US20180237080A1 - Truck bed extension apparatus - Google Patents

Truck bed extension apparatus Download PDFInfo

- Publication number

- US20180237080A1 US20180237080A1 US15/961,024 US201815961024A US2018237080A1 US 20180237080 A1 US20180237080 A1 US 20180237080A1 US 201815961024 A US201815961024 A US 201815961024A US 2018237080 A1 US2018237080 A1 US 2018237080A1

- Authority

- US

- United States

- Prior art keywords

- hinge

- tailgate

- configuration

- auxiliary

- truck bed

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Abandoned

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B62—LAND VEHICLES FOR TRAVELLING OTHERWISE THAN ON RAILS

- B62D—MOTOR VEHICLES; TRAILERS

- B62D33/00—Superstructures for load-carrying vehicles

- B62D33/02—Platforms; Open load compartments

- B62D33/023—Sideboard or tailgate structures

- B62D33/027—Sideboard or tailgate structures movable

- B62D33/03—Sideboard or tailgate structures movable by swinging down

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B62—LAND VEHICLES FOR TRAVELLING OTHERWISE THAN ON RAILS

- B62D—MOTOR VEHICLES; TRAILERS

- B62D33/00—Superstructures for load-carrying vehicles

- B62D33/02—Platforms; Open load compartments

- B62D33/023—Sideboard or tailgate structures

- B62D33/027—Sideboard or tailgate structures movable

- B62D33/0273—Movable tailboards for vehicles comprising non-movable sideboards, e.g. pick-up trucks

Definitions

- This invention relates generally to truck tailgate accessories and, more particularly, to a truck bed extension apparatus for selectively increasing the length of a truck bed and enclosing the lengthened truck bed area.

- truck bed extension apparatus that lengthens and encloses the lengthened truck bed. Further, it would be desirable to have a truck bed extension apparatus that is pivotally movable between a stowed configuration substantially co-planar with an inner surface of the truck's tailgate to a deployed configuration extending upwardly from an opened truck tailgate and to a released configuration extending downwardly from the opened truck tailgate.

- a truck bed extension apparatus for use in extending a usable area of a truck having a pickup box and truck bed that defines an open end and that includes a primary tailgate pivotally movable between a closed configuration covering the open end and an open configuration not covering the open end, the extension apparatus having a hinge assembly that includes a hinge plate coupled to the primary tailgate, the hinge plate having a front edge adjacent a free edge of the primary tailgate.

- An auxiliary tailgate includes a lower edge pivotally coupled to the front edge of the hinge plate, the auxiliary tailgate being pivotally movable between a stowed configuration generally co-planar with and adjacent to the hinge plate and a deployed configuration extending upwardly from and perpendicular to the hinge plate.

- a pair of side panels are pivotally coupled to side edges of the auxiliary tailgate, respectively, each side panel being selectively movable between a retracted configuration generally co-planar with and bearing against an inside surface of the auxiliary tailgate and an extended configuration generally perpendicular to the inside surface of the auxiliary tailgate.

- the truck bed is extended and enclosed when the primary tailgate is at the open configuration, the auxiliary tailgate is at the deployed configuration, and the pair of side panels is at the extended configuration.

- some embodiments disclosed herein can provide a truck bed extension apparatus for selectively increasing the length of a pickup truck bed.

- some embodiments disclosed herein can provide a truck bed extension apparatus, as aforesaid, having an auxiliary tailgate that may be stowed away on an inner surface of the truck's primary tailgate or deployed upwardly when the primary tailgate is opened.

- some embodiments disclosed herein can provide a truck bed extension apparatus, as aforesaid, in which the lengthened truck bed may be enclosed by the auxiliary tailgate and foldout side panels.

- an auxiliary tailgate that folds against the primary tailgate about a hinge can suffer from fitment problems caused by sagging of the assembly when folded. For example, when such an auxiliary tailgate is folded into the stowed position and the primary tailgate of the associated vehicle is closed (i.e., oriented generally vertically), the weight of the auxiliary tailgate pulls downwardly on the hinge assembly and can thus sag downwardly. If the auxiliary tailgate sags to a position that is excessively low along the inner surface of the primary tailgate, the auxiliary tailgate can be pinched as a user attempts to close the primary tailgate, i.e., pinched between the end of the primary tailgate and the truck bed.

- an auxiliary tailgate assembly that sags should be mounted higher on the primary tailgate and/or should be sized to a shorter dimension such that it does not become pinched between the primary tailgate and the truck bed.

- Such sizing and/or positioning limits the overall height of the auxiliary tailgate when in a deployed position, and thus can create undesirable effects on aerodynamics and cargo capacity.

- a truck bed extension assembly can include an auxiliary tailgate member having a base edge pivotally attached to a top edge of a primary tailgate with a hinge.

- the hinge can include physical stops limiting movement of the hinge, in the closing direction, to the pre-determined angle, for example, approximately 90 degrees. As such, when the auxiliary tailgate is folded against the primary tailgate, the physical stops on the hinge can prevent sagging of the auxiliary tailgate.

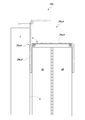

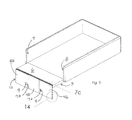

- FIG. 1 is a perspective view of a truck bed extension apparatus according to a preferred embodiment of the present invention illustrating the apparatus in an extended and enclosed configuration;

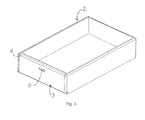

- FIG. 2 is another perspective view of the extension apparatus as in FIG. 1 , illustrating the apparatus in an extended but not enclosed configuration;

- FIG. 3 is another perspective view of the extension apparatus as in FIG. 1 , illustrating the auxiliary tailgate in a released configuration

- FIG. 4 is another perspective view of the extension apparatus as in FIG. 1 , illustrating the auxiliary tailgate in a stowed configuration

- FIG. 5 is another perspective view of the extension apparatus as in FIG. 1 , illustrating the primary tailgate in a closed configuration

- FIG. 6 is a perspective view from reverse angle of the extension apparatus as in FIG. 5 ;

- FIG. 7 a is an isolated view on an enlarged scale taken from FIG. 1 ;

- FIG. 7 b is an isolated view on an enlarged scale taken from FIG. 2 ;

- FIG. 7 c is an isolated view on an enlarged scale taken from FIG. 3 ;

- FIG. 8 a is an isolated view on an enlarged scale taken from FIG. 4 ;

- FIG. 8 b is an isolated view on an enlarged scale taken from FIG. 6 ;

- FIG. 9 is an isolated perspective view of one side panel taken from FIG. 1 ;

- FIG. 10 is an isolated perspective view of another side panel taken from FIG. 1 ;

- FIG. 11 is an isolated perspective view of the auxiliary tailgate taken from FIG. 1 ;

- FIG. 12 a is an isolated view of a first hinge

- FIG. 12 b is an isolated view of a second hinge

- FIG. 13 a is an isolated view on an enlarged scale taken from FIG. 1 ;

- FIG. 13 b is an isolated view on an enlarged scale taken from FIG. 1 ;

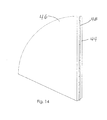

- FIG. 14 is an isolated view on an enlarged scale taken from FIG. 3 .

- FIG. 15 is a schematic side elevational view of a the extension apparatus of FIG. 1 , illustrating a sagging effect of the extension apparatus.

- FIG. 16 is an exploded view of a modification of a portion of the extension apparatus of FIG. 1 .

- FIG. 17 is an enlarged schematic, side elevational view of the hinge of FIG. 16 .

- FIG. 18 is a perspective schematic view of yet another modification of a portion of the extension apparatus of FIG. 1 .

- FIG. 19 is a schematic side elevational view of the hinge of FIG. 16 and showing three different positions of the extension apparatus.

- the truck bed extension apparatus 10 includes an auxiliary tailgate 40 , a pair of side panels 46 , and a hinge assembly 20 for use with a truck bed 2 , also referred to as a pickup box, having a primary tailgate 3 .

