CN102807264A - Liquid purification treatment device having double-tube structure - Google Patents

Liquid purification treatment device having double-tube structure Download PDFInfo

- Publication number

- CN102807264A CN102807264A CN2012101803431A CN201210180343A CN102807264A CN 102807264 A CN102807264 A CN 102807264A CN 2012101803431 A CN2012101803431 A CN 2012101803431A CN 201210180343 A CN201210180343 A CN 201210180343A CN 102807264 A CN102807264 A CN 102807264A

- Authority

- CN

- China

- Prior art keywords

- lamp

- light source

- external light

- socket

- treatment device

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Landscapes

- Physical Water Treatments (AREA)

- Discharge Lamps And Accessories Thereof (AREA)

Abstract

The invention provides a liquid purification treatment device having a double-tube structure, and in the liquid purification treatment device (100) in which ultraviolet rays are irradiated towards water to perform sterilization in a darkroom space, improvement of the starting characteristic of the light source of an electric discharge lamp (10) and miniaturization of the device can be realized. In the liquid purification treatment device having a double-tube structure in which an inner tube (110) and a tube casing (120) are coaxially configured, the ultraviolet lamp (10) is arranged in the inner tube, and a liquid flow path is arranged between the inner tube and the tube casing. The ultraviolet lamp is mounted in an inner tube mounting part arranged in an end part of the tube casing through a socket (60). In the socket, a mounting hole (68) for an external light source is arranged which is parallel with a mounting hole (64) for an ultraviolet lamp, and a small-sized bulb is arranged in the mounting hole for an external light source. A slit is arranged on a socket located on the midway of the light path between the small-sized bulb and the ultraviolet lamp, and light emitted from the small-sized bulb is irradiated to the ultraviolet lamp. In this way, the starting characteristic of the ultraviolet lamp in the darkroom can be improved and miniaturization of the device can be realized.

Description

Technical field

The present invention relates to use ultraviolet ray to carry out the cleaning processing apparatus of handling as the Cress of purpose with sterilization, sterilization etc., especially relate to water such as upper and lower water course, process water, domestic water are carried out the UV purification treatment unit that sterilization, sterilization, deodorizing etc. are handled.

Background technology

In recent years, about the problem pay attention to day by day of water quality.As the ultraviolet sterilizing unit 900 of the known in the past use of the countermeasure of this water correction.For example, as shown in Figure 8 in patent documentation 1, constitute by sterilization container 901 cylindraceous and the low-pressure mercury discharge lamp 902 that is arranged on its central part coaxially.Make circulation in the stream 903 of direction in the gap that is formed between cylindrical container and the low-pressure mercury discharge lamp 902 parallel with Cylindorical rod of the processed water W edge of wanting germicidal treatment, thus, irradiation ultraviolet radiation carries out sterilization.Low-pressure mercury discharge lamp 902 as exciting media, sends the ultraviolet ray that predominant wavelength is 254nm with mercury.

[prior art document]

[patent documentation 1] Japan opens clear 63-084871 communique in fact

Use under the situation of this ultraviolet sterilization apparatus, current are in the illuminated ultraviolet ray between flow periods on every side of the low-pressure mercury discharge lamp 902 of the central part that is arranged at sterilization container.Thus, for making ultraviolet ray from low-pressure mercury discharge lamp 902 irradiation, forming by metallic substance around the sterilization container 901 or by the metallic substance covering, low-pressure mercury discharge lamp 902 is set at the dark place all the time not to external leaks.Therefore, have following problem: when starting low-pressure mercury discharge lamp in the dark, even close switch, the discharge time opening also can postpone.

In addition, known following situation in light source field: in order to improve the starting characteristic under the state that low-pressure mercury discharge lamp places dark situation for a long time, will from the light of external light source after the discharge tube irradiation, apply electric field to low-pressure mercury discharge lamp again.But, external light source is arranged under the situation of ultraviolet sterilization apparatus of double-sleeve structure, can consider; Sterilization container 901 integral body are formed and be arranged on its periphery by transparent material, thus, realize the improvement of starting characteristic; But owing to be pipe irradiation exterior light through dual pipe, current and low-pressure mercury discharge lamp; So efficient is poor, in addition, the problem that also exists ultraviolet sterilization apparatus to maximize.

Summary of the invention

The present invention accomplishes in view of the above problems, and its purpose is that in the liquid purification and treatment device of double-sleeve structure, the startability of the fluid purification when making starting is rapider.In addition, its purpose is to provide a kind of ultraviolet sterilization apparatus of double-sleeve structure, even be provided with under the situation of external light source, also can realize miniaturized with easy structure.

