JP2005109228A - Led device and led illumination apparatus - Google Patents

Led device and led illumination apparatus Download PDFInfo

- Publication number

- JP2005109228A JP2005109228A JP2003342133A JP2003342133A JP2005109228A JP 2005109228 A JP2005109228 A JP 2005109228A JP 2003342133 A JP2003342133 A JP 2003342133A JP 2003342133 A JP2003342133 A JP 2003342133A JP 2005109228 A JP2005109228 A JP 2005109228A

- Authority

- JP

- Japan

- Prior art keywords

- led

- copper foil

- heat

- substrate

- base

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Landscapes

- Arrangement Of Elements, Cooling, Sealing, Or The Like Of Lighting Devices (AREA)

- Non-Portable Lighting Devices Or Systems Thereof (AREA)

- Led Device Packages (AREA)

Abstract

Description

本発明は、複数のLEDを基体に実装しているLED装置およびLED照明装置に関する。 The present invention relates to an LED device and an LED lighting device in which a plurality of LEDs are mounted on a substrate.

回路基板に実装されている複数のLEDを同時に点灯させると、多くの熱が発生する。この熱により、LEDは温度上昇し、樹脂の劣化による短寿命になりやすい。また、LEDは温度上昇すると、光束が減少するようになる。そこで、一般に、放熱手段を設けてLEDの熱を放熱させることが行われている。例えば、金属ベース板のLEDが実装されていない裏面を照明装置の一部に接触させて放熱させているLED照明装置が提供されている(例えば、特許文献1参照。)。

特許文献1は、一般の回路基板ではなく、金属ベース板上に絶縁層を介してLEDを形成するものであるので、高価になるという欠点を有する。 Patent Document 1 has a drawback that it is expensive because an LED is formed on a metal base plate via an insulating layer instead of a general circuit board.

本発明は、基体に実装されたLEDの放熱が十分に行われて温度上昇が抑制されるLED装置およびLED照明装置を提供することを目的とする。 An object of the present invention is to provide an LED device and an LED lighting device in which an LED mounted on a substrate is sufficiently radiated to suppress a temperature rise.

請求項1に記載のLED装置の発明は、複数のLEDと;一方および他方の面にそれぞれの占有率が略同等となるように銅箔が形成され、かつ一方の面に回路パターンの銅箔が形成されてLEDを実装している基体と;基体の他方の面の銅箔に接触させて配設された放熱手段と;を具備していることを特徴とする。 The invention of the LED device according to claim 1 is a copper foil having a plurality of LEDs; a copper foil formed on one and the other surfaces so that the respective occupancy ratios are substantially equal, and a circuit pattern copper foil on one surface And a substrate on which the LED is mounted; and a heat dissipating means arranged in contact with the copper foil on the other surface of the substrate.

本発明および以下の各発明において、特に言及しない限り、各構成は以下による。 In the present invention and each of the following inventions, each configuration is as follows unless otherwise specified.

LEDは、基体に面実装される面実装形または基体にリードフレームが取り付けられる砲弾形のいずれであってもよい。 The LED may be either a surface-mounted type that is surface-mounted on a base or a bullet-type that has a lead frame attached to the base.

銅箔のそれぞれの占有率が略同等とは、当該占有率の差が5%を許容するものである。 The fact that the respective occupation ratios of the copper foils are substantially equal means that the difference in the occupation ratios is allowed to be 5%.

回路パターンは、複数のLEDのそれぞれに電流を供給する電流路である。 The circuit pattern is a current path that supplies current to each of the plurality of LEDs.

本発明によれば、LEDの熱は、基体の一方の面の銅箔から基体に直ちに伝熱し、基体から他方の面の銅箔に伝熱され、さらに放熱手段に伝熱されて放熱される。したがって、LEDの温度上昇が抑制され、LEDの樹脂の劣化または光束の減少が抑制される。 According to the present invention, the heat of the LED is immediately transferred from the copper foil on one side of the base to the base, transferred from the base to the copper foil on the other side, and further transferred to the heat radiating means and dissipated. . Therefore, the temperature rise of the LED is suppressed, and the deterioration of the LED resin or the decrease of the luminous flux is suppressed.

請求項2に記載のLED装置の発明は、請求項1記載のLED装置において、基体の一方および他方の面のそれぞれの表面面積に対するそれぞれの銅箔面積の占有率がともに70%以上であり、かつ当該占有率の差が5%以下であることを特徴とする。 The invention of the LED device according to claim 2 is the LED device according to claim 1, wherein the occupancy ratio of each copper foil area to each surface area of one and the other surfaces of the substrate is 70% or more, And the difference of the said occupation rate is 5% or less, It is characterized by the above-mentioned.

前記占有率が70%以上であると、銅箔面積が大きくなるので、LEDの熱が一方の面の銅箔に伝熱しやすくなり、他方の面の銅箔から伝熱または放熱しやすくなる。すなわち、基体の一方の面から他方の面への熱抵抗が低減される。そして、前記占有率の差が5%以下であると、一方の面の銅箔からの伝熱量と、他方の面からの放熱量が略釣合うので、伝熱しやすくなるとともに、基体の一方の面と他方の面との温度差が小さくなり、基体の反りが防止される。そして、前記占有率が70%以上、前記占有率の差が5%以下の条件は、LEDの温度上昇の抑制に対して、実験的に良好となることが確認された。 When the occupancy is 70% or more, the copper foil area becomes large, so that the heat of the LED is easily transferred to the copper foil on one side, and heat is transferred or released from the copper foil on the other side. That is, the thermal resistance from one surface of the substrate to the other surface is reduced. And when the difference in the occupation ratio is 5% or less, the amount of heat transferred from the copper foil on one side and the amount of heat released from the other side are substantially balanced, so that heat transfer is facilitated, and The temperature difference between the surface and the other surface is reduced, and the substrate is prevented from warping. It was confirmed that the conditions where the occupation ratio is 70% or more and the difference between the occupation ratios is 5% or less are experimentally good for suppressing the temperature rise of the LED.

本発明によれば、基体の一方および他方の面のそれぞれの表面面積に対するそれぞれの銅箔面積の占有率がともに70%以上であり、かつ当該占有率の差が5%以下とすることにより、LEDの熱が放熱手段により良好に放熱されるとともに、基体の反りが生じないことが確認された。 According to the present invention, the occupancy of each copper foil area with respect to the surface area of each of the one and other surfaces of the substrate is 70% or more, and the difference in the occupancy is 5% or less, It was confirmed that the heat of the LED was dissipated well by the heat dissipating means and the substrate was not warped.

請求項3に記載のLED装置の発明は、請求項1または2記載のLED装置と;LED装置を配設しているLED照明装置本体と;LEDを点灯させる点灯装置と;を具備していることを特徴とする。

The invention of the LED device according to

点灯装置は、LEDを発光(点灯)させるAC−DC変換装置や電圧調整装置などにより構成され、LED照明装置本体内に設けてもよく、LED照明装置本体と別置であってもよい。 The lighting device is configured by an AC-DC conversion device, a voltage adjustment device, or the like that emits light (lights) the LED, and may be provided in the LED lighting device body or may be provided separately from the LED lighting device body.

本発明によれば、請求項1または2記載のLED装置を具備するので、LEDの温度上昇が抑制され、光束の減少が抑制されるLED照明装置が提供される。 According to the present invention, since the LED device according to claim 1 or 2 is provided, an LED illumination device is provided in which the temperature rise of the LED is suppressed and the decrease of the luminous flux is suppressed.

請求項1の発明によれば、LEDの熱を基体の一方および他方の銅箔を介して放熱手段により放熱させるので、LEDの温度上昇を所定値以下に抑制することができて、LEDの樹脂の劣化または光束の減少を抑制することができる。 According to the first aspect of the present invention, the heat of the LED is dissipated by the heat dissipating means via the one and the other copper foils of the base, so that the temperature rise of the LED can be suppressed to a predetermined value or less, and the LED resin Degradation or decrease in luminous flux can be suppressed.

請求項2の発明によれば、基体の一方および他方の面のそれぞれの表面面積に対するそれぞれの銅箔面積の占有率がともに70%以上であり、かつ当該占有率の差が5%以下とすることにより、LEDの熱を放熱手段により良好に放熱させることができるとともに、基体の一方および他方の面の温度差による基体の反りを防止することができる。 According to the invention of claim 2, the occupancy ratios of the respective copper foil areas with respect to the respective surface areas of the one and the other surfaces of the substrate are both 70% or more, and the difference between the occupancy ratios is 5% or less. Accordingly, the heat of the LED can be radiated favorably by the heat radiating means, and the warpage of the substrate due to the temperature difference between one and the other surfaces of the substrate can be prevented.

請求項3の発明によれば、請求項1または2記載のLED装置を具備するので、LEDの温度上昇が抑制され、光束の減少が抑制されるLED照明装置を提供することができる。

According to the invention of

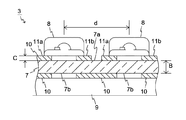

以下、本発明の一実施の形態について、図面を参照して説明する。図1〜図2は、本発明の一実施の形態を示し、図1はLED照明装置であり、(a)は一部切り欠き概略正面図、(b)は下面図、(c)は(a)のA−A方向の上面図、図2はLED装置の一部断面図である。 Hereinafter, an embodiment of the present invention will be described with reference to the drawings. 1 to 2 show an embodiment of the present invention, FIG. 1 shows an LED lighting device, (a) is a partially cutaway schematic front view, (b) is a bottom view, and (c) is ( FIG. 2 is a partial cross-sectional view of the LED device.

図1に示すLED照明装置1は、天井面2に配設される直付け照明器具であり、LED装置3、LED照明装置本体としての照明器具本体4、点灯装置5およびアダプタ6を有して構成されている。

An LED lighting device 1 shown in FIG. 1 is a direct-mounted lighting fixture disposed on a ceiling surface 2, and includes an

LED装置(LEDモジュール)3は、基体7、面実装形のLED8および放熱手段としての金属台9を有して構成されている。

The LED device (LED module) 3 includes a

基体7は、例えば略平面状のガラスエポキシからなり、その外形が例えば20×20mm、厚さBが約1.1mmに形成されている。そして、図2に示すように、一方の面7aおよび他方の面7bに銅箔10が形成され、一方の面7aの銅箔10にLED8に通電させる回路パターン11a,11bが形成されている。銅箔10の厚さCは、0.035mmにされている。そして、回路パターン11a,11b間にLED8が実装されている。

The

そして、基体7の一方および他方の面7a,7bのそれぞれの表面面積に対するそれぞれの銅箔10の面積の占有率がともに70%以上となるように、かつ、それぞれの占有率の差が5%以下となるように、基体7の表面上に銅箔10が形成されている。

Then, the occupancy ratios of the respective copper foils 10 to the respective surface areas of the one and the

LED8は、例えば白色光を放射するものであり、周知の構成により形成されている。そして、回路パターン11a,11b間の3.5Vの印加電圧により、例えば20mAの電流が流れて発光する。すなわち、LED8の1個当りの電力Pは、0.07Wとなっている。そして、LED8,8間の距離dが4mmとなるようにして、LED8は、基体7の一方の面7aに実装されている。このLED8,8間の距離dは、実験式(条件式)d≧14×B^0.52×C^(−0.1)×P^0.63より導かれたものである。実験式において、記号^は、べき乗を表わしている。また、記号B,C,Pは、それぞれ上述した基体7の厚さ、銅箔10の厚さ、LED8の1個当りの電力を示している。

The

金属台9は、例えばアルミニウムからなり、外形の大きさが基体7の大きさと略同等に形成され、厚さが例えば3mmに形成されている。そして、金属体9は、基体7の他方の面7bの銅箔10に接触(密着)するようにして配設されている。また、図1(c)に示すように、中央部付近から一端部に亘ってリード線12,12を沿わせる凹部13が形成されている。

The

上述のようにして、LED装置3が形成されている。そして、図1において、照明器具本体4は、上面および下面に開口14,14を有して枠状に形成され、内部にLED装置3を配設している。すなわち、LED装置3の縁部は、照明器具本体4に支持され、金属台9が上面の開口14を閉塞し、基体7の一方の面7aおよびLED8が下面の開口14に臨んでいる。そして、金属体9の上面が金属からなる所定長の連結管15,15に連結されている取付板16にねじ止めされることにより、照明器具本体4は、アダプタ6に支持されている。

The

アダプタ6は、略円柱状に形成され、内部に点灯装置5を収納している。そして、上面側に一対の電極刃(図示しない。)が設けられている。この電極刃は、天井面2に配設された引掛シーリング17の電極刃挿入穴(図示しない。)に挿入され、アダプタ6が回動されることにより、引掛シーリング17の電源極(図示しない。)に載置されて電気的に接続される。引掛シーリング17の電源極は、天井面2の裏側に配線された電源コード(図示しない。)により商用交流電源に電気的に接続されている。

The

そして、アダプタ6の電極刃は、点灯装置5の入力端子に電気的に接続されている。また、点灯装置5の出力端子からリード線12,12が導出され、このリード線12,12は、連結管15,15の内部および金属台9の凹部13を挿通して基体6の共通入力部に接続されている。

The electrode blade of the

点灯装置5は、AC−DC変換装置や電圧調整装置などにより構成され、各LED8に例えば20mAの電流を通電させてLED8を点灯(発光)させる。そして、LED8が点灯すると、照明器具本体4の下面の開口14から白色光が出射される。

The

次に、本発明の一実施の形態の作用について述べる。 Next, the operation of the embodiment of the present invention will be described.

点灯装置5からLED装置3の共通入力部に給電されると、それぞれのLED8が点灯(発光)する。

When power is supplied from the

LED8が点灯(発光)すると、LED8からの熱は、基体7の一方の面7aの銅箔10に拡散して伝熱される(ヒートスプレッダー効果)。そして、基体7を介して基体7の他方の面7bの銅箔10に伝熱される。他方の面7bには、金属台9が銅箔10に接触するように配設されているので、他方の面7bの銅箔10に伝熱した熱は、金属台9に伝熱し、主として金属台9の表面および金属製の取付板16より放熱される。ここで、銅箔10と金属台9とは、必ずしも完全に密着している必要はなく、銅箔10がヒートスプレッダー効果を奏するので、部分的接触があれば所要の放熱特性を得ることができる。以上のようにして、LED8の熱が放熱され、LED8の温度上昇が抑制される。この結果、LED8からの光束の減少が抑制され、被覆樹脂の劣化が防止されて長寿命化されるようになる。

When the

そして、基体7の一方の面7aの銅箔10および他方の面7bの銅箔10は、それぞれの基体7の表面面積に対して70%以上の占有率となるように形成され、かつ、それぞれの占有率の差が5%以下となるように形成されている。したがって、LED8の熱量を多く伝熱させ、放熱させるので、LED8の温度上昇が所定値以下に抑制される。また、基体7の一方の面7aおよび他方の面7bの温度差が小さいので、基体7に反りなどが生じることが防止される。これらは、実験において確認された。この結果、基体7の他方の面7bの銅箔10に、金属台9などの放熱手段を容易に接触させることができ、LED装置3またはLED照明装置1が安価に形成される。

And the

また、LED8,8間の距離dが上述した実験式(条件式)d≧14×B^0.52×C^(−0.1)×P^0.63であると、LED8の温度上昇が所定値以下に抑制され、かつ、基体7の一方の面7aおよび他方の面7bにおける温度差が10℃以下となることが確認された。

Further, if the distance d between the

そして、LED照明装置1は、上述したLED装置3を具備するので、LED8の温度上昇が抑制され、光束の減少が抑制される。

And since the LED lighting apparatus 1 comprises the

なお、放熱手段は、金属台9に限らず、放熱フィンなどの放熱器であってもよく、照明器具本体4を天井面2などに直付けするときの取付体やシャーシなどでもよい。

The heat radiating means is not limited to the

1…LED照明装置

3…LED装置

4…LED照明装置本体としての照明器具本体

5…点灯装置

6…基体

8…LED

9…放熱手段としての金属台

DESCRIPTION OF SYMBOLS 1 ...

9 ... Metal stand as heat dissipation means

Claims (3)

一方および他方の面にそれぞれの占有率が略同等となるように銅箔が形成され、かつ一方の面に回路パターンの銅箔が形成されてLEDを実装している基体と;

基体の他方の面の銅箔に接触させて配設された放熱手段と;

を具備していることを特徴とするLED装置。 A plurality of LEDs;

A substrate on which LEDs are mounted by forming copper foils on one and other surfaces so that the respective occupation ratios are substantially equal, and forming a copper foil of a circuit pattern on one surface;

Heat dissipation means disposed in contact with the copper foil on the other side of the substrate;

An LED device comprising:

LED装置を配設しているLED照明装置本体と;

LEDを点灯させる点灯装置と;

を具備していることを特徴とするLED照明装置。 An LED device according to claim 1 or 2;

An LED lighting device body in which the LED device is disposed;

A lighting device for lighting the LED;

LED lighting device characterized by comprising.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2003342133A JP2005109228A (en) | 2003-09-30 | 2003-09-30 | Led device and led illumination apparatus |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2003342133A JP2005109228A (en) | 2003-09-30 | 2003-09-30 | Led device and led illumination apparatus |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| JP2005109228A true JP2005109228A (en) | 2005-04-21 |

Family

ID=34536519

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2003342133A Pending JP2005109228A (en) | 2003-09-30 | 2003-09-30 | Led device and led illumination apparatus |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2005109228A (en) |

Cited By (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2007096285A (en) * | 2005-08-29 | 2007-04-12 | Kyocera Corp | Light emitting device mounting substrate, light emitting device accommodating package, light emitting device and lighting device |

| JP2007273213A (en) * | 2006-03-31 | 2007-10-18 | Nidec Sankyo Corp | Light source body and lighting system |

| WO2008156020A1 (en) * | 2007-06-19 | 2008-12-24 | Sharp Kabushiki Kaisha | Substrate and illuminating apparatus |

| JP2009004129A (en) * | 2007-06-19 | 2009-01-08 | Sharp Corp | Substrate, and illumination device |

| JP2009016095A (en) * | 2007-07-02 | 2009-01-22 | Sharp Corp | Illuminating device and substrate |

| US7686469B2 (en) | 2006-09-30 | 2010-03-30 | Ruud Lighting, Inc. | LED lighting fixture |

| US9028087B2 (en) | 2006-09-30 | 2015-05-12 | Cree, Inc. | LED light fixture |

| US9243794B2 (en) | 2006-09-30 | 2016-01-26 | Cree, Inc. | LED light fixture with fluid flow to and from the heat sink |

| US9541246B2 (en) | 2006-09-30 | 2017-01-10 | Cree, Inc. | Aerodynamic LED light fixture |

| EP3346320A4 (en) * | 2015-09-01 | 2018-10-24 | Panasonic Intellectual Property Management Co., Ltd. | Image display device |

| US10490143B2 (en) | 2015-09-01 | 2019-11-26 | Panasonic Intellectual Property Management Co., Ltd. | Video display device |

| US10642097B2 (en) | 2015-09-01 | 2020-05-05 | Panasonic Intellectual Property Management Co., Ltd. | Image display device including multiple light source substrates |

| US10643556B2 (en) | 2015-09-01 | 2020-05-05 | Panasonic Intellectual Property Management Co., Ltd. | Video display device |

| US10809569B2 (en) | 2015-09-01 | 2020-10-20 | Panasonic Intellectual Property Management Co., Ltd. | Video display device |

| US10976601B2 (en) | 2015-09-01 | 2021-04-13 | Panasonic Intellectual Property Management Co., Ltd. | Video display device |

-

2003

- 2003-09-30 JP JP2003342133A patent/JP2005109228A/en active Pending

Cited By (22)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2007096285A (en) * | 2005-08-29 | 2007-04-12 | Kyocera Corp | Light emitting device mounting substrate, light emitting device accommodating package, light emitting device and lighting device |

| JP4564465B2 (en) * | 2006-03-31 | 2010-10-20 | 日本電産ピジョン株式会社 | Light source body and lighting device |

| JP2007273213A (en) * | 2006-03-31 | 2007-10-18 | Nidec Sankyo Corp | Light source body and lighting system |

| US9039223B2 (en) | 2006-09-30 | 2015-05-26 | Cree, Inc. | LED lighting fixture |

| US9261270B2 (en) | 2006-09-30 | 2016-02-16 | Cree, Inc. | LED lighting fixture |

| US7686469B2 (en) | 2006-09-30 | 2010-03-30 | Ruud Lighting, Inc. | LED lighting fixture |

| US9541246B2 (en) | 2006-09-30 | 2017-01-10 | Cree, Inc. | Aerodynamic LED light fixture |

| US8070306B2 (en) | 2006-09-30 | 2011-12-06 | Ruud Lighting, Inc. | LED lighting fixture |

| US8425071B2 (en) | 2006-09-30 | 2013-04-23 | Cree, Inc. | LED lighting fixture |

| US9028087B2 (en) | 2006-09-30 | 2015-05-12 | Cree, Inc. | LED light fixture |

| US9534775B2 (en) | 2006-09-30 | 2017-01-03 | Cree, Inc. | LED light fixture |

| US9243794B2 (en) | 2006-09-30 | 2016-01-26 | Cree, Inc. | LED light fixture with fluid flow to and from the heat sink |

| WO2008156020A1 (en) * | 2007-06-19 | 2008-12-24 | Sharp Kabushiki Kaisha | Substrate and illuminating apparatus |

| JP2009004129A (en) * | 2007-06-19 | 2009-01-08 | Sharp Corp | Substrate, and illumination device |

| JP2009016095A (en) * | 2007-07-02 | 2009-01-22 | Sharp Corp | Illuminating device and substrate |

| EP3346320A4 (en) * | 2015-09-01 | 2018-10-24 | Panasonic Intellectual Property Management Co., Ltd. | Image display device |

| US10490143B2 (en) | 2015-09-01 | 2019-11-26 | Panasonic Intellectual Property Management Co., Ltd. | Video display device |

| US10642097B2 (en) | 2015-09-01 | 2020-05-05 | Panasonic Intellectual Property Management Co., Ltd. | Image display device including multiple light source substrates |

| US10643556B2 (en) | 2015-09-01 | 2020-05-05 | Panasonic Intellectual Property Management Co., Ltd. | Video display device |

| US10663793B2 (en) | 2015-09-01 | 2020-05-26 | Panasonic Intellectual Property Management Co., Ltd. | Image display device |

| US10809569B2 (en) | 2015-09-01 | 2020-10-20 | Panasonic Intellectual Property Management Co., Ltd. | Video display device |

| US10976601B2 (en) | 2015-09-01 | 2021-04-13 | Panasonic Intellectual Property Management Co., Ltd. | Video display device |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4492486B2 (en) | Lighting equipment using LED | |

| JP2007324137A (en) | Lighting system | |

| JP2009218204A (en) | Light emitting module and illuminating apparatus | |

| JP2008034140A (en) | Led lighting device | |

| JP5445846B2 (en) | Lighting device | |

| JP2005109228A (en) | Led device and led illumination apparatus | |

| JP2010153044A (en) | Light source unit and luminaire | |

| JP2009301810A (en) | Illuminating device | |

| JP2011070972A (en) | Self-ballasted lamp, and lighting equipment | |

| JP2010135747A (en) | Light-emitting module and lighting apparatus | |

| JP2011154832A5 (en) | ||

| JP2009004129A (en) | Substrate, and illumination device | |

| JP2004055800A (en) | Led lighting device | |

| JP4602477B1 (en) | Lighting device | |

| JP5333488B2 (en) | LED lighting device | |

| JP2010170903A (en) | Socket for light source, and lighting fixture | |

| JP2010102897A (en) | Light source unit and luminaire | |

| JP2004095655A (en) | Led device and led illumination device | |

| JP2011258454A (en) | Light source and lighting fixture | |

| JP5308125B2 (en) | lighting equipment | |

| JP7091953B2 (en) | Lighting equipment | |

| JP2011096649A (en) | Illumination device | |

| JP2011181252A (en) | Lighting fixture | |

| JP2008252141A (en) | Led-lighting device | |

| JP5105597B2 (en) | LED mounting device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20060721 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20070611 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070620 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20070820 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20081224 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20090427 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20090507 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20090603 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20090917 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20100128 |