EP2691701B1 - Method for optimising the burnout of exhaust gases of an incinerator - Google Patents

Method for optimising the burnout of exhaust gases of an incinerator Download PDFInfo

- Publication number

- EP2691701B1 EP2691701B1 EP12712955.9A EP12712955A EP2691701B1 EP 2691701 B1 EP2691701 B1 EP 2691701B1 EP 12712955 A EP12712955 A EP 12712955A EP 2691701 B1 EP2691701 B1 EP 2691701B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- combustion

- nozzle

- fluid

- primary

- combustion chamber

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000007789 gas Substances 0.000 title claims description 44

- 238000000034 method Methods 0.000 title claims description 27

- 238000002485 combustion reaction Methods 0.000 claims description 106

- 239000012530 fluid Substances 0.000 claims description 25

- 238000002156 mixing Methods 0.000 claims description 15

- 239000000567 combustion gas Substances 0.000 claims description 11

- 239000003546 flue gas Substances 0.000 claims description 11

- UGFAIRIUMAVXCW-UHFFFAOYSA-N Carbon monoxide Chemical compound [O+]#[C-] UGFAIRIUMAVXCW-UHFFFAOYSA-N 0.000 claims description 9

- 239000011343 solid material Substances 0.000 claims 4

- 239000007787 solid Substances 0.000 description 20

- MWUXSHHQAYIFBG-UHFFFAOYSA-N nitrogen oxide Inorganic materials O=[N] MWUXSHHQAYIFBG-UHFFFAOYSA-N 0.000 description 15

- 238000000265 homogenisation Methods 0.000 description 10

- 239000000203 mixture Substances 0.000 description 9

- 230000002093 peripheral effect Effects 0.000 description 9

- 239000000446 fuel Substances 0.000 description 8

- 238000001035 drying Methods 0.000 description 7

- 238000002347 injection Methods 0.000 description 7

- 239000007924 injection Substances 0.000 description 7

- 229910052760 oxygen Inorganic materials 0.000 description 5

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 4

- 239000001301 oxygen Substances 0.000 description 4

- 238000011084 recovery Methods 0.000 description 3

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 3

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 2

- 229910052757 nitrogen Inorganic materials 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- 239000002028 Biomass Substances 0.000 description 1

- 238000009825 accumulation Methods 0.000 description 1

- 239000003054 catalyst Substances 0.000 description 1

- 239000003638 chemical reducing agent Substances 0.000 description 1

- 238000004939 coking Methods 0.000 description 1

- 239000000470 constituent Substances 0.000 description 1

- 239000000356 contaminant Substances 0.000 description 1

- 238000011109 contamination Methods 0.000 description 1

- 239000002826 coolant Substances 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- 238000000354 decomposition reaction Methods 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000007599 discharging Methods 0.000 description 1

- 239000003344 environmental pollutant Substances 0.000 description 1

- 238000005243 fluidization Methods 0.000 description 1

- 229930195733 hydrocarbon Natural products 0.000 description 1

- 150000002430 hydrocarbons Chemical class 0.000 description 1

- 239000011261 inert gas Substances 0.000 description 1

- JEIPFZHSYJVQDO-UHFFFAOYSA-N iron(III) oxide Inorganic materials O=[Fe]O[Fe]=O JEIPFZHSYJVQDO-UHFFFAOYSA-N 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 229910017464 nitrogen compound Inorganic materials 0.000 description 1

- 150000002830 nitrogen compounds Chemical class 0.000 description 1

- QJGQUHMNIGDVPM-UHFFFAOYSA-N nitrogen group Chemical group [N] QJGQUHMNIGDVPM-UHFFFAOYSA-N 0.000 description 1

- 231100000719 pollutant Toxicity 0.000 description 1

- 239000002243 precursor Substances 0.000 description 1

- 238000000197 pyrolysis Methods 0.000 description 1

- 239000003473 refuse derived fuel Substances 0.000 description 1

- 239000002893 slag Substances 0.000 description 1

- 239000004449 solid propellant Substances 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

- 238000004056 waste incineration Methods 0.000 description 1

- 239000002699 waste material Substances 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23G—CREMATION FURNACES; CONSUMING WASTE PRODUCTS BY COMBUSTION

- F23G5/00—Incineration of waste; Incinerator constructions; Details, accessories or control therefor

- F23G5/08—Incineration of waste; Incinerator constructions; Details, accessories or control therefor having supplementary heating

- F23G5/14—Incineration of waste; Incinerator constructions; Details, accessories or control therefor having supplementary heating including secondary combustion

- F23G5/16—Incineration of waste; Incinerator constructions; Details, accessories or control therefor having supplementary heating including secondary combustion in a separate combustion chamber

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23G—CREMATION FURNACES; CONSUMING WASTE PRODUCTS BY COMBUSTION

- F23G5/00—Incineration of waste; Incinerator constructions; Details, accessories or control therefor

- F23G5/08—Incineration of waste; Incinerator constructions; Details, accessories or control therefor having supplementary heating

- F23G5/14—Incineration of waste; Incinerator constructions; Details, accessories or control therefor having supplementary heating including secondary combustion

- F23G5/16—Incineration of waste; Incinerator constructions; Details, accessories or control therefor having supplementary heating including secondary combustion in a separate combustion chamber

- F23G5/165—Incineration of waste; Incinerator constructions; Details, accessories or control therefor having supplementary heating including secondary combustion in a separate combustion chamber arranged at a different level

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23L—SUPPLYING AIR OR NON-COMBUSTIBLE LIQUIDS OR GASES TO COMBUSTION APPARATUS IN GENERAL ; VALVES OR DAMPERS SPECIALLY ADAPTED FOR CONTROLLING AIR SUPPLY OR DRAUGHT IN COMBUSTION APPARATUS; INDUCING DRAUGHT IN COMBUSTION APPARATUS; TOPS FOR CHIMNEYS OR VENTILATING SHAFTS; TERMINALS FOR FLUES

- F23L7/00—Supplying non-combustible liquids or gases, other than air, to the fire, e.g. oxygen, steam

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23L—SUPPLYING AIR OR NON-COMBUSTIBLE LIQUIDS OR GASES TO COMBUSTION APPARATUS IN GENERAL ; VALVES OR DAMPERS SPECIALLY ADAPTED FOR CONTROLLING AIR SUPPLY OR DRAUGHT IN COMBUSTION APPARATUS; INDUCING DRAUGHT IN COMBUSTION APPARATUS; TOPS FOR CHIMNEYS OR VENTILATING SHAFTS; TERMINALS FOR FLUES

- F23L9/00—Passages or apertures for delivering secondary air for completing combustion of fuel

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23L—SUPPLYING AIR OR NON-COMBUSTIBLE LIQUIDS OR GASES TO COMBUSTION APPARATUS IN GENERAL ; VALVES OR DAMPERS SPECIALLY ADAPTED FOR CONTROLLING AIR SUPPLY OR DRAUGHT IN COMBUSTION APPARATUS; INDUCING DRAUGHT IN COMBUSTION APPARATUS; TOPS FOR CHIMNEYS OR VENTILATING SHAFTS; TERMINALS FOR FLUES

- F23L9/00—Passages or apertures for delivering secondary air for completing combustion of fuel

- F23L9/02—Passages or apertures for delivering secondary air for completing combustion of fuel by discharging the air above the fire

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23L—SUPPLYING AIR OR NON-COMBUSTIBLE LIQUIDS OR GASES TO COMBUSTION APPARATUS IN GENERAL ; VALVES OR DAMPERS SPECIALLY ADAPTED FOR CONTROLLING AIR SUPPLY OR DRAUGHT IN COMBUSTION APPARATUS; INDUCING DRAUGHT IN COMBUSTION APPARATUS; TOPS FOR CHIMNEYS OR VENTILATING SHAFTS; TERMINALS FOR FLUES

- F23L2900/00—Special arrangements for supplying or treating air or oxidant for combustion; Injecting inert gas, water or steam into the combustion chamber

- F23L2900/07002—Injecting inert gas, other than steam or evaporated water, into the combustion chambers

Definitions

- the present invention relates to a method for optimizing the combustion of exhaust gases of a combustion plant according to the preamble of claim 1.

- a method for optimizing the combustion of exhaust gases of a combustion plant is described for example in the EP-A-1508745 described.

- Incinerators for burning solid fuels such as municipal waste, refuse derived fuels, biomass and other materials are well known to those skilled in the art.

- Such plants include a combustion chamber in which the solid is burned with supply of primary air, which is referred to as primary combustion.

- the solid from the inlet into the combustion chamber to the outlet through various sub-processes, which can be roughly subdivided into drying, ignition, combustion and ash burning. In each of these sub-processes, exhaust gases of different composition are generated.

- the primary air While in the drying phase, the primary air only absorbs moisture from the solid to be burned, can be found in the ignition phase pyrolytic decomposition products.

- the oxygen supplied in the ignition phase is often completely converted, so that the exhaust gas flow generated in this phase has very little or no oxygen.

- exhaust gases are formed with typical compositions of CO, CO 2 , O 2 , H 2 O and N 2 , while finally over the ash ash practically unused air is present.

- these different exhaust gas streams pass into a secondary combustion chamber arranged downstream in the direction of flow, where they are burnt out with the supply of secondary air, which is referred to as secondary combustion.

- a method comprising a combustion of the solid and an afterburning of the incompletely combusted exhaust gas constituents is known, for example, from US Pat WO 2007/090510

- the aim of this invention is to reduce the primary nitrogen compounds NH 3 and HCN in order to minimize the formation of nitrogen oxides (NO x ) in the post-combustion chamber.

- EP-A-1077077 relates to a similar process as that of WO 2007/090510 , wherein the denitrification of the flue gases, the SNCR method is used in which no catalyst is used, but a reducing agent is injected into the flue gases.

- Such SNCR processes operate at temperatures of 850 to 1000 ° C and require sophisticated control.

- the reduction of nitrogen oxides is also in WO 99/58902 addressed.

- the gases emerging from the combustion chamber are homogenized with the addition of an oxygen-free or oxygen-poor medium in a mixing stage, after which the homogenized exhaust gas flow passes through a steady zone in which the nitrogen oxides already formed are to be reduced.

- the amount of accumulating pyrolysis gas is so large that the locally available secondary air quantity is insufficient for complete burnout. This causes unburned gases to escape from the post-combustion chamber, resulting in, for example, CO peaks in the chimney.

- the peripheral wall surrounding the combustion chamber or the afterburning chamber can be damaged on the one hand by the prevailing high temperatures.

- caking or coking may occur in this area, which must be removed in time-consuming maintenance work.

- EP-A-1081434 The problem of reducing the amount of unburned substances and in particular CO, try about in EP-A-1081434 .

- EP-A-1382906 and US-B-5313895 approached procedures. So is about according to US-B-5313895 a mixed fluid is introduced, the gases leaving the combustion chamber in a Eddy current offset.

- a special nozzle arrangement is described, by means of which a rotating flow in the flow channel is produced in a plane of injection of the flame in the region of the flame ceiling.

- US-B-5313895 described method the problem of present in the combustion chamber temperature imbalance only unsatisfactory way.

- the temperature in the inlet-side region should be reduced by means of injection of water droplets or water vapor.

- this is disadvantageous in terms of the energy recovery balance.

- the aim of the present invention is thus to provide a method for optimizing the burnout of exhaust gases of a combustion plant, which on the one hand ensures a high degree of operational reliability and which, on the other hand, allows a high energy recovery from the combustion to be obtained.

- the method according to the invention comprises the steps of introducing the solid to be combusted via an inlet into a combustion chamber defining a primary combustion chamber, combusting the solid in the primary combustion chamber in the form of a combustion bed conveyed via a combustion grate by supplying primary air and the combusted solid via a combustion chamber in the conveying direction the inlet opposite outlet is discharged from the primary combustion chamber.

- the primary combustion gases liberated upon combustion of the solid become downstream in the flow direction, i. usually arranged above the combustion chamber, a secondary combustion chamber defining afterburner chamber burned under supply of secondary air.

- the exhaust gases containing the primary combustion gases are homogenized in a mixing zone. This is done by means of a fluid introduced via a nozzle.

- nozzle is to be understood as an indefinite article; Thus, the term includes both a single and multiple nozzles.

- Homogenization is understood in this context to mean that the exhaust gases or the individual exhaust gas streams of different composition are mixed in such a way that the most homogeneous possible gas mixture is obtained.

- the mixing zone now at least approximately immediately adjoins the combustion bed in the flow direction of the exhaust gases. As a rule, it is thus arranged in other words at least approximately directly above the combustion bed. This allows very hot exhaust gas streams, such as may occur in the ignition or combustion zone, practically immediately above the combustion bed with the cooler exhaust gas streams from the drying and ash combustion zone to mix and thus compensate for temperature peaks early or lower.

- the method allows the energy recovery balance to be unaffected, as would be the case with cooling by means of a cooling medium.

- the homogenization of the exhaust gas streams generated in the individual combustion zones results in a gas mixture which is optimally preconditioned for afterburning in the secondary combustion chamber.

- the present invention thus allows to ensure an optimal combustion of the exhaust gases even at low (secondary) excess air; the emission of pollutants, such as CO or unburned hydrocarbons, can thus be kept very low even with small amounts of supplied secondary air.

- the fluid is introduced via one or more nozzles.

- the exit velocity of the fluid from the nozzle is about 40 to about 120 m / s, wherein the nozzle is aligned in the sense of the present invention at an angle of -10 ° to + 10 ° relative to the inclination of the combustion grate.

- nozzles In addition to the nozzles defined above, there may be other nozzles that are not oriented at the angle defined above relative to the inclination of the combustion grate.

- Inclination of the combustion grate in this context is understood to mean the total inclination of the grate (and not the orientation of possibly existing individual grate steps).

- the inventive alignment of the nozzle ensures that even with the inventive arrangement of the mixing zone immediately above the fuel bed excessive swirling of solids is avoided by the rust.

- the inventive injection rate of the fluid also contributes from about 40 to about 120 m / s.

- the found combination of nozzle arrangement according to the invention and injection rate thus makes it possible in total to connect the mixing zone in the direction of flow of the exhaust gases at least approximately directly to the combustion bed, without resulting in excessive unwanted swirling of the solids from the combustion grid.

- the mixing zone is appropriately spaced from the combustion grate. Furthermore, the mixing zone may extend at most to a distance of 2 meters measured from the fuel bed. When considered in the flow direction of the exhaust gases, the mixing zone thus ends after a maximum of 2 meters and thus still at a sufficient distance before the secondary air injection. In the invention At least approximately immediately adjacent to the combustion bed subsequent mixing zone, said upper limit is sufficient to obtain the desired homogenization of the exhaust gases.

- the exit velocity of the fluid from the nozzle is about 90 m / s.

- the exit velocity refers to the velocity that the fluid has on exit from the nozzle opening.

- the nozzles used as standard usually have a circular nozzle cross-section of 60 mm to 200 mm. It is conceivable that the nozzle cross-section continuously tapers in the direction of the nozzle orifice so that the diameter of the outlet opening of the nozzle is 60 mm to 90 mm.

- the respective nozzle is preferably oriented at an angle of -10 ° to + 5 °, more preferably -5 ° to + 5 °, relative to the inclination of the combustion grate.

- the respective nozzle may be oriented at an angle of -10 ° to 0 ° relative to the inclination of the combustion grate.

- the fluid comprises a flue gas returned from a downstream zone of the secondary combustion chamber.

- the recirculation preferably takes place from one zone between the steam generator and the fireplace.

- the amount of introduced flue gas is about 5 to 35% of the amount of primary air supplied, preferably about 20%.

- any other conceivable fluid can be used, in particular air, an inert gas, such as nitrogen, water vapor or mixtures thereof.

- the injection of the fluid takes place via a nozzle or nozzle row arranged in this region.

- a very pronounced temperature imbalance and thus damage or contamination of the peripheral wall surrounding the combustion chamber can be effectively prevented.

- the respective nozzle when a recirculated flue gas is used as the fluid, preferably has an outer tube and an inner tube extending in the axial direction of the outer tube and enclosed by the inner tube, wherein the inner tube is intended for guiding the flue gas and the outer tube for guiding air ,

- the inner diameter of the inner tube is about 70 mm, while the inner diameter of the outer tube, i. the outer diameter of the present between inner tube and outer tube annular gap, about 110 mm.

- the air flow in this embodiment serves as a shield which protects the nozzle from the accumulation of contaminants entrained in the flue gas. Especially in the inlet side area Temperatures such deposits could easily lead to caking, which can lead to failure of the nozzle in extreme cases; This is effectively prevented according to the described embodiment. It has proven to be advantageous if at least 1 nozzle per meter of the combustion chamber width is provided. Preferably, the introduction of the fluid via at least two nozzles, more preferably at least six nozzles. This ensures as complete as possible homogenization with a relatively small amount of injected fluid.

- a combustor of an incinerator for carrying out the method may include a peripheral wall enclosing a primary combustion chamber, an inlet for introducing the solid to be combusted into the primary combustion chamber, a combustion grate for combustion of the solid, an outlet disposed opposite the inlet in the conveying direction of the solid for discharging the combusted solid from the primary combustion chamber and a nozzle for homogenizing the exhaust gases released during the combustion of primary combustion gases include.

- the nozzle is arranged in a range of at most 3 meters, preferably 0.5 meters to 3 meters, most preferably 0.5 to 2 meters above the combustion grate. In general, the nozzle is arranged in the peripheral wall of the combustion chamber, preferably in the region of the inlet or the outlet.

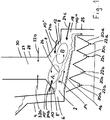

- the solid to be burned 2 is filled in a hopper 4 and of this usually introduced by means of a Dosierstössels via an inlet 6 into the combustion chamber 8.

- the combustion chamber 8 comprises a peripheral wall 10, which encloses an upwardly tapering, primary combustion chamber 12.

- the solid 2 is conveyed in the form of a fuel bed 14 via a (advancing) combustion grate 16 through which primary air flows and thereby burned.

- a drying zone In the conveying direction F, there are successively a drying zone, an ignition zone, a combustion zone and an ash combustion zone, before the burnt solid is discharged via an outlet 18 arranged opposite the inlet 6 and subsequently fed to a slag conveyor via a purifier.

- the distribution of the primary air takes place in the embodiment shown via individual sub-wind chambers 20a, 20b, 20c, 20d, which are fed via separate primary air lines 22a, 22b, 22c, 22d.

- nozzles 24a, 24b, 24c via which a fluid is introduced into the combustion chamber 8.

- the nozzles are designed such that the exit velocity of the fluid from the nozzles is 40 to 120 m / s.

- a nozzle 24a is disposed in the inlet side region 8 'of the combustion chamber 8, specifically in an inlet facing, obliquely upwardly extending portion 10' of the peripheral wall 10.

- Two nozzles 24b, 24c are shown in FIG outlet side region 8 "is arranged, wherein a nozzle 24b in the obliquely upwardly extending portion 10" and in which the end face 25 defining, perpendicular part 10 '''of the peripheral wall is arranged.

- any other number and arrangement of nozzles suitable for the purposes of the present invention is also conceivable.

- the exhaust gases which contain the combustion gases liberated during the combustion, are homogenized in a mixing zone 26 which adjoins the combustion bed 14 at least approximately directly in the flow direction thereof.

- This homogenization is indicated in the figure by dashed arrows, where A schematically denotes the region of relatively high temperature and relatively high concentration of primary combustion gases, and B denotes the region of lower temperature and lower concentration of primary combustion gases.

- an afterburner chamber 28 which is connected downstream of the combustion chamber 8 and defines a secondary combustion chamber 27, in which the exhaust gases are burned with the supply of secondary air.

- an afterburner chamber 28 in which the exhaust gases are burned with the supply of secondary air.

- nozzles 32a, 32b are provided for introducing the secondary air.

- Fig. 2 illustrated introduces the fluid with actuated nozzle in position to the fact that the O 2 concentration measured locally in the exhaust gas flow generated in the combustion zone (shown in bold solid lines) approximately corresponds to the global O 2 concentration (shown in thin dashed lines) in the exhaust gas generated in the combustion chamber , In contrast, when the nozzle is not actuated in the OFF position, the locally measured O 2 concentration is much lower than that measured globally.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Incineration Of Waste (AREA)

- Combustion Of Fluid Fuel (AREA)

- Air Supply (AREA)

Description

Die vorliegende Erfindung betrifft ein Verfahren zur Optimierung des Ausbrands von Abgasen einer Verbrennungsanlage gemäss dem Oberbegriff des Anspruchs 1. Ein derartiges Verfahren wird z.B. in der

In jedem dieser Teilprozesse werden Abgase unterschiedlicher Zusammensetzung generiert. Während in der Trocknungsphase die Primärluft lediglich Feuchtigkeit aus dem zu verbrennenden Feststoff aufnimmt, finden sich in der Zündungsphase pyrolytische Zersetzungsprodukte. Im Gegensatz zur Trocknungsphase wird der in der Zündungsphase zugeführte Sauerstoff oft vollständig umgesetzt, sodass der in dieser Phase generierte Abgasstrom nur sehr wenig oder gar keinen Sauerstoff aufweist. In der Verbrennungsphase entstehen Abgase mit typischen Zusammensetzungen aus CO, CO2, O2, H2O und N2, während schliesslich über dem Ascheausbrand praktisch unverbrauchte Luft vorliegt.The present invention relates to a method for optimizing the combustion of exhaust gases of a combustion plant according to the preamble of claim 1. Such a method is described for example in the

In each of these sub-processes, exhaust gases of different composition are generated. While in the drying phase, the primary air only absorbs moisture from the solid to be burned, can be found in the ignition phase pyrolytic decomposition products. In contrast to the drying phase, the oxygen supplied in the ignition phase is often completely converted, so that the exhaust gas flow generated in this phase has very little or no oxygen. In the combustion phase, exhaust gases are formed with typical compositions of CO, CO 2 , O 2 , H 2 O and N 2 , while finally over the ash ash practically unused air is present.

In der Regel gelangen diese unterschiedlichen Abgasströme nach der Primärverbrennung in eine in Strömungsrichtung abwärts angeordnete Nachbrennkammer, wo sie unter Zuführung von Sekundärluft ausgebrannt werden, was als Sekundärverbrennung bezeichnet wird.As a rule, after the primary combustion, these different exhaust gas streams pass into a secondary combustion chamber arranged downstream in the direction of flow, where they are burnt out with the supply of secondary air, which is referred to as secondary combustion.

Ein eine Verbrennung des Feststoffs und eine Nachverbrennung der unvollständig verbrannten Abgasbestandteile umfassendes Verfahren ist etwa aus der

Die Verminderung von Stickoxiden wird zudem in

Als Resultat der verschiedenen Verbrennungszonen ergibt sich nebst den Unterschieden in der Zusammensetzung der Abgasströme auch eine Temperaturschieflage. So liegt in der Zündungs- und der Verbrennungszone eine wesentlich höhere Temperatur vor als etwa in der Ascheausbrandzone. Diese Schieflage wird in der Nachverbrennungskammer noch verstärkt, da die in der Zündungs- und Verbrennungszone generierten Abgase über einen höheren Anteil an verbrennbaren Primärverbrennungsgasen verfügen als das in der Ascheausbrandzone generierte Abgas, und die Verbrennung dieser verbrennbaren Gase die Temperatur zusätzlich erhöht.As a result of the various combustion zones, apart from the differences in the composition of the exhaust gas streams, there is also a temperature imbalance. Thus, a much higher temperature is present in the ignition zone and the combustion zone than in the ash combustion zone, for example. This imbalance is exacerbated in the post-combustion chamber because the exhaust gases generated in the ignition and combustion zones have a higher proportion of combustible primary combustion gases than the exhaust generated in the ash combustion zone, and the combustion of these combustible gases additionally increases the temperature.

Gerade im einlassseitigen Bereich kann die die Brennkammer bzw. die Nachbrennkammer umgebende periphere Wand einerseits durch die vorherrschenden hohen Temperaturen Schaden nehmen. Andererseits können in diesem Bereich aufgrund der hohen Temperaturen Anbackungen oder Verkokungen auftreten, die in aufwändigen Wartungsarbeiten entfernt werden müssen.Especially in the inlet-side region, the peripheral wall surrounding the combustion chamber or the afterburning chamber can be damaged on the one hand by the prevailing high temperatures. On the other hand, because of the high temperatures, caking or coking may occur in this area, which must be removed in time-consuming maintenance work.

Dem Problem, die Menge an unverbrannten Substanzen und insbesondere CO zu vermindern, versuchen etwa die in

Die Aufgabe wird gelöst durch ein Verfahren gemäss Anspruch 1. Bevorzugte Ausführungsformen der Erfindung sind in den abhängigen Ansprüchen wiedergegeben.The object is achieved by a method according to claim 1. Preferred embodiments of the invention are given in the dependent claims.

Mithin umfasst das erfindungsgemässe Verfahren die Schritte, dass der zu verbrennende Feststoff über einen Einlass in eine einen primären Verbrennungsraum definierende Brennkammer eingeführt wird, der Feststoff im primären Verbrennungsraum in Form eines über einen Verbrennungsrost geförderten Brennbetts unter Zuführung von Primärluft verbrannt und der verbrannte Feststoff über einen in Förderrichtung dem Einlass gegenüberliegend angeordneten Auslass aus dem primären Verbrennungsraum ausgetragen wird.Thus, the method according to the invention comprises the steps of introducing the solid to be combusted via an inlet into a combustion chamber defining a primary combustion chamber, combusting the solid in the primary combustion chamber in the form of a combustion bed conveyed via a combustion grate by supplying primary air and the combusted solid via a combustion chamber in the conveying direction the inlet opposite outlet is discharged from the primary combustion chamber.

Die bei der Verbrennung des Feststoffes frei werdenden primären Verbrennungsgase werden in einer in deren Strömungsrichtung stromabwärts, d.h. in der Regel oberhalb der Brennkammer angeordneten, einen sekundären Verbrennungsraum definierenden Nachbrennkammer unter Zuführung von Sekundärluft verbrannt.The primary combustion gases liberated upon combustion of the solid become downstream in the flow direction, i. usually arranged above the combustion chamber, a secondary combustion chamber defining afterburner chamber burned under supply of secondary air.

Vor Eintritt in den sekundären Verbrennungsraum, d.h. in Strömungsrichtung stromaufwärts und somit in der Regel unterhalb davon, werden die die primären Verbrennungsgase enthaltenden Abgase in einer Mischzone homogenisiert. Dies erfolgt mittels eines über eine Düse eingeführten Fluids.Before entering the secondary combustion chamber, i. upstream of, and thus typically below, the exhaust gases containing the primary combustion gases are homogenized in a mixing zone. This is done by means of a fluid introduced via a nozzle.

In diesem Zusammenhang ist "eine" (Düse) als unbestimmter Artikel zu verstehen; damit umfasst der Begriff sowohl eine einzige als auch mehrere Düsen.In this context, "a" (nozzle) is to be understood as an indefinite article; Thus, the term includes both a single and multiple nozzles.

Unter Homogenisierung wird in diesem Zusammenhang verstanden, dass die Abgase bzw. die einzelnen Abgasströme unterschiedlicher Zusammensetzung derart gemischt werden, dass ein möglichst homogenes Gasgemisch erhalten wird. Erfindungsgemäss schliesst nun die Mischzone in Strömungsrichtung der Abgase wenigstens annähernd unmittelbar an das Brennbett an. In der Regel ist sie somit mit anderen Worten wenigstens annähernd unmittelbar oberhalb des Brennbetts angeordnet. Dies erlaubt es, sehr heisse Abgasströme, wie sie etwa in der Zündungs- oder Verbrennungszone entstehen können, praktisch unmittelbar oberhalb des Brennbettes mit den kühleren Abgasströmen aus der Trocknungs- und Ascheausbrandzone zu mischen und somit Temperaturspitzen frühzeitig auszugleichen bzw. zu senken. Gleichzeitig erlaubt es das Verfahren, dass die Energierückgewinnungsbilanz nicht beeinträchtigt wird, wie dies etwa bei der Kühlung mittels eines Kühlmediums der Fall wäre.Homogenization is understood in this context to mean that the exhaust gases or the individual exhaust gas streams of different composition are mixed in such a way that the most homogeneous possible gas mixture is obtained. According to the invention, the mixing zone now at least approximately immediately adjoins the combustion bed in the flow direction of the exhaust gases. As a rule, it is thus arranged in other words at least approximately directly above the combustion bed. This allows very hot exhaust gas streams, such as may occur in the ignition or combustion zone, practically immediately above the combustion bed with the cooler exhaust gas streams from the drying and ash combustion zone to mix and thus compensate for temperature peaks early or lower. At the same time, the method allows the energy recovery balance to be unaffected, as would be the case with cooling by means of a cooling medium.

Im Übrigen wird durch die Homogenisierung der in den einzelnen Verbrennungszonen generierten Abgasströme ein Gasgemisch erhalten, das optimal für die Nachverbrennung im sekundären Verbrennungsraum vorkonditioniert ist. Im Resultat erlaubt es die vorliegende Erfindung somit, selbst bei niedrigem (Sekundär)luftüberschuss einen optimalen Ausbrand der Abgase zu gewährleisten; die Emission an Schadstoffen, wie etwa CO oder unverbrannten Kohlenwasserstoffen, kann somit auch bei geringen Mengen an zugeführter Sekundärluft sehr gering gehalten werden.Incidentally, the homogenization of the exhaust gas streams generated in the individual combustion zones results in a gas mixture which is optimally preconditioned for afterburning in the secondary combustion chamber. As a result, the present invention thus allows to ensure an optimal combustion of the exhaust gases even at low (secondary) excess air; the emission of pollutants, such as CO or unburned hydrocarbons, can thus be kept very low even with small amounts of supplied secondary air.

Weiter wurde gefunden, dass die Mischung der in der Verbrennungszone generierten, reduzierten stickstoffhaltigen Verbrennungsgase (Stickoxid-Vorläufer-Substanzen) mit dem über der Trocknungs- bzw. der Ausbrandzone vorliegenden Sauerstoff nicht in einer Zunahme an Stickoxiden resultiert. Dies kann dadurch erklärt werden, dass im Zuge der Mischung des Abgasstromes aus der Verbrennungszone mit den in den in der Trocknungs- und Ausbrandzone anfallenden sauerstoffreichen Abgasströmen gleichzeitig dessen Temperatur gesenkt wird, was die Bildung von thermischem NOx unterbindet.It has also been found that the mixture of the reduced nitrogenous combustion gases (nitrogen oxide precursor substances) generated in the combustion zone with the oxygen present above the drying zone or the burnout zone does not result in an increase in nitrogen oxides. This can be explained by the fact that in the course of mixing the exhaust gas stream from the combustion zone with the resulting in the drying and Ausbrandzone oxygen-rich exhaust gas streams at the same time its temperature is lowered, which prevents the formation of thermal NO x .

Wie oben ausgeführt, wird das Fluid erfindungsgemäss über eine oder mehrere Düsen eingeführt.As stated above, according to the invention, the fluid is introduced via one or more nozzles.

Erfindungsgemäss beträgt die Austrittsgeschwindigkeit des Fluids aus der Düse ca. 40 bis ca. 120 m/s, wobei die Düse im Sinne der vorliegenden Erfindung in einem Winkel von -10° bis +10° relativ zur Neigung des Verbrennungsrosts ausgerichtet wird.According to the invention, the exit velocity of the fluid from the nozzle is about 40 to about 120 m / s, wherein the nozzle is aligned in the sense of the present invention at an angle of -10 ° to + 10 ° relative to the inclination of the combustion grate.

Zusätzlich zu den oben definierten Düsen können weitere Düsen vorhanden sein, die nicht im oben definierten Winkel relativ zur Neigung des Verbrennungsrosts ausgerichtet sind.In addition to the nozzles defined above, there may be other nozzles that are not oriented at the angle defined above relative to the inclination of the combustion grate.

Unter Neigung des Verbrennungsrosts wird in diesem Zusammenhang die totale Neigung des Rostes (und nicht die Ausrichtung gegebenenfalls vorhandener einzelner Roststufen) verstanden.Inclination of the combustion grate in this context is understood to mean the total inclination of the grate (and not the orientation of possibly existing individual grate steps).

Durch die erfindungsgemässe Ausrichtung der Düse wird gewährleistet, dass auch bei erfindungsgemässer Anordnung der Mischzone unmittelbar oberhalb des Brennbetts ein übermässiges Aufwirbeln von Feststoffen vom Rost vermieden wird.The inventive alignment of the nozzle ensures that even with the inventive arrangement of the mixing zone immediately above the fuel bed excessive swirling of solids is avoided by the rust.

Zur Vermeidung einer Aufwirbelung von Feststoffen trägt auch die erfindungsgemässe Eindüsgeschwindigkeit des Fluids von ca. 40 bis ca. 120 m/s bei.To prevent fluidization of solids, the inventive injection rate of the fluid also contributes from about 40 to about 120 m / s.

Die gefundene Kombination von erfindungsgemässer Düsenanordnung und Eindüsgeschwindigkeit ermöglicht somit insgesamt, die Mischzone in Strömungsrichtung der Abgase wenigstens annähernd unmittelbar an das Brennbett anzuschliessen, ohne dass es zu einem übermässigen unerwünschten Aufwirbeln der Feststoffe vom Verbrennungsrost kommt.The found combination of nozzle arrangement according to the invention and injection rate thus makes it possible in total to connect the mixing zone in the direction of flow of the exhaust gases at least approximately directly to the combustion bed, without resulting in excessive unwanted swirling of the solids from the combustion grid.

Dass bereits mit der erfindungsgemässen Eindüsgeschwindigkeit von ca. 40 bis ca. 120 m/s eine gute Homogenisierung erhalten werden kann, ist umso überraschender, als im Stand der Technik wesentlich höhere Werte gelehrt werden. So wird etwa in der

Eine besonders gute Homogenisierung wird erreicht, wenn gemäss einer bevorzugten Ausführungsform die Austrittsgeschwindigkeit des Fluids aus der Düse ca. 90 m/s beträgt.

Die Austrittsgeschwindigkeit bezieht sich dabei auf die Geschwindigkeit, die das Fluid beim Austritt aus der Düsenöffnung aufweist. Die standardmässig verwendeten Düsen weisen in der Regel einen kreisförmigen Düsenquerschnitt von 60 mm bis 200 mm auf. Denkbar ist, dass sich der Düsenquerschnitt in Richtung zur Düsenmündung hin stetig verjüngt, sodass der Durchmesser der Austrittsöffnung der Düse 60 mm bis 90 mm beträgt.

Um ein durch die Einführung des Fluids verursachtes Aufwirbeln der Feststoffe zu minimieren, wird die jeweilige Düse bevorzugt in einem Winkel von -10° bis +5°, bevorzugter von -5° bis +5°, relativ zur Neigung des Verbrennungsrosts ausgerichtet. Die jeweilige Düse kann in einem Winkel von -10° bis 0° relativ zur Neigung des Verbrennungsrosts ausgerichtet sein. Gemäss einer weiteren bevorzugten Ausführungsform umfasst das Fluid ein aus einer stromabwärts des sekundären Verbrennungsraums nachgeschalteten Zone zurückgeführtes Rauchgas. In konventionell ausgestalteten Müllverbrennungsanlagen erfolgt die Zurückführung dabei vorzugsweise aus einer Zone zwischen dem Dampferzeuger und dem Kamin. In der Regel beträgt die Menge an eingeführtem Rauchgas ca. 5 bis 35% der zugeführten Primärluftmenge, vorzugsweise ca. 20%. Alternativ oder zusätzlich zum Rauchgas kann jedes andere erdenkliche Fluid verwendet werden, insbesondere Luft, ein Inertgas, wie z.B. Stickstoff, Wasserdampf oder Mischungen davon.That good homogenization can already be obtained with the injection rate of about 40 to about 120 m / s according to the invention is all the more surprising since significantly higher values are taught in the prior art. So will be in the

A particularly good homogenization is achieved if, according to a preferred embodiment, the exit velocity of the fluid from the nozzle is about 90 m / s.

The exit velocity refers to the velocity that the fluid has on exit from the nozzle opening. The nozzles used as standard usually have a circular nozzle cross-section of 60 mm to 200 mm. It is conceivable that the nozzle cross-section continuously tapers in the direction of the nozzle orifice so that the diameter of the outlet opening of the nozzle is 60 mm to 90 mm.

In order to minimize swirling of the solids caused by the introduction of the fluid, the respective nozzle is preferably oriented at an angle of -10 ° to + 5 °, more preferably -5 ° to + 5 °, relative to the inclination of the combustion grate. The respective nozzle may be oriented at an angle of -10 ° to 0 ° relative to the inclination of the combustion grate. According to a further preferred embodiment, the fluid comprises a flue gas returned from a downstream zone of the secondary combustion chamber. In conventionally configured waste incineration plants, the recirculation preferably takes place from one zone between the steam generator and the fireplace. In general, the amount of introduced flue gas is about 5 to 35% of the amount of primary air supplied, preferably about 20%. Alternatively or in addition to the flue gas, any other conceivable fluid can be used, in particular air, an inert gas, such as nitrogen, water vapor or mixtures thereof.

Da die höchsten Temperaturen in der Regel im einlassseitigen Bereich der Brennkammer vorliegen, erfolgt die Eindüsung des Fluids gemäss einer bevorzugten Ausführungsform über eine in diesem Bereich angeordnete Düse bzw. Düsenreihe. Somit kann eine sehr ausgeprägte Temperaturschieflage und somit eine Beschädigung oder Verunreinigung der den Verbrennungsraum umgebenden peripheren Wand wirksam verhindert werden.Since the highest temperatures are generally present in the inlet-side region of the combustion chamber, according to a preferred embodiment, the injection of the fluid takes place via a nozzle or nozzle row arranged in this region. Thus, a very pronounced temperature imbalance and thus damage or contamination of the peripheral wall surrounding the combustion chamber can be effectively prevented.

Insbesondere dann, wenn als Fluid ein zurückgeführtes Rauchgas verwendet wird, weist die jeweilige Düse vorzugsweise ein Aussenrohr und ein in axialer Richtung des Aussenrohrs verlaufendes und von diesem umschlossenes Innenrohr auf, wobei das Innenrohr zur Führung des Rauchgases bestimmt ist und das Aussenrohr zur Führung von Luft. Vorzugsweise beträgt der Innendurchmesser des Innenrohrs dabei ca. 70 mm, während der Innendurchmesser des Aussenrohrs, d.h. der Aussendurchmesser des zwischen Innenrohr und Aussenrohr vorliegenden Ringspalts, ca. 110 mm beträgt.In particular, when a recirculated flue gas is used as the fluid, the respective nozzle preferably has an outer tube and an inner tube extending in the axial direction of the outer tube and enclosed by the inner tube, wherein the inner tube is intended for guiding the flue gas and the outer tube for guiding air , Preferably, the inner diameter of the inner tube is about 70 mm, while the inner diameter of the outer tube, i. the outer diameter of the present between inner tube and outer tube annular gap, about 110 mm.

Der Luftstrom dient in dieser Ausführungsform als Abschirmung, der die Düse vor der Anlagerung von im Rauchgas mitgeführten Verunreinigungen schützt. Gerade bei den im einlassseitigen Bereich vorliegenden Temperaturen könnten solche Anlagerungen leicht zu Anbackungen führen, die im Extremfall zum Ausfall der Düse führen können; dies wird gemäss der geschilderten Ausführungsform wirksam unterbunden.

Es hat sich als vorteilhaft erwiesen, wenn pro Meter der Brennkammerbreite mindestens 1 Düse vorgesehen ist. Bevorzugt erfolgt die Einführung des Fluids über mindestens zwei Düsen, bevorzugter mindestens sechs Düsen. Dies gewährleistet eine möglichst vollständige Homogenisierung bei relativ geringer Menge an eingedüstem Fluid. Eine Brennkammer einer Verbrennungsanlage zum Durchführen des Verfahrens kann eine einen primären Verbrennungsraum umschliessende periphere Wand, einen Einlass zur Einführung des zu verbrennenden Feststoff in den primären Verbrennungsraum, einen Verbrennungsrost zur Verbrennung des Feststoffes, einen dem Einlass in Förderrichtung des Feststoffes gegenüberliegend angeordneten Auslass zur Austragung des verbrannten Feststoffes aus dem primären Verbrennungsraum und eine Düse zur Homogenisierung der die bei der Verbrennung frei werdenden primären Verbrennungsgase enthaltenden Abgase umfassen. Dabei ist die Düse in einem Bereich von höchstens 3 Meter, bevorzugt 0,5 Meter bis 3 Meter, am meisten bevorzugt 0,5 bis 2 Meter oberhalb des Verbrennungsrostes angeordnet.

In der Regel ist die Düse in der peripheren Wand der Brennkammer angeordnet, vorzugsweise im Bereich des Einlasses oder des Auslasses.The air flow in this embodiment serves as a shield which protects the nozzle from the accumulation of contaminants entrained in the flue gas. Especially in the inlet side area Temperatures such deposits could easily lead to caking, which can lead to failure of the nozzle in extreme cases; This is effectively prevented according to the described embodiment.

It has proven to be advantageous if at least 1 nozzle per meter of the combustion chamber width is provided. Preferably, the introduction of the fluid via at least two nozzles, more preferably at least six nozzles. This ensures as complete as possible homogenization with a relatively small amount of injected fluid. A combustor of an incinerator for carrying out the method may include a peripheral wall enclosing a primary combustion chamber, an inlet for introducing the solid to be combusted into the primary combustion chamber, a combustion grate for combustion of the solid, an outlet disposed opposite the inlet in the conveying direction of the solid for discharging the combusted solid from the primary combustion chamber and a nozzle for homogenizing the exhaust gases released during the combustion of primary combustion gases include. The nozzle is arranged in a range of at most 3 meters, preferably 0.5 meters to 3 meters, most preferably 0.5 to 2 meters above the combustion grate.

In general, the nozzle is arranged in the peripheral wall of the combustion chamber, preferably in the region of the inlet or the outlet.

Um zu vermeiden, dass die Homogenisierung mit einer Aufwirbelung des im Brennbett vorliegenden Feststoffs einhergeht, ist die Düse in einem Winkel von -10° bis +10°, bevorzugt von -10° bis +5°, bevorzugter von -5° bis +5°, relativ zur Neigung des Verbrennungsrostes ausgerichtet. Des Weiteren kann die jeweilige Düse in einem Winkel von -10° bis 0° relativ zur Neigung des Verbrennungsrosts ausgerichtet sein. Die Erfindung wird anhand der anliegenden Figuren veranschaulicht. Von diesen zeigt

- Fig. 1

- eine schematische Darstellung einer Brennkammer und einer teilweise dargestellten Nachbrennkammer zur Durchführung des Verfahrens gemäss der vorliegenden Erfindung; und

- Fig. 2

- eine graphische Darstellung der gemessenen O2-Konzentration (in Vol-%) bzw. CO-Konzentration (in mg/m3 im Normzustand) über die Zeit in einem in der Verbrennungszone generierten Abgasstrom, wobei die Düsen in einzelnen Zeitintervallen ein- bzw. ausgeschaltet sind.

- Fig. 1

- a schematic representation of a combustion chamber and a partially shown Nachbrennkammer for carrying out the method according to the present invention; and

- Fig. 2

- a graphical representation of the measured O 2 concentration (in% by volume) or CO concentration (in mg / m 3 in the standard state) over time in an exhaust gas stream generated in the combustion zone, the nozzles at individual time intervals on or are turned off.

Wie in

Der Feststoff 2 wird in Form eines Brennbetts 14 über einen von Primärluft durchströmten (Vorschub-)Verbrennungsrost 16 gefördert und dabei verbrannt. In Förderrichtung F liegen dabei aufeinanderfolgend eine Trocknungszone, eine Zündungszone, eine Verbrennungszone und eine Ascheausbrandzone vor, ehe der verbrannte Feststoff über einen dem Einlass 6 gegenüberliegend angeordneten Auslass 18 ausgetragen und in der Folge über einen Entschlacker einer Schlackenförderung zugeführt wird. Die Verteilung der Primärluft erfolgt in der gezeigten Ausführungsform über einzelne Unterwindkammern 20a, 20b, 20c, 20d, die über separate Primärluftleitungen 22a, 22b, 22c, 22d gespeist werden.The solid 2 is conveyed in the form of a

In der peripheren Wand 10 der Brennkammer sind in

Die Düsen sind dabei derart ausgestaltet, dass die Austrittsgeschwindigkeit des Fluids aus den Düsen 40 bis 120 m/s beträgt.The nozzles are designed such that the exit velocity of the fluid from the nozzles is 40 to 120 m / s.

In der gezeigten Ausführungsform ist eine Düse 24a im einlassseitigen Bereich 8' der Brennkammer 8 angeordnet, spezifisch in einem dem Einlass zugewandten, schräg nach oben verlaufenden Teil 10' der peripheren Wand 10. Zwei Düsen 24b, 24c sind im auslassseitigen Bereich 8" angeordnet, wobei eine Düse 24b im schräg nach oben verlaufenden Teil 10" und eine in dem die Stirnseite 25 definierenden, senkrecht verlaufenden Teil 10''' der peripheren Wand angeordnet ist. Denkbar ist aber auch jede andere für die Zwecke der vorliegenden Erfindung geeignete Zahl und Anordnung der Düsen.In the embodiment shown, a nozzle 24a is disposed in the inlet side region 8 'of the

Mittels der Düsen 24a, 24b, 24c werden die Abgase, welche die bei der Verbrennung freiwerdenden Verbrennungsgase enthalten, in einer in deren Strömungsrichtung wenigsten annähernd unmittelbar an das Brennbett 14 anschliessenden Mischzone 26 homogenisiert. Diese Homogenisierung wird in der Figur mittels gestrichelter Pfeile angedeutet, wobei A schematisch den Bereich mit relativ hoher Temperatur und relativ hoher Konzentration an primären Verbrennungsgasen bezeichnet, und B den Bereich mit tieferer Temperatur und tieferer Konzentration primärer Verbrennungsgase bezeichnet. Nach der Homogenisierung, also in der Figur oberhalb der mit A und B bezeichneten Bereiche, liegen die Abgase in Form eines homogenen Gasgemischs vor.By means of the

Dieses strömt in eine der Brennkammer 8 nachgeschaltete, einen sekundären Verbrennungsraum 27 definierende Nachbrennkammer 28, in welcher die Abgase unter Zuführung von Sekundärluft verbrannt werden. Hierzu sind in der peripheren Wand 30 der Nachbrennkammer 28 weitere Düsen 32a, 32b zur Einführung der Sekundärluft vorgesehen.This flows into an

Wie in

Betreffend CO-Konzentration wird bei betätigter Düse ein relativ tiefer, annähernd konstanter Wert erhalten, während bei nicht betätigter Düse relativ hohe und stark divergierende Werte erhalten werden, was die Homogenisierung der Abgase durch die Einführung des Fluids weiter veranschaulicht.Concerning CO concentration, a relatively low, approximately constant value is obtained when the nozzle is actuated, while relatively high and strongly diverging values are obtained when the nozzle is not actuated, which further illustrates the homogenization of the exhaust gases by the introduction of the fluid.

Claims (8)

- Method for optimizing the burnout of exhaust gases of an incinerator, said method comprising the steps, that

the solid material (2) to be combusted is introduced via an inlet (6) into a combustion chamber (8) defining a primary combustion space (12),

the solid material (2) in the primary combustion space (12), in the form of a combustion bed (14) conveyed over a combustion grate (16), is combusted with admission of primary air and the combusted solid material is discharged from the primary combustion space (12) via an outlet (18) arranged opposite the inlet (6) in the conveying direction (F), and

the primary combustion gases released during the combustion of the solid material (2) are combusted, with admission of secondary air, in a secondary combustion chamber (28) defining a secondary combustion space (27) and arranged downstream of the combustion chamber (8) in the flow direction of said primary combustion gases,

the exhaust gases containing the primary combustion gases being homogenized in a mixing zone (26) by means of a fluid introduced via a nozzle (24a, 24b, 24c) before entry into the secondary combustion space (27),

the mixing zone (26) adjoining the combustion bed (14) at least approximately directly in the flow direction of the exhaust gases,

characterized in that the exit speed of the fluid from the nozzle (24a, 24b, 24c) is 40 to 120 m/s, and in that the nozzle (24a, 24b, 24c) is oriented at an angle from -10° to +10° relative to the inclination of the combustion grate (16). - Method as claimed in one of the preceding claims, characterized in that the exit speed of the fluid from the nozzle (24a, 24b, 24c) is 90 m/s.

- Method as claimed in one of the preceding claims, characterized in that the nozzle (24a, 24b, 24c) is oriented at an angle from -5° to +5° relative to the inclination of the combustion grate (16).

- Method as claimed in one of the preceding claims, characterized in that the fluid comprises a flue gas returned from a subsequent zone downstream of the secondary combustion space (27).

- Method as claimed in claim 4, characterized in that the quantity of introduced flue gas is 5% to 35%, preferably approximately 20%, of the admitted quantity of primary air.

- Method as claimed in one of the preceding claims, characterized in that the fluid is injected via a nozzle (24a) arranged in the inlet-side region of the combustion chamber (8).

- Method as claimed in either of claims 4 and 5, characterized in that the nozzle (24a, 24b, 24c) has an outer pipe and an inner pipe running in the axial direction of the outer pipe and surrounded thereby, the inner pipe being intended to carry the flue gas and the outer pipe being intended to carry air.

- Method as claimed in one of the preceding claims, characterized in that the fluid is introduced via at least two nozzles (24a, 24b, 24c), preferably at least six nozzles.

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL12712955.9T PL2691701T5 (en) | 2011-03-29 | 2012-03-28 | Method for optimising the burnout of exhaust gases of an incinerator |

| NO12712955A NO2691701T3 (en) | 2011-03-29 | 2012-03-28 | |

| RS20171117A RS56483B2 (en) | 2011-03-29 | 2012-03-28 | Method for optimising the burnout of exhaust gases of an incinerator |

| EP12712955.9A EP2691701B2 (en) | 2011-03-29 | 2012-03-28 | Method for optimising the burnout of exhaust gases of an incinerator |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP11002575A EP2505919A1 (en) | 2011-03-29 | 2011-03-29 | Method for optimising the burn-off of exhaust gases of an incinerator assembly by homogenization of the flue gases above the combustion bed by means of flue gas injection |

| PCT/EP2012/001361 WO2012130446A1 (en) | 2011-03-29 | 2012-03-28 | Method for optimising the burnout of exhaust gases of an incinerator |

| EP12712955.9A EP2691701B2 (en) | 2011-03-29 | 2012-03-28 | Method for optimising the burnout of exhaust gases of an incinerator |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP2691701A1 EP2691701A1 (en) | 2014-02-05 |

| EP2691701B1 true EP2691701B1 (en) | 2017-08-23 |

| EP2691701B2 EP2691701B2 (en) | 2024-03-20 |

Family

ID=44501668

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP11002575A Withdrawn EP2505919A1 (en) | 2011-03-29 | 2011-03-29 | Method for optimising the burn-off of exhaust gases of an incinerator assembly by homogenization of the flue gases above the combustion bed by means of flue gas injection |

| EP12712955.9A Active EP2691701B2 (en) | 2011-03-29 | 2012-03-28 | Method for optimising the burnout of exhaust gases of an incinerator |

Family Applications Before (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP11002575A Withdrawn EP2505919A1 (en) | 2011-03-29 | 2011-03-29 | Method for optimising the burn-off of exhaust gases of an incinerator assembly by homogenization of the flue gases above the combustion bed by means of flue gas injection |

Country Status (9)

| Country | Link |

|---|---|

| US (1) | US20140182492A1 (en) |

| EP (2) | EP2505919A1 (en) |

| JP (1) | JP2014513786A (en) |

| ES (1) | ES2647667T5 (en) |

| FI (1) | FI2691701T4 (en) |

| NO (1) | NO2691701T3 (en) |

| PL (1) | PL2691701T5 (en) |

| RS (1) | RS56483B2 (en) |

| WO (1) | WO2012130446A1 (en) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2015068517A (en) * | 2013-09-27 | 2015-04-13 | 日立造船株式会社 | Combustion operation method in combustion furnace and combustion furnace |

| JP6260058B2 (en) * | 2014-09-12 | 2018-01-17 | 三菱重工環境・化学エンジニアリング株式会社 | Stoker-type incinerator |

| WO2020071142A1 (en) * | 2018-10-05 | 2020-04-09 | 三菱重工業株式会社 | Stoker-type incineration equipment, and method for incinerating to-be-incinerated matter |

| US10816197B2 (en) * | 2018-12-07 | 2020-10-27 | Eco Burn Inc. | System for the dynamic movement of waste in an incinerator |

| WO2020189394A1 (en) * | 2019-03-15 | 2020-09-24 | 日立造船株式会社 | Incinerator |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5313895A (en) | 1990-11-22 | 1994-05-24 | Hitachi Zosen Corporation | Method of inhibiting formation of unburned substances in refuse incinerator, and refuse incinerator |

| EP1077077A2 (en) | 1999-08-12 | 2001-02-21 | ABB (Schweiz) AG | Method for the thermal treatment of solids |

| EP1081434A1 (en) | 1999-08-30 | 2001-03-07 | Von Roll Umwelttechnik AG | Device for generating a rotating gas flow |

| EP1508745A2 (en) | 2003-08-22 | 2005-02-23 | Fisia Babcock Environment GmbH | Method to reduce the production of NOx in combustion chambers and apparatus to implement said method |

| DE102004037442A1 (en) | 2004-08-02 | 2006-03-16 | Alstom Technology Ltd | Waste and/or compensation fuel thermal treatment method for combustion chamber, involves keeping direct heat exchange between exhaust gas and secondary air low through small dimensioned direct contact area within mantle nozzle |

| JP2009121747A (en) * | 2007-11-15 | 2009-06-04 | Hitachi Zosen Corp | Secondary combustion air blow-in method in secondary combustion chamber |

Family Cites Families (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3716088A1 (en) * | 1987-04-09 | 1989-02-02 | Muellverbrennungsanlage Wupper | METHOD FOR BURNING IN PARTICULAR MUELL |

| JPH04350411A (en) * | 1990-11-22 | 1992-12-04 | Hitachi Zosen Corp | Method of restricting occurrence of non-ignited substance in refuse incinerator |

| JP2662746B2 (en) * | 1991-04-04 | 1997-10-15 | 日立造船株式会社 | Grate type incinerator |

| JP2758090B2 (en) * | 1991-10-21 | 1998-05-25 | 株式会社クボタ | CO control method in incinerator |

| JP3596690B2 (en) * | 1995-06-15 | 2004-12-02 | 石川島播磨重工業株式会社 | Method and apparatus for reducing NOx generation in electric furnace |

| JP3210859B2 (en) * | 1996-05-01 | 2001-09-25 | 株式会社クボタ | Secondary combustion gas supply mechanism of garbage incinerator |

| JPH10110926A (en) * | 1996-08-14 | 1998-04-28 | Nippon Sanso Kk | Combustion type harm removal apparatus |

| JPH10205734A (en) * | 1997-01-14 | 1998-08-04 | Takuma Co Ltd | Secondary air supply method in stoker type combustion furnace |

| JP3319327B2 (en) | 1997-03-26 | 2002-08-26 | 日本鋼管株式会社 | Combustion control method and device for refuse incinerator |

| JPH10288325A (en) * | 1997-04-16 | 1998-10-27 | N K K Plant Kensetsu Kk | Generation restraint method of dioxins contained in exhaust gas in refuse incinerator |

| US6336415B1 (en) | 1998-05-11 | 2002-01-08 | Alstom (Switzerland) Ltd | Method for the heat treatment of solids |

| NL1015519C2 (en) * | 2000-06-14 | 2001-12-28 | Amsterdam Gem Dienst Afvalverw | Flue gas recirculation at a waste incineration plant. |

| DE10051733B4 (en) * | 2000-10-18 | 2005-08-04 | Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e.V. | Process for the gradual combustion of fuels |

| JP3661662B2 (en) * | 2002-03-28 | 2005-06-15 | Jfeエンジニアリング株式会社 | Method for recovering metals in waste incineration ash and waste incinerator |

| WO2004092648A1 (en) * | 2003-04-18 | 2004-10-28 | Jfe Engineering Corporation | Method of controlling combustion of waste incinerator and waste incinerator |

| EP1899058A1 (en) * | 2005-04-29 | 2008-03-19 | W.R. Grace & Co.-Conn. | Nox reduction compositions for use in partial burn fcc processes |

| EP1726876B1 (en) * | 2005-05-27 | 2015-05-06 | Takuma Co., Ltd. | Improved method of combusting solid waste |

| DE102006005464B3 (en) | 2006-02-07 | 2007-07-05 | Forschungszentrum Karlsruhe Gmbh | Primary reduction of the formation of nitric oxide, nitrous oxide and ammonia in exhaust fumes comprises combusting fuel in a furnace having a gas hot bed, supplying a secondary oxygen gas and axially mixing the exhaust components |

| US7975628B2 (en) * | 2006-09-13 | 2011-07-12 | Martin GmbH für Umwelt- und Energietechnik | Method for supplying combustion gas in incineration systems |

-

2011

- 2011-03-29 EP EP11002575A patent/EP2505919A1/en not_active Withdrawn

-

2012

- 2012-03-28 ES ES12712955T patent/ES2647667T5/en active Active

- 2012-03-28 JP JP2014501477A patent/JP2014513786A/en active Pending

- 2012-03-28 FI FIEP12712955.9T patent/FI2691701T4/en active

- 2012-03-28 NO NO12712955A patent/NO2691701T3/no unknown

- 2012-03-28 RS RS20171117A patent/RS56483B2/en unknown

- 2012-03-28 EP EP12712955.9A patent/EP2691701B2/en active Active

- 2012-03-28 WO PCT/EP2012/001361 patent/WO2012130446A1/en active Application Filing

- 2012-03-28 PL PL12712955.9T patent/PL2691701T5/en unknown

- 2012-03-28 US US14/008,798 patent/US20140182492A1/en not_active Abandoned

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5313895A (en) | 1990-11-22 | 1994-05-24 | Hitachi Zosen Corporation | Method of inhibiting formation of unburned substances in refuse incinerator, and refuse incinerator |

| EP1077077A2 (en) | 1999-08-12 | 2001-02-21 | ABB (Schweiz) AG | Method for the thermal treatment of solids |

| EP1081434A1 (en) | 1999-08-30 | 2001-03-07 | Von Roll Umwelttechnik AG | Device for generating a rotating gas flow |

| EP1508745A2 (en) | 2003-08-22 | 2005-02-23 | Fisia Babcock Environment GmbH | Method to reduce the production of NOx in combustion chambers and apparatus to implement said method |

| DE102004037442A1 (en) | 2004-08-02 | 2006-03-16 | Alstom Technology Ltd | Waste and/or compensation fuel thermal treatment method for combustion chamber, involves keeping direct heat exchange between exhaust gas and secondary air low through small dimensioned direct contact area within mantle nozzle |

| JP2009121747A (en) * | 2007-11-15 | 2009-06-04 | Hitachi Zosen Corp | Secondary combustion air blow-in method in secondary combustion chamber |

Non-Patent Citations (5)

| Title |

|---|

| DD, MASSNAHMEN ZUR MINDERUNG FEUERRAUMSEITIGER KORROSIONEN, no. hh |

| F. KRÜL L: "Verfahren zur nummerischen Simulation von Müllrostfeuerung", DISSERTATION, 2001, pages 1 - 237, XP055491976 |

| KRULL: "Die Auswirkung unterschiedlicher Sekundärluftverteilungen auf den Verbrennungsablauf in einer Müllrostfeuerung", pages 1 - 6 |

| OBERNBERGER: "Abbrand- und NOx-Simulation für Biomassefeuerung", BMVIT, September 2003 (2003-09-01), pages 1 - 155, XP002407054 |

| REIMANN D.O.: "Rostfeuerung zur Abfallverbrennung", article FERDINAND KRULL, WALTER BIENERT: "Von der konventionellen W alzenrostfeuerung zurfreiprogrammierbaren Feuerleistungsregelung mitOptimierung der Feuerraumgeometriein der MV A Diisseldorf", pages: 519 - 546 |

Also Published As

| Publication number | Publication date |

|---|---|

| RS56483B1 (en) | 2018-01-31 |

| US20140182492A1 (en) | 2014-07-03 |

| EP2505919A1 (en) | 2012-10-03 |

| ES2647667T5 (en) | 2024-09-19 |

| ES2647667T3 (en) | 2017-12-26 |

| NO2691701T3 (en) | 2018-01-20 |

| FI2691701T4 (en) | 2024-04-04 |

| EP2691701A1 (en) | 2014-02-05 |

| JP2014513786A (en) | 2014-06-05 |

| WO2012130446A1 (en) | 2012-10-04 |

| PL2691701T5 (en) | 2024-07-15 |

| EP2691701B2 (en) | 2024-03-20 |

| RS56483B2 (en) | 2024-04-30 |

| PL2691701T3 (en) | 2018-01-31 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1698827B1 (en) | Process for burning fuels and more particularly wastes | |

| DE102006005464B3 (en) | Primary reduction of the formation of nitric oxide, nitrous oxide and ammonia in exhaust fumes comprises combusting fuel in a furnace having a gas hot bed, supplying a secondary oxygen gas and axially mixing the exhaust components | |

| EP2691701B1 (en) | Method for optimising the burnout of exhaust gases of an incinerator | |

| DE2461078A1 (en) | PROCESS FOR REDUCING POLLUTANTS DURING INCINERATION PROCESSES AND DEVICE FOR CONDUCTING THESE | |

| DE2300522A1 (en) | DEVICE FOR BURNING FUEL OR. FUELS | |

| DE3716088A1 (en) | METHOD FOR BURNING IN PARTICULAR MUELL | |

| EP0498014A1 (en) | Method of supplying combustion air and firing installation | |

| EP0111874A1 (en) | A device for burning coal dust | |

| DE3915992A1 (en) | Process for the reduction of nitrogen oxides | |

| EP3076076A1 (en) | Method for grate firings combustion management and grate firing | |

| WO1999058902A1 (en) | Method for the heat treatment of solids | |

| EP1754937B1 (en) | Burner head and method of combusting fuel | |

| EP1281026B1 (en) | Method and device for incinerating organic waste material | |

| DE4230311C1 (en) | Process and incinerator for incinerating waste | |

| DE4402172C2 (en) | Process for combusting fuel and plant for carrying out the process | |

| DE102006034032B4 (en) | Thermal exhaust gas purification device and method for thermal exhaust gas purification | |

| DE4401821C2 (en) | Process for burning substances, in particular waste and biomass, and device for carrying out the process | |

| EP4155643A1 (en) | Device and method for drying material and asphalt mixing system comprising such a device | |

| EP0611919A1 (en) | Method for supplying combustion gas containing oxygen to an incinerator with a grate furnace and apparatus for carrying out the method | |

| DE102004037442B4 (en) | Process for the thermal treatment of waste in a thermal waste treatment plant and thermal waste treatment plant | |

| EP1926936A1 (en) | Burner arrangement for a combustion chamber, associated combustion chamber and method for combusting fuel | |

| AT397551B (en) | INCINERATOR | |

| DE3625397C2 (en) | ||

| EP3260776B1 (en) | Lance system, boiler- containing lance system and method for reducing nox | |

| DE2816282C2 (en) | Incinerator with a fluidized bed |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20130923 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: WALDNER, MAURICE, HENRI |

|

| DAX | Request for extension of the european patent (deleted) | ||

| 17Q | First examination report despatched |

Effective date: 20160303 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: F23G 5/16 20060101AFI20170208BHEP Ipc: F23L 7/00 20060101ALI20170208BHEP Ipc: F23L 9/02 20060101ALI20170208BHEP |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20170322 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: CH Ref legal event code: NV Representative=s name: PATENTANWAELTE SCHAAD, BALASS, MENZL AND PARTN, CH |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 921750 Country of ref document: AT Kind code of ref document: T Effective date: 20170915 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502012011081 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: FP |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2647667 Country of ref document: ES Kind code of ref document: T3 Effective date: 20171226 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| REG | Reference to a national code |

Ref country code: NO Ref legal event code: T2 Effective date: 20170823 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170823 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170823 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171223 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170823 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171123 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171124 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170823 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170823 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170823 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R026 Ref document number: 502012011081 Country of ref document: DE |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170823 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170823 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170823 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| 26 | Opposition filed |

Opponent name: DOOSAN LENTJES GMBH Effective date: 20180517 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170823 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170823 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170823 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20180331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180328 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180331 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 921750 Country of ref document: AT Kind code of ref document: T Effective date: 20180328 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180328 |

|

| APBM | Appeal reference recorded |

Free format text: ORIGINAL CODE: EPIDOSNREFNO |

|

| APBP | Date of receipt of notice of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA2O |

|

| APAH | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOSCREFNO |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20120328 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170823 |

|

| APBQ | Date of receipt of statement of grounds of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA3O |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |