JP4784559B2 - ワイパーブレード - Google Patents

ワイパーブレード Download PDFInfo

- Publication number

- JP4784559B2 JP4784559B2 JP2007145773A JP2007145773A JP4784559B2 JP 4784559 B2 JP4784559 B2 JP 4784559B2 JP 2007145773 A JP2007145773 A JP 2007145773A JP 2007145773 A JP2007145773 A JP 2007145773A JP 4784559 B2 JP4784559 B2 JP 4784559B2

- Authority

- JP

- Japan

- Prior art keywords

- pair

- spring plate

- blade

- plate member

- wiper

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000013013 elastic material Substances 0.000 claims description 6

- 210000000078 claw Anatomy 0.000 description 11

- 238000012986 modification Methods 0.000 description 4

- 230000004048 modification Effects 0.000 description 4

- 238000003825 pressing Methods 0.000 description 4

- 239000005357 flat glass Substances 0.000 description 3

- 230000002093 peripheral effect Effects 0.000 description 3

- 239000011347 resin Substances 0.000 description 3

- 229920005989 resin Polymers 0.000 description 3

- 238000005452 bending Methods 0.000 description 2

- 238000006243 chemical reaction Methods 0.000 description 2

- JEIPFZHSYJVQDO-UHFFFAOYSA-N iron(III) oxide Inorganic materials O=[Fe]O[Fe]=O JEIPFZHSYJVQDO-UHFFFAOYSA-N 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 238000005192 partition Methods 0.000 description 2

- 230000003014 reinforcing effect Effects 0.000 description 2

- VZSRBBMJRBPUNF-UHFFFAOYSA-N 2-(2,3-dihydro-1H-inden-2-ylamino)-N-[3-oxo-3-(2,4,6,7-tetrahydrotriazolo[4,5-c]pyridin-5-yl)propyl]pyrimidine-5-carboxamide Chemical compound C1C(CC2=CC=CC=C12)NC1=NC=C(C=N1)C(=O)NCCC(N1CC2=C(CC1)NN=N2)=O VZSRBBMJRBPUNF-UHFFFAOYSA-N 0.000 description 1

- 239000000470 constituent Substances 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 239000004576 sand Substances 0.000 description 1

- 230000011218 segmentation Effects 0.000 description 1

- 238000000638 solvent extraction Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60S—SERVICING, CLEANING, REPAIRING, SUPPORTING, LIFTING, OR MANOEUVRING OF VEHICLES, NOT OTHERWISE PROVIDED FOR

- B60S1/00—Cleaning of vehicles

- B60S1/02—Cleaning windscreens, windows or optical devices

- B60S1/04—Wipers or the like, e.g. scrapers

- B60S1/32—Wipers or the like, e.g. scrapers characterised by constructional features of wiper blade arms or blades

- B60S1/38—Wiper blades

- B60S1/3848—Flat-type wiper blade, i.e. without harness

- B60S1/3849—Connectors therefor; Connection to wiper arm; Attached to blade

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60S—SERVICING, CLEANING, REPAIRING, SUPPORTING, LIFTING, OR MANOEUVRING OF VEHICLES, NOT OTHERWISE PROVIDED FOR

- B60S1/00—Cleaning of vehicles

- B60S1/02—Cleaning windscreens, windows or optical devices

- B60S1/04—Wipers or the like, e.g. scrapers

- B60S1/32—Wipers or the like, e.g. scrapers characterised by constructional features of wiper blade arms or blades

- B60S1/38—Wiper blades

- B60S1/3806—Means, or measures taken, for influencing the aerodynamic quality of the wiper blades

- B60S1/381—Spoilers mounted on the squeegee or on the vertebra

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60S—SERVICING, CLEANING, REPAIRING, SUPPORTING, LIFTING, OR MANOEUVRING OF VEHICLES, NOT OTHERWISE PROVIDED FOR

- B60S1/00—Cleaning of vehicles

- B60S1/02—Cleaning windscreens, windows or optical devices

- B60S1/04—Wipers or the like, e.g. scrapers

- B60S1/32—Wipers or the like, e.g. scrapers characterised by constructional features of wiper blade arms or blades

- B60S1/40—Connections between blades and arms

- B60S1/4006—Connections between blades and arms for arms provided with a hook-shaped end

- B60S1/4009—Connections between blades and arms for arms provided with a hook-shaped end comprising a detachable intermediate element mounted on the hook-shaped end

- B60S1/4016—Connections between blades and arms for arms provided with a hook-shaped end comprising a detachable intermediate element mounted on the hook-shaped end the element being provided with retention means co-operating with the hook-shaped end of the arm

- B60S1/4019—Connections between blades and arms for arms provided with a hook-shaped end comprising a detachable intermediate element mounted on the hook-shaped end the element being provided with retention means co-operating with the hook-shaped end of the arm the retention means being protrusions or holes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60S—SERVICING, CLEANING, REPAIRING, SUPPORTING, LIFTING, OR MANOEUVRING OF VEHICLES, NOT OTHERWISE PROVIDED FOR

- B60S1/00—Cleaning of vehicles

- B60S1/02—Cleaning windscreens, windows or optical devices

- B60S1/04—Wipers or the like, e.g. scrapers

- B60S1/32—Wipers or the like, e.g. scrapers characterised by constructional features of wiper blade arms or blades

- B60S1/38—Wiper blades

- B60S1/3848—Flat-type wiper blade, i.e. without harness

- B60S1/3849—Connectors therefor; Connection to wiper arm; Attached to blade

- B60S1/3851—Mounting of connector to blade assembly

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60S—SERVICING, CLEANING, REPAIRING, SUPPORTING, LIFTING, OR MANOEUVRING OF VEHICLES, NOT OTHERWISE PROVIDED FOR

- B60S1/00—Cleaning of vehicles

- B60S1/02—Cleaning windscreens, windows or optical devices

- B60S1/04—Wipers or the like, e.g. scrapers

- B60S1/32—Wipers or the like, e.g. scrapers characterised by constructional features of wiper blade arms or blades

- B60S1/38—Wiper blades

- B60S1/3848—Flat-type wiper blade, i.e. without harness

- B60S1/3849—Connectors therefor; Connection to wiper arm; Attached to blade

- B60S1/3865—Connectors having an integral pivot pin for connection with the wiper arm

- B60S1/3867—Connectors having an integral pivot pin for connection with the wiper arm pin formed on the interior of side walls

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60S—SERVICING, CLEANING, REPAIRING, SUPPORTING, LIFTING, OR MANOEUVRING OF VEHICLES, NOT OTHERWISE PROVIDED FOR

- B60S1/00—Cleaning of vehicles

- B60S1/02—Cleaning windscreens, windows or optical devices

- B60S1/04—Wipers or the like, e.g. scrapers

- B60S1/32—Wipers or the like, e.g. scrapers characterised by constructional features of wiper blade arms or blades

- B60S1/38—Wiper blades

- B60S1/3848—Flat-type wiper blade, i.e. without harness

- B60S1/3874—Flat-type wiper blade, i.e. without harness with a reinforcing vertebra

- B60S1/3875—Flat-type wiper blade, i.e. without harness with a reinforcing vertebra rectangular section

- B60S1/3877—Flat-type wiper blade, i.e. without harness with a reinforcing vertebra rectangular section embedded in the squeegee

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60S—SERVICING, CLEANING, REPAIRING, SUPPORTING, LIFTING, OR MANOEUVRING OF VEHICLES, NOT OTHERWISE PROVIDED FOR

- B60S1/00—Cleaning of vehicles

- B60S1/02—Cleaning windscreens, windows or optical devices

- B60S1/04—Wipers or the like, e.g. scrapers

- B60S1/32—Wipers or the like, e.g. scrapers characterised by constructional features of wiper blade arms or blades

- B60S1/38—Wiper blades

- B60S1/3848—Flat-type wiper blade, i.e. without harness

- B60S1/3874—Flat-type wiper blade, i.e. without harness with a reinforcing vertebra

- B60S1/3875—Flat-type wiper blade, i.e. without harness with a reinforcing vertebra rectangular section

- B60S1/3881—Flat-type wiper blade, i.e. without harness with a reinforcing vertebra rectangular section in additional element, e.g. spoiler

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60S—SERVICING, CLEANING, REPAIRING, SUPPORTING, LIFTING, OR MANOEUVRING OF VEHICLES, NOT OTHERWISE PROVIDED FOR

- B60S1/00—Cleaning of vehicles

- B60S1/02—Cleaning windscreens, windows or optical devices

- B60S1/04—Wipers or the like, e.g. scrapers

- B60S1/32—Wipers or the like, e.g. scrapers characterised by constructional features of wiper blade arms or blades

- B60S1/38—Wiper blades

- B60S2001/3812—Means of supporting or holding the squeegee or blade rubber

- B60S2001/3824—Means of supporting or holding the squeegee or blade rubber the blade or squeegee pivoting about an axis parallel to blade longitudinal axis

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- Quality & Reliability (AREA)

Description

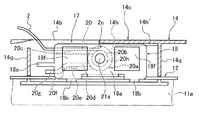

このワイパーブレードは、ブレードラバーと、バネ板部材をワイパーアーム先端に取り付けるための取り付け具と、ブレードラバーとバネ板部材とを被覆するブレードカバー(スポイラー)とから大略構成されている。

前記ワイパーブレードを被覆するブレードカバーが弾性材からなり、前記ブレードカバーは前記バネ板部材の長手方向に延び、その延びる方向の中央に前記ワイパーアーム先端に連結される前記取り付け具を設置するための取り付け開口が設けられ、該取り付け開口には前記長手方向に延びかつその一部を被覆ししかもその内部に異物の侵入を防ぐための可撓性切片が一体に形成されていることを特徴とする。

図1は本発明に係わる実施例1のワイパーブレード10を車両1のワイパーアーム2に適用した状態を示す斜視図、図2は図1に示すワイパーブレード10の拡大斜視図、図3は図2に示すワイパーブレード10の分解斜視図である。

(変形例)

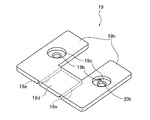

図24ないし図26は、先に述べたブレードカバー14の可撓性切片14cの変形例を示している。

(実施例2)

図27は、実施例2に係わるブレードカバー14´の斜視図である。この可撓性切片14c´は、ブレードカバー14´の上面部14g´にその幅方向中央部分にその長手方向に延びる1個のスリット14d´を形成することにより形成されている。

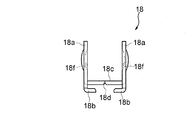

14 ブレードカバー

14b 取り付け開口

14c 可撓性切片

14d スリット

14f (ブレードカバー)側面部

14g (ブレードカバー)上面部

17 取り付け具

Claims (5)

- ブレードラバーに弧状に湾曲する長尺形状のバネ板部材を宛がって長尺形状の中央部に設けた取り付け具を介して車両に設けられたワイパーアームに連結されるワイパーブレードにおいて、

前記ワイパーブレードを被覆するブレードカバーが弾性材からなり、前記ブレードカバーは前記バネ板部材の長手方向に延び、その延びる方向の中央に前記ワイパーアーム先端に連結される前記取り付け具を設置するための取り付け開口が設けられ、該取り付け開口には前記長手方向に延びかつその一部を被覆ししかもその内部に異物の侵入を防ぐための可撓性切片が一体に形成されていることを特徴とするワイパーブレード。 - 前記可撓性切片は、前記ブレードカバーの上面部分に前記バネ板部材の幅方向両側に前記バネ板部材の長手方向に延びる一対のスリットを形成することにより形成されていることを特徴とする請求項1に記載のワイパーブレード。

- 前記可撓性切片は、その幅方向中央部に、前記ワイパーアーム先端のU字形状部に当接しかつ長手方向に延びる膨出部が形成されていることを特徴とする請求項2に記載のワイパーブレード。

- 前記可撓性切片は、その取り付け開口の上面部分でかつその幅方向中央部分に前記バネ板部材の長手方向に延びる1個のスリットを形成することにより形成されていることを特徴とする請求項1に記載のワイパーブレード。

- 前記取り付け具は、前記バネ板部材の幅方向に間隔を開けて対向する一対の対向壁部を有して前記ブレードラバーを前記バネ板部材を介して保持する対向壁部構成部材と前記ワイパーアームが締結されるクリップ部材を前記一対の対向壁部を横断する方向に延びる横断方向軸線の回りに支持する保持板とからなり、該保持板には前記一対の対向壁部に臨む側の面に円弧状膨出部が形成され、前記一対の対向壁部には前記保持板に臨む側の面に前記円弧状膨出部に嵌合して該保持板を横断方向軸線を含む面に対して直交する直交方向軸線の周りに相対回動可能に支承する円弧状凹所が形成されていることを特徴とする請求項1に記載のワイパーブレード。

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007145773A JP4784559B2 (ja) | 2007-05-31 | 2007-05-31 | ワイパーブレード |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007145773A JP4784559B2 (ja) | 2007-05-31 | 2007-05-31 | ワイパーブレード |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2008296765A JP2008296765A (ja) | 2008-12-11 |

| JP4784559B2 true JP4784559B2 (ja) | 2011-10-05 |

Family

ID=40170686

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2007145773A Expired - Fee Related JP4784559B2 (ja) | 2007-05-31 | 2007-05-31 | ワイパーブレード |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4784559B2 (ja) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5195447B2 (ja) * | 2009-01-16 | 2013-05-08 | 市光工業株式会社 | ワイパーブレード |

| JP2011218966A (ja) * | 2010-04-09 | 2011-11-04 | Ichikoh Ind Ltd | ワイパーブレード |

| CN106103212B (zh) * | 2013-11-06 | 2018-04-06 | 费德罗-莫格尔汽车配件公司 | 挡风玻璃雨刮装置 |

| EP2985191A1 (fr) * | 2014-07-17 | 2016-02-17 | Valeo Systèmes d'Essuyage | Balai plat caréné d'essuie-glace |

| JP6150928B1 (ja) * | 2016-06-03 | 2017-06-21 | 林 英樹 | ブレードラバー、ワイパーブレード |

| JP6244447B2 (ja) * | 2016-12-26 | 2017-12-06 | アスモ株式会社 | ラバーホルダ及びワイパブレード |

| CN107323425A (zh) * | 2017-05-27 | 2017-11-07 | 厦门拓派汽车配件有限公司 | 用于无骨雨刷的一体式导流板 |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS58112667A (ja) * | 1981-12-28 | 1983-07-05 | Nippon Kokan Kk <Nkk> | サイロのシユ−トパイプの取付方法 |

| JPS59136027A (ja) * | 1983-01-21 | 1984-08-04 | 本田技研工業株式会社 | 車両用電気回路 |

| JP2000272477A (ja) * | 1999-03-25 | 2000-10-03 | Asmo Co Ltd | 車両用ワイパ装置 |

| JP4091493B2 (ja) * | 2003-07-08 | 2008-05-28 | アスモ株式会社 | 連結装置、及びワイパブレード |

| JP2006076505A (ja) * | 2004-09-10 | 2006-03-23 | Asmo Co Ltd | ワイパブレード |

| JP2007015636A (ja) * | 2005-07-11 | 2007-01-25 | Mitsuba Corp | ワイパ装置 |

-

2007

- 2007-05-31 JP JP2007145773A patent/JP4784559B2/ja not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2008296765A (ja) | 2008-12-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4784559B2 (ja) | ワイパーブレード | |

| US7603742B2 (en) | Wiper blade and wiper system having the same | |

| JP5444454B2 (ja) | フロントガラス用ワイパー装置 | |

| US9932017B2 (en) | Vehicle wiper | |

| EP2230140B1 (en) | Wiper blade | |

| JP2010519108A (ja) | ワイパーブレードとワイパーアームとを枢着結合するための結合部材 | |

| JP2007504995A (ja) | フロントガラスのワイパーアーム | |

| JP2004517769A (ja) | 枢着式に結合されたワイパブレードを備えたワイパアーム | |

| JP2005536385A (ja) | ワイパブレード | |

| JP4659635B2 (ja) | ワイパブレード | |

| KR20100134597A (ko) | 윈드스크린 와이퍼 장치 | |

| JP2007504043A (ja) | フロントガラスのワイパー装置 | |

| KR20150006834A (ko) | 차창 와이퍼 아암 및 이를 제조하기 위한 방법 | |

| JP2015500172A (ja) | ウィンドスクリーン用ワイパーアーム | |

| JP4867814B2 (ja) | ワイパーブレード | |

| US20110094050A1 (en) | Vehicle provided with at least two windscreen wiper devices | |

| JP3228713B2 (ja) | 車両用ワイパ装置 | |

| JP5115484B2 (ja) | ワイパーブレード | |

| KR20100131497A (ko) | 탄성을 가지고 길다랗게 형성된 이동부재와, 윈드스크린에 접하여 위치되는 유연한 재료의 길다란 와이퍼 블레이드를 구비하는 윈드스크린 와이퍼 장치 | |

| JP5195447B2 (ja) | ワイパーブレード | |

| CN101722933B (zh) | 雨刮 | |

| KR101766946B1 (ko) | 윈드스크린용 와이퍼 장치 | |

| JP4830806B2 (ja) | ワイパーブレード | |

| US11560124B2 (en) | Wiper lever assembly and wiper blade | |

| JP2007237855A (ja) | ワイパブレード |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20090330 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20110329 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20110330 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110513 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20110614 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20110627 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4784559 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20140722 Year of fee payment: 3 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |