JPWO2013073211A1 - 太陽電池及び太陽電池の製造方法 - Google Patents

太陽電池及び太陽電池の製造方法 Download PDFInfo

- Publication number

- JPWO2013073211A1 JPWO2013073211A1 JP2013544145A JP2013544145A JPWO2013073211A1 JP WO2013073211 A1 JPWO2013073211 A1 JP WO2013073211A1 JP 2013544145 A JP2013544145 A JP 2013544145A JP 2013544145 A JP2013544145 A JP 2013544145A JP WO2013073211 A1 JPWO2013073211 A1 JP WO2013073211A1

- Authority

- JP

- Japan

- Prior art keywords

- layer

- transparent conductive

- solar cell

- photoelectric conversion

- columnar crystal

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000000034 method Methods 0.000 title claims description 84

- 238000004519 manufacturing process Methods 0.000 title claims description 32

- 239000002245 particle Substances 0.000 claims abstract description 85

- 238000006243 chemical reaction Methods 0.000 claims abstract description 84

- 239000013078 crystal Substances 0.000 claims description 113

- 238000007747 plating Methods 0.000 claims description 60

- 230000009467 reduction Effects 0.000 claims description 34

- 229910052751 metal Inorganic materials 0.000 claims description 29

- 239000002184 metal Substances 0.000 claims description 29

- 238000010438 heat treatment Methods 0.000 claims description 14

- 239000000203 mixture Substances 0.000 claims description 11

- 230000015572 biosynthetic process Effects 0.000 claims description 9

- 238000005304 joining Methods 0.000 abstract description 5

- 239000010410 layer Substances 0.000 description 396

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 48

- 239000011247 coating layer Substances 0.000 description 44

- 230000008569 process Effects 0.000 description 33

- 238000009713 electroplating Methods 0.000 description 31

- 229910052759 nickel Inorganic materials 0.000 description 24

- 229920005989 resin Polymers 0.000 description 23

- 239000011347 resin Substances 0.000 description 23

- 239000010949 copper Substances 0.000 description 18

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 17

- 229910052802 copper Inorganic materials 0.000 description 17

- 239000000758 substrate Substances 0.000 description 16

- 239000000243 solution Substances 0.000 description 15

- 229910021417 amorphous silicon Inorganic materials 0.000 description 14

- 239000011230 binding agent Substances 0.000 description 13

- 238000007650 screen-printing Methods 0.000 description 13

- BASFCYQUMIYNBI-UHFFFAOYSA-N platinum Chemical compound [Pt] BASFCYQUMIYNBI-UHFFFAOYSA-N 0.000 description 12

- 239000004065 semiconductor Substances 0.000 description 11

- 229910003437 indium oxide Inorganic materials 0.000 description 10

- PJXISJQVUVHSOJ-UHFFFAOYSA-N indium(iii) oxide Chemical compound [O-2].[O-2].[O-2].[In+3].[In+3] PJXISJQVUVHSOJ-UHFFFAOYSA-N 0.000 description 10

- 239000002904 solvent Substances 0.000 description 10

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 description 9

- 229910052709 silver Inorganic materials 0.000 description 9

- 239000004332 silver Substances 0.000 description 9

- 238000004544 sputter deposition Methods 0.000 description 9

- 239000000969 carrier Substances 0.000 description 7

- 238000010586 diagram Methods 0.000 description 7

- VXQBJTKSVGFQOL-UHFFFAOYSA-N 2-(2-butoxyethoxy)ethyl acetate Chemical compound CCCCOCCOCCOC(C)=O VXQBJTKSVGFQOL-UHFFFAOYSA-N 0.000 description 6

- 238000005229 chemical vapour deposition Methods 0.000 description 6

- 239000011231 conductive filler Substances 0.000 description 6

- 230000007423 decrease Effects 0.000 description 6

- 239000008151 electrolyte solution Substances 0.000 description 6

- 229910052697 platinum Inorganic materials 0.000 description 6

- 238000007639 printing Methods 0.000 description 6

- 239000010408 film Substances 0.000 description 5

- 230000004048 modification Effects 0.000 description 5

- 238000012986 modification Methods 0.000 description 5

- 238000001878 scanning electron micrograph Methods 0.000 description 5

- 239000003822 epoxy resin Substances 0.000 description 4

- 229910044991 metal oxide Inorganic materials 0.000 description 4

- 150000004706 metal oxides Chemical class 0.000 description 4

- 229910021421 monocrystalline silicon Inorganic materials 0.000 description 4

- 229920000647 polyepoxide Polymers 0.000 description 4

- 239000010409 thin film Substances 0.000 description 4

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 3

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 description 3

- 229910021586 Nickel(II) chloride Inorganic materials 0.000 description 3

- 239000000853 adhesive Substances 0.000 description 3

- 230000001070 adhesive effect Effects 0.000 description 3

- BFNBIHQBYMNNAN-UHFFFAOYSA-N ammonium sulfate Chemical compound N.N.OS(O)(=O)=O BFNBIHQBYMNNAN-UHFFFAOYSA-N 0.000 description 3

- 229910052921 ammonium sulfate Inorganic materials 0.000 description 3

- 235000011130 ammonium sulphate Nutrition 0.000 description 3

- 238000000137 annealing Methods 0.000 description 3

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 3

- 229910052799 carbon Inorganic materials 0.000 description 3

- 239000011248 coating agent Substances 0.000 description 3

- 238000000576 coating method Methods 0.000 description 3

- 229910000365 copper sulfate Inorganic materials 0.000 description 3

- ARUVKPQLZAKDPS-UHFFFAOYSA-L copper(II) sulfate Chemical compound [Cu+2].[O-][S+2]([O-])([O-])[O-] ARUVKPQLZAKDPS-UHFFFAOYSA-L 0.000 description 3

- DOBRDRYODQBAMW-UHFFFAOYSA-N copper(i) cyanide Chemical compound [Cu+].N#[C-] DOBRDRYODQBAMW-UHFFFAOYSA-N 0.000 description 3

- 239000007789 gas Substances 0.000 description 3

- 239000001257 hydrogen Substances 0.000 description 3

- 229910052739 hydrogen Inorganic materials 0.000 description 3

- 229910052738 indium Inorganic materials 0.000 description 3

- APFVFJFRJDLVQX-UHFFFAOYSA-N indium atom Chemical compound [In] APFVFJFRJDLVQX-UHFFFAOYSA-N 0.000 description 3

- 239000007791 liquid phase Substances 0.000 description 3

- QMMRZOWCJAIUJA-UHFFFAOYSA-L nickel dichloride Chemical compound Cl[Ni]Cl QMMRZOWCJAIUJA-UHFFFAOYSA-L 0.000 description 3

- LGQLOGILCSXPEA-UHFFFAOYSA-L nickel sulfate Chemical compound [Ni+2].[O-]S([O-])(=O)=O LGQLOGILCSXPEA-UHFFFAOYSA-L 0.000 description 3

- 229910000363 nickel(II) sulfate Inorganic materials 0.000 description 3

- 239000001301 oxygen Substances 0.000 description 3

- 229910052760 oxygen Inorganic materials 0.000 description 3

- 239000012071 phase Substances 0.000 description 3

- 238000000206 photolithography Methods 0.000 description 3

- 238000009832 plasma treatment Methods 0.000 description 3

- 229910021420 polycrystalline silicon Inorganic materials 0.000 description 3

- 239000002243 precursor Substances 0.000 description 3

- 239000000523 sample Substances 0.000 description 3

- 238000004528 spin coating Methods 0.000 description 3

- 238000005507 spraying Methods 0.000 description 3

- 229920001187 thermosetting polymer Polymers 0.000 description 3

- 238000010894 electron beam technology Methods 0.000 description 2

- 230000012447 hatching Effects 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- 239000002105 nanoparticle Substances 0.000 description 2

- 238000011946 reduction process Methods 0.000 description 2

- 239000002356 single layer Substances 0.000 description 2

- ATJFFYVFTNAWJD-UHFFFAOYSA-N Tin Chemical compound [Sn] ATJFFYVFTNAWJD-UHFFFAOYSA-N 0.000 description 1

- XLOMVQKBTHCTTD-UHFFFAOYSA-N Zinc monoxide Chemical compound [Zn]=O XLOMVQKBTHCTTD-UHFFFAOYSA-N 0.000 description 1

- 238000010521 absorption reaction Methods 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 229910052787 antimony Inorganic materials 0.000 description 1

- WATWJIUSRGPENY-UHFFFAOYSA-N antimony atom Chemical compound [Sb] WATWJIUSRGPENY-UHFFFAOYSA-N 0.000 description 1

- 238000000889 atomisation Methods 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 239000011370 conductive nanoparticle Substances 0.000 description 1

- 238000002425 crystallisation Methods 0.000 description 1

- 230000008025 crystallization Effects 0.000 description 1

- 238000009792 diffusion process Methods 0.000 description 1

- 239000006185 dispersion Substances 0.000 description 1

- 239000000945 filler Substances 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 238000009413 insulation Methods 0.000 description 1

- 230000031700 light absorption Effects 0.000 description 1

- 239000007769 metal material Substances 0.000 description 1

- 238000001000 micrograph Methods 0.000 description 1

- 150000002815 nickel Chemical class 0.000 description 1

- 238000001579 optical reflectometry Methods 0.000 description 1

- 238000003672 processing method Methods 0.000 description 1

- 238000002834 transmittance Methods 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L31/00—Semiconductor devices sensitive to infrared radiation, light, electromagnetic radiation of shorter wavelength or corpuscular radiation and specially adapted either for the conversion of the energy of such radiation into electrical energy or for the control of electrical energy by such radiation; Processes or apparatus specially adapted for the manufacture or treatment thereof or of parts thereof; Details thereof

- H01L31/02—Details

- H01L31/0224—Electrodes

- H01L31/022408—Electrodes for devices characterised by at least one potential jump barrier or surface barrier

- H01L31/022425—Electrodes for devices characterised by at least one potential jump barrier or surface barrier for solar cells

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L31/00—Semiconductor devices sensitive to infrared radiation, light, electromagnetic radiation of shorter wavelength or corpuscular radiation and specially adapted either for the conversion of the energy of such radiation into electrical energy or for the control of electrical energy by such radiation; Processes or apparatus specially adapted for the manufacture or treatment thereof or of parts thereof; Details thereof

- H01L31/02—Details

- H01L31/0224—Electrodes

- H01L31/022408—Electrodes for devices characterised by at least one potential jump barrier or surface barrier

- H01L31/022425—Electrodes for devices characterised by at least one potential jump barrier or surface barrier for solar cells

- H01L31/022433—Particular geometry of the grid contacts

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L31/00—Semiconductor devices sensitive to infrared radiation, light, electromagnetic radiation of shorter wavelength or corpuscular radiation and specially adapted either for the conversion of the energy of such radiation into electrical energy or for the control of electrical energy by such radiation; Processes or apparatus specially adapted for the manufacture or treatment thereof or of parts thereof; Details thereof

- H01L31/02—Details

- H01L31/0224—Electrodes

- H01L31/022466—Electrodes made of transparent conductive layers, e.g. TCO, ITO layers

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L31/00—Semiconductor devices sensitive to infrared radiation, light, electromagnetic radiation of shorter wavelength or corpuscular radiation and specially adapted either for the conversion of the energy of such radiation into electrical energy or for the control of electrical energy by such radiation; Processes or apparatus specially adapted for the manufacture or treatment thereof or of parts thereof; Details thereof

- H01L31/18—Processes or apparatus specially adapted for the manufacture or treatment of these devices or of parts thereof

- H01L31/1884—Manufacture of transparent electrodes, e.g. TCO, ITO

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E10/00—Energy generation through renewable energy sources

- Y02E10/50—Photovoltaic [PV] energy

Landscapes

- Engineering & Computer Science (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- Electromagnetism (AREA)

- General Physics & Mathematics (AREA)

- Computer Hardware Design (AREA)

- Power Engineering (AREA)

- Sustainable Development (AREA)

- Sustainable Energy (AREA)

- Life Sciences & Earth Sciences (AREA)

- Manufacturing & Machinery (AREA)

- Photovoltaic Devices (AREA)

Abstract

Description

Claims (19)

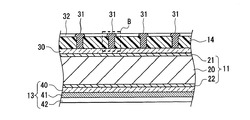

- 光電変換部と、

前記光電変換部の主面上に形成された透明導電層と、

前記透明導電層上に形成された集電極と、

を備え、

前記透明導電層は、その表面に粒子を有する太陽電池。 - 前記透明導電層は、透明導電性酸化物から構成され、

前記粒子の組成は、前記透明導電性酸化物の還元物である請求項1記載の太陽電池。 - 前記粒子の粒径は、10nm以上200nm以下である請求項1又は2記載の太陽電池。

- 前記粒子は、前記透明導電層の前記表面のうち前記集電極との接合部分に選択的に存在する請求項1〜3のいずれか1項に記載の太陽電池。

- 前記粒子は、前記接合部分の全体に亘って一様に存在する請求項4記載の太陽電池。

- 前記粒子は、前記透明導電層の前記表面のうち前記透明導電性酸化物の結晶粒界が形成される部分において、その他の部分よりも高密度で存在する請求項1〜5のいずれか1項に記載の太陽電池。

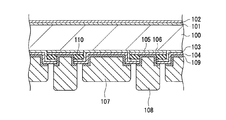

- 光電変換部と、

前記光電変換部の主面上に形成された電極と、

を備え、

前記電極は、

前記光電変換部の主面上に形成された透明導電性の柱状結晶層と、

前記柱状結晶層上に形成された透明導電性の非柱状結晶層と、

前記非柱状結晶層上に形成された集電極と、

を有する太陽電池。 - 前記柱状結晶層及び前記非柱状結晶層は、透明導電性酸化物から構成され、

前記非柱状結晶層の組成は、前記透明導電性酸化物の還元物である請求項7記載の太陽電池。 - 前記非柱状結晶層は、前記集電極との接合部分に選択的に存在する請求項7又は8記載の太陽電池。

- 光電変換部と、

前記光電変換部の主面上に形成された電極と、

を備え、

前記電極は、

前記光電変換部の主面上に形成された透明導電性の高密度層と、

前記高密度層上に形成され、前記高密度層よりも密度が低い透明導電性の低密度層と、

前記低密度層上に形成された集電極と、

を有する太陽電池。 - 前記高密度層及び前記低密度層は、透明導電性酸化物から構成され、

前記低密度層の組成は、前記透明導電性酸化物の還元物である請求項10記載の太陽電池。 - 前記低密度層は、前記集電極との接合部分に選択的に存在する請求項10又は11記載の太陽電池。

- 前記集電極は、金属めっき電極である請求項1〜12のいずれか1項に記載の太陽電池。

- 光電変換部の主面上に透明導電性酸化物から構成される透明導電層を形成し、前記透明導電層の表面のうち集電極を形成する部分における前記透明導電性酸化物を還元して粒子を形成した後、当該部分上に前記集電極を形成する太陽電池の製造方法。

- 前記粒子の形成後に、前記透明導電性酸化物を熱処理して結晶化させる請求項14記載の太陽電池の製造方法。

- 前記透明導電性酸化物を熱処理して結晶化させた後、当該透明導電性酸化物を還元して前記粒子を形成する請求項14記載の太陽電池の製造方法。

- 光電変換部の主面上に透明導電性酸化物から構成される透明導電層を形成し、前記透明導電層の表面のうち集電極を形成する部分における前記透明導電性酸化物を還元して非柱状結晶層を形成した後、当該部分上に前記集電極を形成する工程を備え、

前記工程では、前記非柱状結晶層の形成前又は形成後に、前記透明導電性酸化物を熱処理して前記非柱状結晶層以外の部分に柱状結晶層を形成する太陽電池の製造方法。 - 光電変換部の主面上に透明導電性酸化物から構成される透明導電層を形成し、前記透明導電層の表面のうち集電極を形成する部分における前記透明導電性酸化物を還元して低密度層を形成した後、当該部分上に前記集電極を形成する工程を備え、

前記工程では、前記低密度層の形成前又は形成後に、前記透明導電性酸化物を熱処理して前記低密度層以外の部分に前記低密度層よりも密度が高い高密度層を形成する太陽電池の製造方法。 - 金属めっきにより前記集電極を形成する請求項14〜18のいずれか1項に記載の太陽電池の製造方法。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PCT/JP2011/076623 WO2013073045A1 (ja) | 2011-11-18 | 2011-11-18 | 太陽電池及び太陽電池の製造方法 |

| JPPCT/JP2011/076623 | 2011-11-18 | ||

| PCT/JP2012/057709 WO2013073211A1 (ja) | 2011-11-18 | 2012-03-26 | 太陽電池及び太陽電池の製造方法 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JPWO2013073211A1 true JPWO2013073211A1 (ja) | 2015-04-02 |

| JP5971634B2 JP5971634B2 (ja) | 2016-08-17 |

Family

ID=48429155

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2013544145A Expired - Fee Related JP5971634B2 (ja) | 2011-11-18 | 2012-03-26 | 太陽電池及び太陽電池の製造方法 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US20140182675A1 (ja) |

| JP (1) | JP5971634B2 (ja) |

| DE (1) | DE112012004806B4 (ja) |

| WO (2) | WO2013073045A1 (ja) |

Families Citing this family (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5991945B2 (ja) * | 2013-06-07 | 2016-09-14 | 信越化学工業株式会社 | 太陽電池および太陽電池モジュール |

| JP6284740B2 (ja) * | 2013-10-23 | 2018-02-28 | 株式会社カネカ | 太陽電池の製造方法 |

| JP2015159198A (ja) * | 2014-02-24 | 2015-09-03 | 三菱電機株式会社 | 光起電力素子、その製造方法およびその製造装置 |

| JP6345968B2 (ja) * | 2014-03-31 | 2018-06-20 | 株式会社カネカ | 太陽電池の製造方法 |

| JP6688230B2 (ja) * | 2015-01-07 | 2020-04-28 | 株式会社カネカ | 太陽電池およびその製造方法、ならびに太陽電池モジュール |

| JP6624930B2 (ja) * | 2015-12-26 | 2019-12-25 | 日亜化学工業株式会社 | 発光素子及びその製造方法 |

| WO2017143403A1 (en) | 2016-02-25 | 2017-08-31 | Newsouth Innovations Pty Limited | A method and an apparatus for treating a surface of a tco material in a semiconductor device |

| WO2017168474A1 (ja) * | 2016-03-30 | 2017-10-05 | パナソニックIpマネジメント株式会社 | 太陽電池セル、太陽電池モジュール、太陽電池セルの製造方法 |

| JP6526157B2 (ja) * | 2016-11-17 | 2019-06-05 | エルジー エレクトロニクス インコーポレイティド | 太陽電池パネル |

| US11302829B2 (en) | 2017-03-29 | 2022-04-12 | Kaneka Corporation | Photovoltaic device and method for manufacturing photovoltaic device |

| CN110137278A (zh) * | 2019-04-11 | 2019-08-16 | 西南石油大学 | 原位还原制备电镀种子层的异质结太阳电池及其制备方法 |

| DE102021000956A1 (de) * | 2021-02-23 | 2022-08-25 | Forschungszentrum Jülich GmbH | Verfahren zur Metallisierung eines Bauelements sowie auf diese Weise hergestellte Bauelemente |

| FR3142632A1 (fr) | 2022-11-30 | 2024-05-31 | Commissariat A L'energie Atomique Et Aux Energies Alternatives | Ensemble pour module photovoltaïque, module photovoltaïque et procédé de fabrication de l’ensemble et du module |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4675468A (en) * | 1985-12-20 | 1987-06-23 | The Standard Oil Company | Stable contact between current collector grid and transparent conductive layer |

| JPH0779003A (ja) * | 1993-06-30 | 1995-03-20 | Kyocera Corp | 半導体素子の製法 |

| JPH07106614A (ja) * | 1993-09-30 | 1995-04-21 | Kyocera Corp | 半導体素子の製法 |

| JPH09116179A (ja) * | 1995-10-20 | 1997-05-02 | Sanyo Electric Co Ltd | 光起電力素子 |

| JP2000058888A (ja) * | 1998-08-03 | 2000-02-25 | Sanyo Electric Co Ltd | 太陽電池及びその製造方法 |

| JP2006286822A (ja) * | 2005-03-31 | 2006-10-19 | Sanyo Electric Co Ltd | 光起電力素子及びその製造方法 |

| JP2010508636A (ja) * | 2006-11-01 | 2010-03-18 | バリラン ユニバーシティ | 集電体及び導電性配線としてのニッケル−コバルト合金、並びに透明導電性酸化物上へのこれらの堆積 |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5415700A (en) | 1993-12-10 | 1995-05-16 | State Of Oregon, Acting By And Through The State Board Of Higher Education On Behalf Of Oregon State University | Concrete solar cell |

| TWI234885B (en) * | 2002-03-26 | 2005-06-21 | Fujikura Ltd | Electroconductive glass and photovoltaic cell using the same |

| CN101273464B (zh) * | 2005-09-30 | 2011-04-20 | 三洋电机株式会社 | 太阳能电池和太阳能电池模块 |

| FR2910711B1 (fr) * | 2006-12-20 | 2018-06-29 | Centre Nat Rech Scient | Heterojonction a interface intrinsequement amorphe |

| US20100243042A1 (en) * | 2009-03-24 | 2010-09-30 | JA Development Co., Ltd. | High-efficiency photovoltaic cells |

| TWI381537B (zh) * | 2009-05-13 | 2013-01-01 | Ind Tech Res Inst | 太陽能電池裝置及其製造方法 |

| US20120285501A1 (en) * | 2010-12-29 | 2012-11-15 | E.I. Du Pont De Nemours And Company | Integrated back-sheet for back contact photovoltaic module |

-

2011

- 2011-11-18 WO PCT/JP2011/076623 patent/WO2013073045A1/ja active Application Filing

-

2012

- 2012-03-26 WO PCT/JP2012/057709 patent/WO2013073211A1/ja active Application Filing

- 2012-03-26 JP JP2013544145A patent/JP5971634B2/ja not_active Expired - Fee Related

- 2012-03-26 DE DE112012004806.7T patent/DE112012004806B4/de not_active Expired - Fee Related

-

2014

- 2014-03-07 US US14/200,866 patent/US20140182675A1/en not_active Abandoned

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4675468A (en) * | 1985-12-20 | 1987-06-23 | The Standard Oil Company | Stable contact between current collector grid and transparent conductive layer |

| JPH0779003A (ja) * | 1993-06-30 | 1995-03-20 | Kyocera Corp | 半導体素子の製法 |

| JPH07106614A (ja) * | 1993-09-30 | 1995-04-21 | Kyocera Corp | 半導体素子の製法 |

| JPH09116179A (ja) * | 1995-10-20 | 1997-05-02 | Sanyo Electric Co Ltd | 光起電力素子 |

| JP2000058888A (ja) * | 1998-08-03 | 2000-02-25 | Sanyo Electric Co Ltd | 太陽電池及びその製造方法 |

| JP2006286822A (ja) * | 2005-03-31 | 2006-10-19 | Sanyo Electric Co Ltd | 光起電力素子及びその製造方法 |

| JP2010508636A (ja) * | 2006-11-01 | 2010-03-18 | バリラン ユニバーシティ | 集電体及び導電性配線としてのニッケル−コバルト合金、並びに透明導電性酸化物上へのこれらの堆積 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP5971634B2 (ja) | 2016-08-17 |

| DE112012004806T5 (de) | 2014-08-28 |

| WO2013073211A1 (ja) | 2013-05-23 |

| US20140182675A1 (en) | 2014-07-03 |

| DE112012004806B4 (de) | 2019-02-28 |

| WO2013073045A1 (ja) | 2013-05-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5971634B2 (ja) | 太陽電池及び太陽電池の製造方法 | |

| JP6065009B2 (ja) | 太陽電池モジュール | |

| US6214636B1 (en) | Photovoltaic device with improved collector electrode | |

| JP5735093B1 (ja) | 太陽電池及びその製造方法 | |

| CN109148616B (zh) | 硅异质结太阳电池及其制备方法 | |

| WO2013046351A1 (ja) | 太陽電池及び太陽電池の製造方法 | |

| JP6438980B2 (ja) | 太陽電池およびその製造方法、ならびに太陽電池モジュール | |

| US9496440B2 (en) | Solar cell module | |

| WO2012105155A1 (ja) | 光電変換装置及びその製造方法 | |

| CN113130671A (zh) | 硅异质结太阳电池及其制备方法 | |

| EP2600421A2 (en) | Solar cell and method for manufacturing same | |

| TWI472046B (zh) | Solar cells and their manufacturing methods, with solar modules | |

| US9761752B2 (en) | Solar cell, solar cell module, method for manufacturing solar cell, and method for manufacturing solar cell module | |

| JP2007149633A (ja) | 透光性導電膜基板の製造方法 | |

| JP6096054B2 (ja) | 太陽電池の製造方法 | |

| KR20140133317A (ko) | 은 나노와이어 및 은 격자 복합 패턴을 포함하는 투명전극 및 이의 제조방법 | |

| WO2019003818A1 (ja) | 太陽電池およびその製造方法、ならびに太陽電池モジュール | |

| JP5987127B1 (ja) | 光発電素子及びその製造方法 | |

| JP2014229712A (ja) | 太陽電池およびその製造方法、ならびに太陽電池モジュール | |

| JP2018041753A (ja) | 光発電素子及びその製造方法 | |

| TWI405347B (zh) | Cigs太陽能電池 | |

| JP2018190819A (ja) | 光発電素子及びその製造方法 | |

| TW201428993A (zh) | 晶形光伏打電池及其製造方法 | |

| JP6097068B2 (ja) | 太陽電池およびその製造方法、ならびに太陽電池モジュール | |

| CN117810314A (zh) | 太阳能电池及其制备方法、光伏组件和光伏系统 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A711 | Notification of change in applicant |

Free format text: JAPANESE INTERMEDIATE CODE: A711 Effective date: 20150224 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20150519 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20150703 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20151110 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20160108 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20160621 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20160704 |

|

| R151 | Written notification of patent or utility model registration |

Ref document number: 5971634 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R151 |

|

| LAPS | Cancellation because of no payment of annual fees |