To achieve these goals, the present invention provides the liquid purification and treatment device of the double-sleeve structure with following characteristic.

A kind of liquid purification and treatment device 100 of double-sleeve structure, the liquid purification and treatment device 100 of said double-sleeve structure comprises: the interior pipe 110 that is formed by the ultraviolet (uv) transmission material of straight tube-like; Cover the lateral shell 120 of said interior pipe 110; Be configured in said in the UV-lamp 10 that by discharge lamp constitute of pipe in 110; And be arranged on the liquid flow path 150 between said interior pipe 110 and the shell 120, wherein,

Said UV-lamp 10 comprises: the discharge tube 11 of the straight tube-like that is formed by the ultraviolet (uv) transmission material; Be configured in the inner pair of discharge electrodes 14,15 in two ends of this discharge tube; The lead-in wire electrode 17 that is connected and extends with discharge electrode 14,15 to the discharge tube outside; With the luminescence-utraviolet material 13 that is sealed in the discharge tube,

Said cap 50 comprises: first recess 51, this first recess 51 possess the medial surface 53 chimeric with cap fastening part 133, and flange surface 54; With second recess 52 that is communicated with said first recess,

Between said inclination trim 132 and said flange surface 54, dispose annular resilient seal part 90, said annular resilient seal part 90 and this inclination trim 132, this flange surface 54 and said interior pipe side butt,

The chimeric socket 60 that the said UV-lamp 10 of maintenance is arranged in said second recess 52,

Said socket 60 comprises UV-lamp maintaining part 61 and the diameter pedestal 65 bigger than this UV-lamp maintaining part,

Said UV-lamp maintaining part 61 has UV-lamp open hole 64, and this UV-lamp open hole 64 comprises: with first periphery 62 of the inner peripheral surface butt of said inner tube portion; And with first inner peripheral surface 63 of the periphery butt of said UV-lamp end,

Said pedestal 65 has: with second periphery 66 of medial surface 55 butts of second recess 52 of said cap 50; The power supply terminal fairlead 67 that extends from the end of said UV-lamp 10; And external light source open hole 68,

In said external light source open hole 68, taken in external light source 70, this external light source 70 is along from the direction irradiates light of pedestal 65 towards UV-lamp maintaining part 61,

Be formed with slit 69 in said UV-lamp maintaining part 61, this slit 69 is positioned on the straight line of central axis of the central axis that links said UV-lamp open hole 64 and external light source open hole 68, and is positioned at the side of the discharge electrode 14 of said UV-lamp,

Said slit 69 and said in pipe 110 ejaculation direction the place ahead of being positioned at said external light source, the light that irradiates from said external light source 70 shine said interior end face 111 of managing when shine discharge electrode 14 through said slit 69 and discharge tube 11.

In addition, a kind of liquid purification and treatment device of double-sleeve structure is provided, it is characterized in that,

Said shell is managed installation portion in also having with opposed the other end, said shell end,

The pipe installation portion is provided with said cap, annular resilient seal part and socket in said,

At least on the pedestal of the socket that is arranged at an end, be formed with the external light source open hole,

Said slit and said interior pipe are positioned at ejaculation direction the place ahead of said external light source; The light that irradiates from said external light source is when shining discharge electrode through said slit and discharge tube; The light that in interior pipe, is directed from said interior surface feeding sputtering of managing arrives another socket through the other end, and shines another discharge electrode through another slit.

In addition, a kind of liquid purification and treatment device of double-sleeve structure is provided, it is characterized in that, said external light source is a glass mold pressing bulb.

Invention according to technical scheme 1 record is accommodated in the socket that is used for keeping UV-lamp with external light source, can realize the miniaturized of the liquid purification and treatment device of double-sleeve structure.In addition, can the radiating light decay from external light source be shone to UV-lamp less, can improve the delay of passing through the ultraviolet purifying treatment of implementing at the switch closure initial stage of liquid purification and treatment device.

In addition; Invention according to technical scheme 2 records; The external light source that one side of any socket in the socket that is disposed through the interior pipe installation portion in opposed shell end is taken in; Leaded light in interior pipe and with light to the guiding of another socket side, can also utilize the UV-lamp end of this another socket side of rayed.Thus, can further improve the delay of passing through the ultraviolet purifying treatment of implementing at the switch closure initial stage of liquid purification and treatment device.

In addition, according to the invention of technical scheme 3 record, because external light source forms by the glass molding bulb, so suppressed to make the situation of external light source deterioration owing to the ultraviolet ray that irradiates from UV-lamp.

(invention effect)

According to the present invention, a kind of ultraviolet sterilization apparatus can be provided, the startability of the fluid purification when making starting is rapider.In addition, a kind of ultraviolet sterilization apparatus of double-sleeve structure can be provided,, also can realize miniaturized with easy structure even be provided with under the situation of external light source.

Description of drawings

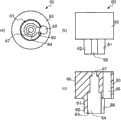

Fig. 1 be the expression embodiment of the present invention liquid purification and treatment device structure one the example sketch chart, Fig. 1 (a) is a front view, Fig. 1 (b) is a side-view.

Fig. 2 is the sectional view of the liquid purification and treatment device of Fig. 1.

Fig. 3 is the schematic sectional view that amplifies the A part of ground presentation graphs 2.

Fig. 4 is the explanatory view of shell 120 of the liquid purification and treatment device of pie graph 1, and Fig. 4 (a) is a front view, and Fig. 4 (b) is the A-A line side cross sectional view along Fig. 4 (a), and Fig. 4 (c) is the sectional view with the orthogonal direction of A-A line.

Fig. 5 is the explanatory view of cap of the liquid purification and treatment device of pie graph 1, and Fig. 5 (a) is a vertical view, and Fig. 5 (b) is the A-A line side cross sectional view along Fig. 5 (a).

Fig. 6 is the explanatory view of socket of the liquid purification and treatment device of pie graph 1, and Fig. 6 (a) is a vertical view, and Fig. 6 (b) is the side-view of slit side, and Fig. 6 (c) is a longitudinal section.

Fig. 7 is the general profile chart of variation of end that amplifies a side opposite with the A part of ground explanatory view 2.

Fig. 8 is the general profile chart that ultraviolet sterilization apparatus in the past is described.

The explanation of Reference numeral

10 UV-lamps

11 discharge tubes

14,15 discharge electrodes

50 caps

51 first recesses

52 second recesses

54 flange surfaces

60,80 sockets

61,81 UV-lamp maintaining parts

65,85 pedestals

68 external light source open holes

69,89 slits

70 external light sources

90 O shapes ring

100 liquid purification and treatment devices

Pipe in 110

120 shells

123 water inlets

124 water outlets

150 liquid flow paths

Pipe installation portion in 130

900 sterilizing units

901 sterilization containers

902 Cooper-Hewitt lamps

903 streams

W liquid

Embodiment

Below, with reference to the liquid purification and treatment device of Fig. 1~Fig. 7 explanation as an embodiment of the invention.

Fig. 1 be the expression embodiment of the present invention liquid purification and treatment device structure one the example sketch chart, Fig. 1 (a) is a front view, Fig. 1 (b) is a side-view.Fig. 2 is the sectional view of the liquid purification and treatment device of Fig. 1.Liquid purification and treatment device 100 has: roughly columned shell 120; Be arranged at the interior pipe installation portion 130,130 of the both ends of the surface 121,122 of shell 120; The cap 50,50 of pipe installation portion 130,130 in being installed on respectively with mode that can dismounting; And pipe installation portion 130,130 and be set to the interior pipe 110 and the UV-lamp 10 of the inside of shell 120 in passing.Shell 120 and interior pipe 110 are thickly sealed by liquid, are provided with water inlet 123 and water outlet 124 integratedly at shell 120.

When water inlet 123 is sent into the liquid W that carries out UV treatment, flow in the liquid flow path 150 of liquid W in the space that is formed between shell tube face 125 and the interior pipe 110, and be discharged to the outside of liquid purification and treatment device 100 from water outlet 124.At this moment, never illustrated external power source irradiates ultraviolet ray from UV-lamp 10 when UV-lamp 10 power supplies, and ultraviolet ray shines flowing fluid W in liquid flow path 150 through interior pipe 110 and carries out UV treatment.

So far structure and the ultraviolet sterilization apparatus of aforesaid double-sleeve structure 900 are basic identical.In this embodiment, following aspect is different, and near external light source 70 this respects of especially after disposing with predetermined structure interior pipe installation portion 130, stating are different with ultraviolet sterilization apparatus 90.

Fig. 3 is the enlarged view that amplifies the A part of ground presentation graphs 2.Fig. 4 is the explanatory view of shell 120 of the liquid purification and treatment device of pie graph 1; Fig. 4 (a) is a vertical view; Fig. 4 (b) is the A-A line side cross sectional view along Fig. 4 (a), and Fig. 4 (c) is along passing the sectional view of the broken line of water inlet and water outlet with the orthogonal direction of A-A line.Fig. 5 is the explanatory view of cap of the liquid purification and treatment device of pie graph 1, and Fig. 5 (a) is a vertical view, and Fig. 5 (b) is the A-A line side cross sectional view along Fig. 5 (a).Fig. 6 is the explanatory view of socket of the liquid purification and treatment device of pie graph 1, and Fig. 6 (a) is a vertical view, and Fig. 6 (b) is the side-view of slit side, and Fig. 6 (c) is a longitudinal section.

In addition, be formed with plane of reflection 126 in the inboard of shell tube face 125.Plane of reflection 126 also can directly use the base material of shell 120, also can wait ultraviolet reflecting film is set through implement electroplating processes on the surface.In addition, shell 120 can also not adopt metallic substance, but is employed in the resin material that the plane of reflection that is made up of single or multiple lift ultraviolet reflecting film that can not transmitting UV with the opposed internal surface setting of UV-lamp forms.

Pipe installation portion 130,130 in the end 121,122 of shell 120 has formed respectively.Interior pipe installation portion 130 is outstanding laterally general cylindrical shape shape, and central authorities are provided with the shell open-ended 131 of the inside that arrives shell 120.The diameter of shell open-ended 131 is roughly consistent with the external diameter of interior pipe 110.Periphery at interior pipe installation portion 130 is formed with cap fastening part 133, with the cap of stating after can fixing 50 disassembled and assembled freely.In this embodiment, be formed with ridge, fix through screwing togather cap 50.In addition, terminal part forms inclination trim 132.Inclination trim 132 forms the cone surface that tilts from the central side of shell open-ended 131 end side towards cap fastening part 133.

In pipe 110 be co-axial cylindric with the central axis of shell 120, form by the material of ultraviolet (uv) transmission property such as silica glass, fluorine-type resin material.Can use for example PFA (tetrafluoroethylene-perfluoroalkyl vinyl ether copolymer), FEP (tetrafluoraoethylene-hexafluoropropylene copolymer (4,6 fluorochemical)), PTFE (tetrafluoroethylene (tetrafluoride)) etc. as the fluorine-type resin material.Especially preferably the material that the light of wavelength 254nm is had high transmissivity.

UV-lamp 10 is elongated straight tube shape cylindraceous, and 12,12 are respectively arranged with discharge electrode 14,15 at two ends.In this embodiment, 1 UV-lamp is configured on the central axis of shell 120.UV-lamp 10 has: the discharge tube 11 that is made up of silica tube; Discharge electrode 14,15; And the luminescence-utraviolet material 13 that is sealed in discharge tube 11 inside, for example argon gas, neon and mercury etc.Opposed discharge electrode the 14, the 15th, the cup-shaped cold cathode electrode of cylinder that for example opposed discharge electrode side is formed recess, the electrode of getter material that adopted surface coated.In addition, be respectively arranged with lead-in wire electrode 17,17 in the side of leaning on each UV- lamp end 12,12 of discharge electrode 14,15, this lead-in wire electrode 17,17 is exported to the outside from discharge tube 11 quilts.Specifically, for example the mercury discharge lamp of the long 150mm of lamp, lamp footpath 4.7mm is lighted with lamp current 10mA through the lead-in wire electrode, thus, can send with 254nm and 185nm is the light of predominant wavelength.

Between the plane of reflection 126 of shell 120 and interior pipe 110, be provided with the fluid flowing path 150 that the liquid W that Gong to be processed passes through.In this embodiment, the space between shell tube face 125 and the interior pipe 110 becomes fluid flowing path 150.Fluid flowing path 150 also can be not shown dividing plate or helical part to be set and the fluid flowing path that becomes labyrinth structure or spirane structure in this space.

Below, describe being installed in a socket 60 and an external light source 70 on the shell end 121.

UV-lamp maintaining part 61 is from the C annular cylinder shape shape of the outstanding cross section C word shape of pedestal 65, and circumferential lateral surface is first periphery 62, and interior all sides are first inner peripheral surface 63.As shown in Figure 3, in UV-lamp maintaining part 61 is fitted in the end of pipe, chimeric and maintain UV-lamp 10 in the inside of UV-lamp maintaining part 61.That is, first periphery 62 contacts with the end inner peripheral surface of interior pipe, and first inner peripheral surface 63 contacts with UV-lamp end periphery.In addition, the position by otch of C ring becomes slit 69, and slit 69 is formed on the lateral entire area parallel with central axis of UV-lamp maintaining part 61, promptly spread all over from and pedestal 65 between boundary member to the scope the end.

Externally be provided with external light source 70 in the light source open hole 68.Shown in Fig. 6 (a), when UV-lamp maintaining part 61 sides were observed, external light source open hole 68 was set at the position of a part and the location overlap that is formed with slit 69 of UV-lamp maintaining part 61.In other words, a part is overlapping with the position by otch of the UV-lamp maintaining part 61 that is C annular cylinder shape shape.Like this, can be efficiently with from after the irradiates light guiding UV-lamp 10 of the external light source 70 stated.

Said slit 69 is positioned on the straight line of central axis of the central axis that links UV-lamp open hole 64 and external light source open hole 68.In addition; The length of said slit 69 is the length that arrives the side of discharge electrode 14 from the sealing of discharge tube 11; Specifically; As shown in Figure 3, be the length that arrives the part of facing with the lower zone that leans on sealed sides of discharge electrode 14 from the position of facing with the internal space of the end of discharge tube 11.Like this, can pass slit 69 and discharge tube 11 and discharge electrode 14 is less shone in decay from the light of external light source 70 radiation.In addition, because slit 69 is positioned at pipe 110 inboard, so the part of the light that radiates from external light source 70 just can not shone discharge electrode 14 through interior pipe 110.Therefore, can further suppress the decay of radiating light.

External light source 70 is through so that direction of illumination leans on the mode of UV-lamp maintaining part 61 sides that the miniature incandescent lamp that glass molding (mold) forms is inserted and secured in the external light source open hole 68.If the miniature incandescent lamp that adopts glass molding to form, then can reduce external light source 70 because from the ultraviolet ray of UV-lamp 10 irradiations and the situation of deterioration.In addition, also can use the for example LED of TOHKEMY 2010-205942 number disclosed glass capsulation (photodiode).

In addition, interior pipe 110 is positioned near the upper base of socket base 65, and inner tube face 111 is roughly consistent with the ora terminalis of the opening of external light source open hole 68.That is, inner tube face 111 externally is configured to and the optical axis of external light source 70 quadrature roughly in direction of illumination the place ahead of light source 70.In the part of the light that radiates from external light source 70 thus, can import to from inner tube face 111 efficiently in the pipe 110.

Below, cap and the socket that is installed on another shell end 122 described.

Interior pipe installation portion 130 on the shell end 122 that is arranged at a side opposite with shell end 121 also is provided with cap 50 and socket 60, interior pipe 110 and UV-lamp 10 are installed in the predetermined position, and liquid seals thickly.On the paper right side of Fig. 2, that is, the end face of a side opposite with the A part is not taken in external light source 70 in socket 60.Other aspects are identical with aforesaid situation about being installed on the interior pipe installation portion 130 that is arranged at shell end 121, so detailed here.

In addition, as shown in Figure 7, can also adopt socket 80 with external light source open hole 68.That is, form, and constitute than these UV-lamp maintaining part 81 big pedestals 85 with diameter by the UV-lamp maintaining part 81 that forms outward with interior pipe 110 corresponding shape by rubber-like materials such as rubber or flexible resins.In addition, with socket 60 shown in Figure 6 likewise, be formed with slit 89 in UV-lamp maintaining part 81, UV-lamp maintaining part 81 is from the C annular cylinder shape shape of the outstanding cross section C word shape of pedestal 85.Inner tube face 112 is opposed with the pedestal 85 of socket 80.

Such socket that external light source is not set 60 or socket 80 are being provided under the situation of another shell end 122 sides; Aforesaid import to from inner tube face 111 in the part of the light that radiates of the external light sources 70 of pipe in 110, the inner tube face 112 towards opposition side when the inside of interior pipe 110 is carried out the internal surface reflection repeatedly advances.Owing to dispose pedestal 85 (65) opposed to each other, so by pedestal 85 (65) reflections with inner tube face 112.The part of the light that is reflected by pedestal 85 (65) is through slit 89 (69) irradiation discharge electrodes 15.That is the light that, radiates from external light source 70 shines discharge electrode 14,15 these both sides at the isolating two ends that are positioned at UV-lamp 10.

Under the situation that the socket 60 of not taking in external light source is set, only prepare identical socket and get final product, thereby can reduce the part number, compare with the situation of prepared socket 80, can reduce cost.In addition, the slit 69 (89) that lays respectively at shell end 121 and shell end 122 is preferably the opposed position that is positioned on the straight line.During in interior pipe, advancing in the interreflection, a part of light transmission and advancing towards discharge tube.Therefore, the position of the slit 69 (89) through making the two ends that are positioned at UV-lamp 10 is opposed, thereby can reduce the decrement during in interior pipe, advancing, and can shine via the electrode of slit to UV-lamp with the less light of decaying.

External light source 70 constitutes: lighted before UV-lamp 10 applies the high-tension while or applying high-voltage at illustrated power supply never, and extinguish after the light of the irradiation scheduled time.Because UV-lamp 10 is set at as in the darkroom spatial shell 120.So the starting characteristic of the discharge of dark place is poor, but through irradiation, can reduces starting characteristic in the darkroom and be discharge ionization voltage and shorten the discharge time opening from the light of external light source 70.In this embodiment, because outer electrode is configured in the socket 60, so, can raise the efficiency and realize miniaturized.

When the light that radiates from external light source 70 shines discharge electrode 14,15, can produce initiating electron through photovoltaic effect.Especially to being coated with discharge electrode that caesium cpd etc. has a getter material of electron emission when carrying out rayed, can increase the generation of initiating electron.When producing initiating electron, shorten by the time opening that is applied in to the discharge that high-voltage produced of discharge electrode 14,15.In this embodiment, under the situation that external light source 70 is not lighted, need light the time opening in several seconds to tens seconds, and external light source 70 is lighted when afterwards starting, can light with interior at 0.1 second.That is, the initial stage at the switch of closed liquid purifying processing device 100, reduce significantly in the time of not carrying out UV treatment of not lighting time durations of UV-lamp 10, can eliminate the delay of UV treatment.

Above-mentioned embodiment is the illustration of each side only.The present invention does not explain because of these being defined property of record ground.For example, the slit that is arranged at socket is not limited to the grooving of rectangular shape, can also adopt the grooving in the hole that has circle, ellipse, trilateral, rectangle etc., and socket can also be formed by the soft silicone material of light transmission.

In addition, in above-mentioned embodiment, and shell and/or interior pipe adopt dual structure and the liquid purification and treatment device that a plurality of UV-lamps also are contained in double-sleeve structure of the present invention are set.And processed water is not limited to water, and the liquid beyond the water, air gas are in addition handled and also is contained in the present invention.

According to the liquid purification and treatment device of double-sleeve structure of the present invention, can eliminate the delay of the ultraviolet purifying treatment at switch closure initial stage.In addition, can obtain following effect: can provide a kind of owing to external light source being arranged on the ultraviolet sterilization apparatus of realizing miniaturized and the decay that suppresses external light source light in the socket.

Utilizability on the industry

Thus; Can be applicable to the purposes that requires liquid cleaning to purify, the various liquid treatment equipments such as liquid treatment of for example can be applied to water purifier, watercooler, humidifier, dishwasher, washing machine, dental chair, water treatment down, go up water treatment, bacterium being handled, comprising in drinking water treatment, organism etc.

Claims (3)

1. the liquid purification and treatment device of a double-sleeve structure, the liquid purification and treatment device of said double-sleeve structure comprises: the interior pipe that is formed by the ultraviolet (uv) transmission material of straight tube-like; Cover the lateral shell of said interior pipe; Be configured in said in the UV-lamp that constitutes by discharge lamp in the pipe; And be arranged on said in the pipe and shell between liquid flow path,

The liquid purification and treatment device of said double-sleeve structure is characterised in that,

Said UV-lamp comprises: the discharge tube of the straight tube-like that is formed by the ultraviolet (uv) transmission material; Be configured in the inner pair of discharge electrodes in two ends of this discharge tube; The lead-in wire electrode that is connected and extends with discharge electrode to the discharge tube outside; And be sealed in the luminescence-utraviolet material in the discharge tube,

Pipe installation portion in the end of said shell has, pipe installation portion comprises the opening and the inclination trim that can pass through slotting said interior pipe in this,

Cap with mode that can dismounting be fixed in said in the periphery of pipe installation portion,

Said cap comprises: first recess, this first recess possess the medial surface chimeric with the cap fastening part, reach flange surface; With second recess that is communicated with said first recess,

Between said inclination trim and said flange surface, dispose the annular resilient seal part, said annular resilient seal part and this inclination trim, this flange surface and said interior pipe side butt,

The chimeric socket that the said UV-lamp of maintenance is arranged in said second recess,

Said socket comprises UV-lamp maintaining part and the diameter pedestal bigger than this UV-lamp maintaining part,

Said UV-lamp maintaining part has the UV-lamp open hole, and this UV-lamp open hole comprises: with first periphery of the inner peripheral surface butt of said inner tube portion; And with first inner peripheral surface of the periphery butt of said UV-lamp end,

Said pedestal has: with second periphery of the medial surface butt of second recess of said cap; The power supply terminal fairlead that extends from the end of said UV-lamp; And the external light source open hole,

In said external light source open hole, taken in external light source, this external light source is along from the direction irradiates light of pedestal towards the UV-lamp maintaining part,

Be formed with slit in said UV-lamp maintaining part, this slit is positioned on the straight line of central axis of the central axis that links said UV-lamp open hole and external light source open hole, and is positioned at the side of the discharge electrode of said UV-lamp,

Said slit and said in pipe be positioned at ejaculation direction the place ahead of said external light source, the light that irradiates from said external light source shine the end face of managing in said when shining discharge electrode through said slit and discharge tube.

2. the liquid purification and treatment device of double-sleeve structure as claimed in claim 1 is characterized in that,

Said shell is managed installation portion in also having with opposed the other end, said shell end,

The pipe installation portion is provided with said cap, annular resilient seal part and socket in said,

At least on the pedestal of the socket that is arranged at an end, be formed with the external light source open hole,

Said slit and said interior pipe are positioned at ejaculation direction the place ahead of said external light source; The light that irradiates from said external light source is when shining discharge electrode through said slit and discharge tube; The light that in interior pipe, is directed from said interior surface feeding sputtering of managing arrives another socket through the other end, and shines another discharge electrode through another slit.

3. according to claim 1 or claim 2 the liquid purification and treatment device of double-sleeve structure is characterized in that,

Said external light source is the glass molding bulb.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2011124064A JP2012250166A (en) | 2011-06-02 | 2011-06-02 | Liquid purification treatment apparatus of double tube structure |

| JP2011-124064 | 2011-06-02 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN102807264A true CN102807264A (en) | 2012-12-05 |

| CN102807264B CN102807264B (en) | 2015-09-23 |

Family

ID=47231156

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201210180343.1A Active CN102807264B (en) | 2011-06-02 | 2012-06-01 | The liquid purification and treatment device of double-sleeve structure |

Country Status (2)

| Country | Link |

|---|---|

| JP (1) | JP2012250166A (en) |

| CN (1) | CN102807264B (en) |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN106430404A (en) * | 2016-09-29 | 2017-02-22 | 圆融健康科技(深圳)有限公司 | Sterilizing unit and sterilizing device |

| CN107921160A (en) * | 2015-09-03 | 2018-04-17 | 日机装株式会社 | Sterilizing unit |

| CN109790051A (en) * | 2016-08-30 | 2019-05-21 | 日机装株式会社 | Ultraviolet light sterilizing device |

| CN113860422A (en) * | 2015-09-25 | 2021-12-31 | 首尔伟傲世有限公司 | Sterilization module, water purifying device and system comprising water purifying device |

| CN114620797A (en) * | 2017-07-12 | 2022-06-14 | 首尔伟傲世有限公司 | Fluid treatment device |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6292900B2 (en) * | 2014-01-27 | 2018-03-14 | スタンレー電気株式会社 | Liquid purification treatment equipment |

| JP6670459B2 (en) * | 2015-03-27 | 2020-03-25 | Toto株式会社 | Sanitary washing equipment |

| CN111620408A (en) * | 2020-07-10 | 2020-09-04 | 重庆瑞朗电气有限公司 | Barrel and degassing unit are used in disinfection |

| CN113003653B (en) * | 2021-03-16 | 2023-04-11 | 重庆四联光电科技有限公司 | Overflowing type water sterilizing device |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS6384871U (en) * | 1986-11-22 | 1988-06-03 | ||

| JPH10134778A (en) * | 1996-10-31 | 1998-05-22 | Toshiba Lighting & Technol Corp | Electrodeless discharge lamp unit and liquid treatment equipment |

| CN1502563A (en) * | 2002-11-27 | 2004-06-09 | 株式会社日本光电科技 | Ultraviolet ray device for treating liquid and method thereof |

| CN101533753A (en) * | 2008-03-11 | 2009-09-16 | 优志旺电机株式会社 | High-pressure discharge lamp, manufacturing method thereof and light irradiation device |

-

2011

- 2011-06-02 JP JP2011124064A patent/JP2012250166A/en not_active Withdrawn

-

2012

- 2012-06-01 CN CN201210180343.1A patent/CN102807264B/en active Active

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS6384871U (en) * | 1986-11-22 | 1988-06-03 | ||

| JPH10134778A (en) * | 1996-10-31 | 1998-05-22 | Toshiba Lighting & Technol Corp | Electrodeless discharge lamp unit and liquid treatment equipment |

| CN1502563A (en) * | 2002-11-27 | 2004-06-09 | 株式会社日本光电科技 | Ultraviolet ray device for treating liquid and method thereof |

| CN101533753A (en) * | 2008-03-11 | 2009-09-16 | 优志旺电机株式会社 | High-pressure discharge lamp, manufacturing method thereof and light irradiation device |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN107921160A (en) * | 2015-09-03 | 2018-04-17 | 日机装株式会社 | Sterilizing unit |

| CN113860422A (en) * | 2015-09-25 | 2021-12-31 | 首尔伟傲世有限公司 | Sterilization module, water purifying device and system comprising water purifying device |

| CN113860422B (en) * | 2015-09-25 | 2023-10-24 | 首尔伟傲世有限公司 | Sterilization module, water purification device and system comprising water purification device |

| CN109790051A (en) * | 2016-08-30 | 2019-05-21 | 日机装株式会社 | Ultraviolet light sterilizing device |

| CN109790051B (en) * | 2016-08-30 | 2021-11-26 | 日机装株式会社 | Ultraviolet light sterilizing device |

| CN106430404A (en) * | 2016-09-29 | 2017-02-22 | 圆融健康科技(深圳)有限公司 | Sterilizing unit and sterilizing device |

| CN106430404B (en) * | 2016-09-29 | 2019-10-29 | 圆融健康科技(深圳)有限公司 | Sterili-sation unit and sterilizing unit |

| CN114620797A (en) * | 2017-07-12 | 2022-06-14 | 首尔伟傲世有限公司 | Fluid treatment device |

Also Published As

| Publication number | Publication date |

|---|---|

| CN102807264B (en) | 2015-09-23 |

| JP2012250166A (en) | 2012-12-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN102807264B (en) | The liquid purification and treatment device of double-sleeve structure | |

| CN104822395B (en) | Ultraviolet sterilizer | |

| TWI583406B (en) | Device for disinfecting gase and/or liquids and use thereof | |

| JP5863061B2 (en) | Device for sterilizing a fluid by exposing the fluid to ultraviolet light | |

| JP2008530765A (en) | Lamp holder for dielectric barrier discharge lamp | |

| CN101823779A (en) | Electrodeless ultraviolet sterilization device | |

| CN213326824U (en) | Deep ultraviolet LED dynamic water flow sterilization device and water purification equipment | |

| CN208429900U (en) | A kind of overflow-type LED ultraviolet sterilization device | |

| CN110563079A (en) | Overflowing type sterilization and disinfection device, water purification pipeline and water purification equipment | |

| JP2015139712A (en) | Apparatus for liquid cleaning | |

| CN212669271U (en) | Ultraviolet sterilization device | |

| JP6292900B2 (en) | Liquid purification treatment equipment | |

| CN214360380U (en) | Ultraviolet sterilization device | |

| JP2012240033A (en) | Ultraviolet purifying device | |

| CN214829168U (en) | Overflowing type sterilizing device | |

| JP6736027B2 (en) | Excimer lamp for liquid processing | |

| CN104964180B (en) | A kind of full angle photocatalyst superhigh power LED lamp | |

| CN111170404A (en) | Overflowing type sterilizing device | |

| JP2021006477A (en) | Xenon flash lamp irradiation device for container sterilization | |

| JP6880632B2 (en) | Excimer lamp unit | |

| CN210915413U (en) | Semi-immersed ultraviolet germicidal lamp | |

| JP6813811B2 (en) | Xenon flash lamp irradiation device for container sterilization | |

| CN212198593U (en) | Water treatment equipment | |

| CN212315624U (en) | Ultraviolet sterilization device with bidirectional irradiation | |

| JPH0324548A (en) | Light source device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant |