EP0307932A1 - Maske - Google Patents

Maske Download PDFInfo

- Publication number

- EP0307932A1 EP0307932A1 EP88115194A EP88115194A EP0307932A1 EP 0307932 A1 EP0307932 A1 EP 0307932A1 EP 88115194 A EP88115194 A EP 88115194A EP 88115194 A EP88115194 A EP 88115194A EP 0307932 A1 EP0307932 A1 EP 0307932A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- masking member

- present

- flange

- masking

- article

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 230000000873 masking effect Effects 0.000 title claims abstract description 314

- 229920006327 polystyrene foam Polymers 0.000 claims abstract description 55

- 229920001169 thermoplastic Polymers 0.000 claims abstract description 54

- 239000004416 thermosoftening plastic Substances 0.000 claims abstract description 54

- 239000012790 adhesive layer Substances 0.000 claims description 54

- 238000007666 vacuum forming Methods 0.000 claims description 43

- 238000004381 surface treatment Methods 0.000 claims description 18

- 229920005669 high impact polystyrene Polymers 0.000 claims description 7

- 239000004797 high-impact polystyrene Substances 0.000 claims description 7

- -1 polyethylene Polymers 0.000 claims description 5

- 239000004698 Polyethylene Substances 0.000 claims description 3

- 229920000573 polyethylene Polymers 0.000 claims description 3

- 239000004743 Polypropylene Substances 0.000 claims description 2

- 229920001155 polypropylene Polymers 0.000 claims description 2

- 239000004793 Polystyrene Substances 0.000 abstract description 15

- 239000006260 foam Substances 0.000 abstract description 12

- 239000003960 organic solvent Substances 0.000 abstract description 5

- 238000000576 coating method Methods 0.000 description 43

- 239000011248 coating agent Substances 0.000 description 40

- 239000011247 coating layer Substances 0.000 description 25

- 238000010438 heat treatment Methods 0.000 description 11

- 230000003247 decreasing effect Effects 0.000 description 10

- 239000000853 adhesive Substances 0.000 description 9

- 230000001070 adhesive effect Effects 0.000 description 9

- 238000005520 cutting process Methods 0.000 description 8

- 239000002335 surface treatment layer Substances 0.000 description 8

- XEKOWRVHYACXOJ-UHFFFAOYSA-N Ethyl acetate Chemical compound CCOC(C)=O XEKOWRVHYACXOJ-UHFFFAOYSA-N 0.000 description 6

- YXFVVABEGXRONW-UHFFFAOYSA-N Toluene Chemical compound CC1=CC=CC=C1 YXFVVABEGXRONW-UHFFFAOYSA-N 0.000 description 6

- 239000007789 gas Substances 0.000 description 6

- 239000002184 metal Substances 0.000 description 6

- 239000003190 viscoelastic substance Substances 0.000 description 5

- 229920002223 polystyrene Polymers 0.000 description 4

- OKKJLVBELUTLKV-UHFFFAOYSA-N Methanol Chemical compound OC OKKJLVBELUTLKV-UHFFFAOYSA-N 0.000 description 3

- 238000007664 blowing Methods 0.000 description 3

- 239000000839 emulsion Substances 0.000 description 3

- 239000010410 layer Substances 0.000 description 3

- 239000003973 paint Substances 0.000 description 3

- 239000002904 solvent Substances 0.000 description 3

- 229920003169 water-soluble polymer Polymers 0.000 description 3

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 2

- 238000001125 extrusion Methods 0.000 description 2

- 238000005187 foaming Methods 0.000 description 2

- 238000003780 insertion Methods 0.000 description 2

- 230000037431 insertion Effects 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- 238000000034 method Methods 0.000 description 2

- 238000007747 plating Methods 0.000 description 2

- 229920002635 polyurethane Polymers 0.000 description 2

- 239000004814 polyurethane Substances 0.000 description 2

- 239000004800 polyvinyl chloride Substances 0.000 description 2

- 229920000915 polyvinyl chloride Polymers 0.000 description 2

- 239000011347 resin Substances 0.000 description 2

- 229920005989 resin Polymers 0.000 description 2

- 238000007738 vacuum evaporation Methods 0.000 description 2

- 239000004604 Blowing Agent Substances 0.000 description 1

- 239000004952 Polyamide Substances 0.000 description 1

- 239000004820 Pressure-sensitive adhesive Substances 0.000 description 1

- 238000000071 blow moulding Methods 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 238000005260 corrosion Methods 0.000 description 1

- 230000007797 corrosion Effects 0.000 description 1

- 238000007598 dipping method Methods 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 239000002984 plastic foam Substances 0.000 description 1

- 229920002647 polyamide Polymers 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- 239000007921 spray Substances 0.000 description 1

- 238000005507 spraying Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D—PROCESSES FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D1/00—Processes for applying liquids or other fluent materials

- B05D1/32—Processes for applying liquids or other fluent materials using means for protecting parts of a surface not to be coated, e.g. using stencils, resists

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B12/00—Arrangements for controlling delivery; Arrangements for controlling the spray area

- B05B12/16—Arrangements for controlling delivery; Arrangements for controlling the spray area for controlling the spray area

- B05B12/20—Masking elements, i.e. elements defining uncoated areas on an object to be coated

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B12/00—Arrangements for controlling delivery; Arrangements for controlling the spray area

- B05B12/16—Arrangements for controlling delivery; Arrangements for controlling the spray area for controlling the spray area

- B05B12/20—Masking elements, i.e. elements defining uncoated areas on an object to be coated

- B05B12/26—Masking elements, i.e. elements defining uncoated areas on an object to be coated for masking cavities

Definitions

- masking members consisting of a polystyrene foam sheet (USSN 061,700, USSN 100,524, USSN 101,689).

