US20130011129A1 - Camera assembly capable of adjusting angle of camera - Google Patents

Camera assembly capable of adjusting angle of camera Download PDFInfo

- Publication number

- US20130011129A1 US20130011129A1 US13/195,862 US201113195862A US2013011129A1 US 20130011129 A1 US20130011129 A1 US 20130011129A1 US 201113195862 A US201113195862 A US 201113195862A US 2013011129 A1 US2013011129 A1 US 2013011129A1

- Authority

- US

- United States

- Prior art keywords

- camera

- shaft

- gear

- hole

- base

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03B—APPARATUS OR ARRANGEMENTS FOR TAKING PHOTOGRAPHS OR FOR PROJECTING OR VIEWING THEM; APPARATUS OR ARRANGEMENTS EMPLOYING ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ACCESSORIES THEREFOR

- G03B37/00—Panoramic or wide-screen photography; Photographing extended surfaces, e.g. for surveying; Photographing internal surfaces, e.g. of pipe

- G03B37/02—Panoramic or wide-screen photography; Photographing extended surfaces, e.g. for surveying; Photographing internal surfaces, e.g. of pipe with scanning movement of lens or cameras

-

- H—ELECTRICITY

- H04—ELECTRIC COMMUNICATION TECHNIQUE

- H04N—PICTORIAL COMMUNICATION, e.g. TELEVISION

- H04N23/00—Cameras or camera modules comprising electronic image sensors; Control thereof

- H04N23/50—Constructional details

- H04N23/51—Housings

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03B—APPARATUS OR ARRANGEMENTS FOR TAKING PHOTOGRAPHS OR FOR PROJECTING OR VIEWING THEM; APPARATUS OR ARRANGEMENTS EMPLOYING ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ACCESSORIES THEREFOR

- G03B17/00—Details of cameras or camera bodies; Accessories therefor

- G03B17/02—Bodies

Definitions

- the disclosure generally relates to camera assemblies, and more particularly to a camera assembly capable of adjusting an angle of a camera.

- a camera of an internet protocol (IP) phone is fixed to a base of the IP phone.

- IP internet protocol

- an user can either manually adjust a stand of the IP phone or move the base of the IP phone to make the camera aim at a target image.

- this manual method is cumbersome and ineffective for more precise measurements.

- FIG. 1 is a perspective, isometric view of an electronic device of an exemplary embodiment of the disclosure, in which the electronic device comprises a camera to shoot a target image.

- FIG. 2 is a perspective, isometric view of a camera assembly of the disclosure, in which the camera assembly is mounted in the electronic device of FIG. 1 , and the camera rotates around an axis of the second shaft.

- FIG. 3 is a disassembled perspective view of FIG. 2 .

- FIG. 4 is a perspective, isometric view of a base of FIG. 2 .

- FIG. 5 is a perspective, isometric view of the camera of FIG. 1 .

- FIG. 6 is a sketching view of a connection relationship between the camera and a first shaft.

- FIG. 7 is a perspective, isometric view of the camera assembly of the disclosure, in which the camera rotates around an axis of the first shaft.

- FIG. 1 is a perspective, isometric view of an electronic device 200 of the disclosure.

- FIG. 2 is a perspective, isometric view of a camera assembly 100 with an exemplary embodiment of the disclosure.

- the electronic device 200 comprises a camera 300 to shoot a target image.

- the camera assembly 100 is mounted in the electronic device 200 to adjust the camera 300 to aim at the target image.

- the electronic device 200 is an internet protocol (IP) phone.

- IP internet protocol

- the camera assembly 100 comprises a hollow base 10 , a first gear 20 , a first shaft 30 , a second gear 40 , a second shaft 50 , a driving device 60 and a driving gear 70 .

- the camera 300 is received in the base 10 and rotatably connected to the base 10 .

- One end of the first shaft 30 is fixed with the first gear 20

- another end of the first shaft 30 is rotatably connected with the camera 300 .

- One end of the second shaft 50 is fixed with the base 10

- another end of the second shaft 50 is fixed with the second gear 40 .

- the first shaft 30 and the second shaft 50 are perpendicular with each other.

- the driving device 60 drives the driving gear 70 to engage with the first gear 20 and the second gear 40 , respectively, which lead to the camera 300 capable of rotating around an axis A 1 of the first shaft 30 and an axis A 2 of the second shaft 50 , respectively. By this way, the camera 300 is adjusted to aim at the target image.

- the base 10 comprises a first base 11 and a second base 12 .

- the first base 11 and the second base 12 are fixed together by a plurality of bolts 80 to collectively form a receiving space 13 to receive the camera 300 .

- the base 10 defines a first hole 14 , a second hole 15 and a groove 16 in an interior wall 17 of the base 10 .

- the first hole 14 , the second hole 15 and the groove 16 are all communicating with the receiving space 13 .

- the camera 300 comprises a lens 320 to aim at the target image, and a protruding portion 330 projecting from an exterior surface 350 of the camera 300 .

- the camera 300 defines a receiving hole 310 , and a third hole 340 communication with the receiving hole 310 .

- the camera 300 is received in the receiving space 13 of the base 10 with the receiving hole 310 of the camera 300 opposite to the first hole 14 of the base 10 , the lens 320 of the camera 30 opposite to the second hole 15 , and the protruding portion 330 of the camera 30 received in the groove 16 of the base 10 and capable of sliding along the groove 16 .

- the camera 300 when the camera 300 rotates around the axis A 1 of the first shaft 30 , the camera 300 can rotate along the groove 16 of the base 10 with the lens 320 of the camera 300 moving toward the second hole 15 of the base 10 .

- the camera 300 rotates around the axis A 2 of the second shaft 50 , the camera 300 fails to move relative to the base 10 by engagement of the protruding portion 330 of the camera 300 and the groove 16 of the base 10 , which leads to the camera 300 rotating around the axis of the second shaft 50 together with the base 10 .

- the protruding portion 320 of the camera 300 is substantially in a shape of an arc, and the center of the arc is located in the axis A 1 of the first shaft 30 .

- the camera 300 is substantially in a shape of a ball, and the receiving space 13 is correspondingly ball shaped.

- the first shaft 30 comprises a first end 31 defining a through hole 311 , and a second end 32 fixed with the first gear 20 .

- the first end 31 passes through the first hole 14 of the base 10 and extends into the receiving hole 310 of the camera 300 .

- One end of a third shaft 90 inserts through the through hole 311 of the first shaft 30 and extends into the third hole 340 of the camera 300 , and another end of the third shaft 90 matches with a nut 91 .

- An axis of the third shaft 90 is collinear with that of the second shaft 50 .

- the camera 300 is fixed with the third shaft 90 and capable of rotating relatively to the first shaft 30 around the axis of the third shaft 90 .

- the camera 300 rotates around the axis A 2 of the second shaft 50 together with the base 10 , the third shaft 90 rotates in the through hole 311 of the first shaft 30 , which keeps the first shaft 30 quiescence.

- the driving device 60 comprises an output shaft 61 .

- the driving gear 70 is fixed to the output shaft 61 .

- the driving device 60 controls the output shaft 61 moving by a controlling device (not shown), which lead to the driving gear 70 moving along the output shaft 61 to engage with the first gear 20 and the second gear 40 , respectively.

- the driving device 60 is a step motor.

- the driving gear 70 comprises a first driving gear 71 engaged with the first gear 20 , and a second driving gear 72 integrated with the first driving gear 71 and engaged with the second gear 40 .

- the first driving gear 71 and the first gear 20 are umbrella gears

- the second driving gear 72 and the second the second gear 40 are spur gears.

- the driving device 60 drives the driving gear 71 to engage with the first gear 20 , which lead to the first gear 20 and the first shaft 30 rotating.

- the camera 300 rotates around the axis A 1 of the first shaft 30 , to adjust the angle of the lens 320 right and left.

- the driving device 60 drives the second driving gear 72 to engage with the second gear 40 , which lead to the second gear 40 and the second shaft 50 rotating, and the camera 300 and the base 10 rotate around the axis A 2 of the second shaft 50 together to adjust the angle of the lens 320 up and down.

- the lens 320 of the camera 300 aims at the target image with precise measurements effectively.

Landscapes

- Engineering & Computer Science (AREA)

- Multimedia (AREA)

- Signal Processing (AREA)

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Accessories Of Cameras (AREA)

- Studio Devices (AREA)

Abstract

Description

- 1. Technical Field

- The disclosure generally relates to camera assemblies, and more particularly to a camera assembly capable of adjusting an angle of a camera.

- 2. Description of Related Art

- Generally, a camera of an internet protocol (IP) phone is fixed to a base of the IP phone. To adjust the camera, an user can either manually adjust a stand of the IP phone or move the base of the IP phone to make the camera aim at a target image. However, this manual method is cumbersome and ineffective for more precise measurements.

- Therefore, a need exists in the industry to overcome the described limitations.

- Many aspects of the present embodiments can be better understood with reference to the following drawings. The components in the drawings are not necessarily drawn to scale, the emphasis instead being placed upon clearly illustrating the principles of the present embodiments. Moreover, in the drawings, all the views are schematic, and like reference numerals designate corresponding parts throughout the several views.

-

FIG. 1 is a perspective, isometric view of an electronic device of an exemplary embodiment of the disclosure, in which the electronic device comprises a camera to shoot a target image. -

FIG. 2 is a perspective, isometric view of a camera assembly of the disclosure, in which the camera assembly is mounted in the electronic device ofFIG. 1 , and the camera rotates around an axis of the second shaft. -

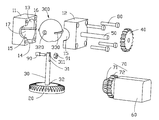

FIG. 3 is a disassembled perspective view ofFIG. 2 . -

FIG. 4 is a perspective, isometric view of a base ofFIG. 2 . -

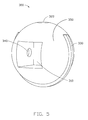

FIG. 5 is a perspective, isometric view of the camera ofFIG. 1 . -

FIG. 6 is a sketching view of a connection relationship between the camera and a first shaft. -

FIG. 7 is a perspective, isometric view of the camera assembly of the disclosure, in which the camera rotates around an axis of the first shaft. - The disclosure is illustrated by way of example and not by way of limitation in the figures of the accompanying drawings in which like references indicate similar elements. It should be noted that references to “an” or “one” embodiment in this disclosure are not necessarily to the same embodiment, and such references mean at least one.

-

FIG. 1 is a perspective, isometric view of anelectronic device 200 of the disclosure.FIG. 2 is a perspective, isometric view of acamera assembly 100 with an exemplary embodiment of the disclosure. Theelectronic device 200 comprises acamera 300 to shoot a target image. Thecamera assembly 100 is mounted in theelectronic device 200 to adjust thecamera 300 to aim at the target image. In the embodiment, theelectronic device 200 is an internet protocol (IP) phone. - The

camera assembly 100 comprises ahollow base 10, afirst gear 20, afirst shaft 30, asecond gear 40, asecond shaft 50, adriving device 60 and adriving gear 70. Thecamera 300 is received in thebase 10 and rotatably connected to thebase 10. One end of thefirst shaft 30 is fixed with thefirst gear 20, another end of thefirst shaft 30 is rotatably connected with thecamera 300. One end of thesecond shaft 50 is fixed with thebase 10, another end of thesecond shaft 50 is fixed with thesecond gear 40. In the embodiment, thefirst shaft 30 and thesecond shaft 50 are perpendicular with each other. Thedriving device 60 drives thedriving gear 70 to engage with thefirst gear 20 and thesecond gear 40, respectively, which lead to thecamera 300 capable of rotating around an axis A1 of thefirst shaft 30 and an axis A2 of thesecond shaft 50, respectively. By this way, thecamera 300 is adjusted to aim at the target image. - With reference to

