US2747825A - Paint pail holder - Google Patents

Paint pail holder Download PDFInfo

- Publication number

- US2747825A US2747825A US296139A US29613952A US2747825A US 2747825 A US2747825 A US 2747825A US 296139 A US296139 A US 296139A US 29613952 A US29613952 A US 29613952A US 2747825 A US2747825 A US 2747825A

- Authority

- US

- United States

- Prior art keywords

- ladder

- paint

- pail

- paint pail

- holder

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06C—LADDERS

- E06C7/00—Component parts, supporting parts, or accessories

- E06C7/14—Holders for pails or other equipment on or for ladders

- E06C7/146—Holders for pails or other equipment on or for ladders made from wire

Definitions

- PAINT PAIL HOLDER Filed June 28, 1952 INVENTUR 90mm) /4. Lac/zenmayer t ATTORNEY Ufllttid States tr PAINT PAIL HOLDER Roman A. Lachenmayer, St. Paul, Minn.

- a feature of the present invention resides in the fact that the paint pail support is designed for attachment to either side of the ladder depending upon the position best suited to the painter and to the work being done.

- the device is reversible so that the paint pail may be quickly moved from one side of the ladder to the other when desired.

- a feature of the present invention resides in the provision of a paint pail support which is extremely simple in form and which may be produced at low cost.

- the device comprises two main parts which are normally secured together by a separable connection such as a pivot bolt. Both parts of the structure are preferably formed of wire or bar type material which is bent to the desired form.

- One type of the structure comprises a receptacle for supporting the pail while the other part comprises a device designed for attachment to the ladder.

- a feature of the present invention lies in the provision of a paint pail holder which is attached to a ladder engaging bracket and which includes a supporting portion extending downwardly from the ladder bracket to engage the side wall of the ladder. As a result the paint pail support is pressed against the side of the ladder, thus holding the support in proper relation to the ladder.

- a further feature of the present invention lies in the provision of a ladder engaging bracket which includes a central pivot engaging portion designed to overlie the outer surface of a ladder rail.

- This pivot support is connected by two spaced transverse members which are designed to extend over the forward surface of the ladder rail. Diverging hooks are connected to the ends of the transverse portions, each hook being designed to extend along the inner surface of the ladder rail with the uppermost hook engaging over a ladder rung. While one hook engages the rung the other hook holds the bracket in fixed relation to the ladder.

- a further feature of the present invention resides in the provision of a pail encircling ring which is supported above the base of the paint pail supporting portion of the 2,747,825 Patented May 29, 1956 structure.

- the ring is of sufiicient diameter to encircle the largest paint pail normally used on such occasions and holds the paint pail from tilting while supported upon the base portion of the holder.

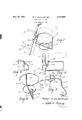

- Figure 1 is a perspective view of the paint pail holder in position on a ladder.

- Figure 2 is a side elevational view of the paint pail holder in readiness for use.

- Figure 3 is a front elevational view of the holder.

- Figure 4 is a perspective view of the pail holding portion of the apparatus.

- Figure 5 is a perspective view of the ladder attachment bracket, the bracket being tilted to better disclose the construction thereof.

- the paint pail holder is designated in general by the letter A and is designed for attachment with a ladder such as B.

- the ladder of the type normally employed uses a pair of generally parallel side rails 10 which are connected by longitudinally spaced rungs 11.

- the rails 19 may vary somewhat in size and shape, but are normally of substantially standard size.

- the holder A includes a pivot supporting eye 12, one end of which is bent downwardly as indicated at 13 and off-set at its lower end as indicated at 14.

- the holder is normally formed of two lengths of wire rod or similar material which may be of any desired cross section.

- the off-set lower end 14 of the downwardly extending portion 13 is connected to a horizontally extending supporting portion 15 designed to extend beneath the paint pail to support the same.

- An upwardly directed portion 16 is connected to the horizontally extending portion 15 at a point spaced from the eye 12 a distance sufficient to accommodate a paint pail C therebetween.

- the upper extremity of the upwardly extending portion 16 is bent into ring shaped form to form a can encircling ring 17.

- a ring shaped member 19 may be spot welded to the horizontally extending portion 15 in axial alignment with the ring 17.

- the ring 19 is normally of smaller diameter than the ring 17 so that a smaller can of paint, or the tapered lower end of a paint pot may be readily supported thereupon.

- the ladder engaging bracket portion of the device is indicated in general by the numeral 20.

- This bracket portion includes a central loop 21 which is of proper size to accommodate a pivot bolt, the ends 22 and 23 of the loop 21 being bent into alignment to provide oppositely directed portions 24 and 25.

- These aligned portions 24 and 25 are bent at substantially right angles to provide ladder rail spanning portions 26 and 27 which are designed to extend over the forward edge surface 29 of the ladder rails 10.

- the ends of the ladder spanning portions are provided with diverging shanks 3t) and 31 which terminate in inwardly directed hook ends 32 and 33.

- the hook ends face one another so that when one hook end is hooked over a ladder rung, the extremity of the hook is directed downwardly while the other hook is directed upwardly in spaced relation.

- the bracket 20 is designed to fit about the rail 10 of a ladder B.

- the transversely extending portions 26 and 27 extend over the forward face 19 of the rail, while the eye or loop 21 extends on the outside of the rail, while the hook extremities 32 and 33 lie against the inner surface of the rail 10.

- the bracket fixes the position of the pail support when hooked upon a ladder rung.

- a pivot bolt 34 extends through the loop 21 and through the eye 12 to pivotally connect the two main parts of the pail holder.

- a wing nut 35 or other suitable tightening means is provided upon the bolt 34 so that the two parts may be clamped in proper angular relation.

- the bracket is designed to pivot relative to the pail holder so as to compensate for varying angles at which the ladder may be inclined and also to permit the ladder engaging bracket to be pivoted into a reverse direction when the bracket is attached to the opposite rail 10 from the one illustrated in the drawings.

- the offset 14 beneath the pivot point engages against the outer surface of the ladder rail and provides a brace for the horizontally extending portion 15. This greatly strengthens the support and permits the support to be made of lighter weight material than would otherwise be necessary.

- a paint pail holder including two main portions formed of metal rod material, one of said portions comprising a ladder engaging bracket portion and the other a paint container holding portion, said ladder engaging bracket portion comprising a single strip of metal rod material having a central loop section to accommodate a pivot bolt, an integral pair of aligned oppositely directed rod end portions bent in right angles to provide a pair of spaced ladder rail supports and inwardly directed ladder rung hook ends facing one another in spaced relationship to said pair of spaced ladderv rail supports, said paint pail holding portion comprising a metal rod having a supporting eye section to accommodate a pivot bolt, an integral rod section extending downwardly from said eye section in offset relationship thereto to engage against a ladder rail, an integral pail supporting rod section extending horizontally from said downwardly extending section, an integral upwardly directed section connected to the horizontally extended section and having a can encircling ring at the end thereof on a plane parallel to the axis of the said horizontally extending supporting rod section, and pivot bolt means connecting the ladder engaging bracket portion to the paint pa

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Details Of Rigid Or Semi-Rigid Containers (AREA)

Description

y 9, 1956 R. A. LACHENMAYER 2,747,

PAINT PAIL. HOLDER Filed June 28, 1952 INVENTUR 90mm) /4. Lac/zenmayer t ATTORNEY Ufllttid States tr PAINT PAIL HOLDER Roman A. Lachenmayer, St. Paul, Minn.

Application June 28, 1952, Serial No. 296,139

2 Claims. (Cl. 248-210) recognized that difficulty exists in painting while standing upon a ladder due to the fact that the paint pail, when suspended from a ladder, is not readily accessible. The previous devices have been usually cumbersome and complicated and also costly to produce. As a result not many paint pail supports are on the market at the present time in spite of the numerous devices which have been patented.

It is an object of the present invention to provide a device for supporting a paint pail to one side of a ladder where it is readily accessible for use. By supporting the paint in this manner much time and effort is saved, resulting in decreased cost, as well as increased convenience.

A feature of the present invention resides in the fact that the paint pail support is designed for attachment to either side of the ladder depending upon the position best suited to the painter and to the work being done. The device is reversible so that the paint pail may be quickly moved from one side of the ladder to the other when desired.

A feature of the present invention resides in the provision of a paint pail support which is extremely simple in form and which may be produced at low cost. The device comprises two main parts which are normally secured together by a separable connection such as a pivot bolt. Both parts of the structure are preferably formed of wire or bar type material which is bent to the desired form. One type of the structure comprises a receptacle for supporting the pail while the other part comprises a device designed for attachment to the ladder.

A feature of the present invention lies in the provision of a paint pail holder which is attached to a ladder engaging bracket and which includes a supporting portion extending downwardly from the ladder bracket to engage the side wall of the ladder. As a result the paint pail support is pressed against the side of the ladder, thus holding the support in proper relation to the ladder.

A further feature of the present invention lies in the provision of a ladder engaging bracket which includes a central pivot engaging portion designed to overlie the outer surface of a ladder rail. This pivot support is connected by two spaced transverse members which are designed to extend over the forward surface of the ladder rail. Diverging hooks are connected to the ends of the transverse portions, each hook being designed to extend along the inner surface of the ladder rail with the uppermost hook engaging over a ladder rung. While one hook engages the rung the other hook holds the bracket in fixed relation to the ladder.

A further feature of the present invention resides in the provision of a pail encircling ring which is supported above the base of the paint pail supporting portion of the 2,747,825 Patented May 29, 1956 structure. The ring is of sufiicient diameter to encircle the largest paint pail normally used on such occasions and holds the paint pail from tilting while supported upon the base portion of the holder.

These and other objects and novel features of the present invention will be more clearly and fully set forth in the following specification and claims.

In the drawings forming a part of my specification:

Figure 1 is a perspective view of the paint pail holder in position on a ladder.

Figure 2 is a side elevational view of the paint pail holder in readiness for use.

Figure 3 is a front elevational view of the holder.

Figure 4 is a perspective view of the pail holding portion of the apparatus.

Figure 5 is a perspective view of the ladder attachment bracket, the bracket being tilted to better disclose the construction thereof.

The paint pail holder is designated in general by the letter A and is designed for attachment with a ladder such as B. The ladder of the type normally employed uses a pair of generally parallel side rails 10 which are connected by longitudinally spaced rungs 11. The rails 19 may vary somewhat in size and shape, but are normally of substantially standard size. The holder A includes a pivot supporting eye 12, one end of which is bent downwardly as indicated at 13 and off-set at its lower end as indicated at 14. The holder is normally formed of two lengths of wire rod or similar material which may be of any desired cross section. The off-set lower end 14 of the downwardly extending portion 13 is connected to a horizontally extending supporting portion 15 designed to extend beneath the paint pail to support the same. An upwardly directed portion 16 is connected to the horizontally extending portion 15 at a point spaced from the eye 12 a distance sufficient to accommodate a paint pail C therebetween. The upper extremity of the upwardly extending portion 16 is bent into ring shaped form to form a can encircling ring 17.

In order to form a more secure support for the paint pail a ring shaped member 19 may be spot welded to the horizontally extending portion 15 in axial alignment with the ring 17. The ring 19 is normally of smaller diameter than the ring 17 so that a smaller can of paint, or the tapered lower end of a paint pot may be readily supported thereupon.

The ladder engaging bracket portion of the device is indicated in general by the numeral 20. This bracket portion includes a central loop 21 which is of proper size to accommodate a pivot bolt, the ends 22 and 23 of the loop 21 being bent into alignment to provide oppositely directed portions 24 and 25. These aligned portions 24 and 25 are bent at substantially right angles to provide ladder rail spanning portions 26 and 27 which are designed to extend over the forward edge surface 29 of the ladder rails 10. The ends of the ladder spanning portions are provided with diverging shanks 3t) and 31 which terminate in inwardly directed hook ends 32 and 33. The hook ends face one another so that when one hook end is hooked over a ladder rung, the extremity of the hook is directed downwardly while the other hook is directed upwardly in spaced relation.

