mit beschränkter Haftung | Device for wrapping piece or packaged goods |

| DE20101909U1 (en) * | 2001-01-25 | 2002-06-13 | MSK-Verpackungs-Systeme GmbH, 47533 Kleve | Device for wrapping a stack of goods |

| FR2867452B1 (en) | 2004-03-11 | 2007-06-01 | Thimon | METHOD AND DEVICE FOR SHAPING AND REMOVING HIGH PURPOSE OF A PACKAGING COVER ON A PALLETIZED LOAD |

| FR2893005A1 (en) | 2005-11-10 | 2007-05-11 | Thimon Sa | METHOD AND MACHINE FOR PREPARING AND REMOVING A PACKAGING SLEEVE FROM A PALLETIZED LOAD |

| US20080236108A1 (en) * | 2007-03-29 | 2008-10-02 | Parmley Steven M | Package Wrapping Machine with Detection of Lip Features of Trayed Products to be Wrapped |

-

2010

- 2010-11-22 FR FR1004538A patent/FR2967648B1/en not_active Expired - Fee Related

-

2011

- 2011-11-22 DK DK11804717.4T patent/DK2643220T3/en active

- 2011-11-22 CN CN201180065639.2A patent/CN103370260B/en active Active

- 2011-11-22 EP EP11804717.4A patent/EP2643220B1/en active Active

- 2011-11-22 US US13/988,701 patent/US10343798B2/en not_active Expired - Fee Related

- 2011-11-22 ES ES11804717.4T patent/ES2527818T3/en active Active

- 2011-11-22 WO PCT/FR2011/000612 patent/WO2012069712A1/en active Application Filing

Also Published As

| Publication number | Publication date |

|---|---|

| CN103370260A (en) | 2013-10-23 |

| FR2967648B1 (en) | 2012-12-07 |

| DK2643220T3 (en) | 2015-01-26 |

| CN103370260B (en) | 2015-03-04 |

| WO2012069712A1 (en) | 2012-05-31 |

| ES2527818T3 (en) | 2015-01-30 |

| WO2012069712A8 (en) | 2014-04-17 |

| US10343798B2 (en) | 2019-07-09 |

| EP2643220A1 (en) | 2013-10-02 |

| US20130232919A1 (en) | 2013-09-12 |

| FR2967648A1 (en) | 2012-05-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2643220B1 (en) | Method and machine for the robot wrapping of a palletized load with a cover made of flexible plastics material | |

| EP1574433B1 (en) | Method and apparatus for the manufacturing and applying at high speed of a packaging hood on a palettised load. | |

| EP1951577B1 (en) | Method and machine for preparing and depositing a stretch-film packaging sleeve on a palletized load | |

| KR101968334B1 (en) | Automatic packing apparatus for mask | |

| CA2886722C (en) | Apparatus for filling bags with adjustment of the opening/closing travel of the bag-holder valves | |

| CN106477099A (en) | Line style tubing packer | |

| CN111295338B (en) | Machine for forming filter bags for infusion products | |

| EP3031548B1 (en) | Ring setting module and method for distribution of rings using a ring storage barrel | |

| EP2551222A1 (en) | Installation for handling products, especially slices of food | |

| EP1060988B1 (en) | Method and device for making and applying a flexible heat-shrinkable hood on palletized load | |

| CH681538A5 (en) | ||

| KR20170032863A (en) | Bale wrapper | |

| JP4398220B2 (en) | Rice polishing bagging and packaging equipment | |

| FR2566635A1 (en) | Device for automatic transfer of a shoe between machines | |

| FR2574753A1 (en) | METHOD AND MACHINE FOR FILLING AND STOPPING BOTTLES | |

| FR3013687A1 (en) | DEVICE FOR CONVEYING A CASE FOR A MACHINE | |

| EP1422143A1 (en) | Apparatus for wrapping a load by means of a plastic foil | |

| KR101636724B1 (en) | Gate unit for guiding apparatus of clipping system | |

| WO2022033807A1 (en) | Machine for preparing a strip provided with tags and thread segments for the manufacture of infusion bag systems | |

| FR2703324A1 (en) | Machines for packaging containers in a net | |

| IT9019992A1 (en) | BAGGING AND BOXING MACHINE PARTICULARLY FOR SPOOLS OF YARNS AND SIMILAR | |

| FR2462343A1 (en) | Transfer installation for packages - moves packages from supply shaft to compartments of moving conveyor with drivers and back stops | |

| EP0305463A1 (en) | Process and machine for automatically making up parcels of bags held together by straps | |

| FR2716666A1 (en) | Method and apparatus for handling trunk-shaped trays of pyramids and placing them in a package | |

| FR2730212A1 (en) | Packing machine for cheeses or similar products |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20130516 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| DAX | Request for extension of the european patent (deleted) | ||

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: B65B 9/13 20060101AFI20140228BHEP Ipc: B65B 11/00 20060101ALI20140228BHEP Ipc: B65B 57/00 20060101ALI20140228BHEP |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20140522 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: JACONELLI, JEAN-CHRISTOPHE |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 694465 Country of ref document: AT Kind code of ref document: T Effective date: 20141115 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: FRENCH |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602011011200 Country of ref document: DE Effective date: 20141224 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 Effective date: 20150120 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2527818 Country of ref document: ES Kind code of ref document: T3 Effective date: 20150130 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 694465 Country of ref document: AT Kind code of ref document: T Effective date: 20141105 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20141105 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150305 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141105 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141105 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150205 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141105 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150305 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141105 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141105 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141105 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141105 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141105 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150206 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141105 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141105 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20141130 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: HU Ref legal event code: AG4A Ref document number: E023315 Country of ref document: HU |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141105 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20141130 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141105 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20141130 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141105 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602011011200 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141105 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20150806 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 5 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20141122 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141105 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141105 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141105 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141105 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20141122 Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141105 Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141105 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 6 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141105 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141105 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20231124 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20231208 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20231026 Year of fee payment: 13 Ref country code: HU Payment date: 20231108 Year of fee payment: 13 Ref country code: FR Payment date: 20231127 Year of fee payment: 13 Ref country code: DK Payment date: 20231130 Year of fee payment: 13 Ref country code: DE Payment date: 20231127 Year of fee payment: 13 |