WO1989008921A1 - X-ray imaging plate, method for producing x-ray imaging plate, phosphor of photostimulated luminescence material, and method for producing phosphor of photostimulated luminescence material - Google Patents

X-ray imaging plate, method for producing x-ray imaging plate, phosphor of photostimulated luminescence material, and method for producing phosphor of photostimulated luminescence material Download PDFInfo

- Publication number

- WO1989008921A1 WO1989008921A1 PCT/JP1989/000238 JP8900238W WO8908921A1 WO 1989008921 A1 WO1989008921 A1 WO 1989008921A1 JP 8900238 W JP8900238 W JP 8900238W WO 8908921 A1 WO8908921 A1 WO 8908921A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- phosphor

- luminescence material

- ray imaging

- producing

- imaging plate

- Prior art date

Links

Classifications

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K11/00—Luminescent, e.g. electroluminescent, chemiluminescent materials

- C09K11/08—Luminescent, e.g. electroluminescent, chemiluminescent materials containing inorganic luminescent materials

- C09K11/77—Luminescent, e.g. electroluminescent, chemiluminescent materials containing inorganic luminescent materials containing rare earth metals

- C09K11/7728—Luminescent, e.g. electroluminescent, chemiluminescent materials containing inorganic luminescent materials containing rare earth metals containing europium

- C09K11/7737—Phosphates

- C09K11/7738—Phosphates with alkaline earth metals

- C09K11/7739—Phosphates with alkaline earth metals with halogens

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K11/00—Luminescent, e.g. electroluminescent, chemiluminescent materials

- C09K11/08—Luminescent, e.g. electroluminescent, chemiluminescent materials containing inorganic luminescent materials

- C09K11/62—Luminescent, e.g. electroluminescent, chemiluminescent materials containing inorganic luminescent materials containing gallium, indium or thallium

- C09K11/626—Halogenides

- C09K11/628—Halogenides with alkali or alkaline earth metals

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K11/00—Luminescent, e.g. electroluminescent, chemiluminescent materials

- C09K11/08—Luminescent, e.g. electroluminescent, chemiluminescent materials containing inorganic luminescent materials

- C09K11/77—Luminescent, e.g. electroluminescent, chemiluminescent materials containing inorganic luminescent materials containing rare earth metals

- C09K11/7704—Halogenides

- C09K11/7705—Halogenides with alkali or alkaline earth metals

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K11/00—Luminescent, e.g. electroluminescent, chemiluminescent materials

- C09K11/08—Luminescent, e.g. electroluminescent, chemiluminescent materials containing inorganic luminescent materials

- C09K11/77—Luminescent, e.g. electroluminescent, chemiluminescent materials containing inorganic luminescent materials containing rare earth metals

- C09K11/7728—Luminescent, e.g. electroluminescent, chemiluminescent materials containing inorganic luminescent materials containing rare earth metals containing europium

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K11/00—Luminescent, e.g. electroluminescent, chemiluminescent materials

- C09K11/08—Luminescent, e.g. electroluminescent, chemiluminescent materials containing inorganic luminescent materials

- C09K11/77—Luminescent, e.g. electroluminescent, chemiluminescent materials containing inorganic luminescent materials containing rare earth metals

- C09K11/7728—Luminescent, e.g. electroluminescent, chemiluminescent materials containing inorganic luminescent materials containing rare earth metals containing europium

- C09K11/7729—Chalcogenides

- C09K11/7731—Chalcogenides with alkaline earth metals

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K11/00—Luminescent, e.g. electroluminescent, chemiluminescent materials

- C09K11/08—Luminescent, e.g. electroluminescent, chemiluminescent materials containing inorganic luminescent materials

- C09K11/77—Luminescent, e.g. electroluminescent, chemiluminescent materials containing inorganic luminescent materials containing rare earth metals

- C09K11/7728—Luminescent, e.g. electroluminescent, chemiluminescent materials containing inorganic luminescent materials containing rare earth metals containing europium

- C09K11/7732—Halogenides

- C09K11/7733—Halogenides with alkali or alkaline earth metals

-

- G—PHYSICS

- G21—NUCLEAR PHYSICS; NUCLEAR ENGINEERING

- G21K—TECHNIQUES FOR HANDLING PARTICLES OR IONISING RADIATION NOT OTHERWISE PROVIDED FOR; IRRADIATION DEVICES; GAMMA RAY OR X-RAY MICROSCOPES

- G21K4/00—Conversion screens for the conversion of the spatial distribution of X-rays or particle radiation into visible images, e.g. fluoroscopic screens

Definitions

- This invention relates to improvements applicable to an X-ray imaging plate, a method for producing an X-ray imaging plate, a phosphor of a photostimulated luminescence material, and a method for producing a phosphor of a photo ⁇ stimulated luminescence material.

- this invention relates to various improvements applicable to the foregoing objects including enhancement of the luminescence intensity and the humidity resistance of an X-ray imaging plate, capability of correction of the camber of an X-ray imaging plate, enhancement of the luminescence intensity of a phosphor of a photostimulated luminescence material, and capability of the luminescence of a phosphor of a photosti ⁇ mulated luminescence material by excitation with a light having some of the wavelengths generally emitted by a semiconductor laser, thereby allowing the X-ray image memo ⁇ rized in an X-ray imaging plate made of this phosphor of a photostimulated luminescence material to be read by employ ⁇ ing a semiconductor laser.

- An X-ray is extensively employed for diagnosis of the body of an animal including the human body, by using the difference in absorbtion rate of the X-ray.

- an X-ray imaging plate which is based on the natural phenomenon wherein a phosphor of a photostimulated lumines- cence material, whenever being exposed to an X-ray, stores the energy of the X-ray therein, the stored energy being allowed to be converted to fluorescence having a wavelength which is visible or reactive on or sensitive with silver halogenides, whenever it is exposed to a light such as a laser having a specific wavelength.

- Examplary phosphors of photostimulated lumines ⁇ cence materials which can be used for this purpose are alkaline earth metals activated by bivalent europium, which are compounds made from some of the combination of alkaline earth metals and bivalent europium, for example, barium chloride bromide activated by bivalent europium or BaClBr:Eu 2+ .

- Fig. 1 illustrates the band diagram of a phosphor of a photostimulated luminescence material consisting of barium chloride bromide activated by bivalent europium (BaClBr:Eu 2+ ) .

- C and V 1 respectively represent the conduction band and the valence band of BaClBr

- C2 and V2 respectively represent the excited state and the ground state of Eu

- T represents a lattice defect or vacancy occurring accompanied by removal of a negative ion from the atom of BaClBr.

- T functions as a luminescence center.

- This phenomenon is interpreted that electrons belonging to bivalent europium located in the area exposed to an X-ray have moved to luminescence centers T which are located in the area of europium which area was exposed to the X-ray, from the geometrical viewpoints but requires less amount of energy to be excited.

- the X-ray energy is memorized in a type of memory means which is allowed to emit fluorescence which is allowed to react on or to be sensitive with a no screen type X-ray film, when such a memory means is exposed to a light having a less amount of energy or having a wavelength of 500 through 900n ⁇

- a phosphor of a photostimulated lumi ⁇ nescence material in which electrons belonging to a biva ⁇ lent europium have moved to luminescence centers T (a level which is allowed to emit fluorescence by being supplied a less amount of energy) which is located at the geometrical area which is exposed to an X-ray, is exposed to a specific light e.g. a laser, the electrons trapped in luminescence centers T are excited to the conduction band Ci of an alkaline earth metal which constitutes the phosphor of the photostimulated luminescence material.

- An X-ray imaging plate employing the foregoing phosphor of a photostimulated luminescence material can be produced by producing a plate et al. of a phosphor of a photostimulated luminescence material, just from the theo ⁇ retical viewpoints. From the industrial viewpoints, how ⁇ ever, an X-ray imaging plate is produced generally by producing a layer of a phosphor of a photostimulated lumi ⁇ nescence material on a substrate film made from a trans ⁇ parent resin e.g. polyethylene terephthalate (Hereinafter referred to as Mylar (( ⁇ )trade name of polyethylene tere ⁇ phthalate)), as illustrated in Fig. 3.

- a trans ⁇ parent resin e.g. polyethylene terephthalate (Hereinafter referred to as Mylar (( ⁇ )trade name of polyethylene tere ⁇ phthalate)

- a layer of a mixture of an europium halogenide and a haloge- nide of an alkaline earth metal which has a large atomic weight and a large magnitude of the X-ray absorbtion rate is produced on a transparent film of Mylar or the like, before the layer is calcined in a reducing atmosphere e.g. a mixture of hydrogen and nitrogen or a mixture of carbon onooxide and carbon dioxide, for the purpose to reduce tervalent europium to bivalent europium.

- a layer of a phosphor of a photostimulated luminescence mate ⁇ rial consisting of an alkaline earth metal activated by bivalent europium is produced, before the layer is crushed into powder.

- the powder is mixed with a binder of a polymer e.g. polymethyl methacrylate and with a solvent e.g. toluene.

- a binder of a polymer e.g. polymethyl methacrylate

- a solvent e.g. toluene.

- the liquid mixture is exten ⁇ ded on a substrate film 5 of Mylar et al. having the thickness of approximately 70 micrometers, to produce a layer 1 of a phosphor of a photostimulated luminescence material having the thickness of 250 through 300 micro ⁇ meters, before being covered by a thin protection film 6 of Mylar et al. having the thickness of approximately 10 micrometers, which is set on the layer 1 employing a layer of an adhesive 4.

- An X-ray imaging plate produced as described above is allowed to be used in two independent methods.

- One is to produce a picture on a photofilm.

- an X-ray imaging plate is exposed to a weak X- ray through an object e.g. a human body.

- a pattern representing the X-ray absorbtion areas and the X-ray non-absorbtion areas of the object is memorized as a pattern consisting of a group of luminescence centers in ⁇ cluded in the X-ray imagimg plate.

- the X-ray imaging plate is overlaid on a photofilm sensitive on fluorescence, before the X-ray imaging plate is exposed to a laser e.g. He-Ne laser having the wavelength of 630nm.

- the pattern representing the X-ray absorbtion areas and the X-ray non-absorbtion areas of the object memorized as a pattern consisting of a group of lumines ⁇ cence centers is copied on the photofilm.

- the other is to produce an image on a CRT tube et al.

- a laser e.g. He-Ne laser having a wave ⁇ length of 630nm is scanned along each picture element constituting the pattern representing the X-ray absorbtion areas and the X-ray non-absorbtion areas of the object memorized as a pattern consisting of a group of lumines ⁇ cence centers.

- each picture element emits a small spot of fluorescence which is picked up with a photo- multiplier or the like.

- a train of electric pulses representing the X-ray absorbtion areas and the X- ray non-absorbtion areas of the object is output. Based on this train of electric pulses representing the X-ray ab ⁇ sorbtion areas and the X-ray non-absorbtion areas of the object, an image is produced on a CRT tube et al.

- the sensitivity of an X-ray imag ⁇ ing plate is proportional to the quantity of electrons trapped in luminescence centers.

- the pattern memorized in an X-ray imaging plate is read out usually by employing He- Ne laser having a wavelength of approximately 630nm. Since He-Ne laser is large in size, however, development of technology is required wherein a semiconductor laser e.g. an AlGaAs laser having a wavelength of approximately 830nm is allowed to be employed. Since a longer wavelength of a read-out laser is accompanied by a less magnitude of lumi ⁇ nescence intensity of a phosphor of a photostimulated lumi ⁇ nescence material, an X-ray imaging plate is inevitably accompanied by a drawback wherein a semiconductor laser which is small in size and which has a wavelength of 830nm is not accepted as a read-out laser.

- He- Ne laser having a wavelength of approximately 630nm. Since He-Ne laser is large in size, however, development of technology is required wherein a semiconductor laser e.g. an AlGaAs laser having a wavelength of approximately 830nm is allowed to be employed. Since

- an X-ray imaging plate having a struc- ture wherein a plate of a mixture of a phosphor of a photo ⁇ stimulated luminescence material and a binder is put be ⁇ tween a substrate film of Mylar and a cover film of Mylar is accompanied by a drawback wherein the X-ray imaging plate is not durable in the humid environment, because the intensity of luminescence is decreased following the em ⁇ ployment thereof particularly in the humid environment.

- an X-ray imaging plate produced by em ⁇ ploying the traditional method of an X-ray imaging plate wherein a phosphor of a photostimulated luminescence mate ⁇ rial produced by calcination of a mixture of an europium halogenide and a halogenide of an alkaline earth metal is crushed into powder, a mixture of the powder of the phos ⁇ phor of the photostimulated luminescence material and a binder is spread on a resin film e.g. a film of Mylar, to produce a sheet containing the phosphor of the photostimu ⁇ lated luminescence material and the binder, the sheet is heated to purge the binder and another resin film e.g.

- a Mylar film is placed to cover the dried sheet containing the phosphor of the photostimulated luminescence material and the binder, is unsatisfactory from the viewpoints of the sensitivity and the resolving power.

- this drawback is assumed to be removed by decrease of the rela ⁇ tive quantity of the binder and increase of the relative quantity of a phosphor of a- photostimulated luminescence material, an overreduction of the relative quantity of a binder causes difficulty in producing a plane resin film of Mylar, resultantly causing reduction of the resolving power due to dispersion of a laser on the surface of the phosphor of the photostimulated luminescence material.

- the sensi ⁇ tivity is decreased also by this reason.

- an improved method for producing an X- ray imaging plate wherein a liquid mixture of powder of a phosphor of a photostimulated luminescence material and a binder is spread on a resin film e.g. a Mylar film, the liquid mixture film is dried to produce a sheet of the phosphor of the photostimulated luminescence material and the binder, the sheet of the phosphor of the photostimulated luminescence material and the binder is removed from the resin film, and sheet of the phosphor of the photostimulated luminescence material and the binder is calcinated in a reducing atmosphere around 800 through 900 degrees centigrade, for the purpose to cure the defects occurred during the crushing period and to decrease the relative quantity of the binder and increase the relative quantity of the phosphor of the photostimulated lumines- cence material.

- This improved method is, however, involved with a drawback wherein the X-ray imaging plate is readily cambered during the process.

- An X-ray imaging p l ate of this invention com ⁇ prises a phosphor of a photostimulated luminescence mate ⁇ ria l made of the ha logenide of an a lkal ine earth meta l activated by bivalent europium.

- BaXX'- Eu wherein X or X 1 is at least one kind of halogen selec ⁇ ted from the group of F, Cl, Br and I

- This phosphor of the photostimulated luminescence material is useful as a material of an X-ray imaging plate, because it has the photostimulated luminescence nature or the na ⁇ ture to emit a near ultraviolet ray, provided being excited with an electromagnetic wave including visible ray and infrared ray, after being exposed to an X-ray.

- a bivalent metal fluorohalide phosphor activated by bivalent europium which is expressed as a composition formula reading :

- the symbols including x, y, p, a and b are num ⁇ bers which satisfy the following conditions : (x+y+p) is no larger than 1, y is no larger than 0.2, p is no less than 0.001 and no larger than 0.2, (a+b) is no larger than 1.

- This phosphor of the photostimulated luminescence material emits a near ultraviolet ray spectrum having the peak around 390nm, in response to excitation with an X-ray, an ultraviolet ray, an electron beam et al.

- this phos ⁇ phor of the photostimulated luminescence ma-terial is highly sensitive to an X-ray and emits a fluorescence whose wave ⁇ length is included in the highest range of the spectro- scopic sensitivity, this is extensively employed as a phos- pher for a sensitizer of an X-ray film (Japanene Examined Patent No. 51-28591).

- the relation between the intensity of fluorescence and the wavelength of the exciting light or the spectrum of the intensity of fluorescence relative to the wavelength of the light for excitation has a peak around 580nm. Therefore, He-Ne laser is usually employed for excitation of the phosphor of photostimulated luminescence material.

- M is at least one alkaline earth metal selected from the group including Ba, Sr and Ca,

- X or X' is at least one halogenide selected from the group including Cl, Br and I,

- X does not equal to X 1 , a is a number which is no less than 0.1 and no larger than 10, and x is a positive number which is no larger than

- phosphors of photostimulated luminescence materials belonging to the family of BaClBr:Eu has a peak of the luminescence spectrum around 410nm, provided being excited with an X-ray, an ultravio l et ray or an e lectron beam.

- the relation bet ⁇ ween the intensity of f luorescence and the wavelength of the exciting l ight or the spectrum of the intensity of f luorescence re lative to the wavelength of the light for excitation has peaks around 580nm and around 700nm, result- antly allowing not only He-Ne laser but also semiconductor lasers to be employed for excitation.

- the aforementioned phosphor of the photostimu ⁇ lated luminescence material can be produced by calcination of the corresponding materials thereof at a temperature range of 600 through 1, 000 degrees centigrade.

- the foregoing phosphor of the photostimul ated luminescence material particul ar ly the phosphor of the photostimulated luminescence materials be longing to the fami ly of BaC lBr .Eu has a large peak in the visible wave-length range of the spectrum of the excit ⁇ ing light, and it has a les s sensitivity in the lumines ⁇ cence wavelength range of the semiconductor lasers .

