JP6065429B2 - Air conditioner - Google Patents

Air conditioner Download PDFInfo

- Publication number

- JP6065429B2 JP6065429B2 JP2012155314A JP2012155314A JP6065429B2 JP 6065429 B2 JP6065429 B2 JP 6065429B2 JP 2012155314 A JP2012155314 A JP 2012155314A JP 2012155314 A JP2012155314 A JP 2012155314A JP 6065429 B2 JP6065429 B2 JP 6065429B2

- Authority

- JP

- Japan

- Prior art keywords

- refrigerant

- air conditioner

- pipe

- less

- heat exchanger

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2400/00—General features or devices for refrigeration machines, plants or systems, combined heating and refrigeration systems or heat-pump systems, i.e. not limited to a particular subgroup of F25B

- F25B2400/12—Inflammable refrigerants

- F25B2400/121—Inflammable refrigerants using R1234

Landscapes

- Other Air-Conditioning Systems (AREA)

- Lubricants (AREA)

Description

本発明は温暖化係数の低い冷媒を用いた空気調和機に関する。 The present invention relates to an air conditioner using a refrigerant having a low global warming potential.

現在、空気調和機などの冷媒には、オゾン層を破壊しないHFC系フロン冷媒が使用されている。しかしこのHFC系冷媒は、温暖化係数が非常に高く、温暖化防止のため、排出規制の対象となっている。そのため、温暖化係数の低い冷媒の使用が検討されている。特にカーエアコンではR−134aの代替冷媒として、温暖化係数が4で、圧力がR−134Aとほぼ同等のHFO−1234yfが提案されている(特許文献1)。 Currently, HFC-based chlorofluorocarbon refrigerants that do not destroy the ozone layer are used for refrigerants such as air conditioners. However, this HFC refrigerant has a very high global warming potential and is subject to emission regulations to prevent global warming. Therefore, the use of a refrigerant with a low global warming potential has been studied. Particularly in car air conditioners, HFO-1234yf having a warming coefficient of 4 and a pressure almost equal to that of R-134A has been proposed as an alternative refrigerant for R-134a (Patent Document 1).

しかしながら、HFO−1234yfは従来の空気調和機に使用されているR−410Aと比較して、同じ温度に対する飽和ガスの比容積が大きく、同じ冷房能力、または暖房能力を得るためには、冷媒の体積循環量を増加させる必要があり、その結果、配管の冷媒流速が増加して、冷媒の圧力損失が大きくなるという課題があった。 However, HFO-1234yf has a larger specific volume of saturated gas for the same temperature than R-410A used in conventional air conditioners, and in order to obtain the same cooling capacity or heating capacity, As a result, it is necessary to increase the volume circulation amount. As a result, the refrigerant flow velocity of the pipe increases, and the pressure loss of the refrigerant increases.

そこで、本発明は、HFO−1234yfやその混合冷媒を空気調和機に使用する場合に、冷凍サイクルのガス冷媒が流れる配管の管径を大きくして、エネルギー効率の高い空気調和機を提供することを目的とする。 Therefore, the present invention provides an air conditioner with high energy efficiency by increasing the pipe diameter of the pipe through which the gas refrigerant of the refrigeration cycle flows when using HFO-1234yf or its mixed refrigerant in an air conditioner. With the goal.

本発明の空気調和機は、圧縮機、四方弁、室外熱交換器、減圧器それぞれを冷媒配管で接続して構成した室外機と室内熱交換器を有する室内機とを接続冷媒配管で接続して冷凍サイクルを構成した空気調和機であって、上記冷凍サイクルの冷媒は、HFO−1234yfの単一冷媒、または、HFO−1234yfを主成分とし、R−32を22%未満含む混合冷媒とするとともに、冷房定格能力が4kW以下である前記空気調和機の前記冷媒配管および前記接続冷媒配管のガス側冷媒配管の内径は、前記空気調和機に対応するR−410A用の4kW以下である空気調和機のガス側冷媒配管の1.2〜1.8倍で、9.5mm〜14mmの内径の配管としたものである。 The air conditioner of the present invention connects an outdoor unit configured by connecting a compressor, a four-way valve, an outdoor heat exchanger, and a decompressor with refrigerant pipes and an indoor unit having an indoor heat exchanger with a connecting refrigerant pipe. an air conditioner which constitutes a refrigeration cycle Te, refrigerant in the refrigeration cycle, a single refrigerant of HFO-1234y f, or as a main component HFO-1234yf, a mixed refrigerant containing R-32 less than 22% In addition, the inner diameter of the refrigerant pipe of the air conditioner having a cooling rated capacity of 4 kW or less and the gas side refrigerant pipe of the connecting refrigerant pipe is 4 kW or less for R-410A corresponding to the air conditioner. This is a pipe having an inner diameter of 9.5 mm to 14 mm, which is 1.2 to 1.8 times the gas side refrigerant pipe of the conditioner.

これにより、温暖化係数の低い冷媒を使用しても、圧力損失を低減させ、従来のR−410Aを用いた空気調和機と同等の性能を得ることができる。 Thereby, even if it uses a refrigerant | coolant with a low warming coefficient, pressure loss can be reduced and the performance equivalent to the air conditioner using conventional R-410A can be obtained.

本発明によれば、空気調和機に温暖化係数の低い冷媒を使用しても、圧力損失を低減させ、エネルギー効率を向上させることができる。 ADVANTAGE OF THE INVENTION According to this invention, even if it uses a refrigerant | coolant with a low warming coefficient for an air conditioner, pressure loss can be reduced and energy efficiency can be improved.

第1の発明は、冷房定格能力が4kW以下である空気調和機の冷媒配管および接続冷媒配管のガス側冷媒配管の内径が、R−410A用の4kW以下である空気調和機のガス側冷媒配管の1.2〜1.8倍で、9.5mm〜14mmの内径の配管としたものであり、R−410Aを用いた空気調和機と同等の性能を得ることができる。 1st invention is the gas side refrigerant | coolant piping of the air conditioner whose inside diameter of the refrigerant | coolant piping of the air conditioner whose cooling rated capacity is 4 kW or less, and the gas side refrigerant | coolant piping of connection refrigerant | coolant piping is 4 kW or less for R-410A 1.2 to 1.8 times, and a pipe having an inner diameter of 9.5 mm to 14 mm, and the same performance as an air conditioner using R-410A can be obtained.

第2の発明は、冷房定格能力が4kWを超え、6kW以下である空気調和機の冷媒配管および接続冷媒配管のガス側冷媒配管の内径が、R−410A用の4kWを超え、6kW以下である空気調和機のガス側冷媒配管の1.2〜1.7倍で、13mm〜19mmの内径の配管としたものであり、R−410Aを用いた空気調和機と同等の性能を得ることができる。 In the second invention, the inner diameter of the refrigerant pipe of the air conditioner having a cooling rated capacity of over 4 kW and 6 kW or less and the gas-side refrigerant pipe of the connecting refrigerant pipe is over 4 kW for R-410A and 6 kW or less. It is 1.2 to 1.7 times the gas-side refrigerant piping of an air conditioner, and has an inner diameter of 13 mm to 19 mm. The same performance as an air conditioner using R-410A can be obtained. .

第3の発明は、冷房定格能力が6kWを超え、8kW以下である空気調和機の冷媒配管および接続冷媒配管のガス側冷媒配管の内径が、R−410A用の6kWを超え、8kW以下である空気調和機のガス側冷媒配管の1.5〜2.1倍で、16mm〜23mmの内径の配管としたものであり、R−410Aを用いた空気調和機と同等の性能を得ることができる。 In the third aspect of the invention, the inner diameter of the refrigerant pipe of the air conditioner having a cooling rated capacity of over 6 kW and 8 kW or less and the gas side refrigerant pipe of the connecting refrigerant pipe is over 6 kW for R-410A and 8 kW or less. It is 1.5 to 2.1 times the gas-side refrigerant piping of the air conditioner, and has a diameter of 16 mm to 23 mm. The same performance as an air conditioner using R-410A can be obtained. .

第4の発明は、冷房定格能力が8kWを超え、24kW以下である空気調和機の冷媒配管および接続冷媒配管のガス側冷媒配管の内径が、R−410A用の8kWを超え、24kW以下である空気調和機のガス側冷媒配管の1.5〜2.1倍で、16mm〜23mmの内径の配管としたものであり、R−410Aを用いた空気調和機と同等の性能を得ることができる。 In the fourth aspect of the invention, the inner diameter of the refrigerant piping of the air conditioner having a cooling rated capacity exceeding 8 kW and 24 kW or less and the gas-side refrigerant piping of the connecting refrigerant piping is exceeding 8 kW for R-410A and 24 kW or less. It is 1.5 to 2.1 times the gas-side refrigerant piping of the air conditioner, and has a diameter of 16 mm to 23 mm. The same performance as an air conditioner using R-410A can be obtained. .

第5の発明は、冷房定格能力が4kW以下である空気調和機の冷媒配管および接続冷媒配管のガス側冷媒配管の内径を、前記空気調和機に対応するR−410A用の4kW以下である空気調和機のガス側冷媒配管の1〜1.2倍で、7.9mm〜10mmの内径の配管としたものであり、R−410Aを用いた空気調和機と同等の性能を得ることができる。 In the fifth aspect of the present invention, the inner diameter of the refrigerant pipe of the air conditioner having a cooling rated capacity of 4 kW or less and the gas side refrigerant pipe of the connection refrigerant pipe is 4 kW or less for R-410A corresponding to the air conditioner. It is 1 to 1.2 times the gas-side refrigerant piping of the conditioner, and has a diameter of 7.9 mm to 10 mm, and the same performance as an air conditioner using R-410A can be obtained.

第6の発明は、冷房定格能力が4kWを超え、6kW以下である空気調和機の冷媒配管および接続冷媒配管のガス側冷媒配管の内径を、R−410A用の4kWを超え、6kW以下である空気調和機のガス側冷媒配管の1〜1.25倍で、11mm〜14mmの内径の配管としたものであり、R−410Aを用いた空気調和機と同等の性能を得ることができる。 In the sixth aspect of the invention, the inner diameter of the refrigerant pipe of the air conditioner and the connecting refrigerant pipe of the air conditioner whose cooling rated capacity exceeds 4 kW and 6 kW or less exceeds 4 kW for R-410A and is 6 kW or less. It is 1 to 1.25 times the gas side refrigerant pipe of the air conditioner and has a diameter of 11 mm to 14 mm, and the same performance as an air conditioner using R-410A can be obtained.

第7の発明は、冷房定格能力が6kWを超え、8kW以下である空気調和機の冷媒配管および接続冷媒配管のガス側冷媒配管の内径を、R−410A用の6kWを超え、8kW以下である空気調和機のガス側冷媒配管の1.2〜1.5倍で、13mm〜17mmの内径の配管としたものであり、R−410Aと同等の性能を得ることができる。 In the seventh invention, the inner diameter of the gas side refrigerant pipe of the refrigerant pipe of the air conditioner and the connecting refrigerant pipe of the air conditioner whose cooling rated capacity exceeds 6 kW and 8 kW or less exceeds 6 kW for R-410A and is 8 kW or less. This is a pipe having an inner diameter of 13 mm to 17 mm, which is 1.2 to 1.5 times the gas side refrigerant pipe of the air conditioner, and can achieve the same performance as R-410A.

第8の発明は、冷房定格能力が8kWを超え、24kW以下である空気調和機の冷媒配管および接続冷媒配管のガス側冷媒配管の内径を、R−410A用の8kWを超え、24kW以下である空気調和機のガス側冷媒配管の1.2〜1.5倍で、13mm〜17mmの内径の配管としたものであり、R−410Aと同等の性能を得ることができる。 In the eighth aspect of the invention, the inner diameter of the refrigerant pipe of the air conditioner and the connecting refrigerant pipe of the air conditioner whose cooling rated capacity exceeds 8 kW and 24 kW or less exceeds 8 kW for R-410A and is 24 kW or less. This is a pipe having an inner diameter of 13 mm to 17 mm, which is 1.2 to 1.5 times the gas side refrigerant pipe of the air conditioner, and can achieve the same performance as R-410A.

第9の発明は、第1から第8の発明の空気調和機において、地球温暖化係数が、3以上で750以下、望ましくは350以下、更に望ましくは150以下となるように、単一冷媒または2成分混合した冷媒を用いたもので、地球温暖化防止に貢献することができる。 According to a ninth aspect of the present invention, in the air conditioner of the first to eighth aspects, the single refrigerant or the refrigerant is adjusted so that the global warming potential is 3 or more and 750 or less, preferably 350 or less, more preferably 150 or less. one using a two-component mixing combined refrigerant, can contribute to the prevention of global warming.

第10の発明は、第1から第9の発明の空気調和機において、圧縮機に用いる冷凍機油として、ポリオキシアルキレングリコール類、ポリビニルエーテル類、ポリ(オキシ)アルキレングリコールまたはそのモノエーテルとポリビニルエーテルの共重合体、ポリオールエステル類、及びポリカーボネート類のいずれかの含酸素化合物を主成分とする合成油か、アルキルベンゼン類やΑオレフィン類を主成分とする合成油、または鉱油を用いたもので、温暖化防止に貢献するとともに、空気調和機の信頼性の向上に貢献することができる。 According to a tenth aspect of the present invention, in the air conditioner of the first to ninth aspects, polyoxyalkylene glycols, polyvinyl ethers, poly (oxy) alkylene glycols or monoethers thereof and polyvinyl ethers are used as refrigerating machine oil used in the compressor. A synthetic oil mainly composed of an oxygen-containing compound of any of the copolymers, polyol esters, and polycarbonates, or a synthetic oil mainly composed of alkylbenzenes and olefins, or a mineral oil, This contributes to the prevention of global warming and the improvement of the reliability of air conditioners.

以下、本発明の実施の形態について説明する。なお、この実施の形態によって本発明が限定されるものではない。 Embodiments of the present invention will be described below. Note that the present invention is not limited to the embodiments.

(実施の形態1)

図1は、本発明の実施の形態1における空気調和機の冷凍サイクル図である。

(Embodiment 1)

FIG. 1 is a refrigeration cycle diagram of an air conditioner according to Embodiment 1 of the present invention.

図1において、この空気調和は、冷媒を圧縮する圧縮機1、冷房暖房運転時の冷媒回路を切り替える四方弁2、冷媒と外気の熱を交換する室外熱交換器3、冷媒を減圧する減圧器4、を冷媒配管10で接続して室外機5を構成し、冷媒と室内空気の熱を交換する室内熱交換器6を有す室内機7と、前記室外機5とを液側接続冷媒配管8、ガス側接続冷媒配管9で環状に接続して構成してある。

In FIG. 1, this air conditioning includes a compressor 1 that compresses a refrigerant, a four-way valve 2 that switches a refrigerant circuit during cooling and heating operation, an

本実施の形態による空気調和機を構成する冷媒回路には温暖化係数の低い冷媒が封入してあり、この温暖化係数の低い冷媒の一例としてのハイドロフルオロオレフィンはテトラフルオロプロペン(HFO−1234yf、HFO−1234ze、HFO−1243zf)またはトリフルオロプロペンをベース成分とし、ジフルオロメタン(R−32)を22%未満含む混合冷媒を使用し、空気調和機の冷房定格能力が4kW以下であるガス側接続冷媒配管9の内径は、9.5mm〜14mmとしてある。 The refrigerant circuit constituting the air conditioner according to the present embodiment is filled with a refrigerant having a low warming coefficient, and hydrofluoroolefin as an example of the refrigerant having a low warming coefficient is tetrafluoropropene (HFO-1234yf, HFO-1234ze, HFO-1243zf) or trifluoropropene as a base component, using a mixed refrigerant containing less than 22% of difluoromethane (R-32), and a gas-side connection in which the cooling capacity of the air conditioner is 4 kW or less The inner diameter of the refrigerant pipe 9 is 9.5 mm to 14 mm.

冷房運転時には、圧縮機1によって圧縮された冷媒は高温高圧の冷媒となって四方弁2を通って室外熱交換器3に送られる。そして、外気と熱交換して放熱し、高圧の液冷媒となり、減圧器4に送られる。減圧器4では減圧されて低温低圧の二相冷媒となり、液側接続冷媒配管8を通って室内機7に送られる。室内機7では、冷媒は室内熱交換器6に入り室内空気と熱交換して吸熱し、蒸発気化して低温のガス冷媒となる。この時室内空気は冷却されて室内を冷房する。さらに冷媒はガス側接続冷媒配管9を通って、室外機5に戻り、四方弁2を経由して圧縮機1に戻される。

During the cooling operation, the refrigerant compressed by the compressor 1 becomes a high-temperature and high-pressure refrigerant and is sent to the

暖房運転時には、圧縮機1によって圧縮された冷媒は高温高圧の冷媒となって四方弁2、ガス側接続冷媒配管9を通り、室内機7に送られる。高温高圧の冷媒は室内熱交換器6に入り、室内空気と熱交換して放熱し、冷却され高圧の液冷媒となる。この時、室内空気は加熱されて室内を暖房する。その後、冷媒は液側接続冷媒配管8を通って、減圧器4に送られ、減圧器4において減圧されて低温低圧の二相冷媒となり、室外熱交換器3に送られて外気と熱交換して蒸発気化し、四方弁2を経由して圧縮機1へ戻される。

During the heating operation, the refrigerant compressed by the compressor 1 becomes a high-temperature and high-pressure refrigerant, passes through the four-way valve 2 and the gas side connection refrigerant pipe 9, and is sent to the indoor unit 7. The high-temperature and high-pressure refrigerant enters the indoor heat exchanger 6, exchanges heat with indoor air, dissipates heat, and is cooled to become high-pressure liquid refrigerant. At this time, the room air is heated to heat the room. Thereafter, the refrigerant passes through the liquid side connecting

次に、本実施の形態による空気調和機の配管径による作用について説明する。 Next, the effect | action by the piping diameter of the air conditioner by this Embodiment is demonstrated.

空気調和機のガス側接続冷媒配管9内の冷媒の流れが層流状態とすると、ガス側接続冷媒配管9を流れる冷媒の圧力損失は下記の式1であらわされる。 When the refrigerant flow in the gas side connection refrigerant pipe 9 of the air conditioner is in a laminar flow state, the pressure loss of the refrigerant flowing through the gas side connection refrigerant pipe 9 is expressed by the following equation (1).

ここで、ΔP : 圧力損失

F : 摩擦係数

L : 配管長

D : 配管内直径

Ρ : 密度

U : 流速

V : 動粘性係数

Ν : 比容積

Η : 粘性係数

Φ : 体積冷凍能力

ΔH : 冷凍効果

A : 配管断面積

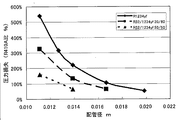

この式に対して、図2に、配管長:5m、冷房定格能力:4kW、冷媒R−410A、R−32/1234yf=22/78wt%、50/50wt%の飽和ガス冷媒の圧力損失を算出し、配管径を横軸に、R−410Aの配管外径9.52mm、配管内径7.93mmの圧力損失を100として表している。

Where ΔP: pressure loss

F: Coefficient of friction

L: Pipe length

D: Diameter in the pipe

Ρ: Density

U: Flow velocity

V: Kinematic viscosity coefficient

Ν: Specific volume

:: Viscosity coefficient

Φ: Volumetric refrigerating capacity

ΔH: Freezing effect

A: Pipe cross-sectional area For this equation, FIG. 2 shows a pipe length: 5 m, cooling rated capacity: 4 kW, refrigerant R-410A, R-32 / 1234yf = 22/78 wt%, 50/50 wt% saturated gas refrigerant The pressure loss of the R-410A pipe outer diameter of 9.52 mm and the pipe inner diameter of 7.93 mm is represented as 100 with the pipe diameter on the horizontal axis.

図2より、R−1234yfは、配管内径が12mm以上で、R−32/R−1234yf=22/78wt%は、配管内径が10mm以上で、R−32/R−1234yf=50/50wt%は、配管内径が8.9mm以上で、R−410Aの圧力損失と同等となる。 From FIG. 2, R-1234yf has a pipe inner diameter of 12 mm or more, R-32 / R-1234yf = 22/78 wt% has a pipe inner diameter of 10 mm or more, and R-32 / R-1234yf = 50/50 wt% The inner diameter of the pipe is 8.9 mm or more, which is equivalent to the pressure loss of R-410A.

また、通常、空気調和機に使用される冷媒配管は、25.4mm(1インチ)を8または16で除した値の整数倍の配管外径が使用されるため、R−1234yfおよびR−32/R−1234yf=22/78wy%は、配管外径が11.1mm以上(配管肉厚を0.8mmとすると、内径9.5mm)で、R−32/R−1234yf=50/50wt%は、配管外径が9.5mm以上(配管肉厚を0.8mmとすると、内径7.9mm)の配管を使用すれば、圧力損失がR−410Aとほぼ同等以下となり、性能低下を防止することができる。 Further, since the refrigerant pipe used for the air conditioner normally has a pipe outer diameter that is an integral multiple of a value obtained by dividing 25.4 mm (1 inch) by 8 or 16, R-1234yf and R-32 / R-1234yf = 22 / 78wy% is a pipe outer diameter of 11.1 mm or more (if the pipe wall thickness is 0.8 mm, the inner diameter is 9.5 mm), and R-32 / R-1234yf = 50/50 wt% If a pipe with a pipe outer diameter of 9.5 mm or more (inner diameter of 7.9 mm when the pipe wall thickness is 0.8 mm) is used, the pressure loss will be almost equal to or less than that of R-410A, and performance degradation will be prevented. Can do.

ここで、上記「R−410Aの圧力損失とほぼ同等以下」とは、本発明においては前記条件でのR−410Aの圧力損失を100とした場合の±20%と見做し、前記各値、すなわちR−1234yf、R−32/R−1234yf=22/78wt%と、R−32/R−1234yf=50/50wt%の各配管内径は、R−410Aの配管内径7.9mmの圧力損失を100とした場合、それぞれ前者は1.2〜1.8倍で、9.5mm〜14mmの内径(R−1234yf、R−32/R−1234yf=22/78wt%の場合)、後者は1〜1.2倍で、7.9mm〜10mmの内径(R−32/R−1234yf=50/50wt%の場合)となる。 Here, the above “substantially equal to or less than the pressure loss of R-410A” is regarded as ± 20% when the pressure loss of R-410A under the above conditions is set to 100 in the present invention. That is, each pipe inner diameter of R-1234yf, R-32 / R-1234yf = 22/78 wt% and R-32 / R-1234yf = 50/50 wt% is a pressure loss of a pipe inner diameter of R-410A of 7.9 mm. The former is 1.2 to 1.8 times, the inner diameter is 9.5 mm to 14 mm (in the case of R-1234yf, R-32 / R-1234yf = 22/78 wt%), and the latter is 1 The inner diameter of 7.9 mm to 10 mm (in the case of R-32 / R-1234yf = 50/50 wt%) is -1.2 times.

さらに、図3に、配管長:5m、冷房定格能力:6kW、冷媒R−410A、R−32/1234yf=22/78wt%、50/50wt%の飽和ガス冷媒の圧力損失を算出し、配管径を横軸に、R−410Aの配管外径12.7mm、配管内径11.1mmの圧力損失を100として表している。 Further, in FIG. 3, the pressure loss of the saturated gas refrigerant of pipe length: 5 m, cooling capacity: 6 kW, refrigerant R-410A, R-32 / 1234yf = 22/78 wt%, 50/50 wt% is calculated. On the horizontal axis, the pressure loss of the pipe outer diameter of R-410A 12.7 mm and the pipe inner diameter 11.1 mm is represented as 100.

図3より、R−1234yfは、配管内径が17mm以上で、R−32/R−1234yf=20/80wt%は、配管内径が15mm以上で、R−32/R−1234yf=50/50wt%は、配管内径が12mm以上で、R−410Aの圧力損失と同等となる。 From FIG. 3, R-1234yf has a pipe inner diameter of 17 mm or more, R-32 / R-1234yf = 20/80 wt% has a pipe inner diameter of 15 mm or more, and R-32 / R-1234yf = 50/50 wt% The inner diameter of the pipe is 12 mm or more, which is equivalent to the pressure loss of R-410A.

また、通常使用される冷媒配管は、25.4mmを8で除した値の整数倍の配管外径が使用されるため、R−1234yfは、配管外径が15.5mm以上(配管肉厚を1mmとすると、内径17.5mm)で、R−32/R−1234yf=22/78wt%は、配管外径が13.9mm以上(配管肉厚を1mmとすると、内径15.9mm)で、R−32/R−1234yf=50/50wt%は、配管外径が11.1mm以上(配管肉厚を0.8mmとすると、内径12.7mm)の配管を使用すれば、圧力損失がR−410Aとほぼ同等以下となり、性能低下を防止することができる。 In addition, since the refrigerant outer diameter generally used is a pipe outer diameter that is an integral multiple of a value obtained by dividing 25.4 mm by 8, R-1234yf has a pipe outer diameter of 15.5 mm or more (the pipe wall thickness is 1mm, the inner diameter is 17.5mm), R-32 / R-1234yf = 22 / 78wt%, the pipe outer diameter is 13.9mm or more (when the pipe wall thickness is 1mm, the inner diameter is 15.9mm) -32 / R-1234yf = 50/50 wt%, when using a pipe with a pipe outer diameter of 11.1 mm or more (when the pipe thickness is 0.8 mm, the inner diameter is 12.7 mm), the pressure loss is R-410A As a result, it is possible to prevent performance degradation.

ここで、前記の場合と同様、「R−410Aの圧力損失とほぼ同等以下」とは、本発明においては前記条件でのR−410Aの圧力損失を100とした場合の±20%と見做し、前記各値、すなわちR−1234yf、R−32/R−1234yf=22/78wt%と、R−32/R−1234yf=50/50wt%の各配管内径は、R−410Aの配管内径11.1mmの圧力損失を100とした場合、それぞれ前者は1.2〜1.7倍で、13mm〜19mmの内径(R−1234yf、R−32/R−1234yf=22/78wt%の場合)、後者は1〜1.25倍で、11mm〜14mmの内径(R−32/R−1234yf=50/50wt%の場合)となる。 Here, as in the case described above, “substantially equal to or less than the pressure loss of R-410A” is considered to be ± 20% in the present invention when the pressure loss of R-410A under the above conditions is 100. The pipe inner diameters of the respective values, that is, R-1234yf, R-32 / R-1234yf = 22/78 wt%, and R-32 / R-1234yf = 50/50 wt% are the pipe inner diameter 11 of R-410A. When the pressure loss of 1 mm is 100, the former is 1.2 to 1.7 times, and the inner diameter of 13 mm to 19 mm (in the case of R-1234yf, R-32 / R-1234yf = 22/78 wt%), The latter is 1 to 1.25 times and has an inner diameter of 11 mm to 14 mm (in the case of R-32 / R-1234yf = 50/50 wt%).

さらに、図4に、配管長:5m、冷房定格能力:8kW、冷媒R−410A、R−32/1234yf=22/78wt%、50/50wt%の飽和ガス冷媒の圧力損失を算出し、配管径を横軸に、R−410Aの配管外径15.9mm、配管内径13.9mmの圧力損失を100として表している。 Further, FIG. 4 shows the pipe length: 5 m, the cooling capacity: 8 kW, the refrigerant R-410A, the R-32 / 1234yf = 22/78 wt%, the pressure loss of the saturated gas refrigerant of 50/50 wt%, and the pipe diameter , The pressure loss of the pipe outer diameter of 15.9 mm and the pipe inner diameter of 13.9 mm of R-410A is represented as 100.

図4より、R−1234yfは、配管内径が21mm以上で、R−32/R−1234yf=22/78wt%は、配管内径が18mm以上で、R−32/R−1234yf=50/50wt%は、配管内径が15mm以上で、R−410Aの圧力損失と同等以下となる。 From FIG. 4, R-1234yf has a pipe inner diameter of 21 mm or more, R-32 / R-1234yf = 22/78 wt% has a pipe inner diameter of 18 mm or more, and R-32 / R-1234yf = 50/50 wt% The inner diameter of the pipe is 15 mm or more, which is equal to or less than the pressure loss of R-410A.

通常使用される冷媒配管は、25.4mmを8で除した値の整数倍の配管外径が使用されるため、R−1234yfは、配管外径が19.1mm以上で、R−32/R−1234yf=22/78wt%は、配管外径が16.7mm以上で、R−32/R−1234yf=50/50wt%は、配管外径が13.9mm以上の配管を使用すれば、圧力損失がR−410Aと同等またはそれ以下となり、性能低下を防止することができる。 The refrigerant pipe used normally has a pipe outer diameter that is an integral multiple of the value obtained by dividing 25.4 mm by 8; therefore, R-1234yf has a pipe outer diameter of 19.1 mm or more, and R-32 / R -1234yf = 22/78 wt% is a pipe outer diameter of 16.7 mm or more, R-32 / R-1234yf = 50/50 wt% is a pressure loss if a pipe with a pipe outer diameter of 13.9 mm or more is used. Becomes equal to or less than that of R-410A, and performance degradation can be prevented.

ここで、前記の場合と同様、「R−410Aの圧力損失とほぼ同等以下」とは、本発明においては前記条件でのR−410Aの圧力損失を100とした場合の±20%と見做し、前記各値、すなわちR−1234yf、R−32/R−1234yf=22/78wt%と、R−32/R−1234yf=50/50wt%の各配管内径は、R−410Aの配管内径13.9mmの圧力損失を100とした場合、それぞれ前者は1.5〜2.1倍で、16mm〜23mmの内径(R−1234yf、R−32/R−1234yf=22/78wt%の場合)、後者は1.2〜1.5で、13mm〜17mmの内径(R−32/R−1234yf=50/50wt%の場合)となる。 Here, as in the case described above, “substantially equal to or less than the pressure loss of R-410A” is considered to be ± 20% in the present invention when the pressure loss of R-410A under the above conditions is 100. The pipe inner diameters of the respective values, that is, R-1234yf, R-32 / R-1234yf = 22/78 wt%, and R-32 / R-1234yf = 50/50 wt% are the pipe inner diameter 13 of R-410A. When the pressure loss of .9 mm is 100, the former is 1.5 to 2.1 times, and the inner diameter is 16 mm to 23 mm (in the case of R-1234yf, R-32 / R-1234yf = 22/78 wt%), The latter is 1.2 to 1.5 and has an inner diameter of 13 mm to 17 mm (in the case of R-32 / R-1234yf = 50/50 wt%).

また、配管長:5m、冷房定格能力:8kW以上、24kW以下の場合においても、前記式1による計算の結果から、R−410Aの圧力損失を100とした場合の±20%と見做し、R−1234yf、R−32/R−1234yf=22/78wt%と、R−3

2/R−1234yf=50/50wt%の各配管内径は、それぞれ前者は1.5〜2.1倍で、16mm〜23mmの内径(R−1234yf、R−32/R−1234yf=22/78wt%の場合)、後者は1.2〜1.5倍で、13mm〜17mm以上の内径(R−32/R−1234yf=50/50wt%の場合)となる。

In addition, even when the pipe length is 5 m and the cooling rated capacity is 8 kW or more and 24 kW or less, from the result of calculation by the above formula 1, it is assumed that the pressure loss of R-410A is set to ± 20% when 100, R-1234yf, R-32 / R-1234yf = 22/78 wt%, R-3

The inner diameter of each pipe of 2 / R-1234yf = 50 / 50wt% is 1.5 to 2.1 times the former, and the inner diameter of 16mm to 23mm (R-1234yf, R-32 / R-1234yf = 22 / 78wt) %)), The latter is 1.2 to 1.5 times, and the inner diameter is 13 mm to 17 mm or more (in the case of R-32 / R-1234yf = 50/50 wt%).

なお、室外機5、室内機7のガス冷媒が流れる配管も、上記と同様の配管径の配管を用いても同様の効果を奏す。

In addition, the same effect can be obtained even if the piping through which the gas refrigerant of the

また、この実施の形態の空気調和機に使用する混合冷媒は、そのGWPが、3以上で750以下、望ましくは350以下、更に望ましくは150以下となるように、先に述べたそれぞれの成分の2成分混合もしくは3成分混合で作成してある。これによって、万一回収されない冷媒が大気に放出されても地球温暖化に対しその影響を極少に保つことができる。 In addition, the mixed refrigerant used in the air conditioner of this embodiment has a GWP of 3 or more and 750 or less, preferably 350 or less, and more preferably 150 or less. It is prepared by two-component mixing or three-component mixing. As a result, even if a refrigerant that cannot be recovered is released into the atmosphere, the effect on global warming can be kept to a minimum.

また、圧縮機に用いる冷凍機油として、ポリオキシアルキレングリコール類、ポリビニルエーテル類、ポリ(オキシ)アルキレングリコールまたはそのモノエーテルとポリビニルエーテルの共重合体、ポリオールエステル類、及びポリカーボネート類のいずれかの含酸素化合物を主成分とする合成油か、アルキルベンゼン類やΑオレフィン類を主成分とする合成油、または鉱油を用いており、空気調和機の信頼性の向上に貢献することができる。 The compressor oil used in the compressor may include any of polyoxyalkylene glycols, polyvinyl ethers, poly (oxy) alkylene glycols or their monoether and polyvinyl ether copolymers, polyol esters, and polycarbonates. A synthetic oil mainly composed of an oxygen compound, a synthetic oil mainly composed of alkylbenzenes and soot olefins, or a mineral oil is used, which can contribute to improving the reliability of the air conditioner.

本発明によれば、低GWP冷媒を使用する冷凍サイクルの高効率を図ることができ、ヒートポンプ温水暖房器等のさまざまな機器に搭載可能であり、温暖化防止に貢献することができる。 ADVANTAGE OF THE INVENTION According to this invention, the high efficiency of the refrigerating cycle using a low GWP refrigerant | coolant can be aimed at, and it can mount in various apparatuses, such as a heat pump hot water heater, and can contribute to global warming prevention.

1 圧縮機

2 四方弁

3 室外熱交換器

4 減圧器

5 室外機

6 室内熱交換器

7 室内機

8 液側接続冷媒配管

9 ガス側接続冷媒配管

DESCRIPTION OF SYMBOLS 1 Compressor 2 Four-

Claims (10)

空気調和機であって、上記冷凍サイクルの冷媒は、HFO−1234yfの単一冷媒、または、HFO−1234yfを主成分とし、R−32を22%未満含む混合冷媒とするとともに、冷房定格能力が8kWを超え、24kW以下である前記空気調和機の前記冷媒配管および前記接続冷媒配管のガス側冷媒配管の内径は、前記空気調和機に対応するR−410A用の8kWを超え、24kW以下である空気調和機のガス側冷媒配管の1.5〜2.1倍で、16mm〜23mmの内径の配管としたことを特徴とする空気調和機。 An air having a refrigeration cycle configured by connecting an outdoor unit configured by connecting a compressor, a four-way valve, an outdoor heat exchanger, and a decompressor with refrigerant pipes and an indoor unit having an indoor heat exchanger by connecting refrigerant pipes a conditioner, a refrigerant of the refrigeration cycle, a single refrigerant of HFO-1234y f, or as a main component HFO-1234yf, with a mixed refrigerant containing R-32 less than 22%, the cooling rated capacity The internal diameter of the refrigerant pipe of the air conditioner that exceeds 8 kW and 24 kW or less and the gas-side refrigerant pipe of the connection refrigerant pipe exceeds 8 kW for R-410A corresponding to the air conditioner and is 24 kW or less. An air conditioner characterized by being a pipe having an inner diameter of 16 mm to 23 mm, which is 1.5 to 2.1 times the gas side refrigerant pipe of the air conditioner.

、または鉱油を用いたことを特徴とする請求項1から9のいずれか1項に記載の空気調和機。 As a refrigerating machine oil used in a compressor, polyoxyalkylene glycols, polyvinyl ethers, poly (oxy) alkylene glycols or their monoether and polyvinyl ether copolymers, polyol esters, and polycarbonate oxygenates The air conditioner according to any one of claims 1 to 9, characterized in that a synthetic oil mainly composed of benzene, a synthetic oil mainly composed of alkylbenzenes and soot olefins, or a mineral oil is used.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2012155314A JP6065429B2 (en) | 2011-12-08 | 2012-07-11 | Air conditioner |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2011268851 | 2011-12-08 | ||

| JP2011268851 | 2011-12-08 | ||

| JP2012155314A JP6065429B2 (en) | 2011-12-08 | 2012-07-11 | Air conditioner |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2013139990A JP2013139990A (en) | 2013-07-18 |

| JP6065429B2 true JP6065429B2 (en) | 2017-01-25 |

Family

ID=49037575

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2012155314A Active JP6065429B2 (en) | 2011-12-08 | 2012-07-11 | Air conditioner |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP6065429B2 (en) |

Families Citing this family (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20160341453A1 (en) * | 2014-03-17 | 2016-11-24 | Mitsubishi Electric Corporation | Refrigeration cycle apparatus |

| JPWO2016051606A1 (en) * | 2014-10-03 | 2017-04-27 | 三菱電機株式会社 | Air conditioner |

| JP2018048653A (en) * | 2015-02-02 | 2018-03-29 | 株式会社デンソー | Piping joint |

| CZ309012B6 (en) * | 2017-02-01 | 2021-11-24 | Mitsubishi Electric Corporation | Compressor |

| US11365335B2 (en) | 2017-12-18 | 2022-06-21 | Daikin Industries, Ltd. | Composition comprising refrigerant, use thereof, refrigerating machine having same, and method for operating said refrigerating machine |

| US11549695B2 (en) | 2017-12-18 | 2023-01-10 | Daikin Industries, Ltd. | Heat exchange unit |

| US11906207B2 (en) | 2017-12-18 | 2024-02-20 | Daikin Industries, Ltd. | Refrigeration apparatus |

| US11441802B2 (en) | 2017-12-18 | 2022-09-13 | Daikin Industries, Ltd. | Air conditioning apparatus |

| US11549041B2 (en) | 2017-12-18 | 2023-01-10 | Daikin Industries, Ltd. | Composition containing refrigerant, use of said composition, refrigerator having said composition, and method for operating said refrigerator |

| US11441819B2 (en) | 2017-12-18 | 2022-09-13 | Daikin Industries, Ltd. | Refrigeration cycle apparatus |

| US11493244B2 (en) | 2017-12-18 | 2022-11-08 | Daikin Industries, Ltd. | Air-conditioning unit |

| US11435118B2 (en) | 2017-12-18 | 2022-09-06 | Daikin Industries, Ltd. | Heat source unit and refrigeration cycle apparatus |

| CN113637457A (en) | 2017-12-18 | 2021-11-12 | 大金工业株式会社 | Composition containing refrigerant, use thereof, refrigerator having same, and method for operating refrigerator |

| CN111479910A (en) | 2017-12-18 | 2020-07-31 | 大金工业株式会社 | Refrigerating machine oil for refrigerant or refrigerant composition, method for using refrigerating machine oil, and use as refrigerating machine oil |

| US11820933B2 (en) | 2017-12-18 | 2023-11-21 | Daikin Industries, Ltd. | Refrigeration cycle apparatus |

| WO2019124140A1 (en) * | 2017-12-18 | 2019-06-27 | ダイキン工業株式会社 | Refrigeration cycle device |

| US11506425B2 (en) | 2017-12-18 | 2022-11-22 | Daikin Industries, Ltd. | Refrigeration cycle apparatus |

| CN116097048A (en) * | 2020-09-04 | 2023-05-09 | 大金工业株式会社 | Use of refrigerant in refrigeration cycle device and refrigeration cycle device |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH07190517A (en) * | 1993-12-27 | 1995-07-28 | Toshiba Corp | Refrigeration cycle |

| JP2001248941A (en) * | 1999-12-28 | 2001-09-14 | Daikin Ind Ltd | Refrigeration unit |

| JP4815656B2 (en) * | 2000-04-19 | 2011-11-16 | ダイキン工業株式会社 | Refrigeration equipment |

| JP2009300001A (en) * | 2008-06-13 | 2009-12-24 | Mitsubishi Electric Corp | Refrigerating cycle device |

| JP2010002074A (en) * | 2008-06-18 | 2010-01-07 | Mitsubishi Electric Corp | Mixed refrigerant and refrigerating cycle device using the same |

| JP5213538B2 (en) * | 2008-06-19 | 2013-06-19 | 三菱電機株式会社 | Renewal method of refrigeration cycle equipment |

| JP4906792B2 (en) * | 2008-06-19 | 2012-03-28 | 三菱電機株式会社 | Vapor compression heat pump equipment |

| JP2010261679A (en) * | 2009-05-11 | 2010-11-18 | Panasonic Corp | Refrigerating cycle |

| JP2011002217A (en) * | 2009-05-18 | 2011-01-06 | Panasonic Corp | Refrigerating device and air conditioning apparatus |

| GB0915004D0 (en) * | 2009-08-28 | 2009-09-30 | Ineos Fluor Holdings Ltd | Heat transfer composition |

| WO2011144905A2 (en) * | 2010-05-20 | 2011-11-24 | Mexichem Amanco Holding S.A. De C.V. | Heat transfer compositions |

| JP5813107B2 (en) * | 2011-05-23 | 2015-11-17 | 三菱電機株式会社 | Air conditioner |

-

2012

- 2012-07-11 JP JP2012155314A patent/JP6065429B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| JP2013139990A (en) | 2013-07-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6065429B2 (en) | Air conditioner | |

| KR102706207B1 (en) | Refrigeration cycle unit | |

| US11906207B2 (en) | Refrigeration apparatus | |

| US11820933B2 (en) | Refrigeration cycle apparatus | |

| US11435118B2 (en) | Heat source unit and refrigeration cycle apparatus | |

| US20200363105A1 (en) | Air-conditioning unit | |

| US20230132359A2 (en) | Refrigeration cycle apparatus | |

| EP2249104A1 (en) | Refrigerating apparatus | |

| JP2017145975A (en) | Refrigeration cycle device, process of manufacture of refrigeration cycle device, drop-in method for refrigeration cycle device, and replace method for refrigeration cycle device | |

| WO2019124329A1 (en) | Refrigerant cycling device | |

| JP2011002217A (en) | Refrigerating device and air conditioning apparatus | |

| JPWO2016114217A1 (en) | Working medium for heat cycle | |

| JP2011106770A (en) | Heat exchanger and refrigerating cycle device | |

| WO2018181057A1 (en) | Refrigeration device | |

| WO2015093183A1 (en) | Air conditioner | |

| WO2013084455A1 (en) | Heat exchanger and air conditioner provided with same | |

| JP2011033289A (en) | Refrigerating cycle device | |

| JP2020073640A (en) | Refrigeration cycle apparatus | |

| JP2013120029A (en) | Air conditioner | |

| JP6725639B2 (en) | Refrigeration cycle equipment | |

| CN114556031B (en) | Refrigeration cycle device | |

| JP2011158177A (en) | Refrigeration cycle apparatus | |

| JP2011252638A (en) | Air conditioner |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20150709 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20160426 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20160510 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20160617 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20160624 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20161129 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20161212 |

|

| R151 | Written notification of patent or utility model registration |

Ref document number: 6065429 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R151 |