US20080109085A1 - Method and apparatus for hip femoral resurfacing tooling - Google Patents

Method and apparatus for hip femoral resurfacing tooling Download PDFInfo

- Publication number

- US20080109085A1 US20080109085A1 US11/593,168 US59316806A US2008109085A1 US 20080109085 A1 US20080109085 A1 US 20080109085A1 US 59316806 A US59316806 A US 59316806A US 2008109085 A1 US2008109085 A1 US 2008109085A1

- Authority

- US

- United States

- Prior art keywords

- datum

- femoral head

- tool

- ball

- axis

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Abandoned

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B17/00—Surgical instruments, devices or methods, e.g. tourniquets

- A61B17/16—Bone cutting, breaking or removal means other than saws, e.g. Osteoclasts; Drills or chisels for bones; Trepans

- A61B17/17—Guides or aligning means for drills, mills, pins or wires

- A61B17/1739—Guides or aligning means for drills, mills, pins or wires specially adapted for particular parts of the body

- A61B17/1742—Guides or aligning means for drills, mills, pins or wires specially adapted for particular parts of the body for the hip

- A61B17/175—Guides or aligning means for drills, mills, pins or wires specially adapted for particular parts of the body for the hip for preparing the femur for hip prosthesis insertion

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B17/00—Surgical instruments, devices or methods, e.g. tourniquets

- A61B17/16—Bone cutting, breaking or removal means other than saws, e.g. Osteoclasts; Drills or chisels for bones; Trepans

- A61B17/1662—Bone cutting, breaking or removal means other than saws, e.g. Osteoclasts; Drills or chisels for bones; Trepans for particular parts of the body

- A61B17/1664—Bone cutting, breaking or removal means other than saws, e.g. Osteoclasts; Drills or chisels for bones; Trepans for particular parts of the body for the hip

- A61B17/1668—Bone cutting, breaking or removal means other than saws, e.g. Osteoclasts; Drills or chisels for bones; Trepans for particular parts of the body for the hip for the upper femur

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2/00—Filters implantable into blood vessels; Prostheses, i.e. artificial substitutes or replacements for parts of the body; Appliances for connecting them with the body; Devices providing patency to, or preventing collapsing of, tubular structures of the body, e.g. stents

- A61F2/02—Prostheses implantable into the body

- A61F2/30—Joints

- A61F2/32—Joints for the hip

- A61F2/36—Femoral heads ; Femoral endoprostheses

- A61F2/3601—Femoral heads ; Femoral endoprostheses for replacing only the epiphyseal or metaphyseal parts of the femur, e.g. endoprosthetic femoral heads or necks directly fixed to the natural femur by internal fixation devices

- A61F2/3603—Femoral heads ; Femoral endoprostheses for replacing only the epiphyseal or metaphyseal parts of the femur, e.g. endoprosthetic femoral heads or necks directly fixed to the natural femur by internal fixation devices implanted without ablation of the whole natural femoral head

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2/00—Filters implantable into blood vessels; Prostheses, i.e. artificial substitutes or replacements for parts of the body; Appliances for connecting them with the body; Devices providing patency to, or preventing collapsing of, tubular structures of the body, e.g. stents

- A61F2/02—Prostheses implantable into the body

- A61F2/30—Joints

- A61F2/46—Special tools or methods for implanting or extracting artificial joints, accessories, bone grafts or substitutes, or particular adaptations therefor

- A61F2/4603—Special tools or methods for implanting or extracting artificial joints, accessories, bone grafts or substitutes, or particular adaptations therefor for insertion or extraction of endoprosthetic joints or of accessories thereof

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2/00—Filters implantable into blood vessels; Prostheses, i.e. artificial substitutes or replacements for parts of the body; Appliances for connecting them with the body; Devices providing patency to, or preventing collapsing of, tubular structures of the body, e.g. stents

- A61F2/02—Prostheses implantable into the body

- A61F2/30—Joints

- A61F2/46—Special tools or methods for implanting or extracting artificial joints, accessories, bone grafts or substitutes, or particular adaptations therefor

- A61F2/4603—Special tools or methods for implanting or extracting artificial joints, accessories, bone grafts or substitutes, or particular adaptations therefor for insertion or extraction of endoprosthetic joints or of accessories thereof

- A61F2/4607—Special tools or methods for implanting or extracting artificial joints, accessories, bone grafts or substitutes, or particular adaptations therefor for insertion or extraction of endoprosthetic joints or of accessories thereof of hip femoral endoprostheses

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B17/00—Surgical instruments, devices or methods, e.g. tourniquets

- A61B17/16—Bone cutting, breaking or removal means other than saws, e.g. Osteoclasts; Drills or chisels for bones; Trepans

- A61B17/1637—Hollow drills or saws producing a curved cut, e.g. cylindrical

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B17/00—Surgical instruments, devices or methods, e.g. tourniquets

- A61B17/56—Surgical instruments or methods for treatment of bones or joints; Devices specially adapted therefor

- A61B17/58—Surgical instruments or methods for treatment of bones or joints; Devices specially adapted therefor for osteosynthesis, e.g. bone plates, screws, setting implements or the like

- A61B17/88—Osteosynthesis instruments; Methods or means for implanting or extracting internal or external fixation devices

- A61B17/8897—Guide wires or guide pins

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2/00—Filters implantable into blood vessels; Prostheses, i.e. artificial substitutes or replacements for parts of the body; Appliances for connecting them with the body; Devices providing patency to, or preventing collapsing of, tubular structures of the body, e.g. stents

- A61F2/02—Prostheses implantable into the body

- A61F2/30—Joints

- A61F2/30767—Special external or bone-contacting surface, e.g. coating for improving bone ingrowth

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2/00—Filters implantable into blood vessels; Prostheses, i.e. artificial substitutes or replacements for parts of the body; Appliances for connecting them with the body; Devices providing patency to, or preventing collapsing of, tubular structures of the body, e.g. stents

- A61F2/02—Prostheses implantable into the body

- A61F2/30—Joints

- A61F2/46—Special tools or methods for implanting or extracting artificial joints, accessories, bone grafts or substitutes, or particular adaptations therefor

- A61F2/4657—Measuring instruments used for implanting artificial joints

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2/00—Filters implantable into blood vessels; Prostheses, i.e. artificial substitutes or replacements for parts of the body; Appliances for connecting them with the body; Devices providing patency to, or preventing collapsing of, tubular structures of the body, e.g. stents

- A61F2/02—Prostheses implantable into the body

- A61F2/30—Joints

- A61F2002/30001—Additional features of subject-matter classified in A61F2/28, A61F2/30 and subgroups thereof

- A61F2002/30003—Material related properties of the prosthesis or of a coating on the prosthesis

- A61F2002/30004—Material related properties of the prosthesis or of a coating on the prosthesis the prosthesis being made from materials having different values of a given property at different locations within the same prosthesis

- A61F2002/30011—Material related properties of the prosthesis or of a coating on the prosthesis the prosthesis being made from materials having different values of a given property at different locations within the same prosthesis differing in porosity

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2/00—Filters implantable into blood vessels; Prostheses, i.e. artificial substitutes or replacements for parts of the body; Appliances for connecting them with the body; Devices providing patency to, or preventing collapsing of, tubular structures of the body, e.g. stents

- A61F2/02—Prostheses implantable into the body

- A61F2/30—Joints

- A61F2002/30001—Additional features of subject-matter classified in A61F2/28, A61F2/30 and subgroups thereof

- A61F2002/30108—Shapes

- A61F2002/30199—Three-dimensional shapes

- A61F2002/30205—Three-dimensional shapes conical

- A61F2002/3021—Three-dimensional shapes conical frustoconical

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2/00—Filters implantable into blood vessels; Prostheses, i.e. artificial substitutes or replacements for parts of the body; Appliances for connecting them with the body; Devices providing patency to, or preventing collapsing of, tubular structures of the body, e.g. stents

- A61F2/02—Prostheses implantable into the body

- A61F2/30—Joints

- A61F2002/30001—Additional features of subject-matter classified in A61F2/28, A61F2/30 and subgroups thereof

- A61F2002/30108—Shapes

- A61F2002/30199—Three-dimensional shapes

- A61F2002/30205—Three-dimensional shapes conical

- A61F2002/30217—Three-dimensional shapes conical hollow cones, e.g. tubular-like cones

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2/00—Filters implantable into blood vessels; Prostheses, i.e. artificial substitutes or replacements for parts of the body; Appliances for connecting them with the body; Devices providing patency to, or preventing collapsing of, tubular structures of the body, e.g. stents

- A61F2/02—Prostheses implantable into the body

- A61F2/30—Joints

- A61F2002/30001—Additional features of subject-matter classified in A61F2/28, A61F2/30 and subgroups thereof

- A61F2002/30316—The prosthesis having different structural features at different locations within the same prosthesis; Connections between prosthetic parts; Special structural features of bone or joint prostheses not otherwise provided for

- A61F2002/30329—Connections or couplings between prosthetic parts, e.g. between modular parts; Connecting elements

- A61F2002/30331—Connections or couplings between prosthetic parts, e.g. between modular parts; Connecting elements made by longitudinally pushing a protrusion into a complementarily-shaped recess, e.g. held by friction fit

- A61F2002/30332—Conically- or frustoconically-shaped protrusion and recess

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2/00—Filters implantable into blood vessels; Prostheses, i.e. artificial substitutes or replacements for parts of the body; Appliances for connecting them with the body; Devices providing patency to, or preventing collapsing of, tubular structures of the body, e.g. stents

- A61F2/02—Prostheses implantable into the body

- A61F2/30—Joints

- A61F2002/30001—Additional features of subject-matter classified in A61F2/28, A61F2/30 and subgroups thereof

- A61F2002/30316—The prosthesis having different structural features at different locations within the same prosthesis; Connections between prosthetic parts; Special structural features of bone or joint prostheses not otherwise provided for

- A61F2002/30329—Connections or couplings between prosthetic parts, e.g. between modular parts; Connecting elements

- A61F2002/30331—Connections or couplings between prosthetic parts, e.g. between modular parts; Connecting elements made by longitudinally pushing a protrusion into a complementarily-shaped recess, e.g. held by friction fit

- A61F2002/30378—Spherically-shaped protrusion and recess

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2/00—Filters implantable into blood vessels; Prostheses, i.e. artificial substitutes or replacements for parts of the body; Appliances for connecting them with the body; Devices providing patency to, or preventing collapsing of, tubular structures of the body, e.g. stents

- A61F2/02—Prostheses implantable into the body

- A61F2/30—Joints

- A61F2/30721—Accessories

- A61F2/30734—Modular inserts, sleeves or augments, e.g. placed on proximal part of stem for fixation purposes or wedges for bridging a bone defect

- A61F2002/30738—Sleeves

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2/00—Filters implantable into blood vessels; Prostheses, i.e. artificial substitutes or replacements for parts of the body; Appliances for connecting them with the body; Devices providing patency to, or preventing collapsing of, tubular structures of the body, e.g. stents

- A61F2/02—Prostheses implantable into the body

- A61F2/30—Joints

- A61F2/30767—Special external or bone-contacting surface, e.g. coating for improving bone ingrowth

- A61F2002/30934—Special articulating surfaces

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2/00—Filters implantable into blood vessels; Prostheses, i.e. artificial substitutes or replacements for parts of the body; Appliances for connecting them with the body; Devices providing patency to, or preventing collapsing of, tubular structures of the body, e.g. stents

- A61F2/02—Prostheses implantable into the body

- A61F2/30—Joints

- A61F2/32—Joints for the hip

- A61F2/36—Femoral heads ; Femoral endoprostheses

- A61F2/3601—Femoral heads ; Femoral endoprostheses for replacing only the epiphyseal or metaphyseal parts of the femur, e.g. endoprosthetic femoral heads or necks directly fixed to the natural femur by internal fixation devices

- A61F2/3603—Femoral heads ; Femoral endoprostheses for replacing only the epiphyseal or metaphyseal parts of the femur, e.g. endoprosthetic femoral heads or necks directly fixed to the natural femur by internal fixation devices implanted without ablation of the whole natural femoral head

- A61F2002/3605—Femoral heads ; Femoral endoprostheses for replacing only the epiphyseal or metaphyseal parts of the femur, e.g. endoprosthetic femoral heads or necks directly fixed to the natural femur by internal fixation devices implanted without ablation of the whole natural femoral head made of two or more concentric caps fitted onto one another

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2/00—Filters implantable into blood vessels; Prostheses, i.e. artificial substitutes or replacements for parts of the body; Appliances for connecting them with the body; Devices providing patency to, or preventing collapsing of, tubular structures of the body, e.g. stents

- A61F2/02—Prostheses implantable into the body

- A61F2/30—Joints

- A61F2/46—Special tools or methods for implanting or extracting artificial joints, accessories, bone grafts or substitutes, or particular adaptations therefor

- A61F2/4603—Special tools or methods for implanting or extracting artificial joints, accessories, bone grafts or substitutes, or particular adaptations therefor for insertion or extraction of endoprosthetic joints or of accessories thereof

- A61F2002/4625—Special tools or methods for implanting or extracting artificial joints, accessories, bone grafts or substitutes, or particular adaptations therefor for insertion or extraction of endoprosthetic joints or of accessories thereof with relative movement between parts of the instrument during use

- A61F2002/4627—Special tools or methods for implanting or extracting artificial joints, accessories, bone grafts or substitutes, or particular adaptations therefor for insertion or extraction of endoprosthetic joints or of accessories thereof with relative movement between parts of the instrument during use with linear motion along or rotating motion about the instrument axis or the implantation direction, e.g. telescopic, along a guiding rod, screwing inside the instrument

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2/00—Filters implantable into blood vessels; Prostheses, i.e. artificial substitutes or replacements for parts of the body; Appliances for connecting them with the body; Devices providing patency to, or preventing collapsing of, tubular structures of the body, e.g. stents

- A61F2/02—Prostheses implantable into the body

- A61F2/30—Joints

- A61F2/46—Special tools or methods for implanting or extracting artificial joints, accessories, bone grafts or substitutes, or particular adaptations therefor

- A61F2/4603—Special tools or methods for implanting or extracting artificial joints, accessories, bone grafts or substitutes, or particular adaptations therefor for insertion or extraction of endoprosthetic joints or of accessories thereof

- A61F2002/4625—Special tools or methods for implanting or extracting artificial joints, accessories, bone grafts or substitutes, or particular adaptations therefor for insertion or extraction of endoprosthetic joints or of accessories thereof with relative movement between parts of the instrument during use

- A61F2002/4628—Special tools or methods for implanting or extracting artificial joints, accessories, bone grafts or substitutes, or particular adaptations therefor for insertion or extraction of endoprosthetic joints or of accessories thereof with relative movement between parts of the instrument during use with linear motion along or rotating motion about an axis transverse to the instrument axis or to the implantation direction, e.g. clamping

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2/00—Filters implantable into blood vessels; Prostheses, i.e. artificial substitutes or replacements for parts of the body; Appliances for connecting them with the body; Devices providing patency to, or preventing collapsing of, tubular structures of the body, e.g. stents

- A61F2/02—Prostheses implantable into the body

- A61F2/30—Joints

- A61F2/46—Special tools or methods for implanting or extracting artificial joints, accessories, bone grafts or substitutes, or particular adaptations therefor

- A61F2002/4631—Special tools or methods for implanting or extracting artificial joints, accessories, bone grafts or substitutes, or particular adaptations therefor the prosthesis being specially adapted for being cemented

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2/00—Filters implantable into blood vessels; Prostheses, i.e. artificial substitutes or replacements for parts of the body; Appliances for connecting them with the body; Devices providing patency to, or preventing collapsing of, tubular structures of the body, e.g. stents

- A61F2/02—Prostheses implantable into the body

- A61F2/30—Joints

- A61F2/46—Special tools or methods for implanting or extracting artificial joints, accessories, bone grafts or substitutes, or particular adaptations therefor

- A61F2002/4677—Special tools or methods for implanting or extracting artificial joints, accessories, bone grafts or substitutes, or particular adaptations therefor using a guide wire

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2/00—Filters implantable into blood vessels; Prostheses, i.e. artificial substitutes or replacements for parts of the body; Appliances for connecting them with the body; Devices providing patency to, or preventing collapsing of, tubular structures of the body, e.g. stents

- A61F2/02—Prostheses implantable into the body

- A61F2/30—Joints

- A61F2/46—Special tools or methods for implanting or extracting artificial joints, accessories, bone grafts or substitutes, or particular adaptations therefor

- A61F2002/4687—Mechanical guides for implantation instruments

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2220/00—Fixations or connections for prostheses classified in groups A61F2/00 - A61F2/26 or A61F2/82 or A61F9/00 or A61F11/00 or subgroups thereof

- A61F2220/0025—Connections or couplings between prosthetic parts, e.g. between modular parts; Connecting elements

- A61F2220/0033—Connections or couplings between prosthetic parts, e.g. between modular parts; Connecting elements made by longitudinally pushing a protrusion into a complementary-shaped recess, e.g. held by friction fit

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2230/00—Geometry of prostheses classified in groups A61F2/00 - A61F2/26 or A61F2/82 or A61F9/00 or A61F11/00 or subgroups thereof

- A61F2230/0063—Three-dimensional shapes

- A61F2230/0067—Three-dimensional shapes conical

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2250/00—Special features of prostheses classified in groups A61F2/00 - A61F2/26 or A61F2/82 or A61F9/00 or A61F11/00 or subgroups thereof

- A61F2250/0014—Special features of prostheses classified in groups A61F2/00 - A61F2/26 or A61F2/82 or A61F9/00 or A61F11/00 or subgroups thereof having different values of a given property or geometrical feature, e.g. mechanical property or material property, at different locations within the same prosthesis

- A61F2250/0023—Special features of prostheses classified in groups A61F2/00 - A61F2/26 or A61F2/82 or A61F9/00 or A61F11/00 or subgroups thereof having different values of a given property or geometrical feature, e.g. mechanical property or material property, at different locations within the same prosthesis differing in porosity

- A61F2250/0024—Special features of prostheses classified in groups A61F2/00 - A61F2/26 or A61F2/82 or A61F9/00 or A61F11/00 or subgroups thereof having different values of a given property or geometrical feature, e.g. mechanical property or material property, at different locations within the same prosthesis differing in porosity made from both porous and non-porous parts, e.g. adjacent parts

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2310/00—Prostheses classified in A61F2/28 or A61F2/30 - A61F2/44 being constructed from or coated with a particular material

- A61F2310/00005—The prosthesis being constructed from a particular material

- A61F2310/00011—Metals or alloys

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2310/00—Prostheses classified in A61F2/28 or A61F2/30 - A61F2/44 being constructed from or coated with a particular material

- A61F2310/00005—The prosthesis being constructed from a particular material

- A61F2310/00179—Ceramics or ceramic-like structures

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2310/00—Prostheses classified in A61F2/28 or A61F2/30 - A61F2/44 being constructed from or coated with a particular material

- A61F2310/00389—The prosthesis being coated or covered with a particular material

- A61F2310/00395—Coating or prosthesis-covering structure made of metals or of alloys

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2310/00—Prostheses classified in A61F2/28 or A61F2/30 - A61F2/44 being constructed from or coated with a particular material

- A61F2310/00389—The prosthesis being coated or covered with a particular material

- A61F2310/00395—Coating or prosthesis-covering structure made of metals or of alloys

- A61F2310/00407—Coating made of titanium or of Ti-based alloys

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2310/00—Prostheses classified in A61F2/28 or A61F2/30 - A61F2/44 being constructed from or coated with a particular material

- A61F2310/00389—The prosthesis being coated or covered with a particular material

- A61F2310/00395—Coating or prosthesis-covering structure made of metals or of alloys

- A61F2310/00413—Coating made of cobalt or of Co-based alloys

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2310/00—Prostheses classified in A61F2/28 or A61F2/30 - A61F2/44 being constructed from or coated with a particular material

- A61F2310/00389—The prosthesis being coated or covered with a particular material

- A61F2310/00395—Coating or prosthesis-covering structure made of metals or of alloys

- A61F2310/00419—Other metals

- A61F2310/00491—Coating made of niobium or Nb-based alloys

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2310/00—Prostheses classified in A61F2/28 or A61F2/30 - A61F2/44 being constructed from or coated with a particular material

- A61F2310/00389—The prosthesis being coated or covered with a particular material

- A61F2310/00395—Coating or prosthesis-covering structure made of metals or of alloys

- A61F2310/00419—Other metals

- A61F2310/00544—Coating made of tantalum or Ta-based alloys

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2310/00—Prostheses classified in A61F2/28 or A61F2/30 - A61F2/44 being constructed from or coated with a particular material

- A61F2310/00389—The prosthesis being coated or covered with a particular material

- A61F2310/00592—Coating or prosthesis-covering structure made of ceramics or of ceramic-like compounds

Definitions

- the present invention relates generally to systems, kits and methods for joint prosthesis installation tools.

- the present invention includes jigs and methods for installing a stemless ball component to a prepared femoral head along an axis defined by the prepared femoral head and jigs for installing a sleeve component for adapting a ball component to a prepared femoral head along an axis defined by the prepared femoral head.

- Orthopedic implants are constructed from materials that are stable in biological environments and withstand physical stress with minimal or controlled deformation. Such materials must possess strength, resistance to corrosion, biocompatibility, and good wear properties. Also, the implants include various interacting parts, which undergo repeated long-term physical stress inside the body.

- the bone/implant interface and the connection between various parts of the implant must be durable and resistant to breakdown. This is especially important since installation of an orthopedic implant often involves an extensive and difficult medical procedure, and therefore replacement or revision of the installed implant is typically difficult and traumatic.

- a hip joint is a ball-in-socket joint, and includes a rounded femoral head and a cup-like socket (acetabular cup) located in the pelvis.

- acetabular cup The surfaces of the rounded femoral head and the acetabular cup continually abrade each other as a person walks. The abrasion, along with normal loading, creates stress on the hip joint and adjacent bones. If the femoral head or the acetabular cup is replaced with an implant, this stress must be well tolerated by the implant's bearing surfaces to prevent implant failure.

- FIG. 1 shows the proximal portion of a femur 1 with the upper portion of the shaft 3 , a neck 5 and a head 7 .

- a shaft axis A-A is aligned with the shaft 3 and a head axis B-B is generally aligned with the neck 5 .

- the shaft 3 is primarily composed of cortical bone while the neck 5 and head 7 are primarily composed of trabecular bone with cortical bone at the surface.

- Implantable joint prostheses have long been used to provide an artificial hip. When the prosthesis is situated in this position, significant forces such as axial, bending, and rotational forces are imparted to the device.

- Conventional total hip replacements use an intramedullary stem as part of the femoral prosthesis. The stem passes into the marrow cavity of the femoral shaft. These stem type prostheses are very successful but when they fail the stem can create considerable damage inside the bone. The implant can move about inside the bone causing the intramedullary cavity to be damaged. Because a stiff stem transmits the forces more directly into the femoral shaft, such implants have the further disadvantage that they can weaken the surrounding bone nearer to the hip joint due to stress shielding.

- Stems designed for biological ingrowth typically rely on the bone itself to grow into a specially prepared surface of the component, resulting in firmly anchoring the implant within the medullary canal.

- a shortfall of this approach is that, in contrast to components that utilize cement fixation, surfaces designed for biological ingrowth do not provide for immediate fixation because it takes time for the bone to grow into the specially prepared surface.

- Press-fit stems precisely engineered to fit within a surgically prepared medullary canal may or may not have specially prepared surfaces and typically rely on an interference fit of some portion of the component within the medullary canal of the bone to achieve stable fixation.

- stem-type femoral head resurfacing prostheses consist of a bearing cap provided with a central pin that guides the prosthesis during the insertion.

- the guiding is important because it ensures that the prosthesis will be seating at the appropriate orientation planned by the surgeon with regard to the bone.

- a consequence of the misalignment of the prosthesis is a sub-optimal load transfer to the bone that can lead to the failure of the prosthetic joint.

- a stem-type resurfacing prostheses requires the surgeon to remove enough bone in the neck of the femur so that it can host the pin of the prosthesis and the stem can contribute to stress shielding. Therefore the stem-type prosthesis is not as bone preserving as a stemless prosthesis, either in the short term or long term.

- the femoral head be prepared to provide a properly oriented and shaped bone interface for the implant by shaping the head.

- the outer prepared bone interface with the implant is symmetrical around a prepared head axis B-B passing through and established with reference to the central region of the femoral neck and is typically cylindrical or conical but may be a more complex tapering solid of revolution.

- the proximal portion of the prepared head can be a flat surface, tapered, domed, chamfered, or any combination of these features and is usually performed as a separate resection. If a stem is used, it may be cylindrical, conical or a more complex tapering solid of revolution and is typically short compared to a conventional intramedullary stem.

- the portion of the bone that hosts the prosthesis must be shaped so that it matches the shape of the prosthesis.

- the size and shape of the bone may fit exactly the shape and size of the prosthesis or may provide room for cementing to take place or have an excess of bone in a region to allow press-fit fixation, depending on the preferred fixation method.

- a guide wire or pin introduced into the femoral head is typically used to establish the tooling landmark or datum that establishes and defines the prepared head axis B-B.

- the guide pin provides an axis of revolution for the various measuring and cutting tools used in the preparation process as shown in FIG. 4 and discussed later.

- the guide wire When introduced into the femoral head, the guide wire creates a corresponding bore that also provides a datum for the axis B-B in the absence of the guide wire. Based on pre-operative planning, the surgeon initially places the guide wire, either freehand or using measurement and guidance tools based on various anatomical reference points on the femur.

- the pin In order to place the pin, the pin is driven or inserted in the proximal surface of the femoral head directed toward the greater trochanter and approximately down the mid-lateral axis of the femoral neck.

- a gauge having an extended stylus that allows measurement of the position of the pin with respect to the neck is then typically used to make a preliminary check of the pin position. By revolving the gauge, the surgeon can evaluate the position of the pin to ensure that the femoral neck will not be undercut when the cutting tool is revolved around the pin. If the surgeon is satisfied that the pin position meets these criteria, the guide wire is used as the axis of revolution for the shaping cutter or reamer to prepare the head to receive the implant.

- a stem-type resurfacing prosthesis For a traditional stem-type resurfacing prosthesis, the stem cavity is used to guide the stem and prosthesis into position.

- a stem-type resurfacing prosthesis has provided an acceptable method of guiding the prosthesis with respect to the femoral head axis because the stem cavity approximates the head axis datums and the stem serves as tooling to guide the prosthesis along an axis approximating the femoral head axis during installation by engaging the stem cavity.

- stem and stem cavity do not exist and the stem cannot serve as tooling to guide the prosthesis. It is desirable to have tooling and a surgical method for use with a stemless prosthesis that allows implanting the prosthesis along the femoral head axis with at least the same accuracy achieved by stem-type resurfacing prosthesis.

- a jig or tool is used to control the direction of the travel and the seating force vector of a femoral prosthesis component with respect to an axis previously used to create the outer surface of the resected or shaped femoral head surface that will mate with the prosthesis component.

- a tool and method for seating the sleeve component of a two-part prosthesis guides the sleeve on a guide pin or Kirschner wire located in the head axis used as a datum to create the femoral head resection.

- the sleeve inner and outer distal surfaces are typically in the shape of a truncated cone, but may also incorporate other anti-rotational or locking features.

- the inner surface of the sleeve is shaped and dimensioned to mate with a prepared femoral head.

- the sleeve proximal portion has a central hole capable of allowing the guide pin to pass through it.

- the tool also has a central cannulated bore capable of receiving the guide pin and slidingly journaling on the guide pin to insure that the tool is aligned with the datum provided by the guide pin. Consequently, the tool and sleeve are aligned with the femoral head axis while seating the sleeve.

- the tool distal portion has holding features that conform to a portion of the sleeve outer surface and retains the sleeve with suitable features such as detents. Because of the tapered sleeve exterior configuration mating with the holding features, the sleeve will tend to strongly lock with the tool as a result of the force applied to the tool as the sleeve is seated.

- the tool incorporates release features, such as an extractor assembly that forces pins against the sleeve, to release the prosthesis from the tool.

- these releasing features are symmetrical about the tool and femoral head axis in order to insure that the sleeve is not cocked with respect to the axis by the releasing action.

- a method for using the prosthesis holding tool of the first embodiment.

- the sleeve prosthesis is first attached to the prosthesis holder. If necessary, bone cement is applied to the interior surface of the sleeve or to the mating prepared femoral head surface.

- the tip of the guide pin is introduced into the hole of the sleeve and the cannulated bore of the prostheses holder and the holder is used to drive the sleeve along the axis defined by the guide pin until the sleeve is mated with the prepared femoral head. Then sufficient pressure is applied to seat the prosthesis as required by the selected fixation method.

- the extractor assembly of the prosthesis holding tool is next used to release the sleeve and the prosthesis holding tool can be removed from the guide pin.

- the guide pin is then removed from the patient, and a ball component is seated on the sleeve using a suitable tool.

- a prosthesis holding tool similar to the first embodiment is adapted to be used when the guide pin has been removed prior to using the tool.

- the prosthesis holder of the second embodiment has a central pin projecting from the distal prosthesis holding portion to pass through the hole in the proximal portion of the sleeve and enter the bore in the prepared femoral head previously occupied by the guide pin.

- the operation and method of the second embodiment is the same as the first embodiment except that, after preparing the femoral head, the guide pin is removed prior to the step of seating the sleeve.

- the invention is used to seat a ball component rather than a sleeve.

- an alignment jig is temporarily attached to the femoral neck.

- a pin location guide is fitted on the guide pin projecting from the femoral head which provides a datum.

- a frame with various translational and rotational adjustments is connected with the location guide, and also fastened to the femoral neck.

- the guide pin position and consequently the femoral head axis are determined and the alignment jig is constrained to align with the axis.

- the guide pin is then removed.

- the partial ball component and a suitable prosthesis holding tool are then engaged with the alignment jig to allow the prosthesis and holding tool to be installed by translating the prosthesis and tool along the head axis B-B to create a secondary datum.

- the alignment jig of the third embodiment also has the capability to establish a new axis for the alignment pin if necessary.

- the various translational and rotational adjustments of the jig can be re-adjusted to a new axis location.

- a pin location guide can be reinstalled and used as a guide to drive in a new alignment pin that can, in turn, be used for a secondary re-surfacing of the femoral head.

- the prosthesis can be installed on the newly prepared head and the prosthesis installed along the new axis as described in the previous paragraph.

- the tooling of the third embodiment is modified to provide a separate axis alignment jig and prostheses alignment jig.

- the axis alignment jig is fitted directly over the guide pin without the use of a pin location guide to determine the head axis and is used to install a mount, typically a mounting pin, on the side of the femoral neck in a predetermined relationship to the head axis B-B.

- the axis alignment jig is next removed and then the guide pin is removed.

- the prosthesis is installed in the prosthesis alignment jig and the jig is aligned with the prepared femoral head axis B-B using the mount on the side of the neck.

- the prosthesis alignment jig is then used to install the prosthesis in a manner similar to the third embodiment.

- FIG. 1 is a cross-sectional side view of the upper portion of a human femur

- FIG. 2 is a cross-sectional side view of a two-piece femoral resurfacing prosthesis showing a sleeve and ball component installed on a prepared femoral head;

- FIG. 3 is a perspective view of a sleeve and ball component corresponding to the sleeve and ball component shown in FIG. 2 ;

- FIG. 4 is a view of a step in the preparation of a femoral head as shown in FIG. 2 , wherein a guide pin has been installed along a femoral head axis B-B and is used to prepare a femoral head surface suitable for a prosthesis by revolving a cutter about the pin;

- FIG. 5 is a perspective view of a prosthesis holding tool for a sleeve prosthesis according to the first embodiment of the invention

- FIGS. 6-10 show perspective views of a sequence of steps in the method of use according to the first embodiment of the invention.

- FIGS. 11-12 show the prosthesis holder according to the second embodiment of the invention and the method of use according to the second embodiment of the invention

- FIG. 13 is a perspective view according to the third embodiment of the invention showing an alignment jig attached to a femoral neck to install a ball prosthesis on a prepared femoral head along femoral neck access;

- FIGS. 14-19 show perspective views of a sequence of steps of a method of using the alignment jig of FIG. 13 including, starting in FIG. 16 , the use of a prosthesis holder guided by the jig to install the prosthesis;

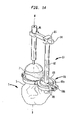

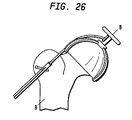

- FIGS. 20-26 show a sequence of perspective views according to a fourth embodiment of the present invention and the method of use of an alignment jig to determine the position of a secondary alignment pin on the side of the femoral neck using an alignment jig and then using a separate prosthesis holder engaged on the secondary pin to install the ball component prosthesis.

- a proximal femur as depicted in FIG. 1 has been surgically prepared for the implantation of a stemless femoral hip resurfacing prosthesis.

- the preparation consists of a re-shaping of the femoral head 7 , in this instance, as a surface of revolution about the prepared femoral head axis B-B.

- the femoral head 7 has been re-shaped by known surgical techniques as a prepared femoral head 7 ′, such that the femoral head surface 9 has been removed, creating a prepared femoral head surface 9 ′.

- a ball component 20 is fitted over the sleeve 10 .

- the axis B-B passes approximately through the center of the femoral neck 5 , the center of the prepared femoral head 7 ′, the center of the sleeve 10 , the center of a hole 12 in the sleeve distal end and the center of the ball component 20 .

- a two-part modular prosthesis having a sleeve component 10 and ball component 20 is depicted on the prepared femoral head.

- a unitary ball prosthesis 20 ′ (not shown), integrating the features of the sleeve 10 and the ball 20 will also be discussed.

- FIG. 3 shows in an exploded perspective view the prosthesis of FIG. 2 .

- the sleeve component 10 fits closely inside at least a portion of the ball component 20 .

- the sleeve 10 is generally a tapering solid of revolution about a central axis having a sleeve cavity which is configured to interface with the prepared femoral head surface 9 ′.

- the distal portion of the sleeve is in the configuration of a hollow truncated cone.

- either of the inner or outer surfaces of the sleeve can define any hollow cylinder or tapering surfaces such as an ogive or any parabolic surface capable of being fit over a matched prepared femoral head surface 9 ′.

- the proximal portion 12 can be a different shape of revolution about the central axis, for example a flat surface, a spherical domed surface or a chamfered flat surface. When present, the proximal portion 12 may be closely configured to the prepared femoral head surface 9 ′ or may have clearance from the prepared femoral head surface.

- the sleeve 10 may be a solid metallic or ceramic structure or it may have a tissue ingrowth surface such as a porous inner surface integrated with or attached to a solid outer layer.

- the sleeve may also be porous throughout.

- the ball component 20 has a spherical outer surface that serves as the bearing for the implant when assembled with a mating acetabular cup.

- the ball component 20 has a bore that has an inner surface allowing it to closely conform to the distal sleeve outer surface or in the instance of a a one-piece ball prosthesis 20 ′, the prepared femoral head surface 9 ′.

- the body of the ball component 20 is preferably made of a metallic or ceramic material similar to those described for the sleeve 10 with the exception that the material is typically solid throughout and has a suitable hardness and durability to provide a bearing surface or substrate.

- the ball component 20 may be coated or have a surface layer of ceramic material.

- the hemispherical outer surface must function as a bearing and requires a fine finish. It is also necessary that a prosthesis holder provide suitable handling of the prosthesis to prevent damage to the implant bearing surface during installation.

- FIG. 4 shows the preparation of the prepared femoral head 7 ′, such that the femoral head surface 9 has been removed to create the distal portion of the prepared femoral surface 9 ′.

- the part of the prosthesis that comes in contact with the bone can be tapered, domed, chamfered, cylindered or any combination of any of these features.

- the portion of the bone that hosts the prosthesis is shaped so that it matches the shape of the prosthesis.

- the size and shape of the bone may fit exactly the shape and size of the prosthesis or it may provide room for bone cement or provide an excess of bone in some area to allow press-fit fixation, depending on the preferred fixation method.

- the bone shape is typically symmetrical around a prepared femoral head axis B-B and created by an appropriately shaped cutter 32 that revolves about a guide pin 30 , located in a femoral neck bore 31 .

- the surface 9 ′, the cutter 32 , the pin 30 and the bore 31 are co-axial with the axis B-B.

- the symmetrical axis B-B of the bone is also the axis along which it is desirable to guide the prosthesis for proper installation.

- the cutter 32 may also shape the proximal portion of the surface 9 ′.

- FIGS. 5 and 6 depict a prosthesis holding tool 50 according to an aspect of the first embodiment of the invention for seating the sleeve component 10 of a two-part prosthesis onto the prepared femoral head 7 ′ of the femur 1 .

- the tool 50 is cannulated with a central bore 51 to allow guiding on the guide pin 30 initially used to prepare the femoral head.

- the sleeve 10 has a central hole 12 in the proximal portion to allow the guide pin 30 to pass through it.

- the central bore 51 of the tool 50 is capable of receiving the guide pin 30 and slidingly journaling on the guide pin to insure that the tool is aligned with the prepared femoral head axis B-B while seating the sleeve.

- the tool distal portion has a sleeve interface 52 for receiving the sleeve 10 .

- the sleeve interface 52 has holding features 54 that conform to a portion of the sleeve outer surface and retain the sleeve with suitable features such as detents 55 or tines. Because of the preferred tapered sleeve exterior configuration wedging with the holding features 54 , the sleeve 10 will tend to strongly lock with the sleeve interface 52 as a result of the force of seating the sleeve 10 on the head 7 ′.

- the tool incorporates release features, such as an extractor assembly 60 that forces pins 64 against the proximal portion of the sleeve, to release the sleeve from the tool.

- the releasing features are symmetrical about the tool and femoral head axis in order to insure that the sleeve is not cocked with respect to the axis by the releasing action.

- the pins 64 are centrally connected and slidingly journalled on the handle 56 of the tool 50 by an extractor cage 62 in order to ensure that the extractor pins 64 apply force symmetrically about the handle axis and consequently the femoral head axis B-B in order to ensure that the sleeve 10 is not cocked during the separation of the tool from the sleeve.

- a camming lever 68 drives the extractor cage 62 and consequently the extractor pins 64 parallel to the axis B-B when actuated.

- a return spring 66 is provided to keep the cage 62 positively engaged with the cam of the lever 68 .

- FIGS. 5-10 illustrate the method of using the prosthesis holding tool 50 .

- the sleeve prosthesis 10 is first inserted into the sleeve interface 52 and retained by the tines 55 of the retention prongs 54 located symmetrically about the interface. If necessary, bone cement is applied to the interior surface of the sleeve 10 or to the mating prepared femoral head surface 9 ′. Using the tool, the sleeve 10 is brought into position to introduce the proximal end of the tip of the guide pin 30 into the central hole 12 of the sleeve and the cannulated bore 51 of the prostheses holder 50 .

- the handle 56 of the holder is used by the surgeon to drive the sleeve 10 along the axis B-B defined by the guide pin until the sleeve is mated with the prepared femoral head 7 ′ as shown in FIGS. 5 and 6 . Sufficient pressure is applied to seat the prosthesis as required by the selected fixation method. If necessary, the tool 50 is held in position while the bone cement sets. As seen in FIG. 7 , the extractor assembly 60 of the prosthesis holding tool is then actuated by rotating the handle 68 toward the handle 56 . As further seen in FIG.

- this actuation drives the extractor cage 62 and pins 64 distally against the proximal portion of the sleeve 10 to overcome the locking force and detents in order to release the sleeve.

- the handle 68 is returned to the initial position, withdrawing the pins 64 by the action of the spring 64 .

- the prosthesis holding tool 50 can then be removed from the guide pin 30 as shown in FIG. 9 .

- the guide pin 30 is next removed from the femoral head 7 ′, as in FIG. 10 and a ball component 20 may be seated on the sleeve 10 in a subsequent operation.

- FIGS. 11-12 show a prosthesis holder according to an aspect of the second embodiment of the invention and a sequence of steps of the method of use of the second embodiment of the invention.

- a prosthesis holding tool 50 similar to the first embodiment is adapted to be used after removing the guide pin 30 prior to being used.

- the guide pin 30 is removed from the femoral head 7 ′.

- a central alignment pin 70 projects from the center of the handle 56 in place of the bore 51 previously used to receive the guide pin 30 .

- the central alignment pin 70 is first passed through the hole 12 in the proximal portion of the sleeve and the sleeve is captured, as in the first embodiment, by the holding features 54 and detents 55 of the sleeve interface 52 .

- the tool 50 is positioned with the alignment pin 70 aligned with the axis B-B and guided toward the femoral head 7 ′ until the alignment pin 70 is seated in the bore 31 to slidingly journal the tool along the axis B-B.

- the tool, operation and method of the second embodiment is the same as the first embodiment except that, of course, the guide pin 30 is already removed prior to seating the sleeve.

- FIGS. 13-19 show tools and methods according to an aspect of the third embodiment of the invention wherein an alignment jig 80 is attached to a femoral neck 5 to install a ball prosthesis 20 ′ on a prepared femoral head 7 ′ along a prepared femoral head axis B-B determined from the guide pin 30 .

- the invention is used to seat the ball component 20 ′ rather than the sleeve 10 .

- the ball component 20 ′ depicted is a one-piece type prosthesis with a cavity fitting directly on the prepared femoral head 7 ′ although the aspects of the invention applicable to a one-piece ball component 20 ′ are also applicable to any modular ball component such as ball component 20 .

- Fitting a ball component 20 ′ presents problems because the axis B-B cannot be directly located by the datums of the previous embodiments, either by guiding on the guide pin 30 or the bore 31 , during the installation of the ball because the pin must be removed prior to installing the component and the bore is inaccesible as the head 7 ′ enters the cavity 10 .

- an alignment jig 80 is used to transfer the datum for the axis B-B to create a secondary datum at a position sufficiently distant from the femoral head 7 ′ to allow a path for the ball component 20 to be installed on the head.

- a sequence of steps of the method of using the alignment jig 80 is illustrated in FIGS. 13-19 including, starting in FIG. 16 , the use of a prosthesis holding tool 50 guided by the jig to install the prosthesis.

- the alignment jig 80 is attached to a proximal portion of the femur 1 , preferably at the femoral neck 5 .

- the femoral head 7 has been prepared, as previously discussed with respect to FIG. 4 and the guide pin 30 is temporarily left in place.

- the alignment jig 80 is comprised of a femoral mount 81 , an axial extension 82 and a radial extension 84 with a pin location guide 86 at the proximal end of the extension.

- the pin location guide 86 is an aperture having a central axis that can be aligned to be co-axial with the femoral head axis datum provided by the guide pin 30 or the bore 31 and consequently with axis B-B.

- the jig 80 has various clamps, slides and rotational adjustments that provide sufficient degrees of freedom to allow the pin location guide 86 to be co-axially positioned with axis B-B.

- the pin locator 87 has a bore with a central axis.

- the bore is sized to slidingly engage on the guide pin 30 projecting from the femoral head and the locator 87 has an outer surface coaxial with the bore that slidingly engages the pin location guide 86 to translate the datum for the axis B-B originally established by the guide pin 30 .

- the pin locator 87 may also be configured with a projecting alignment pin, to locate the datum for axis B-B using the bore 31 in the same manner as the pin 70 of the tool 50 in the second embodiment of the invention.

- the femoral mount 81 is first attached to the proximal femur 1 , preferably at the femoral neck 5 .

- the attachment may be by friction means using, for example, a hinged clamping mechanism, as shown, or by set screws or bone screws, care being taken to not compromise the integrity of the femoral bone at the interface with the clamp.

- the mount 81 incorporates a multi-axis adjuster 88 comprising a spherical cavity 88 a and a binder bolt 88 b .

- the spherical cavity 88 a engages a split spherical collet 89 and can apply a clamping force using the binder bolt 88 b as shown.

- the collet 89 is slidingly engaged with the axial extension 82 which passes through a central cavity of the collet to provide an axial adjustment. Consequently, when the adjuster 88 is not clamped, the spherical interface 88 a provides the collet 89 with three degrees of rotational freedom and allows the axial extension 82 to translate relative to the collet. When clamped, the three rotational degrees of freedom and the translational degree of freedom are locked because the binder bolt 88 b constricts the spherical cavity 88 a onto the split collet 89 , which in turn constricts the collet onto the axial extension 82 . Two of the rotational degrees of freedom allow the axial extension 82 to be positioned parallel to the guide pin 30 and axis B-B while the third degree of freedom allows rotation of the axial extension 82 about its axis.

- the axial extension 82 has a radial adjustment 85 at its proximal end with a suitable clamping mechanism, such as a set screw, to slidingly engage the distal portion of the radial extension 84 and lock the joint when desired.

- a suitable clamping mechanism such as a set screw

- the jig 80 is mounted on the femoral neck 5 and the jig joints are adjusted and locked to allow the pin locator 87 to engage the pin location guide 86 , the datum provide by the guide pin 10 , and consequently the prepared femoral head axis B-B, are determined and the pin alignment guide 86 is constrained to align with the axis and bore of the guide.

- the pin alignment guide 86 can now be used as a new datum to determine the axis B-B.

- the guide pin 30 is then removed as shown in FIG. 15 .

- the partial ball component 20 ′ and a prosthesis holding tool 50 adapted to retain a ball component are mounted on the alignment jig 80 to allow the ball 20 ′ to be installed by translating the prosthesis and tool along the axis B-B as established by the jig using the new datum remote from the femoral head.

- the prosthesis holding tool 50 has been modified to retain and selectably release the ball component 20 ′.

- the ball component 20 ′ has a finely finished bearing surface that must be suitably handled to protect the finish.

- the ball 20 ′ is gripped by three retention prongs 54 , that are pivotably mounted to an interface body 52 .

- the prongs 54 may be capable of elastic deformation or spring loaded and may be released by a suitable pivot arm connected to a release button in the handle 58 as will be understood by a person of skill in the art.

- detents 55 or tines may be engaged on the planar portion of the partial ball component 20 ′ to prevent rotation of the ball as shown in FIG. 16A .

- the tines 55 project inwardly from the spherical inner surface of the prongs 54 at the position corresponding to the planar portion of the partial ball component 20 ′.

- the prongs 54 are deflected outward to install the ball component 20 ′ and capture the ball component when the ball component is fully seated and the prongs 44 and tines 55 move inward.

- the ball 20 ′ may be released by overcoming a spring preload or deflecting the retention prongs 54 and tines 55 either as a result of the frictional retention force created by the interface of the ball cavity with the prepared femoral head surface 9 ′ as the tool 50 is retracted or by a plunger acting on the ball to eject it from the tool.

- the prosthesis holding tool 50 is guided along the axis B-B by the sliding engagement of the cylindrical tool handle 56 with the bore of the pin alignment guide 86 that is now used as a new datum to determine the axis B-B and control the path of the tool and consequently the ball component along the axis until seated on the prepared femoral head 7 ′ as shown in FIGS. 17 and 18 .

- the ball 20 ′ has been released from the retention prongs 54 and the tool retracted and subsequently removed as shown in FIG. 19 .

- FIGS. 20-26 show a sequence of perspective views according to a fourth embodiment of the present invention similar to the third embodiment except that the datum for the axis B-B is not absolutely determined and the tooling is simplified by the use of a separate axis alignment jig and prostheses alignment jig.

- the axis alignment jig 90 is used to determine the position of a secondary alignment pin on the side of the femoral neck relative to the axis B-B, then the axis alignment jig is removed and the prosthesis alignment 100 is engaged on the secondary pin to install the ball component prosthesis.

- the axis alignment jig 90 has, at its proximal end, a tube with a bore 92 sized to slidingly engage and journal the guide pin 30 .

- the guide pin 30 is the datum for the axis B-B of a prepared femoral head 7 ′.

- the jig 90 has an extension having a slotted fitting 96 .

- the jig is placed with the bore 92 directly over the guide pin to locate the datum for axis B-B.

- a mount typically a mounting pin 94 , is then placed on the side of the femoral neck in a predetermined relationship to the axis B-B determined by the slot in the fitting 96 as shown in FIG. 21 .

- an axis defined by the pin 94 will intersect the axis B-B because the slot orients the pin 94 to intersect the axis B-B.

- the surgeon places the pin approximately perpendicular to the axis B-B in a freehand manner, but a supplemental tool establishing an axis perpendicular to the axis of the bore 92 for guiding the pin 94 may be mounted proximal to the slot of fitting 96 to insure that the pin 94 is perpendicular to the axis B-B by using, for instance, a bore in the supplemental tool that is perpendicular to the axis when mounted to the fitting 96 to guide the pin.

- the axis alignment jig 90 is then removed followed by the guide pin 30 .

- the prosthesis alignment jig 100 is similar to the pin alignment jig 90 except that rather than having a cylindrical portion with a bore 92 mounted at the proximal end, a prosthesis holder 102 is mounted to a mount 101 .

- the ball 20 ′ is gripped by three retention prongs 106 , that are connected to an interface body in a manner similar to that described in connection with the third embodiment.

- the ball 20 ′ may be captured or released by deflecting the retention prongs 106 , as shown, or by any of the methods discussed above in connection with the third embodiment.

- the prosthesis 20 ′ is installed in the prosthesis alignment jig 100 and the jig 100 is aligned with the femoral head axis using the mount 94 on the side of the femur as shown in FIG. 25 .

- the prosthesis alignment jig 100 is then used to install the prosthesis 10 in a manner similar to the third embodiment as shown in FIG. 26 . Subsequently, the retention prongs 106 are released, the jig 100 is removed, and the pin 94 is removed.

- the pin 94 may have flats oriented parallel with the head axis B-B that slidingly engage with the slots of the fittings 96 of both the jigs 90 and 100 to prevent rotation about the pin axis and keep the jigs aligned with the head axis.

- a pair of stops may be fixed on the pin 94 at both sides of the fittings 96 to establish a radial datum that is transferred from the pin jig 90 to the prosthesis jig 100 to prevent the radial translation or rotation of the prosthesis jig relative to the pin.

- the pin alignment jig 90 may be fitted with a joint such as multi-axial adjuster 88 configured to allow the pin 94 to be clamped by the collet 89 to lock the position of the jig in alignment with axis B-B.

- the proximal portion of the alignment jig 90 has a fitting allowing the proximal portion to be detached and replaced with a second proximal portion having the features of the prosthesis jig 100 and allowing the prosthesis to translate only in the axis B-B.

- the modular components of tools according to the embodiments of the invention described above are particularly well suited for inclusion in a kit that can be used by a surgeon to implant femoral ball components 20 and 20 ′ of different sizes by providing the various prosthesis holders of the invention in various sizes corresponding to the prostheses sizes.

- any use of the words such as “including,” “containing,” “comprising,” “having” and the like, means “including without limitation” and shall not be construed to limit any general statement that it follows to the specific or similar items or matters immediately following it.

Landscapes

- Health & Medical Sciences (AREA)

- Orthopedic Medicine & Surgery (AREA)

- Life Sciences & Earth Sciences (AREA)

- Animal Behavior & Ethology (AREA)

- Veterinary Medicine (AREA)

- Engineering & Computer Science (AREA)

- Biomedical Technology (AREA)

- Heart & Thoracic Surgery (AREA)

- Transplantation (AREA)

- Oral & Maxillofacial Surgery (AREA)

- General Health & Medical Sciences (AREA)

- Public Health (AREA)

- Surgery (AREA)

- Vascular Medicine (AREA)

- Cardiology (AREA)

- Physical Education & Sports Medicine (AREA)

- Dentistry (AREA)

- Nuclear Medicine, Radiotherapy & Molecular Imaging (AREA)

- Medical Informatics (AREA)

- Molecular Biology (AREA)

- Prostheses (AREA)

Abstract

Tools and methods for implanting hip resurfacing femoral prostheses along a path defined by the axis of a shaped femoral head surface are described. The prostheses are stemless partial ball components having an outer surface shaped to conform to an acetabular socket and may be a two part design having a mating sleeve component with an internal bore adapted to receive the shaped femoral head. The tools and methods are capable of accurately implanting both one and two piece ball components and sleeves without requiring the prosthesis to have a central stem or the preparation of a stem cavity in the femoral head and neck.

Description

- The present invention relates generally to systems, kits and methods for joint prosthesis installation tools. The present invention includes jigs and methods for installing a stemless ball component to a prepared femoral head along an axis defined by the prepared femoral head and jigs for installing a sleeve component for adapting a ball component to a prepared femoral head along an axis defined by the prepared femoral head.

- Artificial joint prostheses are widely used today, restoring joint mobility to patients affected by a variety of conditions, including degeneration of the joint and bone structure. Typically, the failed bone structure is replaced with an orthopedic implant that mimics, as closely as possible, the structure of the natural bone and performs its functions. The satisfactory performance of these implants can be affected not only by the design of the component itself, but also by the surgical positioning of the implanted component and the long-term fixation of the implant. Improper placement or positioning of the implant can adversely affect the goal of satisfactorily restoring the clinical bio-mechanics of the joint as well as impairing adequate fixation of the component when implanted.

- Orthopedic implants are constructed from materials that are stable in biological environments and withstand physical stress with minimal or controlled deformation. Such materials must possess strength, resistance to corrosion, biocompatibility, and good wear properties. Also, the implants include various interacting parts, which undergo repeated long-term physical stress inside the body.

- For these reasons, among others, the bone/implant interface and the connection between various parts of the implant must be durable and resistant to breakdown. This is especially important since installation of an orthopedic implant often involves an extensive and difficult medical procedure, and therefore replacement or revision of the installed implant is typically difficult and traumatic.

- The requirements for the useful life of the implant continue to grow with the increase in human life expectancy. Also, as implants improve, younger patients are considered as implant candidates. It is therefore desirable to develop implants that, while durable in their own right, minimize the difficulty of replacement

- The strength and longevity of implants in large part depend on the bone/implant interface. Various methods of connection are known in the art. For example, a hip joint is a ball-in-socket joint, and includes a rounded femoral head and a cup-like socket (acetabular cup) located in the pelvis. The surfaces of the rounded femoral head and the acetabular cup continually abrade each other as a person walks. The abrasion, along with normal loading, creates stress on the hip joint and adjacent bones. If the femoral head or the acetabular cup is replaced with an implant, this stress must be well tolerated by the implant's bearing surfaces to prevent implant failure.

- Depending on the type of bone, the location of the bone within the body and individual characteristics, bone has a wide variation in mechanical characteristics. Bone is generally categorized as trabecular or cancellous bone, which is porous and has an open cancellated structure, and cortical bone, which is dense. Considering the femoral bone of the hip joint,