JP5470483B1 - Copper alloy sheet with excellent conductivity and stress relaxation properties - Google Patents

Copper alloy sheet with excellent conductivity and stress relaxation properties Download PDFInfo

- Publication number

- JP5470483B1 JP5470483B1 JP2013090390A JP2013090390A JP5470483B1 JP 5470483 B1 JP5470483 B1 JP 5470483B1 JP 2013090390 A JP2013090390 A JP 2013090390A JP 2013090390 A JP2013090390 A JP 2013090390A JP 5470483 B1 JP5470483 B1 JP 5470483B1

- Authority

- JP

- Japan

- Prior art keywords

- copper alloy

- mpa

- alloy plate

- stress relaxation

- less

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 229910000881 Cu alloy Inorganic materials 0.000 title claims abstract description 61

- 239000010949 copper Substances 0.000 claims abstract description 17

- 238000004519 manufacturing process Methods 0.000 claims abstract description 9

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 claims abstract description 8

- 229910052802 copper Inorganic materials 0.000 claims abstract description 8

- 239000012535 impurity Substances 0.000 claims abstract description 3

- 238000000137 annealing Methods 0.000 claims description 63

- 238000005097 cold rolling Methods 0.000 claims description 30

- 238000005096 rolling process Methods 0.000 claims description 21

- 239000013078 crystal Substances 0.000 claims description 17

- 238000001953 recrystallisation Methods 0.000 claims description 13

- 238000000034 method Methods 0.000 claims description 5

- 229910052709 silver Inorganic materials 0.000 claims description 5

- 229910052749 magnesium Inorganic materials 0.000 claims description 4

- 229910052718 tin Inorganic materials 0.000 claims description 4

- 229910052725 zinc Inorganic materials 0.000 claims description 4

- 238000002441 X-ray diffraction Methods 0.000 claims description 3

- 229910052796 boron Inorganic materials 0.000 claims description 3

- 229910052804 chromium Inorganic materials 0.000 claims description 3

- 230000005611 electricity Effects 0.000 claims description 3

- 229910052742 iron Inorganic materials 0.000 claims description 3

- 229910052748 manganese Inorganic materials 0.000 claims description 3

- 229910052759 nickel Inorganic materials 0.000 claims description 3

- 229910052698 phosphorus Inorganic materials 0.000 claims description 3

- 229910052710 silicon Inorganic materials 0.000 claims description 3

- 229910052719 titanium Inorganic materials 0.000 abstract description 12

- 229910052726 zirconium Inorganic materials 0.000 abstract description 11

- 230000017525 heat dissipation Effects 0.000 abstract description 8

- 239000000463 material Substances 0.000 description 30

- 230000000052 comparative effect Effects 0.000 description 11

- 229910045601 alloy Inorganic materials 0.000 description 10

- 239000000956 alloy Substances 0.000 description 10

- 238000012360 testing method Methods 0.000 description 9

- 238000010438 heat treatment Methods 0.000 description 7

- 238000012545 processing Methods 0.000 description 7

- 230000020169 heat generation Effects 0.000 description 6

- 230000007423 decrease Effects 0.000 description 5

- 239000004973 liquid crystal related substance Substances 0.000 description 5

- 238000005259 measurement Methods 0.000 description 5

- 229910001069 Ti alloy Inorganic materials 0.000 description 4

- 238000005098 hot rolling Methods 0.000 description 3

- 238000005452 bending Methods 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- 229910052799 carbon Inorganic materials 0.000 description 1

- 238000005260 corrosion Methods 0.000 description 1

- 230000007797 corrosion Effects 0.000 description 1

- 238000005520 cutting process Methods 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 229910052738 indium Inorganic materials 0.000 description 1

- 238000004949 mass spectrometry Methods 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 229910052750 molybdenum Inorganic materials 0.000 description 1

- 229910052758 niobium Inorganic materials 0.000 description 1

- 229910052760 oxygen Inorganic materials 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 238000005498 polishing Methods 0.000 description 1

- 239000002994 raw material Substances 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22F—CHANGING THE PHYSICAL STRUCTURE OF NON-FERROUS METALS AND NON-FERROUS ALLOYS

- C22F1/00—Changing the physical structure of non-ferrous metals or alloys by heat treatment or by hot or cold working

- C22F1/08—Changing the physical structure of non-ferrous metals or alloys by heat treatment or by hot or cold working of copper or alloys based thereon

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C9/00—Alloys based on copper

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B1/00—Conductors or conductive bodies characterised by the conductive materials; Selection of materials as conductors

- H01B1/02—Conductors or conductive bodies characterised by the conductive materials; Selection of materials as conductors mainly consisting of metals or alloys

- H01B1/026—Alloys based on copper

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Crystallography & Structural Chemistry (AREA)

- Conductive Materials (AREA)

- Non-Insulated Conductors (AREA)

- Contacts (AREA)

Abstract

【課題】高強度、高導電性および優れた応力緩和特性を兼ね備えた銅合金板、該銅合金板を用いた大電流用電子部品及び放熱用電子部品並びに銅合金板の製造方法を提供する。

【解決手段】ZrおよびTiのうちの一種または二種を合計で0.01〜0.50質量%含有し、残部が銅およびその不可避的不純物から成り、70%IACS以上の導電率、および330MPa以上の0.2%耐力を有し、150℃で1000時間保持後の応力緩和率が15%以下である銅合金板である。

【選択図】なしA copper alloy plate having high strength, high conductivity, and excellent stress relaxation characteristics, a high-current electronic component and a heat dissipation electronic component using the copper alloy plate, and a method for producing the copper alloy plate are provided.

One or two of Zr and Ti are contained in a total amount of 0.01 to 0.50% by mass, the balance is made of copper and its inevitable impurities, the conductivity is 70% IACS or higher, and 330 MPa. A copper alloy sheet having the above 0.2% proof stress and having a stress relaxation rate of 15% or less after holding at 150 ° C. for 1000 hours.

[Selection figure] None

Description

本発明は銅合金板及び通電用又は放熱用電子部品に関し、特に、電機・電子機器、自動車等に搭載される端子、コネクタ、リレー、スイッチ、ソケット、バスバー、リードフレーム、放熱板等の電子部品の素材として使用される銅合金板、及び該銅合金板を用いた電子部品に関する。中でも、電気自動車、ハイブリッド自動車等で用いられる大電流用コネクタや端子等の大電流用電子部品の用途、又はスマートフォンやタブレットPCで用いられる液晶フレーム等の放熱用電子部品の用途に好適な銅合金板及び該銅合金板を用いた電子部品に関するものである。 TECHNICAL FIELD The present invention relates to a copper alloy plate and electronic parts for energization or heat dissipation, and in particular, electronic parts such as terminals, connectors, relays, switches, sockets, bus bars, lead frames, heat sinks, etc. mounted on electric machines / electronic devices, automobiles, etc. The present invention relates to a copper alloy plate used as a material for the above and an electronic component using the copper alloy plate. Among them, copper alloys suitable for use in high current electronic parts such as connectors and terminals for large currents used in electric cars, hybrid cars, etc., or for use in electronic parts for heat dissipation such as liquid crystal frames used in smartphones and tablet PCs The present invention relates to a plate and an electronic component using the copper alloy plate.

自動車や電機・電子機器等には、端子、コネクタ、スイッチ、ソケット、リレー、バスバー、リードフレーム、放熱板等の電気又は熱を伝えるための部品が組み込まれており、これら部品には銅合金が用いられている。ここで、電気伝導性と熱伝導性は比例関係にある。 Parts such as terminals, connectors, switches, sockets, relays, bus bars, lead frames, heat sinks, etc., that transmit electricity or heat are built into automobiles, electrical equipment, electronic devices, etc., and these parts are made of copper alloy. It is used. Here, electrical conductivity and thermal conductivity are in a proportional relationship.

近年、電子部品の小型化に伴い、通電部における銅合金の断面積が小さくなる傾向にある。断面積が小さくなると、通電した際の銅合金からの発熱が増大する。また、成長著しい電気自動車やハイブリッド電気自動車で用いられる電子部品には、バッテリー部のコネクタ等の著しく高い電流が流される部品があり、通電時の銅合金の発熱が問題になっている。発熱が過大になると、銅合金は高温環境に晒されることになる。 In recent years, with the miniaturization of electronic components, the cross-sectional area of the copper alloy in the current-carrying part tends to be small. When the cross-sectional area becomes small, heat generation from the copper alloy when energized increases. In addition, electronic parts used in fast-growing electric vehicles and hybrid electric vehicles include parts through which a remarkably high current flows, such as a connector of a battery unit, and heat generation of a copper alloy during energization is a problem. When the heat generation becomes excessive, the copper alloy is exposed to a high temperature environment.

コネクタ等の電子部品の電気接点では、銅合金板にたわみが与えられ、このたわみで発生する応力により、接点での接触力を得ている。たわみを与えた銅合金を高温下で長時間保持すると、応力緩和現象により、応力すなわち接触力が低下し、接触電気抵抗の増大を招く。この問題に対処するため銅合金には、発熱量が減ずるよう導電性により優れることが求められ、また発熱しても接触力が低下しないよう応力緩和特性により優れることも求められている。 In an electrical contact of an electronic component such as a connector, a deflection is given to the copper alloy plate, and a contact force at the contact is obtained by a stress generated by the deflection. When a bent copper alloy is held at a high temperature for a long time, the stress, that is, the contact force is reduced due to the stress relaxation phenomenon, and the contact electric resistance is increased. In order to cope with this problem, the copper alloy is required to be more excellent in conductivity so that the amount of heat generation is reduced, and is also required to be superior in stress relaxation characteristics so that the contact force does not decrease even if heat is generated.

一方、例えばスマートフォンやタブレットPCの液晶には液晶フレームと呼ばれる放熱部品が用いられている。このような放熱用途の銅合金板においても、応力緩和特性を高めると、外力による放熱板のクリープ変形が抑制され、放熱板周りに配置される液晶部品、ICチップ等に対する保護性が改善される等の効果を期待できる。このため、放熱用途の銅合金板においても、応力緩和特性に優れることが望まれている。 On the other hand, for example, a heat radiating component called a liquid crystal frame is used for a liquid crystal of a smartphone or a tablet PC. Even in such a copper alloy plate for heat dissipation, when stress relaxation characteristics are enhanced, creep deformation of the heat sink due to external force is suppressed, and the protection against liquid crystal components, IC chips, etc. disposed around the heat sink is improved. Etc. can be expected. For this reason, it is desired that the copper alloy plate for heat dissipation also has excellent stress relaxation characteristics.

CuにZrやTiを添加すると応力緩和特性が向上することが知られていている(例えば、特許文献1参照)。導電率が高く比較的高い強度と良好な応力緩和特性を有する材料としては、例えばC15100(0.1質量%Zr−残Cu)、C15150(0.02質量%Zr−残Cu)、C18140(0.1質量%Zr−0.3質量%Cr−0.02質量%Si−残Cu)、C18145(0.1質量%Zr−0.2質量%Cr−0.2質量%Zn−残Cu)、C18070(0.1質量%Ti−0.3質量%Cr−0.02質量%Si−残Cu)、C18080(0.06質量%Ti−0.5質量%Cr−0.1質量%Ag−0.08質量%Fe−0.06質量%Si−残Cu)等の合金が、CDA(Copper Development Association)に登録されている。 It is known that when Zr or Ti is added to Cu, the stress relaxation characteristics are improved (see, for example, Patent Document 1). Examples of materials having high electrical conductivity and relatively high strength and good stress relaxation characteristics include C15100 (0.1 mass% Zr-residual Cu), C15150 (0.02 mass% Zr-residual Cu), C18140 (0 .1 mass% Zr-0.3 mass% Cr-0.02 mass% Si-residual Cu), C18145 (0.1 mass% Zr-0.2 mass% Cr-0.2 mass% Zn-residual Cu) C18070 (0.1 mass% Ti-0.3 mass% Cr-0.02 mass% Si-residual Cu), C18080 (0.06 mass% Ti-0.5 mass% Cr-0.1 mass% Ag) Alloys such as -0.08 mass% Fe-0.06 mass% Si-residual Cu) are registered in CDA (Copper Development Association).

しかしながら、CuにZrまたはTiを添加した銅合金(以下、Cu−Zr−Ti系合金とする)は、比較的良好な応力緩和特性を有するとはいうものの、その応力緩和特性のレベルは大電流を通電する部品又は大熱量を放散する部品の用途として必ずしも十分とはいえなかった。例えば、特許文献1が開示する銅合金板は、0.05〜0.3質量%のZrを添加するとともに、Mg、Ti、Zn、Ga、Y、Nb、Mo、Ag、In、Snの中の一種以上を0.01〜0.3質量%添加し、さらに中間焼鈍後の結晶粒径を20〜100μmに調整することにより、応力緩和特性を改善したものであるが、実施例における150℃で1000時間保持後の応力緩和率は最低でも17.2%である。 However, although a copper alloy obtained by adding Zr or Ti to Cu (hereinafter referred to as a Cu-Zr-Ti alloy) has relatively good stress relaxation characteristics, the level of the stress relaxation characteristics is a large current. It is not always sufficient as a use of a component that supplies electricity or a component that dissipates a large amount of heat. For example, in the copper alloy plate disclosed in Patent Document 1, 0.05 to 0.3% by mass of Zr is added, and Mg, Ti, Zn, Ga, Y, Nb, Mo, Ag, In, and Sn are included. The stress relaxation characteristics are improved by adding one or more of 0.01 to 0.3% by mass and adjusting the crystal grain size after intermediate annealing to 20 to 100 μm. The stress relaxation rate after holding for 1000 hours is at least 17.2%.

そこで、本発明は、高強度、高導電性および優れた応力緩和特性を兼ね備えた銅合金板を提供することを目的とし、具体的には、応力緩和特性が改善されたCu−Zr−Ti系合金を提供することを課題とする。さらには、本発明は、該銅合金の製造方法及び大電流用途又は放熱用途に好適な電子部品を提供することをも目的とする。 Therefore, an object of the present invention is to provide a copper alloy plate having high strength, high conductivity, and excellent stress relaxation characteristics, and specifically, a Cu-Zr-Ti system having improved stress relaxation characteristics. It is an object to provide an alloy. Furthermore, another object of the present invention is to provide a method for producing the copper alloy and an electronic component suitable for high current use or heat dissipation use.

上記課題を解決するために鋭意検討した結果、本発明者は、応力緩和特性を向上させる元素を適量銅合金板中に含有させることにより、高強度、高導電性および優れた応力緩和特性を兼ね備えた銅合金板が得られることを見出した。 As a result of intensive studies to solve the above problems, the present inventor combines high strength, high electrical conductivity, and excellent stress relaxation characteristics by including an appropriate amount of an element that improves stress relaxation characteristics in the copper alloy sheet. It has been found that a copper alloy sheet can be obtained.

以上の知見を基礎として完成した本発明は一側面において、Zrを0.02〜0.50質量%含有し、残部が銅およびその不可避的不純物から成り、70%IACS以上の導電率、および330MPa以上の0.2%耐力を有し、ばね限界値Kb(MPa)と、0.2%耐力σ(MPa)との関係が、Kb≧(σ−50)で与えられ、X線回折法を用い圧延面において厚み方向に求めた(111)面および(311)面の回折積分強度をそれぞれI (111) およびI (311) としたときに、I (111) /I (311) が2.0以下であり、150℃で1000時間保持後の応力緩和率が10%以下である銅合金板である。 The present invention completed on the basis of the above knowledge, in one aspect, contains 0.02 to 0.50% by mass of Zr, the balance is made of copper and its inevitable impurities, has a conductivity of 70% IACS or higher, and 330 MPa. The above-mentioned 0.2% yield strength, the relationship between the spring limit value Kb (MPa) and the 0.2% yield strength σ (MPa) is given by Kb ≧ (σ−50). When the integrated diffraction intensities of the (111) plane and (311) plane obtained in the thickness direction on the rolling surface used are I (111) and I (311) , respectively , I (111) / I (311) is 2. A copper alloy sheet having a stress relaxation rate of 10% or less after being held at 150 ° C. for 1000 hours.

本発明に係る銅合金板は更に別の一実施態様において、Ag、Fe、Co、Ni、Cr、Mn、Zn、Mg、Si、P、SnおよびBのうちの一種以上を合計で0.001〜1.0質量%含有する。 In yet another embodiment, the copper alloy plate according to the present invention is 0.001 in total of at least one of Ag, Fe, Co, Ni, Cr, Mn, Zn, Mg, Si, P, Sn, and B. having free to 1.0 mass%.

本発明は別の一側面において、上記銅合金板を用いた通電用電子部品である。 In another aspect, the present invention is an electronic component for energization using the copper alloy plate.

本発明は更に別の一側面において、上記銅合金板を用いた放熱用電子部品である。 In another aspect of the present invention, there is provided a heat dissipating electronic component using the copper alloy plate.

本発明は更に別の一側面において、インゴットを、800〜1000℃で厚み3〜30mmまで熱間圧延した後、冷間圧延と再結晶焼鈍とを繰り返し、最終の冷間圧延の後、歪取焼鈍を施す銅合金板の製造方法であって、

(A)最終の冷間圧延前の再結晶焼鈍において、炉内温度を350〜800℃として、銅合金板の平均結晶粒径を50μm以下に調整し、

(B)最終の冷間圧延において、総加工度を25〜99%、1パスあたりの圧延加工度を20%以下とし、

(C)歪取焼鈍において、連続焼鈍炉を用い、炉内温度を300〜700℃、炉内で銅合金板に付加される張力を1〜4MPaとして、銅合金板を通板し、0.2%耐力を15〜45MPa低下させる、

ことを含む上記銅合金板の製造方法である。

In another aspect of the present invention, the ingot is hot-rolled at a temperature of 800 to 1000 ° C. to a thickness of 3 to 30 mm, and then cold rolling and recrystallization annealing are repeated. A method for producing a copper alloy sheet for annealing,

(A) In the recrystallization annealing before the final cold rolling, the furnace temperature is set to 350 to 800 ° C., the average crystal grain size of the copper alloy plate is adjusted to 50 μm or less,

(B) In the final cold rolling, the total workability is 25 to 99%, the rolling workability per pass is 20% or less,

(C) In strain relief annealing, a continuous annealing furnace is used, the furnace temperature is 300 to 700 ° C., the tension applied to the copper alloy sheet in the furnace is 1 to 4 MPa, and the copper alloy sheet is passed through, 0 .2% proof stress is reduced by 15 to 45 MPa,

It is a manufacturing method of the said copper alloy plate including this.

本発明によれば、高強度、高導電性および優れた応力緩和特性を兼ね備えた銅合金板及びその製造方法、並びに大電流用途又は放熱用途に好適な電子部品を提供することが可能である。この銅合金は、端子、コネクタ、スイッチ、ソケット、リレー、バスバー、リードフレーム等の電子部品の素材として好適に使用することができ、特に大電流を通電する電子部品の素材又は大熱量を放散する電子部品の素材として有用である。 ADVANTAGE OF THE INVENTION According to this invention, it is possible to provide the copper alloy board which has high intensity | strength, high electroconductivity, and the outstanding stress relaxation characteristic, its manufacturing method, and an electronic component suitable for a large current use or a heat dissipation use. This copper alloy can be suitably used as a material for electronic parts such as terminals, connectors, switches, sockets, relays, bus bars, lead frames, etc., and particularly dissipates the material or the large amount of heat of electronic parts that carry a large current. Useful as a material for electronic components.

(特性)

本発明の実施の形態に係る銅合金板は、70%IACS以上の導電率を有し、且つ330MPa以上の0.2%耐力を有する。導電率が70%IACS以上であれば、通電時の発熱量が純銅と同等といえる。また、0.2%耐力が330MPa以上であれば、大電流を通電する部品の素材又は大熱量を放散する部品の素材として必要な強度を有しているといえる。

(Characteristic)

The copper alloy plate according to the embodiment of the present invention has a conductivity of 70% IACS or more and a 0.2% proof stress of 330 MPa or more. If the electrical conductivity is 70% IACS or higher, it can be said that the amount of heat generated during energization is equivalent to that of pure copper. In addition, if the 0.2% proof stress is 330 MPa or more, it can be said that the material has a strength necessary for a material for a component that conducts a large current or a material for a component that dissipates a large amount of heat.

本発明の実施の形態に係る銅合金板の応力緩和特性については、0.2%耐力の80%の応力を付加し、150℃で1000時間保持した時の銅合金板の応力緩和率が15%以下であり、より好ましくは10%以下である。通常のCu−Zr−Ti系合金の応力緩和率は25〜35%程度であるが、これを15%以下にすることで、コネクタに加工した後に大電流を通電しても接触力低下に伴う接触電気抵抗の増加が生じ難くなり、また、放熱板に加工した後に熱と外力が同時に加わってもクリープ変形が生じ難くなる。 Regarding the stress relaxation characteristics of the copper alloy plate according to the embodiment of the present invention, the stress relaxation rate of the copper alloy plate when the stress of 80% of 0.2% proof stress is applied and held at 150 ° C. for 1000 hours is 15 % Or less, more preferably 10% or less. The stress relaxation rate of a normal Cu—Zr—Ti alloy is about 25 to 35%, but by reducing this to 15% or less, even if a large current is applied after processing into a connector, the contact force decreases. Increase in contact electrical resistance is unlikely to occur, and creep deformation is unlikely to occur even if heat and external force are applied simultaneously after processing into a heat sink.

(合金成分濃度)

本発明の実施の形態に係る銅合金板は、Zr及びTiのうちの一種又は二種を合計で0.01〜0.50質量%、より好ましくは0.02〜0.20質量%含有する。これにより、通常のCu−Zr−Ti系合金に比べて強度及び応力緩和特性が改善される。Zr及びTiのうちの一種又は二種の合計が0.01質量%未満になると、330MPa以上の0.2%耐力および15%以下の応力緩和率を得ることが難しくなる。Zr及びTiのうちの一種又は二種の合計が0.5質量%を超えると、熱間圧延割れ等により合金の製造が困難になる。Zrを添加する場合にはその添加量を0.01〜0.45質量%に調整することが好ましく、Tiを添加する場合にはその添加量を0.01〜0.20質量%に調整することが好ましい。添加量が下限値を下回ると応力緩和特性の改善効果が得られにくく、添加量が上限値を超えると導電率や製造性の悪化を招くことがある。

(Alloy component concentration)

The copper alloy plate according to the embodiment of the present invention contains one or two of Zr and Ti in a total amount of 0.01 to 0.50% by mass, more preferably 0.02 to 0.20% by mass. . Thereby, compared with a normal Cu-Zr-Ti-based alloy, strength and stress relaxation characteristics are improved. When the total of one or two of Zr and Ti is less than 0.01% by mass, it becomes difficult to obtain a 0.2% proof stress of 330 MPa or more and a stress relaxation rate of 15% or less. If the total of one or two of Zr and Ti exceeds 0.5% by mass, it becomes difficult to produce an alloy due to hot rolling cracks or the like. When adding Zr, it is preferable to adjust the addition amount to 0.01 to 0.45 mass%, and when adding Ti, the addition amount is adjusted to 0.01 to 0.20 mass%. It is preferable. When the addition amount is less than the lower limit value, it is difficult to obtain the effect of improving the stress relaxation characteristics, and when the addition amount exceeds the upper limit value, conductivity and manufacturability may be deteriorated.

Cu−Zr−Ti系合金には、強度や耐熱性を改善するために、Ag、Fe、Co、Ni、Cr、Mn、Zn、Mg、Si、P、SnおよびBのうちの一種以上を含有させることができる。ただし、添加量が多すぎると、導電率が低下して70%IACSを下回ったり、合金の製造性が悪化したりする場合があるので、添加量は総量で1.0質量%以下、より好ましくは0.5質量%以下とする。また、添加による効果を得るためには、添加量を総量で0.001質量%以上にすることが好ましい。 Cu-Zr-Ti alloy contains at least one of Ag, Fe, Co, Ni, Cr, Mn, Zn, Mg, Si, P, Sn and B in order to improve strength and heat resistance. Can be made. However, if the amount added is too large, the electrical conductivity may be reduced to be less than 70% IACS, or the manufacturability of the alloy may be deteriorated. Therefore, the amount added is preferably 1.0% by mass or less in total. Is 0.5 mass% or less. Moreover, in order to acquire the effect by addition, it is preferable to make addition amount 0.001 mass% or more in total amount.

(ばね限界値)

ばね限界値を指標に金属組織を調整することにより、銅合金板の応力緩和特性が改善される。本発明に係る銅合金板においては、製品のばね限界値をKb(MPa)、0.2%耐力をσ(MPa)としたときに、Kb≧(σ−100)の関係に、より好ましくは、Kb≧(σ−50)の関係に調整することで、応力緩和特性が向上する。Kb<(σ−100)の場合は、応力緩和率が15%を超える。Kbの上限値は特に規制されないが、通常はσを超える値になることはない。

(Spring limit value)

By adjusting the metal structure using the spring limit value as an index, the stress relaxation characteristics of the copper alloy plate are improved. In the copper alloy plate according to the present invention, when the spring limit value of the product is Kb (MPa) and the 0.2% proof stress is σ (MPa), the relationship of Kb ≧ (σ−100) is more preferable. , Kb ≧ (σ−50), the stress relaxation characteristics are improved. In the case of Kb <(σ-100), the stress relaxation rate exceeds 15%. The upper limit value of Kb is not particularly restricted, but usually does not exceed σ.

(圧延面の結晶方位)

圧延面に配向する結晶粒の方位を制御することで、銅合金板の応力緩和特性がより改善される。本発明に係る銅合金板においては、製品の圧延面において、I(111)/I(311)を5.0以下、好ましくは2.0以下に調整することにより、応力緩和特性が向上する。ここで、I(111)およびI(311)はそれぞれX線回折法を用いて銅合金板の厚み方向に求めた(111)面および(311)面の回折積分強度である。I(111)/I(311)が5.0を超えると、応力緩和率が15%を超える。I(111)/I(311)の下限値は応力緩和特性改善の点からは制限されないものの、I(111)/I(311)は典型的には0.01以上の値をとる。

(Crystal orientation of rolling surface)

By controlling the orientation of crystal grains oriented on the rolling surface, the stress relaxation characteristics of the copper alloy sheet are further improved. In the copper alloy sheet according to the present invention, the stress relaxation property is improved by adjusting I (111) / I (311) to 5.0 or less, preferably 2.0 or less on the rolled surface of the product. Here, I (111) and I (311) are diffraction integrated intensities of the (111) plane and the (311) plane, respectively, obtained in the thickness direction of the copper alloy plate using the X-ray diffraction method. When I (111) / I (311) exceeds 5.0, the stress relaxation rate exceeds 15%. Although the lower limit of I (111) / I (311 ) is not limited in terms of the stress relaxation characteristics improved, I (111) / I ( 311) typically takes a value of more than 0.01.

(厚み)

製品の厚みは0.1〜2.0mmであることが好ましい。厚みが薄すぎると、通電部断面積が小さくなり通電時の発熱が増加するため大電流を流すコネクタ等の素材として不適であり、また、わずかな外力で変形するようになるため放熱板等の素材としても不適である。一方で、厚みが厚すぎると、曲げ加工が困難になる。このような観点から、より好ましい厚みは0.2〜1.5mmである。厚みが上記範囲となることにより、通電時の発熱を抑えつつ、曲げ加工性を良好なものとすることができる。

(Thickness)

The thickness of the product is preferably 0.1 to 2.0 mm. If the thickness is too thin, the cross-sectional area of the current-carrying part will decrease and heat generation will increase during energization, making it unsuitable as a material for connectors that carry large currents, and because it will deform with a slight external force, It is also unsuitable as a material. On the other hand, if the thickness is too thick, bending becomes difficult. From such a viewpoint, a more preferable thickness is 0.2 to 1.5 mm. When the thickness is in the above range, the bending workability can be improved while suppressing heat generation during energization.

(用途)

本発明の実施の形態に係る銅合金板は、端子、コネクタ、リレー、スイッチ、ソケット、バスバー、リードフレーム、放熱板等の電子部品の用途に好適に使用することができ、特に、電気自動車、ハイブリッド自動車等で用いられる大電流用コネクタや端子等の大電流用電子部品の用途、又はスマートフォンやタブレットPCで用いられる液晶フレーム等の放熱用電子部品の用途に有用である。

(Use)

The copper alloy plate according to the embodiment of the present invention can be suitably used for applications of electronic components such as terminals, connectors, relays, switches, sockets, bus bars, lead frames, heat sinks, in particular, electric vehicles, It is useful for applications of high-current electronic components such as high-current connectors and terminals used in hybrid vehicles and the like, or heat-dissipation electronic components such as liquid crystal frames used in smartphones and tablet PCs.

(製造方法)

純銅原料として電気銅等を溶解し、カーボン脱酸等により酸素濃度を低減した後、Zr及びTiのうちの一種又は二種と、必要に応じて他の合金元素を添加し、厚み30〜300mm程度のインゴットに鋳造する。このインゴットを例えば800〜1000℃の熱間圧延により厚み3〜30mm程度の板とした後、冷間圧延と再結晶焼鈍とを繰り返し、最終の冷間圧延で所定の製品厚みに仕上げ、最後に歪取り焼鈍を施す。最終冷間圧延後のばね限界値は、100MPaに満たないほど低いが、その後の歪取焼鈍により上昇する。

(Production method)

After dissolving electrolytic copper or the like as a pure copper raw material and reducing the oxygen concentration by carbon deoxidation or the like, one or two of Zr and Ti, and other alloy elements are added as necessary, and the thickness is 30 to 300 mm. Cast into a moderate ingot. After this ingot is made into a plate having a thickness of about 3 to 30 mm by hot rolling at 800 to 1000 ° C., for example, cold rolling and recrystallization annealing are repeated, and finally finished to a predetermined product thickness by cold rolling. Apply strain relief annealing. The spring limit value after the final cold rolling is so low that it does not reach 100 MPa, but rises by subsequent strain relief annealing.

再結晶焼鈍では、圧延組織の一部または全てを再結晶化させる。また、適当な条件で焼鈍することにより、Zr、Ti等が析出し、合金の導電率が上昇する。最終冷間圧延前の再結晶焼鈍では、銅合金板の平均結晶粒径を50μm以下に調整する。平均結晶粒径が大きすぎると、製品の0.2%耐力を330MPa以上に調整することが難しくなる。 In recrystallization annealing, part or all of the rolling structure is recrystallized. Further, by annealing under appropriate conditions, Zr, Ti, etc. are precipitated, and the electrical conductivity of the alloy is increased. In the recrystallization annealing before the final cold rolling, the average crystal grain size of the copper alloy sheet is adjusted to 50 μm or less. If the average crystal grain size is too large, it will be difficult to adjust the 0.2% yield strength of the product to 330 MPa or more.

最終冷間圧延前の再結晶焼鈍の条件は、目標とする焼鈍後の結晶粒径および目標とする製品の導電率に基づき決定する。具体的には、バッチ炉または連続焼鈍炉を用い、炉内温度を350〜800℃として焼鈍を行えばよい。バッチ炉では350〜600℃の炉内温度において30分から30時間の範囲で加熱時間を適宜調整すればよい。連続焼鈍炉では450〜800℃の炉内温度において5秒から10分の範囲で加熱時間を適宜調整すればよい。一般的にはより低温でより長時間の条件で焼鈍を行うと、同じ結晶粒径でより高い導電率が得られる。 The conditions for recrystallization annealing before the final cold rolling are determined based on the target crystal grain size after annealing and the target product conductivity. Specifically, annealing may be performed by using a batch furnace or a continuous annealing furnace and setting the furnace temperature to 350 to 800 ° C. In a batch furnace, the heating time may be appropriately adjusted at a temperature in the furnace of 350 to 600 ° C. in the range of 30 minutes to 30 hours. In a continuous annealing furnace, the heating time may be appropriately adjusted within a range of 5 seconds to 10 minutes at a furnace temperature of 450 to 800 ° C. Generally, when annealing is performed at a lower temperature for a longer time, higher conductivity can be obtained with the same crystal grain size.

最終冷間圧延では、一対の圧延ロール間に材料を繰り返し通過させ、目標の板厚に仕上げてゆく。最終冷間圧延の総加工度と1パスあたりの加工度を制御する。

総加工度R(%)は、R=(t0−t)/t0×100(t0:最終冷間圧延前の板厚、t:最終冷間圧延後の板厚)で与えられる。また、1パスあたりの加工度r(%)とは、圧延ロールを1回通過したときの板厚減少率であり、r=(T0−T)/T0×100(T0:圧延ロール通過前の厚み、T:圧延ロール通過後の厚み)で与えられる。

総加工度Rは25〜99%とするのが好ましい。Rが小さすぎると、0.2%耐力を330MPa以上に調整することが難しくなる。Rが大きすぎると、圧延材のエッジが割れることがある。

In the final cold rolling, the material is repeatedly passed between a pair of rolling rolls to finish the target plate thickness. The total workability of final cold rolling and the workability per pass are controlled.

The total workability R (%) is given by R = (t 0 −t) / t 0 × 100 (t 0 : plate thickness before final cold rolling, t: plate thickness after final cold rolling). Further, the processing degree r (%) per pass is a sheet thickness reduction rate when the rolling roll passes once, and r = (T 0 −T) / T 0 × 100 (T 0 : rolling roll) Thickness before passing, T: Thickness after passing the rolling roll).

The total processing degree R is preferably 25 to 99%. If R is too small, it becomes difficult to adjust the 0.2% proof stress to 330 MPa or more. When R is too large, the edge of the rolled material may be broken.

1パスあたりの加工度rは20%以下とすることが好ましい。rが大きすぎるとI(111)/I(311)が増加し、全パスの中にrが20%を超えるパスが一つでも含まれるとI(111)/I(311)を5.0以下に調整することが難しくなる。 The processing degree r per pass is preferably 20% or less. If r is too large increases I (111) / I (311 ), the path that r is more than 20% among all paths include even one I a (111) / I (311) 5.0 It becomes difficult to adjust to the following.

本発明の歪取焼鈍は連続焼鈍炉を用いて行う。バッチ炉の場合、コイル状に巻き取った状態で材料を加熱するため、加熱中に材料が変形を起こし材料に反りが生じる。したがって、バッチ炉は本発明の歪取焼鈍に不適である。 The strain relief annealing of the present invention is performed using a continuous annealing furnace. In the case of a batch furnace, since the material is heated in a state of being wound in a coil shape, the material is deformed during the heating, and the material is warped. Therefore, the batch furnace is not suitable for the strain relief annealing of the present invention.

連続焼鈍炉において、炉内温度を300〜700℃とし、5秒から10分の範囲で加熱時間を適宜調整し、歪取焼鈍後の0.2%耐力(σ)を歪取焼鈍前の0.2%耐力(σ0)に対し10〜50MPa低い値、好ましくは15〜45MPa低い値に調整する。これにより、最終冷間圧延上がりにおいて低かったKbが充分に上昇する。(σ0−σ)が小さすぎても大きすぎても、Kbが充分に上昇せず、Kb≧(σ−100)の関係を得ることが難しくなる。 In the continuous annealing furnace, the furnace temperature is set to 300 to 700 ° C., the heating time is appropriately adjusted in the range of 5 seconds to 10 minutes, and the 0.2% proof stress (σ) after the stress relief annealing is 0 before the stress relief annealing. Adjust to a value 10 to 50 MPa lower, preferably 15 to 45 MPa lower than 2% proof stress (σ 0 ). Thereby, Kb which was low in the final cold rolling is sufficiently increased. If (σ 0 −σ) is too small or too large, Kb does not rise sufficiently, and it becomes difficult to obtain a relationship of Kb ≧ (σ−100).

歪取焼鈍においては、連続焼鈍炉内において材料に付加される張力を1〜5MPa、より好ましくは1〜4MPaに調整する。張力が大きすぎると、I(111)/I(311)を5.0以下に調整することが難しくなる。また、Kbの上昇が充分ではなくなる傾向にある。一方、張力が小さすぎると、焼鈍炉を通板中の材料が炉壁と接触し、材料の表面やエッジに傷が付くことがある。 In the strain relief annealing, the tension applied to the material in the continuous annealing furnace is adjusted to 1 to 5 MPa, more preferably 1 to 4 MPa. If the tension is too large, it becomes difficult to adjust I (111) / I (311) to 5.0 or less. Further, the increase in Kb tends to be insufficient. On the other hand, if the tension is too small, the material in the passing plate of the annealing furnace may come into contact with the furnace wall, and the surface or edge of the material may be damaged.

本発明に係る銅合金板によれば、Kb≧(σ−100)なる特徴およびI(111)/I(311)≦5.0なる特徴をCu−Zr−Ti系合金に付与することにより、応力緩和特性を改善することを一つの特徴としているが、そのための製造条件を整理して示すと、

(1)Kb≧σ−100のためには、

a.歪取焼鈍において、(σ0−σ)=10〜50MPaに調整する、

b.歪取焼鈍における炉内張力を5MPa以下に調整する、

(2)I(111)/I(311)≦5.0のためには、

a.最終冷間圧延において、1パスあたりの加工度を20%以下に調整する、

b.歪取焼鈍における炉内張力を5MPa以下に調整する、

ことが好ましい。

According to the copper alloy sheet according to the present invention, by imparting a feature of Kb ≧ (σ-100) and a feature of I (111) / I (311) ≦ 5.0 to the Cu—Zr—Ti alloy, One of the features is to improve the stress relaxation characteristics.

(1) For Kb ≧ σ−100,

a. In the strain relief annealing, (σ 0 −σ) = 10 to 50 MPa,

b. Adjusting the furnace tension in the strain relief annealing to 5 MPa or less,

(2) For I (111) / I (311) ≦ 5.0,

a. In the final cold rolling, the degree of processing per pass is adjusted to 20% or less,

b. Adjusting the furnace tension in the strain relief annealing to 5 MPa or less,

It is preferable.

以下に本発明の実施例を比較例と共に示すが、これらの実施例は本発明及びその利点をよりよく理解するために提供するものであり、発明が限定されることを意図するものではない。 Examples of the present invention will be described below together with comparative examples, but these examples are provided for better understanding of the present invention and its advantages, and are not intended to limit the invention.

溶銅に合金元素を添加した後、厚みが200mmのインゴットに鋳造した。インゴットを950℃で3時間加熱し、熱間圧延により厚み15mmの板にした。熱間圧延板表面の酸化スケールをグラインダーで研削、除去した後、焼鈍と冷間圧延を繰り返し、最終の冷間圧延で所定の製品厚みに仕上げた。最後に連続焼鈍炉を用い歪取焼鈍を行った。 After adding the alloy element to the molten copper, it was cast into an ingot having a thickness of 200 mm. The ingot was heated at 950 ° C. for 3 hours and formed into a plate having a thickness of 15 mm by hot rolling. After grinding and removing the oxide scale on the surface of the hot rolled plate with a grinder, annealing and cold rolling were repeated, and the product was finished to a predetermined product thickness by final cold rolling. Finally, strain relief annealing was performed using a continuous annealing furnace.

最終冷間圧延前の焼鈍(最終再結晶焼鈍)は、バッチ炉を用い、加熱時間を5時間とし炉内温度を350〜700℃の範囲で調整し、焼鈍後の結晶粒径と導電率を変化させた。焼鈍後の結晶粒径の測定においては、圧延方向に直角な断面を鏡面研磨後に化学腐食し、切断法(JIS H0501(1999年))により平均結晶粒径を求めた。 For annealing before final cold rolling (final recrystallization annealing), a batch furnace is used, the heating time is 5 hours, the furnace temperature is adjusted in the range of 350 to 700 ° C, and the crystal grain size and conductivity after annealing are adjusted. Changed. In the measurement of the crystal grain size after annealing, a cross section perpendicular to the rolling direction was subjected to chemical corrosion after mirror polishing, and the average crystal grain size was determined by a cutting method (JIS H0501 (1999)).

最終冷間圧延では、総加工度および1パスあたりの加工度を制御した。また、最終冷間圧延後の材料の0.2%耐力を求めた。連続焼鈍炉を用いた歪取り焼鈍では、炉内温度を500℃とし加熱時間を1秒から15分の間で調整し、焼鈍後の0.2%耐力を種々変化させた。また、炉内において材料に付加する張力を種々変化させた。なお、一部の例では歪取り焼鈍を行わなかった。 In the final cold rolling, the total workability and the workability per pass were controlled. Moreover, the 0.2% yield strength of the material after final cold rolling was calculated | required. In strain relief annealing using a continuous annealing furnace, the furnace temperature was 500 ° C., the heating time was adjusted between 1 second and 15 minutes, and the 0.2% proof stress after annealing was variously changed. In addition, various tensions were added to the material in the furnace. In some cases, strain relief annealing was not performed.

製造途中の材料および歪取焼鈍後の材料につき、次の測定を行った。

(成分)

歪取焼鈍後の材料の合金元素濃度をICP−質量分析法で分析した。

The following measurement was performed on the material in the process of manufacturing and the material after strain relief annealing.

(component)

The alloy element concentration of the material after strain relief annealing was analyzed by ICP-mass spectrometry.

(0.2%耐力)

最終冷間圧延後および歪取焼鈍後の材料につき、JIS Z2241に規定する13B号試験片を引張方向が圧延方向と平行になるように採取し、JIS Z2241に準拠して圧延方向と平行に引張試験を行い、0.2%耐力を求めた。

(0.2% yield strength)

For the material after the final cold rolling and strain relief annealing, sample No. 13B specified in JIS Z2241 was taken so that the tensile direction was parallel to the rolling direction, and pulled in parallel with the rolling direction in accordance with JIS Z2241. Tests were performed to determine 0.2% yield strength.

(ばね限界値)

歪取焼鈍後の材料から、幅10mm、長さ100mmの短冊形状の試験片を、試験片の長手方向が圧延方向と平行になるように採取し、JIS H3130に規定されているモーメント式試験により圧延方向と平行な方向のばね限界値を測定した。

(Spring limit value)

A strip-shaped test piece having a width of 10 mm and a length of 100 mm was taken from the material after strain relief annealing so that the longitudinal direction of the test piece was parallel to the rolling direction, and was subjected to a moment type test specified in JIS H3130. The spring limit value in the direction parallel to the rolling direction was measured.

(導電率)

歪取焼鈍後の材料から、試験片の長手方向が圧延方向と平行になるように試験片を採取し、JIS H0505に準拠し四端子法により20℃での導電率を測定した。

(conductivity)

A test piece was taken from the material after strain relief annealing so that the longitudinal direction of the test piece was parallel to the rolling direction, and the conductivity at 20 ° C. was measured by a four-terminal method in accordance with JIS H0505.

(結晶方位)

歪取焼鈍後の材料の表面に対し、厚み方向に(111)面および(311)面のX線回折積分強度を測定した。X線回折装置には(株)リガク製RINT2500を使用し、Cu管球にて、管電圧25kV、管電流20mAで測定を行った。

(Crystal orientation)

The X-ray diffraction integrated intensity of the (111) plane and (311) plane was measured in the thickness direction with respect to the surface of the material after strain relief annealing. RINT 2500 manufactured by Rigaku Corporation was used as the X-ray diffractometer, and measurement was performed with a Cu tube bulb at a tube voltage of 25 kV and a tube current of 20 mA.

(応力緩和率)

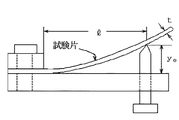

歪取焼鈍後の材料から、幅10mm、長さ100mmの短冊形状の試験片を、試験片の長手方向が圧延方向と平行になるように採取した。図1のように、l=50mmの位置を作用点として、試験片にy0のたわみを与え、圧延方向の0.2%耐力(JIS Z2241に準拠して測定)の80%に相当する応力(s)を負荷した。y0は次式により求めた。

y0=(2/3)・l2・s / (E・t)

ここで、Eは圧延方向のヤング率であり、tは試料の厚みである。150℃にて1000時間加熱後に除荷し、図2のように永久変形量(高さ)yを測定し、応力緩和率{[y(mm)/y0(mm)]×100(%)}を算出した。

(Stress relaxation rate)

A strip-shaped test piece having a width of 10 mm and a length of 100 mm was collected from the material after strain relief annealing so that the longitudinal direction of the test piece was parallel to the rolling direction. As shown in FIG. 1, the stress corresponding to 80% of 0.2% proof stress (measured in accordance with JIS Z2241) in the rolling direction is applied to the test piece with the position of l = 50 mm as a working point, giving y 0 deflection. (S) was loaded. y 0 was determined by the following equation.

y 0 = (2/3) · l 2 · s / (E · t)

Here, E is the Young's modulus in the rolling direction, and t is the thickness of the sample. Unloading after heating at 150 ° C. for 1000 hours, and measuring the amount of permanent deformation (height) y as shown in FIG. 2, stress relaxation rate {[y (mm) / y 0 (mm)] × 100 (%) } Was calculated.

表1に評価結果を示す。最終冷間圧延では複数のパスを実施したが、これら各パスの加工度の中での最大値を示した。表1の最終再結晶焼鈍後の結晶粒径における「<10μm」の表記は、圧延組織の全てが再結晶化しその平均結晶粒径が10μm未満であった場合、および圧延組織の一部のみが再結晶化した場合の双方を含んでいる。 Table 1 shows the evaluation results. In the final cold rolling, a plurality of passes were performed, and the maximum value in the degree of processing of each pass was shown. The notation of “<10 μm” in the crystal grain size after the final recrystallization annealing in Table 1 indicates that when all of the rolling structure is recrystallized and the average crystal grain size is less than 10 μm, and only a part of the rolling structure is used. Both cases of recrystallization are included.

発明例1〜25の銅合金板では、ZrとTiの合計濃度を0.01〜0.50質量%に調整し、最終冷間圧延前の再結晶焼鈍において、結晶粒径を50μm以下に調整し、最終冷間圧延において、総加工度を25〜99%に、1パスあたりの加工度を20%以下に調整し、歪取焼鈍において、材料を連続焼鈍炉に張力1〜5MPaで通板して0.2%耐力を10〜50MPa低下させた。 In the copper alloy plates of Invention Examples 1 to 25, the total concentration of Zr and Ti is adjusted to 0.01 to 0.50 mass%, and the crystal grain size is adjusted to 50 μm or less in the recrystallization annealing before the final cold rolling. In the final cold rolling, the total workability is adjusted to 25 to 99%, the workability per pass is adjusted to 20% or less, and the material is passed through the continuous annealing furnace with a tension of 1 to 5 MPa in strain relief annealing. The 0.2% proof stress was reduced by 10 to 50 MPa.

発明例1〜25の銅合金板では、いずれもZr、Tiの添加量が適正であり、70%IACS以上の導電率、330MPa以上の0.2%耐力、15%以下の応力緩和率を達成できている。また、発明例1〜25の銅合金板では、いずれもKb≧(σ−100)なる関係およびI(111)/I(311)≦5.0なる関係が得られていることが分かる。 In each of the copper alloy plates of Invention Examples 1 to 25, the addition amounts of Zr and Ti are appropriate, and an electrical conductivity of 70% IACS or higher, a 0.2% proof stress of 330 MPa or higher, and a stress relaxation rate of 15% or lower are achieved. is made of. It can also be seen that in the copper alloy plates of Invention Examples 1 to 25, the relationship of Kb ≧ (σ−100) and the relationship of I (111) / I (311) ≦ 5.0 are obtained.

比較例1は歪取焼鈍を行わなかったものであり、応力緩和率が30%を超えた。

比較例2〜4では、歪取焼鈍を行ったものの、炉内での材料張力が5MPaを超えたため、I(111)/I(311)が5.0を超え、特に張力が高かった比較例3では(σ−Kb)も100を超えた。比較例2〜4の応力緩和率は15%を超えた。

比較例5、6では、最終冷間圧延における1パス当たりの加工度が20%を超えたため、I(111)/I(311)が5.0を超え、応力緩和率が15%を超えた。

比較例7、8では歪取焼鈍における0.2%耐力の低下量が過小であり、比較例9、10では歪取焼鈍における0.2%耐力の低下量が過大であった。このため比較例7〜10での(σ0−σ)は、10〜50MPaの範囲から外れた。その結果、(σ−Kb)が100を超え、応力緩和率が15%を超えた。

Comparative Example 1 was not subjected to strain relief annealing, and the stress relaxation rate exceeded 30%.

In Comparative Examples 2 to 4, although strain relief annealing was performed, since the material tension in the furnace exceeded 5 MPa, I (111) / I (311) exceeded 5.0, and the comparatively high tension 3 (σ−Kb) also exceeded 100. The stress relaxation rate of Comparative Examples 2 to 4 exceeded 15%.

In Comparative Examples 5 and 6, since the degree of work per pass in the final cold rolling exceeded 20%, I (111) / I (311) exceeded 5.0 and the stress relaxation rate exceeded 15%. .

In Comparative Examples 7 and 8, the 0.2% yield strength decrease in strain relief annealing was excessively small, and in Comparative Examples 9 and 10, the 0.2% yield strength decrease in strain relief annealing was excessive. For this reason, (σ 0 −σ) in Comparative Examples 7 to 10 deviated from the range of 10 to 50 MPa. As a result, (σ−Kb) exceeded 100 and the stress relaxation rate exceeded 15%.

比較例11では最終冷間圧延における総加工度が25%に満たなかったため、また比較例12では最終冷間圧延前の再結晶焼鈍上がりの結晶粒径が50μmを超えたため、歪取焼鈍後の0.2%耐力が330MPaに満たなかった。 In Comparative Example 11, the total work degree in the final cold rolling was less than 25%, and in Comparative Example 12, the crystal grain size after recrystallization annealing before the final cold rolling exceeded 50 μm. The 0.2% proof stress was less than 330 MPa.

比較例13では、ZrとTiの合計濃度が0.01質量%未満だったため、歪取焼鈍後の0.2%耐力が330MPa未満となり、応力緩和率が15%を超えた。 In Comparative Example 13, since the total concentration of Zr and Ti was less than 0.01% by mass, the 0.2% proof stress after strain relief annealing was less than 330 MPa, and the stress relaxation rate exceeded 15%.

Claims (5)

(A)前記最終の冷間圧延前の再結晶焼鈍において、炉内温度を350〜800℃として、銅合金板の平均結晶粒径を50μm以下に調整し、

(B)前記最終の冷間圧延において、総加工度を25〜99%、1パスあたりの圧延加工度を20%以下とし、

(C)前記歪取焼鈍において、連続焼鈍炉を用い、炉内温度を300〜700℃、炉内で銅合金板に付加される張力を1〜4MPaとして、銅合金板を通板し、0.2%耐力を15〜45MPa低下させる、

ことを含む請求項1又は2に記載の銅合金板の製造方法。 In the method of manufacturing a copper alloy plate, after ingot is hot rolled at 800 to 1000 ° C. to a thickness of 3 to 30 mm, cold rolling and recrystallization annealing are repeated, and after final cold rolling, strain relief annealing is performed. There,

(A) In the recrystallization annealing before the final cold rolling, the furnace temperature is set to 350 to 800 ° C., and the average crystal grain size of the copper alloy plate is adjusted to 50 μm or less,

(B) In the final cold rolling, the total workability is 25 to 99%, the rolling work per pass is 20% or less,

(C) In the strain relief annealing, using a continuous annealing furnace, the furnace temperature is 300 to 700 ° C., the tension applied to the copper alloy sheet in the furnace is 1 to 4 MPa, and the copper alloy sheet is passed through, 0.2% proof stress is reduced by 15 to 45 MPa,

The manufacturing method of the copper alloy plate of Claim 1 or 2 including this.

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013090390A JP5470483B1 (en) | 2012-10-22 | 2013-04-23 | Copper alloy sheet with excellent conductivity and stress relaxation properties |

| KR1020157008502A KR101716991B1 (en) | 2012-10-22 | 2013-06-19 | Copper alloy plate exhibiting excellent conductivity and stress-relaxation properties |

| CN201380054982.6A CN104718302B (en) | 2012-10-22 | 2013-06-19 | Electric conductivity and the excellent copper alloy plate of stress relaxation properties |

| PCT/JP2013/066875 WO2014064961A1 (en) | 2012-10-22 | 2013-06-19 | Copper alloy plate exhibiting excellent conductivity and stress-relaxation properties |

| TW102121874A TWI471428B (en) | 2012-10-22 | 2013-06-20 | Conductive and stress relief characteristics of excellent copper alloy plate |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2012233005 | 2012-10-22 | ||

| JP2012233005 | 2012-10-22 | ||

| JP2013090390A JP5470483B1 (en) | 2012-10-22 | 2013-04-23 | Copper alloy sheet with excellent conductivity and stress relaxation properties |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2013242254A Division JP5525101B2 (en) | 2012-10-22 | 2013-11-22 | Copper alloy sheet with excellent conductivity and stress relaxation properties |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP5470483B1 true JP5470483B1 (en) | 2014-04-16 |

| JP2014101574A JP2014101574A (en) | 2014-06-05 |

Family

ID=50544342

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2013090390A Active JP5470483B1 (en) | 2012-10-22 | 2013-04-23 | Copper alloy sheet with excellent conductivity and stress relaxation properties |

Country Status (5)

| Country | Link |

|---|---|

| JP (1) | JP5470483B1 (en) |

| KR (1) | KR101716991B1 (en) |

| CN (1) | CN104718302B (en) |

| TW (1) | TWI471428B (en) |

| WO (1) | WO2014064961A1 (en) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6749121B2 (en) * | 2016-03-30 | 2020-09-02 | Jx金属株式会社 | Copper alloy plate with excellent strength and conductivity |

| JP6749122B2 (en) * | 2016-03-30 | 2020-09-02 | Jx金属株式会社 | Copper alloy plate with excellent strength and conductivity |

| JP6283048B2 (en) * | 2016-03-31 | 2018-02-21 | 株式会社神戸製鋼所 | Copper alloy strip for electrical and electronic parts |

| JP6306632B2 (en) * | 2016-03-31 | 2018-04-04 | Jx金属株式会社 | Copper alloy for electronic materials |

| TWI592946B (en) * | 2016-11-11 | 2017-07-21 | Metal Ind Res & Dev Ct | Copper alloy wire and its manufacturing method |

| JP7213086B2 (en) * | 2018-12-26 | 2023-01-26 | Dowaメタルテック株式会社 | Copper alloy sheet material and manufacturing method thereof |

| TW202035722A (en) * | 2019-03-25 | 2020-10-01 | 日商Jx金屬股份有限公司 | Copper alloy plate, electronic component for passage of electricity, and electronic component for heat dissipation |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6749699B2 (en) * | 2000-08-09 | 2004-06-15 | Olin Corporation | Silver containing copper alloy |

| JP2004256902A (en) * | 2003-02-27 | 2004-09-16 | Nikko Metal Manufacturing Co Ltd | Cu-Cr-Zr ALLOY, AND PRODUCTION METHOD THEREFOR |

| JP3731600B2 (en) * | 2003-09-19 | 2006-01-05 | 住友金属工業株式会社 | Copper alloy and manufacturing method thereof |

| CN100510131C (en) * | 2004-08-17 | 2009-07-08 | 株式会社神户制钢所 | Copper alloy plate for electric and electronic parts having bending workability |

| JP4191159B2 (en) * | 2005-03-14 | 2008-12-03 | 日鉱金属株式会社 | Titanium copper with excellent press workability |

| JP5135496B2 (en) * | 2007-06-01 | 2013-02-06 | Dowaメタルテック株式会社 | Cu-Be based copper alloy sheet and method for producing the same |

| KR101227315B1 (en) * | 2007-08-07 | 2013-01-28 | 가부시키가이샤 고베 세이코쇼 | Copper alloy sheet |

| JP4968533B2 (en) * | 2007-11-30 | 2012-07-04 | 日立電線株式会社 | Copper alloy material for electrical and electronic parts |

| JP5411679B2 (en) | 2009-12-07 | 2014-02-12 | 株式会社Shカッパープロダクツ | Copper alloy material |

| JP5590990B2 (en) * | 2010-06-30 | 2014-09-17 | 株式会社Shカッパープロダクツ | Copper alloy |

| CN103080347A (en) * | 2010-08-27 | 2013-05-01 | 古河电气工业株式会社 | Copper alloy sheet and method for producing same |

| JP5060625B2 (en) * | 2011-02-18 | 2012-10-31 | 三菱伸銅株式会社 | Cu-Zr-based copper alloy plate and manufacturing method thereof |

-

2013

- 2013-04-23 JP JP2013090390A patent/JP5470483B1/en active Active

- 2013-06-19 CN CN201380054982.6A patent/CN104718302B/en active Active

- 2013-06-19 WO PCT/JP2013/066875 patent/WO2014064961A1/en active Application Filing

- 2013-06-19 KR KR1020157008502A patent/KR101716991B1/en active IP Right Grant

- 2013-06-20 TW TW102121874A patent/TWI471428B/en active

Also Published As

| Publication number | Publication date |

|---|---|

| KR101716991B1 (en) | 2017-03-15 |

| JP2014101574A (en) | 2014-06-05 |

| TWI471428B (en) | 2015-02-01 |

| CN104718302A (en) | 2015-06-17 |

| CN104718302B (en) | 2017-06-23 |

| TW201416463A (en) | 2014-05-01 |

| KR20150047624A (en) | 2015-05-04 |

| WO2014064961A1 (en) | 2014-05-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5847787B2 (en) | Copper alloy sheet with excellent conductivity and stress relaxation properties | |

| JP5380621B1 (en) | Copper alloy sheet with excellent conductivity and stress relaxation properties | |

| JP5470483B1 (en) | Copper alloy sheet with excellent conductivity and stress relaxation properties | |

| JP6270417B2 (en) | Copper alloy sheet with excellent conductivity and stress relaxation properties | |

| JP5427971B1 (en) | Copper alloy sheet with excellent conductivity and bending deflection coefficient | |

| JP6128976B2 (en) | Copper alloy and high current connector terminal material | |

| JP5632063B1 (en) | Copper alloy plate, high-current electronic component and heat dissipation electronic component including the same | |

| JP6296728B2 (en) | Copper alloy sheet with excellent conductivity and bending deflection coefficient | |

| JP6328380B2 (en) | Copper alloy sheet with excellent conductivity and bending deflection coefficient | |

| JP2017155340A (en) | Copper alloy sheet excellent in conductivity and stress relaxation characteristic | |

| JP5892974B2 (en) | Copper alloy sheet with excellent conductivity and stress relaxation properties | |

| JP2017002407A (en) | Copper alloy sheet excellent in conductivity and stress relaxation characteristic | |

| JP6222971B2 (en) | Copper alloy sheet with excellent conductivity and stress relaxation properties | |

| WO2014041865A1 (en) | Copper alloy plate having excellent electroconductive properties and stress relaxation properties | |

| JP5449595B1 (en) | Copper alloy sheet with excellent conductivity and bending deflection coefficient | |

| JP5620025B2 (en) | Copper alloy sheet with excellent conductivity and stress relaxation properties | |

| JP5453565B1 (en) | Copper alloy sheet with excellent conductivity and bending deflection coefficient | |

| JP5352750B1 (en) | Copper alloy sheet with excellent conductivity and bending deflection coefficient | |

| JP5536258B1 (en) | Copper alloy sheet with excellent conductivity and stress relaxation properties | |

| JP2014055347A (en) | Copper alloy sheet excellent in conductivity and stress relief properties | |

| JP2017089011A (en) | Copper alloy sheet excellent in conductivity and flexure deflection coefficient | |

| JP2014205864A (en) | Copper alloy sheet excellent in conductivity and stress relaxation property | |

| JP2014208868A (en) | Copper alloy and high-current connector terminal material |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20131203 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20140106 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20140114 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20140203 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5470483 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| S531 | Written request for registration of change of domicile |

Free format text: JAPANESE INTERMEDIATE CODE: R313531 |

|

| S533 | Written request for registration of change of name |

Free format text: JAPANESE INTERMEDIATE CODE: R313533 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| S531 | Written request for registration of change of domicile |

Free format text: JAPANESE INTERMEDIATE CODE: R313531 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |