JP4026280B2 - Polyolefin-based split composite fiber, production method thereof, and fiber molded body using the fiber - Google Patents

Polyolefin-based split composite fiber, production method thereof, and fiber molded body using the fiber Download PDFInfo

- Publication number

- JP4026280B2 JP4026280B2 JP20485199A JP20485199A JP4026280B2 JP 4026280 B2 JP4026280 B2 JP 4026280B2 JP 20485199 A JP20485199 A JP 20485199A JP 20485199 A JP20485199 A JP 20485199A JP 4026280 B2 JP4026280 B2 JP 4026280B2

- Authority

- JP

- Japan

- Prior art keywords

- fiber

- molded body

- composite fiber

- polyolefin

- split

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Multicomponent Fibers (AREA)

- Nonwoven Fabrics (AREA)

- Paper (AREA)

- Absorbent Articles And Supports Therefor (AREA)

Description

【0001】

【発明の属する技術分野】

本発明は、分割性に優れたポリオレフィン系分割型複合繊維、その製造方法及び該繊維を用いた繊維成形体に関する。さらに詳しくは、少なくとも2成分のポリオレフィン系樹脂からなり、繊維断面において、各成分が交互に配列され、かつ繊維内部に中空部を有する複合繊維であって、該繊維の断面は外部応力により特定の扁平形状に変形され、かつ繊維を構成する各成分の一部が剥離した構造を有する分割型複合繊維、その製造方法及び該繊維を用いた繊維成形体に関する。該繊維成形体はバッテリセパレ−タ−、ワイパ−、フィルタ−などの産業資材分野、おむつ、ナプキン、ワイパー等の衛生材料分野等に好適に使用できる。

【0002】

【従来の技術】

従来、極細繊維を得る方法として、海島型や分割型の複合繊維を用いることが知られている。海島型複合繊維を用いる方法は、複数成分を組み合せて紡糸して海島型複合繊維とし、得られた該複合繊維の1成分を溶解除去することにより、極細繊維を得るものである。この方法は、非常に細い繊維を得ることができる反面、1成分を溶解除去するために非経済的である。

【0003】

一方、分割型複合繊維を用いる方法は、複数成分の樹脂を組み合せて紡糸して複合繊維とし、得られた該複合繊維を物理的応力や繊維を構成する樹脂成分の化学薬品に対する収縮差などを利用して、該分割型複合繊維を多数の繊維に分割して極細繊維を得るものである。

【0004】

例えば、複数成分の樹脂を組み合わせた複合繊維として、ポリエステル系樹脂とポリオレフィン系樹脂の組み合せ、ポリエステル系樹脂とポリアミド系樹脂の組み合せ、ポリアミド系樹脂とポリオレフィン系樹脂の組み合わせに代表される分割型複合繊維は、物理的応力により分割は容易に進行するものの、分割して得られた極細繊維及びそれからなる繊維成形体は、異種のポリマーからなる繊維が混在しており、耐薬品性の要求される産業資材分野等への使用が制限されているのが現状である。

【0005】

一方、耐薬品性に優れるポリオレフィン系樹脂同士の組み合せでは、前記異種ポリマーの組み合せに比べて比較的樹脂の相溶性が良いため、得られた分割型複合繊維の分割細繊化には、物理的衝撃を大きくする必要があった。このため、得られた繊維成形体(不織布)は、分割された部分と分割されない部分が存在したり、該複合繊維が物理的衝撃で動き、目付の厚い部分と薄い部分とができるなど、いわゆる、むらが生じて地合が悪くなったり、また高圧液体流処理の加工速度を大幅に下げる必要があるなど、決して満足のできるものではなかった。

【0006】

これを改善するために、特開平4−28922号公報では、オルガノシロキサン及びこれらの変成体を添加した同種の樹脂を用いて分割型複合繊維にすることにより、同種ポリマー同士の分割型複合繊維であっても容易に分割できることが提案されている。しかしながら、かかる方法では分割性は多少向上するものの、該分割型複合繊維を分割して得られた繊維を用いた繊維成形体(不織布)は強力が低下したり、2次加工時の加工性不良などの問題も多い。

【0007】

【発明が解決しようとする課題】

本発明の目的は、これらの欠点を改良したポリオレフィン系分割型複合繊維、その製造方法及び該繊維を用いた繊維成形体を提供することにある。すなわち、特別に分割性を向上させるための添加剤を一切使用せずに、湿式用の繊維などに用いても分割性に優れるポリオレフィン系分割型複合繊維、その製造方法及び該繊維を用いた繊維成形体を提供することである。

【0008】

本発明者らは、上記目的を達成するために、鋭意検討を重ねた。その結果、少なくとも2成分のポリオレフィン系樹脂から構成され、繊維断面において、各成分は交互に配列され、かつ繊維内部に中空部を有する複合繊維であって、該複合繊維の断面は外部応力により特定の扁平形状に変形され、かつ複合繊維を構成する各成分の一部を剥離させた構造の複合繊維とし、係る複合繊維を用いた繊維成形体が従来の欠点を改良できることを見出し、この知見に基づいて本発明を完成した。

【0009】

【課題を解決するための手段】

本発明は、以下から構成されている。

(1)少なくとも2成分のポリオレフィン系樹脂からなり、繊維断面において、各成分は交互に配列され、かつ繊維内部に中空部を有する複合繊維であって、該繊維の断面は外部応力により扁平形状に変形され、変形率(短軸W/長軸L)が0.2〜0.9であり、かつ繊維を構成する各成分の一部が剥離した構造を有することを特徴とする、物理的応力による分割細繊化処理用のポリオレフィン系分割型複合繊維。

【0010】

(2)該複合繊維の断面の形状において、各成分の接触界面の10%以上が剥離している前記(1)項記載のポリオレフィン系分割型複合繊維。

【0011】

(3)該複合繊維の繊維断面の形状において、各成分が放射状に交互に配置されている前記(1)項若しくは(2)項のいずれか1項記載のポリオレフィン系分割型複合繊維。

【0012】

(4)少なくとも2成分のポリオレフィン系樹脂の組合せが、ポリプロピレン系樹脂とポリエチレン系樹脂である前記(1)項〜(3)項のいずれか1項記載のポリオレフィン系分割型複合繊維。

【0013】

(5)該複合繊維の分割前の平均単糸繊度が0.6〜10デシテックス、分割後の平均単糸繊度が0.6デシテックス未満である前記(1)項〜(4)項のいずれか1項記載のポリオレフィン系分割型複合繊維

【0014】

(6)前記(1)項〜(5)項のいずれか一項記載の分割型複合繊維を少なくとも30重量%以上含み、かつ該複合繊維の50重量%以上が分割している繊維成形体。

【0015】

(7)繊維成形体が繊維集合体である前記(6)項記載の繊維成形体。

【0016】

(8)繊維成形体がスパンボンド法により得られる繊維集合体である前記(6)項もしくは前記(7)項のいずれか1項記載の繊維成形体。

【0017】

(9)前記(6)〜(8)のいずれか1項記載の繊維成形体の片面または両面にシートを積層してなる積層繊維成形体。

【0018】

(10)前記(6)項〜(8)項のいずれか1項記載の繊維成形体をシートの両面に積層してなる積層繊維成形体。

【0019】

(11)シートが不織布、フィルム、編物、織物の少なくとも1種から選ばれた前記(9)項もしくは前記(10)項記載の積層繊維成形体。

【0020】

(12)前記(6)項〜(8)項のいずれか1項記載の繊維成形体もしくは前記(9)〜(11)項のいずれか1項記載の積層繊維成形体を用いた吸収性物品。

【0021】

(13)前記(6)項〜(8)項のいずれか1項に記載の繊維成形体もしくは前記(9)項〜(11)項のいずれか1項記載の積層繊維成形体を用いたワイパー。

【0022】

(14)前記(6)項〜(8)項のいずれか1項記載の繊維成形体もしくは前記(9)〜(11)項のいずれか1項記載の積層繊維成形体を用いたバッテリーセパレーター。

【0023】

(15)前記(1)項記載のポリオレフィン系分割型複合繊維の製造方法であって、少なくとも2成分のポリオレフィン系樹脂が交互に配列され、内部に中空部を有する複合繊維に押圧処理及び/または擦過処理を施して該複合繊維を変形させ、2成分接触界面の一部を剥離させることを特徴とするポリオフィン系分割型複合繊維の製造方法。

(16)前記(1)〜(5)のいずれか1項記載のポリオレフィン系分割型複合繊維を含むウェブを物理的応力によって分割細繊化することを特徴とする繊維成形体の製造方法。

【0024】

【発明の実施の形態】

以下、本発明を詳細に説明する。

本発明のポリオレフィン系分割型複合繊維に用いるポリオレフィン系樹脂とは、炭素数が2〜8個の脂肪族α−オレフィン、例えばエチレン、プロピレン、1−ブテン、1−ペンテン、4−メチル−1−ペンテン、3−メチル−1−ブテン、1−ヘキセン、1−オクテン等のα−オレフィンの単独重合体又はこれらのα−オレフィンの2種以上の共重合体、これらα−オレフィンと他のオレフィン及び/または少量の他のエチレン系不飽和モノマー、例えばブタジエン、イソプレン、1,3−ペンタジエン、スチレン、α−メチルスチレン、ポリビニルアルコール、ポリ酢酸ビニル、ポリアクリル酸エステル等のエチレン系不飽和モノマーとの共重合体及びこれらの2種以上の混合物を挙げることができる。

【0025】

代表的にはポリプロピレン系樹脂及びポリエチレン系樹脂を挙げることができる。該ポリプロピレン系樹脂としては、例えばプロピレン単独重合体、プロピレンを70重量%以上含有するプロピレンとプロピレン以外の上記α−オレフィンとの共重合体、例えばエチレン−プロピレン共重合体、エチレン−プロピレン−ブテン共重合体等を挙げることができる。

【0026】

ポリエチレン系樹脂としては、高密度ポリエチレン(HDPE)、直鎖状低密度ポリエチレン(LLDPE)、低密度ポリエチレン(LDPE)等を挙げることができ、中でも高密度ポリエチレンが好ましい。

【0027】

本発明のポリオレフィン系分割型複合繊維は、上記のうち、少なくとも2成分からなるポリオレフィン系樹脂を任意に組み合せることが可能であるが、より好ましい組み合せとして、耐薬品性が高く、コスト的に有利なポリプロピレン樹脂及びポリエチレン樹脂の2成分の組み合せが好適である。

【0028】

本発明のポリオレフィン系分割型複合繊維に好適に使用されるポリプロピレン系樹脂とポリエチレン系樹脂の2成分の組み合せにあっては、該ポリプロピレン系樹脂が高融点樹脂(A成分)となる。かかるポリプロピレン系樹脂は具体的には、チーグラーナッタ触媒、メタロセン触媒等で重合されたシンジオタクチックポリプロピレンやアイソタクチックポリプロピレンが例示できる。原料としての該ポリプロピレン系樹脂のMFRは、溶融紡糸可能な範囲であれば特に制限はなく、紡糸条件等の変更で、繊維成形後のMFRが10〜100g/10分の範囲内となるようなMFRを有するポリプロピレン系樹脂であれば特に問題はない。より好ましくは、繊維成形後のMFRが10〜70g/10分となるようなMFRを有するポリプロピレン系樹脂を用いることである。繊維成形後のMFRが10g/10分以下となるようなMFRを有するポリプロピレン系樹脂を用いると、得られる複合繊維の中空率は高く維持できるものの可紡性良く、細い繊維に成形(紡糸)することが難しくなる。また繊維成形後のMFRが100g/10分を超える場合は、得られる複合繊維の中空率を高く維持することが難しく、またフィラメントにする場合、可紡性が悪くなる場合がある。

【0029】

一方、ポリエチレン系樹脂は、前記ポリプロピレン系樹脂の融点より低い低融点樹脂(B成分)であって、具体的には、高密度ポリエチレン(HDPE)、直鎖状低密度ポリエチレン(LLDPE)、低密度ポリエチレン(LDPE)を例示することができる。また、これらの2種以上の混合物であっても良い。原料としてのポリエチレン系樹脂のMFRは溶融紡糸可能な範囲であれば良く、紡糸条件等の変更で、繊維成形後のMFRが10〜100g/10分の範囲内となるMFRを有するポリエチレン系樹脂であれば特に問題はない。より好ましくは、繊維成形後のMFRが10〜60g/10分となるよなMFRを有するポリエチレン系樹脂を用いることである。繊維成形後のMFRが10g/10分以下となるようなMFRを有するするポリエチレン系樹脂を用いると、得られる複合繊維の中空率は高く維持できるものの可紡性が著しく不良となり、細い繊維に成形することが難しくなる。また、MFRが100g/10分を超える場合は、得られる複合繊維の中空率の維持が難しく、またフィラメントにする場合、可紡性が悪くなる場合がある。

【0030】

本発明のポリオレフィン系分割型複合繊維を構成する少なくとも2成分のポリオレフィン系樹脂のうち、最も融点の高い樹脂をA成分としたときの該A成分のMFRをMFR−Aとし、最も融点の低い樹脂をB成分としたときの該B成分のMFRをMFR−Bとしたとき、該MFRの比(MFR−A/MFR−B)は、0.1〜5であることが好ましく、さらに好ましくは、0.5〜3である。この値が0.1未満であったり、5を超える場合には、溶融紡糸時の2成分の口金内の流れ性、中空形状に吐出された後の溶融張力差、冷却時の粘度上昇の差が大きくなるなどの要因で、得られる複合繊維の中空率を維持し、かつ、可紡性良く繊維に成形(紡糸)することが困難となる。

【0031】

本発明に関わるポリオレフィン系樹脂は、本発明の効果を妨げない範囲内でさらに、酸化防止剤、光安定剤、紫外線吸収剤、中和剤、造核剤、エポキシ安定剤、滑剤、抗菌剤、難燃剤、帯電防止剤、顔料、可塑剤、親水剤などの添加剤を適宜必要に応じて添加しても良い。

【0032】

本発明のポリオレフィン系分割型複合繊維の形状は繊維内部に中空部を有し、かつ繊維断面において、繊維外周部及び/または繊維内周部が変形された形状をしていれば、該形状は特に限定されない。該複合繊維の繊維外周部及び該繊維内周部の形状は、円形や異形形状とすることができる。異形形状とは、扁平形、三角形〜八角形等の多角形等を例示することができる。例えば図1〜12に示したようなA、B2成分のポリオレフィン系樹脂から構成される分割型複合繊維にあっては、該A、B2成分が交互に配列した断面形状を例示することができる。もちろん、多成分のポリオレフィン系樹脂から構成される分割型複合繊維にあっては、各成分が互いに交互に配列した断面形状をとることが好ましい。

【0033】

本発明で得られる分割型複合繊維を高圧液体流処理等で分割する場合、分割後の極細繊維の平均単糸繊度は0.6デシテックス未満、特に0.3デシテックス以下となることが好ましい。従って、繊維内部が変形された中空形状の分割型複合繊維の分割セグメント数は、極細繊維の平均繊度が0.6デシテックス未満となるように決めれば良く、分割型複合繊維のセグメント数が多ければ分割後の繊度が小さくなる利点があるが、実際には繊維製造上の容易さから4〜32セグメント数とすることが好ましい。また個々のセグメントの繊度は同一である必要はなく、分割型複合繊維が完全に分割していない場合には、未分割の分割型複合繊維と完全に分割した極細繊維との中間に複数の異なった繊度の繊維が混在していても良い。

【0034】

次に、本発明の分割型複合繊維の繊維断面について説明する。

本発明の分割型複合繊維の繊維断面は、少なくとも2成分のポリオレフィン系樹脂が、交互に配列され、繊維内部に中空部を有する複合繊維であって、該複合繊維の断面は扁平形状に変形され、かつ繊維を構成する各成分の一部が剥離した構造をしていることを特徴とする分割型複合繊維である。この中でも外部応力を繊維表面のどの部分から受けてもほぼ同じ様な効果が得られる構造、例えば各成分が放射状に配置されている構造が好ましい。さらには各成分の各分割セグメントの一部が繊維外周部に少なくとも露出していることが易分割化を達成するためにはより好ましい。

【0035】

該複合繊維の繊維断面が扁平形状に変形されるとは、ポリオレフィン系樹脂が交互に配列された繊維内部が中空部を有する複合繊維断面に於いて、紡糸後もしくは延伸後に繊維の外周部を何らかの外部応力によって、押しつけて変形させることにより、該複合繊維を扁平形状にすることをいう。扁平形状に変形させるための外部応力を加える手段としては特に限定はないが、例えばロール/ロール間加圧により該複合繊維を変形させる方法(A法)、ロール面または角材の端部に通過接触させて擦過により該複合繊維を変形させる方法(B法)、広い開口部から徐々に狭くなる隙間を通し、この時、繊維に辛うじて通過し得る押圧で複合繊維を変形させる方法(C法)、該複合繊維を集束した状態で撚りによる捻り及び引張張力を加えて該複合繊維を変形させる方法(D法)、あるいはこれらの方法の組み合わせても良い。また上記外部応力を加えた後、所定長に切断する場合にもローターカッター、ギロチンカッター等の切断面には物理的な応力が加わりさらに各成分の接触界面は分割し易くなる。該複合繊維の断面形状はこのような前記の種々の手法で扁平形状に変形されるとき、同時に2成分の間の接触界面の一部が剥離されることが重要である。

【0036】

本発明のポリオレフィン系分割型複合繊維の断面の変形率(短軸W/長軸L)は0.2〜0.9、より好ましくは0.2〜0.8、さらに好ましくは0.3〜0.8である。ここで変形率とは、該複合繊維の繊維横断面における繊維外周部の最も長い部分を長軸Lとし、該長軸と直交し、かつ繊維外周部の最も短い部分を短軸Wとした場合の短軸W/長軸Lの比で表したものである。変形率が0.2未満では、該中空部が完全に押し潰され、さらに所期の各成分の断面形状まで潰されて変形するため、分割細繊化後の極細繊維を用いて得られる繊維成形体(不織布)の強力が非常に弱いものとなってしまう。一方、変形率が0.9を超えると、ロール加圧等の外部応力が弱く、各成分の界面に分割性を著しく向上させるほどの歪みを与えることができない。

【0037】

本発明のポリオレフィン系分割型複合繊維の繊維断面において、各構成成分の接触界面の一部が剥離することにより更に分割し易くなる。各構成成分の接触界面は、10%以上剥離していることが更に好ましい。該複合繊維の分割セグメント数に応じて発生する接触界面は、任意の接触界面の一部分のみ剥離していても良い。繊維の全接触界面のうち剥離部分をたして10%以上剥離していればよい。剥離部分が10%未満では、易分割化の傾向を示すものの、低い水圧での高圧液体流処理で、高い分割率で分割するのが難しくなる。一方、各成分の接触界面の10%以上が剥離している場合は、その近傍の界面は外部からの物理的応力を確実に受けているため、剥離にまでは至らなくても確実に歪みが加わっており、より低エネルギーでの分割細繊化が可能となる。

【0038】

本発明の分割型複合繊維の繊維断面を得るには、まず紡糸段階で繊維内部の中空部が占める面積、いわゆる中空率を5%〜40%、より好ましくは10〜30%とすることが好ましい。また、中空形状は特に限定されるものではない。中空率が5%未満では隣接成分同士の接触面積が大きく、外部応力で該複合繊維を扁平形状に変形させようとしても扁平にし難く、結果として易分割化の度合いは小さくなる。また、中空率が40%を超えると、隣接成分同士の接触面積が小さく物理的応力による扁平形状への変形は容易に進行するものの、曳糸性、生産性を維持したまま未分割繊維を生産することが難しくなる。 即ち中空率は5%〜40%、より好ましくは10〜30%とすることにより、曳糸性、生産性を維持したまま、本発明の扁平形状に変形させ易くすることができる。

【0039】

さらに、繊維内部の中空部は、中心部に一カ所のみに限定されることはなく、中空部は2カ所以上でも良いし、繊維断面のどこに配置されていても良い。またA成分またはB成分のいずれか一方に発泡剤を混入して複合繊維に成形すると、発泡剤の作用でA成分またはB成分のいずれか一方に非常に細かな中空部を存在させることができる。この中空部はA、B成分境界部に存在し、隣接成分同士の接触面積を小さくするので、結果として易分割性を著しく向上させることができる。

【0040】

ここで発泡剤としては、例えばアゾジカルボンアミド、バリウムアゾジカルボキシレート、N,N−ジニトロソペンタメチレンテトラミン、p−トルエンスルホニルセミカルバジド、トリヒドラジノトリアジン等を例示することができる。

【0041】

本発明のポリオレフィン系分割型複合繊維において、少なくとも2成分のポリオレフィン系樹脂から構成される該複合繊維の複合比は、10/90〜90/10重量%の範囲でその用いた樹脂成分の合計が100重量%であれば良く、より好ましくは30/70〜70/30重量%であり、最も好ましくは2成分のポリオレフィン系樹脂からなりその複合比が50/50重量%である。かかる範囲の複合比とすることにより、用いた少なくとも2成分のポリオレフィン系樹脂が均一に配置された断面形状となる。さらに分割細繊化後の繊度が一定であり、より均一な繊維集合体とすることができる。

【0042】

本発明のポリオレフィン系分割型複合繊維の分割前の単糸繊度は、特に限定されることはないが、0.6〜10デシテックスであることが好ましく、より好ましくは、1〜6デシテックスである。単糸繊度が0.6デシテックス未満であると溶融紡糸工程での曳糸性が低下する傾向にある。また10デシテックスを超えると、得られたウェブを高圧水流法等で分割細繊化した場合でも、均一性が高く緻密な繊維集合体とすることが難しくなる。また分割後の平均単糸繊度は、0.6デシテッックス未満であることが好ましく、より好ましくは、0.5デシテックス未満である。0.6デシテックス以上だと、分割型複合繊維の最大の特徴である細繊度化による均一で地合によい柔軟な繊維成形体が得られ難くなる。

【0043】

以下、本発明の分割型複合繊維の1例として、ポリプロピレン樹脂と高密度ポリエチレン樹脂を組み合わせた分割型複合繊維の製造方法を例示する。

通常の溶融紡糸機を用いて上記樹脂からなる長繊維を紡出する。紡糸に際し、紡糸温度は200〜330℃の範囲で紡糸することが好ましく、引き取り速度は40m/分〜1500m/分程度とするのが良い。延伸は必要に応じて多段延伸を行っても良く、延伸倍率は通常3〜9倍程度とするのが良い。さらに該複合繊維を扁平形状に変形させる例えばA法の場合、ロールとロール間圧力は1kg/cm〜50kg/cmの範囲とすることにより、扁平状に変形させ、各成分の接触界面を剥離もしくは、歪みを与え、本発明のポリオレフィン系分割型複合繊維を得る。さらに所定長に切断して短繊維とする。また得られたトウは必要に応じて捲縮を付与しても良い。

【0044】

該複合繊維を加圧して扁平形状に変形させるロールは、特に限定されるものではないが、例えば金属ロールと金属ロール、金属ロールとゴムロール、ゴムロールとゴムロールが例示できる。またロール表面は、平面であっても、凹凸状であっても良い。凹凸形状には、ロール回転方向に直交した直線状、或いは波線状等の凸部を有するものなどを例示することができる。これらのロールのなかで好ましいものとして、表面が平面である金属ロール同士の組み合わせ、及び一方が平面、他方が凹凸状面の金属ロールの組合わせを例示できる。加圧して変形させる工程は、紡糸延伸工程の任意の場所で行うことができるが、延伸工程とカット工程の間、即ち延伸工程終了後、上記ロール加圧処理を行って、該複合繊維を変形させた後、所定長に切断する。これは延伸後繊維は製造工程中最も結晶化し剛直な構造となっているため、ロールなどで加圧して扁平に変形させる場合、各成分への接触界面に歪みが起こりやすい。また、従来設備にあっては、新たにロール加圧装置を設置しなくても、捲縮付与装置のクリンパーロール同士でも行うことができる。

【0045】

以上は短繊維の製造工程を開示したが、トウを切断せず、長繊維トウを分繊ガイドなどによりウェブとすることもできる。その後は必要に応じて高次加工工程を経て、種々の用途に応じて繊維成形体に成形される。また紡糸延伸後、フィラメント糸条として巻き取り、これを編成または織成して編織物とした繊維成形体、あるいは前記短繊維を紡績糸とした後、これを編成または織成して編織物とした繊維成形体に成形しても良い。

