JP2007332980A - Fastening structure containing flanged collar - Google Patents

Fastening structure containing flanged collar Download PDFInfo

- Publication number

- JP2007332980A JP2007332980A JP2006162015A JP2006162015A JP2007332980A JP 2007332980 A JP2007332980 A JP 2007332980A JP 2006162015 A JP2006162015 A JP 2006162015A JP 2006162015 A JP2006162015 A JP 2006162015A JP 2007332980 A JP2007332980 A JP 2007332980A

- Authority

- JP

- Japan

- Prior art keywords

- flanged collar

- peripheral surface

- groove

- collar nut

- adhesive

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Landscapes

- Connection Of Plates (AREA)

Abstract

Description

本発明は、フランジ付カラーナットを含む締結構造体に関する。 The present invention relates to a fastening structure including a flanged collar nut.

(a) テーパ形状のフランジ付カラーナットを含む締結構造体

従来、テーパ形状のフランジ付カラーナットを被締結物に挿入し、フランジ付カラーナットにボルトをねじ込んだ締結構造体が提案されている(例えば、特許文献1参照)。ボルトをねじ込む際にフランジ付カラーナットが回転することを防止するために、フランジ付カラーナットの軸部の外周面に接着剤が配置されていることが望ましい。

(b) ストレート形状のフランジ付カラーナットを含む締結構造体

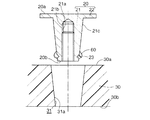

図4は、図示略のボルトがねじ込まれるストレート形状(円筒形状)のフランジ付カラーナット2を樹脂製部材3の取付け穴3aに挿入した締結構造体を示している。ボルト締結する際にフランジ付カラーナット2が回転することを防止するために、フランジ付カラーナットの軸部2aの外周面に接着剤6が配置されている。

(A) Fastening structure including tapered flanged color nut Conventionally, a fastening structure is proposed in which a tapered flanged color nut is inserted into an object to be fastened and a bolt is screwed into the flanged collar nut ( For example, see Patent Document 1). In order to prevent the flanged collar nut from rotating when the bolt is screwed in, it is desirable that an adhesive be disposed on the outer peripheral surface of the shaft portion of the flanged collar nut.

(B) Fastening structure including straight flanged collar nut FIG. 4 shows that a straight (cylindrical) flanged

しかし、従来のフランジ付カラーナットを含む締結構造体にはつぎの問題点がある。

(a) テーパ形状のフランジ付カラーナットを含む締結構造体

フランジ付カラーナットの軸部の外周面に接着剤を配置するために軸部の外周面に接着剤を塗布してフランジ付カラーナットを被締結物に挿入する場合、軸部の外周面への接着剤の塗り方によっては、軸部の外周面全体に接着剤を配置できない場合がある(ムラができる)。フランジ付カラーナットの軸部の外周面全体に接着剤が配置されないと、安定した接着力を得ることができなくなってしまう。

(b) ストレート形状のフランジ付カラーナットを含む締結構造体

図4に示すように、ストレート形状のフランジ付カラーナット2は、樹脂製部材3の取付け穴3aに対して軸ズレを起こしやすい。軸ズレを起こすと、接着剤6のはみ出し、ムラが起きてしまう。

(A) In order to place the adhesive on the outer peripheral surface of the shaft portion of the collar nut with the fastening structure flange including the tapered collar nut with the flange, the adhesive is applied to the outer peripheral surface of the shaft portion, When inserting into the article to be fastened, depending on how the adhesive is applied to the outer peripheral surface of the shaft portion, the adhesive may not be disposed on the entire outer peripheral surface of the shaft portion (unevenness can occur). If the adhesive is not disposed on the entire outer peripheral surface of the shaft portion of the flanged collar nut, a stable adhesive force cannot be obtained.

(B) Fastening structure including straight flanged collar nut As shown in FIG. 4, the straight flanged

本発明の目的は、樹脂製部材にフランジ付カラーナットを接着固定する場合に、従来に比べて、軸部の外周面全体に接着剤を均一に配置できる、フランジ付カラーを含む締結構造体を提供することにある。 An object of the present invention is to provide a fastening structure including a flanged collar that can uniformly dispose an adhesive on the entire outer peripheral surface of the shaft portion, compared to the conventional case, when a flanged collar nut is bonded and fixed to a resin member. It is to provide.

上記目的を達成する本発明はつぎの通りである。

(1) フランジ付カラーナットを樹脂製部材の取付け穴に挿入し、前記樹脂製部材に対して被締結部材をボルトにて締結固定する、フランジ付カラーナットを含む締結構造体であって、

前記フランジ付カラーナットは、該フランジ付カラーナットの軸方向に延びる軸部と前記フランジ付カラーナットの軸方向一端部に設けられるフランジ部とを有しており、該軸部の外周面が前記フランジ付カラーナットの軸方向他端に向かうにつれて小径となるテーパ状とされており、

前記樹脂製部の取付け穴の内周面は、前記樹脂製部材の厚み方向一端から厚み方向他端に向かうにつれて小径となるテーパ状とされており、

前記フランジ付カラーナットの軸部の外周面に溝を形成するとともに、該溝に接着剤を配置した、フランジ付カラーナットを含む締結構造体。

(2) 前記溝の断面形状において、前記溝の、最奥部から前記フランジ付カラーナットの軸方向一端側の開口縁までの距離aは、前記溝の、前記最奥部から前記フランジ付カラーナットの軸方向他端側の開口縁までの距離bよりも大とされている、(1)記載のフランジ付カラーナットを含む締結構造体。

(3) 前記溝の断面形状において、前記溝の、最奥部から前記フランジ付カラーナットの軸方向一端側の開口縁までの距離aは、前記溝の、前記最奥部から前記フランジ付カラーナットの軸方向他端側の開口縁までの距離bの2倍よりも大とされている、(1)記載のフランジ付カラーナットを含む締結構造体。

The present invention for achieving the above object is as follows.

(1) A fastening structure including a flanged collar nut, wherein a flanged collar nut is inserted into a mounting hole of a resin member, and a fastened member is fastened and fixed to the resin member with a bolt.

The flanged collar nut has a shaft portion extending in the axial direction of the flanged collar nut and a flange portion provided at one end of the flanged collar nut in the axial direction. It has a tapered shape with a smaller diameter toward the other axial end of the collar nut with flange.

The inner peripheral surface of the mounting hole of the resin part is tapered so that the diameter decreases from one end in the thickness direction of the resin member to the other end in the thickness direction.

A fastening structure including a flanged collar nut, wherein a groove is formed on the outer peripheral surface of the shaft portion of the flanged collar nut, and an adhesive is disposed in the groove.

(2) In the cross-sectional shape of the groove, the distance a from the innermost part of the groove to the opening edge on one end side in the axial direction of the collar nut with flange is the distance a from the innermost part of the groove to the flanged collar. The fastening structure including the flanged collar nut according to (1), which is larger than the distance b to the opening edge on the other axial end side of the nut.

(3) In the cross-sectional shape of the groove, the distance a from the innermost part of the groove to the opening edge on one end side in the axial direction of the flanged collar nut is the distance a from the innermost part of the groove to the flanged collar. A fastening structure including a flanged collar nut according to (1), which is greater than twice the distance b to the opening edge on the other axial end side of the nut.

上記(1)〜(3)のフランジ付カラーナットを含む締結構造体によれば、以下の効果を得ることができる。

フランジ付カラーナットの軸部の外周面がテーパ状とされており、樹脂製部材の取付け穴の内周面がテーパ状とされており、軸部の外周面に溝を形成するとともに溝内に接着剤を配置している。そのため、軸部の外周面の溝部およびその周囲に予め接着剤を塗布しておいたフランジ付カラーナットを樹脂製部材の取付け穴に挿入していくと、(i)フランジ付カラーナットが取付け穴に挿入されるにつれて軸部の外周面と取付け穴の内周面との間隔が狭くなっていくため、フランジ付カラーナットが取付け穴に挿入されるにつれて接着剤は押し潰されて拡がっていく。また、(ii)フランジ付カラーナットで接着剤が樹脂製部材の厚み方向他端側まで(取付け穴の奥まで)引きずられる。したがって、軸部の外周面全体または略全体にわたって均一にまたは略均一に接着剤を配置できる。

According to the fastening structure including the flanged collar nuts (1) to (3), the following effects can be obtained.

The outer peripheral surface of the shaft portion of the collar nut with flange is tapered, the inner peripheral surface of the mounting hole of the resin member is tapered, and a groove is formed in the outer peripheral surface of the shaft portion and in the groove Adhesive is arranged. For this reason, when a flanged collar nut having an adhesive applied in advance around the groove on the outer peripheral surface of the shaft portion is inserted into the mounting hole of the resin member, (i) the flanged collar nut is attached to the mounting hole. Since the gap between the outer peripheral surface of the shaft portion and the inner peripheral surface of the mounting hole becomes narrower as the sleeve is inserted into the mounting hole, the adhesive is crushed and expanded as the flanged collar nut is inserted into the mounting hole. In addition, (ii) the adhesive is dragged to the other end in the thickness direction of the resin member (to the depth of the mounting hole) by the collar nut with flange. Therefore, the adhesive can be disposed uniformly or substantially uniformly over the entire outer peripheral surface or substantially the entire shaft portion.

上記(2)または(3)のフランジ付カラーナットを含む締結構造体によれば、以下の効果を得ることができる。

溝の断面形状において、溝の、最奥部からフランジ付カラーナットの軸方向一端側の開口縁までの距離aが、溝の、最奥部からフランジ付カラーナットの軸方向他端側の開口縁までの距離bよりも大とされている。そのため、距離aが距離bよりも小とされている場合に比べて、軸部の外周面の溝部およびその周囲に予め接着剤を塗布しておいたフランジ付カラーナットを樹脂製部材の取付け穴に挿入する際、接着剤は、フランジ付カラーナットの軸方向他端側よりも軸方向一端側に拡がりやすくなる(流れやすくなる)。

According to the fastening structure including the flanged collar nut (2) or (3), the following effects can be obtained.

In the cross-sectional shape of the groove, the distance a from the innermost part of the groove to the opening edge on one end side in the axial direction of the collar nut with flange is the opening on the other end side in the axial direction of the collar nut with flange from the innermost part of the groove. The distance b is larger than the distance b to the edge. Therefore, compared to the case where the distance a is smaller than the distance b, the flanged collar nut with the adhesive applied in advance to the groove portion on the outer peripheral surface of the shaft portion is attached to the mounting hole of the resin member. When inserted into the adhesive, the adhesive is more likely to spread (is more likely to flow) to one axial end than the other axial end of the flanged collar nut.

以下に、図1〜図3を参照して、本発明実施例のフランジ付カラーを含む締結構造体を説明する。 Below, with reference to FIGS. 1-3, the fastening structure containing the collar with a flange of this invention Example is demonstrated.

本発明実施例のフランジ付カラーを含む締結構造体10は、図1に示すように、フランジ付カラーナット20を樹脂製部材30の取付け穴31に挿入し、樹脂製部材30に対して被締結部材40をボルト50にて締結固定する締結構造体である。締結構造体10は、フランジ付カラーナット20と、樹脂製部材30と、金属製の被締結部材40と、ボルト50と、フランジ付カラーナット20を樹脂製部材30に接着固定する接着剤60と、を有する。

As shown in FIG. 1, the

フランジ付カラーナット20は、金属製である。フランジ付カラーナット20は、接着剤60を用いて樹脂製部材30に接着固定される。フランジ付カラーナット20は、フランジ付カラーナット20の軸方向(以下、カラー軸方向という)に延びる軸部21と、カラー軸方向一端部に設けられるフランジ部22と、を備える。

The flanged

軸部21は、フランジ付カラー20の軸方向でフランジ部22が設けられていない部分である。軸部21は、ボルト50が挿入されるボルト挿入用穴21aを備える。ボルト挿入用穴21aは、フランジ付カラーナット20をカラー軸方向に貫通する貫通孔であってもよく、袋穴であってもよい(図示例では袋穴である場合を示している)。軸部21の内周面に、ボルト50がねじ込まれる雌ネジ21bが形成されている。

The

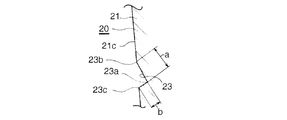

軸部21の外周面21cは、カラー軸方向他端20bに向かうにつれて小径となるテーパ状とされている。外周面21cには、溝23が少なくとも1つ形成されている(本発明図示例では、溝23が1つのみ形成されている場合を示している)。

The outer

溝23は、カラー軸方向と直交する面内で延びている。溝23は、軸部21の全周にわたって形成されている。溝23は、軸部21の、カラー軸方向他端20bからカラー軸方向一端20a側に所定距離隔てた位置に形成されている。溝23の横断面形状は、V字(略V字を含む)形状であってもよく、U字(略U字を含む)形状であってもよく、その他の形状であってもよい。図3に示すように、溝23の横断面形状において、溝23の最奥部23aからカラー軸方向一端20a側の開口縁23bまでの距離aは、溝23の最奥部23aからカラー軸方向他端20b側の開口縁23cまでの距離bの2倍よりも大とされている。溝23の深さは、軸部21の強度に影響がないかまたはあっても無視できる程度に、設定されている。

The

樹脂製部材30は、たとえばCFRPなどのFRP(繊維強化樹脂)製である。樹脂製部材30は、1枚構成であってもよく、複数枚を樹脂製部材30の厚み方向(カラー軸方向と同方向)に重ねた複数枚構成であってもよい。なお、図示例では1枚構成である場合を示している。

The

樹脂製部材30は、軸部21が挿入される(嵌め込まれる、圧入される)取付け穴31を備える。樹脂製部材30は、さらに、フランジ部22を収容する図示略の座ぐり部を備えていてもよい。

The

取付け穴31の内周面31aは、樹脂製部材30の厚み方向一端30aから厚み方向他端30bに向かうにつれて小径となるテーパ状とされている。取付け穴31に、軸部21が、カラー軸方向他端20bを挿入側端にして厚み方向一端30a側から挿入されている。

The inner

カラー軸方向他端20bは樹脂製部材30の厚み方向他端30bと、カラー軸方向に同じかまたは略同じ位置にある。そのため、カラー軸方向他端20bと被締結部材40とを接触(面接触)させることができ、ボルト50の軸力による樹脂製部材30のクリープによる締結力抜けは生じない。

The

被締結部材40と樹脂製部材30は、ワッシャ51(またはボルト50の頭部裏面)とフランジ部22とにより、ボルト軸方向(カラー軸方向と同方向)に挟まれる。

The fastened

接着剤60は、軸部21の外周面21c(溝部23を含む)と取付け穴31の内周面31aとの間Aと、フランジ部22のうち軸部21からカラー半径方向外側に延びている部分の裏面(下面)22aと樹脂製部材30の厚み方向一端30a(面)との間Bに、配置される。接着剤60は、軸部21の外周面21cの溝部23およびその周囲とフランジ部22の裏面22aとに接着剤60を塗布したフランジ付カラー20を、樹脂製部材30の取付け穴31に挿入することで、間A,Bに配置される。なお、図2に示すように、接着剤60を軸部21の外周面21cの溝部23およびその周囲のみに塗布した場合であっても、フランジ付カラー20を取付け穴31に挿入していくと、接着剤60が軸部21の外周面21cと取付け穴31の内周面31aとによって押し潰されて拡がり間Aから間Bに流入するため、フランジ付カラー20に接着剤60を予め塗布しておく部位は、軸部21の外周面21cの溝部23およびその周囲のみであってもよい。

The adhesive 60 extends between the outer

ここで、フランジ付カラー20を含む締結構造体10の締結方法を説明する。

Here, a fastening method of the

フランジ付カラー20を含む締結構造体10の締結方法は、(a)軸部21の外周面21cの溝部23およびその周囲のみに、または軸部21の外周面21cの溝部23およびその周囲とフランジ部22の裏面22bとに接着剤60を塗布する工程と、(b)接着剤60が塗布されたフランジ付カラー20を、樹脂製部材30の取付け穴31に、カラー軸方向他端20bが樹脂製部材30の厚み方向他端30bとカラー軸方向に同一または略同一になるまで挿入し、接着剤60を間A,Bに配置する工程と、(c)接着剤60が硬化した後に、被締結部材40の一面40aがカラー軸方向他端20bに接触するようにして被締結部材40の他側(フランジ付カラーナット20と反対側)から、ボルト50を、被締結部材40のボルト挿通穴41を挿通させて雌ネジ21bにねじ込む工程と、を有する。

The

つぎに、本発明実施例の作用を説明する。 Next, the operation of the embodiment of the present invention will be described.

本発明実施例では、軸部21がテーパ状の外周面21cを備えており、外周面21cに溝23を形成するとともに溝23内に接着剤60を配置している。そのため、軸部21の外周面21cの溝部23およびその周囲に予め接着剤60を塗布しておいたフランジ付カラーナット20を樹脂製部材30の取付け穴31に挿入していくと、(i)フランジ付カラーナット20が取付け穴31に挿入されるにつれて軸部21の外周面21cと取付け穴31の内周面31aとの間隔が狭くなっていくため、フランジ付カラーナット20が取付け穴31に挿入されるにつれて接着剤60は押し潰されて拡がっていく。また、(ii)フランジ付カラーナット20で接着剤60が樹脂製部材30の厚み方向他端30b側まで(取付け穴31の奥まで)引きずられる。したがって、軸部21の外周面21cの全体または略全体にわたって均一に(ムラなく)接着剤60を配置でき、安定した接着力を得ることができる。

In the embodiment of the present invention, the

溝23の横断面形状において、溝23の最奥部23aからカラー軸方向一端20a側の開口縁23bまでの距離aが、溝23の最奥部23aからカラー軸方向他端20b側の開口縁23cまでの距離bの2倍よりも大とされている。そのため、距離aが距離bよりも小とされている場合に比べて、軸部21の外周面21cの溝部23およびその周囲に予め接着剤60を塗布しておいたフランジ付カラーナット20を樹脂製部材30の取付け穴31に挿入する際、接着剤60が、カラー軸方向他端20b側よりもカラー軸方向一端20a側に拡がりやすくなる(流れやすくなる)。

In the cross-sectional shape of the

溝23が、軸部21の、カラー軸方向他端20bからカラー軸方向一端20a側に所定距離隔てた位置に形成されているため、軸部21の外周面21cと取付け穴31の内周面31とで押し潰された接着剤60が、間Aから被締結部材40側に流出する(はみ出す)ことを防止できる。

Since the

軸部21の外周面21cと取付け穴31の内周面31aがテーパ状とされているため、両面21c、31aがテーパ状とされていない場合に比べて(両面21c、31aがストレート状とされている場合に比べて)、フランジ付カラーナット20を挿入するとき、入口が広い。そのため、軸部21の外周面21cの溝部23およびその周囲に予め接着剤60を塗布しておいたフランジ付カラーナット20を樹脂製部材30の取付け穴31に挿入する際に、接着剤60が樹脂製部材30の取付け穴31の入口(厚み方向一端30a)で掻き落とされてしまう(削り落とされてしまう)ことを防止できる。その結果、軸部21の外周面21cの溝部23およびその周囲に接着剤60を予め塗布しておいたフランジ付カラーナット20を樹脂製部材30の取付け穴31に挿入する際に、軸部21の外周面21cの溝部23およびその周囲に塗布した接着剤60の全部を取付け穴31内に入れることができる。

Since the outer

軸部21の外周面21cと取付け穴31の内周面31aがテーパ状とされているため、フランジ付カラーナット20挿入時は入口が広くて入れやすく、挿入するにつれて次第にすぼんでくるので、フランジ付カラーナット20が樹脂製部材30の取付け穴31に対してセンタリングされ(軸ズレすることなく)、フランジ付カラーナット20を取付け穴31に対して正確に位置決めできる。また、フランジ付カラーナット20を樹脂製部材30の取付け穴31に挿入する際に、自動的にセンタリングされるため、作業性も良好である。

Since the outer

10 締結構造体

20 フランジ付カラー

20a フランジ付カラーの軸方向一端

20b フランジ付カラーの軸方向他端

21 軸部

21a ボルト挿入用穴

21b 雌ネジ

21c 軸部の外周面

22 フランジ部

22a フランジ部の裏面

23 溝

23a 溝の最奥部

23b 溝の最奥部からカラー軸方向一端側の開口縁

23c 溝の最奥部からカラー軸方向他端側の開口縁

30 樹脂製部材

30a 樹脂製部材の厚み方向一端

30b 樹脂製部材の厚み方向他端

31 取付け孔

31a 取付け孔の内周面

40 被締結部材

50 ボルト

51 ワッシャ

60 接着剤

A 軸部の外周面と取付け孔の内周面との間

B フランジ部の裏面と樹脂製部材の厚み方向一端との間

a 溝の最奥部からカラー軸方向一端側の開口縁までの距離

b 溝の最奥部からカラー軸方向他端側の開口縁までの距離

10

Claims (3)

前記フランジ付カラーナットは、該フランジ付カラーナットの軸方向に延びる軸部と前記フランジ付カラーナットの軸方向一端部に設けられるフランジ部とを有しており、該軸部の外周面が前記フランジ付カラーナットの軸方向他端に向かうにつれて小径となるテーパ状とされており、

前記樹脂製部の取付け穴の内周面は、前記樹脂製部材の厚み方向一端から厚み方向他端に向かうにつれて小径となるテーパ状とされており、

前記フランジ付カラーナットの軸部の外周面に溝を形成するとともに、該溝に接着剤を配置した、フランジ付カラーナットを含む締結構造体。 A fastening structure including a flanged collar nut, wherein a flanged collar nut is inserted into a mounting hole of a resin member, and a fastened member is fastened and fixed to the resin member with a bolt,

The flanged collar nut has a shaft portion extending in the axial direction of the flanged collar nut and a flange portion provided at one end of the flanged collar nut in the axial direction. It has a tapered shape with a smaller diameter toward the other axial end of the collar nut with flange.

The inner peripheral surface of the mounting hole of the resin part is tapered so that the diameter decreases from one end in the thickness direction of the resin member to the other end in the thickness direction.

A fastening structure including a flanged collar nut, wherein a groove is formed on the outer peripheral surface of the shaft portion of the flanged collar nut, and an adhesive is disposed in the groove.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2006162015A JP2007332980A (en) | 2006-06-12 | 2006-06-12 | Fastening structure containing flanged collar |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2006162015A JP2007332980A (en) | 2006-06-12 | 2006-06-12 | Fastening structure containing flanged collar |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| JP2007332980A true JP2007332980A (en) | 2007-12-27 |

Family

ID=38932652

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2006162015A Pending JP2007332980A (en) | 2006-06-12 | 2006-06-12 | Fastening structure containing flanged collar |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2007332980A (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2015086942A (en) * | 2013-10-30 | 2015-05-07 | トヨタ自動車株式会社 | Fastening structure |

| CN107208678A (en) * | 2015-01-22 | 2017-09-26 | 日产自动车株式会社 | The fastening structure of carbon-fiber reinforced resins material |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS50114565U (en) * | 1974-03-05 | 1975-09-18 | ||

| WO2002065193A1 (en) * | 2001-02-13 | 2002-08-22 | Hitachi, Ltd. | Eyeglasses frame and method for assembling/manufacturing the same, structure for fixing eyegasses lenses |

-

2006

- 2006-06-12 JP JP2006162015A patent/JP2007332980A/en active Pending

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS50114565U (en) * | 1974-03-05 | 1975-09-18 | ||

| WO2002065193A1 (en) * | 2001-02-13 | 2002-08-22 | Hitachi, Ltd. | Eyeglasses frame and method for assembling/manufacturing the same, structure for fixing eyegasses lenses |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2015086942A (en) * | 2013-10-30 | 2015-05-07 | トヨタ自動車株式会社 | Fastening structure |

| CN105246669A (en) * | 2013-10-30 | 2016-01-13 | 丰田自动车株式会社 | Fastening structure |

| US9895839B2 (en) | 2013-10-30 | 2018-02-20 | Toyota Jidosha Kabushiki Kaisha | Fastening structure |

| CN107208678A (en) * | 2015-01-22 | 2017-09-26 | 日产自动车株式会社 | The fastening structure of carbon-fiber reinforced resins material |

| EP3249242A4 (en) * | 2015-01-22 | 2018-03-14 | Nissan Motor Co., Ltd. | Fastening structure for carbon fiber-reinforced resin material |

| CN107208678B (en) * | 2015-01-22 | 2018-10-30 | 日产自动车株式会社 | The fastening structure of carbon-fiber reinforced resins material |

| US10132342B2 (en) | 2015-01-22 | 2018-11-20 | Nissan Motor Co., Ltd. | Fastening structure for carbon fiber-reinforced resin material |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4730217B2 (en) | Fastening structure including flanged collar | |

| US20070292241A1 (en) | Fibrous microencapsulated washer for fasteners | |

| RU2720619C2 (en) | Demountable coupling | |

| KR101346507B1 (en) | Wheel bearing joint unit | |

| EP2951095B1 (en) | Sleeved fastener assembly | |

| US7654782B2 (en) | Weld nut or stud, fastening system and method | |

| EP0999076A2 (en) | Improved studs for connecting a wheel and a brake element to a motor vehicle wheel hub unit | |

| WO2012004087A1 (en) | Nut, fastening arrangement and method of fastening | |

| US20100230228A1 (en) | Device for frictionally coupling two coaxial components | |

| KR20100087759A (en) | Flange coupling, and metal pipe joining structure | |

| WO2016117062A1 (en) | Fastening structure for carbon fiber-reinforced resin material | |

| US11415158B2 (en) | Expansion bolt, and connection assembly comprising such an expansion bolt | |

| US20190093695A1 (en) | Clearance floating anchor nut | |

| JP2007332980A (en) | Fastening structure containing flanged collar | |

| JP2013122316A (en) | Lock ring and threaded stud | |

| US20160177985A1 (en) | Structure securing device | |

| US20160017903A1 (en) | Fluid throttle member | |

| JP6287693B2 (en) | Member connection structure | |

| US8579567B2 (en) | Device for blind fixation | |

| JP2011127762A (en) | Method of assembling rotors having non-complementary flange openings | |

| JP2007332975A (en) | Fastening structure with flanged collar | |

| JP4479691B2 (en) | Fastening structure including flanged collar | |

| JP6283154B2 (en) | Method and apparatus for extended split bushpipe | |

| JP5310970B2 (en) | Device for securing a plastic component to a support part | |

| EP1834123A1 (en) | Flange |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20090211 |

|

| A977 | Report on retrieval |

Effective date: 20100406 Free format text: JAPANESE INTERMEDIATE CODE: A971007 |

|

| A131 | Notification of reasons for refusal |

Effective date: 20100413 Free format text: JAPANESE INTERMEDIATE CODE: A131 |

|

| A02 | Decision of refusal |

Effective date: 20100817 Free format text: JAPANESE INTERMEDIATE CODE: A02 |