明 細 書 Specification

ハーフ露光用ポジ型感光性樹脂層を用いる透明性硬化膜の製造方法 技術分野 Manufacturing method of transparent cured film using positive photosensitive resin layer for half exposure

[0001] 本発明は、ポジ型感光性樹脂層を用いて得られる透明性硬化膜の製造方法に関 する。 The present invention relates to a method for producing a transparent cured film obtained using a positive photosensitive resin layer.

詳細には、基材上に形成された露光感度の異なる 2層のポジ型感光性樹脂層を露 光し、最後にポストベータの工程を経て、透明性硬化膜を製造する方法に関する。 なかでも、上記構造を有する感光性樹脂層をハーフ露光することで、任意の形状の 反射層及び平坦な透過層並びにコンタクトホールを高い精度で作製する方法に適 用可能であり、特に、半透過型液晶表示素子の製造への適用に関する。 More specifically, the present invention relates to a method for producing a transparent cured film by exposing two positive photosensitive resin layers having different exposure sensitivities formed on a substrate and finally passing through a post-beta step. In particular, the photosensitive resin layer having the above-described structure can be applied to a method for producing a reflection layer, a flat transmission layer, and a contact hole with any shape with high accuracy by half exposure, and in particular, semi-transmission. The present invention relates to application to manufacturing of a liquid crystal display element.

背景技術 Background art

[0002] 一般に、薄膜トランジスタ (TFT)型液晶表示素子は反射型、半透過型、透過型の 構造等があり、それぞれ使用するデバイスにより適宜選択される。この中でも屋内外 で昼夜問わず高精細な表示が可能な半透過型が多く用いられている。このような半 透過型液晶表示素子にぉレ、て TFTを平坦化し開口率を広げる目的で平坦化膜が 用いられている。こうした平坦化膜上には反射部の光散乱性をもたせ反射効率を上 げるため表面に不規則な凹凸が作製される。この凹凸上にアルミニウムやモリブデン のような金属が反射板および画素電極として製膜される。一方、透過部には ITOのよ うな透明電極が画素電極として用いられる。これらの画素電極を共通電極と導通させ るために平坦化膜にはコンタクトホールが形成される。 In general, a thin film transistor (TFT) type liquid crystal display element has a reflection type, a semi-transmission type, a transmission type structure, and the like, and is appropriately selected depending on a device to be used. Of these, the transflective type, which allows high-definition display both indoors and outdoors, day and night, is often used. A flattening film is used for the purpose of flattening the TFT and widening the aperture ratio over such a transflective liquid crystal display element. On such a flattened film, irregular irregularities are produced on the surface in order to provide the light scattering property of the reflection part and increase the reflection efficiency. A metal such as aluminum or molybdenum is formed on the irregularities as a reflector and a pixel electrode. On the other hand, a transparent electrode such as ITO is used as the pixel electrode in the transmissive part. A contact hole is formed in the planarization film to make these pixel electrodes conductive with the common electrode.

[0003] このような凹凸とコンタクトホールを作製する方法として、感光性材料を用いて基板 上に厚膜の突起を作製し、その上からさらに感光性材料を塗布し突起をある程度平 坦化することで反射用の凹凸を作製した後、コンタクトホールを形成する方法が多く 用いられている。 [0003] As a method for producing such irregularities and contact holes, a thick film protrusion is formed on a substrate using a photosensitive material, and a photosensitive material is further applied thereon to flatten the protrusion to some extent. Therefore, a method of forming a contact hole after forming a reflection unevenness is often used.

し力、しこのような方法では、感光性材料を用いたパターン形成を 2回行う必要がある ため、素子製造のスループット(生産効率)が上がらず、そのため、このスループット 向上が求められていた。

[0004] そこで近年、感光性材料を塗布後、ハーフトーンマスクを介して露光すること(ノヽ一 フ露光)により、コンタクトホールと反射用の凹凸を同時に作製する方法が提案され、 採用されてきている。 However, in such a method, it is necessary to perform pattern formation twice using a photosensitive material, so that the throughput (production efficiency) of device manufacturing does not increase, and therefore, an improvement in this throughput has been demanded. [0004] Therefore, in recent years, a method of simultaneously producing contact holes and reflection irregularities by applying a photosensitive material and then exposing through a halftone mask (nozzle exposure) has been proposed and adopted. Yes.

ここで用いられる感光性材料は、耐熱性、耐溶剤性などのプロセス耐性に優れてレヽ ること、下地との密着性が良好であること、使用目的に合わせた様々なプロセス条件 で高精度にパターンを形成し得る広いプロセスマージンを有すること、加えて、高感 度且つ高透明性であること並びに現像後の膜ムラが少ないこと等の諸特性が要求さ れる。 The photosensitive material used here has excellent process resistance such as heat resistance and solvent resistance, good adhesion to the substrate, and high accuracy under various process conditions according to the purpose of use. Various characteristics such as having a wide process margin capable of forming a pattern, high sensitivity and high transparency, and less film unevenness after development are required.

そこで、斯かる要求特性の点から、従来、上記の感光性材料としては、ナフトキノン ジアジド化合物を含む感光性樹脂組成物が汎用されてきた。 Therefore, from the viewpoint of such required characteristics, a photosensitive resin composition containing a naphthoquinone diazide compound has been widely used as the photosensitive material.

[0005] ところで、斯カ、る感光性樹脂材料の要求特性の中、重要な特性として、感度とプロ セスマージンが挙げられる。感度の向上は、ディスプレイ素子等の工業的な生産に おいて、その生産時間の大幅な短縮を可能にするので、液晶ディスプレイの需要量 が著しく増大している現在の状況にあっては、感度は、この種の感光性樹脂材料に 要求される最も重要な特性の一つとなっている。また、プロセスマージンは設計どおり の高精度な反射層を形成するためには重要であり、近年基板の大型化に伴い露光 マージン、現像マージンの広いことが歩留まりを向上させる上で必要となっている。 [0005] By the way, among the required characteristics of such photosensitive resin materials, important characteristics include sensitivity and process margin. The improvement in sensitivity makes it possible to drastically shorten the production time in industrial production of display elements, etc., so in the current situation where the demand for liquid crystal displays is significantly increasing, the sensitivity Is one of the most important properties required for this type of photosensitive resin material. In addition, the process margin is important for forming a highly accurate reflective layer as designed. In recent years, a wider exposure margin and development margin are required to improve yields as the substrate becomes larger. .

[0006] しかし、上述のナフトキノンジアジド化合物を含む従来の感光性樹脂材料は、感度 の面において十分満足できるものではなかった。材料中のポリマーについてアルカリ 現像液への溶解性を高めることにより、感度を向上させることも可能ではある力 この 方法には限界があり、また未露光部の溶解も起こって残膜率が低下し、それが大型 ディスプレイ用の基板にとっては膜ムラの原因になるという欠点があった。 [0006] However, the conventional photosensitive resin material containing the naphthoquinonediazide compound described above has not been sufficiently satisfactory in terms of sensitivity. The ability to improve the sensitivity of the polymer in the material by increasing the solubility in alkaline developer. This method has limitations, and dissolution of unexposed areas also occurs, resulting in a decrease in the remaining film ratio. This has the disadvantage that it causes film unevenness for large display substrates.

[0007] そこで、これまでにも、感光性樹脂材料の高感度化を目的として幾つかの提案がな されている。 [0007] Therefore, some proposals have been made so far for the purpose of increasing the sensitivity of the photosensitive resin material.

例えば、アルカリ可溶性樹脂と特定のポリヒドロキシ化合物及びその誘導体の少な くとも何れかとを含有する感放射線性樹脂組成物が提案されて!/、る (例えば、特許文 献 1参照)が、ナフトキノンジアジド化合物を含む従来の感光性樹脂材料は、ハーフト ーンマスクを介した露光では高感度化するほどハーフ露光領域の露光マージンが低

下する傾向にあり高感度と露光マージンの向上を両立することができなかった。 一方、高感度、高解像度の感光性材料として従来、化学増幅型レジストが開発され ており、半導体用レジストとして開発されてきた従来の化学増幅型レジストは、 i線より も短波長の光源 (KrF、 ArF)にも適応することができ、より微細なパターン形成が可 能であることが提案されて!/、る (例えば、特許文献 2参照)。 For example, a radiation-sensitive resin composition containing an alkali-soluble resin and at least one of a specific polyhydroxy compound and a derivative thereof has been proposed! (See, for example, Patent Document 1), but naphthoquinone diazide Conventional photosensitive resin materials containing compounds have a lower exposure margin in the half-exposure area as the sensitivity increases in exposure through a half-tone mask. As a result, it was impossible to achieve both high sensitivity and improved exposure margin. On the other hand, chemically amplified resists have been developed as high-sensitivity, high-resolution photosensitive materials, and conventional chemically amplified resists that have been developed as resists for semiconductors use light sources (KrF , ArF), and it has been proposed that a finer pattern can be formed (see, for example, Patent Document 2).

[0008] しかしながら、上記の化学増幅型レジストにおいても、膜硬化に用いるような高温の 下では、またレジスト剥離液の存在下では、保護基の結合部やエーテル結合の熱架 橋部が容易に分解してしまい、耐熱性及び耐薬品性が著しく低ぐ永久膜として利用 することは殆ど不可能であった。 [0008] However, even in the above-mentioned chemically amplified resist, a protective group bond portion or an ether bond thermal bridge portion can be easily formed at a high temperature used for film curing or in the presence of a resist stripping solution. It was almost impossible to use as a permanent film that decomposed and had extremely low heat resistance and chemical resistance.

また、熱硬化を可能とするために、エポキシ類ゃァミノプラスト類の架橋系を化学増 幅型レジストに導入しょうとしても、露光によりレジスト中の光酸発生剤(以下、 PAGと もいう)から発生した酸の影響により、露光部の架橋が進行し、未露光部との溶解コン トラストが消失するなどの問題が新たに生じるため、斯カ、る架橋系の化学増幅型レジ ストへの導入は困難であった。 In addition, in order to enable thermosetting, even if an epoxy-caminoplast cross-linking system is introduced into a chemically amplified resist, it is generated by a photoacid generator (hereinafter also referred to as PAG) in the resist by exposure. Due to the influence of the acid, the cross-linking of the exposed part proceeds and new problems such as disappearance of the dissolution contrast with the unexposed part occur. It was difficult.

[0009] このような状況の中で、半透過型液晶表示素子の製造、特に平坦化膜の製造にお いては、ハーフ露光用のマスクパターンの開口部の口径や間隔を調整して露光を行 い、コンタクトホールや反射用凹凸パターンを形成している。しかし、マスクの調整量 には限界があり、精度よく凹凸パターンを形成するためには、平坦化膜の露光感度 を低下させることが必要とされている。そのためコンタクトホール形成には、露光量を 大きくすることが必要であり、その結果、素子製造のスループットを向上させることが 困難となっている。 In such a situation, in the manufacture of a transflective liquid crystal display element, particularly in the manufacture of a flattened film, exposure is performed by adjusting the aperture diameter and interval of the mask pattern for half exposure. The contact hole and the uneven pattern for reflection are formed. However, there is a limit to the amount of mask adjustment, and it is necessary to reduce the exposure sensitivity of the planarization film in order to form a concavo-convex pattern with high accuracy. For this reason, it is necessary to increase the exposure amount for forming the contact hole, and as a result, it is difficult to improve the throughput of device manufacturing.

特許文献 1:特開平 4 211255号公報 Patent Document 1: Japanese Patent Laid-Open No. 4 211255

特許文献 2 :米国特許第 5075199号明細書 Patent Document 2: US Patent No. 5075199

発明の開示 Disclosure of the invention

発明が解決しょうとする課題 Problems to be solved by the invention

[0010] 本発明は、上記のような問題点を克服するために、高感度を維持したまま広い露光 マージンを有する透明性硬化膜を製造する方法を提供することを目的とする。なかで も、半透過型液晶表示素子において、 TFT平坦化膜の製造に適用可能な、特に、

ハーフ露光によりコンタクトホールと反射用凹凸を同時に形成するための透明性硬化 膜の製造方法を提供することを目的とする。 In order to overcome the above problems, an object of the present invention is to provide a method for producing a transparent cured film having a wide exposure margin while maintaining high sensitivity. In particular, in transflective liquid crystal display elements, it can be applied to the production of TFT planarization films, It is an object of the present invention to provide a method for producing a transparent cured film for simultaneously forming contact holes and reflective irregularities by half exposure.

課題を解決するための手段 Means for solving the problem

すなわち、第一観点として、基材上に露光感度の異なる 2層のポジ型感光性樹脂 層を、低感度のポジ型感光性樹脂層が前記基材及び高感度のポジ型感光性樹脂 層間に位置するように積層する工程、この積層された 2層のポジ型感光性樹脂層を 露光する工程、該 2層のポジ型感光性樹脂層を露光後加熱する工程、該 2層のポジ 型感光性樹脂層を現像する工程、該 2層のポジ型感光性樹脂層をポストベータする 工程を含む透明性硬化膜の製造方法であって、該低感度のポジ型感光性樹脂層が 下記の (A)成分、(B)成分、(C)成分及び (D)成分を含有するポジ型感光性樹脂層 であることを特徴とする、透明性硬化膜の製造方法。 That is, as a first aspect, two positive photosensitive resin layers having different exposure sensitivities are formed on a base material, and a low sensitivity positive photosensitive resin layer is disposed between the base material and a high sensitivity positive photosensitive resin layer. A step of exposing the two layers of the positive photosensitive resin layer, a step of heating the two layers of the positive photosensitive resin layer after exposure, and a step of exposing the two layers of the positive photosensitive resin layer. A method for producing a transparent cured film comprising a step of developing a photosensitive resin layer and a step of post-betaing the two positive photosensitive resin layers, wherein the low-sensitivity positive photosensitive resin layer comprises the following ( A method for producing a transparent cured film, which is a positive photosensitive resin layer containing component A), component (B), component (C), and component (D).

(A)成分:アルカリ可溶性樹脂 (A) component: alkali-soluble resin

(B)成分: 1分子中二個以上のビュルエーテル基を有する化合物 Component (B): Compound having two or more butyl ether groups in one molecule

(C)成分:ポストベータにより(A)成分と架橋反応する化合物 Component (C): Compound that crosslinks with component (A) by post-beta.

(D)成分:光酸発生剤 Component (D): Photoacid generator

第二観点として、前記露光がハーフ露光である第一観点に記載の透明性硬化膜の 製造方法。 As a second aspect, the method for producing a transparent cured film according to the first aspect, wherein the exposure is half exposure.

第三観点として、前記露光後加熱を温度 80°C乃至 140°Cで行い、且つ前記ポスト ベータを温度 150°C乃至 270°Cで行う第一観点又は第二観点に記載の透明性硬化 膜の製造方法。 As a third aspect, the transparent cured film according to the first aspect or the second aspect, in which the post-exposure heating is performed at a temperature of 80 ° C to 140 ° C and the post beta is performed at a temperature of 150 ° C to 270 ° C. Manufacturing method.

第四観点として、前記高感度のポジ型感光性樹脂層が、それぞれ下記の (A)成分 、(B)成分、(C)成分及び (D)成分を含有するポジ型感光性樹脂層である、第一観 点乃至第三観点のうちのいずれか一項に記載の透明性硬化膜の製造方法。 As a fourth aspect, the high-sensitivity positive photosensitive resin layer is a positive photosensitive resin layer containing the following component (A), component (B), component (C) and component (D): The manufacturing method of the transparent cured film as described in any one of a 1st viewpoint thru | or a 3rd viewpoint.

(A)成分:アルカリ可溶性樹脂 (A) component: alkali-soluble resin

(B)成分: 1分子中二個以上のビュルエーテル基を有する化合物 Component (B): Compound having two or more butyl ether groups in one molecule

(C)成分:ポストベータにより(A)成分と架橋反応する化合物 Component (C): Compound that crosslinks with component (A) by post-beta.

(D)成分:光酸発生剤 Component (D): Photoacid generator

第五観点として、前記低感度のポジ型感光性樹脂層において、(A)成分 100質量

部に基づいて、 1乃至 80質量部の前記(B)成分、 1乃至 70質量部の前記(C)成分、 及び 0. 5乃至 50質量部の前記 (D)成分を含有する、第一観点乃至第四観点のうち V、ずれか一項に記載の透明性硬化膜の製造方法。 As a fifth aspect, in the low-sensitivity positive photosensitive resin layer, (A) component 100 mass 1 to 80 parts by weight of the component (B), 1 to 70 parts by weight of the component (C), and 0.5 to 50 parts by weight of the component (D) Thru | or the manufacturing method of the transparent cured film as described in any one item of V among 4th viewpoint.

第六観点として、基材カ STFT素子を形成した基材である、第一観点乃至第五観点 のうちのいずれか一項に記載の透明性硬化膜の製造方法。 As a sixth aspect, the method for producing a transparent cured film according to any one of the first aspect to the fifth aspect, which is a base material on which a base material STFT element is formed.

第七観点として、第一観点乃至第五観点のうちのいずれか一項に記載の製造方法 によって得られる透明性硬化膜からなる TFTアレイ平坦化膜。 As a seventh aspect, a TFT array planarizing film comprising a transparent cured film obtained by the manufacturing method according to any one of the first aspect to the fifth aspect.

第八観点として、第一観点乃至第五観点のうちのいずれか一項に記載の製造方法 によって得られる透明性硬化膜を有する表示素子。 As an eighth aspect, a display element having a transparent cured film obtained by the production method according to any one of the first aspect to the fifth aspect.

第九観点として、第一観点乃至第五観点のうちのレ、ずれか一項に記載の製造方法 によって得られる透明性硬化膜を有する液晶表示素子。 As a ninth aspect, a liquid crystal display element having a transparent cured film obtained by the manufacturing method according to one of the first aspect and the fifth aspect.

発明の効果 The invention's effect

[0012] 本発明によって得られる透明性硬化膜は、ハーフ露光時に感度が高ぐ且つ露光 マージンが広いという効果を有するため、特に、 TFT平坦化膜の凹凸とコンタクトホ ールを高感度で同時に精度よく形成する半透過型液晶表示素子の製造に好適に用 いること力 Sでさる。 [0012] The transparent cured film obtained by the present invention has an effect of high sensitivity at the time of half exposure and a wide exposure margin. In particular, the unevenness of the TFT flattening film and the contact hole are simultaneously highly sensitive and highly sensitive. It can be applied to the production of a semi-transmission type liquid crystal display device that is accurately formed.

発明を実施するための最良の形態 BEST MODE FOR CARRYING OUT THE INVENTION

[0013] 本発明は、基材上に露光感度の異なる 2層のポジ型感光性樹脂層を、低感度のポ ジ型感光性樹脂層が前記基材及び高感度のポジ型感光性樹脂層の間に位置する ように積層し、この 2層からなるポジ型感光性樹脂層を露光し、露光後加熱 (Post Exp osure Bake : PEB)し、現像し、ポストベータする工程を含むことを特徴とする透明性 硬化膜の製造方法である。 [0013] The present invention provides two positive photosensitive resin layers having different exposure sensitivities on a base material, and the low-sensitivity positive photosensitive resin layer is the base material and the high-sensitivity positive photosensitive resin layer. It is characterized in that it includes a step of exposing the positive photosensitive resin layer consisting of the two layers, post exposure bake (PEB), developing, and post-beta. It is the manufacturing method of transparency cured film.

詳細には、基材上に低感度のポジ型感光性樹脂層を形成し、さらに該低感度層の 上に高感度のポジ型感光性樹脂層を積層して基材上に露光感度の異なる 2層のポ ジ型感光性樹脂層を積層する工程、この積層された 2層のポジ型感光性樹脂層を露 光する工程、該 2層のポジ型感光性樹脂層を露光後加熱する工程、該 2層のポジ型 感光性樹脂層を現像する工程、該 2層のポジ型感光性樹脂層をポストベータするェ 程を含む透明性硬化膜の製造方法であって、該低感度のポジ型感光性樹脂層が下

記の (A)成分、(B)成分、(C)成分及び (D)成分を含有するポジ型感光性樹脂層で あることを特徴とする、透明性硬化膜の製造方法である。 Specifically, a low-sensitivity positive photosensitive resin layer is formed on a substrate, and a high-sensitivity positive photosensitive resin layer is further laminated on the low-sensitivity layer, so that the exposure sensitivity differs on the substrate. The step of laminating two layers of the positive photosensitive resin layer, the step of exposing the two laminated positive photosensitive resin layers, and the step of heating the two positive photosensitive resin layers after exposure A process for developing the two positive photosensitive resin layers, and a method for producing a transparent cured film comprising the step of post-betaing the two positive photosensitive resin layers. Type photosensitive resin layer A method for producing a transparent cured film, which is a positive photosensitive resin layer containing the components (A), (B), (C) and (D).

(A)成分:アルカリ可溶性樹脂 (A) component: alkali-soluble resin

(B)成分: 1分子中二個以上のビュルエーテル基を有する化合物 Component (B): Compound having two or more butyl ether groups in one molecule

(C)成分:ポストベータにより(A)成分と架橋反応する化合物 Component (C): Compound that crosslinks with component (A) by post-beta.

(D)成分:光酸発生剤 Component (D): Photoacid generator

[0014] 本発明の製造方法によれば、基材上に露光感度の異なる 2層のポジ型感光性樹 脂層を積層することで、ハーフトーンマスクを介して露光した際に、高感度のポジ型 感光性樹脂層(以下、高感度層と称す。)と低感度のポジ型感光性樹脂層(以下、低 感度層と称す。)で異なるパターン形状を形成することが可能である。即ち、本発明 の製造方法によれば、ハーフトーンマスクを介することにより、高感度層と低感度層で 異なる画像形状を 1回の露光で形成することができる。 [0014] According to the production method of the present invention, two layers of positive photosensitive resin layers having different exposure sensitivities are laminated on a substrate, so that when exposed through a halftone mask, a high sensitivity is obtained. Different pattern shapes can be formed between a positive photosensitive resin layer (hereinafter referred to as a high sensitivity layer) and a low sensitivity positive photosensitive resin layer (hereinafter referred to as a low sensitivity layer). In other words, according to the manufacturing method of the present invention, different image shapes can be formed in a single exposure by using a halftone mask in the high-sensitivity layer and the low-sensitivity layer.

[0015] 本発明においては、低感度層が前記基材及び高感度層の間に位置するように積 層するため、現像時に、未露光部として高感度層及び低感度が残存し、ハーフ露光 部は高感度層が除去されて低感度層が残存することとなり、完全露光部はポジ型感 光性樹脂層(高感度層と低感度層)がすべて除去されて基材が露出する。 In the present invention, since the low-sensitivity layer is laminated so as to be located between the base material and the high-sensitivity layer, the high-sensitivity layer and the low sensitivity remain as unexposed portions during development, and half exposure is performed. The high-sensitivity layer is removed from the part, and the low-sensitivity layer remains. In the completely exposed part, the positive photosensitive resin layer (high-sensitivity layer and low-sensitivity layer) is completely removed, and the base material is exposed.

ここで言うところのハーフ露光部は、完全露光部よりも少ない露光量で現像が可能 であり、且つ所望の画像 (イメージ)を形成することができる部分である。 The half-exposure portion referred to here is a portion that can be developed with a smaller exposure amount than the complete exposure portion and can form a desired image.

[0016] 所望の画像を得るためには、積層する低感度層と高感度層のインターミキシングを 抑制することが求められる。前記の二つの層においてインターミキシングの抑制が不 充分な場合、低感度層と高感度層の界面が不明瞭となり、ハーフ露光時に所望の画 像が得られ難くなる。 [0016] In order to obtain a desired image, it is required to suppress intermixing between the low-sensitivity layer and the high-sensitivity layer to be laminated. If the intermixing is not sufficiently suppressed in the two layers, the interface between the low-sensitivity layer and the high-sensitivity layer becomes unclear and it is difficult to obtain a desired image during half exposure.

本発明においては、低感度層の形成の際、該層を形成するポジ型感光性樹脂組 成物の溶液を塗布した後に予備乾燥 (加熱処理)することで、該樹脂組成物に含有 される成分同士が架橋し、これにより、有機溶媒に難溶な膜が基材上に形成されるこ ととなる。従って、その後低感度層の上に高感度層を形成する際、該層を形成するポ ジ型感光性樹脂組成物の溶液を塗布しても、低感度層と高感度層がインターミキシ ングを起こすことがない。

[0017] そして、高感度層及び低感度層は、それぞれ、現像が始まるために必要な露光量 より少ない量の光が照射される場合には現像時に膜減りが抑制され、現像が始まる ために必要な露光量の光が照射されてからは、速やかに現像されること(高精度且 つ高感度であること)が望まれる。 In the present invention, when the low-sensitivity layer is formed, it is contained in the resin composition by applying a solution of a positive photosensitive resin composition that forms the layer and then pre-drying (heat treatment). The components are crosslinked with each other, whereby a film hardly soluble in an organic solvent is formed on the substrate. Therefore, when a high-sensitivity layer is subsequently formed on the low-sensitivity layer, the low-sensitivity layer and the high-sensitivity layer do not intermix even if a solution of the photosensitive resin composition that forms the layer is applied. There is no waking. [0017] Then, the high-sensitivity layer and the low-sensitivity layer each cause a reduction in film thickness at the time of development when irradiation is performed with an amount of light that is smaller than the exposure amount necessary for the development to start, and the development starts. It is desired that development is performed promptly (high accuracy and high sensitivity) after irradiation with a necessary amount of light.

[0018] ここでハーフ露光部において、現像時に、低感度層の溶解が終了する露光量と、 高感度層の溶解が開始する露光量の差がハーフ露光マージンとなる。これは、高感 度層と低感度層の感度差と密接に関係し、これら 2つの層の感度差が大きいほどハ ーフ露光マージンは大きくなる。つまり、高感度層は感度が高ければ高いほど、低感 度層は感度が低ければ低いほど露光マージンが広くなる。高精度な画像を得るため には、ハーフ露光マージンが 10mJ以上であることが好ましい。 [0018] Here, in the half-exposure portion, during development, the difference between the exposure amount at which dissolution of the low-sensitivity layer ends and the exposure amount at which dissolution of the high-sensitivity layer starts is the half-exposure margin. This is closely related to the sensitivity difference between the high-sensitivity layer and the low-sensitivity layer. The greater the sensitivity difference between these two layers, the greater the half exposure margin. That is, the higher the sensitivity of the high sensitivity layer, the wider the exposure margin the lower the sensitivity of the low sensitivity layer. In order to obtain a highly accurate image, the half exposure margin is preferably 10 mJ or more.

[0019] 一方、素子製造のスループットを向上させるためには、低感度層がある程度高感度 であることが肝要である。これは、ハーフ露光マージンを大きくすることを目的として、 低感度層の現像の開始に必要な露光量を大きくしすぎると、低感度層の感度を低下 させる結果となり、かえってスループットの低下につながることによる。 On the other hand, in order to improve the throughput of device manufacturing, it is important that the low sensitivity layer has a certain degree of sensitivity. For the purpose of increasing the half-exposure margin, if the amount of exposure required to start development of the low-sensitivity layer is too large, the sensitivity of the low-sensitivity layer will be reduced, leading to a decrease in throughput. by.

そのため、低感度層としては、例えば、感度の高い化学増幅型の感光層であること が好ましい。 Therefore, the low-sensitivity layer is preferably, for example, a highly sensitive chemical amplification type photosensitive layer.

従って、高感度層は高感度な低感度層よりも更に高感度の感光層であることが要 求され、より感度の高!/、化学増幅型の感光層が好まし!/、。 Therefore, the high-sensitivity layer is required to be a photosensitive layer with higher sensitivity than the high-sensitivity low-sensitivity layer, and a higher-sensitivity layer is preferred! / A chemical amplification type photosensitive layer is preferred! /.

[0020] 本発明に用いるポジ型感光性樹脂層は、上記の如く述べた通りであり、所望の画 像を形成した後にポストベータすることで透明な硬化膜が得られる。 [0020] The positive photosensitive resin layer used in the present invention is as described above, and a transparent cured film can be obtained by post-beta formation after forming a desired image.

以下により好まし!/、ポジ型感光性樹脂層につ!/、て述べる。 The following is more preferred! / And the positive photosensitive resin layer! /.

[0021] <低感度ポジ型感光性樹脂層(低感度層) > <Low-sensitivity positive photosensitive resin layer (low-sensitivity layer)>

本発明に用いる低感度層は、(A)成分のアルカリ可溶性樹脂、(B)成分の 1分子 中二個以上のビュルエーテル基を有する化合物、(C)成分のポストベータにより(A) 成分と架橋反応する化合物、及び、(D)成分の光酸発生剤を含有するポジ型感光 性樹脂組成物よりなる。 The low-sensitivity layer used in the present invention comprises (A) an alkali-soluble resin, (B) a compound having two or more butyl ether groups in one molecule, (C) component (A) and component (A) by post-beta. It consists of a positive photosensitive resin composition containing a compound that undergoes a crosslinking reaction and a photoacid generator as component (D).

通常、低感度層は、上記のポジ型感光性樹脂組成物を (E)溶剤に溶解して溶液形 態と為し、該溶液を基材に塗布し、乾燥することで形成できる。以下に、各成分につ

レヽて述べる。 Usually, the low-sensitivity layer can be formed by dissolving the positive photosensitive resin composition described above in (E) solvent to form a solution, applying the solution to a substrate, and drying. Below is a description of each component. Let me tell you.

[0022] [ (A)成分] [0022] [(A) component]

(A)成分はアルカリ可溶性樹脂であり、好適なものとしては、樹脂の構造中に、 (B) 成分のビュルエーテル基を有する化合物との間で熱架橋反応をなしうるための官能 基、並びに、(C)成分のポストベータにより(A)成分と架橋反応する化合物との間で 熱硬化反応をなしうる膜硬化のための官能基を有し、且つ、数平均分子量が 2, 000 乃至 50, 000であるアルカリ可溶性樹脂を挙げることができる。 The component (A) is an alkali-soluble resin, and as a preferred one, a functional group capable of undergoing a thermal crosslinking reaction with the compound having a butyl ether group of the component (B) in the resin structure, and , Having a functional group for film curing that can undergo a thermosetting reaction between the component (A) and a compound that undergoes a crosslinking reaction by post-beta of component (C), and having a number average molecular weight of 2,000 to 50 , 000, an alkali-soluble resin.

換言すると、(A)成分はアルカリ可溶性樹脂であり、好適なものとしては、樹脂の構 造中に、プリベータにより(B)成分のビュルエーテル基を有する化合物との間で熱架 橋反応をなしうるための官能基、並びに、ポストベータにより(C)成分と架橋反応して 熱硬化反応をなしうる膜硬化のための官能基を有し、且つ、数平均分子量が 2, 000 乃至 50, 000であるアルカリ可溶性樹脂を挙げることができる。 In other words, the component (A) is an alkali-soluble resin, and it is preferable that a thermal bridge reaction is performed with the compound having a butyl ether group of the component (B) by a prebeta during the resin structure. And a functional group for film curing that can crosslink with the component (C) by post-beta to form a thermosetting reaction, and the number average molecular weight is 2,000 to 50,000 An alkali-soluble resin that is:

[0023] 熱架橋反応のための官能基は、高められた温度の下 (プリベータの温度)で (B)成 分の化合物中のビュルエーテル基と反応して、(B)成分の化合物との間で熱架橋を なしうる基であり、その代表的な官能基は、カルボキシル基及びフエノール性ヒドロキ シ基の群から選ばれる少なくとも一種である。 [0023] The functional group for the thermal crosslinking reaction reacts with the butyl ether group in the (B) component compound at an elevated temperature (prebeta temperature) to form the (B) component compound. And a typical functional group thereof is at least one selected from the group consisting of a carboxyl group and a phenolic hydroxyl group.

[0024] また、膜硬化のための官能基は、上記の (A)成分及び (B)成分の熱架橋体におい て(露光部にあっては、熱架橋体が更に解離した脱架橋体において)、より高められ た温度(ポストベータの温度)の下で、(C)成分の化合物との間で架橋反応をなし、 膜を硬化せしめうる基である。 [0024] In addition, the functional group for film curing is present in the thermally crosslinked product of the above components (A) and (B) (in the exposed part, in the decrosslinked product in which the thermally crosslinked product is further dissociated). ), A group that undergoes a crosslinking reaction with the compound of component (C) under a higher temperature (post-beta temperature) and can cure the film.

後述するように、(C)成分が、ブロックイソシァネート基を 2個以上有する化合物の 場合、(A)成分が有する膜硬化のための官能基は、(C)成分の化合物との間でブッ ロタ部分が解離したイソシァネート基を介して架橋反応をなし、膜を硬化せしめる。 膜硬化のための官能基として代表的な官能基は、フエノール性ヒドロキシ基以外の ヒドロキシ基及び活性水素を有するァミノ基の群から選ばれる少なくとも一種である。 ここで、活性水素を有するァミノ基とは、反応によりプロトンを放出しうる 1級又は 2級 のアミノ基を意味する。従って、アミド基は、活性水素を持たないので、活性水素を有 するアミノ基に該当しない。

[0025] (A)成分のアルカリ可溶性樹脂は、斯かる構造を有するアルカリ可溶性樹脂であれ ばよく、樹脂を構成する高分子の主鎖の骨格及び側鎖の種類などにっレ、て特に限 定されない。 As will be described later, when the (C) component is a compound having two or more block isocyanate groups, the functional group for film curing that the (A) component has is between the compound of the (C) component. A crosslinking reaction occurs through the isocyanate group from which the broth moiety has been dissociated, and the film is cured. A typical functional group as a functional group for film curing is at least one selected from the group of hydroxy groups other than phenolic hydroxy groups and amino groups having active hydrogen. Here, the amino group having active hydrogen means a primary or secondary amino group capable of releasing a proton by reaction. Therefore, the amide group does not correspond to an amino group having active hydrogen because it does not have active hydrogen. [0025] The alkali-soluble resin of component (A) may be an alkali-soluble resin having such a structure, and is particularly limited depending on the type of main chain skeleton and side chain of the polymer constituting the resin. Not determined.

[0026] 然しながら、(A)成分の樹脂は、数平均分子量が 2, 000乃至 50, 000の範囲内に あるものである。数平均分子量が 50, 000を超えて過大なものであると、現像残渣が 発生し易くなり、感度が大きく低下する。一方、数平均分子量が 2, 000未満で過小 なものであると、現像の際、露光部の膜減りが相当量発生し、硬化不足になる場合が ある。 [0026] However, the resin of component (A) has a number average molecular weight in the range of 2,000 to 50,000. If the number average molecular weight exceeds 50,000, the development residue is likely to be generated, and the sensitivity is greatly reduced. On the other hand, if the number average molecular weight is less than 2,000, and the development is too small, a considerable amount of film loss may occur in the exposed area, resulting in insufficient curing.

[0027] (A)成分のアルカリ可溶性樹脂としては、例えばアクリル系樹脂、ポリヒドロキシスチ レン系樹脂、あるいはポリイミド前駆体又はポリイミド等を挙げることができる。 [0027] Examples of the alkali-soluble resin of component (A) include acrylic resins, polyhydroxystyrene resins, polyimide precursors, and polyimides.

[0028] 本発明にお!/、ては、複数種のモノマーを重合して得られる共重合体(以下、特定共 重合体と称す。)からなるアルカリ可溶性樹脂を (A)成分として用いることもできる。こ の場合、(A)成分のアルカリ可溶性樹脂は、複数種の特定共重合体のブレンド物で あってもよい。 [0028] In the present invention, an alkali-soluble resin composed of a copolymer obtained by polymerizing a plurality of types of monomers (hereinafter referred to as a specific copolymer) is used as the component (A). You can also. In this case, the alkali-soluble resin as the component (A) may be a blend of a plurality of types of specific copolymers.

[0029] すなわち、上記の特定共重合体は、アルカリ可溶性を発現するモノマー、即ちカル ボキシル基及びフエノール性ヒドロキシ基のうち少なくとも一方を有するモノマーの群 力、ら適宜選ばれる少なくとも一種のモノマーと、膜硬化のための官能基を有するモノ マー、即ちフエノール性ヒドロキシ基以外のヒドロキシ基及び活性水素を有するァミノ 基のうち少なくとも一方を有するモノマーの群から適宜選ばれる少なくとも一種のモノ マーとを、必須の構成単位として形成された共重合体であって、その数平均分子量( ポリスチレン換算)が 2, 000乃至 50, 000のものである。 [0029] That is, the specific copolymer includes an alkali-soluble monomer, that is, a group of monomers having at least one of a carboxyl group and a phenolic hydroxy group, and at least one monomer selected as appropriate. A monomer having a functional group for film curing, that is, at least one monomer appropriately selected from the group of monomers having at least one of a hydroxy group other than a phenolic hydroxy group and an amino group having an active hydrogen, is essential. A copolymer having a number average molecular weight (polystyrene equivalent) of 2,000 to 50,000.

なお上記特定共重合体の数平均分子量は及び重量平均分子量は、例えば、 日本 分光(株)製 GPC装置(Shodex (登録商標)カラム KF803Lおよび KF804L)を用 い、溶出溶媒テトラヒドロフランを流量 lml/分でカラム中に (カラム温度 40°C)流して 溶離させるという条件で測定することができる。 The number average molecular weight and the weight average molecular weight of the above specific copolymer are measured using, for example, a GPC apparatus (Shodex (registered trademark) columns KF803L and KF804L) manufactured by JASCO Corporation, and the elution solvent tetrahydrofuran is supplied at a flow rate of lml / min. It can be measured under the condition that it is eluted by flowing through the column (column temperature 40 ° C).

[0030] 上記の「カルボキシル基及びフエノール性ヒドロキシ基のうち少なくとも一方を有す るモノマー」には、カルボキシル基を有するモノマー、フエノール性ヒドロキシ基を有 するモノマー、ならびに、カルボキシル基及びフエノール性ヒドロキシ基の両方を有す

るモノマーが含まれる。これらのモノマーは、カルボキシル基又はフエノール性ヒドロ キシ基を一個有するものに限らず、複数個有するものでもよい。 [0030] The above-mentioned "monomer having at least one of carboxyl group and phenolic hydroxy group" includes a monomer having a carboxyl group, a monomer having a phenolic hydroxy group, and a carboxyl group and a phenolic hydroxy group. Have both Monomer. These monomers are not limited to those having one carboxyl group or phenolic hydroxy group, and may have a plurality thereof.

[0031] また上記の「フエノール性ヒドロキシ基以外のヒドロキシ基及び活性水素を有するァ ミノ基のうち少なくとも一方を有するモノマー」には、フエノール性ヒドロキシ基以外のヒ ドロキシ基を有するモノマー、活性水素を有するアミノ基を有するモノマー、ならびに 、フエノール性ヒドロキシ基以外のヒドロキシ基及び活性水素を有するァミノ基の両方 を有するモノマーが含まれる。これらのモノマーは、フエノール性ヒドロキシ基以外のヒ ドロキシ基又は活性水素を有するアミノ基を一個有するものに限らず、複数個有する ものでもよい。 [0031] The above-mentioned "monomer having at least one of a hydroxy group other than a phenolic hydroxy group and an amino group having an active hydrogen" includes a monomer having a hydroxy group other than a phenolic hydroxy group, and active hydrogen. A monomer having an amino group, and a monomer having both a hydroxy group other than a phenolic hydroxy group and an amino group having an active hydrogen. These monomers are not limited to those having one hydroxyl group other than a phenolic hydroxy group or one amino group having an active hydrogen, and may have a plurality.

以下、上記モノマーの具体例を挙げるが、これらに限定されるものでない。 Hereinafter, although the specific example of the said monomer is given, it is not limited to these.

[0032] カルボキシル基を有するモノマーとしては、例えば、アクリル酸、メタクリル酸、クロト ン酸、モノー(2—(アタリロイルォキシ)ェチル)フタレート、モノー(2—(メタクリロイル ォキシ)ェチル)フタレート、 N- (カルボキシフエニル)マレイミド、 N- (カルボキシフ ェニル)メタクリルアミド、 N— (カルボキシフエニル)アクリルアミド等が挙げられる。 [0032] Examples of the monomer having a carboxyl group include acrylic acid, methacrylic acid, crotonic acid, mono- (2- (acryloyloxy) ethyl) phthalate, mono- (2- (methacryloyloxy) ethyl) phthalate, N -(Carboxyphenyl) maleimide, N- (carboxyphenyl) methacrylamide, N- (carboxyphenyl) acrylamide and the like.

[0033] フエノール性ヒドロキシ基を有するモノマーとしては、例えば、ヒドロキシスチレン、 N (ヒドロキシフエニル)アクリルアミド、 N- (ヒドロキシフエニル)メタクリルアミド、 N- ( ヒドロキシフエニル)マレイミド等が挙げられる。 [0033] Examples of the monomer having a phenolic hydroxy group include hydroxystyrene, N (hydroxyphenyl) acrylamide, N- (hydroxyphenyl) methacrylamide, N- (hydroxyphenyl) maleimide and the like.

[0034] フエノール性ヒドロキシ基以外のヒドロキシ基を有するモノマーとしては、例えば、 2 キシ 6—ヒドロキシノルボルネン一 2—カルボキシリック一 6—ラタトン、 2—ヒドロキシ ェチルメタタリレート、 2 ヒドロキシプロピルメタタリレート、 5 メタクリロイルォキシー 6ーヒドロキシノルボルネン 2 カルボキシリック 6—ラタトン等が挙げられる。 [0034] Examples of the monomer having a hydroxy group other than the phenolic hydroxy group include, for example, 2-hydroxy 6-hydroxynorbornene-1, 2-carboxyl-6-latatane, 2-hydroxyethyl metatalylate, 2-hydroxypropyl metatalylate 5 Methacryloyloxy 6-hydroxynorbornene 2 Carboxylic 6-latathone and the like.

[0035] さらに、活性水素を有するアミノ基を有するモノマーとしては、 2 アミノエチルアタリ レート、 2—アミノメチルメタタリレート等が挙げられる。 [0035] Further, examples of the monomer having an amino group having active hydrogen include 2-aminoethyl acrylate and 2-aminomethyl methacrylate.

[0036] また、特定共重合体は、熱架橋反応のための官能基を有するモノマー及び膜硬化 のための官能基を有するモノマー以外のモノマー(以下、その他モノマーと称す。)を も構成単位として形成された共重合体であってもよい。 [0036] In addition, the specific copolymer includes a monomer having a functional group for thermal crosslinking reaction and a monomer other than a monomer having a functional group for film curing (hereinafter referred to as other monomer) as structural units. It may be a formed copolymer.

[0037] その他モノマーは、具体的には、カルボキシル基及びフエノール性ヒドロキシ基のう

ちの少なくとも一方を有するモノマー、並びに、フエノール性ヒドロキシ基以外のヒドロ キシ基及び活性水素を有するァミノ基のうちの少なくとも一方を有するモノマーと共 重合することが可能なものであればよぐ(A)成分の特性を損ねない限り、特に限定 されるものでない。 [0037] Other monomers specifically include carboxyl groups and phenolic hydroxy groups. Any monomer that can be copolymerized with a monomer having at least one of the above and a monomer having at least one of a hydroxy group other than a phenolic hydroxy group and an amino group having an active hydrogen (A) is acceptable. There is no particular limitation as long as the properties of the components are not impaired.

[0038] その他モノマーの具体例としては、アクリル酸エステル化合物、メタクリル酸エステ ル化合物、マレイミド化合物、アクリロニトリル、マレイン酸無水物、スチレン化合物及 びビュル化合物等が挙げられる。 [0038] Specific examples of other monomers include acrylic acid ester compounds, methacrylic acid ester compounds, maleimide compounds, acrylonitrile, maleic anhydride, styrene compounds, and bur compounds.

[0039] アクリル酸エステル化合物としては、例えば、メチルアタリレート、ェチルアタリレート 、イソプロピルアタリレート、ベンジルアタリレート、ナフチルアタリレート、アントリルァク リレート、アントリルメチルアタリレート、フエニルアタリレート、 2, 2, 2—トリフルォロェ チルアタリレート、 tert ブチルアタリレート、シクロへキシルアタリレート、イソボル二 ルアタリレート、 2—メトキシェチルアタリレート、メトキシトリエチレングリコールアタリレ ート、 2 エトキシェチルアタリレート、テトラヒドロフルフリルアタリレート、 3 メトキシ ブチルアタリレート、 2—メチルー 2—ァダマンチルアタリレート、 2—プロピル 2—ァ ダマンチルアタリレート、 8—メチルー 8—トリシクロデシルアタリレート、及び、 8—ェチ ル一 8—トリシクロデシルアタリレート等が挙げられる。 [0039] Examples of the acrylate compound include methyl acrylate, ethyl acrylate, isopropyl acrylate, benzyl acrylate, naphthyl acrylate, anthryl acrylate, anthryl methyl acrylate, phenyl acrylate, 2, 2 , 2-Trifluoroethyl acrylate, tert-butyl acrylate, cyclohexyl acrylate, isobornyl acrylate, 2-methoxyethyl acrylate, methoxytriethylene glycol acrylate, 2 ethoxyethyl acrylate Furfuryl acrylate, 3-methoxy butyl acrylate, 2-methyl-2-adamantyl acrylate, 2-propyl 2-adamantyl acrylate, 8-methyl-8-tricyclodecyl acrylate and 8-ethOne 8-tricyclodecyl Atari rate, and the like.

[0040] メタクリル酸エステル化合物としては、例えば、メチルメタタリレート、ェチルメタクリレ ート、イソプロピルメタタリレート、ベンジルメタタリレート、ナフチルメタタリレート、アント リノレメタクリレー卜、 ン卜リノレメチノレメタクリレー卜、フエニノレメタクリレー卜、 2, 2, 2—卜リ フルォロェチルメタタリレート、 tert ブチルメタタリレート、シクロへキシルメタクリレー ト、イソボルニルメタタリレート、 2—メトキシェチルメタタリレート、メトキシトリエチレング リコーノレメタタリレート、 2—エトキシェチルメタタリレート、テトラヒドロフノレフリノレメタタリ [0040] Examples of the methacrylic acid ester compound include methyl methacrylate, ethyl methacrylate, isopropyl methacrylate, benzyl methacrylate, naphthyl methacrylate, anthrinole methacrylate, nonlinole methacrylate methacrylate. Rhein, Phenylomethacrylate, 2, 2, 2-Lifluoroethyl methacrylate, tert Butyl methacrylate, Cyclohexyl methacrylate, Isobornyl methacrylate, 2-methoxyethyl Metatalylate, methoxytriethylene glycolate methacrylate, 2-ethoxyethyl methacrylate, tetrahydrofunolefurenoremetatalit

2 プロピルー2 ァダマンチルメタタリレート、 8 メチルー 8 トリシクロデシルメタク リレート、及び、 8—ェチルー 8—トリシクロデシルメタタリレート等が挙げられる。 Examples thereof include 2-propyl-2-adamantyl methacrylate, 8 methyl-8 tricyclodecyl methacrylate, and 8-ethyl-8-tricyclodecyl methacrylate.

[0041] ビュル化合物としては、例えば、メチルビュルエーテル、ベンジルビュルエーテル、 2—ヒドロキシェチノレビニノレエーテノレ、フエニノレビニノレエーテノレ、及び、プロピノレビ二 ルエーテル等が挙げられる。

[0042] スチレン化合物としては、例えば、スチレン、メチルスチレン、クロロスチレン、ブロモ スチレン等が挙げられる。 [0041] Examples of the bur compound include methyl butyl ether, benzyl butyl ether, 2-hydroxy ethino levino reetenole, phenino levino ree tenole, and propino vinyl ether. [0042] Examples of the styrene compound include styrene, methylstyrene, chlorostyrene, bromostyrene, and the like.

[0043] マレイミド化合物としては、例えば、マレイミド、 N—メチルマレイミド、 N—フエニルマ レイミド、及び N—シクロへキシルマレイミド等が挙げられる。 [0043] Examples of the maleimide compound include maleimide, N-methylmaleimide, N-phenylmaleimide, and N-cyclohexylmaleimide.

[0044] 本発明に用いる特定共重合体を得る方法は特に限定されないが、例えば、カルボ キシル基およびフエノール性ヒドロキシ基のうち少なくとも一方を有するモノマーの群 力、ら適宜選ばれる少なくとも一種のモノマーと、フエノール性ヒドロキシ基以外のヒドロ キシ基及び活性水素を有するァミノ基のうち少なくとも一方を有するモノマーの群か ら適宜選ばれる少なくとも一種のモノマーと、所望により上記モノマー以外のモノマー と、所望により重合開始剤等を溶剤中において、 50乃至 110°Cの温度下で重合反 応させることにより、得られる。その際、用いられる溶剤は、特定共重合体を構成する モノマー及び特定共重合体を溶解するものであれば特に限定されなレ、。具体例とし ては、後述する(E)溶剤に記載する溶剤が挙げられる。 [0044] The method for obtaining the specific copolymer used in the present invention is not particularly limited. For example, the group of monomers having at least one of a carboxyl group and a phenolic hydroxy group, and at least one monomer appropriately selected from , At least one monomer appropriately selected from the group of monomers having at least one of a hydroxy group other than a phenolic hydroxy group and an amino group having an active hydrogen, and optionally a monomer other than the above monomers, and optionally polymerization initiation It can be obtained by polymerizing the agent in a solvent at a temperature of 50 to 110 ° C. In this case, the solvent used is not particularly limited as long as it dissolves the monomer constituting the specific copolymer and the specific copolymer. Specific examples include the solvents described in (E) Solvent described later.

このようにして得られる特定共重合体は、通常、この特定共重合体が溶剤に溶解し た溶液の状態である。 The specific copolymer thus obtained is usually in a solution state in which the specific copolymer is dissolved in a solvent.

また、上記のようにして得られた特定共重合体の溶液を、ジェチルエーテルや水等 の撹拌下に投入して再沈殿させ、生成した沈殿物を濾過 '洗浄した後、常圧又は減 圧下で、常温あるいは加熱乾燥することで、特定共重合体の粉体とすることができる 。このような操作により、特定共重合体と共存する重合開始剤や未反応モノマーを除 去すること力 Sでき、その結果、精製した特定共重合体の粉体を得られる。一度の操作 で充分に精製できない場合は、得られた粉体を溶剤に再溶解して、上記の操作を繰 り返し行えば良い。 In addition, the solution of the specific copolymer obtained as described above is re-precipitated by stirring with stirring such as jetyl ether or water, and the generated precipitate is filtered and washed, and then at normal pressure or reduced. The powder of the specific copolymer can be obtained by drying at room temperature or under heat. By such an operation, it is possible to remove the polymerization initiator and unreacted monomer coexisting with the specific copolymer, and as a result, a purified powder of the specific copolymer can be obtained. If sufficient purification is not possible with a single operation, the obtained powder may be redissolved in a solvent and the above operation repeated.

本発明においては、特定共重合体の粉体をそのまま用いても良ぐあるいはその粉 体を、たとえば後述する(E)溶剤に再溶解して溶液の状態として用いても良い。 In the present invention, the powder of the specific copolymer may be used as it is, or the powder may be redissolved in a solvent (E) described later and used as a solution.

[0045] また、(A)成分のアルカリ可溶性樹脂としては、ポリアミド酸、ポリアミド酸エステル、 一部イミド化したポリアミド酸等のポリイミド前駆体、カルボン酸基含有ポリイミド等のポ リイミドを用いることもでき、それらはアルカリ可溶性であれば特にその種類を限定さ れずに用いることができる。

上記ポリイミド前駆体やポリイミドは現像性や使用する溶剤に対する溶解性の観点 力、ら数平均分子量 (ポリエチレンオキサイドおよびポリエチレングリコール換算値) 2, 000乃至 50, 000の範囲内にあるものである。 [0045] As the alkali-soluble resin of component (A), polyamic acid, polyamic acid ester, polyimide precursor such as partially imidized polyamic acid, and polyimide such as carboxylic acid group-containing polyimide can also be used. As long as they are soluble in alkali, the kind thereof can be used without particular limitation. The polyimide precursors and polyimides are within the range of 2,000 to 50,000 in terms of developability and solubility in the solvent used, and number average molecular weight (in terms of polyethylene oxide and polyethylene glycol).

なお、上記ポリイミド前駆体やポリイミドの数平均分子量及び重量平均分子量は、 例えば、 日本分光(株)製 GPC装置(Shodex (登録商標)カラム KD802、 KD803 および KD804)を用い、溶出溶媒 0. lmol%臭化リチウム N, N ジメチルホルムァ ミド溶液を流量 lml/分でカラム中に (カラム温度 40°C)流して溶離させると!/、う条件 で測定すること力できる。 The number average molecular weight and weight average molecular weight of the polyimide precursor and polyimide are, for example, as follows: GPC apparatus (Shodex (registered trademark) columns KD802, KD803, and KD804) manufactured by JASCO Corporation. It is possible to measure under the following conditions when lithium bromide N, N dimethylformamide solution is eluted at a flow rate of lml / min (column temperature 40 ° C).

[0046] ポリイミド前駆体である前記ポリアミド酸は、一般的に(a)テトラカルボン酸二無水物 化合物と(b)ジァミン化合物とを重縮合して得ることができる。 [0046] The polyamic acid as a polyimide precursor can be generally obtained by polycondensation of (a) a tetracarboxylic dianhydride compound and (b) a diamine compound.

[0047] (a)テトラカルボン酸二無水物化合物は特に限定はなぐ具体例を挙げると、ピロメ リット酸二無水物、 3, 3 ' , 4, 4'—ビフエニルテトラカルボン酸二無水物、 3, 3' , 4, 4'一べンゾフエノンテトラカルボン酸二無水物、 3, 3' , 4, 4'—ジフエニルエーテル テトラカルボン酸二無水物、 3, 3' , 4, 4'—ジフエニルスルホンテトラカルボン酸二無 水物などの芳香族テトラカルボン酸、 1 , 2, 3, 4 シクロブタンテトラカルボン酸二無 水物、 1 , 2 ジメチノレー 1 , 2, 3, 4 シクロフ、、タンテトラ力ノレボン酸二無水物、 1 , 2, 3, 4 テトラメチノレー 1 , 2, 3, 4 シクロブタンテトラ力ノレボン酸二無水物、 1 , 2, 3, 4ーシクロペンタンテトラカルボン酸二無水物、 1 , 2, 3, 4—シクロへキサンテトラカル ボン酸二無水物、 3, 4 ジカノレポキシー 1 , 2, 3, 4 テトラヒドロー 1 ナフタレンコ ハク酸二無水物のような脂環式テトラカルボン酸二無水物、 1 , 2, 3, 4 ブタンテトラ カルボン酸二無水物のような脂肪族テトラカルボン酸二無水物を挙げることができる [0047] (a) Specific examples of tetracarboxylic dianhydride compounds include, but are not limited to, pyromellitic dianhydride, 3, 3 ', 4, 4'-biphenyl tetracarboxylic dianhydride, 3, 3 ', 4, 4' monobenzophenone tetracarboxylic dianhydride, 3, 3 ', 4, 4'-diphenyl ether tetracarboxylic dianhydride, 3, 3', 4, 4 ' —Aromatic tetracarboxylic acids such as diphenylsulfone tetracarboxylic acid dihydrate, 1, 2, 3, 4 cyclobutane tetracarboxylic acid dihydrate, 1, 2 dimethinole 1, 2, 3, 4 Cyclofu, tan tetra Force norevon dianhydride, 1, 2, 3, 4 tetramethylolene 1, 2, 3, 4 cyclobutane tetra force norevon dianhydride, 1, 2, 3, 4-cyclopentanetetracarboxylic dianhydride, 1, 2, 3, 4-Cyclohexanetetracarboxylic dianhydride, 3, 4 Dicanolepoxy 1, 2, 3, 4 Tetrahydro Alicyclic tetracarboxylic dianhydrides such as 1-naphthalene co Haq dianhydride, 1, 2, 3, 4 and aliphatic tetracarboxylic dianhydrides such as Butantetora dianhydride

〇 Yes

これらは、 1種又は 2種以上の化合物を組み合わせて用いることができる。 These can be used alone or in combination of two or more compounds.

[0048] また、(b)ジァミン化合物も特に限定されることはなぐ例えば 2, 4 ジァミノ安息香 酸、 2, 5 ジァミノ安息、香酸、 3, 5 ジァミノ安息、香酸、 4, 6 ジアミノー , 3 ベン ゼンジカルボン酸、 2, 5 ジアミノー 1 , 4 ベンゼンジカルボン酸、ビス(4 アミノー 3—カルボキシフエ二ノレ)エーテル、ビス(4 アミノー 3, 5—ジカルボキシフエニル) エーテル、ビス(4—ァミノ一 3—カルボキシフエ二ノレ)スルホン、ビス(4—ァミノ一 3, 5

ージカルボキシフエ二ノレ)スルホン、 4, 4,ージアミノー 3, 3,ージカルボキシビフエ二 ノレ、 4, 4,一ジァミノ一 3, 3,一ジカルボキシ一 5, 5,一ジメチルビフエニル、 4, 4, 一 ジァミノー 3, 3'—ジカルボキシ 5, 5'—ジメトキシビフエニル、 1 , 4 ビス(4 アミ ノ一 3—カルボキシフエノキシ)ベンゼン、 1 , 3—ビス(4—ァミノ一 3—カルボキシフエ ノキシ)ベンゼン、ビス [4— (4—アミノー 3—カルボキシフエノキシ)フエ二ノレ]スルホン 、ビス [4— (4 ァミノ一 3 カルボキシフエノキシ)フエ二ノレ]プロパン、 2, 2 ビス [4 一(4 アミノー 3 カルボキシフエノキシ)フエ二ノレ]へキサフルォロプロパン、 2, 4— ジァミノフエノール、 3, 5 ジァミノフエノール、 2, 5 ジァミノフエノール、 4, 6 ジァ ミノレゾルシノール、 2, 5 ジァミノハイドロキノン、ビス(3 ァミノ一 4 ヒドロキシフエ 二ノレ)エーテル、ビス(4—アミノー 3—ヒドロキシフエ二ノレ)エーテル、ビス(4—アミノー 3, 5—ジヒドロキシフエ二ノレ)エーテル、ビス(3—アミノー 4—ヒドロキシフエ二ノレ)メタ ン、ビス(4—アミノー 3—ヒドロキシフエニル)メタン、ビス(4—アミノー 3, 5—ジヒドロキ シフエ二ノレ)メタン、ビス(3—アミノー 4—ヒドロキシフエ二ノレ)スルホン、ビス(4—ァミノ —3—ヒドロキシフエ二ノレ)スルホン、ビス(4—アミノー 3, 5—ジヒドロキシフエ二ノレ)ス ルホン、 2, 2 ビス(3 アミノー 4 ヒドロキシフエ二ノレ)へキサフルォロプロパン、 2,[0048] In addition, (b) diamine compounds are not particularly limited. For example, 2,4 diaminobenzoic acid, 2,5 diaminobenzoic acid, perfuming acid, 3,5 diaminobenzoic acid, perfuming acid, 4,6 diamino-, 3 Benzene dicarboxylic acid, 2,5 diamino-1,4 benzenedicarboxylic acid, bis (4 amino-3-carboxyphenyl) ether, bis (4 amino-3,5-dicarboxyphenyl) ether, bis (4-amino) 3-Carboxyphenol) sulfone, bis (4-amino) 3, 5 -Dicarboxyphenyl) sulfone, 4,4, -diamino-3,3, -dicarboxybiphenyl, 4,4,1 diamino-1,3,3,1 dicarboxy-1,5,5,1 dimethylbiphenyl, 4, 4, 1 Diamino 3,3'-dicarboxy 5,5'-dimethoxybiphenyl, 1,4 bis (4 amino 3-carboxyphenoxy) benzene, 1,3-bis (4-amino) 3-carboxyphenoxy) benzene, bis [4- (4-amino-3-carboxyphenoxy) phenol] sulfone, bis [4- (4-aminophenoxy) phenol] propane, 2 , 2 bis [4 (4 amino-3 carboxyphenoxy) phenol] hexafluoropropane, 2,4-diaminophenol, 3,5 diaminophenol, 2,5 diaminophenol , 4, 6 diamino resorcinol, 2, 5 diamino hydride Quinone, bis (3-amino-4-hydroxyphenol), bis (4-amino-3-hydroxyphenol) ether, bis (4-amino-3,5-dihydroxyphenol) ether, bis (3-amino) 4-Hydroxyphenol) methane, bis (4-amino-3-hydroxyphenyl) methane, bis (4-amino-3,5-dihydroxyphenyl) methane, bis (3-amino-4-hydroxyphenol) ) Sulfone, bis (4-amino-3-hydroxyphenyl) sulfone, bis (4-amino-3,5-dihydroxyphenol) sulfone, 2,2bis (3-amino-4-hydroxyphenol) hexane Fluoropropane, 2,

2 ビス(4 アミノー 3 ヒドロキシフエ二ノレ)へキサフルォロプロパン、 2, 2 ビス(4 アミノー 3, 5—ジヒドロキシフエ二ノレ)へキサフルォロプロパン、 4, 4'ージアミノー 3 , 3'—ジヒドロキシビフエニル、 4, 4'ージアミノー 3, 3'—ジヒドロキシー 5, 5'—ジメ チルビフエニル、 4, 4, 一ジァミノ一 3, 3'—ジヒドロキシ一 5, 5, 一ジメトキシビフエ二 ル、 1 , 4—ビス(3—ァミノ一 4—ヒドロキシフエノキシ)ベンゼン、 1 , 3—ビス(3—アミ ノー 4—ヒドロキシフエノキシ)ベンゼン、 1 , 4—ビス(4—アミノー 3—ヒドロキシフエノキ シ)ベンゼン、 1 , 3—ビス(4—アミノー 3—ヒドロキシフエノキシ)ベンゼン、ビス [4— (2 Bis (4 amino-3 hydroxyphenenole) hexafluoropropane, 2, 2 Bis (4 amino-3,5-dihydroxyphenenole) hexafluoropropane, 4, 4'-diamino-3, 3 ' —Dihydroxybiphenyl, 4,4′-diamino-3,3′-dihydroxy-5,5′-dimethylbiphenyl, 4,4,1 diamino-1,3,3′-dihydroxy-1,5,5,1 dimethoxybiphenyl, 1,4-bis (3-amino-4-hydroxyphenoxy) benzene, 1,3-bis (3-amino-4-hydroxyphenoxy) benzene, 1,4-bis (4-amino-3-hydroxy) (Phenoxy) benzene, 1,3-bis (4-amino-3-hydroxyphenoxy) benzene, bis [4- (

3—ァミノ一 4—ヒドロキシフエノキシ)フエ二ノレ]スルホン、ビス [4— (3—ァミノ一 4—ヒ ドロキシフエノキシ)フエ二ノレ]プロパン、 2, 2 ビス [4一(3 アミノー 4ーヒドロキシフ エノキシ)フエニル]へキサフルォロプロパン等フエノール性ヒドロキシ基を有するジァ ミン化合物、 1 , 3—ジアミノー 4 メルカプトベンゼン、 1 , 3—ジアミノー 5—メルカプト ベンゼン、 1 , 4ージアミノー 2 メルカプトベンゼン、ビス(4 アミノー 3 メルカプトフ ェニノレ)エーテル、 2, 2 ビス(3 アミノー 4 メルカプトフエ二ノレ)へキサフルォロプ

口パン等チォフエノール基を有するジァミン化合物、 1 , 3—ジァミノベンゼンー4ース ノレホン酸、 1 , 3 ジァミノベンゼン 5 スノレホン酸、 1 , 4ージァミノベンゼン 2— スルホン酸、ビス(4ーァミノベンゼン 3—スルホン酸)エーテル、 4, 4,ージアミノビ フエ二ノレ一 3, 3, 一ジスルホン酸、 4, 4, 一ジァミノ一 3, 3, 一ジメチルビフエニル一 6 , 6 ' ジスルホン酸等スルホン酸基を有するジァミン化合物が挙げられる。また、 p— フエ二レンジァミン、 m フエ二レンジァミン、 4, 4 'ーメチレン ビス(2, 6 ェチノレア 二リン)、 4, 4 ' メチレン一ビス(2 イソプロピル一 6—メチルァニリン)、 4, 4 '—メチ レン一ビス(2, 6 ジイソプロピルァニリン)、 2, 4, 6 トリメチルー 1 , 3 フエ二レン ジァミン、 2, 3, 5, 6 テトラメチルー 1 , 4 フエ二レンジァミン、 o トリジン、 m トリ ジン、 3, 3 ' , 5, 5 '—テトラメチルベンジジン、ビス [4— (3—アミノフエノキシ)フエ二 ノレ]スルホン、 2, 2 ビス [4— (3 アミノフエノキシ)フエ二ノレ]プロパン、 2, 2 ビス [ 4一(3—アミノフエノキシ)フエ二ノレ]へキサフルォロプロパン、 4, 4 'ージアミノー 3, 3 ' 一ジメチルジシクロへキシルメタン、 4, 4 'ージアミノジフエニルエーテル、 3, 4—ジ アミノジフエニルエーテル、 4, 4 'ージアミノジフエニルメタン、 2, 2 ビス(4ーァニリノ )へキサフルォロプロパン、 2, 2 ビス(3 ァニリノ)へキサフルォロプロパン、 2, 2— ビス(3—アミノー 4—トルイノレ)へキサフルォロプロパン、 1 , 4—ビス(4—アミノフエノ キシ)ベンゼン、 1 , 3—ビス(4—アミノフエノキシ)ベンゼン、ビス [4— (4—アミノフエノ キシ)フエ二ノレ]スルホン、 2, 2 ビス [4— (4 アミノフエノキシ)フエ二ノレ]プロパン、 2, 2 ビス [4一(4 アミノフエノキシ)フエ二ノレ]へキサフルォロプロパン等のジァミン 化合物を挙げることが出来る。 3-Amino-1-4-hydroxyphenoxy) phenone] sulfone, bis [4- (3-Amino-4-hydroxyphenoxy) phenol] propane, 2,2 bis [4-1- (3-amino-) 4-hydroxyphenoxy) phenyl] hexafluoropropane and other diamino compounds having a phenolic hydroxy group, 1,3-diamino-4-mercaptobenzene, 1,3-diamino-5-mercaptobenzene, 1,4-diamino-2 mercaptobenzene Bis (4 amino-3 mercaptophenol) ether, 2, 2 bis (3 amino-4-mercaptophenol) hexafluorop Diamine compounds having thiophenolic groups such as oral bread, 1,3-diaminobenzene-4-ose norphonic acid, 1,3-diaminobenzene 5 sulphonic acid, 1,4-diaminobenzene 2-sulfonic acid, bis (4-aminominobenzene 3-sulfonic acid) ether, 4, 4, diaminobiphenyl 3, 3, monodisulfonic acid, 4, 4, monodiamine 3, 3, monodimethylbiphenyl 1, 6, 6 'disulfonic acid, etc. Diamine compounds having Also, p-phenylenediamine, m-phenylenediamine, 4,4'-methylenebis (2,6 ethenorea diphosphorus), 4,4 'methylene monobis (2 isopropyl-6-methylaniline), 4, 4'-methi Renbis (2, 6 diisopropylaniline), 2, 4, 6 trimethyl-1,3 phenylenediamine, 2, 3, 5,6 tetramethyl-1,4 phenylenediamine, o tolidine, m tolidine, 3, 3 ', 5, 5'-tetramethylbenzidine, bis [4— (3-aminophenoxy) phenol] sulfone, 2,2bis [4— (3aminophenoxy) phenol] propane, 2,2bis [4 1- (3-aminophenoxy) phenyl] hexafluoropropane, 4,4'-diamino-3,3'-dimethyldimethylcyclohexyl, 4,4'-diaminodiphenyl ether, 3,4-diaminodiph Enil ether, 4, 4 '- Aminodiphenylmethane, 2, 2bis (4-anilino) hexafluoropropane, 2,2bis (3anilino) hexafluoropropane, 2,2-bis (3-amino-4-toluinore) hexa Fluoropropane, 1,4-bis (4-aminophenoxy) benzene, 1,3-bis (4-aminophenoxy) benzene, bis [4- (4-aminophenoxy) phenylene] sulfone, 2,2bis Examples thereof include diamine compounds such as [4- (4 aminophenoxy) phenol] propane and 2,2bis [4 (4-aminophenoxy) phenol] hexafluoropropane.

これらは、 1種又は 2種以上の化合物を組み合わせて用いることができる。 These can be used alone or in combination of two or more compounds.

[0049] 本発明で用いられるポリアミド酸が(a)テトラカルボン酸二無水物化合物と (b)ジアミ ン化合物から製造される場合、両化合物の配合比、すなわち < (b)ジァミン化合物の 総モル数/ (a)テトラカルボン酸二無水物化合物の総モル数〉は 0. 7乃至 1. 2であ ること力 S望ましい。通常の重縮合反応同様、このモル比が 1に近いほど生成するポリ アミド酸の重合度は大きくなり分子量が増加する。 [0049] When the polyamic acid used in the present invention is produced from (a) a tetracarboxylic dianhydride compound and (b) a diamine compound, the compounding ratio of both compounds, that is, <(b) the total mole of the diamine compound The number / (a) the total number of moles of tetracarboxylic dianhydride compound> is preferably 0.7 to 1.2. As in the normal polycondensation reaction, the closer the molar ratio is to 1, the higher the degree of polymerization of the polyamic acid produced and the higher the molecular weight.

[0050] また、ジァミン化合物を過剰に用いて重合した際、残存するポリアミド酸の末端アミ ノ基に対してカルボン酸無水物を反応させ末端アミノ基を保護することもできる。

このようなカルボン酸無水物の例としてはフタル酸無水物、トリメリット酸無水物、無 水マレイン酸、ナフタル酸無水物、水素化フタル酸無水物、メチルー 5—ノルボルネ ンー 2, 3 ジカルボン酸無水物、無水ィタコン酸、テトラヒドロフタル酸無水物等を挙 げること力 Sでさる。 [0050] When the polymerization is carried out using an excess of the diamine compound, the terminal amino group can be protected by reacting the terminal amino group of the remaining polyamic acid with a carboxylic acid anhydride. Examples of such carboxylic anhydrides include phthalic anhydride, trimellitic anhydride, anhydrous maleic acid, naphthalic anhydride, hydrogenated phthalic anhydride, methyl-5-norbornene-2,3 dicarboxylic anhydride Power, itaconic anhydride, tetrahydrophthalic anhydride, etc.

[0051] ポリアミド酸の製造において、ジァミン化合物とテトラカルボン酸二無水物化合物と の反応の反応温度は— 20乃至 150°C、好ましくは— 5乃至 100°Cの任意の温度を 選択すること力できる。高分子量のポリアミド酸を得るには、反応温度 5°C乃至 40°C、 反応時間 1時間乃至 48時間の範囲にて適宜選択する。低分子量で保存安定性の 高く部分的にイミド化されたポリアミド酸を得るには反応温度 40°C乃至 90°C、反応時 間 10時間以上から選択することがより好ましい。 [0051] In the production of the polyamic acid, the reaction temperature of the reaction between the diamine compound and the tetracarboxylic dianhydride compound can be selected from any temperature of -20 to 150 ° C, preferably -5 to 100 ° C. it can. In order to obtain a high molecular weight polyamic acid, the reaction temperature is appropriately selected within the range of 5 ° C to 40 ° C and the reaction time of 1 hour to 48 hours. In order to obtain a partially imidized polyamic acid having a low molecular weight and high storage stability, it is more preferable to select from a reaction temperature of 40 ° C to 90 ° C and a reaction time of 10 hours or more.

また、末端アミノ基を酸無水物で保護する場合の反応温度は— 20乃至 150°C、好 ましくは 5乃至 100°Cの任意の温度を選択することができる。 The reaction temperature when the terminal amino group is protected with an acid anhydride can be selected from -20 to 150 ° C, preferably 5 to 100 ° C.

[0052] ジァミン化合物とテトラカルボン酸二無水物化合物の反応は溶剤中で行なうことが できる。その際に使用できる溶剤としては、 N, N ジメチルホルムアミド、 N, N ジメ チルァセトアミド、 N メチルピロリドン、 N ビュルピロリドン、 N メチルカプロラクタ ム、ジメチルスルホキシド、テトラメチル尿素、ピリジン、ジメチルスルホン、へキサメチ ノレスルホキシド、 m クレゾール、 γ ブチロラタトン、酢酸ェチル、酢酸ブチル、乳 酸ェチル、 3 メトキシプロピオン酸メチル、 2 メトキシプロピオン酸メチル、 3 メト キシプロピオン酸ェチル、 2 メトキシプロピオン酸ェチル、 3 エトキシプロピオン酸 ェチル、 2—エトキシプロピオン酸ェチル、エチレングリコールジメチルエーテル、ジ エチレングリコーノレジメチノレエーテノレ、ジエチレングリコーノレジェチノレエーテノレ、ジェ チレングリコーノレメチノレエチノレエーテノレ、プロピレングリコーノレジメチノレエーテノレ、ジ プロピレングリコーノレジメチノレエーテノレ、エチレングリコーノレモノメチノレエーテノレ、ェ チレングリコールモノェチルエーテル、ジエチレングリコールモノメチルエーテル、ジ エチレングリコーノレモノェチノレエーテノレ、プロピレングリコーノレモノメチノレエーテノレ、 プロピレングリコーノレモノェチノレエーテノレ、ジプロピレングリコーノレモノメチノレエーテ ノレ、ジプロピレングリコーノレモノェチノレエーテノレ、プロピレングリコーノレモノメチノレエー テノレアセテート、カノレビトーノレアセテート、ェチノレセロソノレブアセテート、シクロへキサ

ノン、メチルェチルケトン、メチルイソブチルケトン、 2—ヘプタノン等を挙げることがで きる。これらは単独でも、混合して使用しても良い。さらに、ポリアミド酸を溶解しない 溶剤であっても、重合反応により生成したポリアミド酸が析出しない範囲で、上記溶 剤に混合して使用してもよい。 [0052] The reaction of the diamine compound and the tetracarboxylic dianhydride compound can be carried out in a solvent. Solvents that can be used include N, N dimethylformamide, N, N dimethylacetamide, N methyl pyrrolidone, N butyl pyrrolidone, N methyl caprolactam, dimethyl sulfoxide, tetramethyl urea, pyridine, dimethyl sulfone, hexamethy Nolesulphoxide, m Cresol, γ-butyrolatatone, ethyl acetate, butyl acetate, ethyl lactic acid, methyl 3 methoxypropionate, methyl 2 methoxypropionate, 3 ethyl methoxypropionate, 2 ethyl methoxypropionate, 3 ethyl ethoxypropionate, 2-Ethoxypropionate, Ethylene glycol dimethyl ether, Diethylene glyconoresin methinoleatenore, Diethyleneglycoleno retino enoenore, Jetylene glucono retino enoino ethinore Nore, Propylene Glycono Resin Methylenoateol, Dipropylene Glycono Resin Methylenoateol, Ethylene Glycolanol Monomethinoleateol, Ethylene Glycol Monoethyl Ether, Diethylene Glycol Monomethyl Ether, Diethylene Glycol Nole Monoethyl Acetate , Propylene glycol monomethino ethenore, propylene glycol mono methino enoate, dipropylene glycol mono methino enoate, dipropylene glycol mono methino enoate, propylene glycol mono methinoate tenole acetate , Canolebitonoreacetate, ethinorecellosonolev acetate, cyclohexa Non, methyl ethyl ketone, methyl isobutyl ketone, 2-heptanone and the like can be mentioned. These may be used alone or in combination. Further, even a solvent that does not dissolve the polyamic acid may be used by mixing with the above-mentioned solvent as long as the polyamic acid generated by the polymerization reaction does not precipitate.

[0053] このようにして得られたポリアミド酸を含む溶液は、ポジ型感光性樹脂組成物の溶 液の調製にそのまま用いることができる。また、ポリアミド酸を水、メタノール、エタノー ル等の貧溶剤に沈殿単離させて回収してから用いることもできる。 [0053] The solution containing the polyamic acid thus obtained can be used as it is for the preparation of a solution of the positive photosensitive resin composition. In addition, the polyamic acid can be used after being isolated by precipitation in a poor solvent such as water, methanol, or ethanol and recovered.

このようにして得られたポリアミド酸はカルボキシル基をエステル化し、ポリアミド酸ェ ステノレとして使用することもできる。 The polyamic acid thus obtained can be esterified with a carboxyl group and used as a polyamic acid ester.

このようにして得られたポリアミド酸は単独で用いても上述のアルカリ可溶性樹脂と 同時に用いてもよい。 The polyamic acid thus obtained may be used alone or at the same time as the alkali-soluble resin described above.

[0054] また、本発明においては、任意のポリイミドを用いることができる。本発明に用いるポ リイミドとは前記ポリアミド酸などのポリイミド前駆体を化学的又は熱的に 50%以上イミ ド化させたものである。これらのポリイミドにはポリアミドイミド、ポリエーテルイミドといつ た共重合体も含む。 In the present invention, any polyimide can be used. The polyimide used in the present invention is obtained by chemically or thermally immobilizing 50% or more of a polyimide precursor such as polyamic acid. These polyimides include polyamideimides, polyetherimides and copolymers.

本発明で用いるポジ型感光性樹脂組成物中のポリイミドは、アルカリ溶解性を与え るためにカルボキシル基もしくはフエノール性ヒドロキシ基を有すること、或いは、熱又 は酸の作用によりカルボン酸又はフエノール性ヒドロキシ基を生成する基を有すること が好ましい。 The polyimide in the positive photosensitive resin composition used in the present invention has a carboxyl group or a phenolic hydroxy group to impart alkali solubility, or a carboxylic acid or phenolic hydroxy group by the action of heat or acid. It preferably has a group that forms a group.

ポリイミドへのカルボキシル基やフエノール性ヒドロキシ基の導入方法は、カルボキ シル基又はフエノール性ヒドロキシ基を有するモノマーを用いる方法、カルボキシル 基又はフエノール性ヒドロキシ基を有する酸無水物でァミン末端を封止する方法、或 いは、ポリイミド前駆体をイミド化する際にイミド化率を 99%以下にする方法等が用い られる。 The method of introducing a carboxyl group or a phenolic hydroxy group into polyimide is a method using a monomer having a carboxyl group or a phenolic hydroxy group, or a method of sealing an amine end with an acid anhydride having a carboxyl group or a phenolic hydroxy group. Alternatively, a method of making the imidization rate 99% or less when imidizing the polyimide precursor is used.

又、ポリイミドへの熱又は酸の作用によるカルボン酸又はフエノール性ヒドロキシ基 を生成する基の導入方法は、熱又は酸の作用によりカルボキシル基又はフエノール 性ヒドロキシ基生成するモノマーを用いる方法、あらかじめ導入したカルボキシル基 又はフエノール性ヒドロキシ基もしくはイミド化後のカルボン酸残基に熱又は酸の作用

により解離する基を反応させる方法がある。 Moreover, the introduction method of the group which produces | generates the carboxylic acid or phenolic hydroxy group by the effect | action of a heat | fever or an acid to a polyimide is the method using the monomer which produces | generates a carboxyl group or a phenolic hydroxy group by the effect | action of a heat | fever or an acid, and introduce | transduced beforehand. Action of heat or acid on carboxyl group or phenolic hydroxy group or carboxylic acid residue after imidization There is a method of reacting a group that dissociates by.

このようなポリイミドは上述のポリイミド前駆体を合成した後、化学イミド化もしくは熱 イミド化を行うことで得ることができる。 Such a polyimide can be obtained by synthesizing the above polyimide precursor and then performing chemical imidization or thermal imidization.

化学イミド化の方法としては一般的にポリイミド前駆体溶液に過剰の無水酢酸およ びピリジンを添加し室温から 100°Cで反応させる方法が用いられる。また、熱イミド化 の方法としては一般的に、ポリイミド前駆体溶液を温度 180°C乃至 250°Cで脱水しな 力 ¾加熱する方法が用いられる。 As a method of chemical imidization, generally, an excess acetic anhydride and pyridine are added to a polyimide precursor solution and reacted at room temperature to 100 ° C. As a method for thermal imidization, generally, a method in which a polyimide precursor solution is heated at a temperature of 180 ° C. to 250 ° C. without being dehydrated is used.

[0055] このようにして得られたポリイミドは単独で用いても上述の他のアルカリ可溶性樹脂( 例えば特定共重合体など)と同時に用いてもよい。 [0055] The polyimide thus obtained may be used alone or at the same time as other alkali-soluble resins (for example, specific copolymers) described above.

[0056] [ (B)成分] [0056] [Component (B)]

(B)成分は、 1分子中二個以上のビュルエーテル基を有する化合物である。これは 、慣用のプリベータ温度で (A)成分のアルカリ可溶性樹脂と熱架橋することができる ようなビュルエーテル基を 1分子中二個以上有する化合物であればよぐその種類及 び構造につ!/、て特に限定されるものでな!/、。 Component (B) is a compound having two or more butyl ether groups in one molecule. This is the type and structure of any compound that has two or more butyl ether groups in one molecule that can be thermally crosslinked with the alkali-soluble resin (A) at a conventional prebeta temperature! /, Not particularly limited!

[0057] この(B)成分の化合物は、(A)成分のアルカリ可溶性樹脂との熱架橋の後、光酸 発生剤の存在下での露光により生じた酸により、(A)成分のアルカリ可溶性樹脂から 分離 (脱架橋)し、その後アルカリ現像液を用いた現像により(A)成分のアルカリ可溶 性樹脂ともに除去される。従って、この種の化合物としては、一般にビュルエーテル 型化学増幅型レジストの成分に使用されるビュルエーテル系化合物などが適用され うる。斯カ、る化合物の使用の場合、該化合物の配合量を変えて熱架橋密度を調整す ることにより、形成される画像を制御することができるという利点を有する。 [0057] The compound of component (B) is obtained by subjecting the component (A) to alkali-solubility due to the acid generated by exposure in the presence of a photoacid generator after thermal crosslinking with the alkali-soluble resin of component (A). After separation (decrosslinking) from the resin, development with an alkaline developer removes both the alkali-soluble resin (A). Therefore, as this type of compound, a bull ether compound generally used as a component of a bull ether type chemically amplified resist can be applied. The use of such a compound has the advantage that the formed image can be controlled by adjusting the thermal crosslinking density by changing the compounding amount of the compound.

[0058] そして、(B)成分の化合物としては、上記ビュルエーテル系化合物の中でも、特に 式(1)及び式(2)で表される化合物が、露光部において残膜ゃ残渣なく現像される 点で、好ましい。 [0058] As the compound of the component (B), among the above butyl ether compounds, the compounds represented by the formulas (1) and (2) are particularly developed without residual film in the exposed area. In terms, it is preferable.

[0059] [化 1] [0059] [Chemical 1]

[0060] (式中、 nは 2乃至 10の整数、 kは 1乃至 10の整数であり、 R1は n価の有機基を表す。 [Wherein, n is an integer of 2 to 10, k is an integer of 1 to 10, and R 1 represents an n-valent organic group.

[0061] [化 2] [0061] [Chemical 2]

[0062] (式中、 mは 2乃至 10の整数を表す。 ) [In the formula, m represents an integer of 2 to 10.]

[0063] 式(1)の nは、 1分子中のビュルエーテル基の数を表すが、 nとしては、 2乃至 4の整 数がより好ましい。そして、式(2)の mも一分子中のビュルエーテル基の数を表すが 、 mとしては、 2乃至 4の整数がより好ましい。 [0063] In formula (1), n represents the number of butyl ether groups in one molecule, and n is more preferably an integer of 2 to 4. M in the formula (2) also represents the number of butyl ether groups in one molecule, and m is more preferably an integer of 2 to 4.

[0064] 前記式(1)及び前記式(2)で表される化合物の具体例としては、ビス(4 (ビニ口 キシメチル)シクロへキシルメチル)グルタレート、トリ(エチレングリコール)ジビュルェ ーテノレ、アジピン酸ジビニノレエステノレ、ジエチレングリコーノレジビニノレエーテノレ、トリス ート、ビス(4 (ビニ口キシ)ブチルイソフタレート、及び 1 , 4ーシクロへキサンジメタノ ールジビュルエーテル等のシクロへキサンジメタノールジビュルエーテル等が挙げら れる。 [0064] Specific examples of the compounds represented by the formula (1) and the formula (2) include bis (4 (vinyloxymethyl) cyclohexylmethyl) glutarate, tri (ethylene glycol) dibutyrenole, dibiadipate Cyclohexane dimethanol dibulle ethers such as ninoreestenole, diethyleneglyconoresininoreethenole, tristoate, bis (4 (vinyloxy) butyl isophthalate, and 1,4-cyclohexanedimethanol dibule ether Etc.

[0065] また、(B)成分の化合物は、(A)成分 100質量部に対して、 1乃至 80質量部、好ま しくは 5乃至 40質量部の割合で使用される。 (B)成分の化合物の使用量が前記範囲 の下限未満の過少量であると、未露光部における膜減りが顕著となり形成されるバタ ーンのレリーフ形状が不良になる。一方、(B)成分の化合物の使用量が前記範囲の 上限を超える過多量であると、膜の感度が大きく低下し、現像後にパターン間の残渣 が生じるようになる。 [0065] The compound of component (B) is used in a proportion of 1 to 80 parts by weight, preferably 5 to 40 parts by weight, per 100 parts by weight of component (A). When the amount of the component (B) compound used is an excessive amount less than the lower limit of the above range, the reduction of the film in the unexposed area becomes remarkable and the formed relief pattern of the pattern becomes poor. On the other hand, if the amount of the component (B) compound used exceeds the upper limit of the above range, the sensitivity of the film is greatly reduced, and residues between patterns are generated after development.

[0066] [ (C)成分] [0066] [(C) component]

(C)成分は、ポストベータにより(A)成分と架橋反応する化合物であり、好適には、 1分子中二個以上のブロックイソシァネート基を有する化合物が用いられる。これは、 (B)成分の化合物との間で熱架橋された或いは更にそれとの間で脱架橋された (A)

成分のアルカリ可溶性樹脂からなる膜に対して、例えば慣用のポストベータ温度で熱 硬化することができるようなブロックイソシァネート基を 1分子中二個以上有する化合 物であればよぐその種類及び構造について特に限定されるものでない。 Component (C) is a compound that undergoes a cross-linking reaction with component (A) by post-beta, and preferably a compound having two or more block isocyanate groups in one molecule. This is either thermally cross-linked with the compound of component (B) or further de-crosslinked with (A) For example, if it is a compound having two or more block isocyanate groups in one molecule that can be thermally cured at a conventional post-beta temperature with respect to a film made of an alkali-soluble resin as a component, the kind and The structure is not particularly limited.

[0067] この(C)成分の化合物は、イソシァネート基(一 NCO)が適当な保護基によりブロッ クされたブロックイソシァネート基を 1分子中二個以上有し、そして熱硬化の際の高温 に曝されると、保護基 (ブロック部分)が熱解離して外れ、生じたイソシァネート基を介 して (A)成分のアルカリ可溶性樹脂中の熱硬化のための官能基(例えばフエノール 性ヒドロキシ基以外のヒドロキシ基及び活性水素を有するアミノ基)相互の間で架橋 反応が進行するものであり、例えば、式(3) [0067] The compound of component (C) has two or more blocked isocyanate groups in which one or more isocyanate groups (one NCO) are blocked by an appropriate protecting group, and is heated at high temperature during thermal curing. Exposure to the functional group (for example, phenolic hydroxy group) for thermal curing in the alkali-soluble resin of component (A) via the generated isocyanate group. Other than the hydroxy group and the amino group having active hydrogen), the crosslinking reaction proceeds between, for example, the formula (3)

[0068] [化 3] [0068] [Chemical 3]

R2— C— N— - - f \ R 2 — C— N—--f \

II I ^ (3) II I ^ (3)

O H O H

[0069] (式中、 R2はブロック部の有機基を表す。)で表される基を 1分子中二個以上 (この基 は同一のものでも、また各々異なってレ、るものでもよ!/、)有する化合物が挙げられる。 [0069] (wherein R 2 represents an organic group in the block part), two or more groups in one molecule (this group may be the same or different from each other). ! /,) Are included.

[0070] 1分子中二個以上のブロックイソシァネート基を有する(C)成分の化合物は、例え ば 1分子中二個以上のイソシァネート基を有する化合物に対して適当なブロック剤を 作用せしめることにより、得ること力 Sでさる。 [0070] For the compound of component (C) having two or more blocked isocyanate groups in one molecule, for example, an appropriate blocking agent is allowed to act on a compound having two or more isocyanate groups in one molecule. With the power S to get.

[0071] 1分子中二個以上のイソシァネート基を有する化合物としては、例えば、イソホロン ジイソシァネート、 1 , 6—へキサメチレンジイソシァネート、メチレンビス(4ーシクロへ キシルイソシァネート)、トリメチルへキサメチレンジイソシァネート等、又はそれらの二 量体、三量体、或いは、これらとジオール類、トリオール類、ジァミン類、トリァミン類と の反応物が挙げられる。 [0071] Examples of the compound having two or more isocyanate groups in one molecule include, for example, isophorone diisocyanate, 1,6-hexamethylene diisocyanate, methylene bis (4-cyclohexyl isocyanate), and trimethyl hexane methacrylate. Examples thereof include diisocyanate and the like, or dimers and trimers thereof, or a reaction product of these with diols, triols, diamines, and triamines.

[0072] ブロック剤としては、例えば、メタノール、エタノール、イソプロパノール、 n—ブタノ一 ノレ、 2—エトキシへキサノール、 2 - N, N—ジメチルァミノエタノール、 2—エトキシェ タノール、シクロへキサノール等のアルコール類、フエノール、 o—二トロフエノール、 p —クロ口フエノーノレ、 o—、 m—又は p—タレゾール等のフエノール類、 ε —力プロラタ タム等のラタタム類、アセトンォキシム、メチルェチルケトンォキシム、メチルイソブチ ノレケトンォキシム、シクロへキサノンォキシム、ァセトフエノンォキシム、ベンゾフエノン

ォキシム等のォキシム類、ピラゾール、 3, 5—ジメチルビラゾール、 3—メチルピラゾ 一ノレ、などのピラゾール類、ドデカンチオール、ベンゼンチオール等のチオール類力 S 挙げられる。 [0072] Examples of the blocking agent include alcohols such as methanol, ethanol, isopropanol, n-butanol, 2-ethoxyhexanol, 2-N, N-dimethylaminoethanol, 2-ethoxyethanol, and cyclohexanol. , Phenol, o-nitrophenol, p—black mouth phenol, o-, m- or p-taresol and other phenols, ε — force prolatata and other ratatams, acetone oxime, methyl ethyl ketone oxime , Methyl isobuteno ketone ketone, cyclohexanone oxime, acetophenone oxime, benzophenone Examples include oximes such as oxime, pyrazoles such as pyrazole, 3,5-dimethylbiazole, and 3-methylpyrazo monole, and thiols such as dodecanethiol and benzenethiol.

[0073] (C)成分の化合物は、ポストベータ温度のようなより高温では、ブロック部分の熱解 離が生じイソシァネート基を介して架橋反応が進行するものである力 S、プリベータ温 度のようなより低温では、イソシァネート基による架橋が進行しないものとするために、 ブロック部分の熱解離の温度がプリベータ温度よりも相当に高いもの、例えば 120°C 乃至 230°Cであるものが(C)成分の化合物として特に好まし!/、。 [0073] The compound of component (C) has a force S that causes the thermal release of the block portion and a crosslinking reaction proceeds through the isocyanate group at higher temperatures such as the post-beta temperature, such as the force S and the pre-beta temperature. In order to prevent crosslinking by isocyanate groups from proceeding at lower temperatures, the temperature of the thermal dissociation of the block portion is considerably higher than the prebeta temperature, for example, 120 ° C to 230 ° C (C) Especially preferred as a component compound!

[0074] 斯かる(C)成分の化合物としては、例えば次の具体例が挙げられる。 [0074] Examples of the compound of the component (C) include the following specific examples.

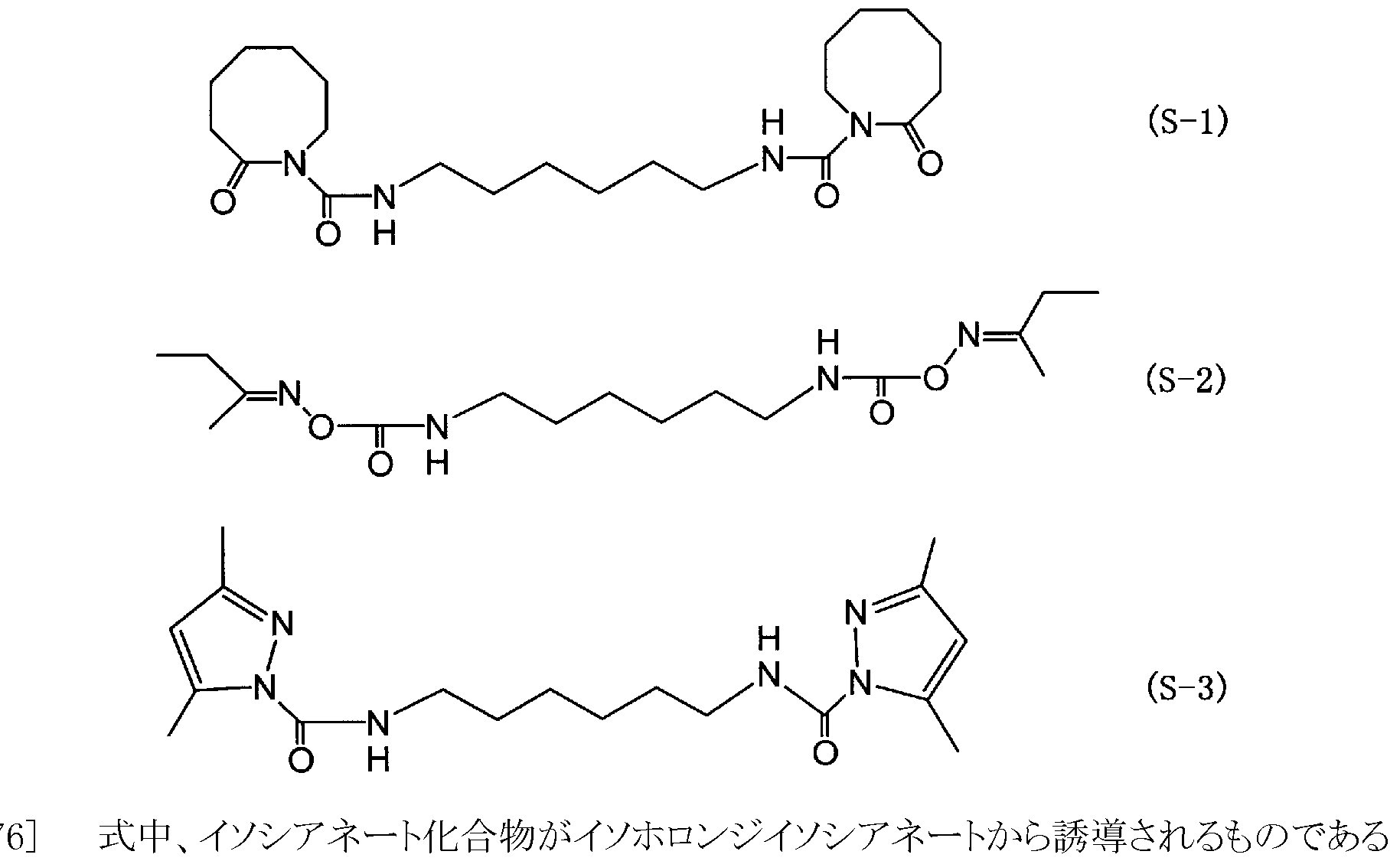

[0075] [化 4] [0075] [Chemical 4]

(C)成分の化合物が、耐熱性、塗膜性の点からより好ましぐ斯様な化合物としては、 以下のものが挙げられる。 Examples of such a compound that the compound (C) is more preferred from the viewpoint of heat resistance and coating properties include the following.

下記式中の Rは有機基を表す。 R in the following formula represents an organic group.

[0077] [化 5]

[0077] [Chemical 5]

冒 SU〕078 Prop SU] 078

[0079] [化 7]

[0079] [Chemical 7]

本発明において、(C)成分の化合物は一種単独で用いてもよぐまた二種以上を 組合せて用いてもよい。

[0081] また、(C)成分の化合物は、(A)成分 100質量部に対して、 3乃至 70質量部、好ま しくは 5乃至 40質量部の割合で使用される。 (C)成分の化合物の使用量が前記範囲 の下限未満の過少量であると、熱硬化が不十分となって満足な硬化膜が得られず、 一方、(C)成分の化合物の使用量が前記範囲の上限を超える過多量であると、現像 が不十分となり、現像残渣を生じるようになる。 In the present invention, the compound of component (C) may be used alone or in combination of two or more. [0081] The compound of component (C) is used in a proportion of 3 to 70 parts by weight, preferably 5 to 40 parts by weight, per 100 parts by weight of component (A). When the amount of the component (C) compound used is an excessive amount less than the lower limit of the above range, the thermosetting is insufficient and a satisfactory cured film cannot be obtained. On the other hand, the amount of the compound (C) component used If the amount exceeds the upper limit of the above range, the development becomes insufficient and a development residue is generated.

[0082] [ (D)成分] [0082] [Component (D)]

(D)成分は、光酸発生剤(PAGともいう)である。これは、露光に使用される光の照 射によって直接もしくは間接的に酸 (スルホン酸類、カルボン酸類など)を発生する物 質であり、斯様な性質を有するものであれば、その種類及び構造などは特に限定さ れるものでない。 Component (D) is a photoacid generator (also referred to as PAG). This is a substance that generates acids (sulfonic acids, carboxylic acids, etc.) directly or indirectly by the irradiation of light used for exposure. If it has such properties, its type and structure Etc. are not particularly limited.

[0083] (D)成分の光酸発生剤としては、例えば、ジァゾメタン化合物、ォニゥム塩化合物、 スルホンイミド化合物、ジスルホン系化合物、スルホン酸誘導体化合物、ニトロべンジ ル化合物、ベンゾイントシレート化合物、鉄アレーン錯体、ハロゲン含有トリアジン化 合物、ァセトフヱノン誘導体化合物、及び、シァノ基含有ォキシムスルホネート化合物 などが挙げられる。従来知られ又は従来から使用されている光酸発生剤は、いずれ も、特に限定されることなぐ本発明において適用することができる。なお、本発明に おいて、(D)成分の光酸発生剤は、一種単独で用いてもよぐまた二種以上を組合 わせて用いてもよい。 [0083] Examples of the photoacid generator of component (D) include diazomethane compounds, onium salt compounds, sulfonimide compounds, disulfone compounds, sulfonic acid derivative compounds, nitrobenzyl compounds, benzoin tosylate compounds, iron arenes. Examples include complexes, halogen-containing triazine compounds, acetophenone derivative compounds, and cyano group-containing oxime sulfonate compounds. Any conventionally known or conventionally used photoacid generator can be applied in the present invention without any particular limitation. In the present invention, the photoacid generator of component (D) may be used alone or in combination of two or more.

[0084] 斯かる光酸発生剤の具体例としては、以下のものが挙げられる。尤も、これらの化 合物は、極めて多数の適用可能な光酸発生剤の中の少数例であり、当然それらに 限定されるものでない。 [0084] Specific examples of such a photoacid generator include the following. However, these compounds are a few examples of a very large number of applicable photoacid generators, and of course are not limited thereto.

[0085] [化 8]

[0085] [Chemical 8]

ジフエ二ルョードニゥムクロリド、ジフエ二ルョードニゥムトリフルォロメタンスルホネー ト、ジフエ二ルョードニゥムメシレート、ジフエ二ルョードニゥムトシレート、ジフエニノレョ 一ドニゥムブ口ミド、ジフエニノレョードニゥムテトラフノレオロボレート、ジフエニノレョード ニゥムへキサフルォロアンチモネート、ジフエニノレョードニゥムへキサフノレオロアルセ ネート、ビス(p— tert—ブチルフエ二ノレ)ョードニゥムへキサフルォロホスフェート、ビ ス(p— tert—ブチルフェニル)ョ一ドニゥムメシレート、ビス(p— tert—ブチルフエ二 ノレ)ョードニゥムトシレート、ビス(p— tert—ブチルフエ二ノレ)ョードニゥムトリフルォロメ タンスノレホネート、ビス(p— tert—ブチルフエ二ノレ)ョードニゥムテトラフノレォロボレー ト、ビス(p— tert—ブチルフエニル)ョードニゥムクロリド、ビス(p—クロ口フエニル)ョ

一ドニゥムクロリド、ビス(p クロ口フエニル)ョードニゥムテトラフルォロボレート、トリフ ェニノレスノレホニゥムクロリド、トリフエニノレスノレホニゥムブ口ミド、トリフエニノレスノレホニゥ ムトリフルォロメタンスルホネート、トリ(p メトキシフエ二ノレ)スルホ二ゥムテトラフルォ ロボレート、トリ(p メトキシフエ二ノレ)スルホニゥムへキサフルォロホスホネート、トリ(p エトキシフエニノレ)スノレホニゥムテトラフノレオロボレート、トリフエニノレホスホニゥムクロ リド、トリフエニルホスホニゥムブロミド、トリ(p メトキシフエニル)ホスホニゥムテトラフ ノレオロボレート、トリ(p メトキシフエニノレ)ホスホニゥムへキサフノレオ口ホスホネート、 トリ(p エトキシフエ二ノレ)ホスホニゥムテトラフルォロボレート、 Diphenyl chloride, difluoride trifluoromethanesulfonate, diphenylmethane mesylate, diphenylfluorate, disulfide, disulfide Ninoredonium tetrafunoleroborate, diphenenoreo nitrohexafluoroantimonate, diphenenoreo neumohexafluororeroarsenate, bis (p-tert-butylphenol Ninore) Hexafluorophosphate, Bis (p-tert-Butylphenyl) iodonymesylate, Bis (p-tert-Butylphenol) Jodonum Tosylate, Bis (p- tert-Butylphenol) Fluoromethane Tansnolephonate, Bis (p-tert-Butylphenol) Oloborate, bis (p-tert-butylphenyl) chloride, bis (p-chlorophenyl) 1donum chloride, bis (p-phloylphenyl) ododne tetrafluoroborate, triphenylenoles norehonum chloride, triphenenolesnorehonombu mouthmid, trifenenores norehon mutrifl Fluoromethanesulfonate, tri (p methoxyphenol) sulfonium tetrafluoroborate, tri (p methoxyphenol) sulfohexafluorophosphonate, tri (p ethoxyphenol) sulephonium tetrafluororeborate, triphenyl Norephosphonium chloride, Triphenyl phosphonium bromide, Tri (p methoxyphenyl) phosphonium tetrafu Noreloborate, Tri (p methoxyphenyl) phosphonium hexafunoleo phosphonate, Tri (p ethoxyphenyl) phosphonium tetra Ruoroboreto,

[化 9] [Chemical 9]

) )

[0092] [化 14]

[0092] [Chemical 14]

式 (64) Formula (64)

式 (66) Formula (66)

[0094] [化 16] [0094] [Chemical 16]

[0095] また、(D)成分の光酸発生剤は、(A)成分のアルカリ可溶性樹脂 100質量部

して 0. 5乃至 50質量部、好ましくは 1乃至 30質量部の割合で使用される。 (D)成分 の光酸発生剤の使用量が前記範囲の下限未満の過少量であると、露光の際、熱架 橋された(B)成分の化合物の (A)成分のアルカリ可溶性樹脂からの解離が進行せ ず、所望のパターンのレリーフが得られにくくなり、一方、(D)成分の光酸発生剤の 使用量が前記範囲の上限を超える過多量であると、ポジ型感光性樹脂組成物の保 存安定性に劣るようになる。 [0095] The photoacid generator of component (D) is 100 parts by mass of the alkali-soluble resin of component (A). And 0.5 to 50 parts by weight, preferably 1 to 30 parts by weight. When the amount of the photoacid generator used as the component (D) is too small below the lower limit of the above range, from the alkali-soluble resin of the component (A) of the component of the component (B) that has been thermally bridged during exposure. If the amount of the photoacid generator used as the component (D) exceeds the upper limit of the above range, the positive photosensitive resin may not be obtained. The storage stability of the composition becomes inferior.

[0096] [ (E)溶剤] [0096] [(E) Solvent]

本発明に用いるポジ型感光性樹脂組成物は、上記 (A)成分乃至 (D)成分を含有 し、通常それらの成分を (E)溶剤に溶解した溶液を塗布して、ポジ型感光性樹脂層 を形成する。 The positive photosensitive resin composition used in the present invention contains the components (A) to (D) described above, and usually a solution obtained by dissolving these components in the solvent (E) is applied to the positive photosensitive resin composition. Forming a layer.

[0097] この(E)溶剤は、(A)成分乃至(D)成分を溶解し、且つ所望により添加される後述 の(F)成分などを溶解するものであり、斯様な溶解能を有する溶剤であれば、その種 類及び構造などは特に限定されるものでない。 [0097] The (E) solvent dissolves the components (A) to (D) and dissolves the component (F) to be added as required, and has such a dissolving ability. As long as it is a solvent, its type and structure are not particularly limited.

斯様な(E)溶剤としては、例えば、エチレングリコールモノメチルエーテル、ェチレ ングリコーノレモノェチノレエーテノレ、メチノレセロソノレブアセテート、ェチノレセロソノレブァ セテート、ジエチレングリコールモノメチルエーテル、ジエチレングリコールモノェチル エーテノレ、プロピレングリコーノレ、プロピレングリコーノレモノメチノレエーテノレ、プロピレ ングリコーノレモノメチノレエーテノレアセテート、プロピレングリコーノレプロピノレエーテノレ アセテート、トルエン、キシレン、メチルェチルケトン、シクロペンタノン、シクロへキサノ ン、 2—ヘプタノン、 γ—ブチ口ラタトン、 2—ヒドロキシプロピオン酸ェチル、 2—ヒドロ キシ 2—メチルプロピオン酸ェチル、エトキシ酢酸ェチル、ヒドロキシ酢酸ェチル、 2 ーヒドロキシー3—メチルブタン酸メチル、 3—メトキシプロピオン酸メチル、 3—メトキ シプロピオン酸ェチル、 3—エトキシプロピオン酸ェチル、 3—エトキシプロピオン酸メ チル、ピルビン酸メチル、ピルビン酸ェチル、酢酸ェチル、酢酸ブチル、乳酸ェチノレ 、乳酸ブチル、 Ν, Ν ジメチルホルムアミド、 Ν, Ν ジメチルァセトアミド、及び Ν— メチルピロリドン等が挙げられる。 Such (E) solvents include, for example, ethylene glycol monomethyl ether, ethylene glycol monomethenoate ethere, methinorecero sonoleb acetate, ethenorecero sonolebate, diethylene glycol monomethyl ether, diethylene glycol monoester. Chill etherenole, propylene glycolate, propylene glycolenomonomethinoatenole, propylene glycolenomonomethinoatenoacetate, propylene glycolenopropenoatenoate acetate, toluene, xylene, methyl ethyl ketone, cyclopentanone, cyclo Hexanone, 2-heptanone, γ-butarate ratataton, 2-hydroxyethyl ethionate, 2-hydroxyethyl 2-methylpropionate, ethoxyethyl ethoxylate, hydroxyacetic acid Tyl, methyl 2-hydroxy-3-methylbutanoate, methyl 3-methoxypropionate, ethyl 3-methoxypropionate, ethyl 3-ethoxypropionate, methyl 3-ethoxypropionate, methyl pyruvate, ethyl pyruvate, ethyl acetate Butyl acetate, ethynole lactate, butyl lactate, 、, ジ メ チ ル dimethylformamide, Ν, ジ メ チ ル dimethylacetamide, and Ν-methylpyrrolidone.

これらの溶剤は、一種単独で、又は二種以上の組合せで使用することができる。 These solvents can be used singly or in combination of two or more.

[0098] これら(Ε)溶剤の中、プロピレングリコールモノメチルエーテル、プロピレングリコー

ノレモノメチノレエーテノレアセテート、 2—ヘプタノン、プロピレングリコーノレプロピノレエ一 テル、プロピレングリコールプロピルエーテルアセテート、乳酸ェチル、乳酸ブチル等 、塗膜性が良好で安全性が高いという観点より好ましい。これら溶剤は、一般にフ オトレジスト材料のための溶剤として用いられている。 [0098] Among these (ii) solvents, propylene glycol monomethyl ether, propylene glycol Nolemonomethylenoateolacetate, 2-heptanone, propyleneglycololepropynolether, propyleneglycolpropyletheracetate, ethyl lactate, butyl lactate and the like are preferable from the viewpoint of good coating properties and high safety. These solvents are generally used as solvents for photoresist materials.

[0099] [ (F)成分] [0099] [Component (F)]

(F)成分は、界面活性剤である。前記ポジ型感光性樹脂組成物の溶液調製時、そ の塗布性を向上させるという目的で、本発明の効果を損なわない限りにおいて、更に 界面活性剤を添加することができる。 Component (F) is a surfactant. When preparing the solution of the positive photosensitive resin composition, a surfactant may be further added for the purpose of improving the coating property as long as the effects of the present invention are not impaired.