- the primary tailgate 3 of a pickup truck is pivotally movable between a closed configuration ( FIG. 5 ) that blocks access to the interior of the pickup box 2 via its open rear end and an open configuration ( FIGS. 2 to 4 ) that allows access to the interior, a.k.a. truck bed, via its open rear end.

- the primary tailgate 3 has a free edge 4 and may include a handle 5 configured to release the primary tailgate 3 to move between closed and open configurations.

- a conventional pickup box 2 may include fasteners adjacent the open rear end that are useful in fastening a portion of the present invention to the pickup box 2 as will be described later.

- the hinge assembly 20 of the truck bed extension apparatus 10 is coupled to the primary tailgate 3 of a truck and provides the means for mounting the additional components to the primary tailgate 3 .

- the hinge assembly 20 includes a hinge plate 22 having a front portion 24 that is, at deployed and released configuration, situated adjacent the free edge 4 of the primary tailgate 3 of a pickup truck.

- the front portion 24 may be coupled to the auxiliary tailgate 40 , such as with bolts (not shown).

- the hinge assembly 20 includes a double hinge member 30 having a first hinge 32 and a second hinge 34 rearwardly displaced from and parallel to the first hinge 32 ( FIG. 7 c ).

- the hinge plate 22 includes a first plate section 26 extending between the first hinge 32 and the second hinge 34 and a second plate section 28 extending rearwardly (away from) the second hinge 34 ( FIG. 7 b ).

- the second plate section 28 may be fixedly attached to the inner surface 6 of the primary tailgate 3 , such as with bolts (not shown), while the first plate section 26 movable relative to the inner surface 6 of the primary tailgate 3 as will be described in more detail below.

- the auxiliary tailgate 40 may have a generally rectangular configuration having a lower edge 42 (or “base edge”) and opposed side edges 44 .

- the auxiliary tailgate 40 may have dimensions that are substantially similar to the dimensions of the primary tailgate 3 .

- the lower edge 42 of the auxiliary tailgate 40 may be operably coupled to the hinge assembly 20 and pivotally movable between a stowed configuration that is generally co-planar with and adjacent to the inner surface 6 of the primary tailgate 3 ( FIG. 4 ) and a deployed configuration generally perpendicular to and extending upwardly from the inner surface 6 of the primary tailgate 3 ( FIG. 2 ).

- a stowed configuration that is generally co-planar with and adjacent to the inner surface 6 of the primary tailgate 3 ( FIG. 4 )

- a deployed configuration generally perpendicular to and extending upwardly from the inner surface 6 of the primary tailgate 3 ( FIG. 2 ).

- the auxiliary tailgate 40 is pivotally movable by operation of the hinge assembly 20 . More particularly, the auxiliary tailgate 40 is pivotally movable to a released configuration generally perpendicular to and extending downwardly from the front portion 24 of the hinge plate 22 and free edge 4 of the primary tailgate 3 ( FIG. 3 ). When the primary tailgate 3 is at its open configuration and the auxiliary tailgate 40 is at the released configuration, access to the interior of the pickup box 2 is not blocked. Movement of the auxiliary tailgate 40 between the deployed configuration and released configuration is by operation (pivotal rotation) of the first hinge 32 .

- the double hinge assembly 20 enables about 270 degrees of rotation upon operation of the first hinge 32 and second hinge 34 , respectively. Specifically, the auxiliary tailgate 40 is rotated about 90 degrees from the stowed configuration ( FIG. 4 ) to the deployed configuration ( FIG. 2 ). Similarly, the auxiliary tailgate 40 is rotated about 180 degrees from the deployed configuration ( FIG. 2 ) to the released configuration ( FIG. 3 ).

- first hinge 32 , second hinge 34 , and hinge plate 22 are required to move the auxiliary tailgate 40 from the stowed configuration to the deployed configuration to the released configuration and back again.

- the hinge plate 22 of the double hinge member 30 lies flat atop the inner surface 6 of the primary tailgate 3 .

- a front portion 24 of the hinge plate 22 and first hinge 32 are adjacent the free edge 4 of the primary tailgate 3 . Movement of the auxiliary tailgate 40 between the deployed and released configurations is by a 180 degree rotational movement of the first hinge 32 , the lower edge 42 of the auxiliary tailgate 40 being coupled to the first hinge 32 .

- Movement of the auxiliary tailgate 40 to the stowed configuration involves rotation of the second hinge 34 . More particularly, the first hinge plate 22 is displaced from the inner surface 6 of the primary tailgate 3 and is rotated by the second hinge 34 until it becomes situated substantially vertical and perpendicular relative to the second plate section 28 ( FIG. 8 a ). At this configuration (stowed), the first hinge 32 and second hinge 34 , while still displaced, are situated in a common vertical plane ( FIG. 8 a ). As a result, the auxiliary tailgate 40 is essentially positioned atop or adjacent the inner surface 6 of the primary tailgate 3 . At the stowed configuration, the primary tailgate 3 may be pivotally moved to the closed configuration in a conventional manner without any interference by the auxiliary tailgate 40 ( FIG. 8 b ).

- the truck bed extension apparatus 10 includes a pair of side panels 46 pivotally coupled to opposed side edges 44 of the auxiliary tailgate 40 , respectively.

- Each side panel 46 may be pivotally attached with hinges 48 and is selectively movable between a between a retracted configuration that is generally co-planar with or bearing against an inside surface of the auxiliary tailgate 40 ( FIG. 3 ) and an extended configuration generally perpendicular to the inside surface of the auxiliary tailgate 40 ( FIG. 1 ).

- the side panels 46 may be selectively rotated to closed positions, such as when the auxiliary tailgate 40 is being moved to the stowed configuration.

- the side panels 46 when moved to the extended configurations, provide extensions of the pickup box side walls.

- the “extended truck bed” is extended and enclosed when the primary tailgate 3 is at the opened configuration, the auxiliary tailgate 40 is at the deployed configuration, and the pair of side panels 46 is at the extended configuration ( FIG. 1 ).

- a post 7 may extend inwardly from a side panel of the pickup box 2 ( FIG. 13 a ). Accordingly, each side panel 46 may define an aperture 7 a complementary to the post 7 for selective attachment thereto.

- a D-ring fastener 8 may extend inwardly from a respective side panel ( FIG. 13 b ).

- each side panel 46 may include a slider 9 configured to selectively engage with the D-ring fastener 8 ( FIG. 13 b ). In either configuration, the side panels 46 are releasably but securely coupled to the side panels of the truck bed itself.

- the aperture 7 a, D-ring fastener 8 and/or slider 9 can be considered as serving as a means for selectively fastening free ends of said pair of side panels 46 to the pickup box 2 at said extended configurations.

- the truck bed extension apparatus 10 may be mounted to the inner surface 6 of a conventional truck primary tailgate 3 , such as by bolting or screwing a portion of the hinge plate 22 of the hinge assembly 20 to the tailgate.

- the primary tailgate 3 With the auxiliary tailgate 40 at the stowed configuration, the primary tailgate 3 may be operated in a customary manner. However, if a user desires to extend the truck bed, the primary tailgate 3 is released to the open configuration and the auxiliary tailgate 40 is rotated to the upstanding/deployed configuration ( FIG. 2 ).

- the pair of side panels 46 may be pivotally moved to respective extended configurations and locked in as described above ( FIG. 1 ).

- auxiliary tailgate 40 can suffer from sagging of the auxiliary tailgate 40 , relative to the primary tailgate 3 when in the stowed and closed position.

- the auxiliary tailgate 40 can sag downwardly.

- the full weight of the auxiliary tailgate 40 and the side panels 46 are supported by the remaining portions of the hinge assembly 20 .

- the full weight of the auxiliary tailgate 40 and the side panels 46 are supported by the front portion 24 of the hinge assembly 20 , the first plate section 26 , and the first and second hinges 32 , 34 .

- the weight W of the auxiliary tailgate 40 and the side panels 46 pulls downwardly on the hinge assembly 20 .

- the weight W is transferred to the hinge assembly through the connection of the auxiliary tailgate 40 to the front portion 24 of the hinge assembly 20 .

- the weight W pulls downwardly on the hinge assembly 20 , causing the auxiliary tailgate 40 and side panels 46 to sag downwardly by a sag amount identified generally by the reference in numeral 50 .

- the sag amount 50 represents a distance by which the auxiliary tailgate 40 is displaced downwardly from a position that would result if the first plate section 26 were normal to the second plate section 28 .

- the sag amount 50 can cause the auxiliary tailgate 40 and side panels 46 to sag below a lower edge of the primary tailgate 3 by an amount 52 .

- auxiliary tailgate 40 and side panels 46 can interfere with the closing of the primary tailgate 3 , by sagging into an area between the lower edge of the primary tailgate 3 and rear edge of a pickup bed.

- the auxiliary tailgate 40 and side panels 46 can be made shorter such that when sagging, in the orientation illustrated in FIG. 15 , they do not interfere with the closing of the primary tailgate 3 .

- Shortening the auxiliary tailgate 40 and/or the side panels 46 can be undesirable. For example, such shortening of the auxiliary tailgate 40 and the side panels 46 will reduce the enclosed volume created by the auxiliary tailgate 40 and the side panels 46 when in the deployed position, with the primary tailgate 3 in an open position. This can also alter the overall aerodynamics of the vehicle to which the extension apparatus 10 is installed.

- An aspect of at least one of the inventions disclosed herein includes the realization that modifying the hinge assembly 20 so as to limit the range of movement of the first plate section 26 relative to the second plate section 28 about the first hinge 32 can prevent the sagging illustrated in FIG. 15 .

- FIGS. 16 and 17 illustrate embodiments of a modification of the hinge assembly 20 , identified generally by the reference numeral 20 A.

- Parts, components, features and advantages of the hinge assembly 20 A that are the same or similar to the corresponding parts, components, features or advantages of the hinge assembly 20 are referred to using the same reference numerals except that a letter “A” is added thereto.

- first plate section 26 A first plate section 26 A

- second hinge plate section 28 A first hinge 32 A.

- the first hinge 32 A includes a hinge pin 54 and a plurality of knuckles.

- a plurality of first knuckles 56 can be attached to the first plate section 26 A and a plurality of second knuckles 58 can be attached to the second plate section 28 A.

- the knuckles 56 are spaced apart from each other along an inner edge of the first plate section 26 A.

- the second knuckles 58 are also spaced apart from one another along an inner edge of the second plate section 28 A.

- the knuckles 56 , 58 are arranged such that they interleave with one another so as to form a continuous cylindrical passage into which the pin 54 is inserted. With the knuckles 56 , 58 moved into alignment such that they are interleaved with one another, and with the pin 54 inserted through the cylindrical passage formed by the aligned knuckles 56 , 58 , the hinge 32 A connects the first and second plate sections 26 A, 28 A such that they can pivot relative to one another about the hinge pin 54 .

- This type of construction and functionality of a hinge is well known in the art.

- the hinge assembly 20 A can be configured to limit movement of the first and second plate sections 26 A, 28 A such that they cannot be moved pivoted to an angle less than 90 degrees, in at least one orientation.

- the knuckles 56 , 58 can be arranged and spaced from each other such that they interfere with the movements of the plate sections 26 A, 28 A.

- the hinge assembly 20 A can include physical stops in one or more locations configured to limit the movement of the first and second plate sections 26 A, 26 B.

- the hinge assembly 20 A can include one or more physical stops 60 configured to limit movement of the hinge plate 28 A relative to the hinge plate section 26 A.

- the physical stop 60 can limit the movement of the first and second hinge plate sections 26 A, 28 A to an angle 62 of approximately 90 degrees, for example, an angle 62 in the range of about 86 degrees to 94 degrees.

- the physical stop 60 can be a separate piece mounted to either or both of the knuckles 56 , 58 or can be formed integrally or monolithically with one or more of the knuckles 56 , 58 .

- the physical stop 60 is attached to knuckle 56 .

- an inner surface of the second hinge plate section 28 A contacts the physical stop 60 , and thereby limits the pivotal movement of the second hinge plate section 28 relative to the first hinge plate section 26 A to the angle 62 .

- the positioning of the physical stop 60 can be chosen so as to provide the desired limitation on the pivoting movement described above. Other angles can also be chosen.

- the physical stop 60 can be placed so as to limit the angle 62 to an angle so it would be greater than 90 degrees, so as to accommodate potential bending of portions of the hinge assembly 20 A and thus prevent undesirable sagging that could result from such bending.

- FIG. 18 illustrates a further modification of the hinge assembly 20 identified generally by the reference numeral 20 B.

- Parts, components, features and advantages of the hinge assembly 20 B that are similar or the same as hinge assemblies 20 or 20 A are identified with the same reference numeral, except that a letter “B” has been added thereto.

- the hinge assembly 20 B is illustrated with only small portions of first and second hinge plate sections 26 B, 28 B and each having a single knuckle 56 B, 58 B.

- the hinge plate sections 26 B, 28 B could have any length and include any number of knuckles 56 B, 58 B.

- the hinge assembly 20 B includes a physical stop 60 B incorporated into juxtaposed ends of the knuckles 56 B, 58 B.

- the knuckle 56 B being directly attached or formed as an integrated portion of the hinge plate section 26 B, can include an end surface 70 .

- the end surface can include a projection or recess configured to cooperate with end surface 72 of knuckle 58 B.

- the end surface 70 can include projection 74 having a predetermined width.

- the width of the projection 74 can extend around the cylindrical passage defined by the knuckle 56 B a predetermined amount.

- end surface 72 of the knuckle 58 B can include a recess 76 configured to be interleaved with projection 74 .

- the recess 76 can extend around the cylindrical passage defined by the knuckle 58 B a predetermined amount.

- the sizes of the projections 74 and the recess 76 can be configured to provide a limited range of movement of the hinge assembly B and in particular, range of pivoting movement of the hinge plate sections 26 B, 28 B, relative to one another.

- the projection and recess interfere with each other, and thereby limit the range of motion of the hinge plate sections 26 B, 28 B.

- the physical stop assembly 60 B can be configured to provide the same limits on range of motion described above with reference to FIG. 17 and the hinge assembly 20 A.

- the extension apparatus 10 A can include any of the above-described embodiments of the hinge assembly 20 A, 20 B.

- the hinge 32 A or 32 B limits the movement of the first hinge plate section 26 A, B to a position roughly normal to the second hinge plate section 28 A, B.

- auxiliary tailgate 40 can be moved to a deployed position in which the first hinge plate section 26 A, B is pivoted upwardly (as viewed in FIG.

- auxiliary tailgate 40 can then be pivoted to a release position approximately 180 degrees from the deployed position, as described above with reference to FIGS. 7-8 .

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Transportation (AREA)

- Mechanical Engineering (AREA)

- Vehicle Step Arrangements And Article Storage (AREA)

- Body Structure For Vehicles (AREA)

- Hinges (AREA)

Abstract

A truck bed extension apparatus can include a hinge assembly having a hinge plate configured to be coupled to a primary tailgate of a pickup. An auxiliary tailgate includes a lower edge pivotally coupled to a front edge of the hinge plate, the auxiliary tailgate being pivotally movable between a stowed configuration co-planar with and adjacent to the hinge plate and a deployed configuration extending upwardly from the hinge plate. A pair of side panels is pivotally coupled to opposed side edges of the auxiliary tailgate and selectively movable between retracted and extended configurations. The hinge assembly can include a limiter configured to limit movement of the hinge assembly to prevent sagging of the auxiliary tailgate when in a stowed configuration.

Description

- Any and all applications for which a foreign or domestic priority claim is identified in the Application Data Sheet as filed with the present application are hereby incorporated by reference under 37 CFR 1.57.

- This invention relates generally to truck tailgate accessories and, more particularly, to a truck bed extension apparatus for selectively increasing the length of a truck bed and enclosing the lengthened truck bed area.

- Therefore, it would be desirable to have a truck bed extension apparatus that lengthens and encloses the lengthened truck bed. Further, it would be desirable to have a truck bed extension apparatus that is pivotally movable between a stowed configuration substantially co-planar with an inner surface of the truck's tailgate to a deployed configuration extending upwardly from an opened truck tailgate and to a released configuration extending downwardly from the opened truck tailgate.

- A truck bed extension apparatus according to some embodiments, for use in extending a usable area of a truck having a pickup box and truck bed that defines an open end and that includes a primary tailgate pivotally movable between a closed configuration covering the open end and an open configuration not covering the open end, the extension apparatus having a hinge assembly that includes a hinge plate coupled to the primary tailgate, the hinge plate having a front edge adjacent a free edge of the primary tailgate. An auxiliary tailgate includes a lower edge pivotally coupled to the front edge of the hinge plate, the auxiliary tailgate being pivotally movable between a stowed configuration generally co-planar with and adjacent to the hinge plate and a deployed configuration extending upwardly from and perpendicular to the hinge plate.

- A pair of side panels are pivotally coupled to side edges of the auxiliary tailgate, respectively, each side panel being selectively movable between a retracted configuration generally co-planar with and bearing against an inside surface of the auxiliary tailgate and an extended configuration generally perpendicular to the inside surface of the auxiliary tailgate. The truck bed is extended and enclosed when the primary tailgate is at the open configuration, the auxiliary tailgate is at the deployed configuration, and the pair of side panels is at the extended configuration.

- Thus, some embodiments disclosed herein can provide a truck bed extension apparatus for selectively increasing the length of a pickup truck bed.

- Additionally, some embodiments disclosed herein can provide a truck bed extension apparatus, as aforesaid, having an auxiliary tailgate that may be stowed away on an inner surface of the truck's primary tailgate or deployed upwardly when the primary tailgate is opened.

- Further, some embodiments disclosed herein can provide a truck bed extension apparatus, as aforesaid, in which the lengthened truck bed may be enclosed by the auxiliary tailgate and foldout side panels.

- Another aspect of at least one of the inventions disclosed herein includes the realization that an auxiliary tailgate that folds against the primary tailgate about a hinge can suffer from fitment problems caused by sagging of the assembly when folded. For example, when such an auxiliary tailgate is folded into the stowed position and the primary tailgate of the associated vehicle is closed (i.e., oriented generally vertically), the weight of the auxiliary tailgate pulls downwardly on the hinge assembly and can thus sag downwardly. If the auxiliary tailgate sags to a position that is excessively low along the inner surface of the primary tailgate, the auxiliary tailgate can be pinched as a user attempts to close the primary tailgate, i.e., pinched between the end of the primary tailgate and the truck bed. Thus, an auxiliary tailgate assembly that sags should be mounted higher on the primary tailgate and/or should be sized to a shorter dimension such that it does not become pinched between the primary tailgate and the truck bed. Such sizing and/or positioning, however, limits the overall height of the auxiliary tailgate when in a deployed position, and thus can create undesirable effects on aerodynamics and cargo capacity.

- Thus, in accordance with at least some of the embodiments disclosed herein, a truck bed extension assembly can include an auxiliary tailgate member having a base edge pivotally attached to a top edge of a primary tailgate with a hinge. The hinge can include physical stops limiting movement of the hinge, in the closing direction, to the pre-determined angle, for example, approximately 90 degrees. As such, when the auxiliary tailgate is folded against the primary tailgate, the physical stops on the hinge can prevent sagging of the auxiliary tailgate.

- Other objects and advantages of the inventions disclosed herein are apparent from the following description taken in connection with the accompanying drawings, wherein is set forth by way of illustration and example, embodiments of this invention.

-

FIG. 1 is a perspective view of a truck bed extension apparatus according to a preferred embodiment of the present invention illustrating the apparatus in an extended and enclosed configuration; -

FIG. 2 is another perspective view of the extension apparatus as inFIG. 1 , illustrating the apparatus in an extended but not enclosed configuration; -

FIG. 3 is another perspective view of the extension apparatus as inFIG. 1 , illustrating the auxiliary tailgate in a released configuration; -

FIG. 4 is another perspective view of the extension apparatus as inFIG. 1 , illustrating the auxiliary tailgate in a stowed configuration; -

FIG. 5 is another perspective view of the extension apparatus as inFIG. 1 , illustrating the primary tailgate in a closed configuration; -

FIG. 6 is a perspective view from reverse angle of the extension apparatus as inFIG. 5 ; -

FIG. 7a is an isolated view on an enlarged scale taken fromFIG. 1 ; -

FIG. 7b is an isolated view on an enlarged scale taken fromFIG. 2 ; -

FIG. 7c is an isolated view on an enlarged scale taken fromFIG. 3 ; -

FIG. 8a is an isolated view on an enlarged scale taken fromFIG. 4 ; -

FIG. 8b is an isolated view on an enlarged scale taken fromFIG. 6 ; -

FIG. 9 is an isolated perspective view of one side panel taken fromFIG. 1 ; -

FIG. 10 is an isolated perspective view of another side panel taken fromFIG. 1 ; -

FIG. 11 is an isolated perspective view of the auxiliary tailgate taken fromFIG. 1 ; -

FIG. 12a is an isolated view of a first hinge; -

FIG. 12b is an isolated view of a second hinge; -

FIG. 13a is an isolated view on an enlarged scale taken fromFIG. 1 ; -

FIG. 13b is an isolated view on an enlarged scale taken fromFIG. 1 ; and -

FIG. 14 is an isolated view on an enlarged scale taken fromFIG. 3 . -

FIG. 15 is a schematic side elevational view of a the extension apparatus ofFIG. 1 , illustrating a sagging effect of the extension apparatus. -

FIG. 16 is an exploded view of a modification of a portion of the extension apparatus ofFIG. 1 . -

FIG. 17 is an enlarged schematic, side elevational view of the hinge ofFIG. 16 . -

FIG. 18 is a perspective schematic view of yet another modification of a portion of the extension apparatus ofFIG. 1 . -

FIG. 19 is a schematic side elevational view of the hinge ofFIG. 16 and showing three different positions of the extension apparatus. - A truck bed extension apparatus according to a preferred embodiment will now be described in detail with reference to

FIGS. 1 to 14 of the accompanying drawings. The truckbed extension apparatus 10 includes anauxiliary tailgate 40, a pair ofside panels 46, and ahinge assembly 20 for use with atruck bed 2, also referred to as a pickup box, having aprimary tailgate 3. - The

primary tailgate 3 of a pickup truck is pivotally movable between a closed configuration (FIG. 5 ) that blocks access to the interior of thepickup box 2 via its open rear end and an open configuration (FIGS. 2 to 4 ) that allows access to the interior, a.k.a. truck bed, via its open rear end. Theprimary tailgate 3 has afree edge 4 and may include ahandle 5 configured to release theprimary tailgate 3 to move between closed and open configurations. Aconventional pickup box 2 may include fasteners adjacent the open rear end that are useful in fastening a portion of the present invention to thepickup box 2 as will be described later. - The

hinge assembly 20 of the truckbed extension apparatus 10 is coupled to theprimary tailgate 3 of a truck and provides the means for mounting the additional components to theprimary tailgate 3. More particularly, thehinge assembly 20 includes ahinge plate 22 having afront portion 24 that is, at deployed and released configuration, situated adjacent thefree edge 4 of theprimary tailgate 3 of a pickup truck. In fact, thefront portion 24 may be coupled to theauxiliary tailgate 40, such as with bolts (not shown). Preferably, thehinge assembly 20 includes a double hinge member 30 having afirst hinge 32 and asecond hinge 34 rearwardly displaced from and parallel to the first hinge 32 (FIG. 7c ). Thehinge plate 22 includes afirst plate section 26 extending between thefirst hinge 32 and thesecond hinge 34 and asecond plate section 28 extending rearwardly (away from) the second hinge 34 (FIG. 7b ). Thesecond plate section 28 may be fixedly attached to theinner surface 6 of theprimary tailgate 3, such as with bolts (not shown), while thefirst plate section 26 movable relative to theinner surface 6 of theprimary tailgate 3 as will be described in more detail below. - The

auxiliary tailgate 40 may have a generally rectangular configuration having a lower edge 42 (or “base edge”) and opposed side edges 44. Theauxiliary tailgate 40 may have dimensions that are substantially similar to the dimensions of theprimary tailgate 3. Thelower edge 42 of theauxiliary tailgate 40 may be operably coupled to thehinge assembly 20 and pivotally movable between a stowed configuration that is generally co-planar with and adjacent to theinner surface 6 of the primary tailgate 3 (FIG. 4 ) and a deployed configuration generally perpendicular to and extending upwardly from theinner surface 6 of the primary tailgate 3 (FIG. 2 ). Clearly, when theprimary tailgate 3 is at its open configuration and theauxiliary tailgate 40 is at the deployed configuration, access to the interior of thepickup box 2 is blocked. - The

auxiliary tailgate 40 is pivotally movable by operation of thehinge assembly 20. More particularly, theauxiliary tailgate 40 is pivotally movable to a released configuration generally perpendicular to and extending downwardly from thefront portion 24 of thehinge plate 22 andfree edge 4 of the primary tailgate 3 (FIG. 3 ). When theprimary tailgate 3 is at its open configuration and theauxiliary tailgate 40 is at the released configuration, access to the interior of thepickup box 2 is not blocked. Movement of theauxiliary tailgate 40 between the deployed configuration and released configuration is by operation (pivotal rotation) of thefirst hinge 32. - It will be understood that the

double hinge assembly 20 enables about 270 degrees of rotation upon operation of thefirst hinge 32 andsecond hinge 34, respectively. Specifically, theauxiliary tailgate 40 is rotated about 90 degrees from the stowed configuration (FIG. 4 ) to the deployed configuration (FIG. 2 ). Similarly, theauxiliary tailgate 40 is rotated about 180 degrees from the deployed configuration (FIG. 2 ) to the released configuration (FIG. 3 ). - In an embodiment, selective operation of the

first hinge 32,second hinge 34, and hingeplate 22 are required to move theauxiliary tailgate 40 from the stowed configuration to the deployed configuration to the released configuration and back again. As shown inFIG. 7b (illustrating the deployed configuration) andFIG. 7c (illustrating the released configuration), thehinge plate 22 of the double hinge member 30 lies flat atop theinner surface 6 of theprimary tailgate 3. In addition, afront portion 24 of thehinge plate 22 andfirst hinge 32 are adjacent thefree edge 4 of theprimary tailgate 3. Movement of theauxiliary tailgate 40 between the deployed and released configurations is by a 180 degree rotational movement of thefirst hinge 32, thelower edge 42 of theauxiliary tailgate 40 being coupled to thefirst hinge 32. - Movement of the

auxiliary tailgate 40 to the stowed configuration (FIG. 4 ), however, involves rotation of thesecond hinge 34. More particularly, thefirst hinge plate 22 is displaced from theinner surface 6 of theprimary tailgate 3 and is rotated by thesecond hinge 34 until it becomes situated substantially vertical and perpendicular relative to the second plate section 28 (FIG. 8a ). At this configuration (stowed), thefirst hinge 32 andsecond hinge 34, while still displaced, are situated in a common vertical plane (FIG. 8a ). As a result, theauxiliary tailgate 40 is essentially positioned atop or adjacent theinner surface 6 of theprimary tailgate 3. At the stowed configuration, theprimary tailgate 3 may be pivotally moved to the closed configuration in a conventional manner without any interference by the auxiliary tailgate 40 (FIG. 8b ). - In another aspect, the truck

bed extension apparatus 10 includes a pair ofside panels 46 pivotally coupled to opposed side edges 44 of theauxiliary tailgate 40, respectively. Eachside panel 46 may be pivotally attached withhinges 48 and is selectively movable between a between a retracted configuration that is generally co-planar with or bearing against an inside surface of the auxiliary tailgate 40 (FIG. 3 ) and an extended configuration generally perpendicular to the inside surface of the auxiliary tailgate 40 (FIG. 1 ). In other words, theside panels 46 may be selectively rotated to closed positions, such as when theauxiliary tailgate 40 is being moved to the stowed configuration. However, theside panels 46, when moved to the extended configurations, provide extensions of the pickup box side walls. To be clear, the “extended truck bed” is extended and enclosed when theprimary tailgate 3 is at the opened configuration, theauxiliary tailgate 40 is at the deployed configuration, and the pair ofside panels 46 is at the extended configuration (FIG. 1 ). - Modern pickup trucks include one of two types of fasteners adjacent the rear open end of the truck bed or pickup box. In one instance, a

post 7 may extend inwardly from a side panel of the pickup box 2 (FIG. 13a ). Accordingly, eachside panel 46 may define anaperture 7 a complementary to thepost 7 for selective attachment thereto. In another instance, a D-ring fastener 8 may extend inwardly from a respective side panel (FIG. 13b ). In this construction, eachside panel 46 may include aslider 9 configured to selectively engage with the D-ring fastener 8 (FIG. 13b ). In either configuration, theside panels 46 are releasably but securely coupled to the side panels of the truck bed itself. As such, theaperture 7 a, D-ring fastener 8 and/orslider 9 can be considered as serving as a means for selectively fastening free ends of said pair ofside panels 46 to thepickup box 2 at said extended configurations. - In use, the truck

bed extension apparatus 10 may be mounted to theinner surface 6 of a conventional truckprimary tailgate 3, such as by bolting or screwing a portion of thehinge plate 22 of thehinge assembly 20 to the tailgate. With theauxiliary tailgate 40 at the stowed configuration, theprimary tailgate 3 may be operated in a customary manner. However, if a user desires to extend the truck bed, theprimary tailgate 3 is released to the open configuration and theauxiliary tailgate 40 is rotated to the upstanding/deployed configuration (FIG. 2 ). To enclose the now extended truck bed, the pair ofside panels 46 may be pivotally moved to respective extended configurations and locked in as described above (FIG. 1 ). - As aspect of at least one of the inventions disclosed herein includes the realization that generic hinge assemblies can suffer from sagging of the

auxiliary tailgate 40, relative to theprimary tailgate 3 when in the stowed and closed position. For example, with reference toFIG. 15 , when theprimary tailgate 3 is in a closed position, such that theinner surface 6 of theprimary tailgate 3 is generally vertical, theauxiliary tailgate 40 can sag downwardly. - More specifically, with continued reference to

FIG. 15 , with thesecond plate section 28 of thehinge assembly 20 mounted to theinner surface 6 of theprimary tailgate 3, the full weight of theauxiliary tailgate 40 and theside panels 46 are supported by the remaining portions of thehinge assembly 20. Namely, the full weight of theauxiliary tailgate 40 and theside panels 46 are supported by thefront portion 24 of thehinge assembly 20, thefirst plate section 26, and the first and second hinges 32, 34. The weight W of theauxiliary tailgate 40 and theside panels 46 pulls downwardly on thehinge assembly 20. The weight W is transferred to the hinge assembly through the connection of theauxiliary tailgate 40 to thefront portion 24 of thehinge assembly 20. - Illustrated in exaggerated scale in

FIG. 15 , the weight W pulls downwardly on thehinge assembly 20, causing theauxiliary tailgate 40 andside panels 46 to sag downwardly by a sag amount identified generally by the reference innumeral 50. Thesag amount 50 represents a distance by which theauxiliary tailgate 40 is displaced downwardly from a position that would result if thefirst plate section 26 were normal to thesecond plate section 28. Thesag amount 50 can cause theauxiliary tailgate 40 andside panels 46 to sag below a lower edge of theprimary tailgate 3 by anamount 52. Sagging as such,auxiliary tailgate 40 andside panels 46 can interfere with the closing of theprimary tailgate 3, by sagging into an area between the lower edge of theprimary tailgate 3 and rear edge of a pickup bed. In order to avoid such interference, theauxiliary tailgate 40 andside panels 46 can be made shorter such that when sagging, in the orientation illustrated inFIG. 15 , they do not interfere with the closing of theprimary tailgate 3. - Shortening the

auxiliary tailgate 40 and/or theside panels 46 can be undesirable. For example, such shortening of theauxiliary tailgate 40 and theside panels 46 will reduce the enclosed volume created by theauxiliary tailgate 40 and theside panels 46 when in the deployed position, with theprimary tailgate 3 in an open position. This can also alter the overall aerodynamics of the vehicle to which theextension apparatus 10 is installed. - An aspect of at least one of the inventions disclosed herein includes the realization that modifying the

hinge assembly 20 so as to limit the range of movement of thefirst plate section 26 relative to thesecond plate section 28 about thefirst hinge 32 can prevent the sagging illustrated inFIG. 15 . -

FIGS. 16 and 17 illustrate embodiments of a modification of thehinge assembly 20, identified generally by the reference numeral 20A. Parts, components, features and advantages of the hinge assembly 20A that are the same or similar to the corresponding parts, components, features or advantages of thehinge assembly 20 are referred to using the same reference numerals except that a letter “A” is added thereto. - With continued reference to

FIG. 16 , a portion of the hinge assembly 20A is illustrated therein, including first plate section 26A, second hinge plate section 28A and first hinge 32A. - The first hinge 32A includes a

hinge pin 54 and a plurality of knuckles. For example, a plurality offirst knuckles 56 can be attached to the first plate section 26A and a plurality ofsecond knuckles 58 can be attached to the second plate section 28A. Theknuckles 56 are spaced apart from each other along an inner edge of the first plate section 26A. Similarly, thesecond knuckles 58 are also spaced apart from one another along an inner edge of the second plate section 28A. - The

knuckles pin 54 is inserted. With theknuckles pin 54 inserted through the cylindrical passage formed by the alignedknuckles hinge pin 54. This type of construction and functionality of a hinge is well known in the art. - In some embodiments, the hinge assembly 20A can be configured to limit movement of the first and second plate sections 26A, 28A such that they cannot be moved pivoted to an angle less than 90 degrees, in at least one orientation. For example, the

knuckles - With reference to

FIG. 17 , the hinge assembly 20A can include one or morephysical stops 60 configured to limit movement of the hinge plate 28A relative to the hinge plate section 26A. For example, thephysical stop 60 can limit the movement of the first and second hinge plate sections 26A, 28A to anangle 62 of approximately 90 degrees, for example, anangle 62 in the range of about 86 degrees to 94 degrees. Thephysical stop 60 can be a separate piece mounted to either or both of theknuckles knuckles - In the illustrated embodiment, the

physical stop 60 is attached to knuckle 56. When the second hinge plate section 28A is moved in the direction of the closingdirection 64, an inner surface of the second hinge plate section 28A contacts thephysical stop 60, and thereby limits the pivotal movement of the secondhinge plate section 28 relative to the first hinge plate section 26A to theangle 62. The positioning of thephysical stop 60 can be chosen so as to provide the desired limitation on the pivoting movement described above. Other angles can also be chosen. For example, thephysical stop 60 can be placed so as to limit theangle 62 to an angle so it would be greater than 90 degrees, so as to accommodate potential bending of portions of the hinge assembly 20A and thus prevent undesirable sagging that could result from such bending. -

FIG. 18 illustrates a further modification of thehinge assembly 20 identified generally by the reference numeral 20B. Parts, components, features and advantages of the hinge assembly 20B that are similar or the same ashinge assemblies 20 or 20A are identified with the same reference numeral, except that a letter “B” has been added thereto. - With reference to

FIG. 18 , the hinge assembly 20B is illustrated with only small portions of first and second hinge plate sections 26B, 28B and each having a single knuckle 56B, 58B. However, it is to be understood that the hinge plate sections 26B, 28B could have any length and include any number of knuckles 56B, 58B. - The hinge assembly 20B includes a physical stop 60B incorporated into juxtaposed ends of the knuckles 56B, 58B.

- For example, the knuckle 56B, being directly attached or formed as an integrated portion of the hinge plate section 26B, can include an

end surface 70. The end surface can include a projection or recess configured to cooperate withend surface 72 of knuckle 58B. - For example, the

end surface 70 can includeprojection 74 having a predetermined width. The width of theprojection 74 can extend around the cylindrical passage defined by the knuckle 56B a predetermined amount. Similarly,end surface 72 of the knuckle 58B can include arecess 76 configured to be interleaved withprojection 74. Additionally, therecess 76 can extend around the cylindrical passage defined by the knuckle 58B a predetermined amount. The sizes of theprojections 74 and therecess 76 can be configured to provide a limited range of movement of the hinge assembly B and in particular, range of pivoting movement of the hinge plate sections 26B, 28B, relative to one another. When moved in a pivoting motion, the projection and recess interfere with each other, and thereby limit the range of motion of the hinge plate sections 26B, 28B. In some embodiments, the physical stop assembly 60B can be configured to provide the same limits on range of motion described above with reference toFIG. 17 and the hinge assembly 20A. - With reference to

FIG. 19 , the extension apparatus 10A can include any of the above-described embodiments of the hinge assembly 20A, 20B. As such, when theauxiliary tailgate 40 andside panels 46 are in the stowed position, with theprimary tailgate 3 in a closed position, in which itsinner surface 6 is generally vertical, the hinge 32A or 32B limits the movement of the first hinge plate section 26A, B to a position roughly normal to the second hinge plate section 28A, B. As such, the sagging described above with regards toFIG. 15 is better prevented. Additionally,auxiliary tailgate 40 can be moved to a deployed position in which the first hinge plate section 26A, B is pivoted upwardly (as viewed inFIG. 19 ) with the auxiliary tailgate extending generally normal to theinner surface 6 of theprimary tailgate 3. Additionally, theauxiliary tailgate 40 can then be pivoted to a release position approximately 180 degrees from the deployed position, as described above with reference toFIGS. 7-8 . - It is understood that while certain forms of this invention have been illustrated and described, it is not limited thereto except insofar as such limitations are included in the following claims and allowable functional equivalents thereof.

Claims (18)

1. A truck bed extension comprising:

a hinge assembly comprising first, second, and third hinge plates and first and second hinges, the hinge assembly configured to be mounted to a tailgate of a pickup truck with a front edge of the first hinge plate adjacent to and spaced inwardly from a free edge of the tailgate;

an auxiliary tailgate having a lower edge coupled to said third hinge plate, said auxiliary tailgate being pivotally movable between a stowed configuration generally co-planar with and adjacent to the first hinge plate in which an entirety of said hinge assembly is spaced inwardly from said free edge of said tailgate, and a deployed configuration extending upwardly from and perpendicular to the first hinge plate in which said second hinge is spaced outwardly from said free edge of said tailgate; and

a pair of side panels pivotally coupled to side edges of said auxiliary tailgate, respectively, each side panel being selectively movable between a retracted configuration generally co-planar with and bearing against an inside surface of said auxiliary tailgate and an extended configuration generally perpendicular to said inside surface of said auxiliary tailgate.

2. The truck bed extension apparatus as in claim 1 , wherein said auxiliary tailgate is pivotally movable to a released configuration generally perpendicular to the first hinge plate and situated in a direction opposite a direction when at said deployed configuration, wherein the auxiliary tailgate is supported by the second hinge which is disposed spaced outwardly from said free edge of said primary tailgate when at said deployed configuration.

3. The truck bed extension apparatus as in claim 2 , wherein:

said auxiliary tailgate is rotated about 90 degrees from said stowed configuration when moved to said deployed configuration;

said auxiliary tailgate is rotated about 180 degrees from said deployed configuration when moved to said released configuration;

said auxiliary tailgate is rotated about 270 degrees from said stowed configuration when moved to said released configuration.

4. The truck bed extension apparatus as in claim 3 , wherein said hinge assembly includes a rotational range of at least 270 degrees.

5. The truck bed extension apparatus as in claim 1 , wherein said hinge assembly includes a rotational range of at least 270 degrees.

6. The truck bed extension apparatus as in claim 1 , wherein

said second hinge plate is positioned adjacent the free edge of the tailgate and is perpendicular to said auxiliary tailgate when said auxiliary tailgate is at said deployed configuration; and

said second hinge plate is displaced from the free edge of the tailgate and is situated vertically and perpendicular to said first hinge plate at said stowed configuration.

7. The truck bed extension apparatus as in claim 1 , wherein said second hinge is positioned forwardly and in a common horizontal plane relative to said first hinge at said deployed configuration and said second hinge is positioned above and in a common vertical plane relative to said first hinge at said stowed configuration.

8. The truck bed extension apparatus as in claim 1 , further comprising means for selectively fastening free ends of said pair of side panels to the pickup box at said extended configurations, respectively.

9. A truck bed extension apparatus comprising:

a hinge assembly that includes a first hinge plate configured to be coupled to a primary tailgate of a pickup truck in a position in which said first hinge plate has a front edge spaced inwardly from an uppermost free edge of the primary tailgate, the inward direction extending from the uppermost free edge toward the pivot attaching the primary tailgate to the truck bed; and

an auxiliary tailgate having a lower edge pivotally coupled to hinge plate assembly, said auxiliary tailgate being pivotally movable between a stowed configuration generally co-planar with and adjacent to the primary tailgate, in which an entirety of said hinge assembly is spaced inwardly from said uppermost free edge of said primary tailgate, and a deployed configuration extending upwardly from and perpendicular to the primary tailgate;

wherein said auxiliary tailgate is pivotally movable to a released configuration generally perpendicular to and extending downwardly from the front edge of the hinge plate and situated in a direction opposite a direction of said deployed configuration and in which said auxiliary tailgate is spaced outwardly from said uppermost free edge of said primary tailgate.

10. The truck bed extension apparatus as in claim 9 , further comprising:

a pair of side panels pivotally coupled to opposed side edges of said auxiliary tailgate, respectively, each side panel being selectively movable between a retracted configuration generally co-planar with and bearing against an inside surface of said auxiliary tailgate and an extended configuration generally perpendicular to said inside surface of said auxiliary tailgate;

wherein the truck bed is extended and enclosed when the primary tailgate is at the open configuration, said auxiliary tailgate is at said deployed configuration, and said pair of side panels is at said extended configuration.

11. The truck bed extension apparatus as in claim 9 , wherein:

said auxiliary tailgate is rotated about 90 degrees from said stowed configuration when moved to said deployed configuration;

said auxiliary tailgate is rotated about 180 degrees from said deployed configuration when moved to said released configuration;

said auxiliary tailgate is rotated about 270 degrees from said stowed configuration when moved to said released configuration.

12. The truck bed extension apparatus as in claim 11 , wherein said hinge assembly includes a rotational range of at least 270 degrees.

13. The truck bed extension apparatus as in claim 9 , wherein said hinge assembly includes a rotational range of at least 270 degrees.

14. The truck bed extension apparatus as in claim 9 , wherein said hinge assembly includes a double hinge member having a first hinge situated along said lower edge of said auxiliary tailgate, said auxiliary tailgate being pivotally movable between said deployed configuration and said released configuration by pivotal movement of said first hinge.

15. The truck bed extension apparatus as in claim 14 , wherein said double hinge member includes a second hinge displaced from said first hinge and pivotally coupled to said first hinge plate, said auxiliary tailgate being pivotally movable between said deployed configuration and said stowed configuration by pivotal movement of said second hinge.

16. The truck bed extension apparatus as in claim 15 , wherein:

said hinge assembly includes:

a second hinge plate intermediate said first hinge and said second hinge;

a third hinge plate extending rearwardly from said second hinge;

said second hinge plate is positioned adjacent the free edge of the primary tailgate and is perpendicular to said auxiliary tailgate when said auxiliary tailgate is at said deployed configuration; and

said second hinge plate is displaced from the free edge of the primary tailgate and is situated vertically and perpendicular to said first hinge plate at said stowed configuration.

17. The truck bed extension apparatus as in claim 15 , wherein said first hinge is positioned forwardly relative to said second hinge and in a common horizontal plane with said second hinge at said deployed configuration and said first hinge is positioned in a common vertical plane relative to said second hinge at said stowed configuration.

18. The truck bed extension apparatus as in claim 9 , further comprising means for selectively fastening free ends of said pair of side panels to the truck bed when said pair of side panels is at said extended configurations, respectively.

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US15/961,024 US20180237080A1 (en) | 2015-10-27 | 2018-04-24 | Truck bed extension apparatus |

| US16/112,452 US20190023331A1 (en) | 2015-10-27 | 2018-08-24 | Truck bed extension apparatus |

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US201562246740P | 2015-10-27 | 2015-10-27 | |

| US14/956,692 US9452793B1 (en) | 2015-10-27 | 2015-12-02 | Truck bed extension apparatus |

| US15/277,273 US9834260B2 (en) | 2015-10-27 | 2016-09-27 | Truck bed extension apparatus |

| PCT/US2016/057510 WO2017074741A1 (en) | 2015-10-27 | 2016-10-18 | Truck bed extension apparatus |

| US15/961,024 US20180237080A1 (en) | 2015-10-27 | 2018-04-24 | Truck bed extension apparatus |

Related Parent Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/US2016/057510 Continuation WO2017074741A1 (en) | 2015-10-27 | 2016-10-18 | Truck bed extension apparatus |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US16/112,452 Continuation-In-Part US20190023331A1 (en) | 2015-10-27 | 2018-08-24 | Truck bed extension apparatus |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US20180237080A1 true US20180237080A1 (en) | 2018-08-23 |

Family

ID=58630953

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US15/277,273 Expired - Fee Related US9834260B2 (en) | 2015-10-27 | 2016-09-27 | Truck bed extension apparatus |

| US15/961,024 Abandoned US20180237080A1 (en) | 2015-10-27 | 2018-04-24 | Truck bed extension apparatus |

Family Applications Before (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US15/277,273 Expired - Fee Related US9834260B2 (en) | 2015-10-27 | 2016-09-27 | Truck bed extension apparatus |

Country Status (4)

| Country | Link |

|---|---|

| US (2) | US9834260B2 (en) |

| CA (1) | CA3003327A1 (en) |

| MX (1) | MX2018005021A (en) |

| WO (1) | WO2017074741A1 (en) |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US11427265B2 (en) * | 2014-08-19 | 2022-08-30 | Magna Exteriors Inc. | Modular tailgate |

| US9956996B2 (en) * | 2016-07-06 | 2018-05-01 | Toyota Motor Engineering & Manufacturing North America, Inc. | Cargo bed extension assembly including cover for a tailgate |

| US10829166B2 (en) * | 2016-12-20 | 2020-11-10 | Xtendabed, Llc | Vehicle bed extender |

| US10710646B2 (en) * | 2017-06-15 | 2020-07-14 | Joshua Reyna | Truck bed extension assembly |

| DE102017217088A1 (en) * | 2017-09-26 | 2019-03-28 | Ford Global Technologies, Llc | Lateral limit for a bed extension |

| US10889223B2 (en) | 2018-11-23 | 2021-01-12 | Zachary D Pascarella | Retrofittable vehicle extension table |

| US10543789B1 (en) * | 2019-02-25 | 2020-01-28 | Ford Global Technologies, Llc | Combination cargo stop and step |

| WO2020209984A1 (en) * | 2019-04-12 | 2020-10-15 | Desimone Steve | Tailgate with integrated modular loading ramp |

| US11618369B2 (en) | 2020-10-05 | 2023-04-04 | Jvis-Usa, Llc | Side wall assembly for use in a pickup truck bed |

| USD1009759S1 (en) * | 2021-03-10 | 2024-01-02 | Canoo Technologies Inc. | Slide out bed floor with integrated brake lights for electric vehicle |

| FR3142740A1 (en) * | 2022-12-01 | 2024-06-07 | Renault S.A.S. | DUMPKIT EXTENSION DEVICE FOR MOTOR VEHICLE WITH REAR DROPPER |

| FR3142739A1 (en) * | 2022-12-01 | 2024-06-07 | Renault S.A.S. | DUMPKIT EXTENSION DEVICE FOR MOTOR VEHICLE WITH REAR DROPPER |

Family Cites Families (36)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US976392A (en) * | 1910-04-04 | 1910-11-22 | William D Paynter | Hinge. |

| US4472639A (en) | 1983-01-03 | 1984-09-18 | Bianchi Barry E | Tailgate attachment for extending the cargo space of vehicles |

| US4531773A (en) | 1983-12-23 | 1985-07-30 | Smith Gareth J | Vehicle tailgate extension assembly |

| CA1244858A (en) | 1984-11-30 | 1988-11-15 | Joseph J. Kardos | Tailgate capable of extending truck box |

| GB2199365A (en) | 1986-12-11 | 1988-07-06 | Gorrigate Limited | Tailgate mechanism |

| US5287596A (en) * | 1988-03-28 | 1994-02-22 | Chen Haw Renn | Hinge with adjustable stop and hold mechanism |

| US5468038A (en) | 1994-09-06 | 1995-11-21 | Sauri; Gregory M. | Multiple configuration tailgate extender |

| US5788311A (en) | 1995-06-06 | 1998-08-04 | Tibbals; Kerry Wayne | Combination step and cargo space extender |

| US5765892A (en) | 1995-10-05 | 1998-06-16 | Covington; James Roy | Extension apparatus for a vehicle cargo area |

| US5775759A (en) | 1996-09-24 | 1998-07-07 | Cummins; Andrew J. | Vehicle bed extender |

| US6193294B1 (en) | 1998-08-06 | 2001-02-27 | Patrick Disner | Truck tailgate accessory |

| US6353967B1 (en) * | 1998-09-02 | 2002-03-12 | Francisco A. Escobar | Ninety-degree door hinge |

| US6158797A (en) | 1999-02-09 | 2000-12-12 | Bauer; Cordell Eric | Truck bed extension |

| CA2321487C (en) | 1999-10-04 | 2009-01-27 | Decoma Exterior Trim Inc. | Tailgate step for pick-up truck bed access |

| US6279980B1 (en) | 2000-03-08 | 2001-08-28 | Mark Straschewski | Integrated pick-up truck bed extender |

| US6454338B1 (en) | 2000-07-28 | 2002-09-24 | Ford Global Technologies, Inc. | Integrated vehicle tailgate |

| US6364392B1 (en) | 2000-12-28 | 2002-04-02 | Adac Plastics, Inc. | Tailgate extender |

| US6378926B1 (en) | 2001-01-04 | 2002-04-30 | Rick Renze | Truck bed extender |

| US6742822B2 (en) * | 2001-02-27 | 2004-06-01 | Mark Willard Vejnar | Auxiliary tailgate and retractable stop |

| US6550841B1 (en) | 2001-12-26 | 2003-04-22 | Canada Inc. | Tailgate nested tailgate bed extender |

| USD485800S1 (en) | 2002-03-05 | 2004-01-27 | Dean P. Smith | Cargo bay extender for a pickup truck |

| US6626478B1 (en) | 2002-11-06 | 2003-09-30 | David J. Minton | Tailgate extender |

| US6908134B1 (en) | 2003-03-26 | 2005-06-21 | Jerald E. Summers | Cargo bed extender |

| US20060033352A1 (en) | 2003-04-17 | 2006-02-16 | James King | Truck tailgate extension |

| US6957840B1 (en) | 2004-11-08 | 2005-10-25 | Endres James L | Tailgate extension system |

| US20080231067A1 (en) | 2005-02-24 | 2008-09-25 | Nagle Rick A | Retractable Tailgate Barrier and Accessory Systems |

| US20060214449A1 (en) | 2005-03-23 | 2006-09-28 | Klusmeier Conrad P | Vehicle bed extender internally mounted |

| US7261357B1 (en) | 2005-11-17 | 2007-08-28 | Bechen Nick R | Tailgate ladder apparatus |

| US8109552B2 (en) | 2006-09-28 | 2012-02-07 | Nelson Charles R | Truck bed extender |

| GB2467319A (en) | 2009-01-29 | 2010-08-04 | Nissan Motor Mfg | Vehicle Door Hinge comprising a double hinge |

| US8182012B1 (en) | 2010-07-02 | 2012-05-22 | Richard Brister | Tailgate extension apparatus |

| US20120023706A1 (en) * | 2010-07-29 | 2012-02-02 | Timothy Fuller | Hinge stop |

| US20130049395A1 (en) | 2011-08-31 | 2013-02-28 | Russell Poirier | Cargo area extension system method and apparatus |

| US9387806B2 (en) | 2013-05-09 | 2016-07-12 | Russell John Bzoza | Truck bed extender |

| BR102014002330B1 (en) | 2014-01-30 | 2022-03-08 | Fca Fiat Chrysler Automoveis Brasil Ltda | REAR DOOR WITH LOAD AREA EXTENDER FOR AUTOMOTIVE CARGO VEHICLE AND AUTOMOTIVE VEHICLE |

| US9452793B1 (en) | 2015-10-27 | 2016-09-27 | Larry A. Quick | Truck bed extension apparatus |

-

2016

- 2016-09-27 US US15/277,273 patent/US9834260B2/en not_active Expired - Fee Related

- 2016-10-18 WO PCT/US2016/057510 patent/WO2017074741A1/en active Application Filing

- 2016-10-18 MX MX2018005021A patent/MX2018005021A/en unknown

- 2016-10-18 CA CA3003327A patent/CA3003327A1/en not_active Abandoned

-

2018

- 2018-04-24 US US15/961,024 patent/US20180237080A1/en not_active Abandoned

Also Published As

| Publication number | Publication date |

|---|---|

| CA3003327A1 (en) | 2017-05-04 |

| WO2017074741A1 (en) | 2017-05-04 |

| US9834260B2 (en) | 2017-12-05 |

| US20170203799A1 (en) | 2017-07-20 |

| MX2018005021A (en) | 2018-07-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US20180237080A1 (en) | Truck bed extension apparatus | |

| US9452793B1 (en) | Truck bed extension apparatus | |

| CN102384153B (en) | Infant fixing device | |

| US9499031B2 (en) | Rear door device in vehicle | |

| US20200399942A1 (en) | Four-bar linkage hinge | |

| US5491875A (en) | Extended cab pickup truck concealed cargo door hinge | |

| US9816303B2 (en) | Double axial hinge for a console | |

| US5632065A (en) | Extended cab pickup truck concealed cargo door hinge having a spring stop detent | |

| US7591046B2 (en) | Sprung hinge for supporting a closure element | |

| US7585011B2 (en) | Leg covering structure for folding seat | |

| JP5342500B2 (en) | Rear parcel shelf hinge structure | |

| US20150197199A1 (en) | Collapsible step bar | |

| US20090102332A1 (en) | Cabinet door locking mechanism | |

| US20170129550A1 (en) | Aerodynamic rear drag reduction system for a trailer | |

| CN102514466B (en) | Skylight of commercial vehicle | |

| US3698464A (en) | Folding door for luggage compartment of vehicles such as motor-coaches for example | |

| CA2360607A1 (en) | Storage tray for use with a tonneau cover assembly | |

| US20030218350A1 (en) | Decklid mechanism for vehicle with retractable top | |

| US20190023331A1 (en) | Truck bed extension apparatus | |

| US7464660B2 (en) | Windshield including vented walk-through door | |

| JP4305105B2 (en) | Vehicle back door structure | |

| US11066112B2 (en) | Rear spoiler device for a utility vehicle | |

| JP2007126891A (en) | Sliding door structure | |

| JP5857679B2 (en) | Trunk lid mounting vehicle structure | |

| KR100453098B1 (en) | Door checker for automobile |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| STCB | Information on status: application discontinuation |

Free format text: ABANDONED -- FAILURE TO RESPOND TO AN OFFICE ACTION |

|

| AS | Assignment |

Owner name: KNOBBE, MARTENS, OLSON & BEAR, LLP, CALIFORNIA Free format text: SECURITY INTEREST;ASSIGNOR:QUICK EXTEND-A-BED, LLC;REEL/FRAME:049559/0613 Effective date: 20190114 |