Self-suction type stud protection device

Technical Field

The invention relates to a stud protection device, in particular to a self-suction type stud protection device.

Background

In production, a plurality of mechanical parts are provided with studs for fastening connection; therefore, in the process of spraying paint on the part, the paint can be adhered to the thread surface of the stud, and in the process of subsequently mounting and fastening the nut, the torque friction value of the nut is increased, the nut cannot be fastened in place, and meanwhile, the phenomenon of thread slipping or falling off can occur; the measures adopted in the prior art are as follows: the thread surface of the stud is wrapped by the adhesive tape, but after the adhesive tape is removed, black marks are often left on the surface which finishes paint spraying, so that the adhesive tape is difficult to process, the appearance is influenced, and unnecessary waste is caused; the surface of the screw thread of the stud can be treated by adopting the traditional threading of the threading die, but the method cannot be used for mass production, and simultaneously, the screw thread is easily damaged in the manual threading process, and the labor intensity is high.

Disclosure of Invention

The invention aims to provide a water tank with simple structure,Convenient operationThe self-suction stud protector.

The invention is realized by the following measures: the utility model provides a from inhaling formula double-screw bolt protector, includes that upper end open-ended cylindric lag tube is in with the setting circular high temperature resistant neodymium iron boron magnetic steel of lag tube inside. Utilize circular high temperature resistant neodymium iron boron magnetic steel to become magnetic connection to the stud, can carry out quick self-priming location to the stud of all directions, realize quick installation.

An adjusting mechanism capable of adjusting the position of the round high-temperature-resistant neodymium iron boron magnetic steel is arranged on the protective sleeve; the bottom of the protective sleeve is provided with a square notch, the adjusting mechanism comprises a connecting rod, one end of the connecting rod penetrates through the square notch to enter the protective sleeve and is fixedly connected with the round high-temperature-resistant neodymium-iron-boron magnetic steel, and the other end of the connecting rod is fixedly provided with a handle;

two pairs of supporting rods are symmetrically arranged on two opposite side walls of the square notch, the other end of each supporting rod positioned on the same side is sleeved with a cuboid neodymium iron boron magnetic steel, a semicircular notch is formed in one side, close to the connecting rod, of each of the two cuboid neodymium iron boron magnetic steels, and the circular high-temperature resistant neodymium iron boron magnetic steel is used for enabling the protection sleeve to be adsorbed on the surface of the connecting rod; be located the bracing piece is peripheral cuboid neodymium iron boron magnetic steel with be provided with the spring between the square notch lateral wall, make circular high temperature resistant neodymium iron boron magnetic steel can reach flexible effect, convenient activity the connecting rod.

The inner wall of the protective sleeve is axially provided with a slideway matched with the bulge, and the circular high-temperature-resistant neodymium-iron-boron magnetic steel can move in the protective sleeve along the direction of the slideway through the matching between the bulge and the slideway.

The lower end face of the bottom of the protective sleeve is provided with a baffle plate for sealing the square notch, so that the rectangular neodymium iron boron magnetic steel is prevented from being sprayed on the surface of the rectangular neodymium iron boron magnetic steel during paint spraying; the middle part of the baffle is provided with a circular through hole matched with the connecting rod for use, so that the connecting rod is convenient to move.

The surface of the part of the connecting rod, which penetrates out of the square notch, is provided with a sliding sleeve, and the sliding sleeve comprises a cylindrical barrel and an annular convex edge arranged on the outer surface of the cylindrical barrel; the inner diameter of the cylindrical barrel is slightly larger than the diameter of the connecting rod, the connecting rod is used for cleaning residual paint on the surface of the connecting rod, and the connecting rod is prevented from moving due to excessive influence of the residual paint.

The square handle is provided with the connecting hole and is connected the connecting chain of connecting hole is convenient for arrange and collect protector, avoids losing.

The protective sleeve is made of cast steel and can be recycled for a long time; the circular high-temperature-resistant neodymium iron boron magnetic steel is made of high-temperature-resistant neodymium iron boron magnetic steel.

When the connecting rod is used, the protecting sleeve is pushed to the stud arranged on the surface of a component lightly, so that the circular high-temperature-resistant neodymium-iron-boron magnetic steel absorbs the end of the stud, the position of the protecting sleeve is adjusted according to the effective thread length of the surface of the stud, and the protecting sleeve is adsorbed on the surface of the connecting rod by virtue of the cuboid neodymium-iron-boron magnetic steel; after the spraying is finished, the protective sleeve is pulled back lightly for continuous recycling.

The invention also provides another self-suction type stud protection device which comprises a cylindrical protection sleeve with an opening at the upper end and circular high-temperature-resistant neodymium-iron-boron magnetic steel arranged in the protection sleeve. The circular high-temperature-resistant neodymium iron boron magnetic steel is used for forming magnetic connection on the stud, so that the studs in all directions can be quickly positioned in a self-absorption mode, and quick installation is realized.

An adjusting mechanism capable of adjusting the position of the round high-temperature-resistant neodymium iron boron magnetic steel is arranged on the protective sleeve; the bottom of the protective sleeve is provided with a circular notch, the adjusting mechanism comprises a connecting rod, one end of the connecting rod penetrates through the circular notch to enter the protective sleeve and is fixedly connected with the circular high-temperature-resistant neodymium iron boron magnetic steel, and the other end of the connecting rod is fixedly provided with a handle;

circular high temperature resistant neodymium iron boron magnetic steel side symmetry is provided with two protruding stupefied, prevents circular high temperature resistant neodymium iron boron magnetic steel is in the protection sleeve internal rotation, protection sleeve inner wall axial be provided with protruding stupefied cooperation slide of using, through protruding stupefied with cooperation between the slide makes circular high temperature resistant neodymium iron boron magnetic steel can follow in the protection sleeve slide direction activity is located the connecting rod both sides protection sleeve bottom end face symmetry is provided with two buckles, the buckle can make protection sleeve card be in the connecting rod surface.

The buckle comprises two pairs of fixed plates which are symmetrically arranged on the lower end face of the protective sleeve, a rotating plate is arranged between the fixed plates and arranged between the fixed plates through a rotating shaft, and a torsion spring is arranged between the rotating plate and the fixed plates, so that the buckle has elasticity and is convenient to move.

A cuboid buckle protective shell is arranged on the lower end face of the bottom of the protective sleeve, so that the protective sleeve is prevented from being sprayed to the surface of the buckle during paint spraying; the lower end face of the buckle protective shell is provided with a circular through hole matched with the connecting rod for use.

The connecting rod penetrates out of the surface of the part of the circular notch, and a sliding sleeve is arranged on the surface of the part of the connecting rod, which penetrates out of the circular notch.

The sliding sleeve comprises a cylindrical barrel body and an annular convex edge arranged on the outer surface of the cylindrical barrel body; the inner diameter of the cylindrical barrel is slightly larger than the diameter of the connecting rod, the connecting rod is used for cleaning residual paint on the surface of the connecting rod, and the connecting rod is prevented from moving due to excessive influence of the residual paint.

The square handle is provided with a connecting hole and a connecting chain for connecting the connecting hole, so that the protective device is convenient to arrange and collect, and the loss is avoided.

The protective sleeve is made of cast steel and can be recycled for a long time; the circular high-temperature-resistant neodymium iron boron magnetic steel is made of high-temperature-resistant neodymium iron boron magnetic steel.

When the connecting rod is used, the protecting sleeve is pushed to the stud arranged on the surface of a component lightly, so that the circular high-temperature-resistant neodymium-iron-boron magnetic steel absorbs the end of the stud, the position of the protecting sleeve is adjusted according to the effective thread length on the surface of the stud, and the protecting sleeve is fixed on the surface of the connecting rod by utilizing a buckle; after the spraying is finished, the protective sleeve is pulled back lightly for continuous recycling.