【0046】

ここで、繊維成形体とは、例えば織物、編物、不織布あるいは不織繊維集合体などがある。不織繊維集合体とは、例えばカード法、エアレイド法、あるいは抄紙法などの方法で均一にしたウェブ状物を示す。また、繊維成形体としては、織物、編物、不織布、繊維集合体を種々積層したものあるいはロッド状物、充填物でも何ら問題ない。

【0047】

かかる工程において、繊維を紡出後、繊維の静電気防止、繊維成形体への加工性向上、例えば抄紙時の分散性、平滑性付与などを目的として界面活性剤を付着させることができる。界面活性剤の種類、濃度は用途に合わせて適宜調整する。付着の方法は、ローラ法、浸漬法などを用いることができる。付着は、紡糸工程、延伸工程、捲縮工程のいずれで付着させても差し支えない。さらに短繊維、長繊維に問わず、紡糸工程、延伸工程、捲縮工程以外の、例えば繊維成形体に成形後、界面活性剤を付着させることもできる。

【0048】

本発明のポリオレフィン系分割型複合繊維の繊維長は、特に限定されるものではないが、カード機を用いてウェブを作製する場合は、一般に20〜76mmのものを用い、抄紙法やエアレイド法では、一般に繊維長が2mm〜20mmのものが好ましく用いられる。繊維長が2mm未満の場合には、物理的衝撃で繊維が動いてしまい、分割に必要なエネルギーを繊維自体が受けにくくなってしまう恐れがある。また、繊維長が76mmを大幅に超える場合はカード機等でのウェブ形成が均一にできず、均一な地合のウェブとするのが難しくなる。

【0049】

本発明のポリオレフィン系分割型複合繊維からなる繊維成形体の製造方法の一例として、不織布の製造方法を例示する。例えば前記ポリオレフィン系分割型複合繊維の短繊維を用いて、カード法、エアレイド法、あるいは抄紙法を用いて必要な目付のウェブを作製する。上記の方法で作製したウェブを、ニードルパンチ法、高圧液体流処理等の公知の方法で分割細繊化して繊維成形体を得ることができる。さらに、この繊維成形体を熱風あるいは熱ロール等の公知の加工方法でさらに処理することもできる。また抄紙法などの非常に短い繊維で構成されたウェブをニードルパンチ法、高圧液体流処理等の公知の方法で分割細繊化する場合に、その物理的応力で繊維が分割すると同時に動いて地合不良となる場合があるため、予め本発明の分割型複合繊維を構成する樹脂の融点よりも低融点で熱融着する繊維を混綿しておき、この低融点繊維で接着された不織布を作製しておくことで地合不良を抑えることができる。

【0050】

繊維成形体の目付は、特に限定されるものではないが、10〜200g/m2のものが好ましく使用できる。目付が10g/m2未満では、高圧液体流処理などの物理的応力で分割細繊化する場合、地合不良な不織布となる場合がある。また目付が200g/m2を超えると、目付が高く、高圧水流が必要となり、地合良く、均一な分割を行うことが困難となる場合がある。

【0051】

本発明の繊維成形体は、本発明の妨げにならない範囲で、必要に応じて本発明の分割型複合繊維に他の繊維を混合して用いることができる。該他の繊維としては、ポリアミド、ポリエステル、ポリオレフィン、アクリルなどの合成繊維、綿、羊毛、麻などの天然繊維、レーヨン、キュプラ、アセテートなどの再生繊維、半合成繊維などが挙げられ、混綿、混紡等の方法で任意に混合することができる。

【0052】

次に、高圧液体流処理について説明する。高圧液体流処理に用いる高圧液体流装置としては、例えば、孔径が0.05〜1.5mm、特に0.1〜0.5mmの噴射孔を孔間隔0.1〜1.5mmで一列あるいは複数列に多数配列した装置を用いる。噴射孔から高水圧で噴射させて得られる高圧液体流を多孔性支持部材上に置いた前記ウェブに衝突させる。これにより本発明の未分割の分割型複合繊維は高圧液体流により、交絡されると同時に細繊化される。噴射孔の配列は前記ウェブの進行方向と直交する方向に列状に配列する。高圧液体流としては、常温あるいは温水を用いても良いし、任意に他の液体を用いても良い。

【0053】

噴射孔とウェブとの間の距離は、10〜150mmとするのが良い。この距離が10mm未満であるとこの処理により得られる繊維成形体の地合が乱れ、一方、この距離が150mmを超えると液体流がウェブに与える物理的衝撃が弱くなり、交絡及び分割細繊化が十分に施されない場合がある。この高圧液体流の処理圧力は、製造方法及び繊維成形体の要求性能によって、制御されるが、一般的には、20kg/cm2〜200kg/cm2の高圧液体流を噴射するのが良い。なお処理する目付等にも左右されるが、前記処理圧力の範囲内において、高圧液体流は順次、低水圧から高水圧へ圧力を上げて処理すると、ウェブの地合が乱れることなく、交絡及び分割細繊化が可能となる。高圧液体流を施す際にウェブを載せる多孔性支持部材としては、例えば50〜200メッシュの金網製あるいは合成樹脂製のメッシュスクリーンや有孔板など高圧液体流が上記ウェブを貫通するものであれば特に限定されない。

【0054】

尚、ウェブの片面より高圧液体流処理を施した後、引き続き交絡処理されたウェブを反転させて、高圧液体流処理を施すことによって、表裏共に緻密で地合の良い繊維成形体を得ることができる。さらに高圧液体流処理を施した後、処理後の繊維成形体から水分を除去する。この水分を除去するに際しては、公知の方法を採用することができる。例えば,マングロール等の絞り装置を用いて、水分をある程度除去した後、熱風循環式乾燥機等の乾燥装置を用いて完全に水分を除去して本発明の繊維成形体を得ることができる。

【0055】

本発明のポリオレフィン系分割型複合繊維は、従来のポリオレフィン系分割型複合繊維に比べ、分割し易く、高圧液体流による物理的衝撃が少なく分割、細繊化が可能である。このため、スパンレースの律速段階である高圧液体流処理の高速化及び高圧液体流の低圧化による地合改善、例えば抄紙法のような繊維長の短い繊維からなるウェブでは、高圧液体流の圧力を低くすることができ、繊維成形体の地合が乱れたり、貫通孔が開くなどの問題を改善することができる。

【0056】

さらに、本発明の繊維成形体の片面もしくは両面に不織布、フィルム、編物、織物等から選ばれた少なくとも1種からなるシートを積層した、積層繊維成形体(以下Aタイプ)や、さらには該繊維成形体を逆に前記シートの両面に積層した積層繊維成形体(以下Bタイプ)として使用することもできる。

Aタイプの場合は分割処理した繊維成形体を他のシートの片面もしくは両面に積層する方が分割効率が良く、好ましい。Bタイプの場合は積層前後、どちらでも繊維成形体は分割されるが、特に積層後の分割処理は他のシートと繊維成形体との絡合作用が得られ好ましい。

【0057】

以上のように、ポリオレフィン系樹脂から構成された分割型複合繊維であっても、容易に分割させることができ、緻密で地合の良い繊維成形体を得ることができる。これにより、本発明のポリオレフィン系分割型複合繊維は、従来のポリオレフィン系分割型複合繊維に比べ、樹脂の耐薬品性を生かしたバッテリセパレーターやワイパー等の産業資材分野等及び衛生材料に好適に使用することができる。

【0058】

【実施例】

以下、本発明を実施例及び比較例によって説明するが、本発明はこれにより限定されるものではない。なお実施例、比較例における用語と物性の測定方法は以下の通りである。

【0059】

(1)MFR:JIS K7210に準拠して測定した。

原料ポリプロピレン樹脂:条件14

原料ポリエチレン樹脂 :条件4

繊維成形後のポリオレフィン系樹脂:条件14

【0060】

(2)ロール加圧前の中空率(%):外部応力により扁平形状に変形させる前の未分割の繊維の断面写真から以下の式により算出した。

中空率(%)=(中空部の断面積/繊維の中空部を含む総断面積)×100

【0061】

(3)繊維引張強伸度:JIS−L1017法に準じ、島津製作所(株)製オートグラフ AGS500Dを用い、試長100mm、引張速度100mm/分で測定した。

【0062】

(4)変形率:外部応力により扁平形状に変形し、高圧液体流処理を行っていない任意に選んだ分割型複合繊維10本の断面写真から、以下の値を計算し、その平均値から変形率を算出した。

変形率=短軸W/長軸L

長軸L:該複合繊維の繊維断面における繊維外周部の最も長い部分

短軸W:該長軸と直交し、かつ繊維外周部の最も短い部分

【0063】

(5)剥離率(%):変形率を求めた写真を用いて、各成分の接触界面の剥離部分の長さと非剥離部分の長さから以下の式より算出した。

剥離率(%)=(全接触界面の剥離部分の長さ/全接触界面の非剥離部分の長さ)×100

【0064】

(6)分割率の測定:分割後の不織布をワックスにて包含し、ミクロトームで繊維軸に対して、直角にスライスして試料片を作成する。これを顕微鏡で観察し、繊維の断面像を画像処理して、セグメントの70%以上が分割された繊維の総断面積(A)と未分割繊維の総断面積(B)を測定し、以下の式で算出した。

分割率(%)={A/(A+B)}×100

【0065】

(7)地合:10人のパネラーに対し、分割細繊化加工後の不織布(1m角)の繊維の分布斑を目視により次のように判定した。

○:7人以上が斑が少なく、また貫通孔もないと感じた。

△:4〜6人が斑が少なく、貫通孔もないと感じた。

×:斑が少ないと感じたのは3人以下であった。

【0066】

(8)高圧液体流処理:ローラカード機、エアレイド機、抄紙機等で作成したウェブを80メッシュの平織りからなるコンベアーベルト上に載せ、コンベアーベルト速度20m/分の速度で、ノズル径0.1mm、ノズルピッチ1mmのノズル直下を通過させ、高圧液体流を噴射した。まず、2MPaで予め予備処理(2段)した後、水圧5MPaの高圧液体流で3段処理した。ウェブを反転させ、さらに水圧5MPaの高圧液体流で3段処理することにより、分割細繊化した不織布を得た。ここで段とは、ノズル直下を通過した回数のことである。

【0067】

実施例1

高融点樹脂Aにポリプロピレン樹脂(ポリプロピレン単独重合体、融点163℃、MFR:16g/10分)、低融点樹脂Bに高密度ポリエチレン樹脂(融点131℃、MFR:16g/10分)とし、分割型複合繊維用口金を用いて、樹脂Aと樹脂Bの容積比率50/50、単糸デニール7.5dtexの分割型複合繊維を紡糸した。得られた未延伸糸は90℃、4.3倍で延伸し、5kg/cmで加圧された表面が平面の金属ロールの間を通過させた後、抄紙用分散剤を付着させ、5mmに切断した。得られた複合繊維の断面は扁平形状に変形され、A、B成分(白地部分と黒地部分で表示、以下、同じ)の接触界面の一部が剥離した図1〜図6に示した繊維断面形状を有する分割型複合繊維が混在したものであった。水分率は20重量%であった。

この短繊維にポリプロピレン(芯)/低密度ポリエチレン(鞘)の鞘芯複合繊維(EAC繊維、2.2dtex×5mm、チッソ(株))を20重量%添加し、角型シートマシン(25cm×25cm)を用い、抄紙法でウェブとした。熊谷理器工業社製ヤンキードライヤーを用い、105℃で3分間乾燥、予備接着を行い、ウェブを得た。前記高圧液体流処理を行った後、さらに80℃のドライヤーで乾燥させ、目付55g/m2の分割型複合繊維を用いた繊維成形体とした。

【0068】

実施例2

金属ロールの圧力を5kg/cmから20kg/cmに変更した以外は実施例1に準拠して、目付50g/m2の分割型複合繊維を用いた繊維成型体を得た。

【0069】

実施例3

高融点樹脂Aにポリプロピレン樹脂(ポリプロピレン単独重合体、融点163℃、MFR:20g/10分)、低融点樹脂Bに高密度ポリエチレン樹脂(融点131℃、MFR:26g/10分)を使用し、分割型複合繊維用口金を用いて、樹脂Aと樹脂Bの容積比率50/50、単糸デニール7.5dtexの分割型複合繊維を紡糸した。得られた未延伸糸は90℃、4.0倍で延伸し、10kg/cmで加圧された表面が平面の金属ロールの間を通過させた後、抄紙用分散剤を付着させ、5mmに切断した。得られた複合繊維の断面は扁平形状に変形され、A、B成分の接触界面の一部が剥離した図1〜図6に示した繊維断面形状を有する分割型複合繊維が混在したものであった。水分率は20重量%であった。この短繊維にポリプロピレン(芯)/低密度ポリエチレン(鞘)の鞘芯複合繊維(EAC繊維、2.2dtex×5mm、チッソ(株))を20wt%添加し、角型シートマシン(25cm×25cm)を用い、抄紙法でウェブとした。熊谷理器工業社製ヤンキードライヤーを用い、105℃で3分間乾燥、予備接着を行い、ウェブを得た。前記高圧液体流処理を行った後、さらに80℃のドライヤーで乾燥させ、目付60g/m2の分割型複合繊維を用いた繊維成形体を得た。

【0070】

実施例4

高融点樹脂Aにポリプロピレン樹脂(ポリプロピレン単独重合体、融点163℃、MFR16)、低融点樹脂Bに高密度ポリエチレン樹脂(融点131℃、MFR:16g/10分)を使用し、分割型複合繊維用口金を用いて、樹脂Aと樹脂Bの容積比率50/50、単糸デニール7.0dtexの分割型複合繊維を紡糸した。得られた未延伸糸は90℃、3.8倍で延伸し、35kg/cmで加圧された表面が平面の金属ロールの間を通過させた後、抄紙用分散剤を付着させ、5mmに切断した。得られた複合繊維の断面は扁平形状に変形され、A、B両成分の接触界面の一部が剥離した図1〜図6に示した繊維断面形状を有する分割型複合繊維が混在したものであった。

この短繊維にポリプロピレン(芯)/低密度ポリエチレン(鞘)の鞘芯複合繊維(EAC繊維、2.2dtex×5mm、チッソ(株))を20重量%添加し、角型シートマシン(25cm×25cm)を用い、抄紙法でウェブとした。熊谷理器工業社製ヤンキードライヤーを用い、105℃で3分間乾燥、予備接着を行い、ウェブを得た。前記高圧液体流処理を行った後、さらに80℃のドライヤーで乾燥させ、目付55g/m2の分割型複合繊維を用いた繊維成形体を得た。

【0071】

実施例5

高融点樹脂Aにポリプロピレン樹脂(ポリプロピレン単独重合体、融点163℃、MFR:35g/10分)、低融点樹脂Bに直鎖状低密度ポリエチレン樹脂(融点131℃、MFR:26g/10分)を使用し、分割型複合繊維用口金を用いて、樹脂Aと樹脂Bの容積比率50/50、単糸デニール8.0dtexの分割型複合繊維を紡糸した。得られた未延伸糸は90℃、4.5倍で延伸し、5kg/cmで加圧された表面が平面の金属ロールの間を通過させた後、抄紙用分散剤を付着させ、5mmに切断した。得られた複合繊維の断面は扁平形状に変形され、A、B成分の接触界面の一部が剥離した図1〜図6に示した繊維断面形状を有する分割型複合繊維が混在したものであった。水分率は20重量%であった。

この短繊維にポリプロピレン(芯)/低密度ポリエチレン(鞘)の鞘芯複合繊維(EAC繊維、2.2dtex×5mm、チッソ(株))を20重量%添加し、角型シートマシン(25cm×25cm)を用い、抄紙法でウェブとした。熊谷理器工業社製ヤンキードライヤーを用い、105℃で3分間乾燥、予備接着を行い、ウェブを得た。前記高圧液体流処理を行った後、さらに80℃のドライヤーで乾燥させ、目付50g/m2の分割型複合繊維を用いた繊維成形体を得た。

【0072】

実施例6

高融点樹脂Aにポリプロピレン樹脂(ポリプロピレン単独重合体、融点163℃、MFR:16g/10分)、低融点樹脂Bに直鎖状低密度ポリエチレン樹脂(融点123℃、MFR:20g/10分)を使用し、分割型複合繊維用口金を用いて、樹脂Aと樹脂Bの容積比率50/50、単糸デニール7.0dtexの分割型複合繊維を紡糸した。得られた未延伸糸は90℃、3.7倍で延伸し、5kg/cmで加圧された表面が平面の金属ロールの間を通過させた後、抄紙用分散剤を付着させ、5mmに切断した。得られた複合繊維の横断面は扁平形状に変形され、A、B成分の接触界面の一部が剥離した図1〜図6に示した繊維断面形状を有する分割型複合繊維が混在したものであった。水分率は20重量%であった。

この短繊維にポリプロピレン(芯)/低密度ポリエチレン(鞘)の鞘芯複合繊維(EAC繊維、2.2dtex×5mm、チッソ(株))を20重量%添加し、角型シートマシン(25cm×25cm)を用い、抄紙法でウェブとした。熊谷理器工業社製ヤンキードライヤーを用い、105℃で3分間乾燥、予備接着を行い、ウェブを得た。前記高圧液体流処理を行った後、さらに80℃のドライヤーで乾燥させ、目付50g/m2の分割型複合繊維を用いた繊維成形体を得た。

【0073】

実施例7

本発明の分割型複合繊維の断面形状を図7を主体とするものに変更した以外は、実施例1に準拠して、目付60g/m2の分割型複合繊維を作製し、該分割型複合繊維を用いて繊維成型体を得た。

【0074】

実施例8

高融点樹脂Aにポリプロピレン樹脂(ポリプロピレン単独重合体、融点163℃、MFR:16g/10分)、低融点樹脂Bに高密度ポリエチレン樹脂(融点131℃、MFR:16g/10分)を使用し、分割型複合繊維用口金を用いて、樹脂Aと樹脂Bの容積比率50/50、単糸デニール7.5dtexの分割型複合繊維を紡糸した。引き取り工程において、アルキルフォスフェートK塩を付着させた。得られた未延伸糸を90℃、4.3倍で延伸した。さらに機械捲縮付与装置のクリンパーロールを3kg/cmに加圧して機械捲縮をかけ51mmに切断した。得られた複合繊維の断面は扁平形状に変形され、A、B成分の接触界面の一部が剥離した図1〜図6に示した繊維断面形状を有する分割型複合繊維が混在したものであった。

得られた短繊維をローラカード機にてウェブとし、前記高圧液体流処理を行った後、さらに80℃のドライヤーで乾燥させて、目付50g/m2の分割型複合繊維を用いた繊維成形体を得た。剥離率が10%であるが、ローラカード機の通過時に分割が過度に進行することはなく、ウェブの地合は良好であった。

【0075】

実施例9

高融点樹脂Aにポリプロピレン樹脂(プロピレン単独重合体、融点163℃、MFR:20g/10分)、低融点樹脂Bに高密度ポリエチレン樹脂(融点131℃、MFR:20g/10分)を使用し、分割型複合繊維用口金を用いて、樹脂Aと樹脂Bの容積比率50/50、中空率10%の分割型複合繊維をスパンボンド法にて紡糸した。紡糸口金より吐出した複合繊維群をエアーサッカーに導入して牽引延伸し、単糸デニール2.0dtexの複合長繊維とし、続いてエアーサッカーより排出された前記長繊維群を、帯電装置により同電荷を付与せしめ帯電させた後、反射板に衝突させて開繊し、開繊した長繊維群を裏面に吸引装置を設けた無端ネット状コンベヤー上に、長繊維ウェブとして捕集した。該長繊維ウェブを表面が平面の金属ロールを圧力10kg/cmで加圧し、120℃に加熱した面積率15%のエンボスロール機にて処理し、前記高圧液体流処理を行った後、さらに80℃のドライヤーで乾燥させて図1〜図6に示した繊維横断面形状を有する分割型複合繊維が混在した目付50g/m2の繊維成形体とした。

【0076】

実施例10

高融点樹脂Aにポリプロピレン樹脂(ポリプロピレン単独重合体、融点163℃、MFR:16g/10分)、融点樹脂Bに発泡剤(ダイブローHC、大日精化(株)製)を0.4重量%添加した高密度ポリエチレン樹脂(融点131℃、MFR:16g/10分)を使用し、分割型複合繊維用口金を用いて、樹脂Aと樹脂Bの容積比率50/50、単糸デニール7.5dtexの分割型複合繊維を紡糸した。得られた未延伸糸は90℃、4.0倍で延伸し、5kg/cmで加圧された表面が平面の金属ロールの間を通過させた後、抄紙用分散剤を付着させ、5mmに切断した。得られた複合繊維の断面は扁平形状に変形され、A、B成分の接触界面の一部が剥離し、各分割セグメント内に気泡が含まれた図1〜図6に示した繊維断面形状を有する分割型複合繊維が混在したものであった。水分率は20重量%であった。

この短繊維にポリプロピレン(芯)/低密度ポリエチレン(鞘)の鞘芯複合繊維(EAC繊維、2.2dtex×5mm、チッソ(株))を20重量%添加し、角型シートマシン(25cm×25cm)を用い、抄紙法でウェブとした。熊谷理器工業社製ヤンキードライヤーを用い、105℃で3分間乾燥、予備接着を行い、ウェブを得た。前記高圧液体流処理を行った後、さらに80℃のドライヤーで乾燥させ、目付55g/m2の分割型複合繊維を用いた繊維成形体を得た。

【0077】

実施例11、12

実施例8の本発明の分割型複合繊維をローラカード機にて目付10g/m2のウェブ(Cと略す)とポリプロピレン(芯)/高密度ポリエチレン(鞘)の鞘芯複合繊維(ESC繊維、チッソ(株))2.2dtex×51mmの短繊維をローラカード機にて目付10g/m2のカードウェブ(Dと略す)を得た。Cを上層、Dを下層に積層したもの(実施例11)及びCを上下層、Dを中層に積層したもの(実施例12)を各々、前記高圧液体流処理を行った後、80℃のドライヤーで乾燥させて繊維成形体を得た。さらに、この繊維成形体を拭き取り用ワイパーに使用したところ、ともに非常に優れた拭き取り性を示した。

【0078】

実施例13

高融点樹脂Aにポリプロピレン樹脂(ポリプロピレン単独重合体、融点163℃、MFR:20g/10分)、低融点樹脂Bに高密度ポリエチレン樹脂(融点131℃、MFR:20g/10分)を使用し、分割型複合繊維用口金を用いて、樹脂Aと樹脂Bの容積比率50/50、中空率10%の分割型複合繊維をスパンボンド法にて紡糸した。紡糸口金より吐出した複合繊維群をエアーサッカーに導入して牽引延伸し、単糸デニール2.0dtexの複合長繊維とし、続いてエアーサッカーより排出された前記長繊維群を、帯電装置により電荷を付与せしめ帯電させた後、反射板に衝突させて開繊し、開繊した長繊維群を裏面に吸引装置を設けた無端ネット状コンベヤー上に、長繊維ウェブとして捕集し、目付10g/m2のウェブを中層とした。

次に芯側にポリプロピレン樹脂(ポリプロピレン単独重合体、融点163℃、MFR:20g/10分)、鞘側に高密度ポリエチレン(融点131℃、MFR:20g/10分)を用いて、樹脂Aと樹脂Bの容積比率50/50とし、単糸デニール2.0dtexの鞘芯複合繊維をスパンボンド法で紡糸して目付5.0g/m2のウェブを中間層の上下に積層した。

さらに該長繊維ウェブを表面が平面の金属ロールを圧力20kg/cmで加圧し、中間層が図1〜図6に示した繊維断面形状の混在した分割型複合繊維のウェブとした後、120℃に加熱した面積率15%のエンボスロール機にて処理し、前記高圧液体流処理を行った後、さらに80℃のドライヤーで乾燥させ本発明の分割型複合繊維を用いた繊維成形体とした。該繊維成形体を大人用オムツの表面材として使用したところ、耐水圧、不織布強力等に優れ、吸収性物品として非常に良好なものであった。

【0079】

比較例1

延伸後、加圧された金属ロールに延伸糸を通さず、図13に示した繊維断面形状にする以外は、実施例1に準拠して、目付55g/m2の分割型複合繊維を得、ついで該複合繊維を用いて繊維成形体とした。

【0080】

比較例2

延伸後、加圧された金属ロールに延伸糸を通さず、図13に示した繊維断面形状にする以外は、実施例6に準拠して、目付50g/m2の分割型複合繊維を作製し、該複合繊維を用いて繊維成形体とした。

【0081】

比較例3

加圧された金属ロールに通さず、図13に示した繊維断面形状にする以外は、実施例9に準拠して、目付50g/m2の分割型複合繊維を作製し、該複合繊維を用いて繊維成形体とした。

【0082】

実施例1〜10、比較例1〜3の紡糸・延伸条件、繊維物性、形状、不織布物性、分割率等を表1及び表2に示した。

【0083】

【表1】

【0084】

【表2】

【0085】

表1、2から明らかなように、本発明の分割型複合繊維を用いた実施例1〜13の繊維成形体は、比較例1〜3のそれと比べて、同条件でも高度に分割している。即ち、従来のような高水圧の高圧液体流処理を行わなくても、分割細繊化が容易に進行するため、抄紙用短繊維であっても地合が乱れることなく分割が可能であり、さらに高圧液体流処理のコストも大幅に削減することができる。さらにスパンボンド法で得られた繊維集合体であっても高度に分割させることができることが分かる。

【0086】

【発明の効果】

本発明の分割型複合繊維は、非常に分割し易いため、特別に易分割させるための添加剤を一切添加せずに、物理衝撃を大きくしなくても極細繊維化が容易に行えるため、特に抄紙用の短繊維として好適に使用でき、緻密で地合いの良い繊維成形体を作製することができる。

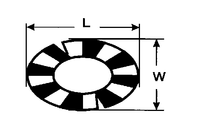

【図面の簡単な説明】

【図1】本発明に用いられる分割型複合繊維の繊維断面の1模式図

【図2】本発明に用いられる分割型複合繊維の繊維断面の1模式図

【図3】本発明に用いられる分割型複合繊維の繊維断面の1模式図

【図4】本発明に用いられる分割型複合繊維の繊維断面の1模式図

【図5】本発明に用いられる分割型複合繊維の繊維断面の1模式図

【図6】本発明に用いられる分割型複合繊維の繊維断面の1模式図

【図7】本発明に用いられる分割型複合繊維の繊維断面の1模式図

【図8】本発明に用いられる分割型複合繊維の繊維断面の1模式図

【図9】本発明に用いられる分割型複合繊維の繊維断面の1模式図

【図10】本発明に用いられる分割型複合繊維の繊維断面の1模式図

【図11】本発明に用いられる分割型複合繊維の繊維断面の1模式図

【図12】本発明に用いられる分割型複合繊維の繊維断面の1模式図

【図13】比較例に用いられる分割型複合繊維の繊維断面の1模式図

【符号の説明】

L(長軸):複合繊維の繊維断面における繊維外周部の最も長い部分

W(短軸):該長軸と直交し、かつ繊維外周部の最も短い部分[0001]

BACKGROUND OF THE INVENTION

The present invention relates to a polyolefin-based segmented composite fiber excellent in segmentability, a method for producing the same, and a fiber molded body using the fiber. More specifically, it is a composite fiber comprising at least two components of a polyolefin-based resin, each component being alternately arranged in the fiber cross section, and having a hollow portion inside the fiber, the cross section of the fiber being specified by external stress. Each component that is deformed into a flat shape and constitutes the fiber Partially peeled structure The present invention relates to a split-type composite fiber having a fiber, a production method thereof, and a fiber molded body using the fiber. The fiber molded body can be suitably used in the field of industrial materials such as battery separators, wipers and filters, and the field of sanitary materials such as diapers, napkins and wipers.

[0002]

[Prior art]

Conventionally, it is known to use a sea-island type or split type composite fiber as a method of obtaining ultrafine fibers. In the method using the sea-island type composite fiber, a combination of a plurality of components is spun to form a sea-island type composite fiber, and one component of the obtained composite fiber is dissolved and removed to obtain ultrafine fibers. Although this method can obtain very fine fibers, it is uneconomical for dissolving and removing one component.

[0003]

On the other hand, the method using split-type composite fiber is a composite fiber obtained by spinning a combination of a plurality of components, and the resulting composite fiber is subjected to physical stress and a difference in shrinkage of the resin component constituting the fiber with respect to chemicals. Utilizing this, the split type composite fiber is divided into a large number of fibers to obtain ultrafine fibers.

[0004]

For example, as a composite fiber combining a plurality of component resins, a split composite fiber represented by a combination of a polyester resin and a polyolefin resin, a combination of a polyester resin and a polyamide resin, or a combination of a polyamide resin and a polyolefin resin Although the splitting easily proceeds due to physical stress, the ultrafine fibers obtained by splitting and the fiber molded body made of the same are mixed with fibers made of different polymers, and are required to have chemical resistance. At present, the use in the material field is restricted.

[0005]

On the other hand, in the combination of polyolefin resins having excellent chemical resistance, the compatibility of the resin is relatively good compared to the combination of the above-mentioned different types of polymers. It was necessary to increase the impact. For this reason, the obtained fiber molded body (nonwoven fabric) has a divided part and a part that is not divided, or the composite fiber is moved by a physical impact, and a so-called thick part and a thin part can be formed. However, it was unsatisfactory because it caused unevenness and the formation became worse, and it was necessary to significantly reduce the processing speed of the high-pressure liquid flow treatment.

[0006]

In order to improve this, Japanese Patent Application Laid-Open No. 4-28922 discloses a split type composite fiber composed of the same kind of polymers by using the same kind of resin to which organosiloxane and a modified product thereof are added. It has been proposed that it can be easily divided even if it exists. However, although the splitting property is somewhat improved by such a method, the strength of the fiber molded body (nonwoven fabric) using the fiber obtained by splitting the split-type conjugate fiber is reduced, or the workability is poor during the secondary processing. There are many problems such as.

[0007]

[Problems to be solved by the invention]

An object of the present invention is to provide a polyolefin-based split composite fiber improved in these disadvantages, a method for producing the same, and a fiber molded body using the fiber. That is, a polyolefin-based splitting composite fiber that is excellent in splitting properties even if it is used for wet fibers, etc., without using any special additives for improving splitting properties, a method for producing the same, and fibers using the fibers It is to provide a molded body.

[0008]

The inventors of the present invention have made extensive studies in order to achieve the above object. As a result, it is composed of at least two component polyolefin resins, and in the fiber cross section, each component is alternately arranged and has a hollow portion inside the fiber, and the cross section of the composite fiber is specified by external stress. It was found that a fiber molded body using a composite fiber that is deformed into a flat shape and having a structure in which a part of each component constituting the composite fiber is peeled off can improve the conventional defects. Based on this, the present invention has been completed.

[0009]

[Means for Solving the Problems]

The present invention includes the following.

(1) Consisting of at least two component polyolefin-based resins, in the fiber cross section, each component is alternately arranged and is a composite fiber having a hollow portion inside the fiber, and the cross section of the fiber is flattened by external stress The deformation rate (short axis W / long axis L) is 0.2 to 0.9, and each component constituting the fiber is deformed. Partially peeled structure It is characterized by having For splitting and finening processing by physical stress Polyolefin-based split composite fiber.

[0010]

(2) The polyolefin-based split composite fiber according to (1) above, wherein 10% or more of the contact interface of each component is peeled in the shape of the cross section of the composite fiber.

[0011]

(3) The polyolefin-based split composite fiber according to any one of (1) or (2), wherein each component is alternately arranged radially in the shape of the fiber cross section of the composite fiber.

[0012]

(4) The polyolefin-based split composite fiber according to any one of the items (1) to (3), wherein the combination of at least two components of the polyolefin-based resin is a polypropylene-based resin and a polyethylene-based resin.

[0013]

(5) Any of the items (1) to (4), wherein the average single yarn fineness before splitting of the composite fiber is 0.6 to 10 dtex, and the average single yarn fineness after splitting is less than 0.6 dtex. 1. Polyolefin-based split composite fiber according to item 1.

[0014]

(6) A fiber molded body containing at least 30% by weight or more of the split-type conjugate fiber according to any one of (1) to (5), wherein 50% by weight or more of the conjugate fiber is split.

[0015]

(7) The fiber molded body according to (6), wherein the fiber molded body is a fiber assembly.

[0016]

(8) The fiber molded body according to any one of (6) or (7), wherein the fiber molded body is a fiber assembly obtained by a spunbond method.

[0017]

(9) A laminated fiber molded body obtained by laminating sheets on one or both sides of the fiber molded body according to any one of (6) to (8).

[0018]

(10) A laminated fiber molded body obtained by laminating the fiber molded body according to any one of (6) to (8) above on both surfaces of a sheet.

[0019]

(11) The laminated fiber molded article according to (9) or (10), wherein the sheet is selected from at least one of a nonwoven fabric, a film, a knitted fabric, and a woven fabric.

[0020]

(12) Absorbent article using the fiber molded body according to any one of (6) to (8) or the laminated fiber molded body according to any one of (9) to (11). .

[0021]

(13) A wiper using the fiber molded body according to any one of (6) to (8) or the laminated fiber molded body according to any one of (9) to (11). .

[0022]

(14) A battery separator using the fiber molded body according to any one of (6) to (8) or the laminated fiber molded body according to any one of (9) to (11).

[0023]

(15) A method for producing a polyolefin-based split composite fiber as described in (1) above, At least two-component polyolefin-based resin is alternately arranged, and the composite fiber having a hollow portion inside is subjected to pressing treatment and / or rubbing treatment to deform the composite fiber, and the two-component contact interface Exfoliate part A method for producing a polyophine-based split composite fiber characterized by the above.

(16) A method for producing a fiber molded body, characterized in that a web containing the polyolefin-based split composite fiber according to any one of (1) to (5) is split and finely divided by physical stress.

[0024]

DETAILED DESCRIPTION OF THE INVENTION

Hereinafter, the present invention will be described in detail.

The polyolefin-based resin used for the polyolefin-based split conjugate fiber of the present invention is an aliphatic α-olefin having 2 to 8 carbon atoms, such as ethylene, propylene, 1-butene, 1-pentene, 4-methyl-1- Homopolymers of α-olefins such as pentene, 3-methyl-1-butene, 1-hexene, 1-octene or copolymers of two or more of these α-olefins, these α-olefins and other olefins, and And / or a small amount of other ethylenically unsaturated monomers such as butadiene, isoprene, 1,3-pentadiene, styrene, α-methylstyrene, polyvinyl alcohol, polyvinyl acetate, polyacrylic acid ester and the like. Mention may be made of copolymers and mixtures of two or more thereof.

[0025]

Typical examples include polypropylene resins and polyethylene resins. Examples of the polypropylene resin include a propylene homopolymer, a copolymer of propylene containing 70% by weight or more of propylene and the above α-olefin other than propylene, such as an ethylene-propylene copolymer and an ethylene-propylene-butene copolymer. A polymer etc. can be mentioned.

[0026]

Examples of the polyethylene-based resin include high-density polyethylene (HDPE), linear low-density polyethylene (LLDPE), and low-density polyethylene (LDPE), among which high-density polyethylene is preferable.

[0027]

The polyolefin-based split conjugate fiber of the present invention can be arbitrarily combined with a polyolefin-based resin composed of at least two components among the above, but a more preferable combination is high in chemical resistance and advantageous in cost. A suitable two-component combination of polypropylene resin and polyethylene resin is preferred.

[0028]

In the combination of two components, a polypropylene resin and a polyethylene resin, preferably used for the polyolefin-based split composite fiber of the present invention, the polypropylene resin becomes a high melting point resin (component A). Specific examples of such a polypropylene resin include syndiotactic polypropylene and isotactic polypropylene polymerized with a Ziegler-Natta catalyst, a metallocene catalyst, or the like. The MFR of the polypropylene resin as a raw material is not particularly limited as long as it can be melt-spun, and the MFR after fiber forming is within a range of 10 to 100 g / 10 minutes by changing the spinning conditions and the like. There is no particular problem as long as it is a polypropylene resin having MFR. More preferably, a polypropylene resin having an MFR such that the MFR after fiber molding is 10 to 70 g / 10 min is used. When a polypropylene resin having an MFR such that the MFR after fiber molding is 10 g / 10 min or less is used, the hollow ratio of the resulting composite fiber can be maintained high, but it is formed (spun) into fine fibers with good spinnability. It becomes difficult. Moreover, when MFR after fiber shaping | molding exceeds 100 g / 10min, it is difficult to maintain the hollow rate of the obtained composite fiber high, and when making it into a filament, spinnability may worsen.

[0029]

On the other hand, the polyethylene resin is a low melting point resin (component B) lower than the melting point of the polypropylene resin, specifically, high density polyethylene (HDPE), linear low density polyethylene (LLDPE), low density. An example is polyethylene (LDPE). Moreover, the mixture of these 2 or more types may be sufficient. The MFR of the polyethylene resin as a raw material may be within a range that can be melt-spun, and it is a polyethylene resin having an MFR in which the MFR after fiber forming is within a range of 10 to 100 g / 10 minutes by changing the spinning conditions and the like. If there is no particular problem. More preferably, a polyethylene resin having an MFR such that the MFR after fiber molding is 10 to 60 g / 10 min is used. When a polyethylene resin having an MFR such that the MFR after fiber molding is 10 g / 10 min or less is used, the hollowness of the resulting composite fiber can be maintained high, but the spinnability becomes extremely poor, and the fiber is molded into a thin fiber. It becomes difficult to do. Moreover, when MFR exceeds 100 g / 10min, it is difficult to maintain the hollow ratio of the obtained composite fiber, and when it is made into a filament, spinnability may be deteriorated.

[0030]

Of the at least two component polyolefin resins constituting the polyolefin splitting conjugate fiber of the present invention, when the resin having the highest melting point is the component A, the MFR of the component A is MFR-A, and the resin having the lowest melting point The MFR ratio (MFR-A / MFR-B) is preferably 0.1 to 5, more preferably, when the MFR of the B component is MFR-B when 0.5-3. If this value is less than 0.1 or exceeds 5, the flowability in the two-component die during melt spinning, the difference in melt tension after being discharged into a hollow shape, the difference in viscosity increase during cooling For example, it becomes difficult to maintain the hollowness of the obtained composite fiber and to form (spin) the fiber with good spinnability due to factors such as an increase in the size.

[0031]

The polyolefin-based resin related to the present invention further includes an antioxidant, a light stabilizer, an ultraviolet absorber, a neutralizing agent, a nucleating agent, an epoxy stabilizer, a lubricant, an antibacterial agent, as long as the effects of the present invention are not impaired. Additives such as flame retardants, antistatic agents, pigments, plasticizers and hydrophilic agents may be added as necessary.

[0032]

If the shape of the polyolefin-based split composite fiber of the present invention has a hollow portion inside the fiber and the fiber cross section has a shape in which the fiber outer peripheral portion and / or the fiber inner peripheral portion is deformed, the shape is There is no particular limitation. The shape of the fiber outer peripheral portion and the fiber inner peripheral portion of the composite fiber can be a circular shape or an irregular shape. Examples of the irregular shape include a flat shape and a polygon such as a triangle to an octagon. For example, in the split type composite fiber composed of polyolefin resin of A and B components as shown in FIGS. 1 to 12, a cross-sectional shape in which the A and B2 components are alternately arranged can be exemplified. Of course, in a split type composite fiber composed of a multi-component polyolefin-based resin, it is preferable to have a cross-sectional shape in which each component is alternately arranged.

[0033]

When the split type composite fiber obtained by the present invention is split by high-pressure liquid flow treatment or the like, the average single fiber fineness of the split ultrafine fiber is preferably less than 0.6 dtex, particularly preferably 0.3 dtex or less. Accordingly, the number of segments of the hollow split-type composite fiber whose inside is deformed may be determined so that the average fineness of the ultrafine fiber is less than 0.6 dtex, and if the number of segments of the split-type composite fiber is large Although there is an advantage that the fineness after the division is reduced, it is actually preferable to set the number of segments to 4 to 32 from the viewpoint of easy fiber production. In addition, the fineness of each segment need not be the same, and if the split-type conjugate fiber is not completely divided, there are a plurality of different values between the undivided split-type conjugate fiber and the completely divided ultrafine fiber. The fibers of different fineness may be mixed.

[0034]

Next, the fiber cross section of the split type composite fiber of the present invention will be described.

The fiber cross section of the split composite fiber of the present invention is a composite fiber in which at least two component polyolefin resins are alternately arranged and has hollow portions inside the fiber, and the cross section of the composite fiber is deformed into a flat shape. And each component of the fiber Partially peeled structure This is a split type composite fiber characterized by Among these, a structure in which almost the same effect can be obtained regardless of which part of the fiber surface receives external stress, for example, a structure in which each component is arranged radially is preferable. Furthermore, in order to achieve easy division, it is more preferable that a part of each divided segment of each component is exposed at least on the outer periphery of the fiber.

[0035]

The fiber cross section of the composite fiber is deformed into a flat shape when the fiber inside where the polyolefin-based resin is alternately arranged has a hollow inside, and the outer periphery of the fiber after spinning or stretching is somehow This means that the composite fiber is flattened by being pressed and deformed by external stress. The means for applying external stress for deforming into a flat shape is not particularly limited. For example, a method of deforming the composite fiber by roll-to-roll pressurization (Method A), passing through the roll surface or the end of a square member A method of deforming the composite fiber by rubbing (Method B), a method of deforming the composite fiber with a pressure that can barely pass through the fiber through a gap gradually narrowing from a wide opening (Method C), A method of deforming the composite fiber by applying twist and tensile tension by twisting in a state where the composite fiber is focused (Method D), or a combination of these methods may be used. In addition, even when cutting to a predetermined length after applying the external stress, physical stress is applied to the cut surface of the rotor cutter, guillotine cutter, etc., and the contact interface of each component is easily divided. When the cross-sectional shape of the composite fiber is deformed into a flat shape by the various methods described above, it is important that a part of the contact interface between the two components is peeled off at the same time.

[0036]

The cross-sectional deformation ratio (short axis W / long axis L) of the polyolefin-based split composite fiber of the present invention is 0.2 to 0.9, more preferably 0.2 to 0.8, and still more preferably 0.3 to 0.9. 0.8. Here, the deformation rate is when the longest portion of the outer periphery of the fiber in the fiber cross section of the conjugate fiber is the long axis L, the shortest portion of the outer periphery of the fiber is perpendicular to the long axis, and the short axis is W This is represented by the ratio of short axis W / long axis L. If the deformation ratio is less than 0.2, the hollow portion is completely crushed and further deformed by being crushed to the desired cross-sectional shape of each component. Therefore, a fiber obtained by using ultrafine fibers after splitting and finening The strength of the molded body (nonwoven fabric) will be very weak. On the other hand, when the deformation ratio exceeds 0.9, external stress such as roll pressurization is weak, and it is not possible to give distortion to the interface of each component so as to remarkably improve the splitting property.

[0037]

In the fiber cross section of the polyolefin-based split composite fiber of the present invention, the contact interface of each constituent component Some peel This makes it easier to divide. More preferably, the contact interface of each component is peeled off by 10% or more. The contact interface generated according to the number of divided segments of the composite fiber may be peeled off only a part of the arbitrary contact interface. . It suffices that the peeled portion of the entire contact interface of the fibers is peeled off by 10% or more. If the peeled portion is less than 10%, it tends to be easily divided, but it becomes difficult to divide at a high dividing rate by high-pressure liquid flow treatment at a low water pressure. On the other hand, when 10% or more of the contact interface of each component is peeled off, the interface in the vicinity receives the physical stress from the outside surely, so that even if it does not reach the peeling, it is surely distorted. In addition, it is possible to split finer with lower energy.

[0038]

In order to obtain a fiber cross section of the split composite fiber of the present invention, it is preferable that the area occupied by the hollow portion inside the fiber at the spinning stage, the so-called hollow ratio is 5% to 40%, more preferably 10 to 30%. . The hollow shape is not particularly limited. When the hollowness is less than 5%, the contact area between adjacent components is large, and even if the composite fiber is deformed into a flat shape by an external stress, it is difficult to make the flat shape flat. As a result, the degree of easy division becomes small. If the hollowness exceeds 40%, the contact area between adjacent components is small, and deformation into a flat shape due to physical stress easily proceeds, but undivided fibers are produced while maintaining stringiness and productivity. It becomes difficult to do. That is, by setting the hollow ratio to 5% to 40%, more preferably 10 to 30%, it is possible to easily deform the flat shape of the present invention while maintaining the stringiness and productivity.

[0039]

Furthermore, the hollow part inside the fiber is not limited to only one central part, and the hollow part may be two or more, or may be arranged anywhere in the fiber cross section. In addition, when a foaming agent is mixed into one of the A component and the B component and molded into a composite fiber, a very fine hollow portion can be present in either the A component or the B component by the action of the foaming agent. . This hollow portion exists at the boundary between the A and B components and reduces the contact area between adjacent components. As a result, it is possible to remarkably improve the easy division property.

[0040]

Examples of the foaming agent include azodicarbonamide, barium azodicarboxylate, N, N-dinitrosopentamethylenetetramine, p-toluenesulfonyl semicarbazide, trihydrazinotriazine and the like.

[0041]

In the polyolefin-based split composite fiber of the present invention, the composite ratio of the composite fiber composed of at least two component polyolefin resins is 10/90 to 90/10% by weight and the total of the resin components used is within the range. It may be 100% by weight, more preferably 30/70 to 70/30% by weight, and most preferably composed of a two-component polyolefin resin and the composite ratio is 50/50% by weight. By setting the composite ratio in such a range, the cross-sectional shape in which the used at least two-component polyolefin resin is uniformly arranged is obtained. Furthermore, the fineness after splitting and finening is constant, and a more uniform fiber assembly can be obtained.

[0042]

The single yarn fineness before splitting of the polyolefin-based split conjugate fiber of the present invention is not particularly limited, but is preferably 0.6 to 10 dtex, and more preferably 1 to 6 dtex. If the single yarn fineness is less than 0.6 dtex, the spinnability in the melt spinning process tends to be reduced. On the other hand, if it exceeds 10 dtex, it becomes difficult to obtain a dense fiber assembly with high uniformity even when the obtained web is divided and finely divided by a high-pressure water flow method or the like. The average single yarn fineness after division is preferably less than 0.6 dtex, and more preferably less than 0.5 dtex. If it is 0.6 dtex or more, it will be difficult to obtain a uniform and comfortable flexible fiber molded article by fineness, which is the greatest characteristic of split-type composite fibers.

[0043]

Hereinafter, as an example of the split composite fiber of the present invention, a method for producing a split composite fiber in which a polypropylene resin and a high density polyethylene resin are combined will be exemplified.

A long fiber made of the above resin is spun using an ordinary melt spinning machine. At the time of spinning, it is preferable to spin at a spinning temperature of 200 to 330 ° C., and the take-up speed is preferably about 40 m / min to 1500 m / min. Stretching may be performed by multistage stretching as necessary, and the stretching ratio is usually about 3 to 9 times. Further, in the case of the method A in which the composite fiber is deformed into a flat shape, for example, the roll-to-roll pressure is set in a range of 1 kg / cm to 50 kg / cm to deform into a flat shape, and the contact interface of each component is peeled off or Then, a strain is applied to obtain the polyolefin-based split composite fiber of the present invention. Furthermore, it cut | disconnects to predetermined length and is set as a short fiber. The obtained tow may be crimped as necessary.

[0044]

Although the roll which pressurizes this composite fiber and deform | transforms into a flat shape is not specifically limited, For example, a metal roll and a metal roll, a metal roll and a rubber roll, a rubber roll and a rubber roll can be illustrated. Further, the roll surface may be flat or uneven. Examples of the concavo-convex shape include those having convex portions such as straight lines or wavy lines orthogonal to the roll rotation direction. Preferred among these rolls are a combination of metal rolls whose surfaces are flat and a combination of metal rolls where one is a flat surface and the other is an uneven surface. The process of pressurizing and deforming can be performed at any place in the spinning and stretching process. However, the roll is pressed between the stretching process and the cutting process, that is, after the stretching process, to deform the composite fiber. And then cut to a predetermined length. This is because the stretched fiber has the most crystallized and rigid structure during the manufacturing process, and therefore, when pressed with a roll or the like and deformed into a flat shape, the contact interface to each component is likely to be distorted. Moreover, in the conventional equipment, it is possible to perform crimping between crimping apparatuses without using a new roll pressurizing apparatus.

[0045]

Although the manufacturing process of the short fiber has been disclosed above, the long fiber tow can be made into a web by a fiber separation guide or the like without cutting the tow. Thereafter, it is subjected to a high-order processing step as necessary, and is formed into a fiber molded body according to various uses. In addition, a fiber molded body that is wound as a filament yarn after spinning and is knitted or woven to form a knitted fabric, or a fiber molded body that is knitted or woven after the short fiber is spun into a knitted fabric. You may shape | mold.

[0046]

Here, examples of the fiber molded body include a woven fabric, a knitted fabric, a nonwoven fabric, and a non-woven fiber assembly. The non-woven fiber aggregate refers to a web-like material made uniform by a method such as a card method, an airlaid method, or a papermaking method. Moreover, as a fiber molded object, what laminated | stacked various woven fabric, a knitted fabric, a nonwoven fabric, a fiber assembly, or a rod-shaped article and a filling thing does not have any problem.

[0047]

In this step, after spinning the fiber, a surfactant can be attached for the purpose of preventing the static electricity of the fiber and improving the processability of the fiber molded body, for example, imparting dispersibility and smoothness during papermaking. The type and concentration of the surfactant are appropriately adjusted according to the application. As a method of attachment, a roller method, a dipping method, or the like can be used. The attachment may be performed in any of a spinning process, a drawing process, and a crimping process. Furthermore, it is also possible to attach the surfactant after molding to, for example, a fiber molded body other than the spinning process, the stretching process, and the crimping process, regardless of whether the fibers are short fibers or long fibers.

[0048]

The fiber length of the polyolefin-based split composite fiber of the present invention is not particularly limited, but when a web is produced using a card machine, generally a 20 to 76 mm one is used, and the papermaking method or airlaid method is used. In general, fibers having a fiber length of 2 mm to 20 mm are preferably used. If the fiber length is less than 2 mm, the fiber may move due to physical impact, and the fiber itself may be difficult to receive energy required for division. Further, when the fiber length greatly exceeds 76 mm, it is difficult to form a web with a card machine or the like, and it is difficult to obtain a uniform web.

[0049]

As an example of a method for producing a fiber molded body comprising the polyolefin-based split composite fiber of the present invention, a method for producing a nonwoven fabric is illustrated. For example, using the short fibers of the polyolefin-based split composite fibers, a web having a required weight per unit area is prepared by a card method, an airlaid method, or a papermaking method. The fiber produced by the above method can be obtained by dividing and finely dividing the web by a known method such as a needle punch method or a high-pressure liquid flow treatment. Furthermore, this fiber molded body can be further processed by a known processing method such as hot air or hot roll. Also, when a web composed of very short fibers such as a papermaking method is divided and finely divided by a known method such as a needle punch method or a high-pressure liquid flow process, the fibers are moved simultaneously with the division of the fibers due to the physical stress. Since there is a possibility of poor bonding, fibers that are heat-bonded at a melting point lower than the melting point of the resin constituting the split-type conjugate fiber of the present invention are mixed in advance, and a nonwoven fabric bonded with this low-melting fiber is produced. By doing so, poor formation can be suppressed.

[0050]

The basis weight of the fiber molded body is not particularly limited, but is 10 to 200 g / m. 2 Can be preferably used. The basis weight is 10g / m 2 If it is less than the above, in the case of splitting and finening with physical stress such as high-pressure liquid flow treatment, a nonwoven fabric with poor formation may be formed. The basis weight is 200 g / m 2 If it exceeds 1, the basis weight is high, a high-pressure water flow is required, and it may be difficult to perform uniform division with good texture.

[0051]

The fiber molded body of the present invention can be used by mixing other fibers with the split-type composite fiber of the present invention, if necessary, within a range that does not hinder the present invention. Examples of the other fibers include synthetic fibers such as polyamide, polyester, polyolefin, and acrylic, natural fibers such as cotton, wool, and hemp, regenerated fibers such as rayon, cupra, and acetate, and semi-synthetic fibers. It can mix arbitrarily by methods, such as.

[0052]

Next, the high-pressure liquid flow process will be described. As a high-pressure liquid flow apparatus used for high-pressure liquid flow treatment, for example, one or more injection holes having a hole diameter of 0.05 to 1.5 mm, particularly 0.1 to 0.5 mm, with a hole interval of 0.1 to 1.5 mm. A device arranged in multiple rows is used. A high-pressure liquid flow obtained by jetting from the jet holes at high water pressure is made to collide with the web placed on the porous support member. As a result, the undivided split composite fiber of the present invention is entangled and simultaneously refined by the high-pressure liquid flow. The injection holes are arranged in a row in a direction perpendicular to the traveling direction of the web. As the high-pressure liquid flow, normal temperature or warm water may be used, or other liquid may be arbitrarily used.

[0053]

The distance between the injection hole and the web is preferably 10 to 150 mm. If this distance is less than 10 mm, the formation of the fiber molded body obtained by this treatment is disturbed. On the other hand, if this distance exceeds 150 mm, the physical impact of the liquid flow on the web is weakened, resulting in entanglement and fine division. May not be adequately applied. The processing pressure of this high-pressure liquid stream is controlled by the production method and the required performance of the fiber molded body, but in general, it is 20 kg / cm. 2 ~ 200kg / cm 2 It is better to inject a high pressure liquid stream. Although it depends on the basis weight to be treated, etc., within the range of the treatment pressure, if the high-pressure liquid flow is processed by increasing the pressure from the low water pressure to the high water pressure sequentially, the entanglement and the web formation are not disturbed. Splitting and finening are possible. As the porous support member on which the web is placed when the high-pressure liquid flow is applied, for example, as long as the high-pressure liquid flow penetrates the web, such as a mesh screen or a perforated plate made of 50-200 mesh metal mesh or synthetic resin There is no particular limitation.

[0054]

In addition, after performing the high-pressure liquid flow treatment from one side of the web, by subsequently inverting the entangled web and performing the high-pressure liquid flow treatment, it is possible to obtain a dense and well-formed fiber molded body on both sides. it can. Furthermore, after performing a high-pressure liquid flow process, a water | moisture content is removed from the fiber molded object after a process. In removing this moisture, a known method can be employed. For example, after removing moisture to some extent using a squeezing device such as Mangroll, moisture can be completely removed using a drying device such as a hot air circulation dryer to obtain the fiber molded body of the present invention.

[0055]

The polyolefin-based segmented composite fiber of the present invention is easier to segment than conventional polyolefin-based segmented composite fibers, and can be segmented and made finer with less physical impact due to the high-pressure liquid flow. For this reason, in high-pressure liquid flow processing, which is the rate-limiting step of spunlace, and formation improvement by reducing the pressure of the high-pressure liquid flow, for example, in webs made of short fibers, such as papermaking, the pressure of the high-pressure liquid flow Can be reduced, and problems such as disordered formation of the fiber molded body and opening of through holes can be improved.

[0056]

Furthermore, a laminated fiber molded body (hereinafter referred to as A type) in which at least one sheet selected from a nonwoven fabric, a film, a knitted fabric, a woven fabric and the like is laminated on one side or both sides of the fiber molded body of the present invention, and further the fiber Conversely, it can also be used as a laminated fiber molded body (hereinafter referred to as B type) in which the molded body is laminated on both sides of the sheet.

In the case of the A type, it is preferable to laminate the fiber molded body subjected to the division treatment on one side or both sides of another sheet because the division efficiency is good. In the case of the B type, the fiber molded body is divided before and after the lamination, but the division treatment after the lamination is particularly preferable because an entanglement effect between the other sheet and the fiber molded body is obtained.

[0057]

As described above, even a split type composite fiber composed of a polyolefin-based resin can be easily split, and a dense and well-formed fiber molded body can be obtained. As a result, the polyolefin-based split composite fiber of the present invention is suitably used in industrial material fields such as battery separators and wipers that make use of the chemical resistance of resins and sanitary materials as compared to conventional polyolefin split-type composite fibers. can do.

[0058]

【Example】

EXAMPLES Hereinafter, although an Example and a comparative example demonstrate this invention, this invention is not limited by this. The terms and methods for measuring physical properties in Examples and Comparative Examples are as follows.

[0059]

(1) MFR: Measured according to JIS K7210.

Raw material polypropylene resin: Condition 14

Raw material polyethylene resin: Condition 4

Polyolefin resin after fiber molding: Condition 14

[0060]

(2) Hollow ratio before roll pressurization (%): Calculated by the following formula from a cross-sectional photograph of undivided fibers before being deformed into a flat shape by external stress.

Hollow ratio (%) = (cross-sectional area of hollow part / total cross-sectional area including hollow part of fiber) × 100

[0061]

(3) Fiber tensile strength and elongation: Measured according to JIS-L1017 method using an autograph AGS500D manufactured by Shimadzu Corporation at a test length of 100 mm and a tensile speed of 100 mm / min.

[0062]

(4) Deformation rate: The following values are calculated from a cross-sectional photograph of 10 arbitrarily selected split type composite fibers that are deformed into a flat shape by external stress and are not subjected to high-pressure liquid flow treatment, and are deformed from the average value. The rate was calculated.

Deformation rate = minor axis W / major axis L

Long axis L: longest part of the fiber outer peripheral part in the fiber cross section of the composite fiber

Short axis W: the shortest part of the outer periphery of the fiber perpendicular to the long axis

[0063]

(5) Peeling rate (%): It was calculated from the following formula from the length of the peeled portion and the length of the non-peeled portion of the contact interface of each component, using the photograph for which the deformation rate was obtained.

Peeling rate (%) = (length of peeled portion of all contact interface / length of non-peeled portion of all contact interface) × 100

[0064]

(6) Measurement of division ratio: A non-woven fabric after division is included with wax and sliced at right angles to the fiber axis with a microtome to create a sample piece. This is observed with a microscope, the cross-sectional image of the fiber is image-processed, and the total cross-sectional area (A) of the fibers in which 70% or more of the segments are divided and the total cross-sectional area (B) of the undivided fibers are measured. It was calculated by the following formula.

Division rate (%) = {A / (A + B)} × 100

[0065]

(7) Formation: For 10 panelists, the fiber distribution unevenness of the non-woven fabric (1 m square) after the division finening process was visually determined as follows.

○: Seven or more people felt that there were few spots and no through holes.

Δ: 4 to 6 people felt that there were few spots and no through holes.

X: 3 or less felt that there were few spots.

[0066]

(8) High-pressure liquid flow treatment: A web created by a roller card machine, airlaid machine, paper machine, etc. is placed on a conveyor belt made of 80 mesh plain weave, and the nozzle diameter is 0.1 mm at a conveyor belt speed of 20 m / min. A high pressure liquid flow was ejected by passing under a nozzle having a nozzle pitch of 1 mm. First, preliminary treatment (2 stages) at 2 MPa was performed, followed by 3 stages treatment with a high-pressure liquid flow having a water pressure of 5 MPa. The web was inverted and further processed in three stages with a high-pressure liquid flow having a water pressure of 5 MPa to obtain a divided finely divided nonwoven fabric. Here, the step is the number of times that the nozzle has passed directly under the nozzle.

[0067]

Example 1

The high melting point resin A is a polypropylene resin (polypropylene homopolymer, melting point 163 ° C., MFR: 16 g / 10 min), and the low melting point resin B is a high density polyethylene resin (melting point 131 ° C., MFR: 16 g / 10 min). A split type composite fiber having a volume ratio of resin A to resin B of 50/50 and a single yarn denier of 7.5 dtex was spun using a base for composite fibers. The obtained unstretched yarn was stretched at 90 ° C, 4.3 times, passed through a metal roll with a flat surface pressed at 5 kg / cm, and then a papermaking dispersant was adhered to 5 mm. Disconnected. The cross section of the obtained composite fiber was deformed into a flat shape, and the cross section of the fiber shown in FIGS. 1 to 6 in which a part of the contact interface of A and B components (indicated by a white background portion and a black background portion, hereinafter the same) peeled off. The split type composite fibers having a shape were mixed. The moisture content was 20% by weight.

Polypropylene (core) / low-density polyethylene (sheath) sheath-core composite fiber (EAC fiber, 2.2 dtex × 5 mm, Chisso Corporation) is added to the short fiber by 20% by weight, and a square sheet machine (25 cm × 25 cm). ) To make a web by the papermaking method. Using a Yankee dryer manufactured by Kumagai Riki Kogyo Co., Ltd., drying was carried out at 105 ° C. for 3 minutes, and preliminary adhesion was performed to obtain a web. After performing the high-pressure liquid flow treatment, it is further dried with a dryer at 80 ° C., and the basis weight is 55 g / m. 2 It was set as the fiber molding using the split type composite fiber.

[0068]

Example 2

According to Example 1 except that the pressure of the metal roll was changed from 5 kg / cm to 20 kg / cm, the basis weight was 50 g / m. 2 A fiber molded body using the split type composite fiber was obtained.

[0069]

Example 3

Polypropylene resin (polypropylene homopolymer, melting point 163 ° C., MFR: 20 g / 10 min) is used for high melting point resin A, and high density polyethylene resin (melting point 131 ° C., MFR: 26 g / 10 min) is used for low melting point resin B. A split type composite fiber having a volume ratio of resin A and resin B of 50/50 and a single yarn denier of 7.5 dtex was spun using a split type composite fiber die. The obtained unstretched yarn was stretched at 90 ° C. and 4.0 times, passed through a metal roll with a flat surface pressed at 10 kg / cm, and then a papermaking dispersant was adhered to 5 mm. Disconnected. The cross section of the obtained composite fiber was deformed into a flat shape, and the split type composite fiber having the fiber cross section shown in FIGS. 1 to 6 in which a part of the contact interface of the A and B components was peeled was mixed. It was. The moisture content was 20% by weight. Polypropylene (core) / low-density polyethylene (sheath) sheath-core composite fiber (EAC fiber, 2.2 dtex × 5 mm, Chisso Corporation) is added to the short fiber by 20 wt%, and a square sheet machine (25 cm × 25 cm). The web was made by the papermaking method. Using a Yankee dryer manufactured by Kumagai Riki Kogyo Co., Ltd., drying was carried out at 105 ° C. for 3 minutes, and preliminary adhesion was performed to obtain a web. After performing the high-pressure liquid flow treatment, it is further dried with a dryer at 80 ° C., and the basis weight is 60 g / m. 2 A fiber molded body using the split type composite fiber was obtained.

[0070]

Example 4

Polypropylene resin (polypropylene homopolymer, melting point 163 ° C., MFR 16) is used for high melting point resin A, and high density polyethylene resin (melting point 131 ° C., MFR: 16 g / 10 min) is used for low melting point resin B. A split type composite fiber having a volume ratio of resin A and resin B of 50/50 and a single yarn denier of 7.0 dtex was spun using a die. The obtained unstretched yarn was stretched at 90 ° C. and 3.8 times, passed through a metal roll having a flat surface pressed at 35 kg / cm, and then a papermaking dispersant was adhered to 5 mm. Disconnected. The cross-section of the obtained composite fiber is deformed into a flat shape, and the mixed composite fibers having the fiber cross-sectional shape shown in FIGS. there were.

Polypropylene (core) / low-density polyethylene (sheath) sheath-core composite fiber (EAC fiber, 2.2 dtex × 5 mm, Chisso Corporation) is added to the short fiber by 20% by weight, and a square sheet machine (25 cm × 25 cm). ) To make a web by the papermaking method. Using a Yankee dryer manufactured by Kumagai Riki Kogyo Co., Ltd., drying was carried out at 105 ° C. for 3 minutes, and preliminary adhesion was performed to obtain a web. After performing the high-pressure liquid flow treatment, it is further dried with a dryer at 80 ° C., and the basis weight is 55 g / m. 2 A fiber molded body using the split type composite fiber was obtained.

[0071]

Example 5

Polypropylene resin (polypropylene homopolymer, melting point 163 ° C., MFR: 35 g / 10 min) to high melting point resin A, and linear low density polyethylene resin (melting point 131 ° C., MFR: 26 g / 10 min) to low melting point resin B A split type composite fiber having a volume ratio of resin A to resin B of 50/50 and a single yarn denier of 8.0 dtex was spun using a base for split type composite fibers. The obtained unstretched yarn was stretched at 90 ° C. and 4.5 times, and the surface pressed at 5 kg / cm was passed between flat metal rolls, and then a papermaking dispersant was adhered to 5 mm. Disconnected. The cross section of the obtained composite fiber was deformed into a flat shape, and the split type composite fiber having the fiber cross section shown in FIGS. 1 to 6 in which a part of the contact interface of the A and B components was peeled was mixed. It was. The moisture content was 20% by weight.

Polypropylene (core) / low-density polyethylene (sheath) sheath-core composite fiber (EAC fiber, 2.2 dtex × 5 mm, Chisso Corporation) is added to the short fiber by 20% by weight, and a square sheet machine (25 cm × 25 cm). ) To make a web by the papermaking method. Using a Yankee dryer manufactured by Kumagai Riki Kogyo Co., Ltd., drying was carried out at 105 ° C. for 3 minutes, and preliminary adhesion was performed to obtain a web. After performing the high-pressure liquid flow treatment, it is further dried with a dryer at 80 ° C., and the basis weight is 50 g / m. 2 A fiber molded body using the split type composite fiber was obtained.

[0072]

Example 6

Polypropylene resin (polypropylene homopolymer, melting point 163 ° C., MFR: 16 g / 10 min) to high melting point resin A, and linear low density polyethylene resin (melting point 123 ° C., MFR: 20 g / 10 min) to low melting point resin B A split type composite fiber having a volume ratio of resin A to resin B of 50/50 and a single yarn denier of 7.0 dtex was spun using a base for split type composite fibers. The obtained unstretched yarn was stretched at 90 ° C., 3.7 times, passed through a metal roll having a flat surface pressed at 5 kg / cm, and then a paper-making dispersant was adhered to 5 mm. Disconnected. The cross-section of the obtained composite fiber is deformed into a flat shape, and the mixed composite fibers having the fiber cross-sectional shape shown in FIGS. there were. The moisture content was 20% by weight.

Polypropylene (core) / low-density polyethylene (sheath) sheath-core composite fiber (EAC fiber, 2.2 dtex × 5 mm, Chisso Corporation) is added to the short fiber by 20% by weight, and a square sheet machine (25 cm × 25 cm). ) To make a web by the papermaking method. Using a Yankee dryer manufactured by Kumagai Riki Kogyo Co., Ltd., drying was carried out at 105 ° C. for 3 minutes, and preliminary adhesion was performed to obtain a web. After performing the high-pressure liquid flow treatment, it is further dried with a dryer at 80 ° C., and the basis weight is 50 g / m. 2 A fiber molded body using the split type composite fiber was obtained.

[0073]

Example 7

According to Example 1, except that the cross-sectional shape of the split-type conjugate fiber of the present invention is changed to that mainly having FIG. 7, the basis weight is 60 g / m. 2 A split type composite fiber was prepared, and a fiber molded body was obtained using the split type composite fiber.

[0074]

Example 8

Polypropylene resin (polypropylene homopolymer, melting point 163 ° C., MFR: 16 g / 10 min) is used as high melting point resin A, and high density polyethylene resin (melting point 131 ° C., MFR: 16 g / 10 min) is used as low melting point resin B. A split type composite fiber having a volume ratio of resin A and resin B of 50/50 and a single yarn denier of 7.5 dtex was spun using a split type composite fiber die. Alkyl phosphate K salt was attached in the take-off process. The obtained undrawn yarn was drawn at 90 ° C. and 4.3 times. Further, the crimper roll of the mechanical crimp imparting device was pressurized to 3 kg / cm and mechanically crimped and cut into 51 mm. The cross section of the obtained composite fiber was deformed into a flat shape, and the split type composite fiber having the fiber cross section shown in FIGS. 1 to 6 in which a part of the contact interface of the A and B components was peeled was mixed. It was.

The obtained short fiber was made into a web with a roller card machine, and after the high-pressure liquid flow treatment, it was further dried with a dryer at 80 ° C., and the basis weight was 50 g / m. 2 A fiber molded body using the split type composite fiber was obtained. Although the peel rate was 10%, the division did not proceed excessively when passing through the roller card machine, and the web was well formed.

[0075]

Example 9

Polypropylene resin (propylene homopolymer, melting point 163 ° C., MFR: 20 g / 10 min) is used for high melting point resin A, and high density polyethylene resin (melting point 131 ° C., MFR: 20 g / 10 min) is used for low melting point resin B. A split type composite fiber having a volume ratio of 50/50 between resin A and resin B and a hollow ratio of 10% was spun by a spunbond method using a split type composite fiber die. The composite fiber group discharged from the spinneret is introduced into the air soccer ball, pulled and drawn to form a single filament denier 2.0 dtex composite long fiber, and then the long fiber group discharged from the air soccer ball is charged with the same charge by a charging device. After being charged and charged, it was opened by colliding with a reflector, and the opened long fiber group was collected as a long fiber web on an endless net-like conveyor provided with a suction device on the back surface. The long fiber web was pressed with a metal roll having a flat surface at a pressure of 10 kg / cm and processed in an embossing roll machine having an area ratio of 15% heated to 120 ° C., and after the high-pressure liquid flow treatment, 80 50 g / m per unit area mixed with split type composite fibers having a fiber cross-sectional shape shown in FIGS. 2 This was a fiber molded body.

[0076]

Example 10

Polypropylene resin (polypropylene homopolymer, melting point 163 ° C., MFR: 16 g / 10 min) is added to high melting point resin A, and 0.4% by weight of foaming agent (die blow HC, manufactured by Dainichi Seika Co., Ltd.) is added to melting point resin B The high-density polyethylene resin (melting point 131 ° C., MFR: 16 g / 10 min) was used, and the split-type composite fiber die was used. The volume ratio of the resin A and the resin B was 50/50, and the single yarn denier was 7.5 dtex. Split-type composite fibers were spun. The obtained unstretched yarn was stretched at 90 ° C. and 4.0 times, passed through a metal roll with a flat surface pressed at 5 kg / cm, and then a papermaking dispersant was adhered to 5 mm. Disconnected. The cross-section of the obtained composite fiber is deformed into a flat shape, part of the contact interface of the A and B components is peeled off, and the fiber cross-sectional shape shown in FIGS. The split type composite fibers possessed were mixed. The moisture content was 20% by weight.

Polypropylene (core) / low-density polyethylene (sheath) sheath-core composite fiber (EAC fiber, 2.2 dtex × 5 mm, Chisso Corporation) is added to the short fiber by 20% by weight, and a square sheet machine (25 cm × 25 cm). ) To make a web by the papermaking method. Using a Yankee dryer manufactured by Kumagai Riki Kogyo Co., Ltd., drying was carried out at 105 ° C. for 3 minutes, and preliminary adhesion was performed to obtain a web. After performing the high-pressure liquid flow treatment, it is further dried with a dryer at 80 ° C. 2 A fiber molded body using the split type composite fiber was obtained.

[0077]

Examples 11 and 12

The split composite fiber of the present invention of Example 8 is 10 g / m in weight with a roller card machine. 2 Web (abbreviated as C) and polypropylene (core) / high-density polyethylene (sheath) sheath-core composite fiber (ESC fiber, Chisso Corp.) 2.2 dtex × 51 mm short fiber using a roller card machine with a basis weight of 10 g / m 2 Card web (abbreviated D). After carrying out the said high pressure liquid flow process, what laminated | stacked C on the upper layer, D laminated | stacked on the lower layer (Example 11), and laminated | stacked C on the upper and lower layers and D laminated | stacked on the middle layer (Example 12), respectively. The fiber molded body was obtained by drying with a dryer. Furthermore, when this fiber molded body was used for a wiper for wiping, both showed very excellent wiping properties.

[0078]

Example 13