- the foregoing phosphor of the photostimulated luminescence material has a drawback wherein it has a less sensitivity in the luminescence wavelength range of the semiconductor lasers which are convenient equipment f or reading out the memorized pattern representing the X-ray absorbtion areas and the X-ray non-absobtion areas of the obj ect, resultantly being inconvenient from the practical viewpoints .

- the objects of this invention are to remove the foregoing variable drawbacks.

- the first object of this invention is to provide an X-ray imaging plate having a large magnitude of the luminescence intensity and a method for producing it.

- the second object of this invention is to provide an X-ray imaging plate resistive against humidity and dura ⁇ ble in the humid environment.

- the third object of this invention is to provide an X-ray imaging plate having a large luminescence intensi ⁇ ty due to a large quantity of a phosphor of a photostimu ⁇ lated luminescence material relative to the quantity of a binder and a method for producing it.

- the fourth object of this invention is to provide a method for producing an X-ray imaging plate having no camber to be produced during the calcination process.

- Fifth object of this invention is to provide a phosphor of a photostimulated luminescence material having a large magnitude of the luminescence intensity and a method for producing it.

- the sixth object of this invention is to provide a phosphor of a photostimulated luminescence material al ⁇ lowing a semiconductor laser having the luminescence wave ⁇ length of approximately 700nm to be employed for reading out a pattern representing the X-ray absorbtion areas and the X-ray non-absorbtion areas of the object and a method for producing it.

- the first means to achieve the first object is to produce an X-ray imaging plate employing only one calcina ⁇ tion step rather than employing two calcination steps which are essential in the prior art wherein the first calcina ⁇ tion step is employed for producing a phosphor of a photo ⁇ stimulated luminescence material and the second calcination step is employed for producing an X-ray imaging plate, after a sheet is produced out of a mixture of powder of the phosphor of the photostimulated luminescence material and a binder (These means correspond to claims 1 and 2).

- the second means to achieve the first object comprises a first step for producing a phosphor of a photo ⁇ stimulated luminescence material by employing calcination, a second step for producing powder of the phosphor of the photostimulated luminescence material by employing a crushing process, a third step for producing a sheet of the mixture of the phosphor of the photostimulated luminescence material and a binder on a substrate film, a fourth step for removing the sheet of the mixture of the phosphor of the photostimulated luminescence material and the binder from the substrate film, and a fifth step for purging the binder by employing calcination, thereby reducing the rela ⁇ tive quantity of the binder in the X-ray imaging plate (These means correspond to claims 4 and 5).

- the means to achieve the second object comprises a layer of a phosphor of a photostimulated luminescence material put between the upper and lower protection films of a resin, further comprising at least one humidity re ⁇ sistant film e.g. an Si0 2 film, an ITO film or the like for additional protection of at least one of the upper and lower protection films (These means correspond to claim 9).

- the means to achieve the third object comprises a calcination step which is applied to a sheet of a mixture of powder of a phosphor of a photostimulated luminescence material and a binder in the oxidizing atmosphere, for the purpose to burn the binder, resultantly increasing the relative quantity of the phosphor of the photostimulated luminescence material and to cure the defects of the phos- phor of the photostimulated luminescence material occurred during the crushing and mixing processes of the phosphor of the photostimulated luminescence material (These means correspond to claims 10 and 13).

- this means is defined as a method for producing an X-ray imaging plate comprising a step for producing (i) a mixture of a compound of a halogen and an element belonging to Ila group, a compound of another halogen and an element belong ⁇ ing to Ila group and an europium halogenide, (ii) a mixture of a compound of a halogen and an element belonging to la group and a compound of a halogen and europium or thallium, or (iii) a mixture of a compound of a halogen and an ele ⁇ ment belonging to Ila group and a compound of another halogen and an element belonging to Ila group, either one compound being selected from a group including silicon oxide, phosphorus oxide, one of the sulfides of Mg, Ca, Sr or Ba, or yttrium oxide, and europium halogenide, a step for crushing the foregoing mixture, a step for producing a mixture of the powder of the foregoing

- the means are defined as a method for producing an X-ray imaging plate comprising a step for producing a mixture of a binder and a phosphor of a photostimulated luminescence material ex ⁇ pressed in a formula, reading : aMX 2 -(l-a)MX' 2 :bEu wherein : M is an element selected from a group including Mg, Ca , Sr and Ba , either of X and X* is an element individually selected from the halogen group, a is a positive number less than 1, and b is a positive number no larger than 0.2, or a formula, reading : MX:aA wherein :

- M is an element selected from la group

- X is a halogen

- A is europium or thallium, and a is a positive number less than 1, or a formula, reading : aMX 2 "(1-a)MX' 2 -cB:bEu wherein :

- M is an element selected from a group including

- B is silicon oxide, phosphorus oxide, one of the sulfides of Mg, Ca, Sr or Ba, or yttrium oxide, a is a positive number less than 1, and either of b and c is a positive number no larger than 0.2, a step for producing' a mixture of powder of any of the foregoing phosphors of photostimulated luminescence mate ⁇ rials and a binder, a step for producing a sheet of any of the foregoing mixtures , and a step for calcinating any of the foregoing sheets , thereby the binder is ashed and removed from any of the sheets , and an X-ray imaging plate comprising the sintered body of a phosphor of a photostimu ⁇ lated luminescence material , expressed in a formula, read ⁇ ing : aMX 2 - ( 1-a) MX ' 2 : bEu wherein :

- M is an element se lected from a group including

- Mg, Ca , Sr and Ba either of X and X' is an element individually selected from the halogen group, a is a positive number less than 1, and b is a positive number no larger than 0.2, or a formula, reading : MX:aA wherein :

- M is an element selected from l a group ,

- X is a halogen

- A is europium or thallium, and a is a positive number less than 1, or a formula, reading : aMX 2 -(l-a)MX' 2 -cB:bEu wherein :

- M is an element selected from a group including

- B is silicon oxide, phosphorus oxide, one of the sulfides of Mg, Ca, Sr or Ba, or yttrium oxide, a is a positive number less than 1, and either of b and c is a positive number no larger than 0.2.

- the means to achieve the fourth object comprises a step for putting a plane plate of quartz or a ceramics on a layer of a phosphor of a photostimulated luminescence material, and a step for calcinating the layer of the phosphor of the photostimulated luminescence material in a reducing atmosphere, thereby the camber of the layer of the phosphor of the photostimulated luminescence material is cured (These means correspond to claims 3 and 6).

- the means to achieve the fifth object is to conduct calcination step (a step to reduce tervalent euro ⁇ pium, tervalent thallium et al. to bivalent europium, biva ⁇ lent thallium et al.) in the mixture of hydrogen and helium (This means corresponds to claim 14).

- the means to achieve the sixth object is to use

- Me and Me' are at least one element selected from the group including Mg, Ca, Sr and Ba

- X and X 1 are elements selected from the group including F, Cl, Br and I and which are different from each other

- x is a number no less than 0.4 and no larger than 0.6

- y is a positive number no larger than 0.1

- z is a number no less than 0.0001 and no larger than 0.03

- Me and Me" are at least one element selected from the group including Mg, Ca, Sr and Ba

- X and X' are elements selected from the group including F, Cl, Br and I and which are different from each other

- x is a number no less than 0.4 and no larger than 0.6

- y is a positive number no larger than 0.1

- z is a number no less than 0.0001 and no larger than 0.03.

- Fig. 1 is a band diagram explaining the function of a phosphor of a photostimulated luminescence material

- Fig. 2a is a cross-sectional view of the layer configuration of a phosphor of a photostimulated lumines ⁇ cence material in accordance with the first one of the means to achieve the second object of this invention

- Fig. 2b is a cross-sectional view of the layer configuration of a phosphor of a photostimulated lumines ⁇ cence material in accordance with the second one of the means to achieve the second object of this invention

- Fig. 3 is a cross-sectional view of the layer configuration of a phosphor of a photostimulated lumines ⁇ cence material available in the prior art, the drawing being illustrated as a reference to Figs. 2a and 2b,

- Fig. 4 is a graph illustrating the results of the means to achieve the second object of this invention, namely a graph showing the relations between the intensity of signals and the length of the time during which the test piece is exposed to the humid environment, wherein a chain line 7 represents the results of the test for humidity resistance for the X-ray imaging plate having the layer configuration illustrated in Fig. 2a, a solid line 8 repre- sents the results of the test for humidity resistance for the X-ray imaging plate having the layer configuration illustrated in Fig.

- a solid line 9 represents the results of the test for humidity resistance for the X-ray imaging plate available in the prior art

- a broken line 10 represents the results of the test for humidity resis ⁇ tance for the X-ray imaging plate having the layer configu ⁇ ration illustrated in Fig. 2b excepting for the protection surrounding the X-ray imaging plate.

- Fig. 5 is a graph illustrating the results of the embodiment described under Item A(2) describing the means to achieve the first object, namely a graph showing the relation between the luminescence intensity and the wave ⁇ length of exciting light (shown in a broken line 11) ,

- Fig. 6 is a picture illustrating the employment of an X-ray imaging plate

- Fig. 7 is a excitation spectrum of BaFCl:Eu ⁇ m the prior art (Japanese Examined Patent No. 51-28591),

- Fig. 8 is a excitation spectrum of BaClBr.Eu in the prior art (Japanese Examined Patent No. 63-28952) , and

- Fig. 9 is a excitation spectrum of BaC ⁇ - BaB ⁇ - yCaS:zEu 2+ in accordance with the means to achieve the sixth object of this invention.

- Embodiments of means to achieve the first object (1) Embodiments corresponding to claims 1 and 2

- an X-ray imaging plate is produced employing a phosphor of a photostimulated luminescence material, as calcinated or sintered, or em ⁇ ploying a phosphor of a photostimulated luminescence mate ⁇ rial which is not crushed.

- the materials including :

- PMMA 40 g dibuthylphthalate 30 g toluene 400 g were mixed for 24 hours employing a ball mill for producing a liquid mixture.

- the liquid mixture was spread on an alumina substrate employing a bar coater to produce a thin film of the mixture having the aforementioned composition extended on an alumina plate.

- a dryer was employed to dry the thin film of the mixture having the aforementioned composition extended on the alumina plate for 7 hours at 50 degrees centigrade, before an electric furnace was employed 600 degrees centigrade for 1 hour in the air to purge the binder.

- a calcination was conducted in an atmosphere con ⁇ taining H 2 and 2 for 1 hour at 895 degrees centigrade, resultantly producing a phosphor of a photostimulated lumi ⁇ nescence material of sintered BaClBr.Eu having the thick- ness of 300 micrometers.

- Tranparent glass plates having the thickness of 0.5mm was set with an adhesives of epoxy resin on the both sides of the aforementioned plate of the phosphor of the photostimulated luminescence material to finish an X-ray imaging plate.

- a method in the prior art was employed to produce an X-ray imaging plate.

- a layer of a mixture of a phosphor of a photostimulated luminescence material and a binder having the thickness of 300 micrometers was produced on a Mylar sheet having the thickness of 250 micrometers, before being piled with another Mylar sheet having the thickness of 50 micrometers on the layer of the phosphor of the photostimu ⁇ lated luminescence material.

- the foregoing X-ray imaging plates were exposed to X-ray emitted with condition 120KV, 200mA and a working time of 0.05sec, through a phantom, before being radiated with a laser having the wavelength of 830nm and the power of lOmW emitted by a semiconductor laser for causing the X- ray imaging plates to emit fluorescence, which was sensed with a photomultiplier et al.

- Table 1 presents the results of the foregoing tests shown on the basis that the signal intensity of the prior art is shown as 100.

- inventions including a step for pro ⁇ ducing a sheet of a mixture of a phosphor of a photostimu ⁇ lated luminescence material and a binder on a substrate sheet, a step for removing the mixture sheet from the substrate sheet, and a clacination step for removing the binder for the purpose to increase the relative quantity of the phosphor of the photostimulated luminescence material.

- a binder of poly- methylmethacrylate and a solvent were mixed to the forego ⁇ ing powder, before being produced a sheet of the phosphor of the photostimulated luminescence material on a Mylar film. After being dried, the sheet of the phosphor of the photostimulated luminescence material alone was removed from the Mylar film.

- the sheet of the phosphor of the photostimulated luminescence material was heated at 600 degrees centigrade for 1 through 40 hours in an atmosphere containing N 2 and 0 2 with a concentration range of 10:1 through 1:5 to purge the binder, it was calcinated in the atmosphere containing H 2 and N 2 for 1 hour at 850 degrees centigrade to produce a calcinated or sintered plate of the phosphor of the photostimulated luminescence material hav- ing the thickness of 300 micrometers.

- quartz glass plates were piled and set with an adhesive on the both sides of the foregoing plate of the phosphor of the photostimulated luminescence mate ⁇ rial to produce an X-ray imaging plate.

- This X-ray imaging plate was compared with ano ⁇ ther X-ray imaging plate available in the prior art which was produced by application of a mixture of powder of a phosphor of a photostimulated luminescence material and PMMA binder to a substrate to produce a sheet having the thickness of 300 micrometers.

- Table 2 presents the results of the foregoing test, on the basis that the signal intensity of the prior art is shown as 100.

- This table shows that the phosphor of the photo ⁇ stimulated luminescence material of this invention is re- markably improved in comparison with the prior art, from the viewpoints of luminescence intensity, because the for ⁇ mer has a larger relative quantity of a phosphor of photo ⁇ stimulated luminescence material and a less relative quan ⁇ tity of a binder and because crystalline defects of the former caused by the the crushing step have been cured by the growth of crystals in the calcination step.

- Fig. 5 illustrates the result of the test, namely a graph showing the relations between the luminescence intensity and the wavelength of the exciting light (shown in a broken line 11).

- a solid line 12 shows the relations between the luminescence intensity and the wave ⁇ length of exciting light of the phosphor of the photo ⁇ stimulated luminescence material in accordance with the embodiment described in Item A(l), calcinated in the mix ⁇ ture of N 2 and H2, measured on the same conditions as the above, and a chain line 13 shows the relations between the luminescence intensity and the wavelength of the exciting light of BaFBr:Eu available in the prior art (Japanese Exanined Patent No. 63-28954), measured on the same condi ⁇ tions as the above.

- the graph evidently shows that an X-ray imaging plate in accordance with this invention has a remarkable magnitude of sensitivity for the exciting light in the wavelength range of 500 through 900nm.

- an X-ray imaging plate 16 in accordance with this invention which was ex ⁇ posed to an X-ray 15 through an object 14, is allowed to emit fluorescence, provided it is exposed to an exciting current 17 having the wavelength range of 500 through 900nm, the fluorescence collected by an optical system 18 being sensed by a light sensor (photomultiplier) 19 to be converted to electric signals.

- an exciting current 17 having the wavelength range of 500 through 900nm

- the fluorescence collected by an optical system 18 being sensed by a light sensor (photomultiplier) 19 to be converted to electric signals.

- a phosphor of a photostimu ⁇ lated luminescence material having the thickness of 300 micrometers was produced on a substrate film of Mylar having the thickness of 50 micrometers.

- the sheet of the phosphor of the photostimulated luminescence material was cut in a size of type A4.

- Mylar films which have layers of silicon dioxide (Si0 2 ) , indium tin oxide (ITO) or the like on one side thereof and which was cut at a size longer than type A4 by 5mm for both lateral and longitudinal directions are plated on the both surface of the layer of the phosphor of the photostimulated luminescence material with an adhesives.

- Fig. 2a is a cross-sectional view of a X-ray imaging plate produced with the foregoing process. Referr ⁇ ing to Fig. 2a, a layer 1 of a phosphor of a photostimu ⁇ lated luminescence material is put between piles of a Mylar film 3 and Si0 2 film 2 and set one another with an adhesive 4.

- the layer 1 of the phosphor of the photostimulated luminescence material is restricted from potential exprosure to the atmosphere.

- a pile of the layer 1 of a phosphor of a photostimulated luminescence material is allowed to be put between piles of a Mylar film 3 and Si ⁇ 2 film 2 and set one another with an adhesive 4.

- Fig. 4 is a graph showing the results of the humidity resistance tests which were conducted under the conditions that the temperature is 60 degrees centigrade and the relative humidity is 90% and which were applied to X-ray imaging plates in accordance with this invention having layer -configurations illustrated in Figs. 2a and 2b and to an X-ray imaging plate of the prior art having a layer configuration wherein a pile of a layer 1 of a phos ⁇ phor of a photostimulated luminescence material 1 and a substrate film 5 is put between piles of a Mylar film 3 and Si0 2 film 2 and set with an adhesive 4.

- Fig. 4 evidently shows that the X-ray imaging plates having the layer configuration illustrated respec ⁇ tively in Figs. 2a and 2b are involved with larger magni ⁇ tude of humidity resistance (shown respectively by a chain line 7 and a solid line 8) with respect to the X-ray imag ⁇ ing plate of a prior art having the layer configuration illustrated in Fig. 3 (of which the humidity resistance was illustrated by a solid line 9).

- a broken line 10 shows the humidity resistance of an X-ray imaging plate which has the similar configuration excepting for the per- iferal edge of the phosphor of a photostimulated lumines ⁇ cence material 1, such humidity resistance being much less than that for the X-ray imaging plates having Fig. 2a or Fig. 2b, caused by producing the size of the piles of the Mylar film 3 and Si0 2 film 2 to be identical to that of the pile of the phosphor of the photostimulated luminescence material 1 and a substrate 5.

- the materials including :

- An electric furnace was employed to calcinate the powder in the atmosphere at approximately 500 degrees cen ⁇ tigrade for 2 hours, before the calcinated phosphor of a photostimulated luminescence material is crushed to the powder of the phosphor of the photostimulated luminescence material having the particle diameter of 30-50 micrometers.

- a mixture of 500g of the powder of the phosphor of the photostimulated luminescence material, 30g of PMMA, 3g of dibuthyl phthalate and 150g of toluene were mixed for 24 hours in a pot for ball mill to produce liquid mixture. After this liquid mixture was spread on a Mylar film by employing a doctor blade, it was dried to produce a sheet of the mixture of the phosphor of the photostimulated lumi ⁇ nescence material and a binder having the thickness of 400 micrometers, which was removed from the Mylar film.

- the temperature of the sheet was increased in an electric furnace up to 600 degrees centigrade employing 6 hours, before the temperature was maintained for one hour and the temperature was decreased down to 200 degrees or less employing 5 hours.

- a semi-sintered sheet having no binder therein and having a relatively less magnitude of camber thereon.

- the semi-sintered sheet was entered into an electric furnace which was filled with a mixture of hydrogen and nitrogen, and the temperature of the sheet was increased up to 900 degrees centigrade employing 9 hours, before the temperature was maintained for 3 hours and the temperature was decreased down to 200 degrees centigrade employing 5 hours.

- the sheet of the phosphor of the photo ⁇ stimulated luminescence material produced employing the foregoing manner was inevitably involved with a camber.

- a quartz plate having a thickness of 0.5mm was put on the sheet of the phosphor of the photostimulated luminescence material, during a period in which the foregoing calcination process was conducted again in the mixture of hydrogen and nitrogen. This process was proved to be effective to cure the camber and to obtain a sheet of a phosphor of a photostimulated luminescence material having the thickness of 300 micrometers but having no camber thereon.

- the sheet of the phosphor of the photostimulated luminescence material was put between two Mylar films having the thickness of 50 micrometers which were set with an adhesive to complete an X-ray imaging plate.

- the materials including :

- EuCl 3 0.652 g were mixed for 6 hours employing a ball mill.

- the cover of the pot was kept open for 3 hours, and the mixture was dried at approximately 150 degrees centigrade for 3 hours under vacuum position.

- the ball mill was employed again for 6 hours for further mixing of the dried mixture.

- An electric furnace was employed to calcinate the mixture in a reducing atmosphere including hydrogen and helium at approximately 900 degrees centigrade for approxi ⁇ mately 2 hours, resultantly producing the powder of a phosphor of a photostimulated luminescence material.

- a mixture containing 500g of the foregoing powder of a phosphor of a photostimulated luminescence material, 30g of PMMA, 3g of dibuthyl phthalate and 150g of toluene was mixed for approximately 20 hours in a ball mill pot to produce a liquid mixture.

- the liquid mixture was spread on a Mylar film, employing a doctor blade. After being dried at approximately 120 degrees centigrade, the Mylar film was removed from a sheet of a phosphor of a photostimulated luminescence material.

- the sheet of the phosphor of the photostimulated luminescence material placed on a quatz plate was put into an electric furnace. After the temperature of the sheet was increased to approximately 150 degrees centigrade in an oxidizing atmosphere (in the air) , the temperature of the sheet was kept unchanged for 2 hours. Thereafter, the temperature of the sheet was further increased to 600 degrees centigrade, before being kept unchanged for approximately 2 hours. Finally, the temperature of the sheet was decreased to 100 degrees centigrade or less. By this step, a semi-sintered sheet containing no binder therein and having no camber thereon was produced.

- the semi-sintered sheet placed on a graphite plate was put into an electric furnace. After the temperature of the sheet was increased up to approximately 800 degrees centigrade in a reducing atmosphere containing a mixture of hydrogen and nitrogen or a mixture of hydrogen and helium, the temperature of the sheet was kept unchanged for approximately 2 hours, before the temperature of the sheet was decreased down to 100 degrees centigrade or less. By this step, a sintered sheet or a sheet of a phosphor of a photostimulated luminescence material having the thickness of approximately 300 micrometers was produced.

- a sheet of tempered glass or quatz glass was set with epoxy resin on one side of the foregoing sintered sheet, and a Mylar film, a tempered glass film or a quatz glass film was set with epoxy resin on the other side of the foregoing sintered sheet, for the purpose to protect the phosphor of the° photostimulated luminescence material from humidity.

- an X-ray imaging plate was produced.

- the finished X-ray imaging plate was placed 70cm apart from the focus of an X-ray tube which was excited with the conditions of 120KV of the tube voltage and 50mA of the tube current, and it was exposed to the X-ray emitted by the foregoing X-ray tube, for 0.2sec. After the exposure, the exposed X-ray imaging plate was excited with a laser having the wavelength of 780nm and having the power of lOmW. The intensity of the fluorescence emitted by the X-ray imaging plate was sensed with a photomultiplier. The results showed that the intensity of the luminescence of the X-ray imaging plate was 3.7 times as large as the prior art. Second Example

- the materials including :

- EuCl 3 -— 0.652 g were mixed for 6 hours employing a ball mill.

- the cover of the pot was kept open for 3 hours, and the mixture was dried at approximately 150 degrees centigrade for 3 hours under vacuum position.

- the ball mill was employed again for 6 hours for further mixing of the dried mixture. If the mixture was wet, vacuum desiccation or heat trealment in the air was employed.

- a mixture containing 500g of the foregoing mixture (the raw material of a phosphor of a photostimu ⁇ lated luminescence material), 30g of PMMA, 3g of dibuthyl phthalate and 150g of toluene was mixed for approximately 20 hours in a ball mill pot to produce a liquid mixture.

- the liquid mixture was spread on a Mylar film, employing a doctor blade. After being dried at approximately 120 de ⁇ grees centigrade, the Mylar film was removed from a sheet of the raw material of a phosphor of a photostimulated luminescence material.

- the sheet of the raw material of a phosphor of a photostimulated luminescence material placed on a quatz plate was put into an electric furnace. After the tempera ⁇ ture of the sheet was increased to approximately 150 de ⁇ grees centigrade in an oxidizing atmosphere (in the air) , the temperature of the sheet was kept unchanged for 2 hours. Thereafter, the temperature of the sheet was further increased to 600 degrees centigrade, before being kept unchanged for approximately 2 hours. Finally, the tempera ⁇ ture of the sheet was decreased to 100 degrees centigrade or less. By this step, a semi-sintered sheet containing no binder therein and having no camber thereon was produced.

- the semi-sintered sheet placed on a graphite plate was put into an electric furnace. After the tempera ⁇ ture of the sheet was increased up to approximately 800 degrees centigrade in a reducing atmosphere containing a mixture of hydrogen and nitrogen or a mixture of hydrogen and helium, the temperature of the .sheet was kept unchanged for approximately 2 hours, before the temperature of the sheet was decreased down to 100 degrees centigrade or less. By this step, a sintered sheet or a sheet of a phosphor of a photostimulated luminescence material having the thickness of approximately 300 micrometers was produced.

- a sheet of tempered glass or quatz glass was set with epoxy resin on one side of the foregoing sintered sheet, and a Mylar film, a tempered glass film or a quatz glass film was set with epoxy resin on the other side of the foregoing sintered sheet, for the purpose to protect the phosphor of the photostimulated luminescence material from humidity.

- an X-ray imaging plate was produced.

- the finished X-ray imaging plate was placed 70cm apart from the focus of an X-ray tube which was excited with the conditions of 120KV of the tube voltage and 50mA of the tube current, and it was exposed to the X-ray emitt ⁇ ed by the foregoing X-ray tube, for 0.2sec. After the exposure, the exposed X-ray imaging plate was excited with a laser having the wavelength of 780nm and having the power of lOmW. The intensity of the fluorescence emitted by the X-ray imaging plate was sensed with a photomultiplier. The results showed that the intensity of the luminescence of the X-rray imaging plate was 3.6 times as large as the prior art.

- TlBr 0.568 g were mixed for 6 hours employing a ball mill.

- the cover of the pot was kept open for 3 hours, and the mixture was dried at approximately 150 degrees centigrade for 3 hours under vacuum position.

- the ball mill was employed again for 6 hours for further mixing of the dried mixture.

- An electric furnace was employed to calcinate the mixture in a reducing atmosphere including hydrogen and helium at approximately 650 degrees centigrade for approxi ⁇ mately 2 hours, resultantly producing the powder of a phosphor of a photostimulated luminescence material.

- a mixture containing 500g of the foregoing powder of a phosphor of a photostimulated luminescence material, 30g of PMMA, 3g of dibuthyl phthalate and 150g of toluene was mixed for approximately 20 hours in a ball mill pot to produce a liquid mixture.

- the liquid mixture was spread on a Mylar film, employing a doctor blade. After being dried at approximately 120 degrees centigrade, the Mylar film was removed from a sheet of a phosphor of a photostimulated luminescence material.

- the sheet of the phosphor of the photostimulated luminescence material placed on a quatz plate was put into an electric furnace. After the temperature of the sheet was increased to approximately 150 degrees centigrade in an oxidizing atmosphere (in the air) , the temperature of the sheet was kept unchanged for 2 hours. Thereafter, the temperature of the sheet was further increased to 550 degrees centigrade, before being kept unchanged for approx ⁇ imately 2 hours. Finally, the temperature of the sheet was decreased to 100 degrees centigrade or less. By this step, a semi-sintered sheet containing no binder therein and having no camber thereon was produced.

- the semi-sintered sheet placed on a graphite plate was put into an electric furnace. After the tempera ⁇ ture of the sheet was increased up to approximately 600 degrees centigrade in a reducing atmosphere containing a mixture of hydrogen and nitrogen or a mixture of hydrogen and helium, the temperature of the sheet was kept unchanged for approximately 2 hours, before the temperature of the sheet was decreased down to 100 degrees centigrade or less. By this step, a sintered sheet or a sheet of a phosphor of a photostimulated luminescence material having the thickness of approximately 300 micrometers was produced.

- a sheet of tempered glass or quatz glass was set with epoxy resin on one side of the foregoing sintered sheet, and a Mylar film, a tempered glass film or a quatz glass film was set with epoxy resin on the other side of the foregoing sintered sheet, for the purpose to protect the phosphor of the- photostimulated luminescence material from humidity.

- an X-ray imaging plate was produced. The finished X-ray imaging plate was placed 70cm apart from the focus of an X-ray tube which was excited with the conditions of 120KV of the tube voltage and 50mA of the tube current, and it was exposed to the X-ray emitt ⁇ ed by the foregoing X-ray tube, for 0.2sec.

- the exposed X-ray imaging plate was excited with a laser having the wavelength of 780nm and having the power of lOmW.

- the intensity of the fluorescence emitted by the X-ray imaging plate was sensed with a photomultiplier. The results showed that the intensity of the luminescence of the X-ray imaging plate was 3.7 times as large as the prior art.

- TlBr 0.568 g were mixed for 6 hours employing a ball mill.

- the cover of the pot was kept open for 3 hours, and the mixture was dried at approximately 150 degrees centigrade for 3 hours under vacuum position.

- the ball mill was employed again for 6 hours for further mixing of the dried mixture. If the mixture was wet, vacuum desiccation or heat trealment in the air was employed.

- a mixture containing 500g of the foregoing mixture (the raw material of a phosphor of a photostimu ⁇ lated luminescence material), 30g of PMMA, 3g of dibuthyl phthalate and 150g of toluene was mixed for approximately 20 hours in a ball mill pot to produce a liquid mixture.

- the liquid mixture was spread on a Mylar film, employing a doctor blade. After being dried at approximately 120 de ⁇ grees centigrade, the Mylar film was removed from a sheet of the raw material of a phosphor of a photostimulated luminescence material.

- the sheet of the raw material of a phosphor of a photostimulated luminescence material placed on a quatz plate was put into an electric furnace. After the tempera ⁇ ture of the sheet was increased to approximately 150 de ⁇ grees centigrade in an oxidizing atmosphere (in the air) , the temperature of the sheet was kept unchanged for 2 hours. Thereafter, the temperature of the sheet was further increased to 550 degrees centigrade, before being kept unchanged for approximately 2 hours. Finally, the tempera ⁇ ture of the sheet was decreased to 100 degrees centigrade or less. By this step, a semi-sintered sheet containing no binder therein and having no camber thereon was produced.

- the semi-sintered sheet placed on a graphite plate was put into an electric furnace. After the tempera ⁇ ture of the sheet was increased up to approximately 600 degrees centigrade in a reducing atmosphere containing a mixture of hydrogen and nitrogen or a mixture of hydrogen and helium, the temperature of the sheet was kept unchanged for approximately 2 hours, before. -the temperature of the sheet was decreased down to 100 degrees centigrade or less. By this step, a sintered sheet or a sheet of a phosphor of a photostimulated luminescence material having the thickness of approximately 300 micrometers was produced.

- a sheet of tempered glass or quatz glass was set with epoxy resin on one side of the foregoing sintered sheet, and a Mylar film, a tempered glass film or a quatz glass film was set with epoxy resin on the other side of the foregoing sintered sheet, for the purpose to protect the phosphor of the photostimulated luminescence material from humidity.

- an X-ray imaging plate was produced.

- the finished X-ray imaging plate was placed 70cm apart from the focus of an X-ray tube which was excited with the conditions of 120KV of the tube voltage and 50mA of the tube current, and it was exposed to the X-ray emitt ⁇ ed by the foregoing X-ray tube, for 0.2sec. After the exposure, the exposed X-ray imaging plate was excited with a laser having the wavelength of 780nm and having the power of lOmW. The intensity of the fluorescence emitted by the X-ray imaging plate was sensed with a photomultiplier. The results showed that the intensity of the luminescence of the X-ray imaging plate was 3.2 times as large as the prior art.

- the materials including :

- EuCl 3 0.652 g CaS 0 . 721 g were mixed for 6 hours employing a ball mill.

- the cover of the pot was kept open for 3 hours, and the mixture was dried at approximately 150 degrees centigrade for 3 hours under vacuum position.

- the ball mill was employed again for 6 hours for further mixing of the dried mixture.

- An electric furnace was employed to calcinate the mixture in a reducing atmosphere including hydrogen and helium at approximately 900 degrees centigrade for approxi ⁇ mately 2 hours, resultantly producing the powder of a phosphor of a photostimulated luminescence material.

- a mixture containing 500g of the foregoing powder of a phosphor of a photostimulated luminescence material, 30g of PMMA, 3g of dibuthyl phthalate and 150g of toluene was mixed for approximately 20 hours in a ball mill pot to produce a liquid mixture.

- the liquid mixture was spread on a Mylar film, employing a doctor blade. After being dried at approximately 120 degrees centigrade, the Mylar film was removed from a sheet of a phosphor of a photostimulated luminescence material.

- the sheet of the phosphor of the photostimulated luminescence material placed on a quatz plate was put into an electric furnace. After the temperature of the sheet was increased to approximately 150 degrees centigrade in an oxidizing atmosphere (in the air) , the temperature of the sheet was kept unchanged for 2 hours. Thereafter, the temperature of the sheet was further increased to 600 degrees centigrade, before being kept unchanged for approximately 2 hours. Finally, the temperature of the sheet was decreased to 100 degrees centigrade or less. By this step, a semi-sintered sheet containing no binder therein and having no camber thereon was produced-.

- the semi-sintered sheet placed on a graphite plate was put into an electric furnace. After the temperature of the sheet was increased up to approximately 800 degrees centigrade in a reducing atmosphere containing a mixture of hydrogen and nitrogen or a mixture of hydrogen and helium, the temperature of the sheet was kept unchanged for approximately 2 hours, before the temperature of the sheet was decreased down to 100 degrees centigrade or less. By this step, a sintered sheet or a sheet of a phosphor of a photostimulated luminescence material having the thickness of approximately 300 micrometers was produced.

- a sheet of tempered glass or quatz glass was set with epoxy resin on one side of the foregoing sintered sheet, and a Mylar film, a tempered glass film or a quatz glass film was set with epoxy resin on the other side of the foregoing sintered sheet, for the purpose to protect the phosphor of the photostimulated luminescence material from humidity.

- an X-ray imaging plate was produced.

- the finished X-ray imaging plate was placed 70cm apart from the focus of an X-ray tube which was excited with the conditions of 120KV of the tube voltage and 50mA of the tube current, and it was exposed to the X-ray emitted by the foregoing X-ray tube, for 0.2sec. After the exposure, the exposed X-ray imaging plate was excited with a laser having the wavelength of 780nm and having the power of lOmW. The intensity of the fluorescence emitted by the X-ray imaging plate was sensed with a photomultiplier. The results showed that the intensity of the luminescence of the X-ray imaging plate was 3.6. times as large as the prior art. The luminescence intensity of the foregoing semi- sintered sheet was 1.8 times as large as the prior art.

- the materials including :

- CaS 0.721 g were mixed for 6 hours employing a ball mill.

- the cover of the pot was kept open for 3 hours, and the mixture was dried at approximately 150 degrees centigrade for 3 hours under vacuum position.

- the ball mill was employed again for 6 hours for further mixing of the dried mixture. If the mixture was wet, vacuum desiccation or heat trealment in the air was employed.

- the liquid mixture was spread on a Mylar film, employing a doctor blade. After being dried at approximately 120 de ⁇ grees centigrade, the Mylar film was removed from a sheet of the raw material of a phosphor of a photostimulated luminescence material.

- the sheet of the raw material of a phosphor of a photostimulated luminescence material placed on a quatz plate was put into an electric furnace. After the tempera ⁇ ture of the sheet was increased to approximately 150 de ⁇ grees centigrade in an oxidizing atmosphere (in the air) , the temperature of the sheet was kept unchanged for 2 hours. Thereafter, the temperature of the sheet was further increased to 600 degrees centigrade, before being kept unchanged for approximately 2 hours. Finally, the tempera ⁇ ture of the sheet was decreased to 100 degrees centigrade or less. By this step, a semi-sintered sheet containing no binder therein and having no camber thereon was produced.

- the semi-sintered sheet placed on a graphite plate was put into an electric furnace. After the tempera ⁇ ture of the sheet was increased up to approximately 800 degrees centigrade in a reducing atmosphere containing a mixture of hydrogen and nitrogen or a mixture of hydrogen and helium, the temperature of the sheet was kept unchanged for approximately 2 hours, before the temperature of the sheet was decreased down to 100 degrees centigrade or less. By this step, a sintered sheet or a sheet of a phosphor of a photostimulated luminescence material having the thickness of approximately 300 micrometers was produced.

- a sheet of tempered glass or quatz glass was set with epoxy resin on one side of the foregoing sintered sheet, and a Mylar film, a tempered glass film or a quatz glass film was set with epoxy resin on the other side of the foregoing sintered sheet, for the purpose to protect the phosphor of the photostimulated luminescence material from humidity.

- an X-ray imaging plate was produced.

- the finished X-ray imaging plate was placed 70cm apart from the focus of an X-ray tube which was excited with the conditions of 120KV of the tube voltage and 50mA of the tube current, and it was exposed to the X-ray emitt ⁇ ed by the foregoing X-ray tube, for 0.2sec. After the exposure, the exposed X-ray imaging plate was excited with a laser having the wavelength of 780nm and having the power of lOmW. The intensity of the fluorescence emitted by the X-ray imaging plate was sensed with a photomultiplier. The results showed that the intensity of the luminescence of the X-ray imaging plate was 3.7 times as large as the prior art. Seventh Example

- the materials including :

- EuCl 3 0.652 g Y 2 0 3 2 . 259 g were mixed for 6 hours employing a ball mill.

- the cover of the pot was kept open for 3 hours, and the mixture was dried at approximately 150 degrees centigrade for 3 hours under vacuum position.

- the ball mill was employed again for 6 hours for further mixing of the dried mixture.

- An electric furnace was employed to calcinate the mixture in a reducing atmosphere including hydrogen and helium at approximately 900 degrees centigrade for approxi ⁇ mately 2 hours, resultantly producing the powder of a phosphor of a photostimulated luminescence material.

- a mixture containing 500g of the foregoing powder of a phosphor of a photostimulated luminescence material, 30g of PMMA, 3g of dibuthyl phthalate and 150g of toluene was mixed for approximately 20 hours in a ball mill pot to produce a liquid mixture.

- the liquid mixture was spread on a Mylar film, employing a doctor blade. After being dried at approximately 120 degrees centigrade, the Mylar film was removed from a sheet of a phosphor of a photostimulated luminescence material.

- the sheet of the phosphor of the photostimulated luminescence material placed on a quatz plate was put into an electric furnace. After the temperature of the sheet was increased to approximately 150 degrees centigrade in an oxidizing atmosphere (in the air) , the temperature of the sheet was kept unchanged for 2 hours. Thereafter, the temperature of the sheet was further increased to 600 degrees centigrade, before being kept unchanged for approximately 2 hours. Finally, the temperature of the sheet was decreased to 100 degrees centigrade or less. By this step, a semi-sintered sheet containing no binder therein and having no camber thereon was produced.

- the semi-sintered sheet placed on a graphite plate was put into an electric furnace. After the temperature of the sheet was increased up to approximately 800 degrees centigrade in a reducing atmosphere containing a mixture of hydrogen and nitrogen or a mixture of hydrogen and helium, the temperature of the sheet was kept unchanged for approximately 2 hours, before the temperature of the sheet was decreased down to 100 degrees centigrade or less. By this step, a sintered sheet or a sheet of a phosphor of a photostimulated luminescence material having the thickness of approximately 300 micrometers was produced.

- a sheet of tempered glass or quatz glass was set with epoxy resin on one side of the foregoing sintered sheet, and a Mylar film, a tempered glass film or a quatz glass film was set with epoxy resin on the other side of the foregoing sintered sheet, for the purpose to protect the phosphor of the photostimulated luminescence material from humidity.

- an X-ray imaging plate was produced.

- the finished X-ray imaging plate was placed 70cm apart from the focus of an X-ray tube which was excited with the conditions of 120KV of the tube voltage and 50mA of the tube current, and it was exposed to the X-ray emitt ⁇ ed by the foregoing X-ray tube, for 0.2sec. After the exposure, the exposed X-ray imaging plate was excited with a laser having the wavelength of 780nm and having the power of l ⁇ mW. The intensity of the fluorescence emitted by the X-ray imaging plate was sensed with a photomultiplier. The results showed that the intensity of the luminescence of the X-ray imaging plate was 3.6 times as large as the prior art. The luminescence intensity of the foregoing semi- sintered sheet was 1.7 times as large as the prior art. Eighth Example

- the materials including :

- Y 2 0 3 2.259 g were mixed for 6 hours employing a ball mill.

- the cover of the pot was kept open for 3 hours, and the mixture was dried at approximately 150 degrees centigrade for 3 hours under vacuum position.

- the ball mill was employed again for 6 hours for further mixing of the dried mixture. If the mixture was wet, vacuum desiccation or heat trealment in the air was employed.

- the liquid mixture was spread on a Mylar film, employing a doctor blade. After being dried at approximately 120 de ⁇ grees centigrade, the Mylar film was removed from a sheet of the raw material of a phosphor of a photostimulated luminescence material.

- the sheet of the raw material of a phosphor of a photostimulated luminescence material placed on a quatz plate was put into an electric furnace. After the tempera ⁇ ture of the sheet was increased to approximately 150 de ⁇ grees centigrade in an oxidizing atmosphere (in the air) , the temperature of the sheet was kept unchanged for 2 hours. Thereafter, the temperature of the sheet was further increased to 600 degrees centigrade, before being kept unchanged for approximately 2 hours. Finally, the tempera ⁇ ture of the sheet was decreased to 100 degrees centigrade or less. By this step, a semi-sintered sheet containing no binder therein and having no camber thereon was produced.

- the semi-sintered sheet placed on a graphite plate was put into an electric furnace. After the tempera ⁇ ture of the sheet was increased up to approximately 900 degrees centigrade in a reducing atmosphere containing a mixture of hydrogen and nitrogen or a mixture of hydrogen and helium, the temperature of the sheet was kept unchanged for approximately 2 hours, before the temperature of the sheet was decreased down to 100 degrees centigrade or less. By this step, a sintered sheet or a sheet of a phosphor of a photostimulated luminescence material having the thickness of approximately 300 micrometers was produced.

- a sheet of tempered glass or quatz glass was set with epoxy resin on one side of the foregoing sintered sheet, and a Mylar film, a tempered glass film or a quatz glass film was set with epoxy resin on the other side of the foregoing sintered sheet, for the purpose to protect the phosphor of the photostimulated luminescence material from humidity.

- an X-ray imaging plate was produced.

- the finished X-ray imaging plate was placed 70cm apart from the focus of an X-ray tube which was excited with the conditions of 120KV of the tube voltage and 50mA of the tube current, and it was exposed to the X-ray emitt ⁇ ed by the foregoing X-ray tube, for 0.2sec. After the exposure, the exposed X-ray imaging plate was excited with a laser having the wavelength of 780nm and having the power of lOmW. The intensity of the fluorescence emitted by the X-ray imaging plate was sensed with a photomultiplier. The results showed that the intensity of the luminescence of the X-ray imaging plate was 3.5 times as large as the prior art.

- any of the sintered sheets of phos ⁇ phor of photostimulated luminescence material in accordance with tne foregoing embodiments accepts a process for curing a camber of a sheet of phosphor of photostimulated lumines ⁇ cence material presented earlier in Item "C.

- Embodiment of a means to achieve the fourth object can be cured by a s econd calcination in a reducing atmosphere containing helium and hydrogen at a temperature range of 800-900 degrees centigrade, the second calcination being conducted under a condition that a quatz plate is piled on the sintered sheet.

- the materials including :

- Distilled water 1,000 g were mixed in a reactor vessel to produce a liquid mixture, which was dried by application of a water heating process at approximately 80 degrees centigrade to be applied thereto for 6 hours, before application of another heating at 80 degrees centigrade to be applied thereto in a dryer for 5 hours.

- the dried mixture was entered into a calcination boat, which was further entered into an electric furnace which was supplied a mixture of H 2 and He with a quantity ratio range of 20:1 through 1:100.

- a calcination process was carried out in the elctric furnace at 800 degrees centigrade for 30min through 10 hours. By this step, a phosphor of a photostimulated luminescence material was obtained.

- This phosphor of the photostimulated luminescence material can be employed as an X-ray imaging plate.

- the foregoing phosphor of the photostimulated luminescence material is crushed into pow ⁇ der, which is mixed with a binder of dibuthyl phthalate and PMMA and with a solvent of toluene, resultantly producing a liquid mixture containing at least a phosphor of a photo ⁇ stimulated luminescence material and PMMA with a quantity ratio of 1:9.5.

- the liquid mixture is spread on a Mylar film having the thickness of 250 micrometers by employing a doctor blade.

- the liquid mixture plate is dried to become a solid sheet of a phosphor of a photostimulated luminescence material having the thickness of 300 micrometers.

- a Mylar film having the thickness of 12 micrometers was set on the foregoing solid sheet of a phosphor of a photostimulated luminescence material with an adhesive of polyester.

- X-ray imaging plates were excited with an X-ray (80KV, 200mA), and were exposed to He-Ne laser (having the wavelength of 630nm and the power of lOmW) and a semiconductor laser (having the wavelength of 830nm and the power of lOmW). The emitted fluorescence was sensed with a photomultiplier.

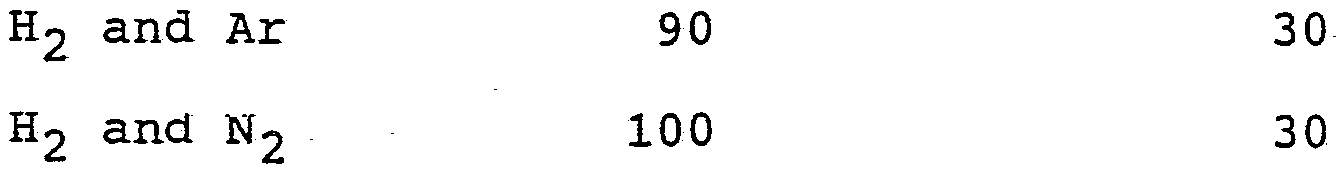

- Table 3 tabulates the results, showing the result of the case in which a mixture of H 2 and N was employed as a reducing gas as a reference or 100.

- composition of phosphors of photostimulated luminescence materials is selected to shift the acceptable or sensitive wavelength range of an exciting light to the wavelength range of a light to be emitted by a semiconductor laser e.g. an AlGaAs laser.

- the materials including BaCl 2 8.553 g

- the foregoing raw materials mixed in a manner described above was entered into a quatz boat, and a calci ⁇ nation process was conducted in a tube furnace for the foregoing " materials.

- the calcination process was conducted 882 degrees centigrade for 90min. in He gas containing H 2 gas by 20vol.% and flowing at a flow rate of lOliters/min.

- the calcinated raw materials were gradually cooled to the ambient tempera ⁇ ture in the aforementioned atmosphere.

- the sintered phos ⁇ phor of the photostimulated luminescence material was crushed, and the powder of the phosphor of the photostimu ⁇ lated luminescence material was obtained.

- the spectrum of this phosphor of the photostimulated luminescence material is shown in Fig. 9.

- a phos ⁇ phor of a photostimulated luminescence material in accord ⁇ ance with this invention has a less sensitivity for an exciting light in the visible wavelength range and has a large sensitivity for an exciting light in the wavelength range of a light to be emitted by a semiconductor laser, thereby allowing a semiconductor laser to be employed as a reading or exciting light.

- any of the methods for producing a phosphor of a photostimulated luminescence material in accordance with this embodiment requires a sufficient degree of the mixture process of the raw materials, the mixing process being allowed to be conducted employing any of the ordinary mixers including a mixer, a ball mill, a V type blender, a rod mill and the like.

- the raw material for acti ⁇ vation is employed in a liquid phase, the liquid mixture of the materials containing the raw material for activation is desirable to be dried, before the foregoing mixing process is conducted. Since the raw material of a phosphor is hygroscopic, the foregoing mixing process is desirable to be conducted in a dry atmosphere or in an inert gas.

- the atmosphere acceptable as a calcination atmosphere includes the ambient atmosphere (an oxidizing atmosphere) , a reducing atmos ⁇ phere, an inert gas atmosphere and the like. Since the ambient atmosphere is oxidizing, however, a reducing atmos ⁇ phere or an inert gas atmosphere is desirable.

- a suitable reducing atmosphere is nitrogen atmosphere containing hy ⁇ drogen no more than 30vol. %.

- a suitable inert gas atmos ⁇ phere includes a nitrogen gas atmosphere, argon gas atmos ⁇ phere, helium gas atmosphere and the like.

- a phosphor of a photostimulated luminescence material made of a complex halogenide sulfide of an alkaline earth metal activated by bivalent europium in accordance with this invention employs bivalent europium as an activator. Therefore, when a phos ⁇ phor of a photostimulated luminescence material is pro ⁇ prised, tervalent europium must be contained in the raw material to be reduced to bivalent europium during a calci ⁇ nation process. Therefore, when a phosphor of a photostimu ⁇ lated luminescence material employing bivalent europium as an activator is produced, a calcination process must be conducted in a reducing atmosphere.

- the desirable calcination temperature depends on the kind and composition of the raw material of a phosphor of a photostimulated luminescence material. As is in the other ordinary cases, a temperature range, 600 through 1,000 degrees centigrade is suitable. Further, a tempera ⁇ ture range, 700 through 950 degrees centigrade, is more preferable.

- the desirable length of time for calcination depends on the kind and/or composition of the raw material, the quantity of the raw material to be entered into a heat resistant vessel in one time, the calcination temperature and the like. Provided the temperature is selected from the foregoing desirable temperature range, a range of 30min. through 48 hours is suitable for the length of time for calcination, and a range of 1 hour through 12 hours is more preferable.

- a crushing process and a classification process are essential. It is desirable that the crushing process and classification process are conducted in a dry atmosphere, an inert gas atmosphere or the like.

- the phosphor of the photostimulated luminescence material in accordance with this invention has a peak of the sensitivity for an exciting light in the wavelength range of infrared ray, provided it has been excited by an X-ray, an ultraviolet ray, an electron beam or the like.

- a phosphor of a pnotostimulated luminescence material in accordance with this invention has a less magnitude of luminescence inten ⁇ sity in the visible wavelength range, resultantly having an advantage for reading it employing a semiconductor laser. As is illustrated in Fig.

- the luminescence intensity of BaClBr-CaS:Eu for 630nm is approximately 60% of that for 780nm. Therefore, an image processing system employing this phosphor of the photostimulated luminescence material is allowed to employ a semiconductor laser rather than a He-Ne laser for reading the X-ray pattern memorized in the X-ray imaging plate, resultantly decreasing the dimention and weight of the equipment for the image pro ⁇ cessing system.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Inorganic Chemistry (AREA)

- Materials Engineering (AREA)

- Organic Chemistry (AREA)

- Physics & Mathematics (AREA)

- General Engineering & Computer Science (AREA)

- High Energy & Nuclear Physics (AREA)

- Luminescent Compositions (AREA)

- Conversion Of X-Rays Into Visible Images (AREA)

Abstract