EP4302930A1 - Hard-core container with fabric pouches - Google Patents

Hard-core container with fabric pouches Download PDFInfo

- Publication number

- EP4302930A1 EP4302930A1 EP23183293.2A EP23183293A EP4302930A1 EP 4302930 A1 EP4302930 A1 EP 4302930A1 EP 23183293 A EP23183293 A EP 23183293A EP 4302930 A1 EP4302930 A1 EP 4302930A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- hard body

- container

- coupled

- toolbox

- rigid

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 239000004744 fabric Substances 0.000 title claims description 7

- 229910052751 metal Inorganic materials 0.000 claims description 7

- 239000002184 metal Substances 0.000 claims description 7

- 239000004033 plastic Substances 0.000 claims description 6

- 238000001746 injection moulding Methods 0.000 claims description 3

- 239000010985 leather Substances 0.000 claims description 2

- 238000002347 injection Methods 0.000 claims 1

- 239000007924 injection Substances 0.000 claims 1

- 239000002991 molded plastic Substances 0.000 claims 1

- 239000000463 material Substances 0.000 description 12

- 238000000034 method Methods 0.000 description 7

- 229920000642 polymer Polymers 0.000 description 5

- 238000003860 storage Methods 0.000 description 4

- 238000010276 construction Methods 0.000 description 3

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 3

- FYYHWMGAXLPEAU-UHFFFAOYSA-N Magnesium Chemical compound [Mg] FYYHWMGAXLPEAU-UHFFFAOYSA-N 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 2

- 229910052782 aluminium Inorganic materials 0.000 description 2

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 2

- 229910052749 magnesium Inorganic materials 0.000 description 2

- 239000011777 magnesium Substances 0.000 description 2

- 239000002861 polymer material Substances 0.000 description 2

- 239000010959 steel Substances 0.000 description 2

- 238000004140 cleaning Methods 0.000 description 1

- 230000003670 easy-to-clean Effects 0.000 description 1

- JEIPFZHSYJVQDO-UHFFFAOYSA-N iron(III) oxide Inorganic materials O=[Fe]O[Fe]=O JEIPFZHSYJVQDO-UHFFFAOYSA-N 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 239000003607 modifier Substances 0.000 description 1

- 239000007779 soft material Substances 0.000 description 1

- 230000005068 transpiration Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D25/00—Details of other kinds or types of rigid or semi-rigid containers

- B65D25/20—External fittings

- B65D25/24—External fittings for spacing bases of containers from supporting surfaces, e.g. legs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25H—WORKSHOP EQUIPMENT, e.g. FOR MARKING-OUT WORK; STORAGE MEANS FOR WORKSHOPS

- B25H3/00—Storage means or arrangements for workshops facilitating access to, or handling of, work tools or instruments

- B25H3/02—Boxes

- B25H3/021—Boxes comprising a number of connected storage elements

- B25H3/022—Boxes comprising a number of connected storage elements in fixed relationship

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D25/00—Details of other kinds or types of rigid or semi-rigid containers

- B65D25/20—External fittings

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D25/00—Details of other kinds or types of rigid or semi-rigid containers

- B65D25/28—Handles

- B65D25/32—Bail handles, i.e. pivoted rigid handles of generally semi-circular shape with pivot points on two opposed sides or wall parts of the conainter

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D81/00—Containers, packaging elements, or packages, for contents presenting particular transport or storage problems, or adapted to be used for non-packaging purposes after removal of contents

- B65D81/02—Containers, packaging elements, or packages, for contents presenting particular transport or storage problems, or adapted to be used for non-packaging purposes after removal of contents specially adapted to protect contents from mechanical damage

Definitions

- This application relates generally to a container. More specifically, this application relates to a hard-core container with fabric pouches.

- a system and a method including a toolbox for storing items such as tools and equipment.

- the container or toolbox may have a hard polymer body or other hard and rigid material, such as aluminum, magnesium, steel, laminated panels, and the like, to make the container light-weight and waterproof.

- the container may also have fabric pouches coupled with it for storing additional items and a closable top to protect stored items.

- the container may include a hard body having side walls and a bottom floor defining an internal cavity.

- One or more soft panels may be coupled with at least one of the side walls.

- a handle may also be coupled with the hard body.

- the container may also include a closable top coupled with the hard body.

- the closable top includes a closure to protect items in the internal cavity of the hard body.

- tool storage boxes are bulky and are heavy to carry around. Some tool storage boxes are made entirely of metal and tend to rust if exposed to moisture. Most tool bags can rip and are hard to clean.

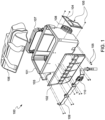

- FIGURE 1 shows an example exploded view of a toolbox according to some embodiments presently disclosed.

- the container 100 includes a hard bottom body or base 101, one or more soft pouches or panels 102, 103, and 104, a closeable top 106, a handle 107, wheels 108, a clip bar 109, and a clip 110.

- the hard body 101 is a rigid container that holds its shape relatively intact under the forces of its own weight and the weight of its contents. In a rigid body any deformity, such as bowed sidewalls, caused by heavy weights disappears and the container reverts to its original shape when such forces are removed.

- the hard body 101 may be formed using plastic injection molding process. Specifically, melted polymer material is pushed into a mold to form the hard body 101 shown in Figure 1 .

- different material may be used to form a rigid body for the container or toolbox, such as aluminum, magnesium, steel, laminated panels, and the like.

- the container 100 is made of a waterproof material, such as plastic or metal sheets, that are not permeable to water. This helps in easy cleaning with water (for example, by hosing it down after work), and also makes it possible to lay down the container 100, such as a toolbox, in puddles of water or wet surroundings without getting the contents of the container 100 wet.

- a waterproof material such as plastic or metal sheets

- the one or more soft panels (or pouches) 102, 103, and/or 104 may be permanently and unremovably attached or be removably coupled with the side walls of the hard body 101.

- the soft panels 102, 103, 104 may be formed from fabric and provide one or more pockets for storing items such as hand tools, power tools, and/or other equipment like flashlights and stud-finders.

- the soft panels 102-104 may be made of other soft materials, such as soft plastic, mesh, leather, or other suitable material.

- the one or more soft pouches or panels may be coupled externally to the walls of the hard body 101.

- the one or more soft panels may also be coupled within the internal cavity defined by the walls of the hard body 101.

- the soft panels may be permanently sewn using thread to the walls of the hard body 101.

- the soft panels may also be unremovably riveted using rivets 105 to the hard body 101.

- the soft panels or pouches may be removably attached to (for example, detachable by user), or directly or indirectly coupled with the hard body 101.

- the soft panels may be attached to the hard body, internally (inside container 100) or externally (outside container 100), by locking clamps, screws or bolts attachable to the hard body, hook-and-loop fasteners (like Velcro ® ) and the like.

- the soft panels 102-104 may be coupled to a top edge of the side wall(s) of the hard body 101.

- the soft panels may also be attached at top or any other point, like the middle, along the walls of the hard body 101.

- the internal and external panels may be disjoint and separate, while in other embodiments, the internal and external soft panels may be integrated as one piece and straddle one or more of the sidewalls of the hard body 101.

- the closeable top 106 may be permanently or removably coupled with the top edge of the side walls of the hard body 101.

- the closeable top 106 is formed from fabric and provides a closure to protect items in the internal cavity of the hard body 101.

- the closure can be, for example, a zipper, Velcro ® , buckles, snap fasteners, eyelets, studs, and/or hooks and eyes.

- the closeable top 106 may be sewn using thread to the hard body 101.

- the closeable top 106 may also be riveted using rivets 105 to the hard body 101.

- the closeable top 106 may include one or more handles for transporting the container 100.

- the closeable top 106 is coupled along the entire top perimeter of the hard body 101.

- the closeable top 106 may be permanently and unremovably attached to the rigid hard body 101, while in other embodiments, the closable top 106 may be removably attached to the hard body 101 by various techniques, such as a zipper, Velcro ® , snap buttons, springy hooks, or other similar techniques that may be used to attach the closable top to a rigid rim of the hard body 101.

- the handle 107 is coupled with one of the walls of the hard body 101.

- the handle 107 may be collapsible for easy transpiration and/or storage of the container 100.

- the handle 107 may be coupled externally to one of the walls of the hard body 101.

- the handle 107 may be formed from rigid material.

- the rigid material can be polymer and/or metal.

- wheels 108 are coupled with the hard body 101.

- the handle 107 may be coupled externally to the hard body 101 for easy transportation of the container 100.

- the wheels 108 may be formed from rigid material.

- the rigid material can be polymer and/or metal.

- the clip bar 109 is coupled with one of the side walls of the hard body 101.

- the clip bar 109 may be formed from rigid material and provides a way to hang items such as, for example, tools and/or equipment.

- the rigid material can be polymer and/or metal.

- the clip bar 109 may be coupled externally to one of the walls of the hard body 101.

- the clip bar 109 may be riveted using rivets 105 to the hard body 101.

- the clip 110 is coupled with the clip bar 109.

- the clip 110 may slide along the clip bar 109.

- the clip 110 provides a way to hang items such as, for example, tools and/or equipment.

- FIGURE 2 shows another example toolbox according to some embodiments presently disclosed.

- the container 200 may be a toolbox and includes a hard body 201, one or more soft panels 202, 203, 204, and a handle 206.

- the hard body 201 includes side walls extending from a bottom floor.

- the side walls and the bottom floor define internal cavity for storing items such as, for example, tools and/or equipment.

- the hard body 201 may be formed using plastic injection molding process. Specifically, melted polymer material is pushed into a mold to form the hard body 201 shown in Figure 2 .

- the one or more soft panels (or pouches) 202, 203, and/or 204 are coupled with the side walls of the hard body 201.

- the soft panels are formed from fabric and provide one or more pockets for storing items such as, for example, tools and/or equipment.

- the one or more soft panels may be permanently and unremovably coupled externally to the walls of the hard body 201.

- the soft panels 202-204 may also be detachable by the user, for example, using screws, hanging hooks, locking clamp mechanisms, hook-and-loop attachments, and the like.

- the one or more soft panels may also be coupled within the internal cavity defined by the walls of the hard body 201. The soft panels may be sewn using thread to the hard body 201.

- the soft panels may also be riveted using rivets 205 to the hard body 201.

- the soft panels are coupled to a top edge of the side wall(s) of the hard body 201.

- the soft panels 202-204 may also be attached at top or any other point, like the middle, along the walls of the hard body 201.

- the internal and external panels may be disjoint and separate, while in other embodiments, the internal and external soft panels may be integrated as one piece and straddle one or more of the sidewalls of the hard body 201.

- the handle 206 is coupled with two opposing side walls of the hard body 201.

- the handle 206 may be riveted to the hard body 201 using rivets 205.

- the handle 206 may be formed from rigid material.

- the rigid material can be polymer and/or metal.

- the handle 206 is attached fixedly to the hard body 201, such that it does not pivot and stays in the same position above the hard body 201, as shown in FIGURE 2 .

- the handle 206 is pivotably attached to the hard body 201, such that it can pivot around its attachment point to the hard body 201 to move out of the way and allow easier access to the internal cavity of the toolbox or container 200.

- a clip bar (not shown in FIGURE 2 ), similar to clip bar 109 of FIGURE 1 , may be coupled with the hard body 201. As described above, clips 110 may be attached to the clip bar to be used to hang various tools and implements from the toolbox 201.

- phrase “A or B” will be understood to include the possibilities of “A” or “B” or “A and B.” It is further understood that any phrase of the form “A/B” shall mean any one of "A", “B”, “A or B", or "A and B”. This construct includes the phrase “and/or" itself.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Purses, Travelling Bags, Baskets, Or Suitcases (AREA)

Abstract

Description

- This application relates generally to a container. More specifically, this application relates to a hard-core container with fabric pouches.

- The drawings, when considered in connection with the following description, are presented for the purpose of facilitating an understanding of the subject matter sought to be protected.

-

FIGURE 1 shows an example exploded view of a toolbox according to some embodiments presently disclosed; and -

FIGURE 2 shows another example toolbox according to some embodiments presently disclosed. - While the present disclosure is described with reference to several illustrative embodiments and example devices described herein, it should be clear that the present disclosure should not be limited to such embodiments. Therefore, the description of the embodiments provided herein is illustrative of the present disclosure and should not limit the scope of the disclosure as claimed. In addition, while following description references particular configurations of container such as a toolbox, it will be appreciated that the disclosure may be applicable with other types of container configurations such as small cabinets.

- Briefly described, a system and a method are disclosed including a toolbox for storing items such as tools and equipment. The container or toolbox may have a hard polymer body or other hard and rigid material, such as aluminum, magnesium, steel, laminated panels, and the like, to make the container light-weight and waterproof. The container may also have fabric pouches coupled with it for storing additional items and a closable top to protect stored items.

- In various embodiments, the container may include a hard body having side walls and a bottom floor defining an internal cavity. One or more soft panels may be coupled with at least one of the side walls. A handle may also be coupled with the hard body.

- In various embodiments, the container may also include a closable top coupled with the hard body. The closable top includes a closure to protect items in the internal cavity of the hard body.

- Building contractors, construction crews, carpet layers, private do-it-yourself (DIY) people, shipping operations and warehouses often use tools and containers, tool storage boxes and tool bags to store their tools. Most tool storage boxes are bulky and are heavy to carry around. Some tool storage boxes are made entirely of metal and tend to rust if exposed to moisture. Most tool bags can rip and are hard to clean.

- Therefore, there is a need for a container that is light-weight, waterproof, easy to clean and flexible to better protect user's tools and/or equipment.

-

FIGURE 1 shows an example exploded view of a toolbox according to some embodiments presently disclosed. In various embodiments, thecontainer 100 includes a hard bottom body orbase 101, one or more soft pouches orpanels closeable top 106, ahandle 107,wheels 108, aclip bar 109, and aclip 110. - In various embodiments, the

hard body 101 is a rigid container that holds its shape relatively intact under the forces of its own weight and the weight of its contents. In a rigid body any deformity, such as bowed sidewalls, caused by heavy weights disappears and the container reverts to its original shape when such forces are removed. includes side walls extending from a bottom floor. The side walls and the bottom floor define internal cavity for storing items such as tools and/or equipment. Thehard body 101 may be formed using plastic injection molding process. Specifically, melted polymer material is pushed into a mold to form thehard body 101 shown inFigure 1 . In other embodiments, different material may be used to form a rigid body for the container or toolbox, such as aluminum, magnesium, steel, laminated panels, and the like. In various embodiments, thecontainer 100 is made of a waterproof material, such as plastic or metal sheets, that are not permeable to water. This helps in easy cleaning with water (for example, by hosing it down after work), and also makes it possible to lay down thecontainer 100, such as a toolbox, in puddles of water or wet surroundings without getting the contents of thecontainer 100 wet. - In various embodiments, the one or more soft panels (or pouches) 102, 103, and/or 104 may be permanently and unremovably attached or be removably coupled with the side walls of the

hard body 101. Thesoft panels hard body 101. The one or more soft panels may also be coupled within the internal cavity defined by the walls of thehard body 101. The soft panels may be permanently sewn using thread to the walls of thehard body 101. The soft panels may also be unremovably riveted usingrivets 105 to thehard body 101. In other embodiments, the soft panels or pouches may be removably attached to (for example, detachable by user), or directly or indirectly coupled with thehard body 101. For example, the soft panels may be attached to the hard body, internally (inside container 100) or externally (outside container 100), by locking clamps, screws or bolts attachable to the hard body, hook-and-loop fasteners (like Velcro ®) and the like. In various embodiments, the soft panels 102-104 may be coupled to a top edge of the side wall(s) of thehard body 101. The soft panels may also be attached at top or any other point, like the middle, along the walls of thehard body 101. In some embodiments, the internal and external panels may be disjoint and separate, while in other embodiments, the internal and external soft panels may be integrated as one piece and straddle one or more of the sidewalls of thehard body 101. - In various embodiments, the

closeable top 106 may be permanently or removably coupled with the top edge of the side walls of thehard body 101. Thecloseable top 106 is formed from fabric and provides a closure to protect items in the internal cavity of thehard body 101. The closure can be, for example, a zipper, Velcro®, buckles, snap fasteners, eyelets, studs, and/or hooks and eyes. Thecloseable top 106 may be sewn using thread to thehard body 101. Thecloseable top 106 may also be riveted usingrivets 105 to thehard body 101. Thecloseable top 106 may include one or more handles for transporting thecontainer 100. In various embodiments, thecloseable top 106 is coupled along the entire top perimeter of thehard body 101. As noted above, in some embodiments, thecloseable top 106 may be permanently and unremovably attached to the rigidhard body 101, while in other embodiments, theclosable top 106 may be removably attached to thehard body 101 by various techniques, such as a zipper, Velcro ®, snap buttons, springy hooks, or other similar techniques that may be used to attach the closable top to a rigid rim of thehard body 101. - In various embodiments, the

handle 107 is coupled with one of the walls of thehard body 101. Thehandle 107 may be collapsible for easy transpiration and/or storage of thecontainer 100. Thehandle 107 may be coupled externally to one of the walls of thehard body 101. Thehandle 107 may be formed from rigid material. The rigid material can be polymer and/or metal. - In various embodiments,

wheels 108 are coupled with thehard body 101. Thehandle 107 may be coupled externally to thehard body 101 for easy transportation of thecontainer 100. Thewheels 108 may be formed from rigid material. The rigid material can be polymer and/or metal. - In various embodiments, the

clip bar 109 is coupled with one of the side walls of thehard body 101. Theclip bar 109 may be formed from rigid material and provides a way to hang items such as, for example, tools and/or equipment. The rigid material can be polymer and/or metal. Theclip bar 109 may be coupled externally to one of the walls of thehard body 101. Theclip bar 109 may be riveted usingrivets 105 to thehard body 101. - In various embodiments, the

clip 110 is coupled with theclip bar 109. Theclip 110 may slide along theclip bar 109. Theclip 110 provides a way to hang items such as, for example, tools and/or equipment. -

FIGURE 2 shows another example toolbox according to some embodiments presently disclosed. In various embodiments, thecontainer 200 may be a toolbox and includes ahard body 201, one or moresoft panels handle 206. - In various embodiments, the

hard body 201 includes side walls extending from a bottom floor. The side walls and the bottom floor define internal cavity for storing items such as, for example, tools and/or equipment. Thehard body 201 may be formed using plastic injection molding process. Specifically, melted polymer material is pushed into a mold to form thehard body 201 shown inFigure 2 . - In various embodiments, the one or more soft panels (or pouches) 202, 203, and/or 204 are coupled with the side walls of the

hard body 201. The soft panels are formed from fabric and provide one or more pockets for storing items such as, for example, tools and/or equipment. The one or more soft panels may be permanently and unremovably coupled externally to the walls of thehard body 201. In some embodiments, the soft panels 202-204 may also be detachable by the user, for example, using screws, hanging hooks, locking clamp mechanisms, hook-and-loop attachments, and the like. The one or more soft panels may also be coupled within the internal cavity defined by the walls of thehard body 201. The soft panels may be sewn using thread to thehard body 201. The soft panels may also be riveted usingrivets 205 to thehard body 201. In various embodiments, the soft panels are coupled to a top edge of the side wall(s) of thehard body 201. The soft panels 202-204 may also be attached at top or any other point, like the middle, along the walls of thehard body 201. In some embodiments, the internal and external panels may be disjoint and separate, while in other embodiments, the internal and external soft panels may be integrated as one piece and straddle one or more of the sidewalls of thehard body 201. - In various embodiments, the

handle 206 is coupled with two opposing side walls of thehard body 201. Thehandle 206 may be riveted to thehard body 201 usingrivets 205. Thehandle 206 may be formed from rigid material. The rigid material can be polymer and/or metal. In some embodiments, thehandle 206 is attached fixedly to thehard body 201, such that it does not pivot and stays in the same position above thehard body 201, as shown inFIGURE 2 . In other embodiments, thehandle 206 is pivotably attached to thehard body 201, such that it can pivot around its attachment point to thehard body 201 to move out of the way and allow easier access to the internal cavity of the toolbox orcontainer 200. - In various embodiments, a clip bar (not shown in

FIGURE 2 ), similar to clip bar 109 ofFIGURE 1 , may be coupled with thehard body 201. As described above, clips 110 may be attached to the clip bar to be used to hang various tools and implements from thetoolbox 201. - It will be understood that unless explicitly stated or specified, the steps described in a process are not ordered and may not necessarily be performed or occur in the order described or depicted. For example, a step A in a process described prior to a step B in the same process, may actually be performed after step B. In other words, a collection of steps in a process for achieving an end-result may occur in any order unless otherwise stated.

- Changes can be made to the claimed invention in light of the above Detailed Description. While the above description details certain embodiments of the invention and describes the best mode contemplated, no matter how detailed the above appears in text, the claimed invention can be practiced in many ways. Details of the system may vary considerably in its implementation details, while still being encompassed by the claimed invention disclosed herein.

- Particular terminology used when describing certain features or aspects of the disclosure should not be taken to imply that the terminology is being redefined herein to be restricted to any specific characteristics, features, or aspects of the disclosure with which that terminology is associated. In general, the terms used in the following claims should not be construed to limit the claimed invention to the specific embodiments disclosed in the specification, unless the above Detailed Description section explicitly defines such terms. Accordingly, the actual scope of the claimed invention encompasses not only the disclosed embodiments, but also all equivalent ways of practicing or implementing the claimed invention.

- It will be understood by those within the art that, in general, terms used herein, and especially in the appended claims (e.g., bodies of the appended claims) are generally intended as "open" terms (e.g., the term "including" should be interpreted as "including but not limited to," the term "having" should be interpreted as "having at least," the term "includes" should be interpreted as "includes but is not limited to," etc.). It will be further understood by those within the art that if a specific number of an introduced claim recitation is intended, such an intent will be explicitly recited in the claim, and in the absence of such recitation no such intent is present. For example, as an aid to understanding, the following appended claims may contain usage of the introductory phrases "at least one" and "one or more" to introduce claim recitations. However, the use of such phrases should not be construed to imply that the introduction of a claim recitation by the indefinite articles "a" or "an" limits any particular claim containing such introduced claim recitation to inventions containing only one such recitation, even when the same claim includes the introductory phrases "one or more" or "at least one" and indefinite articles such as "a" or "an" (e.g., "a" and/or "an" should typically be interpreted to mean "at least one" or "one or more"); the same holds true for the use of definite articles used to introduce claim recitations. In addition, even if a specific number of an introduced claim recitation is explicitly recited, those skilled in the art will recognize that such recitation should typically be interpreted to mean at least the recited number (e.g., the bare recitation of "two recitations," without other modifiers, typically means at least two recitations, or two or more recitations). Furthermore, in those instances where a convention analogous to "at least one of A, B, and C, etc." is used, in general such a construction is intended in the sense one having skill in the art would understand the convention (e.g., "a system having at least one of A, B, and C" would include but not be limited to systems that have A alone, B alone, C alone, A and B together, A and C together, B and C together, and/or A, B, and C together, etc.). In those instances where a convention analogous to "at least one of A, B, or C, etc." is used, in general such a construction is intended in the sense one having skill in the art would understand the convention (e.g., "a system having at least one of A, B, or C" would include but not be limited to systems that have A alone, B alone, C alone, A and B together, A and C together, B and C together, and/or A, B, and C together, etc.). It will be further understood by those within the art that virtually any disjunctive word and/or phrase presenting two or more alternative terms, whether in the description, claims, or drawings, should be understood to contemplate the possibilities of including one of the terms, either of the terms, or both terms. For example, the phrase "A or B" will be understood to include the possibilities of "A" or "B" or "A and B." It is further understood that any phrase of the form "A/B" shall mean any one of "A", "B", "A or B", or "A and B". This construct includes the phrase "and/or" itself.

- The above specification, examples, and data provide a complete description of the manufacture and use of the claimed invention. Since many embodiments of the claimed invention can be made without departing from the spirit and scope of the disclosure, the invention resides in the claims hereinafter appended. It is further understood that this disclosure is not limited to the disclosed embodiments, but is intended to cover various arrangements included within the spirit and scope of the broadest interpretation so as to encompass all such modifications and equivalent arrangements.

Claims (20)

- A container comprising:a rigid hard body having side walls and a bottom floor defining an internal cavity;one or more soft panels coupled with at least one of the side walls; anda handle coupled with the hard body.

- The container of claim 1, wherein the rigid hard body is formed using plastic injection molding process.

- The container of claim 1, wherein the one or more soft panels are riveted to the rigid hard body.

- The container of claim 1, wherein the one or more soft panels are sewn to the rigid hard body.

- The container of claim 1, further comprising a closable top coupled with the hard body, wherein the closable top comprises a closure to protect items in the internal cavity of the rigid hard body.

- The container of claim 5, wherein the closable top is riveted to the rigid hard body.

- The container of claim 5, wherein the closable top is sewn to the rigid hard body.

- The container of claim 5, wherein the handle is collapsible.

- The container of claim 8, further comprising wheels coupled with the rigid hard body.

- The container of claim 5, further comprising a clip bar coupled with the rigid hard body.

- The container of claim 10, wherein the clip bar is unremovably riveted to the rigid hard body.

- The container of claim 11, further comprising a clip coupled with the clip bar.

- A toolbox comprising:a rigid hard body having side walls and a bottom floor defining an internal cavity;one or more soft pouches coupled with at least one of the side walls on the inside or outside of the rigid side walls; anda handle coupled with the hard body.

- The toolbox of claim 13, wherein the rigid hardbody is made of one of injection molded plastic and metal.

- The toolbox of claim 13, wherein the one or more soft panels are made of one of fabric, soft plastic, and leather.

- The toolbox of claim 13, wherein the one or more soft panels are coupled with the rigid hard body using rivets.

- The toolbox of claim 1, wherein the one or more soft panels are coupled with the rigid hard body using sewed threads.

- The toolbox of claim 13, further comprising a clip bar permanently attached to the toolbox.

- The toolbox of claim 18, wherein the clip bar is useable with a clip to hang tools.

- The toolbox of claim 18, wherein the handle is pivotably attached to the rigid hard body.

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US202217859893A | 2022-07-07 | 2022-07-07 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP4302930A1 true EP4302930A1 (en) | 2024-01-10 |

Family

ID=87136631

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP23183293.2A Pending EP4302930A1 (en) | 2022-07-07 | 2023-07-04 | Hard-core container with fabric pouches |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP4302930A1 (en) |

| CN (1) | CN117383053A (en) |

| CA (1) | CA3205641A1 (en) |

| TW (1) | TW202411029A (en) |

Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20030106821A1 (en) * | 2001-06-14 | 2003-06-12 | Zag Industries, Ltd. | Toolbox with external compartment |

| US20040134818A1 (en) * | 2003-01-15 | 2004-07-15 | Cunningham Ian W. | Modular toolbox system |

| US20050189388A1 (en) * | 2000-04-21 | 2005-09-01 | Travelon | Framed soft sided carrier for tools |

| US20060070901A1 (en) * | 2004-10-06 | 2006-04-06 | Adams Robert G | Utility bag assembly for transporting and organizing small items |

| US20070131568A1 (en) * | 2005-12-13 | 2007-06-14 | Georgia Brian D | Law enforcement officer's utility bag |

| US20070194543A1 (en) * | 2005-05-16 | 2007-08-23 | Nikolai Duvigneau | Portable container assembly |

| US20120228841A1 (en) * | 2011-01-14 | 2012-09-13 | Lf Centennial Limited | Rolling tool bag |

| US20160023349A1 (en) * | 2014-07-22 | 2016-01-28 | Milwaukee Electric Tool Corporation | Tool storage devices |

| US20200165036A1 (en) * | 2017-07-31 | 2020-05-28 | Milwaukee Electric Tool Corporation | Storage Device System |

| EP3987973A1 (en) * | 2020-10-21 | 2022-04-27 | Grown-Up Licenses Limited | Carrier having a rigid container and sleeve organizer |

-

2023

- 2023-07-04 EP EP23183293.2A patent/EP4302930A1/en active Pending

- 2023-07-06 CN CN202310823211.4A patent/CN117383053A/en active Pending

- 2023-07-06 TW TW112125191A patent/TW202411029A/en unknown

- 2023-07-06 CA CA3205641A patent/CA3205641A1/en active Pending

Patent Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20050189388A1 (en) * | 2000-04-21 | 2005-09-01 | Travelon | Framed soft sided carrier for tools |

| US20030106821A1 (en) * | 2001-06-14 | 2003-06-12 | Zag Industries, Ltd. | Toolbox with external compartment |

| US20040134818A1 (en) * | 2003-01-15 | 2004-07-15 | Cunningham Ian W. | Modular toolbox system |

| US20060070901A1 (en) * | 2004-10-06 | 2006-04-06 | Adams Robert G | Utility bag assembly for transporting and organizing small items |

| US20070194543A1 (en) * | 2005-05-16 | 2007-08-23 | Nikolai Duvigneau | Portable container assembly |

| US20070131568A1 (en) * | 2005-12-13 | 2007-06-14 | Georgia Brian D | Law enforcement officer's utility bag |

| US20120228841A1 (en) * | 2011-01-14 | 2012-09-13 | Lf Centennial Limited | Rolling tool bag |

| US20160023349A1 (en) * | 2014-07-22 | 2016-01-28 | Milwaukee Electric Tool Corporation | Tool storage devices |

| US20200165036A1 (en) * | 2017-07-31 | 2020-05-28 | Milwaukee Electric Tool Corporation | Storage Device System |

| EP3987973A1 (en) * | 2020-10-21 | 2022-04-27 | Grown-Up Licenses Limited | Carrier having a rigid container and sleeve organizer |

Also Published As

| Publication number | Publication date |

|---|---|

| CN117383053A (en) | 2024-01-12 |

| TW202411029A (en) | 2024-03-16 |

| CA3205641A1 (en) | 2024-01-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US10773374B2 (en) | Tool storage devices | |

| US10350746B2 (en) | Tool storage devices | |

| US6126003A (en) | Tool bag | |

| US20150201722A1 (en) | Hard Bottom Tote | |

| US9345301B2 (en) | Supported composite tool pack | |

| US7874328B2 (en) | Utility bag | |

| US20080169739A1 (en) | Carriable and wall mountable tool storage system | |

| US20080202962A1 (en) | Tool bag | |

| US20160242519A1 (en) | Convertible container assembly | |

| US6945442B2 (en) | Framed soft sided carrier for tools | |

| CA2800605A1 (en) | Tool/material carryall | |

| WO2019010082A1 (en) | Modular storage | |

| US20090250495A1 (en) | Portable Cargo Trailer Tool Pouch | |

| EP4302930A1 (en) | Hard-core container with fabric pouches | |

| US20190047137A1 (en) | Utility tool bag | |

| WO2008100890A2 (en) | Tool container | |

| US20070235491A1 (en) | Storage device | |

| US20050263553A1 (en) | Shop bag | |

| JP2007135992A (en) | Tool housing | |

| US20240140510A1 (en) | Utility cart device | |

| US8622212B2 (en) | Tool holder | |

| JP2010075210A (en) | Fishing bag and fishing tackle case | |

| CA2849455C (en) | Supported composite tool pack | |

| CA2904908C (en) | Worksite bag | |

| KR20160143475A (en) | Combined Ladder Tool Bag |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN PUBLISHED |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC ME MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20240709 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC ME MK MT NL NO PL PT RO RS SE SI SK SM TR |