CN112252118A - Structure improvement technology of plastic track - Google Patents

Structure improvement technology of plastic track Download PDFInfo

- Publication number

- CN112252118A CN112252118A CN202011112996.7A CN202011112996A CN112252118A CN 112252118 A CN112252118 A CN 112252118A CN 202011112996 A CN202011112996 A CN 202011112996A CN 112252118 A CN112252118 A CN 112252118A

- Authority

- CN

- China

- Prior art keywords

- layer

- grid

- cement

- groove

- grid layer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01C—CONSTRUCTION OF, OR SURFACES FOR, ROADS, SPORTS GROUNDS, OR THE LIKE; MACHINES OR AUXILIARY TOOLS FOR CONSTRUCTION OR REPAIR

- E01C13/00—Pavings or foundations specially adapted for playgrounds or sports grounds; Drainage, irrigation or heating of sports grounds

- E01C13/06—Pavings made in situ, e.g. for sand grounds, clay courts E01C13/003

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01C—CONSTRUCTION OF, OR SURFACES FOR, ROADS, SPORTS GROUNDS, OR THE LIKE; MACHINES OR AUXILIARY TOOLS FOR CONSTRUCTION OR REPAIR

- E01C11/00—Details of pavings

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01C—CONSTRUCTION OF, OR SURFACES FOR, ROADS, SPORTS GROUNDS, OR THE LIKE; MACHINES OR AUXILIARY TOOLS FOR CONSTRUCTION OR REPAIR

- E01C13/00—Pavings or foundations specially adapted for playgrounds or sports grounds; Drainage, irrigation or heating of sports grounds

- E01C13/06—Pavings made in situ, e.g. for sand grounds, clay courts E01C13/003

- E01C13/065—Pavings made in situ, e.g. for sand grounds, clay courts E01C13/003 at least one in situ layer consisting of or including bitumen, rubber or plastics

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Road Paving Structures (AREA)

Abstract

A structure improvement technology of a plastic track, set up the slot on the cement bottom layer of the peripheral edge of the plastic track, add two grid layers in the structure of the original plastic track, lay several cement to penetrate the nail and make it form the grid on the cement bottom layer under the plastic track, hang and set up the grid layer on the said cement that takes the form of grid to penetrate the nail, trim the surplus grid layer above the slot to cut off the surplus part and roll up on a section of elastic rubbery soft strip, then stretch it and fill in the bottom in the slot after straining, thus make the surplus grid layer above the slot fix on ground above the slot; the spraying operation of the bottom oil layer is carried out on the ground of the cement bottom layer after the additional arrangement of the grid layer and in the groove, the thickness of the bottom oil layer after condensation can wrap the additional arrangement of the grid layer, the second grid layer is arranged in the spraying finish paint layer, four sides of the second grid layer are tensioned and fixed in the spraying finish paint, and the laying and fixing construction process of the additional arrangement of the two grid layer structure is completed.

Description

Technical Field

The improved plastic track has the performance of preventing the open edge from raising and preventing the hollow bulge from forming bubble, and belongs to the field of plastic track laying (manufacturing) technology.

Background

Plastic runways which are put into use at present probably comprise a plurality of types such as a ventilation type, a full plastic type, a composite type and the like; the plastic runways described above have in common: the whole plastic track is bonded and fixed on the basis of the cement ground by the construction procedures of treatment of the cement bottom layer, spraying of a bottom oil layer (bottom glue), mixed or single particle material laying (forming an elastic layer), spraying of finish paint (glue) (forming a surface wear-resistant layer), scribing and the like; the technical problems common to runways of the above-described type of construction are: the weather resistance is not strong in the using process, the phenomena of peeling while opening of a base layer (bottom oil layer) of the plastic track and the lower cement ground and hollowing and foaming (namely, the phenomenon that the glue opening formed between the plastic layer and the cement base layer falls off) appear in a middle individual area easily occur, and particularly the phenomena of the peeling while opening and the hollowing and foaming are more serious in the freeze-thaw process of repeated freezing and melting in winter in low-temperature rain and snow weather in the north; the open edge and the hollow bubbling part are easy to form a phenomenon of whole block falling off due to the action of external force such as mechanical friction and scratch and the like in use, and the damaged area is increased, so that an incomplete runway is formed; under the condition, the integral attractiveness and the use performance of the plastic track are influenced, and the service life of the plastic track is shortened; therefore, there is a need to improve the design structure of the plastic track in the technical aspect, so as to eliminate the above technical defects.

Disclosure of Invention

Since the students are college students of sports department, the students often cross the plastic track; after frequent tracking observation and investigation analysis, the following results are found: the above-mentioned defects are basically caused by the combination strength of the cement bottom layer and the bottom oil layer (primer) being not firm enough and the weather resistance being not durable enough; therefore, the purpose of the application is to provide a structure improvement technology of the plastic track, so as to eliminate the practical defects that the plastic track has open edge tilting and hollowing and bubbling;

the improved structure of the plastic track is as follows: on the basis of the structural characteristics of the original cement bottom layer, the bottom oil (bottom glue) layer, the mixed or single particle material laying layer and the finish paint (glue) layer, one to two grid layers are additionally arranged (of course, a plurality of grid layers can be additionally arranged according to the requirement); in order to add a grid layer, the structure of the original cement bottom layer needs to be improved as follows; so as to increase the connection performance of the whole plastic track and the cement bottom layer (foundation layer);

firstly, forming a groove on a cement bottom layer at the peripheral edge of the plastic track, wherein the width upper opening degree of the groove is equal to the edge thickness of the plastic track (generally within 0.5-1.5 cm); the depth of the groove is between 4 and 10 centimeters; the groove is made into a dovetail groove shape with a narrow upper part and a wide lower part; the groove is used for placing a mixture of the residual part of the edge of one to two additionally-arranged grid layers and primer (primer);

in order to fix the additionally arranged grid layer, a plurality of cement shooting nails are required to be distributed on the cement bottom layer below the plastic track, and the cement shooting nails are uniformly distributed on the cement bottom layer below the plastic track in a grid shape; the distance between the edges of the grid type formed by the cement shooting nails and the grooves is 3-10 cm, so that the grid type formed by the cement shooting nails can not influence the structural strength of the arranged cement grooves; selecting matched bullets according to the depth of the shooting nails when the cement shooting nails are shot, and compressing the gear ring below each cement shooting nail to the thickness of 1.5-2.5 mm after the shooting of the shooting nails is finished; the gear ring is used as a gasket (note: the gear ring is a component matched with the shooting nail); determining the height of the fixedly added grid layer from the upper surface of the cement bottom layer;

a grid layer is hung on the grid-shaped cement shooting nail, and the grid layer is a net-shaped body (commonly called grid cloth, and finished products are sold in the market) which is knitted and formed by nylon threads (reinforced threads in triangular belts); the grid layer is fixed on the grid-shaped cement shooting nail after being tensioned, the fixed grid layer is positioned between the gear ring and the nail cap, and the tensioned and fixed grid layer is suspended on a terrace above the cement bottom layer; trimming the redundant grid layer (which refers to the excess reserved parts on two sides which are not tensioned by the grid-shaped cement shooting nails and are used for covering the upper surface of the cement bottom layer between the groove and the shooting nails) on the groove, then rolling the redundant grid layer on a section of elastic rubber soft strip, so that the redundant grid layer forms a shaft-shaped body, tensioning the redundant grid layer and then inserting the tensioned redundant grid layer into the bottom in the groove, and thus fixing the redundant grid layer on the groove on the ground on the groove; and finishing the laying and fixing construction process of the additionally-arranged grid layer structure.

Spraying a bottom oil layer (bottom glue) on the ground of the cement bottom layer (including the partial grid layer on the groove and the groove), wherein the cement bottom layer is added with the grid layer, the added grid layer can be wrapped in the thickness of the condensed bottom oil layer (bottom glue), and the ground of the cement bottom layer, the cement shooting nails and the added grid layer are condensed and connected into a whole by the condensed bottom oil layer (bottom glue); filling part of base oil (base glue) into the groove, wherein the height of the filled base oil (base glue) can submerge the shaft-shaped body of the grid layer plugged into the groove; so that the grid layer inserted into the groove is bonded and solidified at the bottom in the groove (the grid layer and the poured base oil are generally within 2 cm of the depth of the groove);

laying a mixed or single particle material laying layer (namely, an elastic layer generally called as 1 cm in thickness) on a bottom oil layer (bottom glue) according to a traditional method, covering a second grid layer (the material is the same as that of the grid layer) on the solidified mixed or single particle material laying layer, tensioning and fixing four sides of the second grid layer, wherein two sides of the second grid layer are tensioned and then plugged into the groove (the method is the same as the treatment process of the grid layer and the groove above), pouring glue solution of the bottom oil (bottom glue) layer into the groove, and the height of the poured glue solution can submerge the second grid layer plugged into the groove and then fill the groove; so as to condense and fix the edges of the two layers of grid layers in the groove; the other two sides of the second grid layer are temporarily tensioned and fixed; preparing for spraying finish paint (glue) on the second grid layer; spraying finish paint (glue) on the tensioned grid layer; the thickness of the condensed finish paint (adhesive) layer can wrap the additionally arranged second grid layer, and the condensed finish paint (adhesive) layer, the second grid layer and the solidified mixed or single particle material laying layer are condensed and connected into a whole; therefore, the main body construction operation process of the plastic track after the structure improvement is completed (the scribing process is irrelevant to the scheme and is not described).

The beneficial technological effect of this application is: firstly, through the technical improvement that the groove is additionally arranged on the ground of the cement bottom layer at the side edge of the plastic track, the grid layer is hung on the grid-type cement shooting nail which is additionally arranged on the ground of the cement bottom layer, and the second grid layer covers the mixed or single particle material laying layer, the side edge of the plastic track and the grid layer are bonded and solidified in the groove of the cement bottom layer, and the side edge of the plastic track which is filled in the groove is embedded in the deep part of the cement bottom layer in a compact manner, so that the technical defect that the easy-opening edge of the plastic track is warped is overcome;

secondly, through the technical improvement that the grid-type cement shooting nails are additionally arranged on the ground of the cement bottom layer and two grid layers are hung on the cement shooting nails, the connection strength between the ground of the cement bottom layer and a bottom oil (bottom glue) layer is fundamentally increased (because the connection means of bonding the bottom oil and the ground is not only relied on, and the occurrence of the phenomenon of hollowing and foaming of the plastic track is eliminated;

thirdly, the integral structural strength of the plastic track in use is greatly improved by adding two layers of grid layers in the structural construction of the traditional plastic track, so that the plastic track with the improved structure is more durable; the weather resistance of the plastic track is prolonged; all of which are significant features and distinct advances over the prior art.

Drawings

In the drawings:

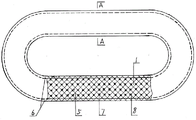

FIG. 1 is a top view of a plastic track with grooves on its sides and a grid layer attached to a grid-type cement nail;

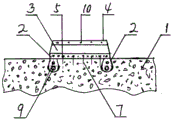

fig. 2 is a sectional view of the structure A-A after the plastic runway is finished after the technical improvement.

Description of reference numerals:

in the figure, 1, a cement bottom layer; 2. a primer (primer) layer; 3. mixed or single particle paving; 4. a finish (glue) layer; 5. a mesh layer; 6. a trench; 7. shooting nails with cement; 8. a ring gear; 9. a soft rubber strip; 10. a second mesh layer.

Detailed Description

As shown in fig. 1 and 2, a structure improvement technique for a plastic track, so as to eliminate the practical defects of the plastic track such as open edge tilting and hollow bubbling;

the improved structure of the plastic track is as follows: on the basis of the structural characteristics of a raw cement bottom layer 1, a bottom oil (bottom glue) layer 2, a mixed or single particle material laying layer 3 and a finish paint (glue) layer 4, one to two grid layers are additionally arranged (a plurality of grid layers can be added according to the requirement); in order to add the grid layer 5, the structure of the original cement bottom layer 1 needs to be improved as follows; so as to increase the connection performance of the whole plastic track and the cement bottom layer (base layer) 1;

firstly, a groove 6 is arranged on a cement bottom layer 1 at the peripheral edge of the plastic track, and the width of an upper opening of the groove 6 is equal to the edge thickness of the plastic track (generally within 0.5-1.5 cm); the depth of the groove 6 is 4-10 cm; the groove 6 is made into a dovetail groove shape with a narrow upper part and a wide lower part; the groove 6 is used for placing a mixture of the residual part of the edge of one to two additionally-arranged grid layers and the primer (primer) 2;

in order to fix the additionally arranged grid layer 5, a plurality of cement shooting nails 7 are required to be distributed on the cement bottom layer 1 below the plastic track, and the cement shooting nails 7 are uniformly distributed on the cement bottom layer 1 below the plastic track in a grid shape; the distance between the edge of the grid type formed by the cement shooting nails 7 and the groove 6 is 3-10 cm, so that the grid type formed by the cement shooting nails 7 can not influence the structural strength of the cement groove 6; when the cement shooting nails 7 are shot, matched bullets are selected according to the shooting depth, and after the cement shooting nails 7 finish shooting, the gear ring 8 below each cement shooting nail 7 is compressed to the thickness of 1.5-2.5 mm; thereby using the gear ring 8 as a gasket (note: the gear ring is a component which is matched with the shooting nail); determining the height of the fixedly added grid layer 5 from the upper part of the cement bottom layer 1;

a grid layer 5 is hung on the grid type cement shooting nail 7, and the grid layer 5 is a net-shaped body (commonly called grid cloth, and sold in the market as a finished product) formed by knitting nylon threads (reinforced threads in triangular belts); the grid layer 5 is fixed on the grid-shaped cement shooting nail 7 after being tensioned, the fixed grid layer 5 is positioned between the gear ring 8 and the nail cap, and the tensioned and fixed grid layer 5 is suspended on the terrace above the cement bottom layer 1; trimming the redundant grid layer (which refers to the excess reserved parts on two sides which are not tensioned by the grid-shaped cement shooting nails and are used for covering the upper surface of the cement bottom layer between the groove and the shooting nails) on the groove 6, then rolling the redundant grid layer on a section of elastic rubber soft strip 9, so that the redundant grid layer forms a shaft-shaped body, then tensioning the redundant grid layer and inserting the tensioned redundant grid layer into the bottom of the groove 6, and thus fixing the redundant grid layer on the groove 6 on the ground of the cement bottom layer 1 on the groove; completing the construction process of laying and fixing the structure additionally provided with the grid layer 5;

spraying a bottom oil layer (bottom glue) 2 on the ground of the cement bottom layer 1 (including the partial grid layer on the groove and the groove), wherein the cement bottom layer 1 is added with the grid layer 5, the added grid layer 5 can be wrapped by the thickness of the condensed bottom oil layer (bottom glue) 2, and the ground of the cement bottom layer 1, the cement shooting nails 7 and the added grid layer 5 are condensed and connected into a whole by the condensed bottom oil layer (bottom glue) 2; filling part of base oil (base glue) 2 into the groove 6, wherein the height of the filled base oil (base glue) 2 can submerge the shaft-shaped body of the grid layer plugged into the groove 6; so that the grid layer 5 inserted into the groove is bonded and solidified at the bottom of the groove 6 (the grid layer 5 and the poured base oil are generally within 2 cm of the depth of the groove);

laying a material layer 3 (generally called an elastic layer, generally with the thickness of about 1 cm) of mixed or single granular materials on a bottom oil layer (bottom glue) 2 according to a traditional method, covering a second grid layer 10 on the cured material layer 3 of the mixed or single granular materials, tensioning and fixing four sides of the second grid layer 10, wherein two sides of the second grid layer 10 are tensioned and then plugged into a groove 6 (the method is the same as the treatment process of the grid layer and the groove), pouring glue solution of the bottom glue (bottom glue) layer 2 into the groove 6, and the height of the poured glue solution can submerge the second grid layer 10 plugged into the groove 6 and then fill the groove; so as to condense and fix the edges of the two layers of grid layers 5 and 10 in the groove 6; the other two sides of the second grid layer 10 are temporarily tightened and fixed; preparing for spraying the finish (adhesive) layer 4 on the second grid layer 10; spraying a finish paint (glue) layer 4 on the tensioned second grid layer 10; the thickness of the condensed finish (adhesive) layer 4 can wrap the additionally arranged second grid layer 10, and the condensed finish (adhesive) layer 4, the second grid layer 10 and the solidified mixed or single-particle paving layer 3 are condensed and connected into a whole; therefore, the main body construction operation process of the plastic track after the structure improvement is completed (the scribing process is irrelevant to the scheme and is not described).

The beneficial technological effect of this application is: firstly, the groove 6 is additionally arranged on the ground of the cement bottom layer 1 at the side edge of the plastic track, the grid layer 5 is hung on the grid-type cement shooting nail 7 additionally arranged on the ground of the cement bottom layer 1, and the second grid layer 10 is covered on the mixed or single particle laying layer 3, so that the side edge of the plastic track and the grid layer are bonded and solidified in the groove 6 of the cement bottom layer 1, and the side edge of the plastic track filling the groove 6 is densely embedded in the deep part of the cement bottom layer 1, thereby eliminating the technical defect that the easy-to-open edge of the plastic track is warped;

secondly, through the technical improvement that the grid-type cement shooting nails 7 are additionally arranged on the ground of the cement bottom layer 1, and the two grid layers 5 and 10 are hung on the cement shooting nails 7, the connection strength between the ground of the cement bottom layer 1 and the bottom oil (bottom glue) layer 2 is fundamentally increased (because the connection means of bonding the pure bottom oil and the ground is not only relied on), so that the occurrence of the phenomenon of hollowing and bubbling of the plastic track is eliminated;

thirdly, the technical improvement of adding two layers of grid layers 5 and 10 in the structural construction of the traditional plastic track greatly improves the integral structural strength of the plastic track in use, so that the plastic track with the improved structure is more durable; the weather resistance of the plastic track is prolonged; all of which are significant features and distinct advances over the prior art.

Claims (1)

1. A structure improvement technology of a plastic track is used for eliminating the practical defects that the plastic track has an opening edge which is tilted and is hollowly and frothed; the method is characterized in that:

firstly, a groove (6) is formed in a cement bottom layer (1) on the peripheral edge of the plastic track, and the width of the groove (6) is equal to the edge thickness of the plastic track; the depth of the groove (6) is between 4 and 10 centimeters; the groove (6) is made into a dovetail groove shape with a narrow upper part and a wide lower part; the groove (6) is used for placing the mixture of the residual part of the edge of the first and second additionally arranged grid layers and the bottom oil (2) for use;

in order to fix the additionally arranged grid layer (5), a plurality of cement shooting nails (7) are distributed on the cement bottom layer (1) below the plastic track, and the cement shooting nails (7) are uniformly distributed on the cement bottom layer (1) below the plastic track in a grid shape; the distance between the edge of the grid type formed by the cement shooting nails (7) and the groove (6) is 3-10 cm, so that the grid type formed by the cement shooting nails (7) can not influence the structural strength of the arranged cement groove (6); when the cement shooting nails (7) are launched, matched bullets are selected according to the shooting depth, and after the cement shooting nails (7) finish shooting, the gear ring (8) below each cement shooting nail (7) is compressed to the thickness of 1.5-2.5 mm; thereby using the ring gear (8) as a gasket; determining the height of the fixedly added grid layer (5) from the upper part of the cement bottom layer (1) according to the time;

a grid layer (5) is hung on the grid-shaped cement shooting nail (7), and the grid layer (5) is a net-shaped body formed by knitting nylon threads; the grid layer (5) is fixed on the grid-shaped cement shooting nail (7) after being tensioned, the fixed grid layer (5) is positioned between the gear ring (8) and the nail cap, and the tensioned and fixed grid layer (5) is suspended on a terrace above the cement bottom layer (1); trimming the surplus grid layer on the groove (6) to remove the surplus part, and then rolling the surplus grid layer on a section of elastic rubber soft strip (9), so that the surplus grid layer forms a shaft-shaped body, and then tightening the surplus grid layer and inserting the surplus grid layer into the bottom of the groove (6), so that the surplus grid layer on the groove (6) is fixed on the ground of the cement bottom layer (1) on the groove; completing the construction process of laying and fixing the structure additionally provided with the grid layer (5);

spraying a bottom oil layer (2) on the ground of the cement bottom layer (1) with the additional grid layer (5), wherein the thickness of the condensed bottom oil layer (2) can wrap the additional grid layer (5), and the condensed bottom oil layer (2) condenses and connects the ground of the cement bottom layer (1), the cement shooting nails (7) and the additional grid layer (5) into a whole; pouring glue solution of a part of the bottom oil layer (2) into the groove (6), wherein the height of the poured glue solution can submerge the shaft-shaped body of the grid layer plugged into the groove (6); so that the grid layer (5) inserted into the groove is bonded and solidified at the bottom in the groove (6);

covering a second grid layer (10) on the material layer (3) of the solidified mixed or single particle material, tensioning and fixing four sides of the second grid layer (10), wherein two sides of the second grid layer (10) are tensioned and then are plugged into the groove (6), glue of the bottom oil layer (2) is poured into the groove (6), and the height of the poured glue can submerge the second grid layer (10) plugged into the groove (6) and then fill the groove; so as to condense and fix the edges of the two layers of grid layers (5, 10) in the groove (6); the other two sides of the second grid layer (10) are temporarily tensioned and fixed; thereby preparing for spraying the finishing paint layer (4) on the second grid layer (10); spraying a finishing paint layer (4) on the tensioned second grid layer (10); the thickness of the condensed finish paint layer (4) can wrap the additionally arranged second grid layer (10), and the condensed finish paint layer (4), the second grid layer (10) and the solidified mixed or single-particle paving layer (3) are condensed and connected into a whole; thus, the main body construction operation process of the plastic track after the structure improvement is completed.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202011112996.7A CN112252118A (en) | 2020-10-16 | 2020-10-16 | Structure improvement technology of plastic track |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202011112996.7A CN112252118A (en) | 2020-10-16 | 2020-10-16 | Structure improvement technology of plastic track |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN112252118A true CN112252118A (en) | 2021-01-22 |

Family

ID=74245583

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202011112996.7A Withdrawn CN112252118A (en) | 2020-10-16 | 2020-10-16 | Structure improvement technology of plastic track |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN112252118A (en) |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102007036005A1 (en) * | 2007-07-30 | 2008-10-23 | Alois Dold | Topsoil stabilization hard plastic grid for e.g. playing field, horse stadium has peripheral cylindrical elements |

| CN104264680A (en) * | 2014-10-01 | 2015-01-07 | 西安科技大学 | Foundation treatment method of collapsible loess slope cut-and-fill joint part |

| CN206843893U (en) * | 2017-06-23 | 2018-01-05 | 惠州利达体育设施工程有限公司 | A kind of high tensile power plastic cement race track |

| CN208023354U (en) * | 2018-02-01 | 2018-10-30 | 安徽熊彩体育科技有限公司 | A kind of new type compound plastic cement race track structure |

| CN209178760U (en) * | 2018-10-29 | 2019-07-30 | 林敦玉 | A kind of prefabrication type synthetic court surface layer |

| CN111648554A (en) * | 2020-06-30 | 2020-09-11 | 北京建筑材料科学研究总院有限公司 | Anti-cracking ground filling leveling layer and construction method thereof |

-

2020

- 2020-10-16 CN CN202011112996.7A patent/CN112252118A/en not_active Withdrawn

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102007036005A1 (en) * | 2007-07-30 | 2008-10-23 | Alois Dold | Topsoil stabilization hard plastic grid for e.g. playing field, horse stadium has peripheral cylindrical elements |

| CN104264680A (en) * | 2014-10-01 | 2015-01-07 | 西安科技大学 | Foundation treatment method of collapsible loess slope cut-and-fill joint part |

| CN206843893U (en) * | 2017-06-23 | 2018-01-05 | 惠州利达体育设施工程有限公司 | A kind of high tensile power plastic cement race track |

| CN208023354U (en) * | 2018-02-01 | 2018-10-30 | 安徽熊彩体育科技有限公司 | A kind of new type compound plastic cement race track structure |

| CN209178760U (en) * | 2018-10-29 | 2019-07-30 | 林敦玉 | A kind of prefabrication type synthetic court surface layer |

| CN111648554A (en) * | 2020-06-30 | 2020-09-11 | 北京建筑材料科学研究总院有限公司 | Anti-cracking ground filling leveling layer and construction method thereof |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US9095763B2 (en) | Method and mixture for foundation of a sports area | |

| US4501420A (en) | Playing surfaces sports | |

| US5678951A (en) | Element for synthetic tennis ground and method for its production | |

| US4341836A (en) | Surfacing for sports areas, more particularly tennis courts | |

| JPH01502763A (en) | sports surface | |

| CN105625140A (en) | Construction method for air-permeable and water-drainage self-grained composite plastic track | |

| CN112252117A (en) | Manufacturing and construction method of improved plastic track | |

| CN112252118A (en) | Structure improvement technology of plastic track | |

| EP0093008B1 (en) | Playing surfaces for sports | |

| KR100497567B1 (en) | Eco-friendly and permeable block and the method to manufacture thereof | |

| CN205062608U (en) | Court composite pad | |

| KR100497565B1 (en) | Eco-friendly and permeable structure of elastic layer for pavement and the method to pave thereof | |

| US20200002900A1 (en) | Artificial turf field apparatus and methods | |

| DE2258566A1 (en) | Outdoor tennis court flooring - comprising a base of foam plastic and a surface of clay granules | |

| CN107217566A (en) | The football pitch of air-and water-permeable | |

| JP2546902B2 (en) | Truck pavement method | |

| US2024158A (en) | Playing court | |

| AU2013270530A1 (en) | Artificial Surfaces and Methods for their Production | |

| CN213267383U (en) | Ventilative type plastic course structure | |

| CN207047646U (en) | The football pitch of air-and water-permeable | |

| CN219824797U (en) | Novel silicon PU runway for sports ground | |

| CN208023351U (en) | A kind of weeping plastic track structure | |

| CN208762824U (en) | A kind of compacting-type EPDM sports ground terrace | |

| RU59663U1 (en) | ROOF FOR BUILDING WITH A FLAT ROOF | |

| RU57753U1 (en) | COATING |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| WW01 | Invention patent application withdrawn after publication |

Application publication date: 20210122 |

|

| WW01 | Invention patent application withdrawn after publication |