EP3363977A1 - Locking element, and a combination of a container with a lock, and the locking element - Google Patents

Locking element, and a combination of a container with a lock, and the locking element Download PDFInfo

- Publication number

- EP3363977A1 EP3363977A1 EP17156784.5A EP17156784A EP3363977A1 EP 3363977 A1 EP3363977 A1 EP 3363977A1 EP 17156784 A EP17156784 A EP 17156784A EP 3363977 A1 EP3363977 A1 EP 3363977A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- locking element

- axle

- elongate body

- lock

- slot

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05C—BOLTS OR FASTENING DEVICES FOR WINGS, SPECIALLY FOR DOORS OR WINDOWS

- E05C19/00—Other devices specially designed for securing wings, e.g. with suction cups

- E05C19/10—Hook fastenings; Fastenings in which a link engages a fixed hook-like member

- E05C19/12—Hook fastenings; Fastenings in which a link engages a fixed hook-like member pivotally mounted around an axis

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05B—LOCKS; ACCESSORIES THEREFOR; HANDCUFFS

- E05B13/00—Devices preventing the key or the handle or both from being used

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05B—LOCKS; ACCESSORIES THEREFOR; HANDCUFFS

- E05B83/00—Vehicle locks specially adapted for particular types of wing or vehicle

- E05B83/02—Locks for railway freight-cars, freight containers or the like; Locks for the cargo compartments of commercial lorries, trucks or vans

- E05B83/08—Locks for railway freight-cars, freight containers or the like; Locks for the cargo compartments of commercial lorries, trucks or vans with elongated bars for actuating the fastening means

- E05B83/10—Rotary bars

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05C—BOLTS OR FASTENING DEVICES FOR WINGS, SPECIALLY FOR DOORS OR WINDOWS

- E05C9/00—Arrangements of simultaneously actuated bolts or other securing devices at well-separated positions on the same wing

- E05C9/08—Arrangements of simultaneously actuated bolts or other securing devices at well-separated positions on the same wing with a rotary bar for actuating the fastening means

Definitions

- the invention relates to a locking element.

- Containers such as bulk containers are used in the transport to move products and raw materials between different locations.

- the containers comprise a space enclosed by a bottom and a circumferential wall, and are available in both open-top versions as well as entirely closed versions, which latter also have a lid fixed to the circumferential wall.

- These containers often also have one or more doors in the circumferential wall in order to load or unload the container, which are hingeable between an open and a closed position. These doors are most often provided with a lock in order to keep the door in the closed state until it is intended to open the door.

- An example of a known lock used for bulk containers comprises a first bar, pivotable around its axis between the open and the closed position of the lock, provided with first coupling means and arranged to the at least one door, furthermore provided with a lever arranged perpendicular to the first bar, which first coupling means engage with second coupling means arranged to the door frame in the closed position, and are released from the second coupling means in the open position.

- the door is provided with two upright walls, extending around the horizontal bar, through which walls a locking pin can be provided, such that the horizontal bar is fixed between the door, the upright walls and the locking pin, in order to retain the horizontal bar and thereby keep the lock closed.

- a locking element comprising:

- the locking element according to the invention may be used to arrest or retain the lock of the door of a bulk container between its closed position and open position in its extended closed position.

- the hook part and/or the elongate body will retain the lock of the bulk container to move to its fully opened position, which allows personnel to evaluate the amount of pressure built up on the door before the door is completely or fully opened.

- the first and second cylindrical end surface will preferably extend completely through the elongate body, and the axle will be accomodated close to either of these end surfaces.

- the axle is arranged at a distance of the end of the elongate body, and consequently, the elongate body will extend on both sides of the axle and abut against the frame. In this position, the elongate body may be suspended from the axle.

- the elongate body When the elongate body is shifted to the extended open position, the elongate body will only be arranged to the axle with an end portion, which allows the elongate body to hinge, e.g. to an extended closed position.

- the elongate body may only be movable to its extended closed position via its extended open position and vice versa.

- the elongate body or the hook member may be provided with a handle, e.g. a rib or protrusion, extending from the elongate body and/or hook part in order to assist in the movement of the respective parts between the positions discussed.

- a handle e.g. a rib or protrusion

- the elongate body and the hook part may be typically made out of one part, which means that there is no actual fixing step necessary to fix the hook part to the elongate body, which eases production and lowers production costs.

- the slot may for instance be made by drilling the two cylindrical end surfaces through the elongate body, and by subsequently milling the path between these channels, although other similar methods may also be used.

- the locking element is preferably made of steel, since it has been found that locking elements made of steel will be able to withstand high forces, to which the locking element will typically be exposed in when keeping a door of a bulk container closed.

- the locking element may be fixed to the door via its frame with suitable fixing means, e.g. screws and/or bolts, welding or other similar techniques.

- the axis of the first cylindrical end surface is parallel to the plane.

- the hook part will be substantially parallel to the door in its stowed position, which further reduces the risk of injuries since the hook part will no longer stick out from the outside of the bulk container.

- the slot is uniformly twisted.

- a uniformly twisted slot which is a slot without (discrete) steps, will allow a fluid movement of the elongate body between the stowed and extended open position. In addition, such slots will be less prone to wear.

- the hook part is arranged to the first end of the elongate body.

- the hook part it is preferred to fix the hook part to the first end of the elongate body since, in that case, the combination of the hook part and the elongate body will have a shape which makes the production of the hook part/elongate body combination easier.

- the hook part is J-shaped or U-shaped.

- J-shaped or U-shaped hook parts have especially been found able to retain the lock of the bulk containers of the prior art in a proper and reliable way.

- the invention further relates to a combination, comprising:

- the hook part and/or elongate member allows personnel to evaluate the pressure developed inside the bulk container, before bringing the lock to its fully open position.

- the lock provided on the container is not the locking element according to the invention, which is also provided on the container.

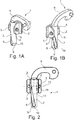

- Figures 1A, 1B and 2 show a locking element 1 according to the invention, with a frame 2, two spaced apart upright walls 3, 4, and an axle 5 extending between the walls 3, 4.

- the locking element 1 further comprises a J-shaped hook member 6, attached to an elongate body 7.

- the elongate body 7 comprises slot 8 with, at a first end 9 of the elongate body 7 a first channel 10. Spaced apart from the first end 9, the slot 8 comprises a second channel 11. Second channel 11 is perpendicular to the first channel 10.

- axle 5 In its stowed position, the axle 5 will be arranged in channel 11 and the elongate body 7 will not be hingable around axle 5 since the elongate body 7 extends on both sides of the axle 5 while lying against frame 2.

- the elongate body 7 is shiftable from its shown stowed position to an extended open position, in which the axle 5 lies in the channel 10, instead of channel 11, by shifting it through slot 8. While shifting, the elongate body 7 will turn approximately 90 degrees around axis 12. By the time that the elongate body 7 reaches its extended open position, it has become pivotable around axis 13.

- Figure 3 shows the locking element 1 as attached to the door 30 of a bulk container 31 with an open top.

- the container 31 is filled with material 32 pushing against door 31.

- the bulk container is provided with a known locking mechanism, comprising a vertical bar 33, a lever 34 fixed to the vertical bar, hingeable in direction A, which causes engaged coupling means 35 at the bottom of the container 31 to disengage.

- Lever 34 is held in its locked position by a locking pin 36, which neutralizes the force exerted on the locking mechanism by contents 32.

- the locking pin 36 Upon removal of the locking pin 36 in order to open the door 30, the contents 32 will, when opening the door by actuating lever 34, in a container according to the prior art, forcefully open the door 30.

- the locking element 1 will serve to retain the horizontal bar 34 in a position between the locked position and the open position.

- Elongate body 7 when shifted to its extended open position can be pivoted in direction B to the position shown in solid lines, where it will retain the lever 34.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Details Of Rigid Or Semi-Rigid Containers (AREA)

Abstract

The invention relates to a locking element, comprising:

- an elongate body, with a plane extending through the longitudinal axis of the elongate body, which body comprises a slot arranged through the body, which slot extends in longitudinal direction and ends on a first end into a first cylindrical end surface and ends on a second end into a second cylindrical end surface, wherein the axis of the second cylindrical end surface is perpendicular to the plane;

- a hook part, fixed to the elongate body, which hook part is parallel to the plane; and

- a frame, comprising two spaced apart walls and an axle, extending between the two walls, which axle is arranged in the slot;

wherein the axle is shiftable from a stowed position, in which the axle is accommodated in the slot near the first end, to an extended open position, in which extended open position the axle is accommodated in the slot near the second end, and in which extended open position the elongate body is pivotable around the axle to an extended closed position. The invention furthermore relates to a container, such as a bulk container with a lock, and a locking element according to the invention.

Description

- The invention relates to a locking element.

- Containers such as bulk containers are used in the transport to move products and raw materials between different locations. The containers comprise a space enclosed by a bottom and a circumferential wall, and are available in both open-top versions as well as entirely closed versions, which latter also have a lid fixed to the circumferential wall. These containers often also have one or more doors in the circumferential wall in order to load or unload the container, which are hingeable between an open and a closed position. These doors are most often provided with a lock in order to keep the door in the closed state until it is intended to open the door.

- An example of a known lock used for bulk containers comprises a first bar, pivotable around its axis between the open and the closed position of the lock, provided with first coupling means and arranged to the at least one door, furthermore provided with a lever arranged perpendicular to the first bar, which first coupling means engage with second coupling means arranged to the door frame in the closed position, and are released from the second coupling means in the open position. In order to keep the door in the closed position, the door is provided with two upright walls, extending around the horizontal bar, through which walls a locking pin can be provided, such that the horizontal bar is fixed between the door, the upright walls and the locking pin, in order to retain the horizontal bar and thereby keep the lock closed.

- In order to increase the efficiency of transport, bulk containers are frequently filled close to or up to the maximum level. Since the material held in bulk containers will typically have a tendency to expand, and especially when the filling degree of the container is relatively high, there will in many cases be a significant development of pressure on the door from the inside. When the door of the container is opened by the container by the removal of the locking pin, the material inside the container, of which the personnel removing the locking pin may not be aware which amount of pressure the material will have developed, may forcefully bring the door towards its open position, which may lead to serious accidents and injuries to the personnel using the bulk container, which may for instance be hit by the door.

- It is an object of the invention to redjuce or even obviate the above-mentioned disadvantages.

- This object is achieved with a locking element, comprising:

- an elongate body, with a plane extending through the longitudinal axis of the elongate body, which body comprises a slot arranged through the body, which slot extends in longitudinal direction and ends on a first end into a first cylindrical end surface and ends on a second end into a second cylindrical end surface, wherein the axis of the second cylindrical end surface is perpendicular to the plane;

- a hook part, fixed to the elongate body, which hook part is parallel to the plane; and

- a frame, comprising two spaced apart walls and an axle, extending between the two walls, which axle is arranged in the slot;

- The locking element according to the invention may be used to arrest or retain the lock of the door of a bulk container between its closed position and open position in its extended closed position. The hook part and/or the elongate body will retain the lock of the bulk container to move to its fully opened position, which allows personnel to evaluate the amount of pressure built up on the door before the door is completely or fully opened.

- The first and second cylindrical end surface will preferably extend completely through the elongate body, and the axle will be accomodated close to either of these end surfaces.

- In the stowed position, the elongate body and the hook part fixed to it will at least be limited in their hingability: the axle is arranged at a distance of the end of the elongate body, and consequently, the elongate body will extend on both sides of the axle and abut against the frame. In this position, the elongate body may be suspended from the axle.

- When the elongate body is shifted to the extended open position, the elongate body will only be arranged to the axle with an end portion, which allows the elongate body to hinge, e.g. to an extended closed position.

- The elongate body may only be movable to its extended closed position via its extended open position and vice versa.

- The elongate body or the hook member may be provided with a handle, e.g. a rib or protrusion, extending from the elongate body and/or hook part in order to assist in the movement of the respective parts between the positions discussed.

- The elongate body and the hook part may be typically made out of one part, which means that there is no actual fixing step necessary to fix the hook part to the elongate body, which eases production and lowers production costs.

- The slot may for instance be made by drilling the two cylindrical end surfaces through the elongate body, and by subsequently milling the path between these channels, although other similar methods may also be used.

- The locking element is preferably made of steel, since it has been found that locking elements made of steel will be able to withstand high forces, to which the locking element will typically be exposed in when keeping a door of a bulk container closed.

- The locking element may be fixed to the door via its frame with suitable fixing means, e.g. screws and/or bolts, welding or other similar techniques.

- In a first preferred embodiment of the locking element according to the invention, the axis of the first cylindrical end surface is parallel to the plane.

- In this preferred embodiment, the hook part will be substantially parallel to the door in its stowed position, which further reduces the risk of injuries since the hook part will no longer stick out from the outside of the bulk container.

- In a second preferred embodiment of the locking element according to the invention, the slot is uniformly twisted.

- A uniformly twisted slot, which is a slot without (discrete) steps, will allow a fluid movement of the elongate body between the stowed and extended open position. In addition, such slots will be less prone to wear.

- In a third preferred embodiment of the locking element according to the invention, the hook part is arranged to the first end of the elongate body.

- It is preferred to fix the hook part to the first end of the elongate body since, in that case, the combination of the hook part and the elongate body will have a shape which makes the production of the hook part/elongate body combination easier.

- In a fourth preferred embodiment of the locking element according to the invention, the hook part is J-shaped or U-shaped.

- J-shaped or U-shaped hook parts have especially been found able to retain the lock of the bulk containers of the prior art in a proper and reliable way.

- The invention further relates to a combination, comprising:

- a container, such as a bulk container, provided with at least one door;

- a lock for locking the door and fixed to the outside of the container, moveable between an open and a closed position, and a lever for operating the lock between the open and closed position; and

- a locking element according to any of the preceding claims, fixed to the outside of the container,

- The hook part and/or elongate member allows personnel to evaluate the pressure developed inside the bulk container, before bringing the lock to its fully open position.

- The lock provided on the container is not the locking element according to the invention, which is also provided on the container.

- In a preferred embodiment of the combination according to the invention the lock comprises:

- a first bar, pivotable around its axis between the open and the closed position of the lock, provided with first coupling means and arranged to the at least one door;

wherein the lever is arranged perpendicular to to the first bar; and - second coupling means arranged to the door frame

wherein the first and second coupling means are engaged in the closed position and are released in the open position. - These and other elements of the invention will be further elucidated in the following figures.

-

Figures 1A and 1B show a perspective views of a locking element according to the invention in the stowed position. -

Figure 2 shows a front view of the locking element according to the invention in the stowed position. -

Figure 3 shows a perspective view of a combination of a container and a locking element according to the invention in the stowed position. -

Figure 4 shows a side view of a combination of a container and a locking element according to the invention in the extended open and closed position. -

Figures 1A, 1B and 2 show alocking element 1 according to the invention, with aframe 2, two spaced apartupright walls axle 5 extending between thewalls locking element 1 further comprises a J-shaped hook member 6, attached to anelongate body 7. Theelongate body 7 comprisesslot 8 with, at afirst end 9 of the elongate body 7 afirst channel 10. Spaced apart from thefirst end 9, theslot 8 comprises asecond channel 11.Second channel 11 is perpendicular to thefirst channel 10. - In its stowed position, the

axle 5 will be arranged inchannel 11 and theelongate body 7 will not be hingable aroundaxle 5 since theelongate body 7 extends on both sides of theaxle 5 while lying againstframe 2. - The

elongate body 7 is shiftable from its shown stowed position to an extended open position, in which theaxle 5 lies in thechannel 10, instead ofchannel 11, by shifting it throughslot 8. While shifting, theelongate body 7 will turn approximately 90 degrees aroundaxis 12. By the time that theelongate body 7 reaches its extended open position, it has become pivotable aroundaxis 13. -

Figure 3 shows thelocking element 1 as attached to thedoor 30 of abulk container 31 with an open top. Thecontainer 31 is filled withmaterial 32 pushing againstdoor 31. The bulk container is provided with a known locking mechanism, comprising avertical bar 33, alever 34 fixed to the vertical bar, hingeable in direction A, which causes engaged coupling means 35 at the bottom of thecontainer 31 to disengage.Lever 34 is held in its locked position by a lockingpin 36, which neutralizes the force exerted on the locking mechanism bycontents 32. Upon removal of the lockingpin 36 in order to open thedoor 30, thecontents 32 will, when opening the door by actuatinglever 34, in a container according to the prior art, forcefully open thedoor 30. In the container according to the present invention, the lockingelement 1 will serve to retain thehorizontal bar 34 in a position between the locked position and the open position. - This is further illustrated in the side view of

figure 4 .Elongate body 7 when shifted to its extended open position (shown in dashed lines) can be pivoted in direction B to the position shown in solid lines, where it will retain thelever 34.

Claims (7)

- Locking element, comprising:- an elongate body, with a plane extending through the longitudinal axis of the elongate body, which body comprises a slot arranged through the body, which slot extends in longitudinal direction and ends on a first end into a first cylindrical end surface and ends on a second end into a second cylindrical end surface, wherein the axis of the second cylindrical end surface is perpendicular to the plane;- a hook part, fixed to the elongate body, which hook part is parallel to the plane; and- a frame, comprising two spaced apart walls and an axle, extending between the two walls, which axle is arranged in the slot;wherein the axle is shiftable from a stowed position, in which the axle is accommodated in the slot near the first end, to an extended open position, in which extended open position the axle is accommodated in the slot near the second end, and in which extended open position the elongate body is pivotable around the axle to an extended closed position.

- Locking element according to claim 1, wherein the the axis of the first cylindrical end surface is parallel to the plane.

- Locking element according to claim 1 or 2,

wherein the slot is uniformly twisted. - Locking element according to claim 1, 2 or 3,

wherein the hook part is arranged to the first end of the elongate body. - Locking element according to any of the preceding claims, wherein the hook part is J-shaped or U-shaped.

- Combination, comprising:- a container, such as a bulk container, provided with at least one door;- a lock for locking the door and fixed to the outside of the container, moveable between an open and a closed position, and a lever for operating the lock between the open and closed position; and- a locking element according to any of the preceding claims, fixed to the outside of the container,wherein the hook part is at a distance of the lever of the lock in the stowed position and the extended open position of the locking element, and wherein the lever of the lock is retained by the hook part in the extended closed position of the locking element.

- Combination according to claim 6, wherein the lock comprises:- a first bar, pivotable around its axis between the open and the closed position of the lock, provided with first coupling means and arranged to the at least one door;

wherein the lever is arranged perpendicular to to the first bar; and- second coupling means arranged to the door frame

wherein the first and second coupling means are engaged in the closed position and are released in the open position.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP17156784.5A EP3363977A1 (en) | 2017-02-17 | 2017-02-17 | Locking element, and a combination of a container with a lock, and the locking element |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP17156784.5A EP3363977A1 (en) | 2017-02-17 | 2017-02-17 | Locking element, and a combination of a container with a lock, and the locking element |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP3363977A1 true EP3363977A1 (en) | 2018-08-22 |

Family

ID=58094273

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP17156784.5A Withdrawn EP3363977A1 (en) | 2017-02-17 | 2017-02-17 | Locking element, and a combination of a container with a lock, and the locking element |

Country Status (1)

| Country | Link |

|---|---|

| EP (1) | EP3363977A1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109281561A (en) * | 2018-11-30 | 2019-01-29 | 国网湖北省电力有限公司黄石供电公司 | A kind of manual locking system of cabinet door for power distributing cabinet |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR319598A (en) * | 1902-03-14 | 1902-11-15 | Camion Freres Soc | Sliding turnstile stopper for shutters |

| GB191402436A (en) * | 1914-01-29 | 1914-12-03 | James Blake | Improvements in or relating to Fastening Devices for use with Doors and the like. |

| GB238386A (en) * | 1924-09-05 | 1925-08-20 | James Blake | Improvements in or relating to fastening devices for use with doors and the like |

| US2295360A (en) * | 1940-12-14 | 1942-09-08 | Reuben W Schneider | Hook fastener for doors and the like |

| US4331354A (en) * | 1980-06-16 | 1982-05-25 | Helding Curtis L | Door push bar lock-out retainer |

| EP0686744A2 (en) * | 1994-06-06 | 1995-12-13 | Carrier Corporation | Safety device for an enclosure door |

| DE202011103940U1 (en) * | 2011-08-01 | 2011-10-19 | Rewald Gmbh | Clamping and locking device for locking door wings pivotally mounted on container side walls for a receivable container |

-

2017

- 2017-02-17 EP EP17156784.5A patent/EP3363977A1/en not_active Withdrawn

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR319598A (en) * | 1902-03-14 | 1902-11-15 | Camion Freres Soc | Sliding turnstile stopper for shutters |

| GB191402436A (en) * | 1914-01-29 | 1914-12-03 | James Blake | Improvements in or relating to Fastening Devices for use with Doors and the like. |

| GB238386A (en) * | 1924-09-05 | 1925-08-20 | James Blake | Improvements in or relating to fastening devices for use with doors and the like |

| US2295360A (en) * | 1940-12-14 | 1942-09-08 | Reuben W Schneider | Hook fastener for doors and the like |

| US4331354A (en) * | 1980-06-16 | 1982-05-25 | Helding Curtis L | Door push bar lock-out retainer |

| EP0686744A2 (en) * | 1994-06-06 | 1995-12-13 | Carrier Corporation | Safety device for an enclosure door |

| DE202011103940U1 (en) * | 2011-08-01 | 2011-10-19 | Rewald Gmbh | Clamping and locking device for locking door wings pivotally mounted on container side walls for a receivable container |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109281561A (en) * | 2018-11-30 | 2019-01-29 | 国网湖北省电力有限公司黄石供电公司 | A kind of manual locking system of cabinet door for power distributing cabinet |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CA2590327C (en) | Loading assembly for transport containers | |

| US11235921B2 (en) | Collapsible intermodal container | |

| US11213941B2 (en) | Tool box | |

| WO2015124836A4 (en) | Isothermal container for preserving of various materials | |

| EP2762421B1 (en) | Locking system applicable in large container | |

| EP3363977A1 (en) | Locking element, and a combination of a container with a lock, and the locking element | |

| US4120415A (en) | Refuse container | |

| US20150246800A1 (en) | Cargo door safety tool | |

| KR102543316B1 (en) | Sliding gates for vessels containing molten metal | |

| US20210171279A1 (en) | Collapsible Intermodal Container Stacker and a Stacking System | |

| ITBO20030118U1 (en) | OPENING AND CLOSING DEVICE FOR TRUCK DOOR HANDLE TRAILERS AND SIMILAR | |

| FI94659B (en) | Door locking mechanism | |

| US11161686B2 (en) | Collapsible intermodal container and a collapsible intermodal container assembly | |

| EP1726477B1 (en) | Partition wall for refrigerated vehicle | |

| US3710513A (en) | Door structure for cargo container | |

| CN211002859U (en) | Container, especially container for transporting goods | |

| KR101627666B1 (en) | Hopper type freight car | |

| KR101927477B1 (en) | High-level waste descend device use wedge locking | |

| GB2534263A (en) | Rolling container provided with a closure and method therefor | |

| US1335643A (en) | Collapsible container | |

| EP0983413B1 (en) | Anti-theft device for locking container or lorry doors | |

| EP3305709B1 (en) | A system for transporting and unloading containers for goods, in particular for bulk material, a container and a container spreader | |

| EP0901952A1 (en) | A container with a locking device for a gate | |

| CN216375883U (en) | Container, especially container for transporting goods | |

| CN203699080U (en) | Overflow box |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20190223 |