US3918820A - Paint applicator - Google Patents

Paint applicator Download PDFInfo

- Publication number

- US3918820A US3918820A US503254A US50325474A US3918820A US 3918820 A US3918820 A US 3918820A US 503254 A US503254 A US 503254A US 50325474 A US50325474 A US 50325474A US 3918820 A US3918820 A US 3918820A

- Authority

- US

- United States

- Prior art keywords

- paint

- casing

- cover plate

- trigger member

- outlet orifice

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C—APPARATUS FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C17/00—Hand tools or apparatus using hand held tools, for applying liquids or other fluent materials to, for spreading applied liquids or other fluent materials on, or for partially removing applied liquids or other fluent materials from, surfaces

- B05C17/002—Hand tools or apparatus using hand held tools, for applying liquids or other fluent materials to, for spreading applied liquids or other fluent materials on, or for partially removing applied liquids or other fluent materials from, surfaces with feed system for supplying material from an external source; Supply controls therefor

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46B—BRUSHES

- A46B11/00—Brushes with reservoir or other means for applying substances, e.g. paints, pastes, water

- A46B11/001—Brushes with reservoir or other means for applying substances, e.g. paints, pastes, water with integral reservoirs

- A46B11/002—Brushes with reservoir or other means for applying substances, e.g. paints, pastes, water with integral reservoirs pressurised at moment of use manually or by powered means

- A46B11/0024—Brushes with reservoir or other means for applying substances, e.g. paints, pastes, water with integral reservoirs pressurised at moment of use manually or by powered means with a permanently displaceable pressurising member that remain in position unless actuated, e.g. lead-screw or ratchet mechanisms, toothpaste tube twisting or rolling devices

Definitions

- the invention relates to a device for applying spreadable compositions to relatively smooth and flat surfaces.

- the invention is a painting device which comprises an applicator pad for applying paint received from a flexible, disposable paint package.

- paint applicator pads have appeared on the market and have become increasingly popular. Unlike paint rollers, pads can be used to cover the corners of a room and have a total contact between the paint applicator and the surface to be painted. Unfortunately, however, painting pads have a number of deficiencies in that they can only hold a limited supply of paint, they must be used in conjunction with a paint pan and they require frequent return to the pan to avoid dripping.

- Brushes are the most universal and versatile painting tool since they can be used over any surface and can pick up paint directly from the paint can. Paint brushes, however, are inefficient for applying paint to a large relatively flat surface.

- the cleaning of the paint applicator system generally involves substantial time and effort and is the most annoying aspect of the painting chore.

- Cleaning generally requires the use of organic solvent for oil base paints or soapy water for water base latex paints.

- the spent solvent is usually disposed to the sewer system, which results in a higher B.O.D. (biological oxygen demand) for sewerage treatment.

- B.O.D. biological oxygen demand

- a substantial quantity of solvent is released into the atmosphere through evaporation.

- some paints contain fungicidal and germicidal compounds which tend to harm common biological sewerage treatment processes while they additionally increase the BOD.

- the present invention provides a device for effectively and conveniently applying paint (and spreadable compositions in general) to relatively large surface areas with a minimum of time and effort involved in paint handling and cleaning.

- the paint is supplied from a flexible paint container having a rupturable seal for supplying paint therethrough.

- the flexible paint container is directly inserted into a casing which serves as both a paint applicator and a paint holding reservoir.

- the casing of the invention has a swingable cover plate, and outlet orifice, and a pistol grip handle which actuates a ratchet means for urging the cover plate inwardly to squeeze the flexible paint container and force paint through the rupturable seal of the paint container to supply paint from the casing.

- An applicator pad is detachably supported upon the casing and contains a hole for receiving paint supplied from the flexible paint container.

- the painting device of the invention substantially reduces the time and effort involved in paint handling, transferring, applying and cleaning as compared to paint applied with the prior art devices.

- the controllably sustained paint supply from the flexible paint container to the applicator pad eliminates the need for a paint pan andreduces the time and motion for paint transfer. Since the paint may be continuously supplied to the applicator surface, there is no need for the use of a foam backing to hold a large paint supply on the pad, and the danger of spillage and dripping is virtually eliminated.

- the paint is supplied directly from the original container to the applicator pad, the

- the invention relates'to a device for supplying paint to an applicator pad having a hole for passage of paint therethrough which comprises 1) a casing for holding a supply of paint, said casing having a rectangular face with a supporting surface for the applicator pad, said face having an outlet orifice positioned for alignment with the hole in the applicator pad; a circular wall opposite the interior surface of the face and extending from the lower section thereof; and a cover plate mounted to swing within the confines of the casing toward the outlet orifice; 2) a handle for grasping the casing; and 3) means for controllably urging the cover plate inward toward the outlet orifice to reduce the volume defined by the casing.

- the paint applicator device of the invention comprises 1) a paint container having opposing flexible walls and a discharge outlet with a rupturable seal; 2) a casing for holding the flexible paint container, and easing having a face with an outlet orifice in alignment with the discharge outlet of the paint container, a cover plate forceably abutting the paint container and adapted to swing within the confines of the casing, a ratchet member slideably mounted in a wall channel generally opposite the outlet orifice and positioned to urge the cover plate toward the outlet orifice'for squeezing paint out of the flexible container, a finger-actuated trigger member which is an outward extension of the ratchet member, a gripping handle facing the trigger member, a compression spring abutting the trigger member and casing surface so that BRIEF DESCRIPTION OF THE DRAWINGS

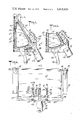

- FIG. 1 is an exploded perspective view of a paint applicator illustrating one embodiment of the present invention.

- FIG. 2 is an enlarged sectional view taken substantially above the plane and in the direction indicated by thearrows of line 2 of FIG. 4.

- FIG. 3 is an enlarged, partial sectional view taken substantially along the plane and in the'direction indicated by the arrows of line 3 of FIG. 4.

- FIG. 4 is a plane view of the back side of an assembled paint applicator taken substantially along line 4 of FIG. 2.

- a paint applicator device of the invention is shown generally comprised of a casing body 10, disposable painting pad 12, trigger mechanism 14, casing cover plate 16, and flexible paint container 18 (paint contents not shown).

- the applicator painting pad 12 consists of fibrous painting surface 20, supporting base 22, non-permanent adhesive bonding surface 24, and opening 26 for the supply of paint therethrough.

- the disposable paint applicator pad can be described as a plush pile fabric having a hole and an adhesive backing surface. If desired, the applicator pad may also be supported on a foam resin material of spongy character such as is generally used on commercially available paint applicator pads.

- the commonly used fibrous painting pad surfaces may be used herein.

- a commercially available pile fabric consisting of grey stock of a mohair plush upholstery velvet was found to be entirely satisfactory for the purposes of the invention.

- the thickness of the pile will be selected according to the nature of the paint and the surface to be painted.

- Disposable paint applicator pad 12 is detachably secured to the casing body by any suitable means. It is particularly convenient to employ a non-permanent adhcsive on the supporting base to secure the pad onto the casing body. The applicator pad can then be discarded merely by stripping away the pad from the casing service much as one would remove strippable.

- the adhesive surface Prior to application, the adhesive surface can be protected by the use of a common silicone treated paper. which is removed just prior to attaching the pad.

- the sizes and shapes of pad 12 and hole 26 will obviously accommodate the size and shape of the casing supporting surface. A rectangular shape of dimensions 4 by 6" and a diameter pad hole are adequate.

- Casing body 10 has a rectangular face 28 for supporting the applicator pad 12 and opening 30 for permitting transfer of paint to the applicator pad.

- Face 28 contains small hole 32 for removal of the applicator pad by inserting a stiff pushing rod therethrough to separate the corner of the pad from the face of the casing.

- a 3/16" hole located about /2 from the corner of the face should be satisfactory for most adhesives.

- the location of opening 30 will preferably be slightly above the center of the face 28 in order to counteract the effect of gravity in spreading and transferring paint evenly over the whole pad area. For example, it was found convenient to place the center of opening 30 about of an inch above the center of face 28 having dimensions 4" by 6" and a hole opening of 6 diameter. Offset of the hole permits the use of the pad with a paint transfer pan merely by mounting the pad upside down to block the face opening.

- the casing body 10 contains edge guides 33 and 34, two pinholes 36 (only one shown) to pivot cover plate 16, and sidewalls 38, and 42.

- Sidewalls 38 and 40 are generally flat and perpendicular to face 28.

- Wall 42 curves out from face 28 in a circular direction.

- the volume defined by face 28 and sidewalls 38, 40 and 42 may vary according to the desired holding capacity.

- Casing wall 42 contains saw-tooth grooves 44 and 46 which are arranged to permit inward movement and prevent outward movement of finger or toe members riding thereon. Casing wall 42 is further provided with channel 48 which permits ratchet member 50 to slide therein.

- Stem 52 is shown integral with casing wall 42 for attaching handle 54 and for housing trigger mechanism 14. Stem 52 has two rectangular sides, a rightangled corner, and bolt 56 to rigidly connect the handle to the casing body. Stern 52 contains aperture 49 for the insertion and movement of trigger member 58 as ratchet member 50 slides within channel 48.

- Handle 54 has a right-angled female cut which mates with stem 52 and is provided with a hole for the insertion of holding bolt 56 on one end and a threaded (or tapered) hole (not shown) on the other end forthe insertion of an extension pole (not shown).

- the mating of handle 54 and stem 52 is such that rotation of the handle a half turn with respect to the stem will line up the bolt hold and change the angle of the handle to the pad surface from 30 to 60. The smaller angle will be convenient for wall painting and the larger angle will be convenient for ceiling painting.

- Trigger mechanism 14 is comprised of ratchet member 50 and trigger 58 which is an outward extension of the ratchet member.

- Ratchet member 50 is arced so that it may slide within arced channel 48 of the casing body and trigger 58 may move back and forth in a channel (not shown) of stem 52.

- Compressing spring 60 will be positioned within a channel of stem 52 (shown in greater detail in FIG. 2) and will abut the stem surface at one end and the trigger 58 at the other end to exert a force on trigger 58 which is transmitted to ratchet member 50.

- Cover plate 16 is comprised of rectangular plate 64 containing hinge pins 66 and 68 which are designed to pivot in holes 36 to permit swinging of the cover plate within the confines of the casing body.

- the cover plate contains spring-loaded toe members 70, 72 and 74 which are designed to ride on saw-toothed elements 46, 50 and 44, respectively.

- Toe members 70, 72 and 74 are positioned by means of yoke 76 and pins 78, 80 and 82, which have enlarged heads so that movement of toe members 70, 72 and 74 is restricted in a plane parallel to rectangular plate 64 along a line defined by toe member slots 84, 86 and 88, respectively.

- Toe members 70, 72 and 74 are spring-loaded by means of tension springs 90, 92 and 94 which are attached to yoke 76 and toe member extensions 96, 98 and 100, respectively.

- the toe member extensions may also serve the function of a toe release means since the extensions may be pushed in a direction toward the cover plate hinges to untrack the toe members from the sawtoothed grooves and thereby permit the cover plate to swing out of the interior of the body casing.

- Toe members 70 and 74 ride on saw-toothed grooves 46 and 44, respectively, to hold cover plate 16 in position.

- Toe member 72 is engaged by the saw-toothed grooves of ratchet member 50 to exert an inward force upon the cover plate 16 to reduce the volume defined by the casing body and thereby urge the contents thereof through opening 30.

- ratchet member 50 swings upwardly or outwardly from the easing body and toe member 72 is engaged by ratchet member 50 in a new advance position as toe members 70 and 74 are engaged by saw-toothed grooves 46 and 44, respectively, to hold cover plate 16 in position and prevent its outward movement.

- spring 60 is compressed to increase the force which it will apply to the trigger and ratchet member.

- the release of the trigger will result in the spring pushing the ratchet member and cover plate inwardly to squeeze the paint located within the casing.

- This arrangement has the advantage of permitting the predetermination of the maximum rate of paint flow by selecting the stiffness of the spring and the hole opening for transferring paint to the painting pad. There is, therefore, no danger of accidental overflow by finger action.

- ones finger may be used to counteract the spring for extremely fine control of the supply of paint delivered from the casing.

- the supply of paint can be remotely controlled since trigger 58 is provided with hole 62 for insertion of a string for pulling.

- the larger handle angle e.g., 60

- the applicator device may be made out of metal or plastie, it is preferable to use a light weight metal such as aluminum for the one piece construction of the triggerratchet member since the saw-teeth thereof transmits the force for pushing the cover plate inwardly.

- Flexible paint container 18 is designed for use in the paint applicator device of the invention.

- Paint container l8 (paint contents not shown) conforms to the available shape and volume defined by rectangular face 28, sidewalls 38, 40 and 42, and cover plate 16 and is flexible enough to be squeezed by the swinging action of the cover plate.

- the paint container must be strong enough to withstand the rigors of transporting and handling and, at the same time be sufficiently stable to withstand the chemical action of the paint contained therein.

- An example of such a material is the commercially available bi-axially stretched polypropylene sheet material having the desired strength and stability.

- Other materials useful for constructing the flexible container are well known to those skilled in the art.

- Paint container 18 is shown containing annular coupler 102 for insertion into opening 30 of face 28 of the casing body.

- the length of coupler 102 is matched with the thickness of face 28 in order to hold the paint container in place within the casing.

- the flexible paint container also includes rupturable seal-104 positioned at the annular coupler entry.

- the paint container may be conveniently constructed by attaching the plastic annular coupler 102 either by glue or by welding .to a plastic bag of the folded sidewall type. Application of a heat seal to the top of the bag, after charging paint to an open bag containing a bottom seal (not shown) and the coupler, completes the bag.

- This method provides a completely sealed bag until a paint conduit is opened by piercing the wall of the mounted bag through the hole of the annular coupler.

- the size of coupler 102 should be such that it fits into casing opening 30 with a slight force and protrudes slightly into the pad opening 26.

- the size of hole 104 should be set depending upon the flow requirement of a given paint.

- the location of the coupler is preferably such that top edge of the flexible paint container comes near the swing axis of cover plate 16, when the bag is mounted.

- FIG. 2 is a cross-sectional view of the trigger mechanism l4 illustrating the means by which the cover plate 16 is urged inwardly to supply paint or any spreadable composition from flexible container 18 to the pad 12.

- ratchet member 50 slides outwardly within channel 48 to engage toe member 72 in an advanced tooth position moving in the direction towards trigger 58.

- Toe member 72 is spring-loaded by means of spring 92 which is attached from toe member extension 98 to yoke 76.

- Toe member 72 is positioned by means of yoke 76 and pin which permit the toe member to move in a line defined by slot 86 which is in a plane parallel to plate 64.

- the release of trigger 58 causes compression spring 60 to exert a greater force thereon which is transmitted from ratchet member 50 to toe member 72 to increase the force which plate 64 will exert on flexible paint container 18 to squeeze the contents therein, thereby supplying paint through annular coupler 102 to applicator pad 12.

- toe member 74 rides on saw-toothed groove 44 which is arranged to prevent the toe member 74 and plate 64 from moving in an upward direction away from face 28.

- Toe member 74 is spring-loaded by means of tension spring 94 which is attached to yoke 76 and toe member extension 100.

- Toe member 74 is secured to plate 64 by means of yoke 76 and pin 82 which permit the toe member to move in a line defined by slot 88 which is on a planeparallel to plate 64.

- FIG. 4 shows the backside of the assembled device embodied by the invention.

- Plate 64 via toe member 72 is urged inwardly by the action of ratchet member 50 which slides inwardly along channel 48.

- ratchet member 50 As ratchet member 50 is moved upward to engage toe member 72 in a new advanced tooth position thereon, toe members 70 and 74 engage saw-toothed grooves 46 and 44, re spectively, to hold the cover plate in position.

- Plate 64 can be raised when in the interior of the body casing defined by face 28 and sidewalls 38, 40 and 42 by pushing toe member extensions 96, 98 and 100 toward hinge pins 66 and 68 to release the spring-loaded toe members from contact with the saw-tooth grooves 46, 50 and 44, respectively.

- a paint device for use with a paint-applying pad having a hole for passage of paint therethrough and a flexible paint container having a discharge outlet which paint device comprises 1) a casing for holding the flexible paint container, and easing having a face for support of the paint-applying pad, said face having an outlet orifice positioned for alignment with the hole in the paint-applying pad and the discharge outlet of the paint container; a circular wall opposite the interior surface of the face and extending from the lower section thereof;,a covered plate adapted to swing within the confines of the casing for applying pressure upon the flexible paint container to force paint through the discharge outlet; and a channel situated in the curved wall of the casing; 2) a ratchet member slidably mounted in the casing wall channel and positioned to urge the cover plate inward toward the outlet orifice; 3) a finger-actuated trigger member which is an outward extension of the ratchet member; 4) a gripping handle facing the trigger member; 5) a compression spring abutting the

- said means comprises a ratchet channel positioned in the curved wall of the casing for retaining the cover plate upon movement of the trigger member toward the gripping handle.

- the device of claim 1 comprising a flexible paint let orifice positioned for the alignment with the hole in the applicator pad; a circular wall opposite the interior surface of the face and extending from the lower section thereof, said circular wall having a channel containing a slidably mounted ratchet member; and a cover plate mounted to swing within the confines of the casing toward the outlet orifice, said cover plate adapted for contact with the slidably mounted ratchet member for urging the cover plate toward the outlet orifice upon application ofa force to the ratchet member; 2) a handle for grasping the casing; and 3) means for actuating the ratchet member for controllably urging the cover plate inward toward the outlet orifice to reduce the volume defined by the casing.

- said means comprises a finger-actuated trigger member facing the handle and being an outward extension of the ratchet member, and a compression spring abutting the trigger member for applying a force thereon which is transmitted to the ratchet member for urging the cover plate inward toward the outlet orifice, said spring positioned so that movement of the trigger member toward the handle compresses the spring and increases the inward force applied upon the plate upon release of the trigger member.

- the device of claim 6 comprising means for retainber toward the handle.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Coating Apparatus (AREA)

Abstract

A general purpose paint applicator which comprises 1) a paint container having opposing flexible walls and a discharge outlet with a rupturable seal; 2) a casing for holding the flexible paint container, said casing having a rigid sidewall with an outlet orifice in alignment with the discharge outlet of the paint container, a cover plate forceably abutting the paint container and adapted to swing within the confines of the casing, a ratchet member slideably mounted in a wall channel generally opposite the outlet orifice and positioned to urge the cover plate toward the outlet orifice for squeezing paint out of the flexible container, a finger-actuated trigger member which is an outward extension of the ratchet member, a gripping handle facing the trigger member, a compression spring abutting the trigger member and casing surface so that movement of the trigger member toward the gripping handle compresses the spring and increases the inward force applied upon the cover plate upon release of the trigger member; and means for retaining the cover plate upon movement of the trigger member toward the gripping handle; and 3) an applicator pad detachably secured to the casing and having a hole in alignment with the outlet orifice thereof so that paint is supplied from the flexible paint container therethrough.

Description

'[22 Filed:

United States Patent 11 1 Kim [4 1 Nov. 11, 1975 1 1 PAINT APPLICATOR Dae Sik Kim, 23 l-learthstone Drive, Medfield, Mass. 02052 Sept. 5, 1974 [21] Appl. No.: 503,254

[76] Inventor:

[52] 11.5. C1. 401/152; 401/156; 401/132; 401/268 [51] Int. Cl. A4613 1/00 [58] Field Of Search 401/208, 152, 17, 172, 401/156, 265, 266, 132, 196, 268; 15/210 [56] References Cited UNlTED STATES PATENTS 2,711.098 6/1955 Ames 401/171 X 2.809.513 10/1957 Ames v 1 401/171 X 2,824,326 2/1958 AmCS 401/208 X 2,824,442 2/1958 Ames 401/171 X 3.070.824 l/l963 Martin 401/208 X 3,116,511 H1964 Hoveland 401/171 3,713,744 l/l973 Sims 15/210 R X Primary Ermniner-Lawrenee Charles Attorney, Agent, or F irmRoy Ott [57] ABSTRACT A general purpose paint applicator which comprises 1 a paint container having opposing flexible walls and a discharge outlet with a rupturable seal; 2) a casing for holding the flexible paint container, said casing having a rigid sidewall with an outlet orifice in alignment with the discharge outlet of the paint container, a cover plate forceably abutting the paint container and adapted to swing within the confines of the casing, a ratchet member slideably mounted in a wall channel generally opposite the outlet orifice and positioned to urge the cover plate toward the outlet orifice for squeezing paint out of the flexible container, a fingeractuated trigger member which is an outward extension of the ratchet member, a gripping handle facing the trigger member, a compression spring abutting the trigger member and easing surface so that movement of the trigger member toward the gripping handle compresses the spring and increases the inward force applied upon the cover plate upon release of the trigger member; and means for retaining the cover plate upon movement of the trigger member toward the gripping handle; and 3) an applicator pad detachably secured to the casing and having a hole in alignment with the outlet orifice thereof so that paint is supplied from the flexible paint container therethrough.

7 Claims, 4 Drawing Figures US. Patent Nov. 11,1975 Sheet10f2 3,918,820

yea

US. Patent Nov. 11, 1975 Sheet 2 012 3,918,820

MKKWW a PAINT APPLICATOR BACKGROUND OF THE INVENTION 1. Field of the Invention This invention relates to a device for applying spreadable compositions to relatively smooth and flat surfaces. In a more specific aspect, the invention is a painting device which comprises an applicator pad for applying paint received from a flexible, disposable paint package.

2. Description of the Prior Art Many devices and systems are employed for painting various surfaces. The most common method of painting a relatively smooth and flat surface area such as the walls and ceiling of a room involves the use of a paint roller. Although a roller is efficient for applying paint to a large flat surface, it requires additional equipment such as a paint pan to transfer the paint from the container to the roller and a paint edger to cover the corners which are not accessible to the roller. The use of this additional equipment, of course, requires the user to expend additional time for cleaning. Also, a rapid rolling action tends to splatter paint over a large area and create additional cleanup chores. A further disadvantage, is that a large portion of the paint roller surface is not in contact with the surface to be painted and thus becomes dead weight and a source of undesirable dripping. This is particularly the case when using the roller to paint a ceiling. i

More recently, paint applicator pads have appeared on the market and have become increasingly popular. Unlike paint rollers, pads can be used to cover the corners of a room and have a total contact between the paint applicator and the surface to be painted. Unfortunately, however, painting pads have a number of deficiencies in that they can only hold a limited supply of paint, they must be used in conjunction with a paint pan and they require frequent return to the pan to avoid dripping.

Brushes are the most universal and versatile painting tool since they can be used over any surface and can pick up paint directly from the paint can. Paint brushes, however, are inefficient for applying paint to a large relatively flat surface.

Since all three of the common painting devices have limited paint holding capacity, a significant portion of the painting time and effort is spent in transferring paint to the applicator. In addition, these devices and the paint pans associated with them need to be cleaned after each painting since they are not designed as disposable items.

There are many commercially available paint applicators which have a sustained supply of paint from either a portable reservoir or a stationary reservoir by means of a conduit. Although a majority of these applicators are for industrial use, some non-industrial rollers and brushes have a pressurized portable paint supply. Undoubtedly, these applicators with a continuous supply of paint will save the time and effort transferring the paint and will eliminate the use of additional tools such as a pan in the case of a roller or pad. Unfortunately, the paint reservoir and conduit system needs cleaning after each operation. Usually this requires substantially more work than that required for cleaning a paint transfer pan.

The cleaning of the paint applicator system generally involves substantial time and effort and is the most annoying aspect of the painting chore. Cleaning generally requires the use of organic solvent for oil base paints or soapy water for water base latex paints. The spent solvent is usually disposed to the sewer system, which results in a higher B.O.D. (biological oxygen demand) for sewerage treatment. Also, a substantial quantity of solvent is released into the atmosphere through evaporation. In addition, some paints contain fungicidal and germicidal compounds which tend to harm common biological sewerage treatment processes while they additionally increase the BOD. It has now been found that these deficiencies and problems associated with the prior art painting systems can be eliminated or reduced by the device of the present invention wherein paint is fed directly from a disposable package to a paint applicator pad without the need of paint pans or reservoir and conduit systems which need to be cleaned after use.

SUMMARY OF THE INVENTION The present invention provides a device for effectively and conveniently applying paint (and spreadable compositions in general) to relatively large surface areas with a minimum of time and effort involved in paint handling and cleaning. The paint is supplied from a flexible paint container having a rupturable seal for supplying paint therethrough. The flexible paint container is directly inserted into a casing which serves as both a paint applicator and a paint holding reservoir. The casing of the invention has a swingable cover plate, and outlet orifice, and a pistol grip handle which actuates a ratchet means for urging the cover plate inwardly to squeeze the flexible paint container and force paint through the rupturable seal of the paint container to supply paint from the casing. An applicator pad is detachably supported upon the casing and contains a hole for receiving paint supplied from the flexible paint container.

The painting device of the invention substantially reduces the time and effort involved in paint handling, transferring, applying and cleaning as compared to paint applied with the prior art devices. The controllably sustained paint supply from the flexible paint container to the applicator pad eliminates the need for a paint pan andreduces the time and motion for paint transfer. Since the paint may be continuously supplied to the applicator surface, there is no need for the use of a foam backing to hold a large paint supply on the pad, and the danger of spillage and dripping is virtually eliminated. In addition, as the paint is supplied directly from the original container to the applicator pad, the

usual cleanup mess and fuss associated with the painting chore is virtually eliminated.

In one embodiment, the invention relates'to a device for supplying paint to an applicator pad having a hole for passage of paint therethrough which comprises 1) a casing for holding a supply of paint, said casing having a rectangular face with a supporting surface for the applicator pad, said face having an outlet orifice positioned for alignment with the hole in the applicator pad; a circular wall opposite the interior surface of the face and extending from the lower section thereof; and a cover plate mounted to swing within the confines of the casing toward the outlet orifice; 2) a handle for grasping the casing; and 3) means for controllably urging the cover plate inward toward the outlet orifice to reduce the volume defined by the casing.

In a more specific embodiment, the paint applicator device of the invention comprises 1) a paint container having opposing flexible walls and a discharge outlet with a rupturable seal; 2) a casing for holding the flexible paint container, and easing having a face with an outlet orifice in alignment with the discharge outlet of the paint container, a cover plate forceably abutting the paint container and adapted to swing within the confines of the casing, a ratchet member slideably mounted in a wall channel generally opposite the outlet orifice and positioned to urge the cover plate toward the outlet orifice'for squeezing paint out of the flexible container, a finger-actuated trigger member which is an outward extension of the ratchet member, a gripping handle facing the trigger member, a compression spring abutting the trigger member and casing surface so that BRIEF DESCRIPTION OF THE DRAWINGS FIG. 1 is an exploded perspective view of a paint applicator illustrating one embodiment of the present invention.

FIG. 2 is an enlarged sectional view taken substantially above the plane and in the direction indicated by thearrows of line 2 of FIG. 4.

FIG. 3 is an enlarged, partial sectional view taken substantially along the plane and in the'direction indicated by the arrows of line 3 of FIG. 4.

FIG. 4 is a plane view of the back side of an assembled paint applicator taken substantially along line 4 of FIG. 2.

.DESCRIPTION OF THE PREFERRED EMBODIMENT Referring to FIG. 1, in detail, a paint applicator device of the invention is shown generally comprised of a casing body 10, disposable painting pad 12, trigger mechanism 14, casing cover plate 16, and flexible paint container 18 (paint contents not shown). The applicator painting pad 12 consists of fibrous painting surface 20, supporting base 22, non-permanent adhesive bonding surface 24, and opening 26 for the supply of paint therethrough. The disposable paint applicator pad can be described as a plush pile fabric having a hole and an adhesive backing surface. If desired, the applicator pad may also be supported on a foam resin material of spongy character such as is generally used on commercially available paint applicator pads. The commonly used fibrous painting pad surfaces may be used herein.

For example, a commercially available pile fabric consisting of grey stock of a mohair plush upholstery velvet was found to be entirely satisfactory for the purposes of the invention. Of course, the thickness of the pile will be selected according to the nature of the paint and the surface to be painted.

Disposable paint applicator pad 12 is detachably secured to the casing body by any suitable means. It is particularly convenient to employ a non-permanent adhcsive on the supporting base to secure the pad onto the casing body. The applicator pad can then be discarded merely by stripping away the pad from the casing service much as one would remove strippable.

wallpaper from a wall surface. Prior to application,the adhesive surface can be protected by the use of a common silicone treated paper. which is removed just prior to attaching the pad. The sizes and shapes of pad 12 and hole 26 will obviously accommodate the size and shape of the casing supporting surface. A rectangular shape of dimensions 4 by 6" and a diameter pad hole are adequate.

Casing body 10 has a rectangular face 28 for supporting the applicator pad 12 and opening 30 for permitting transfer of paint to the applicator pad. Face 28 contains small hole 32 for removal of the applicator pad by inserting a stiff pushing rod therethrough to separate the corner of the pad from the face of the casing. A 3/16" hole located about /2 from the corner of the face should be satisfactory for most adhesives. The location of opening 30 will preferably be slightly above the center of the face 28 in order to counteract the effect of gravity in spreading and transferring paint evenly over the whole pad area. For example, it was found convenient to place the center of opening 30 about of an inch above the center of face 28 having dimensions 4" by 6" and a hole opening of 6 diameter. Offset of the hole permits the use of the pad with a paint transfer pan merely by mounting the pad upside down to block the face opening.

The casing body 10 contains edge guides 33 and 34, two pinholes 36 (only one shown) to pivot cover plate 16, and sidewalls 38, and 42. Sidewalls 38 and 40 are generally flat and perpendicular to face 28. Wall 42 curves out from face 28 in a circular direction. The volume defined by face 28 and sidewalls 38, 40 and 42 may vary according to the desired holding capacity. A

convenient casing volume is represented by a 45 circular section with a radius of 3.5" and a length of 5," which represents about 24 cubic inches or about 1/10 of a gallon. Such a volume would hold slightly more than 1 pound of a typical paint.

Casing wall 42 contains saw- tooth grooves 44 and 46 which are arranged to permit inward movement and prevent outward movement of finger or toe members riding thereon. Casing wall 42 is further provided with channel 48 which permits ratchet member 50 to slide therein. Stem 52 is shown integral with casing wall 42 for attaching handle 54 and for housing trigger mechanism 14. Stem 52 has two rectangular sides, a rightangled corner, and bolt 56 to rigidly connect the handle to the casing body. Stern 52 contains aperture 49 for the insertion and movement of trigger member 58 as ratchet member 50 slides within channel 48.

Trigger mechanism 14 is comprised of ratchet member 50 and trigger 58 which is an outward extension of the ratchet member. Ratchet member 50 is arced so that it may slide within arced channel 48 of the casing body and trigger 58 may move back and forth in a channel (not shown) of stem 52. Compressing spring 60 will be positioned within a channel of stem 52 (shown in greater detail in FIG. 2) and will abut the stem surface at one end and the trigger 58 at the other end to exert a force on trigger 58 which is transmitted to ratchet member 50.

As trigger 58 is pulled towards handle 54, ratchet member 50 swings upwardly or outwardly from the easing body and toe member 72 is engaged by ratchet member 50 in a new advance position as toe members 70 and 74 are engaged by saw- toothed grooves 46 and 44, respectively, to hold cover plate 16 in position and prevent its outward movement. In addition, as trigger 58 is pulled towards the handle, spring 60 is compressed to increase the force which it will apply to the trigger and ratchet member. Thus, the release of the trigger will result in the spring pushing the ratchet member and cover plate inwardly to squeeze the paint located within the casing. This arrangement has the advantage of permitting the predetermination of the maximum rate of paint flow by selecting the stiffness of the spring and the hole opening for transferring paint to the painting pad. There is, therefore, no danger of accidental overflow by finger action. In addition, ones finger may be used to counteract the spring for extremely fine control of the supply of paint delivered from the casing.

The supply of paint can be remotely controlled since trigger 58 is provided with hole 62 for insertion of a string for pulling. The larger handle angle (e.g., 60) will give a more favorable triggering angle for direct pulling of the string when painting a ceiling. Although the applicator device may be made out of metal or plastie, it is preferable to use a light weight metal such as aluminum for the one piece construction of the triggerratchet member since the saw-teeth thereof transmits the force for pushing the cover plate inwardly.

FIG. 2 is a cross-sectional view of the trigger mechanism l4 illustrating the means by which the cover plate 16 is urged inwardly to supply paint or any spreadable composition from flexible container 18 to the pad 12. As trigger 58 protruding through aperture 49 is pulled towards handle 54, ratchet member 50 slides outwardly within channel 48 to engage toe member 72 in an advanced tooth position moving in the direction towards trigger 58. Toe member 72 is spring-loaded by means of spring 92 which is attached from toe member extension 98 to yoke 76. Toe member 72 is positioned by means of yoke 76 and pin which permit the toe member to move in a line defined by slot 86 which is in a plane parallel to plate 64. Movement of trigger 58 towards handle 54 compresses spring 60 at the same time toe 72 is placed in a new advanced positon on ratchet member 50. The release of trigger 58 causes compression spring 60 to exert a greater force thereon which is transmitted from ratchet member 50 to toe member 72 to increase the force which plate 64 will exert on flexible paint container 18 to squeeze the contents therein, thereby supplying paint through annular coupler 102 to applicator pad 12.

As shown in FIG. 3, as plate 64 moves towards face 28, spring-loaded toe member 74 rides on saw-toothed groove 44 which is arranged to prevent the toe member 74 and plate 64 from moving in an upward direction away from face 28. Toe member 74 is spring-loaded by means of tension spring 94 which is attached to yoke 76 and toe member extension 100. Toe member 74 is secured to plate 64 by means of yoke 76 and pin 82 which permit the toe member to move in a line defined by slot 88 which is on a planeparallel to plate 64. Pushing toe member extension 100 (as well as toe member extensions 96 and 98) in a direction away from yoke 76 releases the toe member from the saw-tooth grooves to permit the cover plate to swing out of the interior of the body casing. 1

FIG. 4 shows the backside of the assembled device embodied by the invention. Plate 64 via toe member 72 is urged inwardly by the action of ratchet member 50 which slides inwardly along channel 48. As ratchet member 50 is moved upward to engage toe member 72 in a new advanced tooth position thereon, toe members 70 and 74 engage saw- toothed grooves 46 and 44, re spectively, to hold the cover plate in position. Plate 64 can be raised when in the interior of the body casing defined by face 28 and sidewalls 38, 40 and 42 by pushing toe member extensions 96, 98 and 100 toward hinge pins 66 and 68 to release the spring-loaded toe members from contact with the saw- tooth grooves 46, 50 and 44, respectively.

While certain specific details of construction have been disclosed herein, veryclearly these will suggest many variations to those skilled in the art. It is not intended, therefore, to limit this invention to the precise details disclosed but only as set forth in the claims.

What is claimed is:

l. A paint device for use with a paint-applying pad having a hole for passage of paint therethrough and a flexible paint container having a discharge outlet, which paint device comprises 1) a casing for holding the flexible paint container, and easing having a face for support of the paint-applying pad, said face having an outlet orifice positioned for alignment with the hole in the paint-applying pad and the discharge outlet of the paint container; a circular wall opposite the interior surface of the face and extending from the lower section thereof;,a covered plate adapted to swing within the confines of the casing for applying pressure upon the flexible paint container to force paint through the discharge outlet; and a channel situated in the curved wall of the casing; 2) a ratchet member slidably mounted in the casing wall channel and positioned to urge the cover plate inward toward the outlet orifice; 3) a finger-actuated trigger member which is an outward extension of the ratchet member; 4) a gripping handle facing the trigger member; 5) a compression spring abutting the trigger member for applying a force thereon which is transmitted to the ratchet member for urging the cover plate inward toward the outlet orifice, and spring positioned so that movement of the trigger member toward the gripping handle compresses the spring and increases the inward force applied upon the cover plate upon release of the trigger member; and 6) means for retaining the cover plate upon movement of the trigger member toward the gripping handle.

2. The paint device of claim 1 wherein said means comprises a ratchet channel positioned in the curved wall of the casing for retaining the cover plate upon movement of the trigger member toward the gripping handle.

3. The paint device of claim 2 wherein said cover plate includes a spring-loaded toe member in contact with the ratchet member and a spring-loaded toe member in contact with the wall ratchet channel.

4. The device of claim 1 comprising a flexible paint let orifice positioned for the alignment with the hole in the applicator pad; a circular wall opposite the interior surface of the face and extending from the lower section thereof, said circular wall having a channel containing a slidably mounted ratchet member; and a cover plate mounted to swing within the confines of the casing toward the outlet orifice, said cover plate adapted for contact with the slidably mounted ratchet member for urging the cover plate toward the outlet orifice upon application ofa force to the ratchet member; 2) a handle for grasping the casing; and 3) means for actuating the ratchet member for controllably urging the cover plate inward toward the outlet orifice to reduce the volume defined by the casing.

6. The device of claim 5 wherein said means comprises a finger-actuated trigger member facing the handle and being an outward extension of the ratchet member, and a compression spring abutting the trigger member for applying a force thereon which is transmitted to the ratchet member for urging the cover plate inward toward the outlet orifice, said spring positioned so that movement of the trigger member toward the handle compresses the spring and increases the inward force applied upon the plate upon release of the trigger member.

7. The device of claim 6 comprising means for retainber toward the handle.

Claims (7)

1. A paint device for use with a paint-applying pad having a hole for passage of paint therethrough and a flexible paint container having a discharge outlet, which paint device comprises 1) a casing for holding the flexible paint container, and casing having a face for support of the paint-applying pad, said face having an outlet orifice positioned for alignment with the hole in the paint-applying pad and the discharge outlet of the paint container; a circular wall opposite the interior surface of the face and extending from the lower section thereof; a covered plate adapted to swing within the confines of the casing for applying pressure upon the flexible paint container to force paint through the discharge outlet; and a channel situated in the curved wall of the casing; 2) a ratchet member slidably mounted in the casing wall channel and positioned to urge the cover plate inward toward the outlet orifice; 3) a finger-actuated trigger member which is an outward extension of the ratchet member; 4) a gripping handle facing the trigger member; 5) a compression spring abutting the trigger member for applying a force thereon which is transmitted to the ratchet member for urging the cover plate inward toward the outlet orifice, and spring positioned so that movement of the trigger member toward the gripping handle compresses the spring and increases the inward force applied upon the cover plate upon release of the trigger member; and 6) means for retaining the cover plate upon movement of the trigger member toward the gripping handle.

2. The paint device of claim 1 wherein said means comprises a ratchet channel positioned in the curved wall of the casing for retaining the cover plate upon movement of the trigger member toward the gripping handle.

3. The paint device of claim 2 wherein said cover plate includes a spring-loaded toe member in contact with the ratchet member and a spring-loaded toe member in contact with the wall ratchet channel.

4. The device of claim 1 comprising a flexible paint container having a discharge outlet which comprises a protruding annular coupler adapted for insertion into the outlet orifice of the casing for protecting the casing surface from exposure to paint.

5. A device for supplying a spreadable composition to an applicator pad having a hole for passage of the spreadable composition therethrough which comprises 1) a casing for holding a supply of the spreadable composition, said casing having a face with a supporting surface for the applicator pad, said face having an outlet orifice positioned for the alignment with the hole in the applicator pad; a circular wall opposite the interior surface of the face and extending from the lower section thereof, said circular wall having a channel containing a slidably mounted ratchet member; and a cover plate mounted to swing within the confines of the casing toward the outlet orifice, said cover plate adapted for contact with the slidably mounted ratchet member for urging the cover plate toward the outlet orifice upon application of a force to the ratchet member; 2) a handle for grasping the casing; and 3) means for actuating the ratchet member for controllably urging the cover plate inward toward the outlet orifice to reduce the volume defined by the casing.

6. The device of claim 5 wherein said means comprises a finger-actuated trigger member facing the handle and being an outward extension of the ratchet member, and a compression spring abutting the trigger member for applying a force thereon which is transmitted to the ratchet member for urging the cover plate inward toward the outlet orifice, said spring positioned so that movement of the trigger member toward the handle compresses the spring and increases the inward force applied upon the plate upon reLease of the trigger member.

7. The device of claim 6 comprising means for retaining the cover plate upon movement of the trigger member toward the handle.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US503254A US3918820A (en) | 1974-09-05 | 1974-09-05 | Paint applicator |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US503254A US3918820A (en) | 1974-09-05 | 1974-09-05 | Paint applicator |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US3918820A true US3918820A (en) | 1975-11-11 |

Family

ID=24001338

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US503254A Expired - Lifetime US3918820A (en) | 1974-09-05 | 1974-09-05 | Paint applicator |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US3918820A (en) |

Cited By (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4566816A (en) * | 1983-08-29 | 1986-01-28 | Padco, Inc. | Pressure fed paint roller |

| EP0380258A2 (en) * | 1989-01-24 | 1990-08-01 | William Speakman | Dispensing apparatus |

| US5000602A (en) * | 1989-08-01 | 1991-03-19 | Kim Dae S | Paint applicator |

| WO1993019854A1 (en) * | 1992-04-01 | 1993-10-14 | Minipack Systems Limited | Applicators, particularly for paints |

| WO1996023701A1 (en) * | 1995-01-31 | 1996-08-08 | The Testor Corporation | Paint dispensing system |

| WO1997027949A2 (en) | 1996-01-31 | 1997-08-07 | The Testor Corporation | Paint pouch fitting |

| US6554902B2 (en) * | 2001-07-13 | 2003-04-29 | Ruey Fwu Yan | Device for painting wall members or corner straps |

| US20040247775A1 (en) * | 2003-06-06 | 2004-12-09 | Boulais Dennis R. | Positive displacement coating deposition apparatus and method |

| US20050117959A1 (en) * | 2003-09-23 | 2005-06-02 | Master Stroke Tools, Inc. | Paint cartridge edger and spreader |

| US20080189892A1 (en) * | 2007-02-12 | 2008-08-14 | Joseph Leon Lutgen | Liquid applicator |

| US20160016193A1 (en) * | 2014-07-15 | 2016-01-21 | Nova Wildcat Shur-Line, Llc | Paint edging system and apparatus |

| US10350630B2 (en) * | 2010-09-08 | 2019-07-16 | Ctp Gmbh | Apparatus with pad having a fabric structure to apply a liquid |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2711098A (en) * | 1952-04-21 | 1955-06-21 | George W Williams | Mastic-applying and surfacing-finishing tools |

| US2809513A (en) * | 1953-08-17 | 1957-10-15 | George W Williams | Recess-filling mastic applicator |

| US2824442A (en) * | 1953-08-17 | 1958-02-25 | George W Williams | Mastic applicator and finishing tool |

| US2824326A (en) * | 1955-04-04 | 1958-02-25 | George W Williams | Automatic feed paint and texture applicator |

| US3070824A (en) * | 1959-08-03 | 1963-01-01 | Robert G Marltin | Fountain paint applicator |

| US3116511A (en) * | 1962-08-06 | 1964-01-07 | Hoveland Julian Cleon | Mastic applicator |

| US3713744A (en) * | 1971-03-02 | 1973-01-30 | C Sims | Combination cleaner, polisher and waxing device for walls and floors |

-

1974

- 1974-09-05 US US503254A patent/US3918820A/en not_active Expired - Lifetime

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2711098A (en) * | 1952-04-21 | 1955-06-21 | George W Williams | Mastic-applying and surfacing-finishing tools |

| US2809513A (en) * | 1953-08-17 | 1957-10-15 | George W Williams | Recess-filling mastic applicator |

| US2824442A (en) * | 1953-08-17 | 1958-02-25 | George W Williams | Mastic applicator and finishing tool |

| US2824326A (en) * | 1955-04-04 | 1958-02-25 | George W Williams | Automatic feed paint and texture applicator |

| US3070824A (en) * | 1959-08-03 | 1963-01-01 | Robert G Marltin | Fountain paint applicator |

| US3116511A (en) * | 1962-08-06 | 1964-01-07 | Hoveland Julian Cleon | Mastic applicator |

| US3713744A (en) * | 1971-03-02 | 1973-01-30 | C Sims | Combination cleaner, polisher and waxing device for walls and floors |

Cited By (24)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4566816A (en) * | 1983-08-29 | 1986-01-28 | Padco, Inc. | Pressure fed paint roller |

| EP0380258A2 (en) * | 1989-01-24 | 1990-08-01 | William Speakman | Dispensing apparatus |

| EP0380258A3 (en) * | 1989-01-24 | 1991-05-02 | William Speakman | Dispensing apparatus |

| US5000602A (en) * | 1989-08-01 | 1991-03-19 | Kim Dae S | Paint applicator |

| WO1993019854A1 (en) * | 1992-04-01 | 1993-10-14 | Minipack Systems Limited | Applicators, particularly for paints |

| EP1428583A1 (en) | 1995-01-31 | 2004-06-16 | The Testor Corporation | Paint dispensing system |

| US5622283A (en) * | 1995-01-31 | 1997-04-22 | The Testor Corporation | Paint dispensing system |

| US5683013A (en) * | 1995-01-31 | 1997-11-04 | The Testor Corporation | Paint dispensing system |

| LT4299B (en) | 1995-01-31 | 1998-02-25 | The Testor Corporation | Paint dispensing system |

| WO1996023701A1 (en) * | 1995-01-31 | 1996-08-08 | The Testor Corporation | Paint dispensing system |

| WO1997027949A2 (en) | 1996-01-31 | 1997-08-07 | The Testor Corporation | Paint pouch fitting |

| US5845812A (en) * | 1996-01-31 | 1998-12-08 | The Testor Corporation | Paint pouch fitting |

| US6554902B2 (en) * | 2001-07-13 | 2003-04-29 | Ruey Fwu Yan | Device for painting wall members or corner straps |

| WO2005000478A1 (en) * | 2003-06-06 | 2005-01-06 | Boston Scientific Limited | Positive displacement coating deposition apparatus and method |

| US20040247775A1 (en) * | 2003-06-06 | 2004-12-09 | Boulais Dennis R. | Positive displacement coating deposition apparatus and method |

| US20050117959A1 (en) * | 2003-09-23 | 2005-06-02 | Master Stroke Tools, Inc. | Paint cartridge edger and spreader |

| US7306389B2 (en) | 2003-09-23 | 2007-12-11 | Master Stroke Tools, Inc. | Paint cartridge edger and spreader |

| US20080189892A1 (en) * | 2007-02-12 | 2008-08-14 | Joseph Leon Lutgen | Liquid applicator |

| US8032973B2 (en) | 2007-02-12 | 2011-10-11 | Newell Operating Company | Liquid applicator |

| US10350630B2 (en) * | 2010-09-08 | 2019-07-16 | Ctp Gmbh | Apparatus with pad having a fabric structure to apply a liquid |

| US20160016193A1 (en) * | 2014-07-15 | 2016-01-21 | Nova Wildcat Shur-Line, Llc | Paint edging system and apparatus |

| US10040093B2 (en) * | 2014-07-15 | 2018-08-07 | Nova Wildcat Shur-Line, Llc. | Paint edging system and apparatus |

| AU2015204330B2 (en) * | 2014-07-15 | 2020-02-20 | True Value Company, L.L.C. | Paint edging system and apparatus |

| US10960430B2 (en) | 2014-07-15 | 2021-03-30 | Nova Wildcat Shur-Line, Llc. | Paint edging system and apparatus |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US3918820A (en) | Paint applicator | |

| US3137880A (en) | Quick-acting clamping handle for disposable liquid applicators | |

| US7988376B2 (en) | Fluid applicators and methods of making same | |

| US4168560A (en) | Battery-driven cleaning device | |

| US4639156A (en) | Painting apparatus and method | |

| US2754033A (en) | Ink dispenser | |

| US8834054B2 (en) | Paint trimmer with edging guide | |

| US5605572A (en) | Glue applicator system | |

| US3304573A (en) | Liquid coating equipment | |

| US20200196831A1 (en) | Cleaning tool and containment system | |

| US3850298A (en) | Carrying and storage case for liquid applicator | |

| US4852203A (en) | Paint edger for the application of paint | |

| WO1996027449A9 (en) | Glue applicator system | |

| US4501096A (en) | Hand-held sanding device | |

| US3712748A (en) | Paint applicator | |

| US6474519B1 (en) | Caulking gun holster with tool punch | |

| CA3050376A1 (en) | Surface repair tool | |

| US3226761A (en) | Container applicator | |

| US4215448A (en) | Paint applying tool | |

| US6695181B1 (en) | Mud gun and hopper assembly | |

| US3032801A (en) | Liquid applying device | |

| US20050118345A1 (en) | Paint edger | |

| KR102342273B1 (en) | Mobile Apparatus For Suppling Water Tape | |

| US20190218798A1 (en) | System, Apparatus and Methods for a Hand-Held Drywall Tape Applicator | |

| CN217295536U (en) | Construction tool capable of coating solvent |