The invention also provides a self-suction type stud protection device which comprises a cylindrical protection sleeve with an opening at the upper end and circular high-temperature-resistant neodymium-iron-boron magnetic steel arranged in the protection sleeve. The circular high-temperature-resistant neodymium iron boron magnetic steel is used for forming magnetic connection on the stud, so that the studs in all directions can be quickly positioned in a self-absorption mode, and quick installation is realized.

An adjusting mechanism capable of adjusting the position of the round high-temperature-resistant neodymium iron boron magnetic steel is arranged on the protective sleeve; the bottom of the protective sleeve is provided with a circular notch, the adjusting mechanism comprises a connecting rod, one end of the connecting rod penetrates through the circular notch to enter the protective sleeve and is fixedly connected with the circular high-temperature-resistant neodymium iron boron magnetic steel, and the other end of the connecting rod is fixedly provided with a handle;

the round high-temperature resistant neodymium iron boron magnetic steel in the protective sleeve is adsorbed at the end of a protected stud, and the position of the protective sleeve can be adjusted according to the effective thread length of the protected stud by means of the matching of the internal thread and the external thread.

The connecting rod penetrates out of the surface of the part of the circular notch, and a sliding sleeve is arranged on the surface of the part of the connecting rod, which penetrates out of the circular notch.

The sliding sleeve comprises a cylindrical barrel body and an annular convex edge arranged on the outer surface of the cylindrical barrel body; the inner diameter of the cylindrical barrel is slightly larger than the diameter of the connecting rod; the paint cleaning device is used for cleaning residual paint on the surface of the connecting rod, and the connecting rod is prevented from moving due to excessive influence of the residual paint.

The square handle is provided with a connecting hole and a connecting chain for connecting the connecting hole, so that the protective device is convenient to arrange and collect, and the loss is avoided.

The protective sleeve is made of cast steel and can be recycled for a long time; the circular high-temperature-resistant neodymium iron boron magnetic steel is made of high-temperature-resistant neodymium iron boron magnetic steel.

When the high-temperature-resistant neodymium iron boron magnetic steel protecting sleeve is used, the protecting sleeve is pushed to a stud arranged on the surface of a component lightly, so that the circular high-temperature-resistant neodymium iron boron magnetic steel absorbs the end of the stud, the circular high-temperature-resistant neodymium iron boron magnetic steel is fixed through the square handle and the connecting rod by means of matching of the internal thread and the external thread according to the length of the effective thread on the surface of the stud, the protecting sleeve is rotated, the position of the protecting sleeve is adjusted, and the stud thread is isolated by the protecting sleeve; and after the spraying is finished, the protective sleeve is taken back by slightly pulling, and the protective sleeve is continuously recycled.

The invention has the beneficial effects that: the invention has the advantages of simple structure, convenient operation, quick positioning, recycling and the like, can comprehensively protect studs at various angles, can not leave destructive traces on the surface of a workpiece, is also suitable for studs with different lengths, and has strong practicability.

Drawings

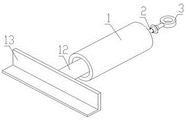

Fig. 1 is a schematic structural diagram of embodiment 1 of the present invention.

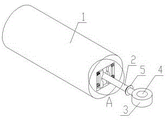

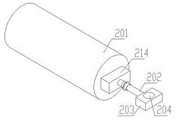

Fig. 2 is a schematic structural view of embodiment 1 of the present invention without a baffle.

Fig. 3 is a detailed view of the detail a of fig. 2.

Fig. 4 is an exploded schematic structural diagram of embodiment 1 of the present invention.

Fig. 5 is a usage state diagram of embodiment 1 of the present invention.

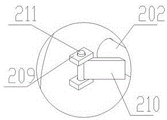

Fig. 6 is a schematic structural diagram of embodiment 2 of the present invention.

Fig. 7 is a schematic structural view of embodiment 2 without a snap protection layer.

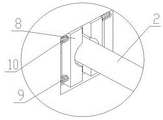

Fig. 8 is a detail view of detail a of fig. 6.

Fig. 9 is an exploded schematic view of embodiment 2 of the present invention.

Fig. 10 is a usage state diagram of embodiment 2 of the present invention.

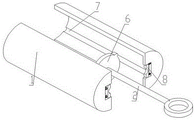

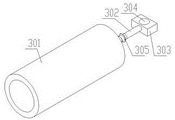

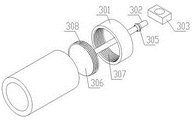

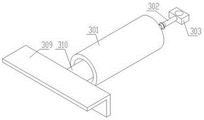

Fig. 11 is a schematic structural diagram of embodiment 3 of the present invention.

Fig. 12 is an exploded schematic view of embodiment 3 of the present invention.

Fig. 13 is a usage state diagram of embodiment 3 of the present invention.

Wherein the reference numerals are:

1. a protective sleeve; 2. a connecting rod; 3. a round handle; 4. connecting holes; 5. a sliding sleeve; 6. round high-temperature resistant neodymium iron boron magnetic steel; 7. a slideway; 8. cuboid neodymium iron boron magnetic steel; 9. a support bar; 10. a spring; 11. a baffle plate; 12. a stud; 13. a component.

201. A protective sleeve; 202. a connecting rod; 203. a square handle; 204. connecting holes; 205. a sliding sleeve; 206. round high-temperature resistant neodymium iron boron magnetic steel; 207. convex edges; 208. a slideway; 209. a fixing plate; 210. rotating the plate; 211. a rotating shaft; 212. a stud; 213. component 214, buckle protective shell.

301. A protective sleeve; 302. a connecting rod; 303. a square handle; 304. connecting holes; 305. a sliding sleeve; 306. round high-temperature resistant neodymium iron boron magnetic steel; 307. an internal thread; 308. an external thread; 309. a member; 310. a stud.

Detailed Description

In order to clearly illustrate the technical features of the present solution, the present solution is explained below by way of specific embodiments.

Example 1

Referring to fig. 1-4, the embodiment of the invention provides a self-suction stud protection device, which is characterized by comprising a cylindrical protection sleeve 1 with an opening at the upper end and a connecting rod 2 arranged on the protection sleeve 1, wherein a square notch is formed in the bottom of the protection sleeve 1, the connecting rod 2 penetrates through the square notch to enter one end of the protection sleeve 1, and a round high-temperature-resistant neodymium-iron-boron magnetic steel 6 is fixedly arranged on one end of the protection sleeve 1, and the high-temperature-resistant neodymium-iron-boron magnetic steel is used for forming magnetic connection on a stud, so that the stud in each direction can be quickly positioned in a self-suction manner, and quick installation is realized; the other end of the connecting rod 2 is fixedly provided with a round handle 3.

Referring to fig. 2 and 3, two pairs of support rods 9 are symmetrically arranged on two opposite side walls of the square notch, the other ends of the support rods 9 positioned on the same side are sleeved with a cuboid neodymium iron boron magnetic steel 8, semicircular notches are formed in the two cuboid neodymium iron boron magnetic steels 8 close to one sides of the connecting rods 2, and the protection sleeve 1 is adsorbed on the surface of the connecting rod 2 by virtue of the cuboid neodymium iron boron magnetic steel 8; be located and be provided with spring 10 between peripheral cuboid neodymium iron boron magnetic steel 8 of bracing piece 9 and the square notch lateral wall, make cuboid neodymium iron boron magnetic steel 8 can reach flexible effect, make things convenient for swing joint pole 2.

Referring to fig. 1-4, a slideway 7 matched with the protrusion is axially arranged on the inner wall of the protective sleeve 1, and the circular high-temperature-resistant neodymium-iron-boron magnetic steel 6 can move in the protective sleeve 1 along the slideway 7 through the matching between the protrusion and the slideway 7; the lower end face of the bottom of the protective sleeve 1 is provided with a baffle 11 for sealing the square notch, so that the spray paint is prevented from being sprayed onto the surface of the cuboid neodymium iron boron magnetic steel 8; the middle part of the baffle is provided with a circular through hole matched with the connecting rod 2 for use, so that the connecting rod 2 can be conveniently moved.

Referring to fig. 1-4, a sliding sleeve 5 is arranged on the surface of the part of the connecting rod 2, which penetrates out of the square notch, and the sliding sleeve 5 comprises a cylindrical barrel and an annular convex edge arranged on the outer surface of the cylindrical barrel; the inner diameter of the cylindrical barrel is slightly larger than the diameter of the connecting rod 2, and the cylindrical barrel is used for cleaning residual paint on the surface of the connecting rod 2 and avoiding excessive residual paint from influencing the movement of the connecting rod 2; the square handle is provided with the connecting holes 4 and the connecting chains for connecting the connecting holes 4, so that the collecting and protecting device is convenient to arrange and avoid being lost; the protective sleeve 1 is made of cast steel and can be recycled for a long time.

Referring to fig. 1-5, when in use, the protection sleeve 1 is slightly pushed to the stud 12 arranged on the surface of the component 13, so that the circular high-temperature-resistant neodymium-iron-boron magnetic steel 6 absorbs the end of the stud 12, the position of the protection sleeve 1 is adjusted according to the effective thread length on the surface of the stud 12, and the protection sleeve 1 is adsorbed on the surface of the connecting rod 2 by virtue of the cuboid neodymium-iron-boron magnetic steel 8; after the spraying is finished, the protective sleeve 1 is pulled back lightly for continuous recycling.

Example 2

Referring to fig. 6-9, the embodiment of the invention provides a buckle adjustment self-suction type stud protection device, which comprises a protection sleeve 201 and a connecting rod 202 arranged on the protection sleeve 201, wherein the protection sleeve 201 is a hollow cylinder with an opening at the upper end, a circular notch is formed in the bottom of the protection sleeve 201, the connecting rod 202 penetrates through the circular notch to enter one end of the protection sleeve 201, a circular high-temperature-resistant neodymium-iron-boron magnetic steel 206 is fixedly arranged, the high-temperature-resistant neodymium-iron-boron magnetic steel is used for forming magnetic connection on the stud, and the stud in each direction can be quickly positioned in a self-suction manner, so that quick installation is realized; the other end of the connecting rod 202 is fixedly provided with a square handle 203;

referring to fig. 6-9, two protruding ridges 207 are symmetrically arranged on the side surface of the circular high temperature resistant ndfeb magnetic steel 206 to prevent the circular high temperature resistant ndfeb magnetic steel 206 from rotating in the protective sleeve 201; the inner wall of the protective sleeve 201 is axially provided with a slideway 208 which is matched with the convex edge 207 for use, and the circular high-temperature-resistant neodymium-iron-boron magnetic steel 206 can move in the protective sleeve 201 along the direction of the slideway 208 through the matching between the convex edge 207 and the slideway 208; be located connecting rod 202 both sides protection sleeve 201 bottom end face symmetry and be provided with two buckles, the buckle can make protection sleeve 201 block on connecting rod 202 surface.

Referring to fig. 7 and 8, the buckle includes two pairs of fixing plates 209 symmetrically disposed on the lower end surface of the protective sleeve 201, a rotating plate 210 is disposed between the fixing plates 209, the rotating plate 210 is disposed between the fixing plates 209 through a rotating shaft 211, and a torsion spring is disposed between the rotating plate 210 and the fixing plates 209, so that the buckle has elasticity and is convenient for moving the connecting rod 202; a cuboid buckle protective shell 214 is arranged on the lower end face of the bottom of the protective sleeve 201 to prevent the paint from being sprayed on the surface of the buckle; the lower end surface of the buckle protection shell 214 is provided with a circular through hole used in cooperation with the connecting rod 202.

Referring to fig. 6, the surface of the portion, which penetrates out of the circular notch, of the connecting rod 202 is provided with a sliding sleeve 205, and the sliding sleeve 205 comprises a cylindrical barrel body and an annular convex edge 207 arranged on the outer surface of the cylindrical barrel body; the inner diameter of the cylindrical barrel is slightly larger than the diameter of the connecting rod 202, so that residual paint on the surface of the connecting rod 202 is cleaned, and the phenomenon that the movement of the connecting rod 202 is influenced by excessive residual paint is avoided; the square handle 203 is provided with the connecting holes 204 and the connecting chains for connecting the connecting holes 204, so that the collecting and protecting device is convenient to arrange and avoid being lost; the protective sleeve 201 is made of cast steel and can be recycled for a long time.

Referring to fig. 6-10, when in use, the protection sleeve 201 is slightly pushed to the stud 212 arranged on the surface of the component 213, so that the circular high-temperature-resistant ndfeb magnet 206 absorbs the end of the stud 212, the position of the protection sleeve 201 is adjusted according to the effective thread length on the surface of the stud 212, and the protection sleeve 201 is fixed on the surface of the connecting rod 202 by using a buckle; after spraying, the protective sleeve 201 is pulled back slightly, and the spraying is recycled.

Example 3

Referring to fig. 11 and 12, the invention discloses a thread adjustment self-suction stud protection device, which comprises a cylindrical protection sleeve 301 with an opening at the upper end and a connecting rod 302 arranged on the protection sleeve 301, wherein a circular notch is formed at the bottom of the protection sleeve 301, the connecting rod 302 penetrates through the circular notch to enter one end of the protection sleeve 301 and is provided with a circular high-temperature-resistant neodymium-iron-boron magnetic steel 306, and the high-temperature-resistant neodymium-iron-boron magnetic steel is used for forming magnetic connection on a stud, so that the stud in each direction can be quickly positioned in a self-suction manner, and quick installation is realized; the other end of the connecting rod 302 is fixedly provided with a square handle 303;

referring to fig. 11 and 12, the side surface of the circular high temperature resistant ndfeb magnet 306 is provided with an external thread 308, the lower half part of the inner side of the protective sleeve 301 is provided with an internal thread 307 matched with the external thread 308, the square handle 303 is rotated, the connecting rod 302 drives the circular high temperature resistant ndfeb magnet 306 to move, the circular high temperature resistant ndfeb magnet 306 is adsorbed at the end of the protected stud, and the position of the protective sleeve 301 can be adjusted according to the effective thread length of the protected stud by matching the internal thread 307 with the external thread 308.

Referring to fig. 11 and 12, the connecting rod 302 is provided with a sliding sleeve 305 penetrating through the surface of the circular notch part; the sliding sleeve 305 includes a cylindrical barrel body and an annular ridge provided on the outer surface of the cylindrical barrel body; the inner diameter of the cylindrical barrel is slightly larger than the diameter of the connecting rod 302; the device is used for cleaning residual paint on the surface of the connecting rod 302, so that the phenomenon that the residual paint is too much to influence the movement of the connecting rod 302 is avoided; the square handle 303 is provided with the connecting hole 304 and a connecting chain for connecting the connecting hole 304, so that the collecting and protecting device is convenient to arrange and avoid being lost; the protective sleeve 301 is made of cast steel and can be recycled for a long time.

Referring to fig. 11-13, in use, the protection sleeve 301 is slightly pushed towards the stud 310 arranged on the surface of the component 309, so that the circular high-temperature-resistant ndfeb magnet 306 absorbs the end of the stud 310, the circular high-temperature-resistant ndfeb magnet 306 is fixed through the square handle 303 and the connecting rod 302 according to the effective thread length on the surface of the stud 310 by means of the matching of the internal thread 307 and the external thread 308, the protection sleeve 301 is rotated, the position of the protection sleeve 301 is adjusted, and the protection sleeve 301 is used for isolating the thread of the stud 310; after spraying, the protective sleeve 301 is pulled back slightly to continue recycling.

The technical features of the present invention which are not described in the above embodiments may be implemented by or using the prior art, and are not described herein again, of course, the above description is not intended to limit the present invention, and the present invention is not limited to the above examples, and variations, modifications, additions or substitutions which may be made by those skilled in the art within the spirit and scope of the present invention should also fall within the protection scope of the present invention.