EP1457282B1 - Continuous casting machine with one thundish car for symmetrically arranged, unilaterally attachable tundishes - Google Patents

Continuous casting machine with one thundish car for symmetrically arranged, unilaterally attachable tundishes Download PDFInfo

- Publication number

- EP1457282B1 EP1457282B1 EP04003454A EP04003454A EP1457282B1 EP 1457282 B1 EP1457282 B1 EP 1457282B1 EP 04003454 A EP04003454 A EP 04003454A EP 04003454 A EP04003454 A EP 04003454A EP 1457282 B1 EP1457282 B1 EP 1457282B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- continuous casting

- plant according

- casting plant

- casting

- distributor channel

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000009749 continuous casting Methods 0.000 title claims description 25

- 238000005266 casting Methods 0.000 claims abstract description 35

- 229910000831 Steel Inorganic materials 0.000 claims abstract description 4

- 239000010959 steel Substances 0.000 claims abstract description 4

- 239000000725 suspension Substances 0.000 claims description 20

- 238000010438 heat treatment Methods 0.000 claims description 12

- 230000008878 coupling Effects 0.000 claims description 5

- 238000010168 coupling process Methods 0.000 claims description 5

- 238000005859 coupling reaction Methods 0.000 claims description 5

- 238000000034 method Methods 0.000 claims description 4

- 230000008569 process Effects 0.000 claims description 4

- 238000005096 rolling process Methods 0.000 claims description 4

- 238000005303 weighing Methods 0.000 claims description 4

- 239000007788 liquid Substances 0.000 claims description 3

- 229910001338 liquidmetal Inorganic materials 0.000 claims description 3

- 239000000463 material Substances 0.000 claims description 3

- 239000002184 metal Substances 0.000 abstract 1

- 230000001681 protective effect Effects 0.000 abstract 1

- 238000009826 distribution Methods 0.000 description 21

- 230000008859 change Effects 0.000 description 3

- 239000002131 composite material Substances 0.000 description 3

- 238000005259 measurement Methods 0.000 description 2

- 230000008901 benefit Effects 0.000 description 1

- 210000000078 claw Anatomy 0.000 description 1

- 150000001875 compounds Chemical class 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21B—MANUFACTURE OF IRON OR STEEL

- C21B3/00—General features in the manufacture of pig-iron

- C21B3/04—Recovery of by-products, e.g. slag

- C21B3/06—Treatment of liquid slag

- C21B3/10—Slag pots; Slag cars

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D11/00—Continuous casting of metals, i.e. casting in indefinite lengths

- B22D11/10—Supplying or treating molten metal

- B22D11/103—Distributing the molten metal, e.g. using runners, floats, distributors

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D41/00—Casting melt-holding vessels, e.g. ladles, tundishes, cups or the like

- B22D41/12—Travelling ladles or similar containers; Cars for ladles

Definitions

- the invention relates to a continuous casting plant for casting strands of liquid Metal, in particular of liquid steel material, and in particular of the type Casting plant with attached rolling mill, with a ladle over one the casting platform on rails movable carriage, with a distributor trough, the one Having pouring tube, and arranged on the carriage lifting device for the Adjustment of the pouring tube at pouring height in the continuous casting mold.

- Distribution gutter cars are known (EP 0 940 205 A1).

- the appropriately equipped Distributor gutters go on multi-line systems and more recently Composite casting back. It is known to provide two distributor door carriages.

- the casting speed can be lowered and the distributor trough becomes inside changed from, for example, 4 to 6 minutes.

- This change time is not at all continuous casting process. So the conditions are at Single-strand casting equipment significantly different.

- a single-strand caster on which are cast compared to slab cross-sections relatively thin strand thicknesses, is due to the faster cooling, a lowering of the casting speed not possible.

- the strand is solidified depending on the thickness in about 1-1.5 minutes.

- One Composite casting can not take place in such cases. At this time could However, no Verteilerrinnen-change take place.

- the invention is based on the object, the workflows on the casting platform to change when changing the tundish by little effort, u.a. making the crane handling easier and at the same time the distribution trolley adapt.

- the stated object is achieved in that only a single Distribution gutter carriage is used, that this is designed as a manipulator is that on a supporting frame connected to the support frame a lifting and lowerable guide block is provided on the symmetrical in both directions Hanging means provided for each one-sided suspended distribution trough and that the guide block height adjustable together with at least one distributor trough is.

- the advantage is the use of only one distributor trough wagon for casting processes that do not allow composite casting.

- the manipulator shortens the way to the heating, because it worked in two directions can be. This relieves crane operation. The crane only drives the Distributor channels from the heating station to the workshop and back again.

- An improvement provides that the Einhticiangesch hang-up for at least have two Ein discomfortzapfen a distributor trough.

- the distributor gutter car can over the raised and lowered guide block each distribution channel in the relevant Lower the heating stand or pick it up again from the heating stand and refill Operation, adjust the pouring tube to the pouring level in the continuous casting mold.

- hooking means in pairs substantially having vertically arranged levers which are transverse to the direction of travel by means of suspension axes and longitudinally or transversely to the direction of travel by means of longitudinal struts and cross struts connected to each other. This will increase the load capacity for gross weights the distribution channel up to 70 t and more guaranteed.

- suspension axes with corresponding retaining claws on the distributor trough ensures a leveling to a selected position of the distributor trough, wherein it is advantageous that at the lower end of each lever a support surface for Counter support surfaces is arranged on the distribution channels.

- An accurate, largely vertical guide for the height adjustment of distribution trough and pouring tube is further achieved in that on the support frame on both sides vertical guide posts are attached and that the guide block from the Suspension axles and the longitudinal struts or transverse struts and other frame parts by means of respectively arranged in the direction of travel guide roller pairs lifting and lowered is guided.

- the guide block at the top with a Traverse which runs transversely to the direction of travel, is completed, to that of bottom as a lifting device, the piston rod centered within the guide block arranged piston-cylinder unit attacks.

- the location of the tundish i. by hanging the distribution channel in suspension axes scored position, and allow by the location of the suspension axis Furthermore, that the hinged distributor trough against the support frame in pairs arranged load cells is supported. This results in very accurate measurement results to the current weight of the distributor trough remaining Melt achieved.

- the movement of the distributor trough during operation can still be improved be made by the suspended distribution channel for the weighing against the Friction-increasing transverse forces by means of coupling rods and rotatable guide rollers is supported.

- Operation on the casting floor can be further simplified by the fact that the Distribution trolley from a left or right heating position to the casting position is movable over the continuous casting mold.

- Another embodiment provides that the SEN heating means for the pouring tube are arranged on the manipulator. Therefore, the pouring tube can still until shortly before Recording of the casting operation to be heated or kept warm.

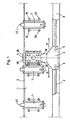

- the casting platform 1 is shown in Fig. 1, on the Rails 2 are laid for a Verteilerspinnen trolley 3 by means of wheels 4 and 5.

- the wheels 5 run, Fig. 2, on the rail 2, which is laid on an upper stage 6 and are provided with drives 4a, 4b.

- the distribution trough carriage 3 carries at least one distributor trough 7, which in operation a ladle 8 is fed. At the distributor trough 7, a pouring tube 9 is attached, which extends into a continuous casting mold 10 in the lowered operating position (FIG. 2).

- a lifting device 11 is centrally arranged further, which consists of a hydraulic piston-cylinder unit 11a.

- the Verteilerrinnen-carriage 3 consists of a traveling frame 13 with a support frame 14 constructed thereon.

- the support frame 14 carries a means the piston-cylinder unit 11a can be raised or lowered guide block 15th

- the guide block 15 (Fig. 3) carries in both directions of travel 16, 17 Ein relie für 18 for the distributor trough 7.

- the distributor trough 7 has their Broadside Ein rehabilitationzapfen 19 and 20.

- the suspension means 18 form Ein cognitivelager 21 for two Ein rehabilitationzapfen 19, 20 per broad side of the distribution channel 7.

- the distribution channel 7 can be lifted via crane cranks 22 by crane, brought to a workshop and by crane back to a position to be described be transported and taken up again from the distributor door carriage 3.

- the suspension means 18 are further formed by pairs of levers 23 (Fig. 4), at the end of the lever 23a supporting surfaces 24 for counter support surfaces 7a the distributor trough 7 are formed.

- the levers 23, which are substantially perpendicular, are per side by means of suspension axes 25 connected.

- the suspension axes 25 form across and across the Driving direction 16, 17 arranged longitudinal struts 26 and cross struts 27 a compound (Fig. 3), which is part of the guide block 15.

- the guide posts 28 connect cross struts 29 and at these perpendicular rails 30 are provided.

- the leader block 15, consisting of suspension axes 25, the longitudinal struts 26, the transverse struts 27th and further frame parts, carries in the direction of travel 16, 17 aligned pairs of guide rollers 32, which roll on the stationary, vertical rails 30.

- the guide block 15 is also completed at the top with a crossbar 33 and firmly connected.

- the cross member 33 extends transversely to the direction of travel 16, 17th At the bottom of the piston engages a centrally located in the guide block 15 Piston-cylinder unit 11a (see also Fig. 4).

- the guide block 15 by means of a handlebar roller 34 which at a Connecting plate 35 is rotatably mounted, additionally supported and guided.

- handlebar rollers 34 are provided in pairs.

- the weight of the distribution trough 7 is supported on a load cell 36. This allows the instantaneous weight content of melt in the distributor trough 7 continuously measured during the casting process.

- the load cells 36 are arranged in pairs above the plane of the suspension axis 25.

- further guide rollers 37, 38 are arranged.

- Fig. 6 which shows a section E-F (see Fig. 8)

- the load cells 36 are of visible above, as well as a pair of guide rollers 32, at the bottom of the vertical Rail 30 adjacent recognizable. Further, the location and attachment of the piston-cylinder unit 11a shown.

- the load cell 36 provides a coupling rod 39 with a guide roller 40, the are also provided in pairs.

- Fig. 7 shows even more clearly the arrangement of the lifting device 11 with the piston-cylinder unit 11a under the traverse 33 by means of a pressure plate 41, to which the Piston rod 11b acts.

- the piston rod 11b raises or lowers the assembly of the Guide blocks 15, of which here the load cells 36, the suspension axis 25, the Traverse 33 and the piston rod 11b are visible.

- the lower part of the piston-cylinder unit 11a is firmly supported on the support frame 14.

- Fig. 8 shows a front view as a section C-D of Fig. 6.

- This illustration shows once again the arrangement of the lifting device 11 as a piston-cylinder unit 11a with the piston rod 11b or the piston in the middle region of the guide block 15.

- the guide rollers 32 abut the vertical rails 30.

- the leadership roles support the high weight of the troughs 7, which empty about 20 t and with Melt filled can be about 65 t.

- the measurement result for the weight still present in the distributor trough 7 melt can be made more accurate that the suspended distribution channel 7 for the weighing process against the friction of increasing transverse forces by means of coupling rods 39 and the guide rollers 40 is supported.

- the Verteilerrinnen-carriage 3 can from the left and right heating positions 42, 43 to over the casting position (Fig. 1-4) of the continuous casting mold 10 or back be moved.

- the SEN heating means are arranged for the pouring tube 9 within the manipulator 12.

- the pouring tube can thereby be heated until just before the start or to be reheated.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Mechanical Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Continuous Casting (AREA)

- Casting Support Devices, Ladles, And Melt Control Thereby (AREA)

- Laying Of Electric Cables Or Lines Outside (AREA)

Abstract

Description

Die Erfindung betrifft eine Stranggießanlage zum Gießen von Strängen aus flüssigem Metall, insbesondere aus flüssigem Stahlwerkstoff, und speziell des Typs einer Gießanlage mit angeschlossener Walzstraße, mit einer Gießpfanne über einem auf der Gießbühne auf Schienen verfahrbaren Wagen, mit einer Verteilerrinne, die ein Gießrohr aufweist, und einer auf dem Wagen angeordneten Hubeinrichtung für die Einstellung des Gießrohrs auf Gießhöhe in der Stranggießkokille.The invention relates to a continuous casting plant for casting strands of liquid Metal, in particular of liquid steel material, and in particular of the type Casting plant with attached rolling mill, with a ladle over one the casting platform on rails movable carriage, with a distributor trough, the one Having pouring tube, and arranged on the carriage lifting device for the Adjustment of the pouring tube at pouring height in the continuous casting mold.

Verteilerrinnen-Wagen sind bekannt (EP 0 940 205 A1). Die entsprechend ausgerüsteten Verteilerrinnen-Wagen gehen auf Mehrstranganlagen und neuerdings auf Verbundgießen zurück. Bekannt ist es, zwei Verteilerrinnen-Wagen vorzusehen. Sobald z.B. bei einer zweistrangigen Brammen-Stranggießanlage ein fliegender Wechsel der nach einer hohen Chargen-Anzahl verbrauchten Verteilerrinne erfolgen muss, kann die Gießgeschwindigkeit abgesenkt werden und die Verteilerrinne wird innerhalb von bspw. 4 bis 6 Minuten gewechselt. Diese Wechselzeit steht nicht bei allen ausgeübten Stranggießverfahren zur Verfügung. So sind die Verhältnisse bei Einstrang-Gießanlagen erheblich unterschiedlich. In einer Einstrang-Gießanlage, auf der gegenüber Brammen-Querschnitten relativ dünne Strangdicken gegossen werden, ist wegen der schnelleren Abkühlung eine Absenkung der Gießgeschwindigkeit nicht möglich. Der Strang ist je nach Dicke in ca. 1- 1,5 Minuten durcherstarrt. Ein Verbundgießen kann somit in solchen Fällen nicht stattfinden. In dieser Zeit könnte allerdings auch kein Verteilerrinnen-Wechsel stattfinden.Distribution gutter cars are known (EP 0 940 205 A1). The appropriately equipped Distributor gutters go on multi-line systems and more recently Composite casting back. It is known to provide two distributor door carriages. As soon as e.g. in a two-tier continuous slab caster a flying change the distribution trough has to be used after a high number of batches, the casting speed can be lowered and the distributor trough becomes inside changed from, for example, 4 to 6 minutes. This change time is not at all continuous casting process. So the conditions are at Single-strand casting equipment significantly different. In a single-strand caster, on which are cast compared to slab cross-sections relatively thin strand thicknesses, is due to the faster cooling, a lowering of the casting speed not possible. The strand is solidified depending on the thickness in about 1-1.5 minutes. One Composite casting can not take place in such cases. At this time could However, no Verteilerrinnen-change take place.

Der Erfindung liegt die Aufgabe zugrunde, die Arbeitsabläufe auf der Gießbühne beim Wechseln der Verteilerrinne durch geringen Aufwand zu verbessem, u.a. das Kranhandling einfacher zu gestalten und gleichzeitig den Verteilerrinnen-Wagen anzupassen.The invention is based on the object, the workflows on the casting platform to change when changing the tundish by little effort, u.a. making the crane handling easier and at the same time the distribution trolley adapt.

Die gestellte Aufgabe wird erfindungsgemäß dadurch gelöst, dass nur ein einziger Verteilerrinnen-Wagen verwendet wird, dass dieser als Manipulator derart ausgebildet ist, dass an einem mit dem Fahrrahmen verbundenen Stützrahmen ein heb- und senkbarer Führungsblock vorgesehen ist, an dem in beiden Fahrrichtungen symmetrisch Einhängemittel für jeweils eine einseitig einhängbare Verteilerrinne vorgesehen sind und dass der Führungsblock zusammen mit zumindest einer Verteilerrinne höheneinstellbar ist. Der Vorteil besteht in der Anwendung nur eines Verteilerrinnen-Wagens für Gießverfahren, mit denen ein Verbundgießen nicht möglich ist. Der Manipulator verkürzt die Wege zum Aufheizstand, da nach zwei Richtungen gearbeitet werden kann. Dadurch wird der Kranbetrieb entlastet. Der Kran fährt nur noch die Verteilerrinnen vom Aufheizstand zur Werkstatt und wieder zurück.The stated object is achieved in that only a single Distribution gutter carriage is used, that this is designed as a manipulator is that on a supporting frame connected to the support frame a lifting and lowerable guide block is provided on the symmetrical in both directions Hanging means provided for each one-sided suspended distribution trough and that the guide block height adjustable together with at least one distributor trough is. The advantage is the use of only one distributor trough wagon for casting processes that do not allow composite casting. The manipulator shortens the way to the heating, because it worked in two directions can be. This relieves crane operation. The crane only drives the Distributor channels from the heating station to the workshop and back again.

Eine Verbesserung sieht vor, dass die Einhängemittel Einhängelager für zumindest zwei Einhängezapfen einer Verteilerrinne aufweisen. Der Verteilerrinnen-Wagen kann über den heb- und senkbaren Führungsblock jede Verteilerrinne in den betreffenden Aufheizstand absetzen oder vom Aufheizstand wieder aufnehmen und im Betrieb die Einstellung des Gießrohrs zum Gießspiegel in der Stranggießkokille vornehmen.An improvement provides that the Einhänggemittel hang-up for at least have two Einhängezapfen a distributor trough. The distributor gutter car can over the raised and lowered guide block each distribution channel in the relevant Lower the heating stand or pick it up again from the heating stand and refill Operation, adjust the pouring tube to the pouring level in the continuous casting mold.

Eine Ausgestaltung besteht darin, dass die Einhängemittel paarweise im wesentlichen senkrecht angeordnete Hebel aufweisen, die quer zur Fahrrichtung mittels Einhängeachsen und längs bzw. quer zur Fahrrichtung mittels Längsstreben und Querstreben miteinander verbunden sind. Dadurch wird die Belastbarkeit bei Brutto-Gewichten der Verteilerrinne bis zu 70 t und mehr gewährleistet. One embodiment is that the hooking means in pairs substantially having vertically arranged levers which are transverse to the direction of travel by means of suspension axes and longitudinally or transversely to the direction of travel by means of longitudinal struts and cross struts connected to each other. This will increase the load capacity for gross weights the distribution channel up to 70 t and more guaranteed.

Die Anordnung von Einhängeachsen bei entsprechenden Haltekrallen an der Verteilerrinne gewährleistet ein Einpendeln auf eine ausgewählte Lage der Verteilerrinne, wobei vorteilhaft ist, dass an den unteren Hebelenden jeweils eine Abstützfläche für Gegenstützflächen an den Verteilerrinnen angeordnet ist.The arrangement of suspension axes with corresponding retaining claws on the distributor trough ensures a leveling to a selected position of the distributor trough, wherein it is advantageous that at the lower end of each lever a support surface for Counter support surfaces is arranged on the distribution channels.

Eine genaue, weitgehend lotrechte Führung für die Höhenverstellung von Verteilerrinne und Gießrohr wird ferner dadurch erzielt, dass an dem Stützrahmen beidseitig senkrechte Führungsstützen befestigt sind und dass der Führungsblock aus den Einhängeachsen und den Längsstreben bzw. Querstreben und weiteren Rahmenteilen mittels jeweils in Fahrrichtung angeordneten Führungsrollen-Paaren heb- und senkbar geführt ist.An accurate, largely vertical guide for the height adjustment of distribution trough and pouring tube is further achieved in that on the support frame on both sides vertical guide posts are attached and that the guide block from the Suspension axles and the longitudinal struts or transverse struts and other frame parts by means of respectively arranged in the direction of travel guide roller pairs lifting and lowered is guided.

Nach weiteren Merkmalen ist vorgesehen, dass der Führungsblock an der Oberseite mit einer Traverse, die quer zur Fahrrichtung verläuft, abgeschlossen ist, an die von unten als Hubeinrichtung die Kolbenstange einer innerhalb des Führungsblocks mittig angeordneten Kolben-Zylinder-Einheit angreift.According to further features, it is provided that the guide block at the top with a Traverse, which runs transversely to the direction of travel, is completed, to that of bottom as a lifting device, the piston rod centered within the guide block arranged piston-cylinder unit attacks.

Die Lage der Verteilerrinne, d.h. die durch das Einhängen der Verteilerrinne in Einhängeachsen erzielte Position, und durch die Lage der Einhängeachse ermöglichen ferner, dass die eingehängte Verteilerrinne gegen den Stützrahmen auf paarweise angeordneten Wägezellen aufgestützt ist. Dadurch werden sehr genaue Messergebnisse zum momentanen Gewicht der in der Verteilerrinne noch vorhandenen Schmelze erzielt.The location of the tundish, i. by hanging the distribution channel in suspension axes scored position, and allow by the location of the suspension axis Furthermore, that the hinged distributor trough against the support frame in pairs arranged load cells is supported. This results in very accurate measurement results to the current weight of the distributor trough remaining Melt achieved.

Die Bewegung der Verteilerrinne während des Betriebs kann noch dadurch verbessert werden, indem die eingehängte Verteilerrinne für den Wägevorgang gegen die Reibung erhöhende Querkräfte mittels Koppelstangen und daran drehbaren Führungsrollen abgestützt ist. The movement of the distributor trough during operation can still be improved be made by the suspended distribution channel for the weighing against the Friction-increasing transverse forces by means of coupling rods and rotatable guide rollers is supported.

Der Betrieb auf der Gießbühne kann femer dadurch vereinfacht werden, dass der Verteilerrinnen-Wagen aus einer linken oder rechten Heizposition bis in die Gießposition über der Stranggießkokille verfahrbar ist.Operation on the casting floor can be further simplified by the fact that the Distribution trolley from a left or right heating position to the casting position is movable over the continuous casting mold.

Eine andere Ausgestaltung sieht vor, dass die SEN-Heizungsmittel für das Gießrohr am Manipulator angeordnet sind. Das Gießrohr kann daher auch noch bis kurz vor Aufnahme des Gießbetriebs aufgeheizt oder warmgehalten werden.Another embodiment provides that the SEN heating means for the pouring tube are arranged on the manipulator. Therefore, the pouring tube can still until shortly before Recording of the casting operation to be heated or kept warm.

In der Zeichnung sind Ausführungsbeispiele der Erfindung dargestellt, die nachstehend näher erläutert werden.In the drawings, embodiments of the invention are shown below be explained in more detail.

Es zeigen:

- Fig. 1

- eine Draufsicht auf eine Gießbühne einer Einstrang-Stranggießanlage,

- Fig. 2

- einen Querschnitt durch die Gießbühne mit Verteilerrinnen-Wagen und Stranggießkokille,

- Fig. 3

- die zu Fig. 2 gehörende Draufsicht auf den Verteilerrinnen-Wagen mit Verteilerrinnen,

- Fig. 4

- eine Seitenansicht des Verteilerrinnen-Wagens mit eingehängten Verteilerrinnen,

- Fig. 5

- einen Teil-Querschnitt durch den Führungsblock,

- Fig. 6

- einen Teil-Schnitt (Draufsicht) auf den Führungsblock, zu Fig. 5 gehörend, gemäß der Schnittangabe E-F aus Fig. 8,

- Fig. 7

- einen Teil-Schnitt A-B gemäß Fig. 6 und

- Fig. 8

- einen Teil-Schnitt C-D gemäß Fig. 6.

- Fig. 1

- a top view of a casting platform of a single-strand continuous casting plant,

- Fig. 2

- a cross section through the casting platform with Verteilerspinnen trolley and continuous casting mold,

- Fig. 3

- 2 belonging to the plan view of the distribution trough wagon with distribution troughs,

- Fig. 4

- a side view of the Verteilerrinnen-car with hinged distribution channels,

- Fig. 5

- a partial cross section through the guide block,

- Fig. 6

- a partial section (top view) on the guide block, belonging to Fig. 5, according to the sectional view EF of Fig. 8,

- Fig. 7

- a partial section AB of FIG. 6 and

- Fig. 8

- a partial section CD of FIG. 6th

Von der Stranggießanlage zum Gießen von Strängen aus flüssigem Metall, insbesondere

aus flüssigem Stahlwerkstoff, ist in Fig. 1 die Gießbühne 1 gezeigt, auf der

Schienen 2 für einen Verteilerrinnen-Wagen 3 mittels Rädern 4 und 5 verlegt sind.

Die Räder 5 laufen, Fig. 2, auf der Schiene 2, die auf einer Oberbühne 6 verlegt ist

und sind mit Antrieben 4a, 4b versehen. From the continuous casting plant for casting strands of liquid metal, in particular

From liquid steel material, the casting platform 1 is shown in Fig. 1, on the

Der Verteilerrinnen-Wagen 3 trägt zumindest eine Verteilerrinne 7, die im Betrieb aus

einer Gießpfanne 8 gespeist wird. An der Verteilerrinne 7 ist ein Gießrohr 9 befestigt,

das in abgesenkter Betriebslage in eine Stranggießkokille 10 hineinreicht (Fig. 2).The

Auf dem Verteilerrinnen-Wagen 3 ist zentral femer eine Hubeinrichtung 11 angeordnet,

die aus einer hydraulischen Kolben-Zylinder-Einheit 11a besteht.On the Verteilerrinnen-carriage 3 a

Auf einer Gießwalzanlage, die bspw. aus einer CSP-Anlage (Compact-Strip-Production)

bestehen kann, werden Formate von ca. 50 - 70 mm Dicke gegossen.

Für ein solches Gieß-Walz-Verfahren ist nur ein einziger Verteilerrinnen-Wagen 3

erforderlich. Dieser ist jedoch mit einem Manipulator 12 mit besonderen Eigenschaften

ausgebildet: Der Verteilerrinnen-Wagen 3 besteht aus einem Fahrrahmen 13 mit

einem darauf aufgebauten Stützrahmen 14. Der Stützrahmen 14 trägt einen mittels

der Kolben-Zylinder-Einheit 11a heb- oder senkbaren Führungsblock 15.On a cast rolling mill, for example, from a CSP plant (Compact Strip Production)

can be made, are poured formats of about 50 - 70 mm thickness.

For such a casting-rolling process, only a single

Der Führungsblock 15 (Fig. 3) trägt in beiden Fahrrichtungen 16, 17 Einhängemittel

18 für die Verteilerrinne 7. Zu diesem Zweck besitzt die Verteilerrinne 7 an ihren

Breitseiten Einhängezapfen 19 und 20. Die Einhängemittel 18 bilden Einhängelager

21 für zwei Einhängezapfen 19, 20 pro Breitseite der Verteilerrinne 7. Die Verteilerrinne

7 kann über vier Kranzapfen 22 per Kran ausgehoben, in eine Werkstatt gebracht

und per Kran wieder in eine noch zu beschreibende Bereitstellungsposition

transportiert und wieder vom Verteilerrinnen-Wagen 3 aufgenommen werden.The guide block 15 (Fig. 3) carries in both directions of

Die Einhängemittel 18 werden weiter durch paarweise angeordnete Hebel 23 gebildet

(Fig. 4), an deren Hebelende 23a Abstützflächen 24 für Gegenstützflächen 7a an

der Verteilerrinne 7 angeformt sind.The suspension means 18 are further formed by pairs of levers 23

(Fig. 4), at the end of the lever

Die Hebel 23, die im wesentlichen senkrecht verlaufen, sind pro Seite mittels Einhängeachsen

25 verbunden. Die Einhängeachsen 25 bilden über längs und quer zur

Fahrrichtung 16, 17 angeordnete Längsstreben 26 und Querstreben 27 einen Verbund

(Fig. 3), der Teil des Führungsblockes 15 ist. The

An dem Stützrahmen 14 sind femer beidseitig und paarweise Führungsstützen 28

befestigt (vgl. auch Fig. 1). Die Führungsstützen 28 verbinden Querstreben 29 und

an diesen sind senkrecht verlaufende Schienen 30 vorgesehen. Der Führungsblock

15, bestehend aus Einhängeachsen 25, den Längsstreben 26, den Querstreben 27

und weiteren Rahmenteilen, trägt in Fahrrichtung 16, 17 ausgerichtete Führungsrollenpaare

32, die an den ortsfesten, senkrechten Schienen 30 abrollen.On the

Der Führungsblock 15 ist außerdem an der Oberseite mit einer Traverse 33 abgeschlossen

und fest verbunden. Die Traverse 33 verläuft quer zur Fahrrichtung 16, 17.

An der Unterseite greift der Kolben einer zentral im Führungsblock 15 angeordneten

Kolben-Zylinder-Einheit 11a an (vgl. auch Fig. 4).The

Gemäß Fig. 5 wird der Führungsblock 15 mittels einer Lenkerrolle 34, die an einer

Verbindungslasche 35 drehgelagert ist, zusätzlich gestützt und geführt. Solche Lenkerrollen

34 sind paarweise vorgesehen. Im Rahmenteil der Einhängeachse 25 und

in der lotrechten Achse stützt sich das Gewicht der Verteilerrinne 7 auf eine Wägezelle

36. Dadurch kann der momentane Gewichtsinhalt an Schmelze in der Verteilerrinne

7 kontinuierlich während des Gießprozesses gemessen werden. Die Wägezellen

36 sind paarweise über der Ebene der Einhängeachse 25 angeordnet. Außerdem

sind weitere Führungsrollen 37, 38 angeordnet.According to Fig. 5, the

In Fig. 6, die einen Schnitt E-F (vgl. Fig. 8) darstellt, sind die Wägezellen 36 von

oben sichtbar, ebenso ist ein Führungsrollenpaar 32, unten an der senkrechten

Schiene 30 anliegend erkennbar. Femer sind die Lage und die Befestigung der Kolben-Zylinder-Einheit

11a gezeigt. Für eine minimale Reibung während des Messvorgangs

der Wägezelle 36 sorgt eine Koppelstange 39 mit einer Führungsrolle 40, die

ebenfalls paarweise vorgesehen sind.In Fig. 6, which shows a section E-F (see Fig. 8), the

Fig. 7 zeigt noch deutlicher die Anordnung der Hubeinrichtung 11 mit der Kolben-Zylinder-Einheit

11a unter der Traverse 33 mittels einer Druckplatte 41, auf die die

Kolbenstange 11b wirkt. Die Kolbenstange 11b hebt oder senkt die Baugruppe des

Führungsblocks 15, von dem hier die Wägezellen 36, die Einhängeachse 25, die

Traverse 33 und die Kolbenstange 11b sichtbar sind. Der untere Teil der Kolben-Zylinder-Einheit

11a ist dabei fest auf dem Stützrahmen 14 aufgestützt.Fig. 7 shows even more clearly the arrangement of the

Fig. 8 stellt eine Vorderansicht als Schnitt C-D aus Fig. 6 dar. Diese Darstellung zeigt

noch einmal die Anordnung der Hubeinrichtung 11 als Kolben-Zylinder-Einheit 11a

mit der Kolbenstange 11b bzw. dem Kolben im Mittenbereich des Führungsblocks

15. Die Führungsrollen 32 liegen an den senkrechten Schienen 30 an. Die Führungsrollen

stützen das hohe Gewicht der Verteilerinne 7, das leer ca. 20 t und mit

Schmelze gefüllt ca. 65 t betragen kann.Fig. 8 shows a front view as a section C-D of Fig. 6. This illustration shows

once again the arrangement of the

Das Messergebnis für das Gewicht noch in der Verteilerrinne 7 vorhandener Schmelze

kann dadurch genauer gestaltet werden, dass die eingehängte Verteilerrinne 7 für

den Wägevorgang gegen die Reibung erhöhender Querkräfte mittels Koppelstangen

39 und den Führungsrollen 40 abgestützt ist.The measurement result for the weight still present in the

Der Verteilerrinnen-Wagen 3 kann aus den links und rechts liegenden Heizpositionen

42, 43 bis über die Gießposition (Fig. 1-4) der Stranggießkokille 10 oder zurück

verfahren werden.The Verteilerrinnen-

Die SEN-Heizungsmittel sind für das Gießrohr 9 innerhalb des Manipulators 12 angeordnet.

Das Gießrohr kann dadurch bis kurz vor dem Anfahrvorgang beheizt oder

nachgewärmt werden. The SEN heating means are arranged for the pouring

- 11

- Gießbühnecasting platform

- 22

- Schienerail

- 33

- Verteilerrinnen-WagenTundishes cars

- 44

- Radwheel

- 4a4a

- Antriebdrive

- 4b4b

- Antriebdrive

- 55

- Radwheel

- 66

- Oberbühneupper stage

- 77

- Verteilerrinnetundish

- 7a7a

- GegenstützflächenAgainst support surfaces

- 88th

- Gießpfanneladle

- 99

- Gießrohrcasting tube

- 1010

- Stranggießkokillecontinuous casting

- 1111

- Hubeinrichtunglifting device

- 11a11a

- Kolben-Zylinder-EinheitPiston-cylinder unit

- 11b11b

- Kolbenstangepiston rod

- 1212

- Manipulatormanipulator

- 1313

- Fahrrahmentrial frame

- 1414

- Stützrahmensupport frame

- 1515

- Führungsblockguide block

- 1616

- Fahrrichtungdriving direction

- 1717

- Fahrrichtungdriving direction

- 1818

- Einhängemittelhooking

- 1919

- EinhängezapfenEinhängezapfen

- 2020

- EinhängezapfenEinhängezapfen

- 2121

- EinhängelagerEinhängelager

- 2222

- Kranzapfencrane pins

- 2323

- Hebellever

- 23a23a

- Hebelende lever end

- 2424

- Abstützflächesupporting

- 2525

- EinhängeachseEinhängeachse

- 2626

- Längsstrebenlongitudinal struts

- 2727

- Querstrebencrossbars

- 2828

- Führungsstützeguide support

- 2929

- Querstrebencrossbars

- 3030

- senkrechte Schienenvertical rails

- 31 3231 32

- Führungsrollen-PaarGuide roller pair

- 3333

- Traversetraverse

- 3434

- Lenkerrollehandlebar role

- 3535

- Verbindungslascheconnecting strap

- 3636

- Wägezelleload cell

- 3737

- Führungsrolleleadership

- 3838

- Führungsrolleleadership

- 3939

- Koppelstangecoupling rod

- 4040

- Führungsrolleleadership

- 4141

- Druckplatteprinting plate

- 4242

- linke Heizpositionleft heating position

- 4343

- rechte Heizpositionright heating position

Claims (10)

- Continuous casting plant for casting strips of liquid metal, particularly of liquid steel material, and especially the category of a casting plant with connected rolling train, with a casting ladle (8), with a carriage (3) movable on rails (3) over the casting platform (1), with at least one distributor channel (7) having a pouring pipe (9), and a stroke device (11), which is arranged on the carriage (3), for setting the pouring pipe (9) to pouring level in the continuous casting mould, wherein the distributor channel carriage (3) comprises a chassis (13) and a support frame (14), characterised in that only a single distributor channel carriage (3) is used, that this is constructed as a manipulator (12) in such a manner that provided at the support frame (14) connected with the chassis (13) is a raisable and lowerable guide block (15) at which suspension means (18), which are symmetrical in both travel directions (16, 17), for a respective distributor channel (7) able to be suspended at one side are provided and that the guide block (15) together with at least one distributor channel (7) is adjustable in height.

- Continuous casting plant according to claim 1, characterised in that the suspension means (18) comprises a suspension mount (21) for at least two suspension pins (19, 20) of a distributor channel (7).

- Continuous casting plant according to one of claims 1 and 2, characterised in that the suspension means (18) comprise levers (23) which are arranged in pairs substantially vertically and which are connected together transversely to the travel direction (16, 17) by means of suspension axles (25) and longitudinally and transversely to the travel direction (16, 17) by means of, respectively, longitudinal struts (26) and transverse struts (27).

- Continuous casting plant according to one of claims 2 and 3, characterised in that respective support surfaces (24) for counter-support surfaces (7a) at the distributor channels (7) are provided at the lower lever ends (23a).

- Continuous casting plant according to one of claims 1 to 4, characterised in that vertical guide supports (28) are fastened to the support frame (14) at both sides and that the guide block (15) is guided to be raisable and lowerable from the suspension axles (25) and the longitudinal struts (26) or transverse struts (27) and further frame parts by means of respective guide roller pairs (32) arranged in travel direction (16, 17).

- Continuous casting plant according to one of claims 1 to 5, characterised in that the guide block (15) is closed at the upper side by a cross member (33) which extends transversely to the travel direction (16, 17) and at which the piston rod (11b) of a piston-cylinder unit (11a), which is arranged centrally within the guide block (15), engages from below as stroke device (11).

- Continuous casting plant according to one of claims 1 to 6, characterised in that the suspended distributor channel (7) is supported relative to the support frame (14) on weighing cells (36) arranged in pairs.

- Continuous casting plant according to one of claims 1 to 7, characterised in that for the weighing process the suspended distributor channel (7) is supported relative to friction-increasing transverse forces by means of coupling rods (39) and guide rollers (40) rotatable thereat.

- Continuous casting plant according to one of claims 1 to 8, characterised in that the distributor channel carriage (3) is movable out of a lefthand or righthand heating position (42; 43) until in the casting position above the continuous casting mould (10) or back.

- Continuous casting plant according to one of claims 1 to 9, characterised in that the SEN heating means for the pouring pipe (9) are arranged at the manipulator (12).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10311280A DE10311280A1 (en) | 2003-03-14 | 2003-03-14 | Continuous caster for casting strands from liquid metal, in particular from liquid steel material with a tundish carriage |

| DE10311280 | 2003-03-14 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1457282A1 EP1457282A1 (en) | 2004-09-15 |

| EP1457282B1 true EP1457282B1 (en) | 2005-10-12 |

Family

ID=32748257

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04003454A Expired - Lifetime EP1457282B1 (en) | 2003-03-14 | 2004-02-17 | Continuous casting machine with one thundish car for symmetrically arranged, unilaterally attachable tundishes |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP1457282B1 (en) |

| AT (1) | ATE306341T1 (en) |

| DE (2) | DE10311280A1 (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101166593B (en) * | 2006-01-31 | 2010-05-26 | Sms西马格股份公司 | Tundish car comprising a lifting mechanism for a tundish |

| CN104379276A (en) * | 2012-06-27 | 2015-02-25 | 西门子Vai金属科技有限责任公司 | Tundish car having tundish for continuous casting machine |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103447517B (en) * | 2013-09-22 | 2016-02-24 | 株洲方远航空铸造有限责任公司 | A kind of portable casting car |

| NO341337B1 (en) * | 2015-07-03 | 2017-10-16 | Norsk Hydro As | Equipment for continuous or semi-continuous casting of metal with improved metal filling arrangement |

| CN110369701B (en) * | 2019-08-14 | 2024-08-09 | 上海应用技术大学 | Continuous casting line feeding system |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2557769C3 (en) * | 1975-12-20 | 1985-01-03 | Mannesmann AG, 4000 Düsseldorf | Intermediate container trolleys for metal, in particular steel, continuous casting systems |

| US4678167A (en) * | 1986-02-26 | 1987-07-07 | Kabushiki Kaisha Kobe Seiko Sho | Tundish car in a continuous casting assembly |

| JPH01107960A (en) * | 1987-10-20 | 1989-04-25 | Nippon Steel Corp | Ladle supporting carriage |

| SU1537361A1 (en) * | 1987-12-17 | 1990-01-23 | Производственное объединение "Уралмаш" | Truck for teeming ladle |

| DE19809446A1 (en) * | 1998-03-05 | 1999-09-09 | Schloemann Siemag Ag | Distribution trough trolleys |

-

2003

- 2003-03-14 DE DE10311280A patent/DE10311280A1/en not_active Withdrawn

-

2004

- 2004-02-17 EP EP04003454A patent/EP1457282B1/en not_active Expired - Lifetime

- 2004-02-17 DE DE502004000094T patent/DE502004000094D1/en not_active Expired - Lifetime

- 2004-02-17 AT AT04003454T patent/ATE306341T1/en active

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101166593B (en) * | 2006-01-31 | 2010-05-26 | Sms西马格股份公司 | Tundish car comprising a lifting mechanism for a tundish |

| CN104379276A (en) * | 2012-06-27 | 2015-02-25 | 西门子Vai金属科技有限责任公司 | Tundish car having tundish for continuous casting machine |

Also Published As

| Publication number | Publication date |

|---|---|

| DE502004000094D1 (en) | 2006-02-23 |

| ATE306341T1 (en) | 2005-10-15 |

| EP1457282A1 (en) | 2004-09-15 |

| DE10311280A1 (en) | 2004-09-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1843867B1 (en) | Tundish car comprising a lifting mechanism for a tundish | |

| DE1963147C3 (en) | Storage of distribution channels on a carousel device for casting ladles in continuous casting plants | |

| WO2009141244A1 (en) | Strand guide segment | |

| EP1457282B1 (en) | Continuous casting machine with one thundish car for symmetrically arranged, unilaterally attachable tundishes | |

| EP3402622B1 (en) | Device for casting | |

| DE2557769C3 (en) | Intermediate container trolleys for metal, in particular steel, continuous casting systems | |

| DE3027789C2 (en) | ||

| DE2021780C3 (en) | Method for adapting the arch guide of a strand emerging from a continuous casting mold and device for this | |

| DE2228196C3 (en) | Device for changing track yokes | |

| AT513067B1 (en) | Distribution trolley with casting distributor for a continuous casting machine | |

| DE2543168A1 (en) | MOVABLE CASTING EQUIPMENT | |

| DE2023407A1 (en) | Continuous casting plant for slabs | |

| EP0940205B1 (en) | Tundish truck | |

| DE1957690A1 (en) | Rail mounting for support frames for con- - tinuous casting plant | |

| WO2018083331A1 (en) | Method and transport cart for transporting away steel strands individually cast in a semi-continuous strand casting system | |

| DE19855652C1 (en) | Changing of rolls in roll stands of different sizes involves pivoting roll mounting into a horizontal position, changing the rolls, and transporting the roll mounting in vertical orientation back to roll stand | |

| DE2617255C3 (en) | System for handling molds | |

| DE1558199C3 (en) | Arrangement on a continuous casting platform with transport tracks running between the new delivery stand and the preheating stand or several casting stands for intermediate containers that can be moved on wagons | |

| DE102008005727B3 (en) | Feeding device for a molten metal and a belt casting device equipped with such a device | |

| DE2226251A1 (en) | FLAME CUTTING MACHINE | |

| AT375851B (en) | DEVICE ON A CONTINUOUS CASTING PLANT | |

| DE3518333A1 (en) | Method for the operation of a continuous casting installation and a flame-cutting machine for cutting off continuously cast castings | |

| DE2024107B (en) | Support device for troughs in continuous metal casting plants | |

| DE2533056C3 (en) | ||

| DE3409291A1 (en) | Method and apparatus for carrying out the method for compound-sealing the annular spaces between the nipples of the anode-carrying bars and the anodes for aluminium production |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20040217 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| AKX | Designation fees paid | ||

| RBV | Designated contracting states (corrected) |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: 8566 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20051012 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20051012 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20051012 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20051012 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20051012 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20051012 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20051012 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060112 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060112 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060112 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060112 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060123 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20060126 |

|

| REF | Corresponds to: |

Ref document number: 502004000094 Country of ref document: DE Date of ref document: 20060223 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060228 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060228 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060313 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060413 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20060713 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061020 |

|

| EN | Fr: translation not filed | ||

| BERE | Be: lapsed |

Owner name: SMS DEMAG A.G. Effective date: 20060228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20051012 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20051012 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080229 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080229 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20051012 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20051012 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20110219 Year of fee payment: 8 Ref country code: AT Payment date: 20110214 Year of fee payment: 8 Ref country code: DE Payment date: 20110218 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20110217 Year of fee payment: 8 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20120217 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120217 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 306341 Country of ref document: AT Kind code of ref document: T Effective date: 20120217 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502004000094 Country of ref document: DE Effective date: 20120901 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120217 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120217 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120901 |