WO2012117763A1 - Silica dispersion composition - Google Patents

Silica dispersion composition Download PDFInfo

- Publication number

- WO2012117763A1 WO2012117763A1 PCT/JP2012/051154 JP2012051154W WO2012117763A1 WO 2012117763 A1 WO2012117763 A1 WO 2012117763A1 JP 2012051154 W JP2012051154 W JP 2012051154W WO 2012117763 A1 WO2012117763 A1 WO 2012117763A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- group

- silica

- dispersion composition

- polyurethane resin

- mass

- Prior art date

Links

- AYJGDLVQTQYBFM-UHFFFAOYSA-N OC12OC1CCC2 Chemical compound OC12OC1CCC2 AYJGDLVQTQYBFM-UHFFFAOYSA-N 0.000 description 1

Classifications

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/08—Processes

- C08G18/0804—Manufacture of polymers containing ionic or ionogenic groups

- C08G18/0833—Manufacture of polymers containing ionic or ionogenic groups containing cationic or cationogenic groups together with anionic or anionogenic groups

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/28—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen characterised by the compounds used containing active hydrogen

- C08G18/30—Low-molecular-weight compounds

- C08G18/32—Polyhydroxy compounds; Polyamines; Hydroxyamines

- C08G18/3203—Polyhydroxy compounds

- C08G18/3206—Polyhydroxy compounds aliphatic

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/28—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen characterised by the compounds used containing active hydrogen

- C08G18/30—Low-molecular-weight compounds

- C08G18/32—Polyhydroxy compounds; Polyamines; Hydroxyamines

- C08G18/3271—Hydroxyamines

- C08G18/3275—Hydroxyamines containing two hydroxy groups

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/28—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen characterised by the compounds used containing active hydrogen

- C08G18/30—Low-molecular-weight compounds

- C08G18/34—Carboxylic acids; Esters thereof with monohydroxyl compounds

- C08G18/348—Hydroxycarboxylic acids

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/28—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen characterised by the compounds used containing active hydrogen

- C08G18/40—High-molecular-weight compounds

- C08G18/42—Polycondensates having carboxylic or carbonic ester groups in the main chain

- C08G18/4266—Polycondensates having carboxylic or carbonic ester groups in the main chain prepared from hydroxycarboxylic acids and/or lactones

- C08G18/4269—Lactones

- C08G18/4277—Caprolactone and/or substituted caprolactone

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/28—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen characterised by the compounds used containing active hydrogen

- C08G18/65—Low-molecular-weight compounds having active hydrogen with high-molecular-weight compounds having active hydrogen

- C08G18/66—Compounds of groups C08G18/42, C08G18/48, or C08G18/52

- C08G18/6633—Compounds of group C08G18/42

- C08G18/6637—Compounds of group C08G18/42 with compounds of group C08G18/32 or polyamines of C08G18/38

- C08G18/6648—Compounds of group C08G18/42 with compounds of group C08G18/32 or polyamines of C08G18/38 with compounds of group C08G18/3225 or C08G18/3271 and/or polyamines of C08G18/38

- C08G18/6655—Compounds of group C08G18/42 with compounds of group C08G18/32 or polyamines of C08G18/38 with compounds of group C08G18/3225 or C08G18/3271 and/or polyamines of C08G18/38 with compounds of group C08G18/3271

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/28—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen characterised by the compounds used containing active hydrogen

- C08G18/67—Unsaturated compounds having active hydrogen

- C08G18/671—Unsaturated compounds having only one group containing active hydrogen

- C08G18/672—Esters of acrylic or alkyl acrylic acid having only one group containing active hydrogen

- C08G18/673—Esters of acrylic or alkyl acrylic acid having only one group containing active hydrogen containing two or more acrylate or alkylacrylate ester groups

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/70—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen characterised by the isocyanates or isothiocyanates used

- C08G18/72—Polyisocyanates or polyisothiocyanates

- C08G18/73—Polyisocyanates or polyisothiocyanates acyclic

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/70—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen characterised by the isocyanates or isothiocyanates used

- C08G18/72—Polyisocyanates or polyisothiocyanates

- C08G18/74—Polyisocyanates or polyisothiocyanates cyclic

- C08G18/76—Polyisocyanates or polyisothiocyanates cyclic aromatic

- C08G18/7657—Polyisocyanates or polyisothiocyanates cyclic aromatic containing two or more aromatic rings

- C08G18/7664—Polyisocyanates or polyisothiocyanates cyclic aromatic containing two or more aromatic rings containing alkylene polyphenyl groups

- C08G18/7671—Polyisocyanates or polyisothiocyanates cyclic aromatic containing two or more aromatic rings containing alkylene polyphenyl groups containing only one alkylene bisphenyl group

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/004—Photosensitive materials

- G03F7/0047—Photosensitive materials characterised by additives for obtaining a metallic or ceramic pattern, e.g. by firing

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/004—Photosensitive materials

- G03F7/027—Non-macromolecular photopolymerisable compounds having carbon-to-carbon double bonds, e.g. ethylenic compounds

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/004—Photosensitive materials

- G03F7/038—Macromolecular compounds which are rendered insoluble or differentially wettable

- G03F7/0388—Macromolecular compounds which are rendered insoluble or differentially wettable with ethylenic or acetylenic bands in the side chains of the photopolymer

Definitions

- the present invention relates to a silica dispersion composition suitably used for solder resist and the like.

- a photosensitive film in which a photosensitive layer is formed by applying a silica dispersion composition on a support and drying it has been used.

- a method for forming a permanent pattern such as a solder resist for example, a photosensitive film is laminated on a substrate such as a copper-clad laminate on which a permanent pattern is formed to form a laminate, and the photosensitive layer in the laminate is formed.

- a method of forming a permanent pattern by performing exposure on the substrate, developing the photosensitive layer after the exposure to form a pattern, and then performing a curing process or the like.

- a pigment dispersant which is a polyurethane resin having one or more nonionic polar molecular chains, (B) a low polar molecular chain, and (C) an active energy ray-curable unsaturated group.

- this proposal relates to a dispersant for carbon black that is suitably used for photoresists that form images by photolithography, and is suitable for solder resists that can be used for semiconductor package substrates with a small L / S (line space).

- the proposed pigment dispersant has a graft chain modified to a basic functional group, the amine value is lowered, silica dispersibility is lowered, melt viscosity is increased, and transferability is inferior. There's a problem.

- silica dispersion composition capable of obtaining a high-performance cured film promptly.

- the present invention can obtain a high-performance cured film excellent in embedding property, thermal shock resistance, developability, insulating property, and resolution of an exposed portion, and a semiconductor package substrate having a small L / S (line space).

- An object of the present invention is to provide a silica dispersion composition suitable for a solder resist that can cope with the above.

- the present inventors have made extensive studies, and as a result, contain a silica dispersant comprising a polyurethane resin having at least an acidic group and a basic group, silica fine particles, and a thermal crosslinking agent,

- the silica dispersant preferably has a graft chain in at least one of a side chain and a terminal, and has an amine value of 0.65 mmol / g or more, so that silica fine particles can be highly filled, melt viscosity, and developability. It is possible to obtain a high-performance cured film that has an excellent insulating property and an excellent resolution of the exposed portion, and has a small L / S (line space). It has been found that a silica dispersion composition suitable for a solder resist that can be applied to a semiconductor package substrate can be obtained.

- the silica dispersion composition of the present invention comprises a silica dispersant comprising a polyurethane resin having at least an acidic group and a basic group, silica fine particles, and a thermal crosslinking agent,

- the amine value of the silica dispersant is 0.65 mmol / g or more.

- a silica dispersion composition suitable for a solder resist that can be used for a semiconductor package substrate having a small (line space) can be provided.

- the silica dispersion composition of the present invention contains a silica dispersant, silica fine particles, and a thermal crosslinking agent, and contains a binder, a polymerizable compound, a photopolymerization initiator, and other components as necessary. It becomes.

- the silica dispersant is a dispersant comprising a polyurethane resin having at least an acidic group and a basic group in one molecule, and preferably having a graft chain and a polymerizable group.

- the silica dispersant is made of a polyurethane resin whose main chain is polyurethane, and is bonded to the main chain or bonded to a side chain bonded to the main chain, or a molecular chain constituting the main chain As above, it has an acidic group and a basic group, and preferably has a graft chain and a polymerizable group.

- the acidic group is not particularly limited and may be appropriately selected depending on the intended purpose. Examples thereof include a carboxyl group, a sulfo group, a phosphonyl group, and —COCH 2 CO—R (where R is a carbon number of 1 to 10).

- -CONHCO-R wherein R represents a hydrocarbon group having 1 to 10 carbon atoms

- -COCH 2 CN a phenolic hydroxyl group

- -R F CH 2 OH where R F is A perfluoroalkyl group

- R F represents a perfluoroalkyl group

- a carboxyl group is particularly preferable from the viewpoint of developability.

- the basic group is not particularly limited and may be appropriately selected depending on the intended purpose. Examples thereof include a primary amino group, a secondary amino group, a tertiary amino group, and a nitrogen-containing heterocycle. However, since the primary amino group and the secondary amino group react with the isocyanate and are taken into the main chain, a tertiary amino group and a nitrogen-containing heterocyclic ring are preferable, and the tertiary amino group is particularly preferable. preferable. Examples of the tertiary amino group include a dimethylamino group and a diethylamino group.

- nitrogen-containing heterocycle examples include 2-pyrrolidone, N-methyl-2-pyrrolidone, 1,3-dimethylimidazolidinone, ⁇ -caprolactam, ⁇ -butyrolactone, and the like.

- the graft chain preferably has at least one of a side chain and a terminal of the polyurethane resin.

- the graft chain include polyester, polymethyl methacrylate, polyethylene oxide, and polystyrene.

- a graft chain having a polyester moiety at the terminal of the polyurethane resin is preferable from the viewpoint of resolution.

- the degree of polymerization of the graft chain is preferably 50 or less, more preferably 5 to 30.

- the content of the graft is preferably 10% by mass to 60% by mass and more preferably 20% by mass to 50% by mass with respect to the entire polyurethane resin.

- polymerizable (crosslinkable) groups There is no restriction

- the polyurethane resin constituting the silica dispersant is a polyurethane resin obtained by reacting an isocyanate compound with a compound having a hydroxyl group or an active hydrogen atom, specifically, a diol compound having an acidic group and a basic group. It is obtained by reacting a diol compound having a diisocyanate compound.

- the diol compound having an acidic group is not particularly limited and may be appropriately selected depending on the intended purpose. Examples thereof include 3,5-dihydroxybenzoic acid, 2,2-bis (hydroxymethyl) propionic acid, 2, 2-bis (2-hydroxyethyl) propionic acid, 2,2-bis (3-hydroxypropyl) propionic acid, bis (hydroxymethyl) acetic acid, bis (4-hydroxyphenyl) acetic acid, 2,2-bis (hydroxymethyl) ) Butyric acid, 4,4-bis (4-hydroxyphenyl) pentanoic acid, tartaric acid, N, N-dihydroxyethylglycine, N, N-bis (2-hydroxyethyl) -3-carboxy-propionamide and the like. These may be used individually by 1 type and may use 2 or more types together.

- the diol compound having a basic group is not particularly limited and may be appropriately selected depending on the intended purpose. Examples thereof include 3- (dimethylamino) -1,2-propanediol. Unlike the graft chain having an amino group, the diol compound having a basic group has a high amine content in the monomer, so that the amine value of the silica dispersant can be increased.

- the diisocyanate compound is not particularly limited and may be appropriately selected depending on the intended purpose. Examples thereof include 2,4-tolylene diisocyanate, dimer of 2,4-tolylene diisocyanate, and 2,6-tolylene diene. Range isocyanate, p-xylylene diisocyanate, m-xylylene diisocyanate, 4,4'-diphenylmethane diisocyanate (MDI), 1,5-naphthylene diisocyanate, 3,3'-dimethylbiphenyl-4,4'-diisocyanate, etc.

- MDI 4,4'-diphenylmethane diisocyanate

- Aromatic diisocyanate compounds aliphatic diisocyanate compounds such as hexamethylene diisocyanate, trimethylhexamethylene diisocyanate, lysine diisocyanate, dimer acid diisocyanate; isophorone diisocyanate, 4,4′-methyle Alicyclic diisocyanate compounds such as bis (cyclohexyl isocyanate), methylcyclohexane-2,4 (or 2,6) diisocyanate, 1,3- (isocyanatomethyl) cyclohexane; 1 mol of 1,3-butylene glycol and tolylene diisocyanate 2

- a diisocyanate compound which is a reaction product of a diol such as an adduct with a mole and a diisocyanate; These may be used individually by 1 type and may use 2 or more types together.

- 4,4'-diphenylmethane diisocyanate (MDI) is particularly preferable from the viewpoint of hard

- a terminal blocking agent When synthesizing the polyurethane resin of the present invention, a terminal blocking agent may be added.

- the end capping agent include monoalcohol compounds, monoisocyanate compounds, polyesters having alcohol at one end, and polyethylene oxides having alcohol at one end. These may be used individually by 1 type and may use 2 or more types together.

- silica dispersant an appropriately synthesized one or a commercially available product may be used.

- the amine value of the silica dispersant is 0.65 mmol / g or more, preferably 0.75 mmol / g or more, and more preferably 0.9 mmol / g or more. If the amine value is less than 0.65 mmol / g, the melt viscosity may increase and the embedding property may deteriorate.

- the amine value is measured, for example, by weighing a sample in a beaker, adding acetic acid, stirring and dissolving, adjusting the measurement temperature to 25 ° C., and then adding 0.1N perchloric acid acetic acid as a titration reagent. And can be determined by titrating with a titration apparatus.

- the acid value of the silica dispersant is preferably 0.3 mmol / g or more, and more preferably 0.45 mmol / g or more. If the acid value is less than 0.3 mmol / g, developability may deteriorate and a residue may be generated in an unexposed area.

- silica fine particles There is no restriction

- the average particle diameter (d50) of the silica fine particles is not particularly limited and may be appropriately selected depending on the intended purpose, but is preferably 0.2 ⁇ m to 3.0 ⁇ m, more preferably 0.3 ⁇ m to 2.5 ⁇ m, 0.5 ⁇ m to 2.5 ⁇ m is particularly preferable.

- the average particle diameter (d50) of the silica particles is less than 0.2 ⁇ m, the coating viscosity may be increased, and when it exceeds 3.0 ⁇ m, smoothness may not be maintained.

- the average particle diameter (d50) of the silica particles is within the particularly preferable range, it is advantageous in terms of coating viscosity, smoothness of the cured film and heat resistance.

- D 50 the average particle size of the silica particles

- D 50 the integration

- D 50 the integration

- D 50 the size distribution analysis method

- the content of the silica fine particles in the silica dispersion composition is preferably 16% by mass to 80% by mass, and more preferably 25% by mass to 70% by mass. When the content is less than 16% by mass, impact resistance may be inferior, and when it exceeds 80% by mass, dispersibility may be insufficient.

- thermo crosslinking agent There is no restriction

- the epoxy resin is not particularly limited and may be appropriately selected depending on the intended purpose. Examples thereof include compounds described in paragraph [0095] of JP-A-2007-2030, and JP-A-2010-72340. Examples include the compounds described in paragraph [0130].

- the polyfunctional oxetane compound is not particularly limited and may be appropriately selected depending on the intended purpose. Examples thereof include the compounds described in paragraph [0096] of JP-A-2007-2030.

- the content of the thermal crosslinking agent in the silica dispersion composition is not particularly limited and may be appropriately selected depending on the intended purpose, but is preferably 1% by mass to 50% by mass, and 2% by mass to 40% by mass. Is more preferable, and 3% by mass to 30% by mass is particularly preferable.

- the content is less than 1% by mass, heat resistance may be inferior, and when it exceeds 50% by mass, developability and crack resistance may be inferior.

- a cured film can be produced with good sensitivity, and the formed cured film is advantageous in that both heat resistance and crack resistance can be achieved.

- the other thermal crosslinking agent can be added separately from the epoxy resin and the polyfunctional oxetane compound.

- the other thermal crosslinking agent is not particularly limited and may be appropriately selected depending on the intended purpose. Examples thereof include compounds described in paragraphs [0098] to [0100] of JP-A-2007-2030. Can be mentioned.

- the binder is not particularly limited and may be appropriately selected depending on the intended purpose.

- acid-modified vinyl group-containing polyurethane resin, unsaturated group-containing polycarboxylic acid resin, acid-modified vinyl group-containing epoxy resin, unsaturated Examples thereof include a resin containing a group and a carboxyl group, and a polyimide precursor.

- the acid-modified vinyl group-containing polyurethane resin is not particularly limited and may be appropriately selected depending on the purpose.

- a polyurethane resin having an ethylenically unsaturated bond (vinyl group) in the side chain ii) A polyurethane resin obtained by reacting a carboxyl group-containing polyurethane with a compound having an epoxy group and a vinyl group in the molecule.

- Polyurethane resin having vinyl groups in the side chain--- The urethane resin having a vinyl group in the side chain is not particularly limited and may be appropriately selected depending on the intended purpose.

- the side chain is represented by the following general formulas (1) to (3). The thing which has at least 1 among functional groups is mentioned.

- R 1 is not particularly limited and may be appropriately selected depending on the intended purpose.

- examples thereof include a hydrogen atom and an alkyl group which may have a substituent. Among these, a hydrogen atom and a methyl group are preferable in terms of high radical reactivity.

- the R 2 and R 3 are not particularly limited and may be appropriately selected depending on the purpose.

- each of R 2 and R 3 is independently a hydrogen atom, a halogen atom, an amino group, a carboxyl group, an alkoxycarbonyl group, a sulfo group.

- a hydrogen atom, a carboxyl group, an alkoxycarbonyl group, an alkyl group which may have a substituent, and an aryl group which may have a substituent are preferable because of high radical reactivity.

- X represents an oxygen atom, a sulfur atom, or —N (R 12 ) —

- R 12 represents a hydrogen atom or a monovalent organic group.

- R 12 is not particularly limited and may be appropriately selected depending on the intended purpose. Examples thereof include an alkyl group which may have a substituent.

- a hydrogen atom, a methyl group, an ethyl group, and an isopropyl group are preferable because of high radical reactivity.

- the substituent that can be introduced is not particularly limited and may be appropriately selected depending on the intended purpose.

- examples thereof include an alkyl group, an alkenyl group, an alkynyl group, an aryl group, an alkoxy group, an aryloxy group, and a halogen atom.

- R 4 to R 8 are not particularly limited and may be appropriately selected depending on the intended purpose.

- An arylsulfonyl group etc. are mentioned.

- a hydrogen atom, a carboxyl group, an alkoxycarbonyl group, an alkyl group which may have a substituent, and an aryl group which may have a substituent are preferable because of high radical reactivity.

- Examples of the substituent that can be introduced include the same as those in the general formula (1).

- Y represents an oxygen atom, a sulfur atom, or —N (R 12 ) —.

- Said R ⁇ 12 > is synonymous with the case of R ⁇ 12 > of the said General formula (1), and its preferable example is also the same.

- R 9 is not particularly limited and may be appropriately selected depending on the purpose.

- examples thereof include a hydrogen atom or an alkyl group which may have a substituent. Among these, a hydrogen atom and a methyl group are preferable in terms of high radical reactivity.

- R 10 and R 11 are not particularly limited and may be appropriately selected depending on the intended purpose.

- a hydrogen atom, a carboxyl group, an alkoxycarbonyl group, an alkyl group which may have a substituent, and an aryl group which may have a substituent are preferable because of high radical reactivity.

- Z represents an oxygen atom, a sulfur atom, —N (R 13 ) —, or an optionally substituted phenylene group.

- R 13 is not particularly limited and may be appropriately selected depending on the intended purpose. Examples thereof include an alkyl group which may have a substituent. Among these, a methyl group, an ethyl group, and an isopropyl group are preferable because of high radical reactivity.

- the urethane resin having an ethylenically unsaturated bond in the side chain includes at least one diisocyanate compound represented by the following general formula (4) and at least one diol compound represented by the following general formula (5):

- At least one of the diisocyanate compound represented by the general formula (4) and the diol compound represented by the general formula (5) is a group represented by the general formulas (1) to (3). If at least one of them is present, a polyurethane resin in which the groups represented by the above general formulas (1) to (3) are introduced into the side chain as a reaction product of the diisocyanate compound and the diol compound is provided. Generated. According to such a method, a polyurethane resin in which the groups represented by the general formulas (1) to (3) are introduced into the side chain can be easily used, rather than replacing and introducing a desired side chain after the reaction of the polyurethane resin. Can be manufactured.

- the diisocyanate compound represented by the general formula (4) is not particularly limited and can be appropriately selected depending on the purpose.

- a triisocyanate compound and a monofunctional alcohol having an unsaturated group Or the product obtained by addition-reacting with 1 equivalent of monofunctional amine compounds is mentioned.

- the triisocyanate compound is not particularly limited and may be appropriately selected depending on the intended purpose. Examples thereof include compounds described in paragraphs [0034] to [0035] of JP-A-2005-250438. Is mentioned.

- the diol compound represented by the general formula (5) is not particularly limited and may be appropriately selected depending on the intended purpose. Examples thereof include polyether diol compounds, polyester diol compounds, and polycarbonate diol compounds.

- the monofunctional alcohol having an unsaturated group or the monofunctional amine compound is not particularly limited and may be appropriately selected depending on the intended purpose.

- paragraphs of JP-A-2005-250438 Examples thereof include compounds described in [0037] to [0040].

- the method for introducing an unsaturated group into the side chain of the polyurethane resin is not particularly limited and may be appropriately selected depending on the intended purpose.

- a method using a diisocyanate compound containing is preferable.

- diisocyanate compounds that can be obtained include compounds having an unsaturated group in the side chain described in paragraphs [0042] to [0049] of JP-A-2005-250438.

- the polyurethane resin having an ethylenically unsaturated bond in the side chain is a diisocyanate containing the unsaturated group from the viewpoint of improving compatibility with other components in the polymerizable composition and improving storage stability.

- Diisocyanate compounds other than the compounds can also be copolymerized.

- the diisocyanate compound to be copolymerized is not particularly limited and may be appropriately selected depending on the intended purpose.

- it is a diisocyanate compound represented by the following general formula (6).

- OCN-L 1 -NCO General formula (6) L 1 represents an aliphatic or aromatic hydrocarbon group which may have a substituent. If necessary, L 1 may have another functional group that does not react with an isocyanate group, for example, an ester, urethane, amide, or ureido group.

- the diisocyanate compound represented by the general formula (6) is not particularly limited and may be appropriately selected depending on the intended purpose.

- Aromatic diisocyanate compounds such as' -diisocyanate; aliphatic diisocyanate compounds such as hexamethylene diisocyanate, trimethylhexamethylene diisocyanate, lysine diisocyanate, dimer diisocyanate; isophorone diisocyanate, 4,4 -Alicyclic diisocyanate compounds such as methylenebis (cyclohexyl

- a method for introducing an unsaturated group into the side chain of the polyurethane resin in addition to the above-described method, a method using a diol compound containing an unsaturated group in the side chain as a raw material for producing a polyurethane resin is also preferable.

- the diol compound containing an unsaturated group in the side chain is not particularly limited and may be appropriately selected depending on the purpose. For example, a commercially available product such as trimethylolpropane monoallyl ether may be used.

- a compound such as a halogenated diol compound, a triol compound or an aminodiol compound and a compound containing an unsaturated group such as a carboxylic acid, acid chloride, isocyanate, alcohol, amine, thiol or halogenated alkyl compound. It may be a compound that is easily produced.

- the diol compound containing an unsaturated group in the side chain is not particularly limited and may be appropriately selected depending on the intended purpose. For example, in paragraphs [0057] to [0060] of JP-A-2005-250438 And the compounds described in paragraphs [0064] to [0066] of JP-A-2005-250438 represented by the following general formula (G).

- R 1 to R 3 each independently represents a hydrogen atom or a monovalent organic group

- A represents a divalent organic residue

- X represents an oxygen atom or a sulfur atom.

- —N (R 12 ) — wherein R 12 represents a hydrogen atom or a monovalent organic group.

- R 1 ⁇ R 3 and X in the general formula (G) said a general formula (1) the same meaning as R 1 ⁇ R 3 and X in preferred embodiments versa.

- the effect of suppressing the excessive molecular movement of the polymer main chain caused by the secondary alcohol having a large steric hindrance can be reduced. It is thought that improvement can be achieved.

- the polyurethane resin having an ethylenically unsaturated bond in the side chain is unsaturated in the side chain from the viewpoint of improving compatibility with other components in the polymerizable composition and improving storage stability, for example.

- a diol compound other than a diol compound containing a group can be copolymerized.

- diol compounds other than the diol compound containing an unsaturated group in the said side chain For example, a polyether diol compound, a polyester diol compound, a polycarbonate diol compound etc. can be selected. Is mentioned.

- the polyether diol compound is not particularly limited and may be appropriately selected depending on the intended purpose. Examples thereof include compounds described in paragraphs [0068] to [0076] of JP-A-2005-250438. It is done.

- the polyester diol compound is not particularly limited and may be appropriately selected depending on the intended purpose. Examples thereof include paragraphs [0077] to [0079] and paragraphs [0083] to [0085] of JP-A-2005-250438. No. 1-No. 8 and no. 13-No. 18 and the like.

- the polycarbonate diol compound is not particularly limited and may be appropriately selected depending on the intended purpose. For example, in the paragraphs [0080] to [0081] and paragraph [0084] of JP-A-2005-250438, No. 9-No. 12 and the like.

- the diol compound which has a substituent which does not react with an isocyanate group other than the diol compound mentioned above can also be used together.

- the diol compound having a substituent that does not react with the isocyanate group is not particularly limited and may be appropriately selected depending on the intended purpose. For example, in paragraphs [0087] to [0088] of JP-A-2005-250438 And the compounds described.

- a diol compound having a carboxyl group can be used in combination with the diol compound described above.

- Examples of the diol compound having a carboxyl group include those represented by the following formulas (X) to (Z).

- R 15 represents a hydrogen atom, a substituent (for example, a halogen atom such as a cyano group, a nitro group, —F, —Cl, —Br, —I, etc., —CONH 2 , —COOR 16 , —OR 16 , —NHCONHR 16 , —NHCOOR 16 , —NHCOR 16 , —OCONHR 16 (wherein R 16 is an alkyl group having 1 to 10 carbon atoms or an aralkyl group having 7 to 15 carbon atoms) As long as it represents an alkyl group, an aralkyl group, an aryl group, an alkoxy group, or an aryloxy group, which may have a group, depending on the purpose.

- a substituent for example, a halogen atom such as a cyano group, a nitro group, —F, —Cl, —Br, —I, etc., —CONH 2

- L 9 , L 10 and L 11 may be the same or different, and each may be a single bond, a substituent (for example, alkyl, aralkyl, aryl, alkoxy, As long as it represents a divalent aliphatic or aromatic hydrocarbon group that may have a divalent aliphatic or aromatic hydrocarbon group, and may be appropriately selected depending on the purpose.

- an alkylene group having 1 to 20 carbon atoms and an arylene group having 6 to 15 carbon atoms are preferable, and an alkylene group having 1 to 8 carbon atoms is more preferable.

- the L 9 to L 11 may have other functional groups that do not react with isocyanate groups, such as carbonyl, ester, urethane, amide, ureido, and ether groups.

- a ring may be formed by two or three of R 15 , L 7 , L 8 and L 9 .

- Ar is not particularly limited as long as it represents a trivalent aromatic hydrocarbon group which may have a substituent, and can be appropriately selected according to the purpose. However, an aromatic group having 6 to 15 carbon atoms is preferred.

- the diol compound having a carboxyl group represented by the formulas (X) to (Z) is not particularly limited and may be appropriately selected depending on the intended purpose.

- the polyurethane resin having an ethylenically unsaturated bond group in the side chain is a resin having a carboxyl group in the side chain.

- the compound which ring-opened tetracarboxylic dianhydride with the diol compound other than the diol compound mentioned above can also be used together.

- the compound obtained by ring-opening the tetracarboxylic dianhydride with a diol compound is not particularly limited and may be appropriately selected depending on the intended purpose. For example, paragraph [0095] to JP 2005-250438 A And the compounds described in [0101].

- polyurethane resin having an ethylenically unsaturated bond in the side chain those having an unsaturated group in the polymer terminal and main chain are also preferably used.

- a plate material having excellent printing durability can be provided.

- an unsaturated group it is especially preferable to have an unsaturated group from the ease of a crosslinking reaction.

- Examples of the method for introducing an unsaturated group at the polymer terminal include the following methods. That is, in the step of synthesizing the polyurethane resin having an ethylenically unsaturated bond in the side chain as described above, in the step of treating with the residual isocyanate group at the polymer end and the alcohol or amine, the alcohol having an unsaturated group. Alternatively, amines or the like may be used. Specific examples of such a compound include the same compounds as those exemplified above as the monofunctional alcohol or monofunctional amine compound having an unsaturated group.

- the unsaturated group is preferably introduced into the polymer side chain rather than the polymer terminal from the viewpoint that the introduction amount can be easily controlled and the introduction amount can be increased, and that the crosslinking reaction efficiency is improved.

- the ethylenically unsaturated bond group to be introduced is not particularly limited and may be appropriately selected depending on the intended purpose. From the viewpoint of forming a crosslinked cured film, a methacryloyl group, an acryloyl group, and a styryl group are preferable, and methacryloyl Group and acryloyl group are more preferable, and methacryloyl group is particularly preferable in terms of both the formability of the crosslinked cured film and the raw storage stability.

- the amount of methacryloyl group introduced is not particularly limited and may be appropriately selected depending on the intended purpose.

- the vinyl group equivalent is preferably 0.05 mmol / g to 3.0 mmol / g, preferably 0.5 mmol. / G to 2.7 mmol / g is more preferable, and 0.75 mmol / g to 2.4 mmol / g is particularly preferable.

- a method for introducing an unsaturated group into the main chain there is a method of using a diol compound having an unsaturated group in the main chain direction for the synthesis of a polyurethane resin.

- the diol compound having an unsaturated group in the main chain direction is not particularly limited and may be appropriately selected depending on the intended purpose. For example, cis-2-butene-1,4-diol, trans-2-butene 1,4-diol, polybutadiene diol and the like.

- the polyurethane resin having an ethylenically unsaturated bond in the side chain can be used in combination with an alkali-soluble polymer containing a polyurethane resin having a structure different from that of the specific polyurethane resin.

- the polyurethane resin having an ethylenically unsaturated bond in the side chain can be used in combination with a polyurethane resin containing an aromatic group in the main chain and / or side chain.

- polyurethane resin (i) having an ethylenically unsaturated bond in the side chain include, for example, P-1 to P— shown in paragraphs [0293] to [0310] of JP-A-2005-250438. And 31 polymers. Among these, polymers of P-27 and P-28 shown in paragraphs [0308] and [0309] are preferable.

- polyurethane resin obtained by reacting a carboxyl group-containing polyurethane with a compound having an epoxy group and a vinyl group in the molecule--

- the polyurethane resin is a polyurethane resin obtained by reacting a carboxyl group-containing polyurethane having a diisocyanate and a carboxylic acid group-containing diol as essential components with a compound having an epoxy group and a vinyl group in the molecule.

- diol component a low molecular diol having a weight average molecular weight of 300 or less and a low molecular diol having a weight average molecular weight of 500 or more may be added as a copolymer component.

- the polyurethane resin By using the polyurethane resin, it is excellent in stable dispersibility with an inorganic filler, crack resistance and impact resistance, so that heat resistance, moist heat resistance, adhesion, mechanical properties and electrical properties are improved.

- the polyurethane resin includes a divalent aliphatic or aromatic hydrocarbon diisocyanate which may have a substituent, a COOH group and two OH groups via any one of a C atom and an N atom.

- a reaction product comprising a carboxylic acid-containing diol as an essential component, which is obtained by reacting the obtained reaction product with a compound having an epoxy group and a vinyl group in the molecule via a —COO— bond It may be.

- the polyurethane resin includes at least one selected from diisocyanates represented by the following general formula (I) and carboxylic acid group-containing diols represented by the following general formulas (II-1) to (II-3): And at least one selected from polymer diols having a weight average molecular weight in the range of 800 to 3,000 represented by the following general formulas (III-1) to (III-5) according to the purpose:

- R 1 may have a substituent (for example, any of an alkyl group, an aralkyl group, an aryl group, an alkoxy group, and a halogeno group is preferable). Represents an aromatic or aromatic hydrocarbon. If necessary, R 1 may have any other functional group that does not react with an isocyanate group, such as an ester group, a urethane group, an amide group, or a ureido group.

- a substituent for example, any of an alkyl group, an aralkyl group, an aryl group, an alkoxy group, and a halogeno group is preferable.

- R 1 may have any other functional group that does not react with an isocyanate group, such as an ester group, a urethane group, an amide group, or a ureido group.

- R 2 represents a hydrogen atom, a substituent (for example, a cyano group, a nitro group, a halogen atom (—F, —Cl, —Br, —I), —CONH 2 , —COOR. 6 , —OR 6 , —NHCONHR 6 , —NHCOOR 6 , —NHCOR 6 , —OCONHR 6 , —CONHR 6 (where R 6 is an alkyl group having 1 to 10 carbon atoms and an aralkyl group having 7 to 15 carbon atoms) Or an alkyl group, an aralkyl group, an aryl group, an alkoxy group, or an aryloxy group.

- a substituent for example, a cyano group, a nitro group, a halogen atom (—F, —Cl, —Br, —I), —CONH 2 , —COOR. 6 , —OR 6 , —NH

- R 3 , R 4 and R 5 may be the same or different from each other, and may be a single bond, a substituent (for example, an alkyl group or an aralkyl group).

- An aryl group, an alkoxy group, and a halogeno group are preferable).

- an alkylene group having 1 to 20 carbon atoms and an arylene group having 6 to 15 carbon atoms are preferable, and an alkylene group having 1 to 8 carbon atoms is more preferable.

- any one of other functional groups that do not react with the isocyanate group in the R 3 , R 4 and R 5 for example, any one of a carbonyl group, an ester group, a urethane group, an amide group, a ureido group, and an ether group. You may have. In addition, you may form a ring by 2 or 3 of said R ⁇ 2 >, R ⁇ 3 >, R ⁇ 4 > and R ⁇ 5 >.

- Ar represents a trivalent aromatic hydrocarbon which may have a substituent, and is preferably an aromatic group having 6 to 15 carbon atoms.

- R 7 , R 8 , R 9 , R 10 and R 11 may be the same or different from each other.

- R 7 , R 9 , R 10 and R 11 are each preferably an alkylene group having 2 to 20 carbon atoms or an arylene group having 6 to 15 carbon atoms, and an alkylene or carbon having 2 to 10 carbon atoms Several to 10 arylene groups are more preferred.

- R 8 represents an alkylene group having 1 to 20 carbon atoms or an arylene group having 6 to 15 carbon atoms, and an alkylene group having 1 to 10 carbon atoms or an arylene group having 6 to 10 carbon atoms is More preferred.

- R 7 , R 8 , R 9 , R 10 and R 11 other functional groups that do not react with isocyanate groups, such as ether groups, carbonyl groups, ester groups, cyano groups, olefin groups, urethane groups , An amide group, a ureido group, or a halogen atom.

- R 12 represents a hydrogen atom, an alkyl group, an aryl group, an aralkyl group, a cyano group, or a halogen atom.

- a hydrogen atom, an alkyl group having 1 to 10 carbon atoms, an aryl group having 6 to 15 carbon atoms, an aralkyl having 7 to 15 carbon atoms, a cyano group, or a halogen atom is preferable, and a hydrogen atom or one carbon atom is preferable. More preferred are ⁇ 6 alkyl and aryl groups having 6 to 10 carbon atoms.

- R 12 may have other functional groups that do not react with isocyanate groups, such as alkoxy groups, carbonyl groups, olefin groups, ester groups, or halogen atoms.

- R 13 represents an aryl group or a cyano group, preferably an aryl group or a cyano group having 6 to 10 carbon atoms.

- m represents an integer of 2 to 4.

- n 1 , n 2 , n 3 , n 4 and n 5 each represents an integer of 2 or more, and an integer of 2 to 100 is preferable.

- n 6 represents 0 or an integer of 2 or more, preferably 0 or an integer of 2 to 100.

- R 14 represents a hydrogen atom or a methyl group

- R 15 represents an alkylene group having 1 to 10 carbon atoms

- R 16 represents a carbon atom. This represents a hydrocarbon group having a number of 1 to 10.

- p represents 0 or an integer of 1 to 10.

- the polyurethane resin may further be copolymerized with a low molecular weight diol containing no carboxylic acid group as a fifth component, and the low molecular weight diol may be any of the above general formulas (III-1) to (III-5).

- the weight average molecular weight is 500 or less.

- the low molecular weight diol containing no carboxylic acid group can be added as long as the alkali solubility is not lowered and the elastic modulus of the cured film can be kept sufficiently low.

- the polyurethane resin in particular, at least one selected from diisocyanates represented by the general formula (I) and carboxylic acid group-containing diols represented by the general formulas (II-1) to (II-3) And at least one selected from polymer diols having a weight average molecular weight in the range of 800 to 3,000 represented by the general formulas (III-1) to (III-5) according to the purpose

- the reaction product of the general formulas (III-1) to (III-5) with the low molecular weight diol containing no carboxylic acid group having a weight average molecular weight of 500 or less is further added to the general formulas (IV-1) to (IV).

- IV-16 which is obtained by reacting a compound having one epoxy group and at least one (meth) acrylic group in the molecule represented by any one of the molecules, and has an acid value of 20 mgKOH / g to 120 mgK

- An alkali-soluble photocrosslinkable polyurethane resin that is OH / g is preferred.

- the polyurethane resin is synthesized by adding the above-mentioned diisocyanate compound and diol compound to an aprotic solvent, and adding a known catalyst having an activity corresponding to the reactivity thereof, followed by heating.

- the molar ratio (Ma: Mb) of the diisocyanate and diol compound used in the synthesis is not particularly limited and can be appropriately selected according to the purpose, preferably 1: 1 to 1.2: 1, and alcohols Alternatively, by treating with an amine or the like, a product having a desired physical property such as molecular weight or viscosity is synthesized in a form in which no isocyanate group remains finally.

- the amount of the ethylenically unsaturated bond introduced into the polyurethane resin is not particularly limited and may be appropriately selected depending on the intended purpose.

- the vinyl group equivalent is 0.05 mmol / g to 3.0 mmol / g.

- 0.5 mmol / g to 2.7 mmol / g is more preferable, and 0.75 mmol / g to 2.4 mmol / g is particularly preferable.

- the polyurethane resin having an ethylenically unsaturated bond in the side chain preferably has a carboxyl group introduced in the side chain together with the ethylenically unsaturated bond group.

- the acid value is preferably 20 mgKOH / g to 120 mgKOH / g, more preferably 30 mgKOH / g to 110 mgKOH / g, and particularly preferably 35 mgKOH / g to 100 mgKOH / g.

- the molecular weight of the polyurethane resin having an ethylenically unsaturated bond in the side chain is not particularly limited and may be appropriately selected depending on the intended purpose, but is preferably 2,000 to 50,000 in terms of weight average molecular weight. 30,000 to 30,000 is more preferable, and 5,000 to 30,000 is particularly preferable. In particular, when the composition is used for a photosensitive solder resist, it is excellent in dispersibility with an inorganic filler, excellent in crack resistance and heat resistance, and excellent in developability of non-image areas with an alkaline developer.

- the content of the acid-modified vinyl group-containing polyurethane resin contained in the total solid content of the silica dispersion composition or the like is preferably 2% by mass to 30% by mass, and more preferably 5% by mass to 25% by mass.

- the content is less than 2% by mass, a sufficiently low elastic modulus at a high temperature of the cured film may not be obtained, and when it exceeds 30% by mass, the developability deterioration and the toughness of the cured film are reduced. May happen.

- the diisocyanate compound and the diol compound are synthesized in an aprotic solvent by adding a known catalyst having an activity corresponding to each reactivity and heating.

- the molar ratio of the diisocyanate and diol compound to be used is preferably 0.8: 1 to 1.2: 1. If an isocyanate group remains at the end of the polymer, the molar ratio can be reduced by treatment with alcohols or amines. It is synthesized in such a way that no isocyanate groups remain entangled.

- the diisocyanate compound represented by the general formula (I) is not particularly limited and may be appropriately selected depending on the intended purpose. Examples thereof include compounds described in paragraph [0021] of JP-A-2007-2030, Etc.

- the high molecular weight diol compound represented by the general formulas (III-1) to (III-5) is not particularly limited and may be appropriately selected depending on the intended purpose. For example, as disclosed in JP-A-2007-2030 Examples thereof include compounds described in paragraphs [0022] to [0046].

- diol compound having a carboxyl group represented by the general formulas (II-1) to (II-3) is not particularly limited and may be appropriately selected depending on the intended purpose. And the compounds described in paragraph [0047] of the publication No. 2030.

- the carboxylic acid group-free low molecular weight diol is not particularly limited and may be appropriately selected depending on the intended purpose. Examples thereof include compounds described in paragraph [0048] of JP-A-2007-2030. It is done.

- the copolymerization amount of the carboxylic acid group-free diol is preferably 95 mol% or less, more preferably 80% or less, and particularly preferably 50% or less in the low molecular weight diol. When the copolymerization amount exceeds 95 mol%, a urethane resin having good developability may not be obtained.

- polyurethane resin obtained by reacting the above (ii) carboxyl group-containing polyurethane with a compound having an epoxy group and a vinyl group in the molecule include, for example, paragraph [0314] of JP-A-2007-2030.

- glycidyl acrylate as an epoxy group- and vinyl group-containing compound is replaced with glycidyl methacrylate, 3,4-epoxycyclohexylmethyl acrylate (trade name: Cyclomer A400, Daicel). Chemical Co., Ltd.), 3,4-epoxycyclohexylmethyl methacrylate (trade name: Cyclomer M400, manufactured by Daicel Chemical Industries), and the like.

- the content of the acid-modified vinyl group-containing polyurethane resin in the silica dispersion composition is not particularly limited and may be appropriately selected depending on the intended purpose, but is preferably 5% by mass to 80% by mass, and preferably 20% by mass. Is more preferably from 75 to 75% by weight, particularly preferably from 30 to 70% by weight. If the content is less than 5% by mass, good crack resistance may not be maintained, and if it exceeds 80% by mass, the heat resistance may fail. On the other hand, when the content is within the particularly preferable range, it is advantageous in terms of both good crack resistance and heat resistance.

- the weight average molecular weight of the acid-modified vinyl group-containing polyurethane resin is not particularly limited and may be appropriately selected depending on the intended purpose, but is preferably 2,000 to 60,000, and preferably 2,000 to 50,000. More preferably, 2,000 to 30,000 is particularly preferable. When the weight average molecular weight is less than 2,000, a sufficiently low elastic modulus at a high temperature of the cured film may not be obtained, and when it exceeds 60,000, coating suitability and developability may be deteriorated. .

- the weight average molecular weight is determined by using, for example, a high-speed GPC apparatus (manufactured by Toyo Soda Co., Ltd., HLC-802A), a 0.5 mass% THF solution as a sample solution, and a column of one TSKgel HZM-M. 200 ⁇ L of sample is injected, eluted with the THF solution, and measured at 25 ° C. with a refractive index detector or UV detector (detection wavelength 254 nm). Next, the weight average molecular weight can be determined from the molecular weight distribution curve calibrated with standard polystyrene.

- the acid value of the acid-modified vinyl group-containing polyurethane resin is not particularly limited and may be appropriately selected depending on the intended purpose. 35 mg KOH / g to 100 mg KOH / g is particularly preferable. If the acid value is less than 20 mgKOH / g, the developability may be insufficient, and if it exceeds 120 mgKOH / g, the development speed may be too high, and the development control may be difficult.

- the said acid value can be measured based on JISK0070, for example. However, if the sample does not dissolve, dioxane or tetrahydrofuran is used as the solvent.

- the vinyl group equivalent of the acid-modified vinyl group-containing polyurethane resin is not particularly limited and may be appropriately selected depending on the intended purpose, but is preferably 0.05 mmol / g to 3.0 mmol / g, preferably 0.5 mmol / g to 2.7 mmol / g is more preferable, and 0.75 mmol / g to 2.4 mmol / g is particularly preferable.

- the vinyl group equivalent can be calculated

- the bromine number can be measured according to, for example, JIS K2605.

- the acid-modified vinyl group-containing epoxy resin is not particularly limited and may be appropriately selected depending on the intended purpose. Examples thereof include those described in Japanese Patent No. 4127010 (Japanese Patent Laid-Open No. 2004-133060). Can be mentioned.

- the polymerizable compound is not particularly limited and may be appropriately selected depending on the intended purpose.

- the compound has at least one addition-polymerizable group in the molecule and has a boiling point of 100 ° C. or higher at normal pressure.

- at least one selected from monomers having a (meth) acryl group is preferable.

- polyethyleneglycol mono (meth) acrylate polypropylene glycol mono (meth) acrylate, phenoxyethyl (meth) ) Monofunctional acrylate such as acrylate; Monofunctional methacrylate; Polyethylene glycol di (meth) acrylate, Polypropylene glycol di (meth) acrylate, Trimethylolethane triacrylate, Trimethylolpropane triacrylate, Trimethylolpropane diacrylate, Neopentylglycol di (Meth) acrylate, pentaerythritol tetra (meth) acrylate, pentaerythritol tri (meth) acrylate, dipentaerythritol hex (Meth) acrylate, dipentaerythritol penta (meth) acrylate,

- trimethylolpropane tri (meth) acrylate pentaerythritol tetra (meth) acrylate, dipentaerythritol hexa (meth) acrylate, and dipentaerythritol penta (meth) acrylate are particularly preferable.

- the content of the polymerizable compound in the silica dispersion composition is not particularly limited and may be appropriately selected depending on the intended purpose, but is preferably 2% by mass to 50% by mass, and 3% by mass to 40% by mass. Is more preferable, and 4% by mass to 35% by mass is particularly preferable.

- the content is less than 2% by mass, pattern formation may not be possible, and when it exceeds 50% by mass, crack resistance may be inferior.

- the content is within the particularly preferable range, it is advantageous in that both good pattern formation and crack resistance can be achieved.

- the photopolymerization initiator is not particularly limited as long as it has the ability to initiate polymerization of the polymerizable compound, and can be appropriately selected according to the purpose.

- a halogenated hydrocarbon derivative for example, a triazine skeleton

- those having an oxadiazole skeleton phosphine oxide, hexaarylbiimidazole, oxime derivatives, organic peroxides, thio compounds, ketone compounds, aromatic onium salts, ketoxime ethers, and the like.

- the halogenated hydrocarbon compound having a triazine skeleton is not particularly limited and may be appropriately selected depending on the intended purpose.

- compounds described in British Patent No. 1388492 compounds described in JP-A-53-133428

- German Patent No. 3337024 Compounds, F.I. C. J. Schaefer et al. Org. Chem.

- halogenated hydrocarbon compound having an oxadiazole skeleton examples include the compounds described in US Pat. No. 4,221,976.

- the oxime derivative is not particularly limited and may be appropriately selected depending on the intended purpose. Examples thereof include compounds described in paragraph [0085] of JP-A-2007-2030.

- the ketone compound is not particularly limited and may be appropriately selected depending on the intended purpose. Examples thereof include compounds described in paragraph [0087] of JP-A-2007-2030.

- the photopolymerization initiator other than the above is not particularly limited and may be appropriately selected depending on the intended purpose. Examples thereof include compounds described in paragraph [0086] of JP-A-2007-2030. It is done.

- a sensitizer can be added for the purpose of adjusting exposure sensitivity and photosensitive wavelength in exposure to the photosensitive layer described later.

- the sensitizer can be appropriately selected by a visible light, an ultraviolet laser, a visible laser or the like as a light irradiation means described later.

- the sensitizer is excited by active energy rays and interacts with other substances (eg, radical generator, acid generator, etc.) (eg, energy transfer, electron transfer, etc.), thereby causing radicals, acids, etc. It is possible to generate a useful group of

- the sensitizer is not particularly limited and may be appropriately selected depending on the intended purpose. Examples thereof include compounds described in paragraph [0089] of JP-A-2007-2030.

- the combination of the photopolymerization initiator and the sensitizer is not particularly limited and may be appropriately selected depending on the intended purpose.

- an electron transfer type initiation system described in JP-A-2001-305734 [ (1) Electron donating initiator and sensitizing dye, (2) Electron accepting initiator and sensitizing dye, (3) Electron donating initiator, sensitizing dye and electron accepting initiator (ternary initiation system) ] Etc. are mentioned.

- the content of the sensitizer is not particularly limited and may be appropriately selected depending on the intended purpose. It is preferably 0.05% by mass to 30% by mass with respect to all components in the silica dispersion composition. 0.1 mass% to 20 mass% is more preferable, and 0.2 mass% to 10 mass% is particularly preferable. When the content is less than 0.05% by mass, the sensitivity to active energy rays decreases, the exposure process takes time, and the productivity may be reduced.

- the sensitizer may be precipitated from the photosensitive layer.

- the said photoinitiator may be used individually by 1 type, and may use 2 or more types together.

- Particularly preferred examples of the photopolymerization initiator include composite light in which phosphine oxides, the ⁇ -aminoalkyl ketones, the halogenated hydrocarbon compound having the triazine skeleton and an amine compound as a sensitizer described later are combined. Examples thereof include an initiator, a hexaarylbiimidazole compound, and titanocene.

- the content of the photopolymerization initiator in the silica dispersion composition is not particularly limited and may be appropriately selected depending on the intended purpose, but is preferably 0.5% by mass to 20% by mass, and preferably 0.5% by mass. % To 15% by mass is more preferable, and 1% to 10% by mass is particularly preferable. When the content is less than 0.5% by mass, the exposed portion tends to be eluted during development, and when it exceeds 20% by mass, the heat resistance may be lowered. On the other hand, when the content is within the particularly preferable range, it is advantageous in that a good pattern can be formed and heat resistance is also improved.

- the other components are not particularly limited and may be appropriately selected depending on the purpose.

- thermoplastic elastomers, fillers, thermosetting accelerators, thermal polymerization inhibitors, plasticizers, colorants (color pigments or Dyes) and the like, and further adhesion promoters to the substrate surface, or other auxiliary agents (for example, conductive particles, fillers, antifoaming agents, flame retardants, leveling agents, peeling accelerators, antioxidants). , Fragrance, surface tension adjusting agent, chain transfer agent, etc.) may be used in combination.

- properties such as the stability, photographic properties, and film properties of the intended photosensitive film can be adjusted.

- thermoplastic elastomer there is no restriction

- These elastomers are composed of a hard segment component and a soft segment component. In general, the former contributes to heat resistance and strength, and the latter contributes to flexibility and toughness.

- the thermoplastic elastomer is described in paragraphs [0197] to [0207] of JP-A-2007-199532.

- the filler is described in detail in, for example, paragraphs [0098] to [0099] of JP-A-2008-250074.

- the thermal polymerization inhibitor is described in detail, for example, in paragraphs [0101] to [0102] of JP-A-2008-250074.

- the thermosetting accelerator is described in detail, for example, in paragraph [0093] of JP-A-2008-250074.

- the plasticizer is described in detail, for example, in paragraphs [0103] to [0104] of JP-A-2008-250074.

- the colorant is described in detail, for example, in paragraphs [0105] to [0106] of JP-A-2008-250074.

- the adhesion promoter is described in detail, for example, in paragraphs [0107] to [0109] of JP-A-2008-250074.

- the silica dispersion composition of the present invention can be used as a liquid resist by coating and drying on a substrate on which a conductor wiring is formed, but is particularly useful for producing a photosensitive film.

- the photosensitive film has at least a support and a photosensitive layer, preferably has a protective film, and further, if necessary, a cushion layer, an oxygen barrier layer (hereinafter abbreviated as PC layer). ) And other layers.

- PC layer oxygen barrier layer

- the PC layer, the photosensitive layer, and the protective film are provided in this order on the support, and the cushion layer, the PC layer, the photosensitive layer, and the protection are provided on the support.

- the form etc. which have a film in this order are mentioned.

- the photosensitive layer may be a single layer or a plurality of layers.

- the photosensitive layer is formed from the silica dispersion composition of the present invention.

- the melt viscosity at 70 ° C. of the photosensitive layer is preferably 1.4 ⁇ 10 3 Pa ⁇ s or less, more preferably 1.0 ⁇ 10 3 Pa ⁇ s or less, and 6.0 ⁇ 10 2 Pa ⁇ s or less. Further preferred.

- the melt viscosity at 70 ° C. of the photosensitive layer exceeds 1.4 ⁇ 10 3 Pa ⁇ s, the embedding property may be deteriorated, and when the melt viscosity at 70 ° C. is in a more preferable range, the embedding property is deteriorated. Is advantageous in that it is sufficiently obtained.

- the melt viscosity at 30 ° C. of the photosensitive layer is preferably 1.0 ⁇ 10 4 Pa ⁇ s or more, more preferably 1.3 ⁇ 10 4 Pa ⁇ s or more, and 3.0 ⁇ 10 4 Pa ⁇ s or more. Further preferred. If the melt viscosity at 30 ° C. of the photosensitive layer is less than 1.0 ⁇ 10 4 Pa ⁇ s, edge fusion may be deteriorated, and if the melt viscosity at 30 ° C. is in a more preferable range, embedding is performed. It is advantageous in that it can be compatible with edge fusion.

- the melt viscosity of the photosensitive layer is measured by, for example, a melt viscosity measuring device such as a rheometer VAR-1000 type (manufactured by Rheological Co., Ltd.), Vibron DD-III type (manufactured by Toyo Baldwin Co., Ltd.) or the like. Can be measured.

- a melt viscosity measuring device such as a rheometer VAR-1000 type (manufactured by Rheological Co., Ltd.), Vibron DD-III type (manufactured by Toyo Baldwin Co., Ltd.) or the like. Can be measured.

- the permanent pattern used in the present invention is obtained by the permanent pattern forming method.

- the permanent pattern is described in paragraphs [0128] to [0283] of Japanese Patent Application Laid-Open No. 2007-2030.

- the printed board used in the present invention has at least a base and a permanent pattern formed by the permanent pattern forming method, and further has other configurations appropriately selected as necessary.

- Synthesis Example 4 ⁇ Synthesis of Silica Dispersant P-2>

- Synthesis Example 3 the same procedure as in Synthesis Example 3 was performed, except that 5.52 g of 3- (dimethylamino) -1,2-propanediol was changed to 6.79 g and 2.21 g of neopentyl glycol was changed to 1.19 g.

- a silica dispersant P-2 solution solid content: 20% by mass having a mass ratio of components represented by the following formula was synthesized.

- CL represents a caprolactone and a number represents mass ratio.

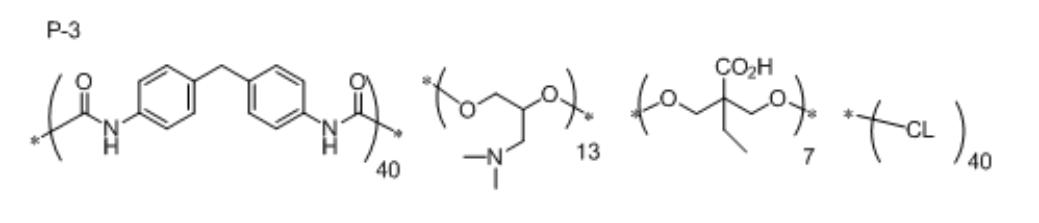

- Synthesis Example 5 ⁇ Synthesis of Silica Dispersant P-3>

- the components represented by the following formulas were used in the same manner as in Synthesis Example 3 except that 5.52 g of 3- (dimethylamino) -1,2-propanediol was changed to 8.15 g and neopentyl glycol was not added.

- a silica dispersant P-3 solution (solid content: 20% by mass) having a mass ratio of 5% was synthesized.

- CL represents a caprolactone and a number represents mass ratio.

- Synthesis Example 9 ⁇ Synthesis of Silica Dispersant P-7>

- Synthesis Example 3 the same procedure as in Synthesis Example 3 was performed except that 5.52 g of 3- (dimethylamino) -1,2-propanediol was changed to 3.84 g and 2.21 g of neopentyl glycol was changed to 3.77 g.

- a silica dispersant P-7 solution solid content 20% by mass having a mass ratio of the components represented by the following formula was synthesized.

- CL represents a caprolactone and a number represents mass ratio.

- light acrylate 130A methoxypolyoxyethylene ether acrylate, manufactured by Kyoeisha Chemical Co., Ltd., bromine number 34.9Br / 100 g

- light acrylate NP-4EA nonylphenyl polyoxyethylene ether acrylate, manufactured by Kyoeisha Chemical Co., Ltd. 17 0.7 parts by mass was added, the temperature was raised to 80 ° C., and the reaction was performed for 4 hours.

- the mixture was cooled to 60 ° C., 60 parts by weight of castor oil (diol HS-2G-150R, manufactured by Toyokuni Seiyaku), 163 parts by weight of Kuraray polyester diol P-2050 (number average molecular weight 2,066, manufactured by Kuraray Co., Ltd.), 29.1 parts by weight of methylol butanoic acid, 49.5 parts by weight of 1,6-hexamethylene diisocyanate, 76.4 parts by weight of isophorone diisocyanate, and 83 parts by weight of propylene glycol monomethyl ether acetate were added and reacted at 60 ° C. for 5 hours. It was.

- castor oil diol HS-2G-150R, manufactured by Toyokuni Seiyaku

- Kuraray polyester diol P-2050 number average molecular weight 2,066, manufactured by Kuraray Co., Ltd.

- 29.1 parts by weight of methylol butanoic acid 49.5 parts by weight

- ⁇ Measurement of acid value> 0.7 g of each silica dispersant was weighed in a 100 mL beaker, 60 mL of a solution of tetrahydrofuran (THF) / water 5/1 (volume ratio) was added, and dissolved by stirring. After adjusting measurement temperature to 25 degreeC, it titrated with the titration apparatus using 0.1N NaOH aqueous solution as a titration reagent, and the acid value was measured.

- THF tetrahydrofuran

- the silica dispersant of P-5 is made of a polyurethane resin having no basic group.

- the silica dispersant of P-6 is made of a polyurethane resin having no acidic group.

- Example 1 Composition of silica dispersion composition solution- -Polyurethane binder solution of Synthesis Example 1 (solid content 45% by mass) ... 25.3 parts by mass-Color pigment: HELIOGEN BLUE D7086 (manufactured by BASF) ... 0.02 parts by mass-Color pigment: Pariotol Yellow D0960 (Manufactured by BASF) 0.005 parts by mass Dispersant: Silica dispersant P-1 solution (solid content 20% by mass) 1.51 parts by mass Polymerizable compound: DCP-A (Kyoeisha Chemical) 4.67 parts by mass ⁇ Initiator: Irgacure 907 (manufactured by BASF) ...

- a silica dispersion composition solution having the above composition is applied onto a polyethylene terephthalate film (16FB50, manufactured by Toray Industries, Inc.) having a thickness of 16 ⁇ m as a support, and dried to form a photosensitive layer having a thickness of 30 ⁇ m on the support. Formed.

- a 20 ⁇ m-thick polypropylene film manufactured by Oji Specialty Paper Co., Ltd., Alphan E-200 was laminated as a protective layer to produce a photosensitive film.

- the substrate was prepared by subjecting a surface of a copper clad laminate (no through hole, copper thickness: 12 ⁇ m) to chemical polishing.

- a vacuum laminator manufactured by Nichigo Morton Co., Ltd., VP130 was used on the copper-clad laminate while peeling off the protective film from the photosensitive film so that the photosensitive layer of the photosensitive film was in contact with the copper-clad laminate.

- a photosensitive laminate was prepared in which the copper-clad laminate, the photosensitive layer, and the polyethylene terephthalate film (support) were laminated in this order.

- the pressure bonding conditions were a vacuum drawing time of 40 seconds, a pressure bonding temperature of 70 ° C., a pressure bonding pressure of 0.2 MPa, and a pressure application time of 10 seconds.

- melt viscosity was measured on condition of the following using rheometer * VAR-1000 type (made by Rheological Co., Ltd.). -Measurement conditions of melt viscosity- Melt viscoelasticity was measured using a plate having a diameter of 20 mm at a strain of 0.005 and a frequency of 1 Hz. The temperature range was 25 ° C. to 85 ° C., and the measurement was performed at a rate of temperature increase of 5 ° C./min. In addition, the melt viscosity in Table 2 shows a value at 70 ° C.

- the polyethylene terephthalate film (support) was peeled off from the photosensitive laminate.

- a 1 mass% sodium carbonate aqueous solution at 30 ° C. is sprayed as a developing solution over the entire surface of the photosensitive layer on the copper clad laminate at a spray pressure of 0.15 MPa.

- the time required until the layer was dissolved and removed was measured, and this was taken as the shortest development time.

- a 1 mass% sodium carbonate aqueous solution at 30 ° C. is sprayed as a developing solution over the entire surface of the photosensitive layer on the copper-clad laminate at a spray pressure of 0.15 MPa for a time twice as short as the shortest developing time, thereby uncured regions.

- developability (development time, residue) was evaluated according to the following criteria.

- -Resolution Observe the surface of the obtained copper-clad laminate with a cured resin pattern with an optical microscope, there is no residue at the bottom of the round hole of the pattern, there is no abnormality such as blistering / peeling of the pattern part, and space can be formed

- the smallest round hole pattern diameter was measured, and the resolution was evaluated according to the following criteria.

- [Development evaluation criteria] -About development time, it evaluated by the said shortest development time. -Residues were visually evaluated according to the following criteria.

- ⁇ No residue ⁇ : Residue is slightly seen on the wall and bottom ⁇ : Residue is clearly seen [Evaluation criteria for resolution] ⁇ : A round hole with a diameter of 90 ⁇ m or less can be resolved, and the resolution is excellent. ⁇ : A round hole with a diameter of 200 ⁇ m or less can be resolved, and the resolution is slightly inferior. , Poor resolution

- the photosensitive layer was irradiated with ultraviolet rays with an energy amount of 1 J / cm 2 using an ultraviolet irradiation device manufactured by Oak Manufacturing. Further, the photosensitive layer was heat-treated at 150 ° C. for 60 minutes to obtain an evaluation substrate on which a solder resist was formed. After connecting a shield wire made of polytetrafluoroethylene to these comb electrodes by Sn / Pb solder so that a voltage is applied between the comb electrodes of the evaluation laminate after heating, 50 V is applied to the evaluation laminate. With the voltage applied, the laminate for evaluation was allowed to stand in a super accelerated high-temperature high-humidity life test (HAST) bath at 130 ° C. and 85% RH for 200 hours.

- HAST high-temperature high-humidity life test

- TCT Thermal shock resistance

- appearance such as cracks and peeling was evaluated by a temperature cycle test (TCT).

- TCT uses a gas-phase cold heat tester, and the electronic component module is left in the gas phase at ⁇ 55 ° C. and 125 ° C. for 30 minutes each, and this is regarded as one cycle under the conditions of 1,000 cycles and 1,500 cycles.

- the thermal shock resistance was evaluated according to the following criteria. ⁇ Evaluation criteria ⁇ ⁇ : No crack occurred ⁇ : Shallow crack occurred ⁇ : Deep crack occurred