WO2019219041A1 - Kitchen waste processing method and processing apparatus - Google Patents

Kitchen waste processing method and processing apparatus Download PDFInfo

- Publication number

- WO2019219041A1 WO2019219041A1 PCT/CN2019/087121 CN2019087121W WO2019219041A1 WO 2019219041 A1 WO2019219041 A1 WO 2019219041A1 CN 2019087121 W CN2019087121 W CN 2019087121W WO 2019219041 A1 WO2019219041 A1 WO 2019219041A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- tank

- oil

- water

- drying

- plate

- Prior art date

Links

- 239000010806 kitchen waste Substances 0.000 title claims abstract description 57

- 238000003672 processing method Methods 0.000 title claims abstract 7

- 238000012545 processing Methods 0.000 title abstract description 6

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims abstract description 203

- 238000001035 drying Methods 0.000 claims abstract description 164

- 239000000463 material Substances 0.000 claims abstract description 95

- 238000000926 separation method Methods 0.000 claims abstract description 79

- 239000007788 liquid Substances 0.000 claims abstract description 77

- 238000011084 recovery Methods 0.000 claims abstract description 49

- 239000002918 waste heat Substances 0.000 claims abstract description 42

- 239000004519 grease Substances 0.000 claims abstract description 19

- 150000003839 salts Chemical class 0.000 claims abstract description 14

- 238000005238 degreasing Methods 0.000 claims description 87

- 238000011010 flushing procedure Methods 0.000 claims description 71

- 239000010865 sewage Substances 0.000 claims description 67

- 238000003756 stirring Methods 0.000 claims description 64

- 238000007789 sealing Methods 0.000 claims description 38

- 239000011229 interlayer Substances 0.000 claims description 32

- 238000010438 heat treatment Methods 0.000 claims description 30

- 238000000034 method Methods 0.000 claims description 17

- 238000009833 condensation Methods 0.000 claims description 16

- 230000005494 condensation Effects 0.000 claims description 16

- 238000005485 electric heating Methods 0.000 claims description 16

- 238000007710 freezing Methods 0.000 claims description 13

- 230000008014 freezing Effects 0.000 claims description 13

- 239000010410 layer Substances 0.000 claims description 13

- 238000001816 cooling Methods 0.000 claims description 12

- 230000009471 action Effects 0.000 claims description 10

- 230000009467 reduction Effects 0.000 claims description 10

- 239000013527 degreasing agent Substances 0.000 claims description 6

- 238000009835 boiling Methods 0.000 claims description 5

- 238000010612 desalination reaction Methods 0.000 claims description 5

- 238000001802 infusion Methods 0.000 claims description 4

- 210000000988 bone and bone Anatomy 0.000 claims description 3

- 238000005119 centrifugation Methods 0.000 claims description 3

- 230000000887 hydrating effect Effects 0.000 claims description 3

- 238000003973 irrigation Methods 0.000 claims description 3

- 230000002262 irrigation Effects 0.000 claims description 3

- 150000002632 lipids Chemical class 0.000 claims description 3

- 239000010808 liquid waste Substances 0.000 claims description 3

- 239000000843 powder Substances 0.000 claims description 3

- 239000000126 substance Substances 0.000 claims description 3

- 238000005115 demineralization Methods 0.000 claims description 2

- 230000002328 demineralizing effect Effects 0.000 claims description 2

- 238000011033 desalting Methods 0.000 claims description 2

- 230000003068 static effect Effects 0.000 claims description 2

- 239000004020 conductor Substances 0.000 claims 1

- 230000000694 effects Effects 0.000 abstract description 8

- 235000019645 odor Nutrition 0.000 abstract 1

- 239000003921 oil Substances 0.000 description 145

- 239000003638 chemical reducing agent Substances 0.000 description 32

- 238000007790 scraping Methods 0.000 description 29

- 230000007246 mechanism Effects 0.000 description 17

- 239000002893 slag Substances 0.000 description 16

- 238000005057 refrigeration Methods 0.000 description 15

- 238000003860 storage Methods 0.000 description 13

- 238000012544 monitoring process Methods 0.000 description 10

- 238000005265 energy consumption Methods 0.000 description 9

- 239000000706 filtrate Substances 0.000 description 9

- 238000007599 discharging Methods 0.000 description 8

- 238000001914 filtration Methods 0.000 description 8

- 238000003032 molecular docking Methods 0.000 description 8

- 230000008569 process Effects 0.000 description 8

- 238000011001 backwashing Methods 0.000 description 7

- 238000004891 communication Methods 0.000 description 7

- 238000009434 installation Methods 0.000 description 7

- 238000000605 extraction Methods 0.000 description 6

- 238000000855 fermentation Methods 0.000 description 6

- 230000004151 fermentation Effects 0.000 description 6

- 239000007789 gas Substances 0.000 description 6

- 238000002347 injection Methods 0.000 description 6

- 239000007924 injection Substances 0.000 description 6

- 102000004169 proteins and genes Human genes 0.000 description 6

- 108090000623 proteins and genes Proteins 0.000 description 6

- 241000894006 Bacteria Species 0.000 description 5

- 239000012530 fluid Substances 0.000 description 5

- 239000010802 sludge Substances 0.000 description 5

- 229920002678 cellulose Polymers 0.000 description 4

- 239000001913 cellulose Substances 0.000 description 4

- 238000004140 cleaning Methods 0.000 description 4

- 230000007613 environmental effect Effects 0.000 description 4

- 244000144972 livestock Species 0.000 description 4

- 235000015097 nutrients Nutrition 0.000 description 4

- 239000007787 solid Substances 0.000 description 4

- 238000012546 transfer Methods 0.000 description 4

- 238000010521 absorption reaction Methods 0.000 description 3

- 230000009286 beneficial effect Effects 0.000 description 3

- 238000012423 maintenance Methods 0.000 description 3

- 238000002156 mixing Methods 0.000 description 3

- 239000007921 spray Substances 0.000 description 3

- 230000001954 sterilising effect Effects 0.000 description 3

- 238000004659 sterilization and disinfection Methods 0.000 description 3

- 238000005406 washing Methods 0.000 description 3

- 230000005856 abnormality Effects 0.000 description 2

- 238000003915 air pollution Methods 0.000 description 2

- 239000003674 animal food additive Substances 0.000 description 2

- 230000003749 cleanliness Effects 0.000 description 2

- 238000005520 cutting process Methods 0.000 description 2

- 230000006378 damage Effects 0.000 description 2

- 238000004332 deodorization Methods 0.000 description 2

- 230000001877 deodorizing effect Effects 0.000 description 2

- 239000010791 domestic waste Substances 0.000 description 2

- 238000001125 extrusion Methods 0.000 description 2

- 239000003337 fertilizer Substances 0.000 description 2

- 230000005484 gravity Effects 0.000 description 2

- 239000002245 particle Substances 0.000 description 2

- 239000004033 plastic Substances 0.000 description 2

- 239000002994 raw material Substances 0.000 description 2

- 230000001960 triggered effect Effects 0.000 description 2

- 238000001291 vacuum drying Methods 0.000 description 2

- 238000013022 venting Methods 0.000 description 2

- 229920000742 Cotton Polymers 0.000 description 1

- 238000009825 accumulation Methods 0.000 description 1

- 230000000903 blocking effect Effects 0.000 description 1

- 238000005266 casting Methods 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 230000007812 deficiency Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 238000005188 flotation Methods 0.000 description 1

- JEGUKCSWCFPDGT-UHFFFAOYSA-N h2o hydrate Chemical compound O.O JEGUKCSWCFPDGT-UHFFFAOYSA-N 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- 239000010813 municipal solid waste Substances 0.000 description 1

- 230000009965 odorless effect Effects 0.000 description 1

- 239000005416 organic matter Substances 0.000 description 1

- 238000006213 oxygenation reaction Methods 0.000 description 1

- 239000013618 particulate matter Substances 0.000 description 1

- 238000004064 recycling Methods 0.000 description 1

- 238000003303 reheating Methods 0.000 description 1

- 230000008439 repair process Effects 0.000 description 1

- 230000000630 rising effect Effects 0.000 description 1

- 238000012216 screening Methods 0.000 description 1

- 238000004062 sedimentation Methods 0.000 description 1

- 239000011343 solid material Substances 0.000 description 1

- 239000000243 solution Substances 0.000 description 1

- 238000001179 sorption measurement Methods 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

- 239000002699 waste material Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B09—DISPOSAL OF SOLID WASTE; RECLAMATION OF CONTAMINATED SOIL

- B09B—DISPOSAL OF SOLID WASTE NOT OTHERWISE PROVIDED FOR

- B09B2101/00—Type of solid waste

- B09B2101/02—Gases or liquids enclosed in discarded articles, e.g. aerosol cans or cooling systems of refrigerators

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B09—DISPOSAL OF SOLID WASTE; RECLAMATION OF CONTAMINATED SOIL

- B09B—DISPOSAL OF SOLID WASTE NOT OTHERWISE PROVIDED FOR

- B09B3/00—Destroying solid waste or transforming solid waste into something useful or harmless

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23K—FODDER

- A23K10/00—Animal feeding-stuffs

- A23K10/10—Animal feeding-stuffs obtained by microbiological or biochemical processes

- A23K10/12—Animal feeding-stuffs obtained by microbiological or biochemical processes by fermentation of natural products, e.g. of vegetable material, animal waste material or biomass

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23K—FODDER

- A23K10/00—Animal feeding-stuffs

- A23K10/20—Animal feeding-stuffs from material of animal origin

- A23K10/26—Animal feeding-stuffs from material of animal origin from waste material, e.g. feathers, bones or skin

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23K—FODDER

- A23K10/00—Animal feeding-stuffs

- A23K10/30—Animal feeding-stuffs from material of plant origin, e.g. roots, seeds or hay; from material of fungal origin, e.g. mushrooms

- A23K10/37—Animal feeding-stuffs from material of plant origin, e.g. roots, seeds or hay; from material of fungal origin, e.g. mushrooms from waste material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D17/00—Separation of liquids, not provided for elsewhere, e.g. by thermal diffusion

- B01D17/02—Separation of non-miscible liquids

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D17/00—Separation of liquids, not provided for elsewhere, e.g. by thermal diffusion

- B01D17/02—Separation of non-miscible liquids

- B01D17/0208—Separation of non-miscible liquids by sedimentation

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B07—SEPARATING SOLIDS FROM SOLIDS; SORTING

- B07B—SEPARATING SOLIDS FROM SOLIDS BY SIEVING, SCREENING, SIFTING OR BY USING GAS CURRENTS; SEPARATING BY OTHER DRY METHODS APPLICABLE TO BULK MATERIAL, e.g. LOOSE ARTICLES FIT TO BE HANDLED LIKE BULK MATERIAL

- B07B11/00—Arrangement of accessories in apparatus for separating solids from solids using gas currents

- B07B11/06—Feeding or discharging arrangements

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B07—SEPARATING SOLIDS FROM SOLIDS; SORTING

- B07B—SEPARATING SOLIDS FROM SOLIDS BY SIEVING, SCREENING, SIFTING OR BY USING GAS CURRENTS; SEPARATING BY OTHER DRY METHODS APPLICABLE TO BULK MATERIAL, e.g. LOOSE ARTICLES FIT TO BE HANDLED LIKE BULK MATERIAL

- B07B7/00—Selective separation of solid materials carried by, or dispersed in, gas currents

- B07B7/06—Selective separation of solid materials carried by, or dispersed in, gas currents by impingement against sieves

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B07—SEPARATING SOLIDS FROM SOLIDS; SORTING

- B07B—SEPARATING SOLIDS FROM SOLIDS BY SIEVING, SCREENING, SIFTING OR BY USING GAS CURRENTS; SEPARATING BY OTHER DRY METHODS APPLICABLE TO BULK MATERIAL, e.g. LOOSE ARTICLES FIT TO BE HANDLED LIKE BULK MATERIAL

- B07B7/00—Selective separation of solid materials carried by, or dispersed in, gas currents

- B07B7/08—Selective separation of solid materials carried by, or dispersed in, gas currents using centrifugal force

- B07B7/083—Selective separation of solid materials carried by, or dispersed in, gas currents using centrifugal force generated by rotating vanes, discs, drums, or brushes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B09—DISPOSAL OF SOLID WASTE; RECLAMATION OF CONTAMINATED SOIL

- B09B—DISPOSAL OF SOLID WASTE NOT OTHERWISE PROVIDED FOR

- B09B5/00—Operations not covered by a single other subclass or by a single other group in this subclass

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B30—PRESSES

- B30B—PRESSES IN GENERAL

- B30B15/00—Details of, or accessories for, presses; Auxiliary measures in connection with pressing

- B30B15/0082—Dust eliminating means; Mould or press ram cleaning means

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B30—PRESSES

- B30B—PRESSES IN GENERAL

- B30B9/00—Presses specially adapted for particular purposes

- B30B9/02—Presses specially adapted for particular purposes for squeezing-out liquid from liquid-containing material, e.g. juice from fruits, oil from oil-containing material

- B30B9/12—Presses specially adapted for particular purposes for squeezing-out liquid from liquid-containing material, e.g. juice from fruits, oil from oil-containing material using pressing worms or screws co-operating with a permeable casing

- B30B9/121—Screw constructions

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F1/00—Treatment of water, waste water, or sewage

- C02F1/40—Devices for separating or removing fatty or oily substances or similar floating material

-

- C—CHEMISTRY; METALLURGY

- C05—FERTILISERS; MANUFACTURE THEREOF

- C05F—ORGANIC FERTILISERS NOT COVERED BY SUBCLASSES C05B, C05C, e.g. FERTILISERS FROM WASTE OR REFUSE

- C05F9/00—Fertilisers from household or town refuse

-

- C—CHEMISTRY; METALLURGY

- C05—FERTILISERS; MANUFACTURE THEREOF

- C05F—ORGANIC FERTILISERS NOT COVERED BY SUBCLASSES C05B, C05C, e.g. FERTILISERS FROM WASTE OR REFUSE

- C05F9/00—Fertilisers from household or town refuse

- C05F9/02—Apparatus for the manufacture

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F26—DRYING

- F26B—DRYING SOLID MATERIALS OR OBJECTS BY REMOVING LIQUID THEREFROM

- F26B25/00—Details of general application not covered by group F26B21/00 or F26B23/00

- F26B25/04—Agitating, stirring, or scraping devices

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02A—TECHNOLOGIES FOR ADAPTATION TO CLIMATE CHANGE

- Y02A40/00—Adaptation technologies in agriculture, forestry, livestock or agroalimentary production

- Y02A40/10—Adaptation technologies in agriculture, forestry, livestock or agroalimentary production in agriculture

- Y02A40/20—Fertilizers of biological origin, e.g. guano or fertilizers made from animal corpses

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P20/00—Technologies relating to chemical industry

- Y02P20/10—Process efficiency

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P20/00—Technologies relating to chemical industry

- Y02P20/10—Process efficiency

- Y02P20/129—Energy recovery, e.g. by cogeneration, H2recovery or pressure recovery turbines

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P20/00—Technologies relating to chemical industry

- Y02P20/50—Improvements relating to the production of bulk chemicals

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P60/00—Technologies relating to agriculture, livestock or agroalimentary industries

- Y02P60/80—Food processing, e.g. use of renewable energies or variable speed drives in handling, conveying or stacking

- Y02P60/87—Re-use of by-products of food processing for fodder production

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P70/00—Climate change mitigation technologies in the production process for final industrial or consumer products

- Y02P70/10—Greenhouse gas [GHG] capture, material saving, heat recovery or other energy efficient measures, e.g. motor control, characterised by manufacturing processes, e.g. for rolling metal or metal working

Definitions

- the PLC controller instructs the stirring motor to stop, the waste heat recovery device stops working, and when the interlayer temperature sensor senses that the temperature drops to the set temperature, the PLC The controller commands the alarm to sound, prompting the discharge.

- the condensing plate of the step 1 of the present invention is composed of a flat plate and a cold plate evaporator, the cold plate evaporator is fixed on the flat plate, the cold plate evaporator is connected to the heat pump system, and the heat pump system is connected with the temperature control switch.

- the plate is made of a temperature guiding material.

- the invention can be provided with a cutting edge at the lower end of the shutter to cut the material falling under the shutter to ensure that the shutter can completely seal the discharge opening.

- the heat energy is transmitted to the stirring shaft and the stirring blade, and the positive pressure heat in the hollow structure of the stirring shaft, the stirring blade repeatedly stirs and heats the material, and the tank body layer heats the negative pressure of the material at a low pressure, which not only accelerates the body in the tank significantly The drying speed of the material, and also significantly saves energy consumption.

- the gap between the end of the shaftless screw 25 and the shutter 27 of the present invention is 2-10 mm, so as to facilitate the recovery and extrusion of the material close to the shutter 27, and then reversely conveyed to ensure that the material is completely squeezed and completely transported. effect.

- the oil-water separation device of the present invention comprises a chassis 71 and a chassis cover 72, a control device 73 and a sewage device 74.

- the side wall of the chassis 71 is in communication with the sewage inlet pipe 75, and the chassis 71 and the chassis cover 72 are sealingly connected.

- the casing 71 is provided with a condensing and oiling mechanism 76, a scraping mechanism 77, a degreasing mechanism 78, and a cooling and heating system 79.

- the degreasing reducer 111 The driving device is driven to facilitate the rotation of the degreaser 112 by the degreasing reducer 111, and the pushing oil butting plate 84 is linearly moved along the sidewall of the degreasing tank 85, and the moving oil reservoir 82 flows into the degreasing tank 85. Go to the oil tank 88.

- the slender material such as the knife, fork and chopsticks passes under the rotation of the separating shaft.

- Separation blade export Other hard materials such as paste materials and bones under the centrifugal action of the separation shaft and the separation blade, the hard material instantaneously collides with the filter mesh under the action of centrifugation to pulverize, and the pulverized powder and paste enter the guide cavity through the filter mesh.

- the material is quickly pushed into the feeding port of the drying tank through the feeding port by the rotation of the conveying guide plate, and the PLC controller Open the electric ball valve, the material enters the drying tank, and then close the electric ball valve.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Polymers & Plastics (AREA)

- Environmental & Geological Engineering (AREA)

- Biotechnology (AREA)

- Health & Medical Sciences (AREA)

- Organic Chemistry (AREA)

- Thermal Sciences (AREA)

- Physics & Mathematics (AREA)

- Mechanical Engineering (AREA)

- Molecular Biology (AREA)

- Food Science & Technology (AREA)

- Physiology (AREA)

- Animal Husbandry (AREA)

- Zoology (AREA)

- Biomedical Technology (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Sustainable Development (AREA)

- Analytical Chemistry (AREA)

- Hydrology & Water Resources (AREA)

- Botany (AREA)

- Water Supply & Treatment (AREA)

- Mycology (AREA)

- Biochemistry (AREA)

- Manufacturing & Machinery (AREA)

- Microbiology (AREA)

- General Engineering & Computer Science (AREA)

- Dispersion Chemistry (AREA)

- Processing Of Solid Wastes (AREA)

- Drying Of Solid Materials (AREA)

Abstract

Disclosed in the present invention are a kitchen waste processing method and a processing apparatus, comprising an automatic lifting material intake apparatus, a salt and grease removal apparatus, an oil-water separation apparatus, an automatic sorting apparatus, a drying apparatus, a waste heat recovery apparatus, and a control system, characterized in that a water outlet of the salt and grease removal apparatus is connected to the oil-water separation apparatus, a material outlet is connected to a material inlet of the automatic sorting apparatus, a material outlet of the automatic sorting apparatus is connected to a material inlet of a drying tank of the drying apparatus by means of an electric ball valve, an air outlet of the drying tank is connected to a vacuum pump by means of the waste heat recovery apparatus, and negative vacuum pressure is formed inside the drying tank by means of the operation of a vacuum pump. Employing the described structure, the present invention features a novel structure, a high degree of automation, a marked solid-liquid separation effect, short drying times, low power consumption, and high operational stability, and also conserves energy, is environmentally friendly, and does not emit odors, among other advantages.

Description

本发明涉及环保设备技术领域,具体地说是一种餐厨废弃物处理方法及处理装置。The invention relates to the technical field of environmental protection equipment, in particular to a kitchen waste disposal method and a processing device.

专利号为201310440932.3,专利名称为餐厨废弃物预处理设备的发明专利,并已授权,该专利于通过在壳体上端设有投料斗和正反转电机,壳体内设有自动分选装置,生物杀菌祛臭祛味干燥装置,油水分离装置,电离除臭装置和汽体冷凝装置,所述投料斗经出料口与自动自动分拣装置的餐厨废弃物进料口相连通,自动自动分拣装置经餐厨废弃物出口与生物杀菌祛臭祛味干燥装置中的进料口相连通,自动自动分拣装置经出液口与油水分离装置相连通,生物杀菌祛臭祛味干燥装置经排气口与汽体冷凝装置相连通,气体冷凝装置与电离除臭装置相连通,达到了自动分拣、发酵处理速度快、发酵均匀、加热速度快、发酵时可自动充氧、气体除臭达标、环保无污染的作用。但还存在如下实质性不足:1、在发酵干燥时,由于采用减压干燥,干燥温度通常在140多度,不但产生大量的高温蒸汽还需要经电离除臭装置进行处理,干燥时间长、耗能高,由于冷凝效果差,导致蒸汽向外散发,而且,由于温度太高,会将餐厨废弃物中含有的有益菌、蛋白质等营养成分全部破坏,是餐厨废弃物中含有的蛋白质等营养成分会被部分破坏;2、当餐厨废弃物被倒入到投料斗内时,过多的油水会经分拣筒流入到干燥槽内,进而延长了干燥时间,增大了干燥负担;3、在餐厨废弃物通过投料斗进入分拣筒内分选时,由于分拣筒由进口端设有小直径过滤网,当细长的固状物进入分拣筒内时,不但很容易插入小直径过滤网内,导致分离轴的负载增大,分离效果不佳,而且分拣筒的小直径过滤网段出膏的含量高,导致排污管道被阻塞;4、当设备需要维护时,由于干燥槽、分拣筒都是整体,需要通过专用设备将轴和干燥槽,或者轴和分拣筒分离,拆装非常麻烦,费时费力。Patent No. 201310440932.3, the patent name is the invention patent of the kitchen waste pretreatment equipment, and has been authorized. The patent is provided with a hopper and a positive and negative motor at the upper end of the casing, and an automatic sorting device is arranged in the casing. a sterilization and deodorizing drying device, an oil-water separation device, an ionization deodorizing device and a vapor condensation device, wherein the feeding hopper is connected to the kitchen waste feeding port of the automatic automatic sorting device through the discharging port, and automatically and automatically The sorting device is connected to the feed port in the biological sterilization, odor and odor drying device through the kitchen waste export, and the automatic automatic sorting device is connected to the oil-water separation device through the liquid outlet, and the biological sterilization odor and odor drying device is The exhaust port is connected with the vapor condensation device, and the gas condensation device is connected with the ionization deodorization device, and the automatic sorting, the fermentation process is fast, the fermentation is uniform, the heating speed is fast, the oxygenation can be automatically performed during the fermentation, and the gas is deodorized. Standardized, environmentally friendly and non-polluting. However, there are still the following substantial disadvantages: 1. During fermentation drying, the drying temperature is usually more than 140 degrees due to drying under reduced pressure. Not only does it generate a large amount of high-temperature steam, but also needs to be treated by an ionization and deodorization device. The drying time is long and consumes. High energy, due to the poor condensation effect, the steam is emitted outwards, and because the temperature is too high, all the nutrients such as beneficial bacteria and protein contained in the kitchen waste are destroyed, which is the protein contained in the kitchen waste. The nutrients will be partially destroyed; 2. When the kitchen waste is poured into the hopper, too much oil will flow into the drying tank through the sorting cylinder, which will prolong the drying time and increase the drying burden; 3. When the kitchen waste is sorted into the sorting cylinder through the feeding hopper, since the sorting cylinder is provided with a small-diameter filter net from the inlet end, it is not only easy when the elongated solid material enters the sorting cylinder. Insertion into the small-diameter filter net causes the load of the separation shaft to increase, the separation effect is not good, and the content of the small-diameter filter network segment of the sorting cylinder is high, which causes the sewage pipeline to be blocked; 4. When the equipment needs In order to maintain, since the drying tank and the sorting cylinder are all integral, it is necessary to separate the shaft and the drying tank, or the shaft and the sorting cylinder by special equipment, which is troublesome and time consuming.

另外,现有的油水分离装置的分离方式大致可分为重力式分离、离心式分离、电分离、吸附分离、气浮分离等,这些油水分离方式均存在各自的实质性缺陷,油水分离时间长、提油效率低、出油纯度低,如重力式分离方式采用沉降池形式,会导致液体流动存在死区,部分液体得不到流动置换,水中有机质会逐渐腐败变臭;气浮分离方式会产生大量臭气;离心式分离方式设备动力部件维护困难,目前只应用于实验室的分析设备等。In addition, the separation methods of the existing oil-water separation devices can be roughly divided into gravity separation, centrifugal separation, electric separation, adsorption separation, air separation, etc. These oil-water separation methods have their own substantial defects, and the oil-water separation time is long. Low oil extraction efficiency and low oil extraction purity. For example, the gravity separation method adopts the form of sedimentation tank, which will lead to the dead zone of liquid flow, some liquids will not be replaced by flow, and the organic matter in water will gradually become corrupt and odor; the air flotation separation method will A large amount of odor is generated; the centrifugal separation method power unit is difficult to maintain, and is currently only used in laboratory analysis equipment.

另外,上述分离方法分离出的油水由于分离不彻底,导致油品差,储存及再利用困难。In addition, the oil and water separated by the above separation method are incompletely separated, resulting in poor oil quality, and difficulty in storage and reuse.

发明内容Summary of the invention

本发明的目的是解决上述现有技术的不足,提供一种更加完善的餐厨废弃物处理方法。The object of the present invention is to solve the above-mentioned deficiencies of the prior art and to provide a more perfect method for treating kitchen waste.

本发明的第二个目的是提供一种结构新颖、处理时间短、功耗低、环保无臭气排放、设备运行稳定性高、分离效果好的餐厨废弃物处理装置A second object of the present invention is to provide a kitchen waste disposal device with novel structure, short processing time, low power consumption, environmental protection and odorless gas discharge, high equipment operation stability, and good separation effect.

本发明解决其技术问题所采用的技术方案是:The technical solution adopted by the present invention to solve the technical problem thereof is:

一种餐厨废弃物处理方法,其特征在于在对物料进行自动处理时,PLC控制器指令料斗电动阀开启,打开密封盖,同时,启动闸板驱动电机动作,带动闸板封住出料口,然后停止,并同时启动正反转电机反转,使无轴螺旋对落入投料斗内的餐厨废弃物进行破碎拧挤,同时,启动降盐降脂装置中的水泵,通过冲洗管对投料斗壁进行喷水,及时除去投料斗壁粘附的油盐,并对进入投料斗内的物料进行降盐降脂处理,物料经拧挤和喷淋后排出的油液通过收液槽收集后通过排液管排到油水分离装置中,当餐厨废弃物被拧挤后,PLC控制器再指令正反转电机正转,分离电机正转、下输送电机正转,闸板驱动电机带动闸板上移,打开出料口,正反转电机带动无轴螺旋旋转将拧挤后的物料经出料口推入分拣筒中,当进入分拣筒时,在分离轴的旋转作用下,刀、叉、筷子等细长物质通过分离叶片导出,其它膏状物料和骨头等硬物质在分离轴和分离叶片的离心作用下,硬物质瞬间在离心作用下与过滤网发生碰撞而粉碎,粉碎后的粉末和膏状物经过滤网进入导流腔内,通过右旋导叶的导流和左旋挡板的配合阻挡,再通过连接导料板在输送轴的旋转作用下将物料通过下料口快速向干燥槽的进料口中推进,PLC控制器打开电动球阀,物料进入到干燥槽内,然后关闭电动球阀,PLC控制器指令搅拌电机动作,带动干燥槽内的搅拌轴对物料进行搅拌干燥,在干燥过程中,先通过PLC控制器指令干燥槽夹层的电加热元件电加热,当干燥槽内的温度上升到80摄氏度时,即停止电加热,PLC控制器启动真空泵,开始对干燥槽内抽真空,当干燥槽内的真空度达到-0.06MPa时,压缩机伴热带停止,压缩机启动进入干燥阶段,同时,PLC控制器指令余热热回收装置5工作,余热回收装置5对干燥装置4中的物料干燥过程中产生的蒸汽进行热交换后,将蒸汽冷凝形成液体余热回收装置蒸汽的热量被余热热回收装置再回收产生50-120℃的热水,其中50-120℃的热水传递至干燥槽内的夹层和搅拌轴的中空结构中,通过干燥槽内和搅拌轴和搅拌叶片对干燥槽内的物料进行再加热,另一部分至将热能传递到冲洗水箱32中,50-70℃的热水通过除盐除脂装置1对餐厨废弃物进行冲洗;在加热过程中,搅拌轴上的螺旋叶片对膏状的餐厨废弃物进行充分搅拌,避免干燥槽内的餐厨废弃物搅拌不均匀而影响干燥质量,干燥过程中始终保持干燥槽体内压力在-0.081~-0.099MPa,使干 燥槽内的沸点在50-65℃时即可沸腾,无需加热到100℃,不但显著加快了槽体内的物料的干燥速度,缩短了干燥时间,而且还显著节省了能量的消耗;A kitchen waste disposal method is characterized in that, when the material is automatically processed, the PLC controller instructs the hopper electric valve to open, opens the sealing cover, and simultaneously activates the ram drive motor to drive the ram to seal the discharge opening. And then stop, and at the same time start the reverse rotation of the positive and negative motor, so that the shaftless screw crushes and squeezes the kitchen waste falling into the feeding hopper, and at the same time, starts the water pump in the salt reduction and fat reduction device, through the flushing tube pair The hopper wall is sprayed with water to remove the oil salt adhered to the hopper wall in time, and the material entering the hopper is subjected to salt reduction and lipid reduction treatment. The oil discharged after the material is squeezed and sprayed is collected through the liquid collection tank. After being discharged into the oil-water separation device through the drain pipe, when the kitchen waste is screwed, the PLC controller instructs the positive and negative motor to rotate forward, the split motor rotates forward and the lower feed motor forwards, and the gate drive motor drives The gate is moved to open the discharge port, and the positive and negative motor drives the shaftless spiral rotation to push the screwed material into the sorting cylinder through the discharge port. When entering the sorting cylinder, under the rotation of the separation shaft, Knife, fork, chopsticks The elongate material is led out through the separation blade, and other hard materials such as paste material and bone are centrifuged under the separation axis and the separation blade, and the hard substance is instantaneously collided with the filter mesh under the action of centrifugation to pulverize, and the pulverized powder and paste are pulverized. The material enters the guiding cavity through the filter net, and is blocked by the diversion of the right-handed guide vane and the cooperation of the left-handed baffle, and then the material is quickly passed to the drying tank through the feeding port by the rotation of the conveying shaft through the connecting guide plate. The feeding port advances, the PLC controller opens the electric ball valve, the material enters the drying tank, and then the electric ball valve is closed. The PLC controller instructs the stirring motor to move, and drives the stirring shaft in the drying tank to stir and dry the material during the drying process. First, the electric heating element of the drying tank interlayer is electrically heated by the PLC controller. When the temperature in the drying tank rises to 80 degrees Celsius, the electric heating is stopped, and the PLC controller starts the vacuum pump to start vacuuming the drying tank when drying. When the vacuum in the tank reaches -0.06MPa, the compressor heating cable stops, the compressor starts to enter the drying stage, and at the same time, the PLC controller commands the rest. The heat recovery device 5 works, and the waste heat recovery device 5 heat-exchanges the steam generated during the drying process of the material in the drying device 4, and then condenses the steam to form a heat of the liquid waste heat recovery device. The heat of the steam is recovered by the waste heat recovery device to generate 50-120 Hot water of °C, wherein 50-120 °C hot water is transferred to the hollow structure of the interlayer and the stirring shaft in the drying tank, and the material in the drying tank is reheated through the drying tank and the stirring shaft and the stirring blade, and the other part To transfer the heat energy to the flushing water tank 32, the hot water of 50-70 ° C is washed by the desalting and degreasing device 1; during the heating process, the spiral blade on the stirring shaft is discarded by the paste-shaped kitchen The material is thoroughly stirred to avoid uneven mixing of the kitchen waste in the drying tank, which affects the drying quality. The pressure in the drying tank is maintained at -0.081 to -0.099 MPa during the drying process, so that the boiling point in the drying tank is 50-65 °C. It can be boiled without heating to 100 ° C, which not only accelerates the drying speed of the material in the tank, shortens the drying time, but also saves energy consumption.

同时,通过余热回收装置将温度降低,降温后变成液态的带有异味的冷凝水再通过真空泵,将其排放到真空泵循环水箱中,随真空泵循环水箱的溢流口,流到油水分离装置中,最终排放到污水处理系统中;At the same time, the temperature is lowered by the waste heat recovery device, and the odorous condensed water which becomes liquid after cooling is passed through a vacuum pump, and discharged into the vacuum pump circulating water tank, and flows to the oil-water separation device with the overflow port of the vacuum pump circulating water tank. And finally discharged into the sewage treatment system;

当水箱温度传感器检测到水箱内的水温大于等于40°时,水箱补水电磁阀动作,给水箱补充凉水降温至小于等于33摄氏度,然后停止补水;When the water tank temperature sensor detects that the water temperature in the water tank is greater than or equal to 40°, the water tank hydrating solenoid valve acts, and the water tank is supplemented with cool water to cool to 33 degrees Celsius or less, and then the water is stopped;

在干燥槽干燥阶段,当干燥槽压力传感器检测到干燥槽内压力持续5分钟低于-0.06MPa时,触发真空压力异常故障报警,报警信号可在触摸屏上显示;或者,在PC计算机、或手机上显示。In the drying stage of the drying tank, when the pressure of the drying tank detects that the pressure in the drying tank is lower than -0.06 MPa for 5 minutes, the vacuum pressure abnormality alarm is triggered, and the alarm signal can be displayed on the touch screen; or, in a PC computer or a mobile phone Displayed on.

当干燥槽夹层的夹层温度传感器的温度达到设定的90-110℃时,PLC控制器指令搅拌电机停止,余热回收装置停止工作,当夹层温度传感器感应到温度降低至设定的温度时,PLC控制器即指令报警器发出声音,提示出料。When the temperature of the interlayer temperature sensor of the drying tank interlayer reaches the set temperature of 90-110 ° C, the PLC controller instructs the stirring motor to stop, the waste heat recovery device stops working, and when the interlayer temperature sensor senses that the temperature drops to the set temperature, the PLC The controller commands the alarm to sound, prompting the discharge.

在油水分离装置进行油水分离时,通过油和水的凝固点不同,在油达到凝固点而水并未达到凝固点的温度范围内,实现油和水的高效油液分离。When the oil-water separation device performs oil-water separation, the oil and water are separated from each other, and the oil and water are separated by high efficiency in the temperature range in which the oil reaches the freezing point and the water does not reach the freezing point.

其方法步骤如下:The method steps are as follows:

1)、制作冷凝板;1), making a condensation plate;

2)、对冷凝板进行降温冷凝,使得冷凝板的温度高于水的凝固点而等于或低于油的凝固点;2) cooling and condensing the condensing plate so that the temperature of the condensing plate is higher than the freezing point of the water and equal to or lower than the freezing point of the oil;

3)、将冷凝后的冷凝板底面放置并接触在静止后的盛有油液的机箱内的液体上表面,将悬浮在液体表面的油冷凝成油脂并粘附到冷凝板上;3) placing the bottom surface of the condensed condensing plate and contacting the upper surface of the liquid in the static oil-filled casing, and condensing the oil suspended on the surface of the liquid into grease and adhering to the condensing plate;

4)、用刮油板刮除粘附在冷凝板上的油脂;4) scraping off the grease adhered to the condensing plate with a scraper;

由于油的浮力大于水和杂物而悬浮于液体表面,因此,如此反复重复上述1-4步骤,即可将油水渣分离彻底,显著提高了提油纯度和提油效率。Since the buoyancy of the oil is greater than that of water and debris, it is suspended on the surface of the liquid. Therefore, the above steps 1-4 are repeated repeatedly to completely separate the oil and water slag, and the purity of the oil and the efficiency of oil extraction are remarkably improved.

本发明还包括步骤5:对刮除后的除油槽进行加热,以使油脂加热后形成液体油而快速流入到接油桶中。The invention further includes the step 5: heating the scraped degreaser tank to heat the grease to form a liquid oil and quickly flowing into the oil tank.

本发明所述步骤1冷凝板是由平板和冷板蒸发器构成,所述冷板蒸发器固定在平板上,所述冷板蒸发器与热泵系统连接,所述热泵系统与温控开关连接,所述平板是由导温材料制成。The condensing plate of the step 1 of the present invention is composed of a flat plate and a cold plate evaporator, the cold plate evaporator is fixed on the flat plate, the cold plate evaporator is connected to the heat pump system, and the heat pump system is connected with the temperature control switch. The plate is made of a temperature guiding material.

本发明所述步骤5除油槽是由槽体和槽体下面的油冷冷凝器构成,所述油冷冷凝器与热泵系统连接。The step 5 deoiling tank of the present invention is composed of a tank body and an oil-cooled condenser below the tank body, and the oil-cooled condenser is connected to the heat pump system.

本发明所述温控开关可以采用PLC控制器,以达到自动控制的作用。The temperature control switch of the invention can adopt a PLC controller to achieve the function of automatic control.

一种餐厨废弃物处理装置,包括固液分离装置、油水分离装置、自动分拣装置、干燥装置和控制系统,所述干燥装置包括干燥槽、搅拌轴和搅拌电机,搅拌轴上设有搅拌叶片,搅拌轴两端分别经轴承、轴承座与干燥槽固定连接,所述搅拌轴与搅拌电机相连接,所述干燥槽的内层和外层之间的夹层内设有加热元件,外层上设有温度传感器,干燥槽下部设有出料口,出料口上设有出料密封门,其特征在于还包括电动球阀、真空泵、余热回收装置,所述自动分拣装置的出料口通过电动球阀与干燥装置的干燥槽的进料口相连接,干燥槽的出汽口通过余热回收装置与真空泵相连接,所述电动球阀、余热回收装置和干燥装置分别与控制系统相连接,通过真空泵的工作使干燥槽内形成真空负压,使干燥过程中压力维持在-0.081至-0.099MPa,不但能将干燥槽内发酵干燥的餐厨废弃物中的有害细菌杀死,保留了有益于牲畜的蛋白质、纤维素和其它营养成分,使发酵干燥后的餐厨废弃物颗粒符合畜牧法的规定而形成牲畜饲料;而且,负压降低了物料中水的沸点,此时干燥槽内的温度在50-65℃左右时,物料中的水即可沸腾,无需将物料加热到100℃,从而大大缩短了干燥时间的能耗;同时,通过余热回收装置,将干燥过程中产生的带有臭味的蒸汽进行冷凝,使臭气分子溶解到冷凝水中排放到污水处理系统中,避免了异味产生。A kitchen waste treatment device comprises a solid-liquid separation device, an oil-water separation device, an automatic sorting device, a drying device and a control system, the drying device comprises a drying tank, a stirring shaft and a stirring motor, and the stirring shaft is provided with stirring The blade and the two ends of the stirring shaft are fixedly connected to the drying tank through a bearing and a bearing seat, and the stirring shaft is connected with the stirring motor, and the heating layer is disposed in the interlayer between the inner layer and the outer layer of the drying tank, and the outer layer There is a temperature sensor, a discharge port is arranged at the lower part of the drying tank, and a discharge sealing door is arranged on the discharge port, which is characterized in that it further comprises an electric ball valve, a vacuum pump and a waste heat recovery device, and the discharge port of the automatic sorting device passes through The electric ball valve is connected with the feeding port of the drying tank of the drying device, and the steam outlet of the drying tank is connected to the vacuum pump through a waste heat recovery device, and the electric ball valve, the waste heat recovery device and the drying device are respectively connected with the control system, and the vacuum pump is connected The work creates a vacuum negative pressure in the drying tank, so that the pressure during the drying process is maintained at -0.081 to -0.099 MPa, which can not only ferment dry in the drying tank. The harmful bacteria in the kitchen waste are killed, retaining the protein, cellulose and other nutrients beneficial to the livestock, so that the fermented and dried kitchen waste particles meet the requirements of the Animal Husbandry Law to form livestock feed; The boiling point of the water in the material is lowered. When the temperature in the drying tank is about 50-65 ° C, the water in the material can boil, and the material does not need to be heated to 100 ° C, thereby greatly reducing the energy consumption of the drying time; Through the waste heat recovery device, the odor-laden steam generated in the drying process is condensed, and the odor molecules are dissolved in the condensed water and discharged into the sewage treatment system, thereby avoiding the generation of odor.

本发明所述固液分离装置包括投料斗、正反转电机和无轴螺旋,所述投料斗内设有无轴螺旋,所述投料斗底部设有收液槽,上端设有密封盖,所述投料斗与收液槽间设有滤网板,所述投料斗的出料口上设有封口装置,所述收液槽底面倾斜,以利于对流体进行导流,所述收液槽经输液管道与油水分离装置相连通,所述无轴螺旋一端与正反转电机固定连接,另一端与投料斗侧壁设有的出料口相对应,所述正反转电机与控制系统相连接,通过封口装置封住出料口,控制系统启动正反转电机反转,对进入投料斗内的餐厨废弃物进行破碎拧挤,将餐厨废弃物中的油水被挤出,油水通过滤网板下流至收液槽,收液槽内的油水经输液管道流入到油水分离装置进行处理,当大部分水分和油脂被拧挤出后,控制系统再指令正反转电机正转、同时驱动封口装置上移,使出料口打开,无轴螺旋将拧挤后的餐厨废弃物正转推出,经出料口进入分拣筒内,使进入发酵干燥槽内的餐厨废弃物的含水量大大减小,大大降低了干燥时间,减少了干燥负担,节约能耗。The solid-liquid separation device of the present invention comprises a feeding hopper, a forward and reverse electric motor and a shaftless screw, wherein the feeding hopper is provided with a shaftless spiral, the bottom of the feeding hopper is provided with a liquid receiving groove, and the upper end is provided with a sealing cover. A filter screen is arranged between the feeding hopper and the liquid receiving tank, and a sealing device is arranged on the discharge opening of the feeding hopper, the bottom surface of the liquid receiving tank is inclined to facilitate the flow of the fluid, and the liquid receiving tank is infused The pipeline is connected to the oil-water separation device, the one end of the shaftless screw is fixedly connected with the positive and negative motor, and the other end is corresponding to the discharge port provided on the side wall of the hopper, and the forward and reverse motor is connected with the control system. The sealing device seals the discharge port, and the control system starts the reverse rotation of the positive and negative motors to crush and squeeze the kitchen waste entering the feeding hopper, and the oil and water in the kitchen waste is squeezed out, and the oil and water pass through the filter screen. The plate flows down to the liquid collection tank, and the oil water in the liquid collection tank flows into the oil-water separation device through the infusion pipe for processing. When most of the moisture and grease are screwed out, the control system instructs the positive and negative motor to rotate forward and simultaneously drive the sealing. The device is moved up so that The material opening is opened, and the shaftless spiral will push the kitchen waste after being pushed out, and enter the sorting cylinder through the discharge port, so that the water content of the kitchen waste entering the fermentation drying tank is greatly reduced, and the diameter is greatly reduced. The drying time reduces the drying burden and saves energy.

本发明可在所述固液分离装置上设有除盐除脂装置,所述除盐除脂装置包括冲洗管、冲洗电磁阀、冲洗泵、冲洗水箱,所述冲洗管固定在投料斗内侧壁,所述冲洗管经冲洗电磁阀与冲洗泵相连接,所述冲洗泵与冲洗水箱相连接,所述冲洗电磁阀和冲洗泵分别经控 制系统控制,以利于对投料斗的四周进行喷淋冲洗,避免油盐粘附在投料斗壁上,同时,还对餐厨废弃物进行的冲洗,大大降低了餐厨废弃物的盐分和油脂,使之更加适宜于成为饲料添加剂或生态肥原料。The invention can be provided with a desalination and degreasing device on the solid-liquid separation device, the desalination and degreasing device comprises an irrigation pipe, a flushing electromagnetic valve, a flushing pump and a flushing water tank, and the flushing pipe is fixed on the inner side wall of the feeding hopper The flushing pipe is connected to the flushing pump via a flushing solenoid valve, and the flushing pump is connected to the flushing water tank, and the flushing solenoid valve and the flushing pump are respectively controlled by a control system to facilitate spray washing of the circumference of the feeding hopper To avoid the adhesion of oil and salt to the wall of the hopper, and at the same time, the washing of the kitchen waste greatly reduces the salt and oil of the kitchen waste, making it more suitable for becoming a feed additive or an ecological fertilizer raw material.

本发明所述封口装置可以包括闸板和动力驱动装置,所述动力驱动装置可以是气缸,或者,也可以是由丝杠、丝母座和闸板驱动电机组成,所述闸板穿过闸板穿孔与出料口端面相配合密封,所述闸板驱动电机与丝杠连接,丝母座与闸板连接,闸板驱动电机旋转带动丝杠转动,丝杠转动带动丝母座上下运动,从而带动闸板上下运动,所述闸板穿过闸板穿孔与出料口端面相配合密封,当含水量高的餐厨废弃物要进入投料斗时,闸板驱动电机驱动闸板封住出料口,当大部分水分被拧挤出后,控制系统再指令正反转电机正转、同时驱动闸板下移,使出料口打开。The sealing device of the present invention may comprise a shutter and a power driving device, and the power driving device may be a cylinder, or may be composed of a screw, a silk socket and a shutter driving motor, the gate passing through the gate The plate perforation is matched with the end surface of the discharge port, the gate drive motor is connected with the lead screw, the wire base is connected with the gate plate, the gate drive motor rotates to drive the screw to rotate, and the screw rotation rotates the wire base to move up and down. Thereby driving the lower plate movement, the ram passes through the ram perforation and the end surface of the discharge port is matched and sealed. When the kitchen waste with high water content is to enter the feeding hopper, the ram drive motor drives the ram to seal out At the material port, when most of the water is squeezed out, the control system instructs the positive and negative motor to rotate forward and simultaneously drives the shutter to move down, so that the discharge port is opened.

本发明所述无轴螺旋端部与闸板间隙为2-10mm,以利于将接近闸板的物料进行回收挤压,然后再反向输送,保证物料达到完全挤压和完全输送的作用。The gap between the shaftless screw end and the ram of the invention is 2-10mm, so as to facilitate the recovery and extrusion of the material close to the ram, and then reversely transport, to ensure the material is fully squeezed and completely transported.

本发明可在所述闸板下端设有刃口,以达到对落入闸板下方的物料进行切割,保证闸板能够完全封住出料口。The invention can be provided with a cutting edge at the lower end of the shutter to cut the material falling under the shutter to ensure that the shutter can completely seal the discharge opening.

本发明所述自动分拣装置包括分拣筒、盖板,破碎刀、分离轴、分离叶片、过滤网、分离电机和物料导流装置,分拣筒上端与盖板相连接,所述分拣筒底部的过滤网是由进口端的无孔出料段和与无孔出料段相连接的有孔出料网段依次连接而成,所述过滤网下部设有导流腔,所述物料导流腔下端面一侧设有冲洗水收液槽,另一侧设有下料口,所述导流腔内设有物料导流装置,所述冲洗水收液槽经滤液网与导流腔隔离,以利于对物料的水分再次过滤分离,所述冲洗水收液槽底部倾斜并与油水分离装置相连通,所述下料口与干燥槽的进料口相连通,所述物料导流装置包括输送轴和输送减速机,所述输送轴经轴承固定在导料腔上,所述输送轴经输送减速机驱动,所述输送减速机经控制系统控制,所述输送轴上由左向右依次右旋导叶、连接导料板和左旋挡板,所述右旋导叶沿输送轴轴向螺旋缠绕,所述连接导料板轴向固定在输送轴上,所述连接导料板一端与右旋导叶固定连接,另一端与左旋挡板固定连接,所述右旋导叶与冲洗水收液槽相对应,所述连接导流板与下料口相对应,当细长的固状物进入分拣筒内时,通过无孔出料段中的分离叶片的导向,使细长固状物通过导料叶片将其导到分离叶片上,并在分离轴的旋转作用下,使诸如塑料袋、刀、叉、筷子或饭盒之类的大物质通过分离叶片导出进入生活垃圾出口,分拣后的酱状餐厨废弃物通过过滤网进入到导流腔内,通过右旋导叶的导流和左旋挡板的配合阻挡后,再通过连接导料板在输送轴的旋转作用下将物料通过下料口快速推入到干燥槽的进料口中,通过控制系统打开电动球阀, 使物料进入到干燥槽内,进一步避免了物料积存在分拣筒内而无法排出。The automatic sorting device of the present invention comprises a sorting cylinder, a cover plate, a crushing knife, a separating shaft, a separating blade, a filter net, a separating motor and a material guiding device, and the upper end of the sorting cylinder is connected with the cover plate, and the sorting The filter net at the bottom of the cylinder is formed by sequentially connecting a non-porous discharge section at the inlet end and a perforated discharge section connected to the non-porous discharge section, and a drainage chamber is arranged at a lower portion of the filter, the material guide A flushing water collecting tank is arranged on one side of the lower end surface of the flow chamber, and a material discharging port is arranged on the other side, and a material guiding device is arranged in the guiding liquid chamber, and the flushing water receiving tank passes through the filtrate network and the guiding cavity. Isolating to facilitate the filtration and separation of the moisture of the material, the bottom of the flushing water receiving tank is inclined and communicates with the oil-water separating device, and the discharging port is connected with the feeding port of the drying tank, the material guiding device The utility model comprises a conveying shaft and a conveying reducer, wherein the conveying shaft is fixed on the guiding cavity via a bearing, the conveying shaft is driven by a conveying reducer, and the conveying reducer is controlled by a control system, and the conveying shaft is from left to right. Right-hand guide vane, connecting guide plate and left-hand baffle The right-handed guide vane is spirally wound along the axial direction of the conveying shaft, and the connecting guide plate is axially fixed on the conveying shaft, and one end of the connecting guide plate is fixedly connected with the right-handed guide vane, and the other end is fixed with the left-handed baffle plate. Connecting, the right-handed guide vane corresponds to the flushing water receiving tank, and the connecting deflector corresponds to the discharging opening, and when the elongated solid enters the sorting cylinder, passes through the non-porous discharging section The guiding of the separating blades, so that the elongated solids are guided to the separating blades through the guiding blades, and under the rotation of the separating shaft, such as a plastic bag, a knife, a fork, a chopstick or a lunch box The material is exported to the domestic waste outlet through the separation blade, and the sorted sauce-like kitchen waste enters the diversion chamber through the filter net, and is blocked by the diversion of the right-hand guide vane and the cooperation of the left-handed baffle, and then connected. The material guide plate pushes the material into the feeding port of the drying tank through the feeding port under the rotation of the conveying shaft, and opens the electric ball valve through the control system to make the material enter the drying tank, further avoiding the material accumulation in the sorting. Cannot be discharged inside the tube

本发明所述输送轴可采用中空的注水腔,所述输送轴侧壁上设有冲洗孔,所述输送轴一端经旋转接头与冲洗水箱中的冲洗泵相连通,所述冲洗泵经控制系统控制,所述注水腔与冲洗孔相连通,当分拣完成后,冲洗水被注入到输送轴的注水腔,通过冲洗孔将过滤网、滤液网和导流腔进行自动冲洗,冲洗后的污水通过滤液网下流至冲洗收液槽,再经管道流入到油水分离装置中,大大方便了清理。The conveying shaft of the present invention can adopt a hollow water injection chamber, and a side of the conveying shaft is provided with a flushing hole, and one end of the conveying shaft is connected to a flushing pump in the flushing water tank via a rotary joint, and the flushing pump is controlled by the control system. Controlling, the water injection chamber is connected with the flushing hole. When the sorting is completed, the flushing water is injected into the water injection chamber of the conveying shaft, and the filtering net, the filtrate net and the guiding cavity are automatically flushed through the flushing hole, and the flushed sewage is washed. The filtrate network flows down to the flushing liquid collection tank, and then flows into the oil-water separation device through the pipeline, which greatly facilitates the cleaning.

本发明所述滤液网的网眼大小为2-10mm,以达到进一步对流体进行过滤的作用。The filtrate mesh of the present invention has a mesh size of 2-10 mm to further filter the fluid.

本发明所述干燥槽内的搅拌轴、搅拌杆和螺旋叶片分别采用中空相连通的结构,所述搅拌轴一端设有回转接头,所述搅拌轴内腔中设有进水管,所述进水管和搅拌轴内壁设有回水间隙,所述进水管一端经回转接头与水箱相连接,另一端封闭,且所述进水管侧壁经分水管穿过搅拌杆空腔与螺旋叶片内腔相连通,所述螺旋叶片上设有回水孔,以使水经回水孔返流进入搅拌轴的进水管与搅拌轴间的回水间隙并回流进入水箱,以利于通过真空余热回收装置将吸收的热能传递给搅拌轴和搅拌叶片,再通过搅拌轴的中空结构内的正压热量、搅拌叶片对物料反复搅拌加热,以及槽体夹层对物料的负压低沸点加热,不但显著加快了槽体内的物料的干燥速度,而且,还显著节省了能量的消耗。The agitating shaft, the stirring rod and the spiral blade in the drying tank of the present invention adopt a structure in which a hollow phase communicates with each other, and one end of the stirring shaft is provided with a rotary joint, and an inlet pipe is arranged in the inner cavity of the stirring shaft, and the inlet pipe is provided The inner wall of the agitating shaft is provided with a return water gap, one end of the inlet pipe is connected to the water tank via a rotary joint, and the other end is closed, and the side wall of the inlet pipe is connected to the inner cavity of the spiral blade through the water pipe of the stirring rod through the water pipe The spiral blade is provided with a water return hole, so that the water flows back through the return hole into the return water gap between the inlet pipe and the stirring shaft of the stirring shaft and flows back into the water tank, so as to facilitate absorption by the vacuum waste heat recovery device. The heat energy is transmitted to the stirring shaft and the stirring blade, and the positive pressure heat in the hollow structure of the stirring shaft, the stirring blade repeatedly stirs and heats the material, and the tank body layer heats the negative pressure of the material at a low pressure, which not only accelerates the body in the tank significantly The drying speed of the material, and also significantly saves energy consumption.

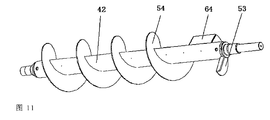

本发明所述干燥槽是由下中开槽体和上中开槽体组成,所述下中开槽体经密封圈和固定螺栓与上中开槽体固定密封连接,所述下中开槽体设有中空内腔,所述中空内腔中设有电加热装置和导热介质,所述电加热装置经控制系统控制,所述导热介质与真空余热回收装置相连通,以达到方便安装和维修的作用。The drying tank of the present invention is composed of a lower middle slotted body and an upper middle slotted body, and the lower middle slotted body is fixedly and sealingly connected with the upper middle slotted body through a sealing ring and a fixing bolt, and the lower middle slotted groove The body is provided with a hollow inner cavity, wherein the hollow inner cavity is provided with an electric heating device and a heat conducting medium, and the electric heating device is controlled by a control system, and the heat conducting medium is connected with the vacuum waste heat recovery device to facilitate installation and maintenance. The role.

本发明可在所述下中开槽体端面圆周设有密封卡槽,所述密封圈经密封卡槽定位,以达到安装快捷的作用。The invention can be provided with a sealing card slot on the circumference of the end face of the lower middle slotted body, and the sealing ring is positioned through the sealing card slot to achieve quick installation.

本发明所述分拣筒是由上中开筒体和下中开筒体组成,所述上中开筒体经橡胶密封圈和固定螺栓与下中开筒体固定密封连接,以达到方便安装和维修的作用。The sorting cylinder of the invention is composed of an upper middle opening cylinder and a lower middle opening cylinder, and the upper middle opening cylinder is fixedly and sealingly connected with the lower middle opening cylinder through a rubber sealing ring and a fixing bolt to achieve convenient installation. And the role of maintenance.

本发明可在所述上中开筒体端面圆周设有密封凹槽,所述橡胶密封圈经密封凹槽定位,以达到安装快捷的作用。The invention can be provided with a sealing groove on the circumference of the end surface of the upper middle opening cylinder, and the rubber sealing ring is positioned through the sealing groove to achieve quick installation.

本发明可在所述真空泵循环水箱上设有溢流口,所述真空泵循环水箱经溢流口与油水分离装置相连通,以利于当真空泵循环水箱内的水到达设定的水位线时,通过溢流口流入到油水分离装置中。The present invention can be provided with an overflow port on the vacuum pump circulating water tank, and the vacuum pump circulating water tank communicates with the oil-water separating device through the overflow port, so as to facilitate passage when the water in the vacuum pump circulating water tank reaches the set water level line. The overflow port flows into the oil-water separation device.

本发明所述真空余热回收装置包括制冷机组一、制冷机组二,所述制冷机组包括压缩机、冷凝器、膨胀阀、表冷器,所述干燥槽的出汽口经蒸汽过滤器依次与制冷机组一的表 冷器和制冷机组二的表冷器与真空泵相连,以使余热回收过程维持在-0.081~0.099MPa压力下进行,制冷机组二的冷凝器通过水泵与冲洗水箱相连;可以将制冷机组一的冷凝器设置在夹层内,也可以将冷凝器设置在干燥槽外部,通过换热循环管路与冷凝器相连通,以利于通过余热回收装置吸收干燥槽内的蒸汽的热能,通过冷凝器一方面将蒸汽的热能传递到干燥槽夹层内,对干燥槽内的物料进行干燥,另一方面将热能传递到冲洗水箱中,通过降盐降脂装置对餐厨废弃物进行冲洗,不但实现了余热回收,而且还显著节约了能耗,缩短了加热时间。The vacuum waste heat recovery device of the present invention comprises a refrigeration unit 1 and a refrigeration unit 2. The refrigeration unit comprises a compressor, a condenser, an expansion valve and a surface cooler, and the steam outlet of the drying tank is sequentially cooled and cooled by a steam filter. The air cooler of the unit 1 and the air cooler of the refrigeration unit 2 are connected to the vacuum pump to maintain the waste heat recovery process at a pressure of -0.081 to 0.099 MPa, and the condenser of the refrigeration unit 2 is connected to the flush water tank through a water pump; The condenser of unit one is disposed in the interlayer, and the condenser may be disposed outside the drying tank, and communicated with the condenser through the heat exchange circulation line to facilitate absorption of heat of steam in the drying tank by the waste heat recovery device, and condensation On the one hand, the heat energy of the steam is transferred to the inner layer of the drying tank to dry the material in the drying tank, and on the other hand, the heat energy is transferred to the flushing water tank, and the kitchen waste is washed by the salt-reducing and fat-reducing device, which not only realizes Waste heat recovery, but also significantly saves energy consumption and shortens heating time.

本发明所述控制系统包括PLC控制器、带有人机界面的触摸屏、报警器和监测传感器,所述监测传感器、报警器和触摸屏分别与PLC控制器相连接,所述监测传感器包括夹层温度传感器、槽体压力传感器、夹层压力传感器、夹层水位传感器、电加热管温度传感器、循环水箱温度传感器、循环水箱液位传感器、压缩机高压传感器、压缩机低压传感器,所述夹层温度传感器、夹层压力传感器和夹层水位传感器分别设置在槽体的夹层内,所述槽体压力传感器设置在槽体的内腔中,所述电加热管温度传感器设置在电加热管末端,所述循环水箱温度传感器和循环水箱液位传感器分别设置在循环水箱内,所述压缩机高压传感器设置在压缩机的出气管、压缩机低压传感器设置在压缩机的进气管上,以检测压缩机的压力,以利于通过在触摸屏上触摸控制模式,使PLC控制器自动接收来自监测传感器的信息,并指令负干燥槽体中的电动球阀、和/或加热元件、和/或余热回收装置动作,使槽体内的物料在负压、低温、密闭的环境下快速干燥,不但避免了气味散发于空气中而形成空气污染,同时,还消灭掉了物料中的细菌、避免了蛋白质、纤维素的破坏。The control system of the present invention comprises a PLC controller, a touch screen with a human-machine interface, an alarm device and a monitoring sensor, wherein the monitoring sensor, the alarm device and the touch screen are respectively connected with a PLC controller, and the monitoring sensor comprises a sandwich temperature sensor, Tank pressure sensor, interlayer pressure sensor, interlayer water level sensor, electric heating tube temperature sensor, circulating water tank temperature sensor, circulating water tank liquid level sensor, compressor high pressure sensor, compressor low pressure sensor, said interlayer temperature sensor, laminated pressure sensor and The interlayer water level sensors are respectively disposed in the interlayer of the tank body, the tank body pressure sensor is disposed in the inner cavity of the tank body, the electric heating tube temperature sensor is disposed at the end of the electric heating tube, the circulating water tank temperature sensor and the circulating water tank The liquid level sensors are respectively disposed in the circulating water tank, and the compressor high pressure sensor is disposed on the outlet pipe of the compressor, and the low pressure sensor of the compressor is disposed on the intake pipe of the compressor to detect the pressure of the compressor to facilitate passing on the touch screen. Touch control mode to make PLC control Automatically receiving information from the monitoring sensor and instructing the electric ball valve in the negative drying tank, and/or the heating element, and/or the waste heat recovery device to operate, so that the material in the tank is quickly dried in a negative pressure, low temperature, and closed environment. It not only avoids the odor generated in the air but also forms air pollution. At the same time, it also eliminates the bacteria in the material and avoids the destruction of protein and cellulose.

本发明可在所述PLC控制器中设置膨胀阀控制板,所述膨胀阀经膨胀阀控制板与PLC控制器连接,以利于通过膨胀阀控制板控制膨胀阀,使槽体温度平稳上升。The invention can be provided with an expansion valve control board in the PLC controller, and the expansion valve is connected to the PLC controller via the expansion valve control board, so as to facilitate the expansion of the tank body by the expansion valve control panel to control the expansion valve.

本发明可在所述过滤器和表冷器间的管路上设有真空泄压阀,所述真空泄压阀与PLC控制器相连接,以达到自动控制泄压和清理滤芯的作用。The invention can be provided with a vacuum pressure relief valve on the pipeline between the filter and the air cooler, and the vacuum pressure relief valve is connected with the PLC controller to achieve automatic control of pressure relief and cleaning of the filter core.

本发明可在所述投料斗上端设有密封盖,所述密封盖经料斗电动阀与投料斗相连接,所述料斗电动阀与PLC控制器相连接,以利于通过PLC控制器自动控制投料斗的开关。The invention can be provided with a sealing cover at the upper end of the feeding hopper, the sealing cover is connected with the feeding hopper via the hopper electric valve, and the hopper electric valve is connected with the PLC controller to facilitate automatic control of the feeding hopper by the PLC controller Switch.

本发明还可在所述PLC控制器中设有蓝牙通信模块,所述PLC控制器经无线通信模块与手机、电脑终端连接,以达到通过手机、电脑终端对设备进行实时监控。The invention can also be provided with a Bluetooth communication module in the PLC controller, and the PLC controller is connected with the mobile phone and the computer terminal via the wireless communication module, so as to realize real-time monitoring of the device through the mobile phone and the computer terminal.

本发明由于采用上述结构和方法,具有结构新颖、自动化程度高、固液分离效果显著、干燥时间短、节约能源、功耗低、环保、无异味排放、设备运行稳定性高等优点。The invention adopts the above structure and method, and has the advantages of novel structure, high degree of automation, remarkable solid-liquid separation effect, short drying time, energy saving, low power consumption, environmental protection, no odor emission, high stability of equipment operation and the like.

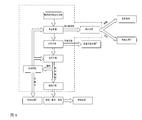

图1是本发明实施例的结构示意图。1 is a schematic structural view of an embodiment of the present invention.

图2是图1的左视图。Figure 2 is a left side view of Figure 1.

图3是本发明中进料固液分离装置和分拣装置的结构示意图。Figure 3 is a schematic view showing the structure of a feed solid-liquid separation device and a sorting device in the present invention.

图4是本发明真空干燥装置的结构示意图。Figure 4 is a schematic view showing the structure of a vacuum drying apparatus of the present invention.

图5是图4的俯视图的剖视图。Figure 5 is a cross-sectional view of the top view of Figure 4 .

图6是本发明真空干燥装置与余热回收装置的结构示意图。Figure 6 is a schematic view showing the structure of a vacuum drying device and a waste heat recovery device of the present invention.

图7是本发明处理示意图。Figure 7 is a schematic illustration of the process of the present invention.

图8是本发明处理流程图。Figure 8 is a process flow diagram of the present invention.

图9是本发明中输送轴的立体结构示意图。Figure 9 is a perspective view showing the structure of the conveying shaft of the present invention.

图10是图9的后视图。Figure 10 is a rear elevational view of Figure 9.

图11是本发明中干燥槽的分解结构示意图。Figure 11 is a schematic exploded view of the drying tank of the present invention.

图12是本发明分拣筒的分解结构示意图。Figure 12 is a schematic exploded view of the sorting cylinder of the present invention.

附图标记:降盐降脂装置1、固液分离装置2、油水分离装置3、自动分拣装置4、干燥装置5、余热回收装置7、真空泵9、电动球阀10、干燥槽11、搅拌轴12、搅拌减速机14、加热元件15、搅拌叶片16、搅拌杆17、冲洗水箱19、冲洗泵20、真空泵循环水箱21、冲洗管22、投料斗23、喂料减速机24、无轴螺旋25、滤网26、闸板27、丝杠28、闸板减速机29、蒸汽过滤器30、收液槽31、分拣筒32、检修盖33、破碎刀34、分拣网35、分拣叶片36、主轴37、电机38、滤液网39、旋转接头41、输送轴42、输送减速机43、输送轴45、导料段46、有孔出料网段47、输送斗48、下料口49、生活垃圾出口50、冲洗水收液槽52、左旋导料片53、右旋导料片54、冲洗孔55、制冷机组一56、制冷机组二57、压缩机58、冷凝器59、膨胀阀60、表冷器61。滤网板62连接导料板64下中开槽体65和上中开槽体66上中开筒体67和下中开筒体68,机箱71和机箱盖板72、控制装置73、排污装置74,污水进水管75冷凝提油机构76、刮油机构77、除油机构78、制冷制热系统79、冷凝板80、刮油板81、移动储油槽82、推油板83、推油对接板84除油槽85、除油板86、除油连接板87、接油桶88、污水泵89、污水排水箱90、排污管91、水冷冷凝器92、冷板蒸发器93、除油冷凝器94、隔渣网筛95、反冲洗管96、污水排空管道97、污水排空阀98、溢流管99、单向阀100、倾斜机箱底板101、冷板减速机102、冷板丝杠103、冷板导向杆104、上罩盖板105、刮油减速机106、移动丝杠107、导向滑道108、滑块109、移动螺母110、除油减速机111、除油丝杠112、气弹簧114。Reference numerals: salt-reducing and lipid-lowering device 1, solid-liquid separation device 2, oil-water separation device 3, automatic sorting device 4, drying device 5, waste heat recovery device 7, vacuum pump 9, electric ball valve 10, drying tank 11, stirring shaft 12. Mixing reducer 14, heating element 15, stirring blade 16, stirring rod 17, flushing water tank 19, flushing pump 20, vacuum pump circulating water tank 21, flushing pipe 22, hopper 23, feed reducer 24, shaftless spiral 25 , filter 26, shutter 27, lead screw 28, shutter reducer 29, steam filter 30, liquid collection tank 31, sorting cylinder 32, access cover 33, crushing knife 34, sorting net 35, sorting blade 36. Main shaft 37, motor 38, filtrate net 39, rotary joint 41, conveying shaft 42, conveying reducer 43, conveying shaft 45, guide section 46, perforated discharge section 47, conveying bucket 48, discharge port 49 , domestic garbage outlet 50, flushing water receiving tank 52, left-handed guiding piece 53, right-handed guiding piece 54, flushing hole 55, refrigeration unit 56, refrigeration unit II 57, compressor 58, condenser 59, expansion valve 60, the surface cooler 61. The screen plate 62 is connected to the middle slotted body 65 of the guide plate 64 and the upper open cylinder 67 and the lower middle open cylinder 68 of the upper middle slotted body 66, the chassis 71 and the chassis cover 72, the control device 73, and the sewage device 74, sewage inlet pipe 75 condensing and oiling mechanism 76, oil scraping mechanism 77, degreasing mechanism 78, cooling and heating system 79, condensing plate 80, scraping plate 81, moving oil storage tank 82, oil plate 83, push oil docking plate 84 Degreasing tank 85, deoiling plate 86, degreasing connecting plate 87, oil tank 88, sewage pump 89, sewage drain tank 90, sewage pipe 91, water-cooled condenser 92, cold plate evaporator 93, degreasing condenser 94, The slag mesh screen 95, the backwashing pipe 96, the sewage evacuation pipe 97, the sewage venting valve 98, the overflow pipe 99, the check valve 100, the inclined chassis bottom plate 101, the cold plate reducer 102, the cold plate screw 103, Cold plate guide bar 104, upper cover plate 105, oil scraper reducer 106, moving screw 107, guide slide 108, slider 109, moving nut 110, degreasing reducer 111, degreaser 112, gas spring 114.

下面结合附图对本发明进一步说明:The present invention is further described below in conjunction with the accompanying drawings:

如附图所示,一种餐厨废弃物处理装置,包括固液分离装置2、油水分离装置3、自动分拣装置4、干燥装置5和控制系统,所述干燥装置5包括干燥槽11、搅拌轴12和搅拌电机14,搅拌轴12上设有搅拌叶片16,搅拌轴12两端分别经轴承、轴承座与干燥槽11固定连接,所述搅拌轴12与搅拌电机14相连接,所述干燥槽11的内层和外层之间的夹层内设有加热元件,外层上设有温度传感器,干燥槽11下部设有出料口,出料口上设有出料密封门,其特征在于还包括电动球阀10、真空泵9、余热回收装置,所述自动分拣装置4的出料口通过电动球阀10与干燥装置5的干燥槽11的进料口相连接,干燥槽11的出汽口通过余热回收装置与真空泵9相连接,所述电动球阀10、余热回收装置和干燥装置5分别与控制系统相连接,通过真空泵29的工作使干燥槽内形成真空负压,使干燥过程中压力维持在-0.081至-0.099MPa,不但能将干燥槽内发酵干燥的餐厨废弃物中的有害细菌杀死,保留了有益于牲畜的蛋白质、纤维素和其它营养成分,使发酵干燥后的餐厨废弃物颗粒符合畜牧法的规定而形成牲畜饲料;而且,负压降低了物料中水的沸点,此时干燥槽内的温度在50-65℃左右时,物料中的水即可沸腾,无需将物料加热到100℃,从而大大缩短了干燥时间的能耗;同时,通过真空余热回收装置7,将干燥过程中产生的带有臭味的蒸汽进行冷凝,使臭气分子溶解到冷凝水中排放到污水处理系统中,避免了异味产生。As shown in the accompanying drawings, a kitchen waste treatment device includes a solid-liquid separation device 2, a water-water separation device 3, an automatic sorting device 4, a drying device 5, and a control system, and the drying device 5 includes a drying tank 11, The agitator shaft 12 and the agitating motor 14 are provided with agitating blades 16 . The two ends of the agitating shaft 12 are fixedly connected to the drying tank 11 via a bearing and a bearing housing, and the agitating shaft 12 is connected to the agitating motor 14 . A heating element is disposed in the interlayer between the inner layer and the outer layer of the drying tank 11, and a temperature sensor is disposed on the outer layer, a discharge port is disposed at a lower portion of the drying tank 11, and a discharge sealing door is disposed on the discharge port, wherein The utility model further includes an electric ball valve 10, a vacuum pump 9, and a waste heat recovery device. The discharge port of the automatic sorting device 4 is connected to the feed port of the drying tank 11 of the drying device 5 through the electric ball valve 10, and the steam outlet of the drying tank 11 The waste heat recovery device is connected to the vacuum pump 9, and the electric ball valve 10, the waste heat recovery device and the drying device 5 are respectively connected to the control system, and a vacuum negative pressure is formed in the drying tank by the operation of the vacuum pump 29 to make the pressure dimension in the drying process. From -0.081 to -0.099 MPa, it not only kills the harmful bacteria in the fermented and dried kitchen waste in the drying tank, but also preserves the protein, cellulose and other nutrients that are beneficial to the livestock, so that the dried and dried kitchen utensils The waste particles meet the requirements of the Animal Husbandry Law to form livestock feed; moreover, the negative pressure reduces the boiling point of the water in the material. When the temperature in the drying tank is about 50-65 ° C, the water in the material can boil, no need to The material is heated to 100 ° C, thereby greatly reducing the energy consumption of the drying time; at the same time, the odor-laden steam generated during the drying process is condensed by the vacuum waste heat recovery device 7 to dissolve the odor molecules into the condensed water and discharged to the condensed water. In the sewage treatment system, the generation of odor is avoided.

本发明所述固液分离装置包括投料斗23、正反转电机24和无轴螺旋25,所述投料斗23内设有无轴螺旋25,所述投料斗23底部设有收液槽31,上端设有密封盖,所述投料斗23与收液槽31间设有滤网板62,所述投料斗23的出料口上设有封口装置,所述收液槽31底面倾斜,以利于对流体进行导流,所述收液槽31经输液管道与油水分离装置3相连通,所述无轴螺旋25一端与正反转电机24固定连接,另一端与投料斗23侧壁设有的出料口相对应,所述正反转电机24与控制系统相连接,通过封口装置封住出料口,控制系统启动正反转电机24反转,对进入投料斗23内的餐厨废弃物进行破碎拧挤,将餐厨废弃物中的油水被挤出,油水通过滤网板62下流至收液槽31,收液槽31内的油水经输液管道流入到油水分离装置进行处理,当大部分水分和油脂被拧挤出后,控制系统再指令正反转电机24正转、同时驱动封口装置上移,使出料口打开,无轴螺旋25将拧挤后的餐厨废弃物正转推出,经出料口进入分拣筒内,使进入发酵干燥槽内的餐厨废弃物的含水量大大减小,大大降低了干燥时间,减少了干燥负担,节约能耗。The solid-liquid separation device of the present invention comprises a hopper 23, a forward and reverse motor 24 and a shaftless screw 25, wherein the hopper 23 is provided with a shaftless spiral 25, and a bottom of the hopper 23 is provided with a liquid receiving groove 31. a sealing cover is arranged at the upper end, and a filter plate 62 is arranged between the feeding hopper 23 and the liquid receiving groove 31. The discharging opening of the feeding hopper 23 is provided with a sealing device, and the bottom surface of the liquid receiving groove 31 is inclined to facilitate the pair. The fluid is diverted, and the liquid receiving tank 31 communicates with the oil-water separation device 3 via the infusion pipe. One end of the shaftless screw 25 is fixedly connected with the positive and negative motor 24, and the other end is provided with the side wall of the feeding hopper 23. Corresponding to the material port, the forward and reverse motor 24 is connected to the control system, and the discharge port is sealed by the sealing device, and the control system starts the reverse rotation of the forward and reverse motor 24 to carry out the kitchen waste entering the feeding hopper 23. Broken and squeezed, the oil and water in the kitchen waste is extruded, the oil water flows down through the filter plate 62 to the liquid collection tank 31, and the oil water in the liquid collection tank 31 flows into the oil-water separation device through the infusion pipeline for processing, when most After the water and grease are squeezed out, the control system then inverts the motor 2 4 forward rotation, at the same time drive the sealing device up, so that the discharge opening is opened, the shaftless screw 25 will push the kitchen waste after the screwing forward, and enter the sorting cylinder through the discharge port to enter the fermentation drying tank The water content of the kitchen waste is greatly reduced, the drying time is greatly reduced, the drying burden is reduced, and energy consumption is saved.

本发明可在所述固液分离装置上设有除盐除脂装置,所述除盐除脂装置1包括冲洗管22、冲洗电磁阀、冲洗泵20、冲洗水箱,所述冲洗管9固定在投料斗内侧壁,所述冲洗管经冲洗电磁阀与冲洗泵相连接,所述冲洗泵与冲洗水箱相连接,所述冲洗电磁阀和冲洗泵分别经控制系统控制,以利于对投料斗的四周进行喷淋冲洗,避免油盐粘附在投料斗23壁上,同时,还对餐厨废弃物进行的冲洗,大大降低了餐厨废弃物的盐分和油脂,使之更加适宜于成为饲料添加剂或生态肥原料。The invention can be provided with a desalination and degreasing device on the solid-liquid separation device, the demineralization and degreasing device 1 comprises an irrigation pipe 22, a flushing electromagnetic valve, a flushing pump 20, a flushing water tank, and the flushing pipe 9 is fixed at The inner side wall of the hopper is connected to the flushing pump via a flushing solenoid valve, and the flushing pump is connected with the flushing water tank, and the flushing solenoid valve and the flushing pump are respectively controlled by the control system to facilitate the circumference of the feeding hopper Spray rinsing to prevent oil and salt from adhering to the wall of the hopper 23, and at the same time, washing the kitchen waste, greatly reducing the salt and oil of the kitchen waste, making it more suitable as a feed additive or Ecological fertilizer raw materials.

本发明所述封口装置可以包括闸板27和动力驱动装置,所述动力驱动装置可以是气缸或液缸,或者,也可以是由丝杠28、丝母座和闸板驱动电机29组成,所述闸板27穿过闸板穿孔与出料口端面相配合密封,所述闸板驱动电机29与丝杠28连接,丝母座与闸板27连接,闸板驱动电机29旋转带动丝杠28转动,丝杠28转动带动丝母座上下运动,从而带动闸板27上下运动,所述闸板27穿过闸板穿孔与出料口端面相配合密封,当含水量高的餐厨废弃物要进入投料斗23时,闸板驱动电机29驱动闸板27封住出料口,当大部分水分被拧挤出后,控制系统再指令正反转电机24正转、同时驱动闸板27下移,使出料口打开。The sealing device of the present invention may include a shutter 27 and a power driving device, and the power driving device may be a cylinder or a liquid cylinder, or may be composed of a lead screw 28, a silk socket and a shutter driving motor 29, The shutter 27 is sealed through the ram perforation and the end surface of the discharge port. The ram drive motor 29 is connected to the lead screw 28, the silk socket is connected to the ram 27, and the ram drive motor 29 rotates to drive the lead screw 28. Rotating, the screw 28 rotates to move the wire base up and down, thereby driving the shutter 27 to move up and down. The shutter 27 passes through the ram perforation and seals the end surface of the discharge port, and the kitchen waste is high when the water content is high. When entering the feeding hopper 23, the shutter driving motor 29 drives the shutter 27 to seal the discharge opening. When most of the moisture is squeezed out, the control system instructs the forward and reverse motor 24 to rotate forward and simultaneously drives the shutter 27 to move downward. , so that the discharge opening is opened.

本发明所述无轴螺旋25端部与闸板27间隙为2-10mm,以利于将接近闸板27的物料进行回收挤压,然后再反向输送,保证物料达到完全挤压和完全输送的作用。The gap between the end of the shaftless screw 25 and the shutter 27 of the present invention is 2-10 mm, so as to facilitate the recovery and extrusion of the material close to the shutter 27, and then reversely conveyed to ensure that the material is completely squeezed and completely transported. effect.

本发明可在所述闸板27下端设有刃口,以达到对落入闸板下方的物料进行切割,保证闸板能够完全封住出料口。The invention can be provided with a cutting edge at the lower end of the shutter 27 to cut the material falling under the shutter to ensure that the shutter can completely seal the discharge opening.