EP3536849B1 - Locking mechanism and an ironing device having the same - Google Patents

Locking mechanism and an ironing device having the same Download PDFInfo

- Publication number

- EP3536849B1 EP3536849B1 EP19160057.6A EP19160057A EP3536849B1 EP 3536849 B1 EP3536849 B1 EP 3536849B1 EP 19160057 A EP19160057 A EP 19160057A EP 3536849 B1 EP3536849 B1 EP 3536849B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- securing member

- iron

- base seat

- locking mechanism

- engaging

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000010409 ironing Methods 0.000 title claims description 22

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 claims description 123

- 229910052742 iron Inorganic materials 0.000 claims description 57

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 230000003100 immobilizing effect Effects 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 230000002441 reversible effect Effects 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F75/00—Hand irons

- D06F75/08—Hand irons internally heated by electricity

- D06F75/10—Hand irons internally heated by electricity with means for supplying steam to the article being ironed

- D06F75/12—Hand irons internally heated by electricity with means for supplying steam to the article being ironed the steam being produced from water supplied to the iron from an external source

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F79/00—Accessories for hand irons

- D06F79/02—Stands or supports neither attached to, nor forming part of, the iron or ironing board

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F75/00—Hand irons

- D06F75/40—Stands or supports attached to the iron

Definitions

- the disclosure relates to a locking mechanism, more particularly to a locking mechanism for an ironing device.

- a conventional ironing device includes an iron and a base seat for receiving the iron thereon.

- the base seat is capable of only receiving the iron as there are no structural connections between the iron and the base seat to secure them to each other. Moving the entire ironing device is inconvenient as both the iron and the base seat would need to be moved separately, or with one hand under the base seat and one hand lifting the iron.

- patent publication US 7 681 343 B2 discloses an ironing appliance comprising an iron and a portable base provided with a surface for setting down the iron when the iron is not being used.

- This ironing appliance comprises means for immobilizing the iron on the base. Unlocking the iron can be done using an unlock button.

- patent publication EP 2 955 265 A2 discloses a steam station comprising an iron and a base station, in which the base station comprises a locking mechanism for securing the iron, wherein the locking mechanism secures the iron around the middle of the iron.

- the locking mechanism is operable to lock/unlock by a single button or a latch.

- patent publication CN 107489011 A discloses a base assembly and an ironing appliance, wherein the base assembly includes a base and a starting part, which is pulled out of the base. At least one position portion is provided in the base and connected to the starting portion to restrict the movement of the iron.

- patent publication EP 2 873 767 A1 discloses a split type steam iron and a locking structure thereof for use for clothing ironing equipment.

- a locking structure is arranged in the base, which comprises a reversible handle and a slide lock touched by the handle. The slide lock is unlocked through turning over the handle, and the handle is held by the hand to lift the iron.

- the object of the disclosure is to provide a locking mechanism that is adapted for securing an iron onto a base seat and that can alleviate the drawback of the prior art.

- a locking mechanism according to claim 1 is provided.

- the locking mechanism is adapted for securing an iron onto a base seat, and includes a first securing member and a controlling member.

- the controlling member is operable for moving the first securing member from a secured position, where the iron is locked to the base seat, to a released position, where the iron is released from the base seat.

- Another object of the disclosure is to provide an ironing device including the iron, the base seat and the abovementioned locking mechanism.

- a first embodiment of an ironing device includes an iron 1, a base seat 2, and a locking mechanism 3 for securing the iron 1 onto the base seat 2.

- the iron 1 has a head portion 11, a rear portion 12 and a handle 13. As the iron 1 is not the focus of the disclosure, further details are omitted for the sake of brevity.

- the base seat 2 includes an insulating plate 21 disposed on a top thereof.

- the insulating plate 21 is shaped corresponding to a bottom of the iron 1 for securely receiving the iron 1 thereon.

- the insulating plate 21 has a plate body 211 and a first hinge portion 212 protruding from the plate body 211.

- the plate body 211 has a top surface formed with an installing slot 213. In this embodiment, both the first hinge portion 212 and the installing slot 213 are proximate to a front end of the base seat 2.

- the locking mechanism 3 includes a first securing member 31, a controlling member 32, a first resilient member 33, a second resilient member 34, a second securing member 35, and an engaging slot 36.

- the first securing member 31 has a pivoting body 311, a first engaging portion 312 disposed on the pivoting body 311, and a second hinge portion 313 protruding downward from the pivoting body 311 and engaging the first hinge portion 212 of the insulating plate 21 so that the pivoting body 311 is pivotally mounted on the base seat 2.

- the first engaging member 31 is movable between a secured position (see FIGS. 4 and 6 ), where the iron 1 is locked to the base seat 2, and a released position (see FIG. 7 ), where the iron 1 is released from the base seat 2 and is permitted to be removed from the base seat 2.

- the first engaging portion 312 has a first hook section 314 (see FIG. 4 ) extending downward.

- the controlling member 32 is disposed in the installing slot 213 of the base seat 2, and has a controlling body 321 and a second engaging portion 322 protruding from the controlling body 321 for engaging with the first engaging portion 312 when the first securing portion 31 is in the secured position.

- the second engaging portion 322 has a second hook section 323 that extends upward for engaging with the first hook section 314 of the first engaging portion 312.

- the controlling member 32 is a button and is operable to move between a locked position (see FIG. 4 and 6 ) and an unlocked position (see FIG. 5 ) .

- the first securing member 31 is in the secured position and the controlling member 32 is in the locked position

- the second hook section 323 of the second engaging portion 322 of the controlling member 32 is engaged with the first hook section 314 of the first engaging portion 312 of the first securing member 31 for maintaining the first securing member 31 in the secured position.

- the second engaging portion 322 is disengaged from the first engaging portion 312 for permitting the first securing member 31 to move to the released position.

- the first resilient member 33 is a torsion spring and has a first section 331 that is connected to the base seat 2 and a second section 332 that is connected to the first securing member 31.

- the first resilient member 33 is disposed for biasing the first securing member 31 toward the released position.

- the second resilient member 34 is a compression spring disposed under the controlling member 32, and is connected to the controlling member 32 and abuts against the base seat 2 for biasing the controlling member 32 toward the locked position.

- the engaging slot 36 is formed in an outer surface of the rear portion 12 of the iron 1.

- the second securing member 35 protrudes from the base seat 2, is spaced apart from the first securing member 31 and proximate to a rear end of the base seat 2, and is disposed for engaging the engaging slot 36.

- the second securing member 35 on the base seat 2 is first engaged with the engaging slot 36 on the iron 1 so that the rear portion 12 of the iron 1 and the rear of the base seat 2 are secured.

- the head portion 11 of the iron 1 is then pressed down against the base seat 2.

- the first securing member 31 is at the released position ( FIG. 7 ). The user may push the first securing member 31 in a direction as shown by an arrow in FIG.

- the controlling member 32 may be pressed downward in a direction as shown by an arrow in FIG. 5 and move the controlling member 32 to the unlocked position, where the second engaging portion 322 becomes disengaged from the first engaging portion 312. Consequently, the first securing member 31 is biased by the first resilient member 33 from the secured position shown in FIG. 6 , through the position shown in FIG. 8 , toward the released position ( FIG. 7 ).

- the iron 1 and the base seat 2 may be separated from each other by lifting the iron 1 forward to disengage the second securing member 35 from the engaging slot 36.

- the first and second securing members 31, 35 are configured to be spaced apart in a front-rear direction to respectively secure the head portion 11 and the rear portion 12 of the iron 1 to the base seat 2.

- the first and second securing members 31, 35 may be proximate respectively to any two opposite ends of the base seat 2.

- the iron 1 and the base seat 2 may be easily secured to and released from each other. Both actions are simple and can be done with one hand, providing convenient usage. Furthermore, the elements of the locking mechanism 3 are few in numbers and have simple structures which reducing production costs.

- a second embodiment of the ironing device according to the disclosure is similar to the first embodiment, the difference being that in this embodiment, the engaging slot 36 is formed in the outer surface of the base seat 2, and the second securing member 35 protrudes from the iron 1 for engaging the engaging slot 36.

- the second embodiment shares the benefits of the first embodiment.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Health & Medical Sciences (AREA)

- Public Health (AREA)

- Seats For Vehicles (AREA)

- Purses, Travelling Bags, Baskets, Or Suitcases (AREA)

- Irons (AREA)

- Clamps And Clips (AREA)

Description

- The disclosure relates to a locking mechanism, more particularly to a locking mechanism for an ironing device.

- A conventional ironing device includes an iron and a base seat for receiving the iron thereon. The base seat is capable of only receiving the iron as there are no structural connections between the iron and the base seat to secure them to each other. Moving the entire ironing device is inconvenient as both the iron and the base seat would need to be moved separately, or with one hand under the base seat and one hand lifting the iron.

- It is noted that patent publication

US 7 681 343 B2 discloses an ironing appliance comprising an iron and a portable base provided with a surface for setting down the iron when the iron is not being used. This ironing appliance comprises means for immobilizing the iron on the base. Unlocking the iron can be done using an unlock button. - It is further noted that

patent publication EP 2 955 265 A2 discloses a steam station comprising an iron and a base station, in which the base station comprises a locking mechanism for securing the iron, wherein the locking mechanism secures the iron around the middle of the iron. The locking mechanism is operable to lock/unlock by a single button or a latch. - It is also noted that patent publication

CN 107489011 A discloses a base assembly and an ironing appliance, wherein the base assembly includes a base and a starting part, which is pulled out of the base. At least one position portion is provided in the base and connected to the starting portion to restrict the movement of the iron. - It is noted that

patent publication EP 2 873 767 A1 discloses a split type steam iron and a locking structure thereof for use for clothing ironing equipment. A locking structure is arranged in the base, which comprises a reversible handle and a slide lock touched by the handle. The slide lock is unlocked through turning over the handle, and the handle is held by the hand to lift the iron. - Therefore, the object of the disclosure is to provide a locking mechanism that is adapted for securing an iron onto a base seat and that can alleviate the drawback of the prior art.

According to the disclosure, a locking mechanism according toclaim 1 is provided. The locking mechanism is adapted for securing an iron onto a base seat, and includes a first securing member and a controlling member. The controlling member is operable for moving the first securing member from a secured position, where the iron is locked to the base seat, to a released position, where the iron is released from the base seat. - Another object of the disclosure is to provide an ironing device including the iron, the base seat and the abovementioned locking mechanism.

- Other features and advantages of the disclosure will become apparent in the following detailed description of the embodiments with reference to the accompanying drawings, of which:

-

FIG. 1 is a perspective view of a first embodiment of an ironing device according to the disclosure; -

FIG. 2 is a partly exploded perspective view of the first embodiment; -

FIG. 3 is a fragmentary exploded perspective view of the first embodiment; -

FIG. 4 is a perspective view of a first securing member and a controlling member of the locking mechanism when the first securing member is in a secured position and the controlling member is in a locked position; -

FIG. 5 is similar toFIG. 4 , but illustrating the controlling member in an unlocked position; -

FIG. 6 is a fragmentary perspective view of the first embodiment, illustrating the first securing member in the secured position and the controlling member in the locked position; -

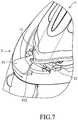

FIG. 7 is similar toFIG. 6 , but illustrating the first securing member in a released position; -

FIG. 8 is similar toFIG. 6 , but illustrating the first securing member between the secured position and the released position; -

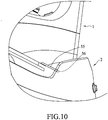

FIG. 9 is a partly exploded perspective view of a second embodiment of the ironing device according to the disclosure; and -

FIG. 10 is a fragmentary side view of the second embodiment. - Before the present invention is described in greater detail, it should be noted that where considered appropriate, reference numerals or terminal portions of reference numerals have been repeated among the figures to indicate corresponding or analogous elements, which may optionally have similar characteristics.

- Referring to

FIGS. 1 to 3 , a first embodiment of an ironing device according to the disclosure includes aniron 1, abase seat 2, and alocking mechanism 3 for securing theiron 1 onto thebase seat 2. - The

iron 1 has ahead portion 11, arear portion 12 and ahandle 13. As theiron 1 is not the focus of the disclosure, further details are omitted for the sake of brevity. - The

base seat 2 includes an insulatingplate 21 disposed on a top thereof. The insulatingplate 21 is shaped corresponding to a bottom of theiron 1 for securely receiving theiron 1 thereon. The insulatingplate 21 has aplate body 211 and afirst hinge portion 212 protruding from theplate body 211. Theplate body 211 has a top surface formed with an installingslot 213. In this embodiment, both thefirst hinge portion 212 and the installingslot 213 are proximate to a front end of thebase seat 2. - Referring to

FIGS. 2 to 4 , thelocking mechanism 3 includes a first securingmember 31, a controllingmember 32, a firstresilient member 33, a secondresilient member 34, a second securingmember 35, and an engagingslot 36. - The first securing

member 31 has a pivotingbody 311, a firstengaging portion 312 disposed on the pivotingbody 311, and asecond hinge portion 313 protruding downward from the pivotingbody 311 and engaging thefirst hinge portion 212 of the insulatingplate 21 so that the pivotingbody 311 is pivotally mounted on thebase seat 2. The first engagingmember 31 is movable between a secured position (seeFIGS. 4 and6 ), where theiron 1 is locked to thebase seat 2, and a released position (seeFIG. 7 ), where theiron 1 is released from thebase seat 2 and is permitted to be removed from thebase seat 2. The firstengaging portion 312 has a first hook section 314 (seeFIG. 4 ) extending downward. - The controlling

member 32 is disposed in the installingslot 213 of thebase seat 2, and has acontrolling body 321 and a secondengaging portion 322 protruding from the controllingbody 321 for engaging with the first engagingportion 312 when the first securingportion 31 is in the secured position. The secondengaging portion 322 has asecond hook section 323 that extends upward for engaging with thefirst hook section 314 of the first engagingportion 312. - Referring to

FIGS 4 to 6 , in this embodiment, the controllingmember 32 is a button and is operable to move between a locked position (seeFIG. 4 and6 ) and an unlocked position (seeFIG. 5 ) . When the first securingmember 31 is in the secured position and the controllingmember 32 is in the locked position, thesecond hook section 323 of the secondengaging portion 322 of the controllingmember 32 is engaged with thefirst hook section 314 of the first engagingportion 312 of the first securingmember 31 for maintaining the first securingmember 31 in the secured position. When the first securingmember 31 is in the secured position and the controllingmember 32 is moved from the locked position to the unlocked position, the secondengaging portion 322 is disengaged from the first engagingportion 312 for permitting the first securingmember 31 to move to the released position. - Referring to

FIG. 3 , the firstresilient member 33 is a torsion spring and has afirst section 331 that is connected to thebase seat 2 and asecond section 332 that is connected to the first securingmember 31. The firstresilient member 33 is disposed for biasing the first securingmember 31 toward the released position. - The second

resilient member 34 is a compression spring disposed under the controllingmember 32, and is connected to the controllingmember 32 and abuts against thebase seat 2 for biasing the controllingmember 32 toward the locked position. - Referring to

FIGS. 1 and2 , in this embodiment, the engagingslot 36 is formed in an outer surface of therear portion 12 of theiron 1. The second securingmember 35 protrudes from thebase seat 2, is spaced apart from the first securingmember 31 and proximate to a rear end of thebase seat 2, and is disposed for engaging the engagingslot 36. - When a user wishes to secure the

iron 1 onto thebase seat 2, the second securingmember 35 on thebase seat 2 is first engaged with the engagingslot 36 on theiron 1 so that therear portion 12 of theiron 1 and the rear of thebase seat 2 are secured. Referring toFIGS. 3 and7 , thehead portion 11 of theiron 1 is then pressed down against thebase seat 2. At this point, the first securingmember 31 is at the released position (FIG. 7 ). The user may push the first securingmember 31 in a direction as shown by an arrow inFIG. 7 against a resilient force of the firstresilient member 33 to turn the first securingmember 31 about thesecond hinge portion 313 and move the first engagingportion 312 toward the secondengaging portion 322 of the controllingmember 32, until the first hook section 314 (FIG. 4 ) and thesecond hook section 323 engage with each other, to secure the first securingmember 31 at the secured position (FIGS. 4 and6 ). In other words, when the first securingmember 31 is at the secured position and the controllingmember 32 is at the locked position as shown inFIGS. 4 and6 , the secondengaging portion 322 is engaged with the first engagingportion 312 and the first securingmember 31 abuts against and secures thehead portion 11 of theiron 1 to secure theiron 1 onto thebase seat 2. In this state, the user may move thebase seat 2 by moving theiron 1, enabling moving of the entire ironing device using only one hand. - Referring to

FIGS. 5 ,6 , and8 , when the user wishes to detach theiron 1 from thebase seat 2, the controllingmember 32 may be pressed downward in a direction as shown by an arrow inFIG. 5 and move the controllingmember 32 to the unlocked position, where the secondengaging portion 322 becomes disengaged from the first engagingportion 312. Consequently, the first securingmember 31 is biased by the firstresilient member 33 from the secured position shown inFIG. 6 , through the position shown inFIG. 8 , toward the released position (FIG. 7 ). When the first securingmember 31 is at the released position, theiron 1 and thebase seat 2 may be separated from each other by lifting theiron 1 forward to disengage the second securingmember 35 from the engagingslot 36. - Referring to

FIGS. 1 and2 , in this embodiment, the first and second securingmembers head portion 11 and therear portion 12 of theiron 1 to thebase seat 2. However, in other embodiments, the first and second securingmembers base seat 2. - In sum, by operation of the first securing

member 31 from the released position to the secured position and operation of the controllingmember 32 from the locked position to the unlocked position, theiron 1 and thebase seat 2 may be easily secured to and released from each other. Both actions are simple and can be done with one hand, providing convenient usage. Furthermore, the elements of thelocking mechanism 3 are few in numbers and have simple structures which reducing production costs. - Referring to

FIGS. 9 and10 , a second embodiment of the ironing device according to the disclosure is similar to the first embodiment, the difference being that in this embodiment, the engagingslot 36 is formed in the outer surface of thebase seat 2, and the second securingmember 35 protrudes from theiron 1 for engaging the engagingslot 36. The second embodiment shares the benefits of the first embodiment. - In the description above, for the purposes of explanation, numerous specific details have been set forth in order to provide a thorough understanding of the embodiments. It will be apparent, however, to one skilled in the art, that one or more other embodiments may be practiced without some of these specific details. It should also be appreciated that reference throughout this specification to "one embodiment," "an embodiment," an embodiment with an indication of an ordinal number and so forth means that a particular feature, structure, or characteristic may be included in the practice of the disclosure. It should be further appreciated that in the description, various features are sometimes grouped together in a single embodiment, figure, or description thereof for the purpose of streamlining the disclosure and aiding in the understanding of various inventive aspects, and that one or more features or specific details from one embodiment may be practiced together with one or more features or specific details from another embodiment, where appropriate, in the practice of the disclosure.

