CN103737583A - Mechanical arm with symmetrical mechanisms - Google Patents

Mechanical arm with symmetrical mechanisms Download PDFInfo

- Publication number

- CN103737583A CN103737583A CN201310692366.5A CN201310692366A CN103737583A CN 103737583 A CN103737583 A CN 103737583A CN 201310692366 A CN201310692366 A CN 201310692366A CN 103737583 A CN103737583 A CN 103737583A

- Authority

- CN

- China

- Prior art keywords

- connecting rod

- revolute pair

- link

- drives

- mechanisms

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Landscapes

- Manipulator (AREA)

Abstract

The invention discloses a mechanical arm with symmetrical mechanisms. The mechanical arm comprises a plurality of parallel mechanism closed loop execution mechanism sub-chains and a series execution mechanism main chain. A main chain connecting rod can be controlled by the mechanism closed loop sub-chains to move in the plane where a four-rod mechanism closed loop sub-chain is located, and spatial motion of a movable platform can be achieved through motion of a plurality of parallel connecting rod sub-chains and a machine body. Control is achieved through resultant movement of four closed-loop sub-chains and the machine body; spatial motion of a tail end executor is achieved through connection of a plurality of connecting rods and the machine body; the tail end executor is small in motion inertia, good in dynamics performance and high in reliability; the mechanisms have the advantages of being compact in structure and easy to control; light rods can be produced; because the mechanisms are large in work space, the gravity of the mechanisms moves backwards, and the mechanisms are kept balanced and can be applied to more occasions.

Description

Technical field

The present invention relates to robot field, particularly there is symmetrical mechanism type manipulator.

Background technology

Traditional serial machine people has the advantages such as simple in structure, cost is low, working space is large, and serial machine people rigidity is low comparatively speaking, can not be applied at a high speed the occasion of large carrying; Parallel robot and traditional serial machine people compare, have without accumulated error, precision compared with high, compact conformation, the feature such as bearing capacity is large, rigidity is high and end effector inertia is little, drive unit can be placed on fixed platform or approach the position of fixed platform, motion parts is lightweight like this, speed is high, and dynamic response is good; But the distinct disadvantage of the parallel robot little and complex structure that is working space.In engineering the existing manipulator with local closed chain as MOTOMAN-K10 do not solve industrial robot exist problem, and the general parallel institution of the Performance Ratio of the parallel robot of the closed loop subchain that contains symmetrical mechanism formula is more superior, have that working space is large, rigidity is high, bearing capacity is strong, inertia is little and end effector precision advantages of higher, can be applied in the complex jobs such as welding, spraying, carrying, handling, assembling, piling, effective raises labour efficiency, and aspect product quality and stability, is improving a lot.Adopt the manipulator of circular cylindrical coordinate type and joint coordinates type effectively and efficiently to tail house, to control, and this mechanism structure good rigidity, machine driving precision are high, working space is large, machine driving loss is little, without accumulated error, can export larger power, have and have good control function.This robot containing parallel closed loop subchain adopts indirect type of drive, can also effectively reduce the needed moment of driving joint.

Summary of the invention

The object of the present invention is to provide and there is symmetrical mechanism type manipulator, solve traditional serial machine people large about required moment, the low and little shortcoming of working space of rigidity.

The present invention achieves the above object by the following technical programs: have symmetrical mechanism type manipulator, its structure and connected mode are:

Described executing agency chain is by fuselage 2, first connecting rod 3, second connecting rod 13, third connecting rod 7, the 4th connecting rod 11, the 5th connecting rod 5, the 6th connecting rod 9, seven-link assembly 14, the 8th connecting rod 31, the 9th connecting rod 17, the tenth connecting rod 18, the 11 connecting rod 19, the 12 connecting rod 33, the 13 connecting rod 35, end effector 21 and frame 1 are formed by connecting, fuselage 2 first links 22 are connected with frame 1 by the first revolute pair 22, fuselage 2 drives by the first revolute pair 22, the first revolute pair 22 drives by motor, 1 second link 25 of fuselage is connected with first connecting rod 3 first links 25 by the second revolute pair 25, first connecting rod 3 drives by the second revolute pair 25, the 3rd link 15 of fuselage 2 is connected with second connecting rod 13 first links 15 by the 3rd revolute pair 15, by the 4th revolute pair 26 and third connecting rod 7, first is connected 26 ends and connects 13 second links 26 of second connecting rod, the 3rd link 27 of second connecting rod 13 is connected with the 4th connecting rod 11 first links 27 by the 5th revolute pair 27, the 4th link of second connecting rod 3 32 is connected with the 12 connecting rod 33 one end by 15 revolute pairs 32, the 12 connecting rod 33 other ends are by the 16 revolute pair the 34 and the 13 connecting rod 35 1 end links, the 13 connecting rod 35 other ends are connected by 2 second links 25 of the second revolute pair 25 and fuselage, the 5th connecting rod 5 one end are connected by 3 second links 4 of the 6th revolute pair 4 and first connecting rod, the 5th connecting rod 5 other ends are connected by 7 second links 6 of the 7th revolute pair 6 and third connecting rod, the 6th connecting rod 9 one end are connected by 7 second links 6 of the 7th revolute pair 6 and third connecting rod, the 6th connecting rod 9 other ends are connected by 11 second links 10 of the 8th revolute pair 10 and the 4th connecting rod, seven-link assembly 14 one end are connected by the 3rd link 16 of the 9th revolute pair 16 and first connecting rod 3, seven-link assembly 14 other ends are connected by the 3rd link 8 of the tenth revolute pair 8 and third connecting rod 7, the 8th connecting rod 31 one end are connected by the 3rd link 8 of the tenth revolute pair 8 and third connecting rod 7, the 8th connecting rod 31 other ends are connected by the 3rd link 12 of the 11 revolute pair 12 and the 4th connecting rod 11, the 4th the 4th, connecting rod 11 link 28 is connected with the 9th connecting rod 17 one end by being rigidly connected, the 9th connecting rod 17 other ends are connected with the tenth connecting rod 18 one end by the 12 revolute pair 29, the tenth connecting rod 18 drives by the 12 revolute pair 29, the 12 revolute pair 29 drives by motor, the tenth connecting rod 18 other ends are connected with the 11 connecting rod 19 one end by the 13 revolute pair 30, the 11 connecting rod 19 drives by the 13 revolute pair 30, the 13 rotates 30 pairs drives by motor, the 11 connecting rod 19 other ends are connected with end effector 21 by the 14 revolute pair 20, end effector 21 drives by the 14 revolute pair 20, the 14 revolute pair 20 drives by motor,

Described the first revolute pair is perpendicular to frame, and the second revolute pair, the 3rd revolute pair, the 4th revolute pair, the 5th revolute pair, the 6th revolute pair, the 7th revolute pair, the 8th revolute pair, the 9th revolute pair, the tenth revolute pair, the 11 revolute pair, the 12 revolute pair and the 13 revolute pair rotation are parallel to each other.

Outstanding advantages of the present invention is:

1, by two parallel closed loop subchains, improved the rigidity of robot mechanism, and the design of closed loop subchain mechanism type improves the working space of robot greatly, can avoid the dead-centre position of mechanism, the sphere of action of micromatic setting Neng Shi robot is larger, and Neng Shi mechanism better keeps balance;

2, compared with the industrial robot that is mounted in each joint with traditional motor, the motor of the robot that mechanism connects by two parallel closed loop subchains is mounted on four-bar mechanism joint, by the kinematic pair on four-bar mechanism, drive closed loop chain movement, thereby indirectly drive tail end connecting rod, make mobility and the activity space of end effector larger, can reduce active moment;

3, compare with robot mechanism of the same type, under equal-wattage, work is more;

4, motor be arranged on connecting rod after, reduced the center of gravity of whole mechanism, and can installation power larger motor is in mechanism, and end effector can be adapted in the complex jobs such as welding, spraying, carrying, handling, assembling, piling;

5, robot mechanism endways actuator by mechanism type control, can make precision higher;

6, between mechanism type mechanism and end execution, with a with gemel connecting rod and end effector, be connected, make actuator flexibility ratio higher, working space is larger than robot in the past, and with gemel connecting rod is made lighter bar, can make whole mechanism power performance better and be easy to control, can make end effector among a small circle, rotate 360 degree round angles, make mechanism can be applicable to more occasions;

7, in two parallel closed loop subchains, rod member is made lighter bar, and mechanism kinematic inertia is little, and dynamic performance is good;

8, the micromatic setting in mechanism is with traditional with compared with the manipulator of local closed chain, center of gravity concentrates on micromatic setting, and balance of mechanism is good, can make robot mechanism bear larger force and moment;

9, six-freedom degree makes mechanism can be applied to more occasions;

Accompanying drawing explanation

Fig. 1 is first structural representation with symmetrical mechanism type manipulator of the present invention.

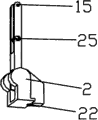

Fig. 2 is the airframe structure schematic diagram with symmetrical mechanism type manipulator of the present invention.

Fig. 3 is the second connecting rod schematic diagram with symmetrical mechanism type manipulator of the present invention.

Fig. 4 is the third connecting rod schematic diagram with symmetrical mechanism type manipulator of the present invention.

Fig. 5 is the 4th connecting rod schematic diagram with symmetrical mechanism type manipulator of the present invention.

Fig. 6 is the 5th connecting rod schematic diagram with symmetrical mechanism type manipulator of the present invention.

Fig. 7 is the 12 connecting rod schematic diagram with symmetrical mechanism type manipulator of the present invention.

Fig. 8 is the 13 connecting rod schematic diagram with symmetrical mechanism type manipulator of the present invention.

Fig. 9 is that the part body with symmetrical mechanism type manipulator of the present invention connects intention.

Figure 10 is the first work schematic diagram with symmetrical mechanism type manipulator of the present invention.

Figure 11 is the second work schematic diagram with symmetrical mechanism type manipulator of the present invention.

The specific embodiment

Below in conjunction with drawings and Examples, technical scheme of the present invention is described further.

Contrast Fig. 1, Fig. 2, Fig. 3, Fig. 4, Fig. 5 and Fig. 6, have symmetrical mechanism type manipulator, and its structure and connected mode are:

Described executing agency chain is by fuselage 2, first connecting rod 3, second connecting rod 13, third connecting rod 7, the 4th connecting rod 11, the 5th connecting rod 5, the 6th connecting rod 9, seven-link assembly 14, the 8th connecting rod 31, the 9th connecting rod 17, the tenth connecting rod 18, the 11 connecting rod 19, the 12 connecting rod 33, the 13 connecting rod 35, end effector 21 and frame 1 are formed by connecting, fuselage 2 first links 22 are connected with frame 1 by the first revolute pair 22, fuselage 2 drives by the first revolute pair 22, the first revolute pair 22 drives by motor, 1 second link 25 of fuselage is connected with first connecting rod 3 first links 25 by the second revolute pair 25, first connecting rod 3 drives by the second revolute pair 25, the 3rd link 15 of fuselage 2 is connected with second connecting rod 13 first links 15 by the 3rd revolute pair 15, by the 4th revolute pair 26 and third connecting rod 7, first is connected 26 ends and connects 13 second links 26 of second connecting rod, the 3rd link 27 of second connecting rod 13 is connected with the 4th connecting rod 11 first links 27 by the 5th revolute pair 27, the 4th link of second connecting rod 3 32 is connected with the 12 connecting rod 33 one end by 15 revolute pairs 32, the 12 connecting rod 33 other ends are by the 16 revolute pair the 34 and the 13 connecting rod 35 1 end links, the 13 connecting rod 35 other ends are connected by 2 second links 25 of the second revolute pair 25 and fuselage, the 5th connecting rod 5 one end are connected by 3 second links 4 of the 6th revolute pair 4 and first connecting rod, the 5th connecting rod 5 other ends are connected by 7 second links 6 of the 7th revolute pair 6 and third connecting rod, the 6th connecting rod 9 one end are connected by 7 second links 6 of the 7th revolute pair 6 and third connecting rod, the 6th connecting rod 9 other ends are connected by 11 second links 10 of the 8th revolute pair 10 and the 4th connecting rod, seven-link assembly 14 one end are connected by the 3rd link 16 of the 9th revolute pair 16 and first connecting rod 3, seven-link assembly 14 other ends are connected by the 3rd link 8 of the tenth revolute pair 8 and third connecting rod 7, the 8th connecting rod 31 one end are connected by the 3rd link 8 of the tenth revolute pair 8 and third connecting rod 7, the 8th connecting rod 31 other ends are connected by the 3rd link 12 of the 11 revolute pair 12 and the 4th connecting rod 11, the 4th the 4th, connecting rod 11 link 28 is connected with the 9th connecting rod 17 one end by being rigidly connected, the 9th connecting rod 17 other ends are connected with the tenth connecting rod 18 one end by the 12 revolute pair 29, the tenth connecting rod 18 drives by the 12 revolute pair 29, the 12 revolute pair 29 drives by motor, the tenth connecting rod 18 other ends are connected with the 11 connecting rod 19 one end by the 13 revolute pair 30, the 11 connecting rod 19 drives by the 13 revolute pair 30, the 13 rotates 30 pairs drives by motor, the 11 connecting rod 19 other ends are connected with end effector 21 by the 14 revolute pair 20, end effector 21 drives by the 14 revolute pair 20, the 14 revolute pair 20 drives by motor,

Described the first revolute pair is perpendicular to frame, and the second revolute pair, the 3rd revolute pair, the 4th revolute pair, the 5th revolute pair, the 6th revolute pair, the 7th revolute pair, the 8th revolute pair, the 9th revolute pair, the tenth revolute pair, the 11 revolute pair, the 12 revolute pair and the 13 revolute pair rotation are parallel to each other.

Contrast Fig. 2, Fig. 3, Fig. 4, Fig. 5, Fig. 6 and Fig. 7, fuselage and first connecting rod motion planar can realize the spatial movement of end effector.

Claims (1)

1. have symmetrical mechanism type manipulator, its structure and connected mode are:

Described executing agency chain is by fuselage, first connecting rod, second connecting rod, third connecting rod, the 4th connecting rod, the 5th connecting rod, the 6th connecting rod, seven-link assembly, the 8th connecting rod, the 9th connecting rod, the tenth connecting rod, the 11 connecting rod, the 12 connecting rod, the 13 connecting rod, end effector and frame are formed by connecting, first link of fuselage is connected with frame by the first revolute pair, fuselage drives by the first revolute pair, the first revolute pair drives by motor, second link of fuselage is connected by first link of the second revolute pair and first connecting rod, first connecting rod drives by the second revolute pair, the 3rd link of fuselage is connected by the 3rd first link of revolute pair and second connecting rod, second link of second connecting rod is connected by the 4th first link of revolute pair and third connecting rod, the 3rd link of second connecting rod is connected with the 4th first link of connecting rod by the 5th revolute pair, the 4th link of second connecting rod is connected with the 12 connecting rod one end by 15 revolute pairs, the 12 connecting rod other end is by the 16 revolute pair and the 13 connecting rod one end link, the 13 connecting rod other end is connected by second link of the second revolute pair and fuselage, the 5th connecting rod one end is connected by second link of the 6th revolute pair and first connecting rod, the 5th connecting rod other end is connected by second link of the 7th revolute pair and third connecting rod, the 6th connecting rod one end is connected by second link of the 7th revolute pair and third connecting rod, the 6th connecting rod other end is connected by second link of the 8th revolute pair and the 4th connecting rod, seven-link assembly one end is connected by second link of the 9th revolute pair and first connecting rod, the seven-link assembly other end is connected by the 3rd link of the tenth revolute pair and third connecting rod, the 8th connecting rod one end is connected by the 3rd link of the tenth revolute pair and third connecting rod, the 8th connecting rod other end is connected by the 3rd link of the 11 revolute pair and the 4th connecting rod, the 4th the 4th, connecting rod link is connected with the 9th connecting rod one end by being rigidly connected, the 9th connecting rod other end is connected with the tenth connecting rod one end by the 12 revolute pair, the tenth connecting rod drives by the 12 revolute pair, the 12 revolute pair drives by motor, the tenth connecting rod other end is connected with the 11 connecting rod one end by the 13 revolute pair, the 11 connecting rod drives by the 13 revolute pair, the 13 revolute pair drives by motor, the 11 connecting rod other end is connected with end effector by the 14 revolute pair, end effector drives by the 14 revolute pair, the 14 revolute pair drives by motor,

Described the first revolute pair is perpendicular to frame, and the second revolute pair, the 3rd revolute pair, the 4th revolute pair, the 5th revolute pair, the 6th revolute pair, the 7th revolute pair, the 8th revolute pair, the 9th revolute pair, the tenth revolute pair and the 11 revolute pair rotation are parallel to each other.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201310692366.5A CN103737583A (en) | 2013-12-17 | 2013-12-17 | Mechanical arm with symmetrical mechanisms |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201310692366.5A CN103737583A (en) | 2013-12-17 | 2013-12-17 | Mechanical arm with symmetrical mechanisms |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN103737583A true CN103737583A (en) | 2014-04-23 |

Family

ID=50494685

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201310692366.5A Pending CN103737583A (en) | 2013-12-17 | 2013-12-17 | Mechanical arm with symmetrical mechanisms |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN103737583A (en) |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4639185A (en) * | 1985-01-21 | 1987-01-27 | Robert Bosch Gmbh | Bag package transfer apparatus |

| US4756655A (en) * | 1986-12-15 | 1988-07-12 | Jameson John W | Mechanical manipulator |

| US5187996A (en) * | 1990-02-15 | 1993-02-23 | Fanuc, Ltd. | Industrial articulated robot provided with a driving linkage |

| US5265489A (en) * | 1990-04-20 | 1993-11-30 | Kabushiki Kaisha Yaskawa Denki | Arm-driving device for industrial robot |

| US6095011A (en) * | 1996-03-14 | 2000-08-01 | Abb Ab | Device for relative movement of two elements |

| CN102085659A (en) * | 2010-12-16 | 2011-06-08 | 广西大学 | Space-controlled five degree of freedom twelve-rod welding robot mechanism |

| CN103009384A (en) * | 2012-12-27 | 2013-04-03 | 广西大学 | Controllable stacking robot |

| CN103029863A (en) * | 2012-12-31 | 2013-04-10 | 广西大学 | Controllable rectangular coordinate type pushing mechanism |

-

2013

- 2013-12-17 CN CN201310692366.5A patent/CN103737583A/en active Pending

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4639185A (en) * | 1985-01-21 | 1987-01-27 | Robert Bosch Gmbh | Bag package transfer apparatus |

| US4756655A (en) * | 1986-12-15 | 1988-07-12 | Jameson John W | Mechanical manipulator |

| US5187996A (en) * | 1990-02-15 | 1993-02-23 | Fanuc, Ltd. | Industrial articulated robot provided with a driving linkage |

| US5265489A (en) * | 1990-04-20 | 1993-11-30 | Kabushiki Kaisha Yaskawa Denki | Arm-driving device for industrial robot |

| US6095011A (en) * | 1996-03-14 | 2000-08-01 | Abb Ab | Device for relative movement of two elements |

| CN102085659A (en) * | 2010-12-16 | 2011-06-08 | 广西大学 | Space-controlled five degree of freedom twelve-rod welding robot mechanism |

| CN103009384A (en) * | 2012-12-27 | 2013-04-03 | 广西大学 | Controllable stacking robot |

| CN103029863A (en) * | 2012-12-31 | 2013-04-10 | 广西大学 | Controllable rectangular coordinate type pushing mechanism |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN103737209A (en) | Welding robot with symmetrical mechanisms | |

| CN103722552B (en) | A kind of controllable multi-degree-of-freedom manipulator | |

| CN103707289A (en) | Controllable multi-degree of freedom welding robot | |

| CN103737578B (en) | A kind of space multi-freedom-degreecontrollable controllable mechanism type fine setting welding robot | |

| CN103737208A (en) | Multi-degree-of-freedom welding robot | |

| CN103737581B (en) | The many bars six degree of freedom welding robot containing parallel closed loop subchain that space is controlled | |

| CN103722553B (en) | A kind of controlled welding robot of multiple freedom parallel mechanism formula | |

| CN103707288A (en) | Multi-degree-of-freedom palletizing robot | |

| CN103707290A (en) | Welding robot with a plurality of closed-ring subchains | |

| CN104096998A (en) | Multi-degree of freedom parallel mechanism type spot welding robot | |

| CN104044134A (en) | Multi-freedom-degree controlled parallel robot | |

| CN103707291A (en) | Multi-degree-of-freedom parallel mechanism type controllable palletizing robot | |

| CN104646881A (en) | Method for performing welding construction by use of multi-DOF (Degree Of Freedom) controllable rocking arm type connecting rod mechanism | |

| CN103722551A (en) | Stacking robot with multiple closed-loop subchains | |

| CN104476050A (en) | Multi-degree-of-freedom institutional mobile welding robot | |

| CN104476054A (en) | Welding construction method through utilizing six-degree-of-freedom five-rod moving type connecting rod mechanism | |

| CN104526690A (en) | Mechanism type mobile mechanical hand with multiple degrees of freedom | |

| CN103737583A (en) | Mechanical arm with symmetrical mechanisms | |

| CN204545772U (en) | A kind of multi link welding robot containing closed-loop subchain | |

| CN104626103A (en) | Multi-freedom-degree parallel mechanism type controllable moving palletizing robot | |

| CN104552270A (en) | Multi-degree-of-freedom controllable moving type connecting rod mechanism | |

| CN104552244A (en) | Parallel controllable mechanism type multi-degree-of-freedom mobile welding robot | |

| CN104440890A (en) | Multi-degree-of-freedom rocker arm type moving connecting rod mechanism | |

| CN204686870U (en) | A kind of seven-link assembly mechanism type mobile welding robot | |

| CN104626138A (en) | Movable mechanical hand with symmetric mechanism |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C02 | Deemed withdrawal of patent application after publication (patent law 2001) | ||

| WD01 | Invention patent application deemed withdrawn after publication |

Application publication date: 20140423 |