- Said polystyrene foam sheet what is called polystyrene paper, may be very suitable for the material of a masking member since said polystyrene foam sheet is inexpensive and easily molded by such as vacuum forming and the like.

- Said masking member consisting of said polystyrene foam sheet may be removed by employing a hook or by heating. Since said polystyrene foam is one of the most brittle of plastic foams, a hook may be easily stuck into said masking member consisting of said polystyrene foam sheet.

- said polystyrene foam sheet of said masking member has a closed cell

- air and blowing gas in said closed cell may expand and simultaneously the masking member may also expand, and then said expanding air and blowing gas will break said closed cell and said air and blowing gas will escape from said closed cell and as the result, the masking member may shrink.

- said high-impact polystyrene is dissolved in an organic solvent, such as toluene, ethyl acetate, and the like but said high-impact polystyrene has better resistance against an organic solvent than said polystyrene foam and said high-impact polystyrene film may protect completely said polystyrene foam sheet from the poorer solvents of polystyrene, such as methanol, ethanol, and the like, and further, said high-impact polystyrene film may protect said polystyrene foam sheet from the strong solvents of polystyrene, such as toluene, ethyl acetate and the like in a short exposure of said strong solvents.

- an organic solvent such as toluene, ethyl acetate, and the like

- said high-impact polystyrene film may protect completely said polystyrene foam sheet from the poorer solvents of polystyrene, such as methanol,

- thermoplastic film may be laminated on one or both side(s) of said polystyrene foam sheet when said polystyrene foam sheet is produced by extrusion foaming, or after said polystyrene foam sheet is produced by extrusion foaming, such as when said polystyrene foam sheet is molded by vacuum forming.

- said thermoplastic film is attached to said polystyrene foam sheet by heating or by using an adhesive.

- the expansion ratio of said polystyrene foam sheet may be commonly from 2 to 50 times and desirably from 7 to 20 times and the thickness of said sheet may be 0.5 to 7 mm, and the thickness of said thermoplastic film may be 0.001 to 1 mm.

- the masking member of the present invention may be produced by vacuum forming, pressing, blow-molding, cutting, and the like from said laminated sheet and if desirable, an adhesive layer may be formed partially or wholly on the surface of said masking member. Said adhesive layer may be formed by coating an adhesive on said surface of said masking member and drying said coated adhesive. It is desirable to use an emulsion type adhesive since said emulsion type adhesive does not make said polystyrene foam sheet of said masking member swell or dissolve and it is desirable to add a water soluble polymer in said emulsion type adhesive to increase cohesion of said adhesive (USSN 001,822). In the case where cohesion of said adhesive is increased by adding said water soluble polymer, said water soluble polymer may prevent transfer of said adhesive to the part of the article to which the masking member has been attached when said masking member is removed from said part.

- Said masking member of the present invention may be used in the coating process of the automobile industry such as the coating of a car body, the coating of bumpers, the corrosion, sound, and vibration-proof treatment of the underside of a car body by using a viscoelastic material such as polyvinylchloride sol, polyurethane, tar-polyurethane, and the like, and also said masking member of the present invention may be used in the coating process of the house hold electric furnishings industry, such as the coating of electric refrigerators, televisions, and the like.

- a viscoelastic material such as polyvinylchloride sol, polyurethane, tar-polyurethane, and the like

- said masking member of the present invention may be used in the coating process of the house hold electric furnishings industry, such as the coating of electric refrigerators, televisions, and the like.

- said masking member of the present invention is used not only in the coating process, but also for other surface treatment, such as plating, vacuum evaporation, and the like.

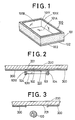

- Masking member A is used to protect the even surfaces of the article.

- An adhesive layer(102) such as the pressure sensitive adhesive layer is formed on the under surface of said body (101) and said adhesive layer(102) is covered with a release sheet(103) such as a polyethylene film, a polyproylene film, a release paper and the like to prevent sticking to another article, the hands of workers and the like when the masking members are handled, one placed upon another, transported, and the like.

- a release sheet(103) such as a polyethylene film, a polyproylene film, a release paper and the like to prevent sticking to another article, the hands of workers and the like when the masking members are handled, one placed upon another, transported, and the like.

- said release sheet(103) is removed from said adhesive layer(102) and said masking member(100) is then attached to an even part(201) of the surface of an article(200) by said adhesive layer (102) thereof, which is necessary to be protected from a coating of viscoelastic material.

- a paint is coated on the surface of said article(200) by such as spraying, dipping and the like to form a coating layer(300) as shown in Figure 2.

- Said part(201) of said surface of said article(200) is not subjected to said coating since said part(201) is covered with said masking member(100) and said coating layer(300) may be cut by an edge(104) of the body(101) of said masking member(100).

- Said part(201) may have hole(s) and in this case, said hole(s) is(are) also not subjected to said coating.

- the volume of said shrunk masking member(100) may be much smaller than the apparent volume of the unshrunk masking member(100) and further, as above described, said coating layer(300) may be cut by an edge(104) of the body(101) of said masking member(100), the removing of said masking member(100) from said part(201) of said article(200) may be very smooth without obstruction of said coating layer(300).

- Said masking member(100) may also be removed by a hook and, in this case, said masking member(100) may be easily removed without obstruction of said coating layer (300).

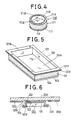

- a masking member(120) comprises a body(121) having a vessel form consisting of a rectangular bottom(121A) and perpendicular walls(121B) which extend upwards from the perimeter of said bottom(121A), and a flange(122) which is extended from the upper edges of said walls(121B), with said body (121) manufactured by vacuum forming of a laminated sheet consisting of a polystyrene foam sheet(121X) and a thermoplastic film(121Y) the same as the first and second embodiments of the present invention.

- An adhesive layer(123) is formed on the under surface of said body(121) and said adhesive layer(123) is covered with a release sheet(124) the same as the first and second embodiments of the present invention.

- said coating layer(320) may be more completely cut by said flange(122) of said masking member(120) than in the cases of the first and second embodiments of the present invention and, as the result, said masking member(120) may be more smoothly removed from said part(221) of said surface of said article(220).

- a number of masking members(120) of this embodiment may advantageously be produced by vacuum forming from said laminated sheet as shown in Fig. 7.

- a number of bodies(121) of masking members(120) are formed arranged in rows and lines, and each body(121) is connected to the other body(121) by the flange(122).

- Cutting lines (125) or grooves are formed between said flange(122) and another said flange(122) and when said masking member(120) is used, said masking member(120) is broken along said cutting lines(125) or grooves by hand.

- Said cutting lines(125) or grooves may be formed simultaneously with vacuum forming or after vacuum forming.

- a masking member(130) comprises a body(131) having a vessel form consisting of a rectangular bottom(131A) and perpendicular walls(131B) which extend upwards from the perimeter of said bottom (131A), a flange(132) which is extended from the upper edges of said walls(131B), and perpendicular walls(133) which extend upwards from the perimeter of said flange(132), with said body(131) manufactured by vacuum forming of a laminated sheet consisting of a polystyrene foam sheet(131X) and a thermoplastic film(131Y) the same as the first, second, and third embodiments of the present invention.

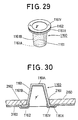

- a masking member(140) comprises a body(141) having a vessel form consisting of a circular bottom(141A) and a perpendicular wall(141B) which extends upwards from the circumference of said bottom(141A), a flange(142) which is extended from the upper edges of said wall(141B), and perpendicular wall(143) which extends downwards from the circumference of said flange(142), with said body(141) manufactured by vacuum forming of a laminated sheet consisting of a polystyrene foam sheet(141X) and a thermoplastic film(141Y) the same as the first, second, third and fourth embodiments of the present invention.

- An adhesive layer(144) is formed on the under surface of said body(141) and said adhesive layer(144) is covered with a release sheet(145) the same as the first, second, third, and fourth embodiments of the present invention.

- a masking member(150) comprises a body(151) having a vessel form consisting of a rectangular bottom(151A) from which a grip (152) is risen and perpendicular walls(151B) which extend upwards from the perimeter of said bottom(151A), with said body(151) made of a laminated layer consisting of a polystyrene foam sheet(151X) and a thermoplastic film(151Y) the same as the first, second, third, fourth, and fifth embodiments of the present invention.

- An adhesive layer(153) is formed on the under surface of said body(151) and said adhesive layer(153) is covered with a release sheet(154) the same as the first, second, third, fourth and fifth embodiments of the present invention.

- the masking member (150) of this embodiment is easily handled by holding said grip(152) of said masking member(150) when said masking member(150) is attached to an even part of the surface of an article which is to be protected from a coating and further, said masking member is easily removed by sticking said grip(152) of said masking member(150) with a hook.

- a masking member(l60) comprises a body(161) having a vessel form consisting of a circular bottom(161A) from which a grip(162) is risen and perpendicular wall which extend upwards from the circumference of said bottom(161A), with said body(161) manufactured by vacuum forming of a laminated sheet consisting of a polystyrene foam sheet(161X) and a thermoplastic film(161Y) the same as the first, second, third, fourth, fifth, and sixth embodiments of the present invention.

- An adhesive layer (163) is formed on the under surface of said body(161) and said adhesive layer(163) is covered with a release sheet (164) the same as the first, second, third, fourth, fifth, and sixth embodiments of the present invention.

- a masking member(170) comprises a body(171) having a vessel form consisting of a rectangular bottom(171A) from which a grip(173) is risen and perpendicular walls(171B) which extend upwards from the perimeter of said bottom(171A), a flange(172) which is extended from the upper edges of said walls(171B), with said body(171) manufactured by vacuum forming of a laminated sheet consisting of a polystyrene foam sheet(171X) and a thermoplastic film(171Y) the same as the prior embodiments of the present invention.

- An adhesive layer(174) is formed on the under surface of said body(171) and said adhesive layer(174) is covered with a release sheet(175) the same as the prior embodiments of the present invention.

- a masking member(180) comprises a body(181) having a vessel form consisting of a rectangular bottom from which a grip(184) is risen and perpendicular walls(181B) which extend upwards from the perimeter of said bottom(181A), a flange(182) which is extended from the upper edges of said walls(181B), and perpendicular walls(183) which extend upwards from the perimeter of said flange(182), with said body(181) manufactured by vacuum forming of a laminated sheet consisting of a polystyrene foam sheet(181X) and a thermoplastic film (181Y) the same as the prior embodiments of the present invention.

- An adhesive layer(185) is formed on the under surface of said body(181) and said adhesive layer(185) is covered with a release sheet(186) the same as the prior embodiments of the present invention.

- a masking member(190) comprises a body(191) having a vessel form consisting of a rectangular bottom(191A) from which a grip is risen and perpendicular walls(191B) which extend upwards from the perimeter of said bottom(191A), a flange(192) which is extended from the upper edges of said walls(191B), and perpendicular walls(193) which extend downwards from the perimeter of said flange(192), with said body(191) manufactured by vacuum forming of a laminated sheet consisting of a polystyrene foam sheet(191X) and a thermoplastic film(191Y) the same as the prior embodiments of the present invention.

- An adhesive layer(195) is formed on the under surface of said body(191) and said adhesive layer(195) is covered with a release sheet(196) the same as the prior embodiments of the present invention.

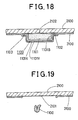

- Masking member B is used to protect the even surface or the protruding part of the article.

- a masking member(1100) comprises a body(1101) having a vessel form consisting of a square bottom(1101A), perpendicular walls(1101B) which extend upwards from the perimeter of said bottom(1101A), a flange(1102) which is extended from the upper edges of said walls(1101B), and an adhesive layer(1103) formed on the surface of said flange (1102), with said masking member(1100) manufactured by vacuum forming of a laminated sheet consisting of a polystyrene foam sheet(1101X) and a thermoplastic film(1101Y). Said adhesive layer(1103) is covered with a release sheet (1104).

- said release sheet (1104) is removed from said adhesive layer(1103) and said masking member(1100) is then attached to an even part(2101) of the surface of an article(2100) by said adhesive layer (1103) thereof.

- a surface treatment such as a coating is effected on the surface of said article(2100) to form a coating layer(3100). Said part(2101) of said surface of said article(2100) is not subjected to said coating since said part(2101) is covered with said masking member(1100).

- said coated article(2100) is heated to dry and/or cure if desired and in cases where the heating temperature is adequately higher than the softening points of the polystyrene foam sheet(1101X) and the thermoplastic film(1101Y) of said body(1101) of said masking member(1100), said masking member(1100) will firstly expand and then shrink by said heating and come off by itself from said part(2101) of said surface of said metal structure(2100) as shown in Fig. 19.

- said release sheet(1115) is removed from said adhesive layer(1114) and said masking member(1110) is then attached to an even part (2111) as shown in Fig. 22, of the surface of an article (2110) by said adhesive layer(1114) thereof, and said part (2111) has a hole(2112).

- a coating is effected on the surface of said metal structure(2110) to form a coating layer(3110).

- Said part(2111) including said hole (2112) is not subjected to said coating since said part (2111) is covered with said masking member(1110) and said coating layer(3110) may be cut by said outer perpendicular wall(1113) of said flange(1112) of said masking member (1110).

- said coated article(2110) is heated to dry and/or cure if desired and in cases where the heating temperature is adequately higher than the softening points of the polystyrene foam sheet(1111X) and the thermoplastic film(1111Y) of said masking member(1110), said masking member(1110) will firstly expand and then shrink by said heating and come off by itself from said part(2111) of said surface of said article(2110).

- said coating layer(3110) may be cut by said outer perpendicular wall (1113) of said flange(1112) of said masking member(1110) as shown in Fig. 22, and said masking member(1110) is also attached by only said adhesive layer(1114) on the surface of said flange(1112) thereof to said part(2111) of said article(2110) the same as the eleventh embodiment of the present invention, the removing of said masking member (1110) from said part(2111) may be very smooth without obstruction of said coating layer(3110) and said adhesive layer(1114) of said masking member(1110).

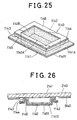

- a masking member (1120) comprises a body(1121) having a vessel form consisting of a rectangular bottom(1121A) from which a grip(1123) is risen, perpendicular walls(1121B) which extend upwards from the perimeter of said bottom(1121A), a flange(1122) which is extended from the upper edges of said walls(1121B), and an adhesive layer(1124) formed on the surface of said flange(1122), with said masking member(1120) manufactured by vacuum forming of a laminated sheet consisting of a polystyrene foam sheet(1121X) and a thermoplastic film (1121Y) the same as the prior embodiments of the present invention, and said adhesive layer(1124) is covered with a release sheet(1125) the same as the prior embodiments of the present invention.

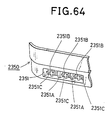

- a masking member(1140) comprises a body(1141A) having a vessel form consisting of a rectangular bottom(1141A), inner perpendicular walls(1141B) which extend upwards from the perimeter of said bottom(1141B), an upper flange(1142) which is extended from the uuper edges of said walls(1141B), outer perpendicular walls(1143) which extend downwards from the perimeter of said upper flange(1142), a lower flange(1144) which is extended from the lower edges of said outer walls (1143), and an adhesive layer(1145) formed on the surface of said upper flange(1142) with said masking member(1140) manufactured by vacuum forming of a laminated sheet consisting of a polystyrene foam sheet(1141X) and a thermoplastic film(1141Y) the same as the prior embodiments of the present invention, and said adhesive layer(1145) is covered with

- Said masking member(1160) can be also removed from said hole(2161) by heating at a temperature higher than the softening points of the polystyrene foam sheet (1161X) and the thermoplastic film(1161Y).

- said masking member(1160) When said masking member(1160) is heated to said temperature, it may be softened and gases such as air, gas of a blowing agent, and the like in the cells of said polystyrene foam may firstly expand and so said masking member may also expand and, then, when said gases leave the cells, said masking member(1160) may shrink rapidly and remove itself naturally from said hole(2161) as shown in Figure 31.

- Said masking member(1200) is manufactured by vacuum forming of a laminated sheet consisting of a polystyrene foam sheet (1201X) and a thermoplastic film(1201Y). Said masking member(1200) of this embodiment is easily handled by holding said grip(1201C) when the masking member(1200) is inserted into the hole of the article or removed from the hole as same as the twentieth embodiment of the present invention. Further, the surface treatment layer on the article may be cut by the upper edge of said inserting part(1201) as same as the eighteenth embodiment so that said masking member(1200) is easily removed from the hole without the obstruction of said surface treatment layer.

- a masking member(1210) comprises an inserting part(1211) having a vessel form consisting of a circular bottom(1211A) from which a grip(1211C) is risen, a perpendicular wall(1211B) which extends upwards from the circumference of said bottom (1211A), and a flange(1212) which is extended from the upper edge of said wall(1211B).

- Said inserting part(1211) has a taper form decreasing in diameter from base of said inserting part(1211) to the top of said inserting part(1211) and the width of said flange(1212) is smaller than the width of the flange(1192) of the masking member(1190) of the twentieth embodiment and said flange(1212) having small width acts as a stopper of the masking member(1210) when said masking member(1210) is inserted into hole.

- Said masking member(1210) is manufactured by vacuum forming of a laminated sheet consisting of a polystyrene foam sheet (1211X) and a thermoplastic film(1211Y).

- Said masking member(1220) of this embodiment is used as same as the seventeenth embodiment, and in this embodiment a surface treatment layer such as a coating layer(3220) may be cut by the edge of said perpendicular wall(1221B) as shown in Figure 39, so that said masking member(1220) is easily removed from the hole(2221) of the article(2220) without obstruction of said coating layer (3220).

- a surface treatment layer such as a coating layer(3220) may be cut by the edge of said perpendicular wall(1221B) as shown in Figure 39, so that said masking member(1220) is easily removed from the hole(2221) of the article(2220) without obstruction of said coating layer (3220).

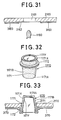

- a masking member (1230) consists of an inserting part(1231) having a vessel form consisting of a circular bottom(1231A) and a perpendicular wall(1231B) in the middle part of which a horizontal rib(1231C) is formed, and a flange(1232) which is extended from the upper edge of said wall(1231B).

- Said masking member(1230) is manufactured by vacuum forming of a laminated sheet consisting of a polystyrene foam sheet (1231X) and a thermoplastic film(1231Y).

- Said masking member(1230) of this embodiment is used as same as the seventeenth embodiment and said horizontal rib(1231C) reinforces said wall(1231B) of said inserting part(1231) of said masking member(1230) so that said masking member(1230) is firmly inserted into the hole of the article.

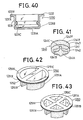

- said inserting part(1241) is reinforced by said cross-shaped bottom(1241A) to prevent crushing of said inserting part (1241) of said masking member when said masking member (1240) is inserted into the hole of the article, and further said masking member(1240) is supported in the inner wall of said hole by only partially contacts at the tips(1241C) of said inserting part(1241) so that removing of said masking member(1240) from the hole may be very easy.

- Figure 42 relates to the twenty-sixth embodiment of the present invention.

- a masking member(1250) consists of an inserting part(1251) which has a vessel form and is divided into two crescent parts(1251A) and (1251B) by a grip(1251C) which is risen from the bottom of said inserting part(1251), and a flange(1252) which is extended from the upper edge of said inserting part(1251).

- Said masking member(1250) of this embodiment is easily manufactured by vacuum forming of a laminated sheet consisting of a polystyrene foam sheet(1251X) and a thermoplastic film(1251Y) and easily removed from the hole since said masking member(1250) partially contacts with the inner wall of the hole, since said inserting part(1251) is divided into two crescent parts(1251A) and (1251B) by said grip(1251C).

- a masking member (1270) consists of an inserting part(1271) having vessel form consisting of a cross-shaped bottom(1271A) and a perpendicular wall(1271B) which extends upwards from the perimeter of said bottom(1271A), a lower flange(1272) which is extended from the upper edge of said wall(1271B), a perpendicular wall(1273) which extends upwards from the circumference of said lower flange(1272), and an upper flange(1274) which is extended from the upper edge of said wall(1273).

- Said masking member(1270) is manufactured by vacuum forming of a laminated sheet consisting of a polystyrene foam sheet(1271X) and a thermoplastic film(1271Y).

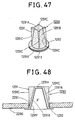

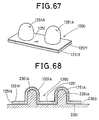

- a masking member(1290) consists of an inserting part(1291) having a vessel form consisting of a circular bottom(1291A) and a perpendicular wall(1291B) which extends upwards from the circumference of said bottom(1291A) and on which plural perpendicular ribs(1291C) are formed, and a flange(1292) which is extended from the upper edge of said wall(1291B).

- Said inserting part(1291) has a taper form decreasing in diameter from the base to the top of said inserting part (1291).

- Said masking member is manufactured by vacuum forming of a laminated sheet consisting of a polystyrene foam sheet(1291X) and a thermoplastic film(1291Y).

- said perpendicular ribs(1291C) reinforce said perpendicular wall(1291B) to prevent crushing of said inserting part(1291) of said masking member(1290) when said masking member(1290) is inserted into a hole(2291) of an article(2290) as shown in Figure 48 and said masking member(1290) is firmly held in said hole(2291) since said perpendicular ribs(1290C) of said masking member(1290) tightly contact to the inner wall of said hole.

- a masking member (1310) consists of an inserting part(1311) having a vessel form consisting of a circular bottom(1311A) from which a grip(1311D) is risen and a perpendicular wall(1311B) which extends upwards from the circumference of said bottom(1311A) and on which plural perpendicular ribs(1311C) are formed, a lower flange(1312) which is extended from the upper edge of said wall(1311B), a perpendicular wall(1313) which extends upwards from the circumference of said flange(1312), and an upper flange(1314) which is extended from the upper edge of said perpendicular wall(1313).

- the masking member(1190) of the twentieth embodiment is inserted into a drainage hole(2341C), as shown in Figure 60, the masking member D, such as the masking member(1320) of the thirty-third embodiment is attached to a bracket(2341D) of part D which is used to attach a part to the under side(2341) of the car body(2340), and as shown in Figure 61, the masking member(100) of the first embodiment is attached to a screw hole(2341E) which is used to attach a part to the under side(2341) of the car body(2340).

- said hole(2341A), said bolt(2341B), said drainage hole(2341C), said bracket(2341D) and said screw hole(2341E) are protected by said masking members of the present invention from the coating of viscoelastic material.

Landscapes

- Details Or Accessories Of Spraying Plant Or Apparatus (AREA)

- Laminated Bodies (AREA)

Applications Claiming Priority (12)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP143499/87U | 1987-09-18 | ||

| JP143498/87U | 1987-09-18 | ||

| JP14349987 | 1987-09-18 | ||

| JP14350187 | 1987-09-18 | ||

| JP143500/87U | 1987-09-18 | ||

| JP14349887 | 1987-09-18 | ||

| JP143501/87U | 1987-09-18 | ||

| JP14350087 | 1987-09-18 | ||

| JP4732888 | 1988-04-07 | ||

| JP47328/88U | 1988-04-07 | ||

| JP5169388 | 1988-04-18 | ||

| JP51693/88U | 1988-04-18 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0307932A1 true EP0307932A1 (de) | 1989-03-22 |

| EP0307932B1 EP0307932B1 (de) | 1993-12-22 |

Family

ID=27550262

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP88115194A Expired - Lifetime EP0307932B1 (de) | 1987-09-18 | 1988-09-16 | Maske |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP0307932B1 (de) |

| CN (1) | CN1016232B (de) |

| AU (1) | AU613958B2 (de) |

| DE (1) | DE3886488T2 (de) |

| SG (1) | SG26402G (de) |

Cited By (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0370796A1 (de) * | 1988-11-23 | 1990-05-30 | Nagoya Oilchemical Co., Ltd. | Isolierverfahren für metallische Gegenstände gegen Korrosion, Schall und Vibration |

| GB2254811A (en) * | 1991-04-19 | 1992-10-21 | Minnesota Mining & Mfg | Masking using a foam web |

| US5266375A (en) * | 1989-11-22 | 1993-11-30 | Nagoya Oilchemical Co., Ltd. | Masking member |

| EP0606694A1 (de) * | 1993-01-14 | 1994-07-20 | Nagoya Oilchemical Co., Ltd. | Abdeckung |

| EP0640404A1 (de) * | 1993-08-24 | 1995-03-01 | NEDSCHROEF PLETTENBERG GmbH | Abdeckkappe |

| EP0676246A1 (de) * | 1993-09-29 | 1995-10-11 | Nagoya Oilchemical Co., Ltd. | Abdeckungselement |

| US5902642A (en) * | 1997-05-12 | 1999-05-11 | Nayoya Oilchemcial Co., Ltd. | Masking member made of engineering plastic |

| EP1033178A2 (de) * | 1993-09-29 | 2000-09-06 | Nagoya Oilchemical Co., Ltd. | Abdeckungselement |

| US6413391B1 (en) | 1999-10-29 | 2002-07-02 | Bae Systems Plc | Masking techniques for metal plating |

| WO2003106046A1 (ja) * | 2002-06-14 | 2003-12-24 | 名古屋油化株式会社 | マスキング材 |

| US9179814B2 (en) | 2012-04-13 | 2015-11-10 | The Procter & Gamble Company | Cleaning article comprising lines of frangibility with marked indicia |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| BE1001535A3 (fr) * | 1988-09-22 | 1989-11-21 | Jean Silvestre | Procede et moyen de masquage. |

| CN1900381B (zh) * | 2006-07-04 | 2010-05-12 | 浙江大学 | 单面阳极氧化铝模板的制备装置 |

| CN102206805B (zh) * | 2010-03-29 | 2013-02-06 | 北京京东方光电科技有限公司 | 磁控溅射设备 |

| CN102337578B (zh) * | 2010-07-19 | 2014-04-02 | 北大方正集团有限公司 | 一种双面电镀槽、板件及电镀方法 |

| CN104549836A (zh) * | 2014-11-15 | 2015-04-29 | 郑州飞机装备有限责任公司 | 零部件凹陷部位表面绝缘工装喷涂方法 |

| CN104437941A (zh) * | 2014-11-17 | 2015-03-25 | 无锡市百顺机械厂 | 喷漆工装 |

| CN105149147A (zh) * | 2015-07-13 | 2015-12-16 | 成都力鑫科技有限公司 | 一种将涂料均匀分布在板材表面的带有防护套喷涂系统 |

| CN105651542B (zh) * | 2015-12-29 | 2020-04-17 | 芜湖东旭光电科技有限公司 | 玻璃基板取样装置和方法 |

| CN106086960B (zh) * | 2016-07-28 | 2017-11-21 | 中国电子科技集团公司第三十八研究所 | 一种用于射频连接器多镀种电镀的局部保护装置 |

| CN110918303B (zh) * | 2019-12-31 | 2024-06-18 | 广西玉柴机器股份有限公司 | 机油滤清器的屏蔽工具及屏蔽方法 |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1316747A (en) * | 1969-10-10 | 1973-05-16 | Shell Int Research | Process for the production of a plastics laminate |

| FR2384683A1 (fr) * | 1977-03-22 | 1978-10-20 | Dourdin | Dispositif pour l'obturation provisoire d'un orifice d'un objet |

| EP0207720A2 (de) * | 1985-06-27 | 1987-01-07 | Nagoya Oilchemical Co., Ltd. | Maske |

| EP0248652A2 (de) * | 1986-06-03 | 1987-12-09 | Nagoya Oilchemical Co., Ltd. | Ausdehnbare und zusammenziehbare Anordnung |

| EP0256782B1 (de) * | 1986-08-06 | 1991-09-04 | Nagoya Oilchemical Co., Ltd. | Maske |

| EP0263637B1 (de) * | 1986-09-30 | 1991-12-27 | Nagoya Oilchemical Co., Ltd. | Maske |

| EP0262946B1 (de) * | 1986-09-30 | 1991-12-27 | Nagoya Oilchemical Co., Ltd. | Maske |

-

1988

- 1988-09-16 CN CN88106800A patent/CN1016232B/zh not_active Expired

- 1988-09-16 DE DE3886488T patent/DE3886488T2/de not_active Expired - Fee Related

- 1988-09-16 EP EP88115194A patent/EP0307932B1/de not_active Expired - Lifetime

- 1988-09-16 AU AU22343/88A patent/AU613958B2/en not_active Ceased

- 1988-09-16 SG SG1995906764A patent/SG26402G/en unknown

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1316747A (en) * | 1969-10-10 | 1973-05-16 | Shell Int Research | Process for the production of a plastics laminate |

| FR2384683A1 (fr) * | 1977-03-22 | 1978-10-20 | Dourdin | Dispositif pour l'obturation provisoire d'un orifice d'un objet |

| EP0207720A2 (de) * | 1985-06-27 | 1987-01-07 | Nagoya Oilchemical Co., Ltd. | Maske |

| EP0248652A2 (de) * | 1986-06-03 | 1987-12-09 | Nagoya Oilchemical Co., Ltd. | Ausdehnbare und zusammenziehbare Anordnung |

| EP0256782B1 (de) * | 1986-08-06 | 1991-09-04 | Nagoya Oilchemical Co., Ltd. | Maske |

| EP0263637B1 (de) * | 1986-09-30 | 1991-12-27 | Nagoya Oilchemical Co., Ltd. | Maske |

| EP0262946B1 (de) * | 1986-09-30 | 1991-12-27 | Nagoya Oilchemical Co., Ltd. | Maske |

Cited By (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0370796A1 (de) * | 1988-11-23 | 1990-05-30 | Nagoya Oilchemical Co., Ltd. | Isolierverfahren für metallische Gegenstände gegen Korrosion, Schall und Vibration |

| US5266375A (en) * | 1989-11-22 | 1993-11-30 | Nagoya Oilchemical Co., Ltd. | Masking member |

| GB2254811A (en) * | 1991-04-19 | 1992-10-21 | Minnesota Mining & Mfg | Masking using a foam web |

| GB2254811B (en) * | 1991-04-19 | 1994-11-30 | Minnesota Mining & Mfg | Masking methods using a foam web |

| EP0606694A1 (de) * | 1993-01-14 | 1994-07-20 | Nagoya Oilchemical Co., Ltd. | Abdeckung |

| EP0640404A1 (de) * | 1993-08-24 | 1995-03-01 | NEDSCHROEF PLETTENBERG GmbH | Abdeckkappe |

| EP0676246A1 (de) * | 1993-09-29 | 1995-10-11 | Nagoya Oilchemical Co., Ltd. | Abdeckungselement |

| EP0676246A4 (de) * | 1993-09-29 | 1996-07-31 | Nagoya Oilchemical | Abdeckungselement. |

| EP1033178A2 (de) * | 1993-09-29 | 2000-09-06 | Nagoya Oilchemical Co., Ltd. | Abdeckungselement |

| EP1033178A3 (de) * | 1993-09-29 | 2002-06-05 | Nagoya Oilchemical Co., Ltd. | Abdeckungselement |

| US5902642A (en) * | 1997-05-12 | 1999-05-11 | Nayoya Oilchemcial Co., Ltd. | Masking member made of engineering plastic |

| US6413391B1 (en) | 1999-10-29 | 2002-07-02 | Bae Systems Plc | Masking techniques for metal plating |

| US6436266B1 (en) | 1999-10-29 | 2002-08-20 | Bae Systems Plc | Masking techniques for metal plating |

| WO2003106046A1 (ja) * | 2002-06-14 | 2003-12-24 | 名古屋油化株式会社 | マスキング材 |

| US9179814B2 (en) | 2012-04-13 | 2015-11-10 | The Procter & Gamble Company | Cleaning article comprising lines of frangibility with marked indicia |

Also Published As

| Publication number | Publication date |

|---|---|

| DE3886488T2 (de) | 1994-06-09 |

| EP0307932B1 (de) | 1993-12-22 |

| CN1031950A (zh) | 1989-03-29 |

| SG26402G (en) | 1995-09-01 |

| DE3886488D1 (de) | 1994-02-03 |

| AU613958B2 (en) | 1991-08-15 |

| CN1016232B (zh) | 1992-04-15 |

| AU2234388A (en) | 1989-03-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0307932B1 (de) | Maske | |

| EP0350031B1 (de) | Maske | |

| US7041193B2 (en) | Method of adhering members and an assembly formed thereby | |

| US5328723A (en) | Masking member | |

| EP0256782B1 (de) | Maske | |

| US20080111394A1 (en) | Baffle for an automotive vehicle and method of use therefor | |

| EP0303268B1 (de) | Methode, um Metallstrukturen korrosionsbeständig, schalldicht und erschütterungssicher zu machen | |

| CA1283283C (en) | Masking member | |

| GB2113573A (en) | Electrostatic paint spraying workpiece support | |

| EP0384695B1 (de) | Abdeckelement | |

| EP0384696B1 (de) | Abdeckelement | |

| JP6769793B2 (ja) | 発泡性穴プラグ | |

| KR20210000470A (ko) | 자동차 부품 도장용 지그 | |

| JPH047265B2 (de) | ||

| EP0384619A1 (de) | Vorrichtung zur Maskierung | |

| JPS60251953A (ja) | 塗装用マスキング治具 | |

| CA2001849A1 (en) | Masking member | |

| JPS60232276A (ja) | 塗装用マスキング治具 | |

| JP7186422B2 (ja) | 噴射ボタン及びエアゾール噴射器 | |

| JPS60251966A (ja) | 塗装用マスキング方法 | |

| JPH0441954Y2 (de) | ||

| JP2005238097A (ja) | マスキング材 | |

| JPS60251964A (ja) | 塗装用マスキング方法 | |

| JPH0522313Y2 (de) | ||

| JPS60251965A (ja) | 塗装用マスキング方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): DE FR GB IT SE |

|

| 17P | Request for examination filed |

Effective date: 19890727 |

|

| 17Q | First examination report despatched |

Effective date: 19900928 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE FR GB IT SE |

|

| ITF | It: translation for a ep patent filed | ||

| REF | Corresponds to: |

Ref document number: 3886488 Country of ref document: DE Date of ref document: 19940203 |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: 732E |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19940831 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19940919 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19940923 Year of fee payment: 7 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: CL |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19941129 Year of fee payment: 7 |

|

| 26N | No opposition filed | ||

| EAL | Se: european patent in force in sweden |

Ref document number: 88115194.8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19950916 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19950917 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19950916 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19960531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19960601 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 88115194.8 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050916 |