As indicated in Figures 1 and 2 of the drawings, the bracket 20 is designed to fit about the rail 10 of a ladder B. The transversely extending portions 26 and 27 extend over the forward face 19 of the rail, while the eye or loop 21 extends on the outside of the rail, while the hook extremities 32 and 33 lie against the inner surface of the rail 10. Thus the bracket fixes the position of the pail support when hooked upon a ladder rung.

A pivot bolt 34 extends through the loop 21 and through the eye 12 to pivotally connect the two main parts of the pail holder. A wing nut 35 or other suitable tightening means is provided upon the bolt 34 so that the two parts may be clamped in proper angular relation. The bracket is designed to pivot relative to the pail holder so as to compensate for varying angles at which the ladder may be inclined and also to permit the ladder engaging bracket to be pivoted into a reverse direction when the bracket is attached to the opposite rail 10 from the one illustrated in the drawings.

When the ladder is in place, the offset 14 beneath the pivot point engages against the outer surface of the ladder rail and provides a brace for the horizontally extending portion 15. This greatly strengthens the support and permits the support to be made of lighter weight material than would otherwise be necessary.

In accordance with the patent statutes, I have described the principles of construction and operation of my paint pail holder and while I have endeavored to set forth the best embodiment thereof, I desire to have it understood that obvious changes may be made within the scope of the following claims.

I claim:

1. A paint pail holder including two main portions formed of metal rod material, one of said portions comprising a ladder engaging bracket portion and the other a paint container holding portion, said ladder engaging bracket portion comprising a single strip of metal rod material having a central loop section to accommodate a pivot bolt, an integral pair of aligned oppositely directed rod end portions bent in right angles to provide a pair of spaced ladder rail supports and inwardly directed ladder rung hook ends facing one another in spaced relationship to said pair of spaced ladderv rail supports, said paint pail holding portion comprising a metal rod having a supporting eye section to accommodate a pivot bolt, an integral rod section extending downwardly from said eye section in offset relationship thereto to engage against a ladder rail, an integral pail supporting rod section extending horizontally from said downwardly extending section, an integral upwardly directed section connected to the horizontally extended section and having a can encircling ring at the end thereof on a plane parallel to the axis of the said horizontally extending supporting rod section, and pivot bolt means connecting the ladder engaging bracket portion to the paint pail holding portion at said hook and eye sections.

2. The structure of claim 1, wherein said ring is an integral portion of said upwardly directed section and the meeting ends of the bend forming the ring are in unjoined and open relationship and said paint pail holding portion includes an auxiliary paint container supporting means.

References Cited in the file of this patent UNITED STATES PATENTS 1,972,064 Moushon Aug. 28, 1934 2,140,045 Bergstrom Dec. 13, 1938 2,150,826 Gill Mar. 14, 1939 2,308,805 Dahl Jan. 19, 1943 2,318,930 Dietrich May 11, 1943 2,466,840 Crawford N Apr. 12, 1949

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US296139A US2747825A (en) | 1952-06-28 | 1952-06-28 | Paint pail holder |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US296139A US2747825A (en) | 1952-06-28 | 1952-06-28 | Paint pail holder |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US2747825A true US2747825A (en) | 1956-05-29 |

Family

ID=23140773

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US296139A Expired - Lifetime US2747825A (en) | 1952-06-28 | 1952-06-28 | Paint pail holder |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US2747825A (en) |

Cited By (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2954093A (en) * | 1959-02-24 | 1960-09-27 | William P Fitzgerald | Hand grip and container supporting attachment for stepladders |

| US3204903A (en) * | 1963-04-15 | 1965-09-07 | Ernest D Stoddard | Iron holder attachment |

| US3239180A (en) * | 1963-10-09 | 1966-03-08 | Bachmann Erik Holm | Can holder |

| US3559939A (en) * | 1968-04-05 | 1971-02-02 | Salvador Luna | Combination support and holder for paint can |

| US3568970A (en) * | 1969-10-13 | 1971-03-09 | John E Mallett | Receptacle holder for ironing boards |

| US4324381A (en) * | 1980-01-16 | 1982-04-13 | Stephen Morris | Beverage container support |

| US4537451A (en) * | 1983-04-13 | 1985-08-27 | Theodore Bredderman | Hanging locker shelves |

| US4824060A (en) * | 1987-04-07 | 1989-04-25 | Korda Edward S | Paint can holder for hollow rung ladders |

| FR2725237A1 (en) * | 1994-10-04 | 1996-04-05 | Tubesca | Shaped metal tool holder, for use on light alloy ladders, for tools such as drill |

| US5788199A (en) * | 1997-01-16 | 1998-08-04 | Arsenault; B. James | Eyeglass holder mounted on a rearview mirror |

| US20070272813A1 (en) * | 2006-05-17 | 2007-11-29 | Vito Monteleone | Paint bucket ladder hook with open grip design handle |

| US20070272814A1 (en) * | 2006-05-17 | 2007-11-29 | Stephen Albert Bardill | Paint bucket ladder hook with closed grip design handle |

| US20090071924A1 (en) * | 2007-09-14 | 2009-03-19 | Georgia-Pacific Consumer Products Lp | Mounting Bracket For Container Of Sheet Products |

| US20140284434A1 (en) * | 2011-07-28 | 2014-09-25 | John Patrick Cundy | Bag-supporting frame apparatus which is mountable on a substrate, and method of using same |

| US20140283449A1 (en) * | 2013-03-20 | 2014-09-25 | Pascal RAPONE | Flower pot holder |

| USD1003076S1 (en) * | 2023-03-07 | 2023-10-31 | D Squared Plant Traps LLC | Display bracket |

| US11864679B1 (en) | 2022-09-16 | 2024-01-09 | D Squared Plant Traps LLC | Display clips |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1972064A (en) * | 1933-06-24 | 1934-08-28 | Frederick C Thomas | Support for attachment to ladders |

| US2140045A (en) * | 1938-03-25 | 1938-12-13 | Ossian W F Bergstrom | Support for paint buckets and the like |

| US2150826A (en) * | 1938-07-15 | 1939-03-14 | Appliance Products Company | Garment hanger support |

| US2308805A (en) * | 1942-10-01 | 1943-01-19 | Dahl Edward | Paint hanger |

| US2318930A (en) * | 1941-12-30 | 1943-05-11 | Dietrich Howard John | Combination paintbrush and pail holder |

| US2466840A (en) * | 1946-09-27 | 1949-04-12 | Jackson E Crawford | Paint can holder |

-

1952

- 1952-06-28 US US296139A patent/US2747825A/en not_active Expired - Lifetime

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1972064A (en) * | 1933-06-24 | 1934-08-28 | Frederick C Thomas | Support for attachment to ladders |

| US2140045A (en) * | 1938-03-25 | 1938-12-13 | Ossian W F Bergstrom | Support for paint buckets and the like |

| US2150826A (en) * | 1938-07-15 | 1939-03-14 | Appliance Products Company | Garment hanger support |

| US2318930A (en) * | 1941-12-30 | 1943-05-11 | Dietrich Howard John | Combination paintbrush and pail holder |

| US2308805A (en) * | 1942-10-01 | 1943-01-19 | Dahl Edward | Paint hanger |

| US2466840A (en) * | 1946-09-27 | 1949-04-12 | Jackson E Crawford | Paint can holder |

Cited By (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2954093A (en) * | 1959-02-24 | 1960-09-27 | William P Fitzgerald | Hand grip and container supporting attachment for stepladders |

| US3204903A (en) * | 1963-04-15 | 1965-09-07 | Ernest D Stoddard | Iron holder attachment |

| US3239180A (en) * | 1963-10-09 | 1966-03-08 | Bachmann Erik Holm | Can holder |

| US3559939A (en) * | 1968-04-05 | 1971-02-02 | Salvador Luna | Combination support and holder for paint can |

| US3568970A (en) * | 1969-10-13 | 1971-03-09 | John E Mallett | Receptacle holder for ironing boards |

| US4324381A (en) * | 1980-01-16 | 1982-04-13 | Stephen Morris | Beverage container support |

| US4537451A (en) * | 1983-04-13 | 1985-08-27 | Theodore Bredderman | Hanging locker shelves |

| US4824060A (en) * | 1987-04-07 | 1989-04-25 | Korda Edward S | Paint can holder for hollow rung ladders |

| FR2725237A1 (en) * | 1994-10-04 | 1996-04-05 | Tubesca | Shaped metal tool holder, for use on light alloy ladders, for tools such as drill |

| US5788199A (en) * | 1997-01-16 | 1998-08-04 | Arsenault; B. James | Eyeglass holder mounted on a rearview mirror |

| US20070272813A1 (en) * | 2006-05-17 | 2007-11-29 | Vito Monteleone | Paint bucket ladder hook with open grip design handle |

| US20070272814A1 (en) * | 2006-05-17 | 2007-11-29 | Stephen Albert Bardill | Paint bucket ladder hook with closed grip design handle |

| US7422183B2 (en) * | 2006-05-17 | 2008-09-09 | Vito Monteleone | Paint bucket ladder hook with open grip design handle |

| US7438267B2 (en) * | 2006-05-17 | 2008-10-21 | Stephen A. Bardill | Paint bucket ladder hook with closed grip design handle |

| US20090071924A1 (en) * | 2007-09-14 | 2009-03-19 | Georgia-Pacific Consumer Products Lp | Mounting Bracket For Container Of Sheet Products |

| US20140284434A1 (en) * | 2011-07-28 | 2014-09-25 | John Patrick Cundy | Bag-supporting frame apparatus which is mountable on a substrate, and method of using same |

| US9296506B2 (en) * | 2011-07-28 | 2016-03-29 | John Patrick Cundy | Bag-supporting frame apparatus which is mountable on a substrate, and method of using same |

| US20140283449A1 (en) * | 2013-03-20 | 2014-09-25 | Pascal RAPONE | Flower pot holder |

| US11864679B1 (en) | 2022-09-16 | 2024-01-09 | D Squared Plant Traps LLC | Display clips |

| USD1003076S1 (en) * | 2023-03-07 | 2023-10-31 | D Squared Plant Traps LLC | Display bracket |

| USD1005008S1 (en) * | 2023-03-07 | 2023-11-21 | D Squared Plant Traps LLC | Display bracket |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US2747825A (en) | Paint pail holder | |

| US5191954A (en) | Ladder rung supported combination platform and utensil rack | |

| US4502566A (en) | Wall stand-off apparatus | |

| US4824060A (en) | Paint can holder for hollow rung ladders | |

| US3312441A (en) | Support for liquid container | |

| US3332653A (en) | Paint bucket holder with attaching bracket and tool stowing means | |

| US4433822A (en) | Paint can receptacle and the like | |

| US2524875A (en) | Paint can holder | |

| US4560127A (en) | Paint caddy | |

| US2677518A (en) | Collapsible clothes support | |

| US2592006A (en) | Prop attachment for ladders | |

| US2710129A (en) | Ladder supporting attachment | |

| US6250595B1 (en) | Paint bucket holder | |

| US3448956A (en) | Paint can holder | |

| US5188089A (en) | Barbecue grill support | |

| US4396174A (en) | Container support | |

| US1455221A (en) | Bucket support | |

| US3001751A (en) | Paint can holder | |

| US2162022A (en) | Adjustable ladder attachment for supporting paint pails | |

| US3420486A (en) | Ladder bracket | |

| US3710894A (en) | Ladder platform attachment | |

| US1551243A (en) | Bucket-holding attachment for ladders | |

| DE3507734A1 (en) | Suspension device for paint spraying pistols of the flow-reservoir type | |

| US2140045A (en) | Support for paint buckets and the like | |

| US3363777A (en) | Clothes caddy |