FIG. 3 andFIG. 4 , thebase 10 comprises afirst base 11 and asecond base 12. Thefirst base 11 and thesecond base 12 are fixed together by a plurality ofbolts 80 to collectively form a receivingspace 13 to receive thecamera 300. Thebase 10 defines afirst hole 14, asecond hole 15 and agroove 16 in aninterior wall 17 of thebase 10. Thefirst hole 14, thesecond hole 15 and thegroove 16 are all communicating with thereceiving space 13. - With reference to

FIG. 5 , thecamera 300 comprises alens 320 to aim at the target image, and a protrudingportion 330 projecting from anexterior surface 350 of thecamera 300. Thecamera 300 defines areceiving hole 310, and athird hole 340 communication with thereceiving hole 310. In assembly, thecamera 300 is received in thereceiving space 13 of thebase 10 with thereceiving hole 310 of thecamera 300 opposite to thefirst hole 14 of thebase 10, thelens 320 of thecamera 30 opposite to thesecond hole 15, and the protrudingportion 330 of thecamera 30 received in thegroove 16 of thebase 10 and capable of sliding along thegroove 16. By this way, when thecamera 300 rotates around the axis A1 of thefirst shaft 30, thecamera 300 can rotate along thegroove 16 of thebase 10 with thelens 320 of thecamera 300 moving toward thesecond hole 15 of thebase 10. When thecamera 300 rotates around the axis A2 of thesecond shaft 50, thecamera 300 fails to move relative to thebase 10 by engagement of the protrudingportion 330 of thecamera 300 and thegroove 16 of thebase 10, which leads to thecamera 300 rotating around the axis of thesecond shaft 50 together with thebase 10. - In the embodiment, the

protruding portion 320 of thecamera 300 is substantially in a shape of an arc, and the center of the arc is located in the axis A1 of thefirst shaft 30. Thecamera 300 is substantially in a shape of a ball, and thereceiving space 13 is correspondingly ball shaped. - Referring to

FIG. 3 , thefirst shaft 30 comprises afirst end 31 defining a throughhole 311, and asecond end 32 fixed with thefirst gear 20. Referring toFIG. 6 , in assembly, thefirst end 31 passes through thefirst hole 14 of thebase 10 and extends into thereceiving hole 310 of thecamera 300. One end of athird shaft 90 inserts through thethrough hole 311 of thefirst shaft 30 and extends into thethird hole 340 of thecamera 300, and another end of thethird shaft 90 matches with anut 91. An axis of thethird shaft 90 is collinear with that of thesecond shaft 50. By this way, thecamera 300 is fixed with thethird shaft 90 and capable of rotating relatively to thefirst shaft 30 around the axis of thethird shaft 90. When thecamera 300 rotates around the axis A2 of thesecond shaft 50 together with thebase 10, thethird shaft 90 rotates in thethrough hole 311 of thefirst shaft 30, which keeps thefirst shaft 30 quiescence. - With reference to

FIG. 7 , thedriving device 60 comprises anoutput shaft 61. Thedriving gear 70 is fixed to theoutput shaft 61. Thedriving device 60 controls theoutput shaft 61 moving by a controlling device (not shown), which lead to thedriving gear 70 moving along theoutput shaft 61 to engage with thefirst gear 20 and thesecond gear 40, respectively. - In the embodiment, the

driving device 60 is a step motor. Thedriving gear 70 comprises afirst driving gear 71 engaged with thefirst gear 20, and asecond driving gear 72 integrated with thefirst driving gear 71 and engaged with thesecond gear 40. Thefirst driving gear 71 and thefirst gear 20 are umbrella gears, thesecond driving gear 72 and the second thesecond gear 40 are spur gears. - In use, to adjust the

camera 300 of theelectronic device 200, thedriving device 60 drives thedriving gear 71 to engage with thefirst gear 20, which lead to thefirst gear 20 and thefirst shaft 30 rotating. As a result, thecamera 300 rotates around the axis A1 of thefirst shaft 30, to adjust the angle of thelens 320 right and left. When thedriving device 60 drives thesecond driving gear 72 to engage with thesecond gear 40, which lead to thesecond gear 40 and thesecond shaft 50 rotating, and thecamera 300 and thebase 10 rotate around the axis A2 of thesecond shaft 50 together to adjust the angle of thelens 320 up and down. By this way, thelens 320 of thecamera 300 aims at the target image with precise measurements effectively. - While the exemplary embodiments have been described, it should be understood that it has been presented by way of example only and not by way of limitation. The breadth and scope of the disclosure should not be limited by the described exemplary embodiments, but only in accordance with the following claims and their equivalents.

Claims (20)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| TW100212188U TWM418311U (en) | 2011-07-04 | 2011-07-04 | Angle adjusting device for camera |

| TW100212188 | 2011-07-04 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| US20130011129A1 true US20130011129A1 (en) | 2013-01-10 |

| US8360663B1 US8360663B1 (en) | 2013-01-29 |

Family

ID=46450491

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US13/195,862 Expired - Fee Related US8360663B1 (en) | 2011-07-04 | 2011-08-02 | Camera assembly capable of adjusting angle of camera |

Country Status (2)

| Country | Link |

|---|---|

| US (1) | US8360663B1 (en) |

| TW (1) | TWM418311U (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2017186134A1 (en) * | 2016-04-27 | 2017-11-02 | 零度智控(北京)智能科技有限公司 | Angle-adjustable camera and unmanned aerial vehicle |

| CN109489947A (en) * | 2018-10-16 | 2019-03-19 | 东莞理工学院 | A kind of multiplicity installation rotating machinery durability analysis instrument of adjustable-angle |

| WO2020135704A1 (en) * | 2018-12-29 | 2020-07-02 | 维沃移动通信有限公司 | Terminal device |

| CN112336296A (en) * | 2020-10-31 | 2021-02-09 | 新乡专知技术服务有限公司 | Special mouth mirror of department of stomatology |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8860789B1 (en) * | 2011-12-09 | 2014-10-14 | Vic G. Rice | Apparatus for producing three dimensional images |

| TW201433730A (en) * | 2013-02-20 | 2014-09-01 | Hon Hai Prec Ind Co Ltd | Rotational tripod head |

| US9965492B1 (en) | 2014-03-12 | 2018-05-08 | Google Llc | Using location aliases |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7527439B1 (en) * | 2004-05-06 | 2009-05-05 | Dumm Mark T | Camera control system and associated pan/tilt head |

| US8221008B2 (en) * | 2006-03-29 | 2012-07-17 | Canon Kabushiki Kaisha | Cradle having panhead function |

| CN101762951B (en) * | 2008-12-23 | 2012-07-25 | 深圳富泰宏精密工业有限公司 | Lens module and electronic device using the same |

| CN101847342A (en) * | 2009-03-24 | 2010-09-29 | 德昌电机(深圳)有限公司 | Display device |

| US7918613B2 (en) * | 2009-06-25 | 2011-04-05 | Vtc Electronics Corporation | Switching mechanism for camera |

-

2011

- 2011-07-04 TW TW100212188U patent/TWM418311U/en not_active IP Right Cessation

- 2011-08-02 US US13/195,862 patent/US8360663B1/en not_active Expired - Fee Related

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2017186134A1 (en) * | 2016-04-27 | 2017-11-02 | 零度智控(北京)智能科技有限公司 | Angle-adjustable camera and unmanned aerial vehicle |

| CN109489947A (en) * | 2018-10-16 | 2019-03-19 | 东莞理工学院 | A kind of multiplicity installation rotating machinery durability analysis instrument of adjustable-angle |

| WO2020135704A1 (en) * | 2018-12-29 | 2020-07-02 | 维沃移动通信有限公司 | Terminal device |

| CN112336296A (en) * | 2020-10-31 | 2021-02-09 | 新乡专知技术服务有限公司 | Special mouth mirror of department of stomatology |

Also Published As

| Publication number | Publication date |

|---|---|

| TWM418311U (en) | 2011-12-11 |

| US8360663B1 (en) | 2013-01-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US8360663B1 (en) | Camera assembly capable of adjusting angle of camera | |

| CN108600596B (en) | camera device and mobile terminal | |

| US9816666B2 (en) | Hand held three-dimensional panoramic pan-tilt kit | |

| US10054842B2 (en) | Gimbal | |

| CN108730713A (en) | A kind of camera pan-tilt and camera chain | |

| CN103994311B (en) | Multi-functional Three Degree Of Freedom intelligent console | |

| CN202203616U (en) | Rotary holder based on 180-degree perspective panoramic camera | |

| CN204305157U (en) | A kind of monitoring camera | |

| US20150158186A1 (en) | Scara robot | |

| CN106425212B (en) | Camera welds carrier strip and carrier | |

| EP1916466A3 (en) | Display screen turning apparatus | |

| CN105526477A (en) | Cloud deck device capable of realizing conversion between transverse shooting and vertical shooting of mobile phone | |

| US10260676B2 (en) | Stabilizer | |

| CN205402146U (en) | 360 rotatory handheld cloud platform of degree | |

| CN104281224A (en) | Terminal with cameras | |

| CN204256344U (en) | Electronics three axle gyrostabilized platform instrument | |

| WO2008084548A1 (en) | Camera unit inspection equipment and camera unit inspection method | |

| WO2020207467A1 (en) | Terminal device | |

| CN205402193U (en) | Cell -phone shake -hands grip can be realized and cradle head device of conversion between bat is erected | |

| US7661404B2 (en) | Angle-adjustable engine starting structure for remote-control toy car | |

| US8928801B2 (en) | Adjustment apparatus for camera module | |

| CN211289372U (en) | Projection device for stage VCR display | |

| CN106838560A (en) | It is applied to the drive device of the angle of pitch of spherical camera eccentric rotary head | |

| CN216870986U (en) | Mobile light for broadcast television engineering | |

| CN205942052U (en) | Module focusing mechanism and use big visual field module focusing system of this mechanism |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| AS | Assignment |

Owner name: HON HAI PRECISION INDUSTRY CO., LTD., TAIWAN Free format text: ASSIGNMENT OF ASSIGNORS INTEREST;ASSIGNOR:LIN, HUNG-TING;REEL/FRAME:026682/0611 Effective date: 20110721 |

|

| STCF | Information on status: patent grant |

Free format text: PATENTED CASE |

|

| FPAY | Fee payment |

Year of fee payment: 4 |

|

| FEPP | Fee payment procedure |

Free format text: MAINTENANCE FEE REMINDER MAILED (ORIGINAL EVENT CODE: REM.); ENTITY STATUS OF PATENT OWNER: LARGE ENTITY |

|

| LAPS | Lapse for failure to pay maintenance fees |

Free format text: PATENT EXPIRED FOR FAILURE TO PAY MAINTENANCE FEES (ORIGINAL EVENT CODE: EXP.); ENTITY STATUS OF PATENT OWNER: LARGE ENTITY |

|

| STCH | Information on status: patent discontinuation |

Free format text: PATENT EXPIRED DUE TO NONPAYMENT OF MAINTENANCE FEES UNDER 37 CFR 1.362 |

|

| FP | Lapsed due to failure to pay maintenance fee |

Effective date: 20210129 |