Claims (13)

- A locking mechanism (3) adapted for securing an iron (1) onto a base seat (2) and including:a first securing member (31); anda controlling member (32) being operable for moving said first securing member (31) from a secured position, where the iron (1) is locked to the base seat (2), to a released position, where the iron (1) is released from the base seat (2);wherein said first securing member (31) has a pivoting body (311) adapted to be pivotally mounted on the base seat (2) for locking the iron (1) to the base seat (2) when said first securing member (31) is in the secured position, and a first engaging portion (312) disposed on said pivoting body (311); andsaid controlling member (32) is adapted to be disposed on the base seat (2) and has a second engaging portion (322) for engaging with said first engaging portion (312) when said first securing portion (31) is in the secured position;wherein said controlling member (32) is operable to move between a locked position and an unlocked position;wherein when said first securing member (31) is in the secured position and said controlling member (32) is in the locked position, said second engaging portion (322) of said controlling member (32) is engaged with said first engaging portion (312) of said first securing member (31) for maintaining said first securing member (31) in the secured position; andwherein when said first securing member (31) is in the secured position and said controlling member (32) is moved from the locked position to the unlocked position, said second engaging portion (322) is disengaged from said first engaging portion (312) for permitting said first securing member (31) to move to the released position;

the locking mechanism (3) being characterized in that said locking mechanism (3) further includes a first resilient member (33) having a first section (331) that is adapted to be connected to the base seat (2) and a second section (332) that is connected to said first securing member (31), said first resilient member (33) being disposed for biasing said first securing member (31) toward the released position. - The locking mechanism (3) as claimed in Claim 1, further characterized by a second resilient member (34) that is connected to said controlling member (32) for biasing said controlling member (32) toward the locked position.

- The locking mechanism (3) as claimed in Claim 1 or Claim 2, further characterized by a second securing member (35) spaced apart from said first securing member (31) for engaging the iron (1) with the base seat (2).

- The locking mechanism (3) as claimed in Claim 3, further characterized by an engaging slot (36) adapted to be formed in an outer surface of the iron (1), said second securing member (35) being adapted for protruding from the base seat (2) and for engaging said engaging slot (36).

- The locking mechanism (3) as claimed in Claim 4, further characterized by an engaging slot (36) adapted to be formed on an outer surface of the base seat (2), said second securing member (35) being adapted for protruding from the iron (1) and for engaging said engaging slot (36).

- The locking mechanism (3) as claimed in any one of Claims 3 to 5, characterized in that said first securing member (31) and said second securing member (35) are adapted to be proximate respectively to two opposite ends of the base seat (2).

- An ironing device including a iron (1) and a base seat (2), characterized in that said ironing device further includes a locking mechanism (3) as claimed in any one of Claims 1 to 6, for securing said iron (1) onto said base seat (2)

- The ironing device as claimed in Claim 7, further characterized in that said locking mechanism (3) further has a second resilient member (34) that is connected to said controlling member (32) for biasing said controlling member (32) toward the locked position.

- The ironing device as claimed in Claim 7 or Claim 8, further characterized in that said base (2) includes an insulating plate (21) disposed on a top thereof, said controlling member (32) and said first securing member (31) being disposed on said insulating plate (21).

- The ironing device as claimed anyone of Claims 7 to 9, further characterized in that said locking mechanism (3) further has a second securing member (35) spaced apart from said first securing member (31) for engaging said iron (1) with said base seat (2).

- The ironing device as claimed in Claim 10, characterized in that said second securing member (35) is disposed on and protruding from said base seat (2), said locking mechanism (3) further having an engaging slot (36) that is formed in an outer surface of said iron (1) for engaging with said second securing member (35).

- The ironing device as claimed in Claim 10, characterized in that said second securing member (35) is disposed on and protruding from said iron (1), said locking mechanism (3) further having an engaging slot (36) that is formed in a surface of said base seat (2) for engaging with said second securing member (35).

- The ironing device as claimed in anyone of Claims 10 to 12, characterized in that said first securing member (31) and said second securing member (35) are proximate respectively to two opposite ends of said base seat (2).

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201810179413.9A CN110230181B (en) | 2018-03-05 | 2018-03-05 | Iron device and base locking mechanism thereof |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP3536849A1 EP3536849A1 (en) | 2019-09-11 |

| EP3536849B1 true EP3536849B1 (en) | 2021-02-17 |

Family

ID=65657265

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19160057.6A Active EP3536849B1 (en) | 2018-03-05 | 2019-02-28 | Locking mechanism and an ironing device having the same |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP3536849B1 (en) |

| CN (1) | CN110230181B (en) |

| ES (1) | ES2857955T3 (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP4424901A1 (en) * | 2023-02-28 | 2024-09-04 | Versuni Holding B.V. | Accessory and garment steamer comprising the same |

| EP4424902A1 (en) * | 2023-02-28 | 2024-09-04 | Versuni Holding B.V. | Garment steamer with a descaling tray and an ironing board |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112853716B (en) * | 2019-11-26 | 2022-07-05 | 漳州灿坤实业有限公司 | Iron device with locking function |

| CN114075779A (en) * | 2021-01-25 | 2022-02-22 | 浙江绍兴苏泊尔生活电器有限公司 | Hanging ironing machine |

| FR3141196B1 (en) * | 2022-10-20 | 2024-10-04 | Seb Sa | Steam diffusion base for a household appliance |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0731800A (en) * | 1993-07-21 | 1995-02-03 | Matsushita Electric Ind Co Ltd | Cordless iron |

| FR2874628B1 (en) * | 2004-09-02 | 2006-12-22 | Seb Sa | IRONING APPARATUS COMPRISING AN IRON AND A PORTABLE BASE |

| EP2516726B1 (en) * | 2009-12-22 | 2018-09-19 | BSH Hausgeräte GmbH | Ironing station |

| CN202090209U (en) * | 2011-01-14 | 2011-12-28 | 张平 | Steam iron with base |

| ES2522893B1 (en) * | 2013-05-15 | 2015-09-08 | Bsh Electrodomésticos España, S.A. | Protective iron support |

| ES2578127T3 (en) * | 2013-11-19 | 2016-07-20 | Ningbo Kaibo Group Co., Ltd | Steam iron of split type with a locking structure |

| CN103614893B (en) * | 2013-11-19 | 2016-01-13 | 宁波凯波集团有限公司 | Be convenient to split type steam iron and the latch-up structure thereof of carrying |

| FR3018831B1 (en) * | 2014-03-24 | 2016-03-11 | Seb Sa | HOUSEHOLD APPLIANCE COMPRISING A DEVICE FOR IRONING AND / OR THREADING TO BE HAND HELD AND A PORTABLE BASE |

| DE102014211099B4 (en) * | 2014-06-11 | 2017-10-26 | De'longhi Braun Household Gmbh | Device for locking a steam iron |

| GB201410423D0 (en) * | 2014-06-11 | 2014-07-23 | Spectrum Brands Uk Ltd | Improvements in and relating to steam stations |

| CN107489011B (en) * | 2017-08-25 | 2019-08-09 | 广东美的环境电器制造有限公司 | Base assembly and ironing electric appliance |

| CN107513854B (en) * | 2017-09-26 | 2023-06-27 | 宁波海歌电器有限公司 | Table type electric iron with lock catch fixing device |

| CN107904907B (en) * | 2017-12-07 | 2019-10-01 | 广东美的环境电器制造有限公司 | Flatiron pedestal and iron device |

-

2018

- 2018-03-05 CN CN201810179413.9A patent/CN110230181B/en active Active

-

2019

- 2019-02-28 ES ES19160057T patent/ES2857955T3/en active Active

- 2019-02-28 EP EP19160057.6A patent/EP3536849B1/en active Active

Non-Patent Citations (1)

| Title |

|---|

| None * |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP4424901A1 (en) * | 2023-02-28 | 2024-09-04 | Versuni Holding B.V. | Accessory and garment steamer comprising the same |

| EP4424902A1 (en) * | 2023-02-28 | 2024-09-04 | Versuni Holding B.V. | Garment steamer with a descaling tray and an ironing board |

| WO2024179709A1 (en) * | 2023-02-28 | 2024-09-06 | Versuni Holding B.V. | Garment steamer with descaling tray |

| WO2024179708A1 (en) * | 2023-02-28 | 2024-09-06 | Versuni Holding B.V. | Accessory and garment steamer comprising the same |

Also Published As

| Publication number | Publication date |

|---|---|

| CN110230181A (en) | 2019-09-13 |

| CN110230181B (en) | 2021-06-01 |

| EP3536849A1 (en) | 2019-09-11 |

| ES2857955T3 (en) | 2021-09-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3536849B1 (en) | Locking mechanism and an ironing device having the same | |

| US11993301B2 (en) | Unlocking device with pause function | |

| JP3976325B2 (en) | Battery cover locking device for portable terminal | |

| US8651502B2 (en) | Latch device for coupling a carrier to a stroller frame | |

| EP2111777B1 (en) | Coupling device for a baby crib frame structure | |

| EP1953033B1 (en) | Child seat base | |

| US5461892A (en) | Fastener for a suitcase | |

| EP2832625B1 (en) | A stroller frame and a foldable and detachable chair frame | |

| JP2000096334A5 (en) | ||

| US20020009194A1 (en) | Cellphone holder | |

| US6273503B1 (en) | Hook-on type baby seat | |

| US7108245B2 (en) | Jack having safety effect | |

| CN112519867A (en) | Unlocking device with pause function | |

| US5906013A (en) | Pivotal device for a playpen | |

| CN106285216B (en) | Zipper puzzle lock | |

| CN108825002B (en) | Flat coded lock | |

| US20050155872A1 (en) | Eyeglass case with clip and pivotable cover | |

| KR102042029B1 (en) | Fob key of vehicle | |

| US9861172B1 (en) | Luggage handle assembly with two push buttons | |

| US4766748A (en) | Knockdown type combination locking device for suitcases | |

| JP3607590B2 (en) | Rice cooker lid | |

| JP2024504956A (en) | Safety belt clamp device and child seat for vehicles | |

| JP2001161618A (en) | Mop handle | |

| CN219699211U (en) | Adjustable anti-hooking wrist writing corrector | |

| JP3463995B2 (en) | Horizontal rotation lock type gutter support |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN PUBLISHED |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20200311 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: D06F 75/12 20060101AFI20200807BHEP |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20200921 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: TSANN KUEN (ZHANGZHOU) ENTERPRISE CO., LTD. |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602019002442 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 1361613 Country of ref document: AT Kind code of ref document: T Effective date: 20210315 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG9D |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20210217 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210517 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210617 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210217 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210217 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210217 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210518 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210517 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 1361613 Country of ref document: AT Kind code of ref document: T Effective date: 20210217 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210217 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210217 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210217 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210217 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210217 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2857955 Country of ref document: ES Kind code of ref document: T3 Effective date: 20210929 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210617 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210217 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210217 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210228 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210217 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210217 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602019002442 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210217 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210217 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210217 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210217 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20211118 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210417 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210228 Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210217 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210217 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210217 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210617 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220228 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220228 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20230216 Year of fee payment: 5 Ref country code: BE Payment date: 20230216 Year of fee payment: 5 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210217 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20190228 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20230427 Year of fee payment: 5 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20230228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210217 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 602019002442 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210217 |