EP1284035B1 - Supply track system - Google Patents

Supply track system Download PDFInfo

- Publication number

- EP1284035B1 EP1284035B1 EP01923633A EP01923633A EP1284035B1 EP 1284035 B1 EP1284035 B1 EP 1284035B1 EP 01923633 A EP01923633 A EP 01923633A EP 01923633 A EP01923633 A EP 01923633A EP 1284035 B1 EP1284035 B1 EP 1284035B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- carrier

- current

- elements

- rail

- wire

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R25/00—Coupling parts adapted for simultaneous co-operation with two or more identical counterparts, e.g. for distributing energy to two or more circuits

- H01R25/14—Rails or bus-bars constructed so that the counterparts can be connected thereto at any point along their length

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21S—NON-PORTABLE LIGHTING DEVICES; SYSTEMS THEREOF; VEHICLE LIGHTING DEVICES SPECIALLY ADAPTED FOR VEHICLE EXTERIORS

- F21S4/00—Lighting devices or systems using a string or strip of light sources

- F21S4/20—Lighting devices or systems using a string or strip of light sources with light sources held by or within elongate supports

- F21S4/28—Lighting devices or systems using a string or strip of light sources with light sources held by or within elongate supports rigid, e.g. LED bars

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21V—FUNCTIONAL FEATURES OR DETAILS OF LIGHTING DEVICES OR SYSTEMS THEREOF; STRUCTURAL COMBINATIONS OF LIGHTING DEVICES WITH OTHER ARTICLES, NOT OTHERWISE PROVIDED FOR

- F21V21/00—Supporting, suspending, or attaching arrangements for lighting devices; Hand grips

- F21V21/34—Supporting elements displaceable along a guiding element

- F21V21/35—Supporting elements displaceable along a guiding element with direct electrical contact between the supporting element and electric conductors running along the guiding element

Definitions

- the present invention relates to a busbar system for lamps according to the preamble of claim 1 and a wire support member.

- busbar systems and wire support elements are known from US-A-3,831,130.

- Conductor rail systems or strip lights are used in a variety of forms, as they offer a high degree of flexibility in the individual planning of lighting structures for specific requirements compared to fixed or built-in luminaires.

- the busbar systems consist of several individual elements, which are assembled according to the modular principle, so that the entire arrangement can be adapted to the premises to be illuminated.

- the basic structure of a busbar system is formed by mounting rails, which are assembled to the desired structure and serve to hold the power supply and control lines and the individual lights.

- the mounting rails must therefore have a high stability and are usually made of metal. They may have different shapes, for example, DIN rails with a Y-profile or an A-profile are known. However, the most widespread are U-shaped mounting rails, which with their middle leg on a support, e.g. a room ceiling or room wall are attached.

- the individual lighting modules are attached, usually the length of a single mounting rail is a multiple of the length of the lighting modules. For example, mounting rails with a length of 3 m or 4.50 m are offered if the luminaire modules have a length of 1.50.

- Such integer aspect ratios are chosen to simplify planning in designing a lighting system.

- corresponding lines run on or within the mounting rails.

- other lines for the transmission of control signals can be provided in addition to the lines for power supply, which opens up the possibility of individually controlling and dimming the individual lights when using a suitable control system.

- the lines run in the form of a through-wiring within the U-shaped mounting rails, wherein in regular Distances that correspond to the length of the luminaire modules, Abgriffbuchsen are arranged.

- the Abgriffbuchsen be clamped in the mounting rails, with undercuts engage behind corresponding projections of the mounting rails.

- the luminaire modules can be mounted at the points specified by the tapping bushes by placing and fastening them on the support rails that are open at the bottom.

- the contacting of the lines via a located on the lamp modules contacting element which has terminal contacts which engage when placing the lamp module on the mounting rail in openings of the pick-up bushing while contact with the corresponding wires in contact. Furthermore, the lighting modules on rotary knobs, which are rotated after placement, thereby ensuring a mechanical attachment to the mounting rails.

- the luminaire modules can each be arranged only at the locations that are predetermined by the Abgriffbuchsen, otherwise no electrical contact is possible.

- busbar systems were developed which have a Stromleitprofil held by the support rails.

- This Stromleitprofil consists of elongated bodies of non-conductive material - usually plastic - extending in the longitudinal direction of the support rails and accessible from a contacting side grooves for receiving wires for the power supply and / or transmission of control signals.

- a luminaire can be disposed at any position within that range, so that there is greater freedom in planning and realization of the lighting system ,

- the length of a single Stromleitprofil body is tuned to the length of the mounting rail. Since support rails are offered in different lengths, it is thus necessary to offer Stromleitprofil body in the appropriate sizes, whereby the total cost of the busbar system can be increased, since a large number of parts must be provided. In addition, it is necessary when assembling two mounting rails to connect the two Stromleitprofile also together. This compound is problematic in that it must be ensured in this area that no accidental contact of a wire is possible. A corresponding standard requires that a 1mm-thick test wire in straight-line stretch can not hit one of the wires. The connection therefore takes place with the help of a so-called row connector, which, however, itself offers no possibility of contacting, which has the consequence that within the connection area between two support rails still no contacting possible.

- the Stromleitprofil forming plastic body are produced by extrusion. This method is disadvantageous in that it allows plastic parts to be manufactured only with limited precision, since the plastic cools very quickly after leaving the extrusion die and changes its shape. This has the consequence that one-piece Stromleitprofil body can be made only to a certain complexity.

- the object is achieved by a busbar system, which has the features of claim 1, or by a wire-holding element according to claim 14.

- the busbar system is characterized in that the Stromleitprofil held by a single support rail consists of at least two adjoining wire support elements made of non-conductive material, which have the grooves for receiving the wires.

- the wire support elements are in their end regions formed such that they overlap overlapping with each other when joining with projections located at their ends so that they form the grooves in the connection region between two wire-holding elements and open to the contacting side channels. These channels are accessible only from the contacting side, but otherwise as well as the grooves of the wire support elements enclosed, so that the aforementioned safety standard is met in these areas.

- a continuous but secure contacting possibility is created over the entire length of a mounting rail away.

- the Stromleitprofils of several individual wire holder elements Due to the modular joining of the Stromleitprofils of several individual wire holder elements, it is possible to offer mounting rails of different lengths, to use them with a Stromleitprofil only wire holder elements of a single length, since the Stromleitprofil only by changing the number of wire holder elements to the length of the mounting rail can be adapted. This results in a significantly lower production cost. Furthermore, no elongated and expensive be created to be produced one-piece plastic parts.

- the wire-holding elements can be produced, for example, by means of the much easier-to-control and less expensive injection molding process.

- the wire holder elements arranged one behind the other at a greater length have an expansion clearance, whereby it is still ensured that there is a possibility of contacting over the connection region and nevertheless contact protection is provided.

- the wire support elements have at their ends locking elements which engage in the assembly of two wire-holding elements and limit a mutual displacement or distance in the longitudinal direction to a predetermined movement play.

- the wire-retaining elements cool and contract, they move away to a predetermined maximum distance, which still provides protection against contact; when heated, they approach each other.

- a continuous Stromleitprofil is formed independently of temperature.

- the wire support members have a length of about 500 mm, wherein the allowed game, with which two adjacent wire support members can move against each other, about 8 mm, which is sufficient for the temperature differences usually occurring in the busbar system.

- the locking elements also have the advantage that the wire support members can be hung together to form a rail, which can be inserted as a whole in the mounting rail, whereby the assembly is facilitated.

- the wire support members on guide arms which engage in corresponding guide grooves which are provided on or in the support rail, so that the wire support members are securely stored.

- the mounting rails may have, for example, an A-profile, a Y-profile or a U-profile, wherein the wire support members are arranged according to the profile on the outside of the support rail or within thereof.

- the wire support members consist of two side wings, which have the grooves for receiving the wires and are to be arranged on the side walls, these side wings are connected to each other at regular intervals via connecting webs. These connecting webs are arranged on the middle leg of the wire rail.

- one of the two side wings may have a parallel to the center leg of the support rail arranged horizontal leg, which forms together with protruding from the connecting webs retaining legs over the length of the support rail away an additional hollow or receiving space, which are used for receiving additional cables or lines can.

- the inventive concept of a modular Stromleitprofils of a plurality of juxtaposed wire support elements provides the ability to realize over an arbitrary length across a continuous contacting possibility by the Stromleitprofil is used after the merger of the support rails in this.

- the DIN rails are usually already assembled ready, i. sold with an already inserted Stromleitprofil with the wires arranged therein. This is because it is easier when creating a trunking system to assemble the already assembled mounting rails, as first add together empty mounting rails and then use the Stromleitprofile.

- a further development of the invention therefore relates to a connecting element which also forms a contacting possibility at these interfaces.

- the connecting element of the contacting side and the two end faces accessible groove-shaped recesses corresponding to the grooves of the Stromleitprofile, wherein in the recesses in each case a metal connector is used, to which the wires to be joined together from both sides can be connected.

- This also consists of a non-conductive material connecting element closes the gap between the Stromleitprofilen two mounting rails and ensures that over the entire length of the busbar system away a luminaire module attached and to the lines of the Busbar system can be connected, since the metal connectors in the transition region form the contact surfaces for the terminal contacts of the lamp module.

- the metal connectors preferably have an elongated contacting plate and U-shaped spring elements arranged at both ends thereof, by means of which the wires are clamped during insertion and pressed against the contacting plate. At the same time, it is ensured by the spring elements that the wires can not move in a pump-like manner during thermal expansion of the wire-holding elements and possibly even emigrate.

- U-shaped mounting rails in which Stromleitprofile are arranged on both side walls, a mechanical connection of two adjacent mounting rails preferably by means of a short U-shaped connecting rail, which engages half in both mounting rails and at the side legs, the connecting elements are arranged.

- the luminaire module has a contacting element with a plurality of terminal contacts, wherein the contacting element from the open side to introduce into the mounting rail and then partially - preferably by 45 ° - to twist.

- the terminal contacts are inserted into the grooves of the Stromleitprofils and brought into contact with the wires.

- the contacting element may preferably be designed such that at least one of the terminal contacts is adjustable in height. Since the arranged at different heights wires of the Stromleitprofils have different functions, an optional contact can be achieved by moving the terminal contacts.

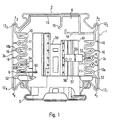

- Base element of the busbar system shown in Fig. 1 is a metal or sheet metal existing U-shaped mounting rail 1, which is fastened with its center leg 2 by fastening means not shown on a support, such as a ceiling or a room wall.

- the cover of the open lower side of the support rail 1 is effected by a cover rail 5.

- this cover rail 5 is part of a mounted on the mounting rail 1 lamp module, in Fig. 1, only the contacting element of the lamp module in the form of a Drehabgriffs 50th is shown, but not its other components, such as the lamp or the associated control or operating device, which may be an electronic ballast (ECG).

- ECG electronic ballast

- the interior of the mounting rail 1 then serves as a receiving space for the operating devices of the lamps in this case.

- 1 Stromleitprofile are arranged on the inner sides of the two side walls 3a and 3b of the support rail, which are inventively formed by a plurality of plastic and composite wire support members 10, each containing two side wings 10a and 10b with a plurality of grooves 11 for receiving the wires 6 ,

- five wires 6 are arranged in the right side wing 10a, while six wires 6 extend on the left side.

- the light By contacting the corresponding wires 6 of the connected light can be assigned a desired function, for example, the light can be used as an emergency light.

- the two control cables for lighting control there is the possibility of using these two Lines to form a bus system over which a plurality of lights can be controlled by means of digital control commands, as is known from more complex lighting systems ago.

- the terminal contact 53 by means of a support member 55 is arranged vertically adjustable on the Drehabgriff 50. By simply moving the support member 55 thus the light connected to the busbar light can be assigned the desired function.

- a wire element 62 guided in a slot 63 of the rotary handle 50 is also provided, the end 62b of which contacts the left lower wire 6 provided for earthing.

- the detailed structure and operation of the contacting element 50 will be explained in more detail later.

- the power supply for the busbar system can be done for example by a suitably adapted Drehabgriff, which is positioned in the longitudinal direction at any point.

- a secure mounting of the two side wings 10a, 10b of the wire retaining element 10 is effected by a plurality of guide arms 12 1 - 12 4 , which engage in corresponding guide grooves 4 1 - 4 4 of the U-shaped mounting rail 1.

- the lined up to a Stromleitprofil several wire retaining elements 10 are inserted during assembly in the longitudinal direction in the support rail 2.

- a plurality of support struts 16 At the back of the side wings 10a and 10b, ie on the side opposite the contacting side of the grooves 11 are a plurality of support struts 16, which ensure a stable mounting of the grooves 11 within the support rail 2, so that they are not pushed back when contacting. In this way, a reliable contacting of the wires 6 is supported.

- connection of the two side wings 10a and 10b takes place at regular intervals via connecting webs 13, which are arranged on the center leg 2 of the support rail 1.

- the connecting webs 13 further have downwardly projecting retaining legs 15, which together with a horizontally projecting from the right side wing 10 a horizontal leg 14 form an additional cavity 8.

- This cavity can be used for the storage of additional cables or lines.

- the horizontal leg 14 still has the task of preventing the contacting element 50 is inserted laterally into the support rail 1, as will also be explained later.

- the shape of the grooves 11 of the wire holder elements 10 is selected such that a contact protection is ensured, as will be explained below with reference to FIG. 2.

- the support rail 1 is shown with a Stromleitprofil disposed therein, but now without the Drehabgriff 50.

- the initially mentioned safety standard provides that the arranged in the Stromleitprofil wires 6 may not be exposed so that a 1mm-thick test wire 7 in straight ahead -Extension on a current-carrying wire 6 can meet.

- the entry angle for the test wire 7 is the most favorable for the wire 6 arranged on the bottom left. As can be seen in FIG.

- the widths, depths and opening shapes of the grooves 11 are dimensioned such that even at the smallest entry angle the test wire 7 can not contact any of the wires 6. In this way, unintentional contact with the wires 6 is avoided and the corresponding safety standard is met.

- FIG. 3 showing a wire retaining element 10 in a perspective view.

- Essential elements of the wire holder element 10 are the two side wings 10a and 10b, which have the grooves 11 for supporting the wires. They are connected to each other via two connecting bridges 13. In this way, in addition with the help of the horizontal leg 14 and the projecting from the connecting webs 13 retaining legs 15 of the aforementioned cavity 8 can be formed, which can be used to support other useful for the lighting system cables or cables.

- On the two side wings 10a, 10b are also also also the guide arms 12 1 to 12 4 , which engage in the recesses 4 1 to 4 4 of the support rail 1 during insertion.

- FIG. 3 and FIG. 4 show the wire-holding element 10 immediately after production.

- the side wings 10a and 10b are folded down by 90 ° about the two folding points A and B (see FIG. 4) and then inserted into the mounting rail 1, whereby the in FIGS. 1 and 2 shown arrangement results.

- the two side wings 10a and 10b on projections 17 and 22, with the help of two assembled wire holder elements 10 overlap overlapping.

- locking heads 18 are further provided, which allow removal of two assembled wire holder elements 10 in the longitudinal direction only up to a certain maximum distance, so that a composed of several wire holder elements 10 Stromleitprofil in his Length is flexible and thus changes in length of the individual made of plastic wire holder elements 10 can be compensated due to temperature differences.

- FIGS. 5 and 6 show two composite wire support elements in an enlarged view, on the one hand from the contacting side (FIG. 5) and on the other from the opposite rear side (FIG. 6).

- the parts belonging to the first wire-holding element 10 1 are provided with the index 1, while the elements belonging to the second wire-holding element 10 2 have the index 2.

- the two wire holder elements 10 1 and 10 2 engage these two overlapping each other in such a way that in each case by a projection 17, the first wire holder element 10 1 and by a projection 22 2 of the second wire holder element 10 2, a channel 23 is formed, the grooves 11 of the two wire holder elements 10 1 and 10 2 connects to each other.

- the grooves 11 of the two wire holder elements 10 1 and 10 2 connects to each other.

- all the channels 23 formed in this way are accessible only from the contacting side, ie, from above, in the connection region, but not from the side. As a result, the required contact protection is ensured even in the region of the channels 23.

- the two locking heads 18 2 allow removal of the two wire holder elements 10 1 and 10 2 only up to a maximum distance, which is predetermined by the fact that at the ends of the locking heads 18 laterally projecting locking projections 19th 2 come against stop walls 20 1 to the plant.

- the ends of the two wire holder elements 10 1 , 10 2 can approach each other so far until their two end faces 21 1 and 21 2 come into contact against each other.

- the wire holder elements 10 shown can be made of plastic in a simple manner by injection molding, whereby they are very inexpensive to manufacture. Furthermore, it is sufficient to produce wire retaining elements 10 in only a single length, since to adapt the Stromleitprofils formed to the different lengths of the wire rails only the number of wire holder elements 10 used must be adjusted, which in turn significantly reduces the manufacturing cost of the entire system.

- the interlocking projections and the locking elements can also be configured differently.

- each support rail 1 may have one or more openings in its upper region.

- the connecting rail 30 is then also provided with corresponding openings through which spring tongues protrude. The spring tongues engage behind the openings of the support rail 1, as soon as the connecting rail 30 in the mounting rail 1 the has reached the appropriate position. In order to solve the support rail 1 and the connecting rail 30 again, only pressure on the spring tongues must be exercised.

- Such a releasable connection is preferably on both sides, which means that the connecting rail 30 has next to its two ends such openings with the corresponding spring tongues.

- a connection detachable on both sides however, an embodiment is also possible which has the connection just described on one side by means of spring tongues, while on the other side of the connecting rail 30 a conventional screw connection is provided.

- the spring tongues arranged at each end of the connecting rail 30 belong to a common rail locking element which is arranged on the center leg of the connecting rail 30, the spring tongues projecting laterally through openings in the upper region of the side walls ,

- the rail-locking element is formed so that the spring tongues are retracted under the action of a force from above on the element in the interior of the connecting rail 30.

- About a provided in the middle leg of the support rails 1 additional opening the rail locking element from above in a simple manner to achieve and operate, for example by means of a screwdriver, so that the connection is released by a simple handle again.

- the wire retaining elements 10 which are not shown in FIG. 7 for reasons of clarity, have a slightly different configuration in the connecting region in order to take account of the additional connecting rail 30 arranged in the mounting rail 1.

- the wire support elements 10 have no support struts 16 in this area.

- two connecting elements 31 are provided on the side legs 30a and 30b of the connecting rail, which have the aforementioned recesses 32.

- metal connectors are arranged, which are connected from both sides with the wires to be joined together.

- the opening shape of the recesses 32 is chosen such that they meet the safety criterion of shock protection.

- the wire holding elements adjacent to the connecting elements 31 are also modified at their ends.

- identical connecting elements 31, each having six recesses 32 are arranged on both sides of the connecting rail 30. This means that the uppermost recess 32 of the arranged on the right side Connecting element 32 remains free, since the corresponding side wing 10 a has only five grooves 11 for holding five wires 6.

- the exact structure of the wire holder elements corresponding connecting elements can be used.

- FIG. 8 The more precise shape of a connecting element 31 is shown in FIG. 8. It consists of a box-shaped base part 33 which is open at the bottom, in which metal connectors 35 are inserted from the underside. The recesses 32 of the base part 33 are accessible from the two end faces via funnel-shaped openings 36, wherein upon insertion of a wire into a funnel-shaped opening 36, this is brought into connection with the metal connector 35. After inserting the metal connectors 35, the base part 33 is closed by a cover plate 34 from the bottom. A contacting by a luminaire module in the region of the connecting element 31 then takes place in that the terminal contacts of the contacting element are pressed against the top of a contacting plate 37 of the metal connector 35. At the end of the metal connector 35, this task is taken over again by the wires, so that no gap is formed in which a contact is not possible.

- a metal connector 35 is shown in Figs. 9a and 9b. It consists of an elongated and on their long sides a little downwardly bent contacting plate 37, whose task is to take over the electric power from the wires and forward. At the ends of the contacting plate 37 is in each case a preferably made of a chromium-nickel alloy U-shaped spring element 38, which is shown individually in Fig. 9b, respectively.

- the spring element 38 has an inwardly bent spring tongue 39, through which a wire inserted into the metal connector 35 is clamped and pressed sufficiently firmly with respect to the electrical contact resistance against the contacting plate 37.

- the wires can move or emigrate in a pump-like manner with a changing thermal expansion of the Stromleitprofils.

- the remote from the wires side of the tinned copper contacting plate 37 forms the contact surface for the contacts of the contacting element.

- To improve the contact between the contacting plate 37 and the wires has the contacting plate 37 on its underside a slightly arcuate or triangular recess 43rd

- the attachment of the spring elements 38 at the ends of the contacting plate 37 is effected by located on the side walls of the spring elements 38 recesses 40, engage in the projections 41 of the contacting plate 37.

- a stable arrangement of Metal connector 35 in the connecting element 31 is further supported by the fact that on the cover plate 34 made of plastic pins 42 are arranged, which press after mounting the cover plate 34 from the bottom against the contacting plates 37 of the metal connector 35. Since the pins 42 also engage in lateral recesses 43 of the downwardly bent longitudinal sides of the contacting plates 37, a lateral displacement of the metal connectors 35 is also prevented at the same time.

- the pins 42 also constitute a barrier by which the migration of the wires is limited.

- the connecting element shown here closes the gap between the wire-holding elements of the Stromleitprofile, so that it is possible to assemble already assembled busbars 1, with consistently contactable Stromleitprofilen, which can be contacted in the connection areas.

- this connecting element is not limited to the illustrated example with the wire retaining elements according to the invention.

- the connecting element illustrated in FIGS. 7 to 9b can also be used for the connection of the light band system mentioned in the introduction, in which the current-conducting profiles are produced by extrusion and are integral.

- an adapted Drehabgriffs for the mains supply can also be provided on the front side of a DIN rail connectable and cooperating with the metal connectors power connector element, through which the wires of the busbar system are connected to the power lines.

- Fig. 10 shows the Drehabgriff 50 with a arranged on its underside cover rail 5 in a perspective view.

- An essential part of the Drehabgriffs 50 are arranged on the outside of the cylindrical base body 61 contacts 53 and 54, which are adjustable in height for an optional contacting of the various wires 6.

- Another, but not freely selectable but given contact with grounding is given by the wire member 62.

- This wire element 62 is guided in a provided on the base body 61 slot 63, wherein one end 62a of the wire member 62 is fixed by clamping its shape in the cover rail 5 of the lamp module.

- the other end 62b protrudes laterally in the height of the ground wire.

- the rotary handle 50 has in its lower region two laterally projecting locking elements 52.

- the contacting of the wires 6 of the Stromleitprofils takes place in that the connected to a lighting module Drehabgriff 50 is inserted into the lower opening of the support rail 1.

- the cylindrical base body 61 is of different heights, the horizontal leg 14 arranged only on the right-hand side of the mounting rail 1 preventing the contacting element 50 from being inserted laterally into the mounting rail 1.

- the laterally disposed locking elements 52 engage inwardly projecting parts of the support rail 1 and the Stromleitprofils and thus provide a mechanical attachment of the luminaire module.

- the terminal contacts 53 and 54 are screwed into the grooves 11 of the wire support members 10, so that the desired electrical contact is made.

- some or all of the contacts may be height adjustable, which in the illustrated example is achieved by the support member 55 of the contact 53 being vertically displaceable within guide rails 56 and 57.

- the support member 55 and the cylindrical base body 61 with the guide rails 56 and 57 are designed so that the support member 55 can easily engage in the corresponding positions of the wires 6, whereby an accurate positioning of the contact 53 is facilitated.

- the slot 63 forms an eccentric stop for the wire member 62 and causes the end 62b of the wire member 62 to be pressed against the grounded left lower wire 6 during rotation of the rotary handle 50.

- a ground between the metallic cover rail 5, which is part of the luminaire module, and the metallic support rail 1 is made.

- the wire member 62 has a certain strength, which is why it preferably consists of a galvanized steel wire or a CrNi wire.

- the cover rail 5 has an elongate slot into which the rotary knob 58 can be inserted in the locked position upwards, so that it is flush with the cover rail 5 below. In this way, a complete closure of the support rail 1 is achieved.

- the cover rail 5 is also used in places where no light modules are arranged. However, in the case of fixing a luminaire module, the cover rail 5 is at the same time also the holder for all elements of the luminaire module, wherein e.g. the or the ballasts are arranged on top of the cover rail 5 and thus protrude into the interior of the U-shaped mounting rail.

- the presented rotary handle 50 makes it possible in a simple manner to make contact with the wires and to mechanically fasten the luminaire module in the busbar system.

- an application of the illustrated Drehabgriffes 50 is advantageous because it is particularly flexible and can be removed again.

- the present invention thus provides a very efficient busbar system, which for the first time offers the possibility of completely free contacting and arrangement of the luminaire modules. This has the consequence that the individual lighting modules no longer need to be adapted to certain lengths to allow a suitable arrangement within the busbar system.

- the application is not limited to the illustrated example of a U-shaped busbar.

- the wire holder elements according to the invention can also be found in busbars with other profiles, such as A-profiles or Y-profiles use. This applies in the same way also for the imaginary connecting element.

- the manufacturing cost can be significantly reduced, since the wire support members can be made in a much simpler and faster way, as is the case with the known Stromleitprofilen.

- the present invention provides a way to circumvent the problems associated with temperature differences that cause length change and displacement of the plastic parts.

Landscapes

- General Engineering & Computer Science (AREA)

- Engineering & Computer Science (AREA)

- Arrangement Of Elements, Cooling, Sealing, Or The Like Of Lighting Devices (AREA)

- Nitrogen And Oxygen Or Sulfur-Condensed Heterocyclic Ring Systems (AREA)

- Saccharide Compounds (AREA)

- Pharmaceuticals Containing Other Organic And Inorganic Compounds (AREA)

- Magnetic Bearings And Hydrostatic Bearings (AREA)

- Installation Of Bus-Bars (AREA)

- Details Of Indoor Wiring (AREA)

- Installation Of Indoor Wiring (AREA)

- Lift-Guide Devices, And Elevator Ropes And Cables (AREA)

- Noodles (AREA)

- Apparatus For Radiation Diagnosis (AREA)

Abstract

Description

Die vorliegende Erfindung betrifft ein Stromschienensystem für Leuchten nach dem Oberbegriff des Anspruches 1 sowie ein Drahthalterungselement. Derartige Stromschienensysteme sowie Drahthalterungselemente sind aus der US-A-3,831,130 bekannt.The present invention relates to a busbar system for lamps according to the preamble of claim 1 and a wire support member. Such busbar systems and wire support elements are known from US-A-3,831,130.

Stromschienensysteme oder Lichtbänder finden in vielfältiger Form Verwendung, da sie gegenüber fest installierten oder eingebauten Leuchten eine hohe Flexibilität bei der individuellen Planung von Beleuchtungsstrukturen für spezifische Anforderungen bieten. So bestehen die Stromschienensysteme aus mehreren einzelnen Elementen, die nach dem Baukasten-Prinzip zusammengesetzt werden, so daß die gesamte Anordnung an die zu beleuchtenden Räumlichkeiten angepaßt werden kann. Es sind Lichtbandsysteme bekannt, mit denen nicht nur zweidimensionale, sondern auch dreidimensionale Strukturen gebildet werden können.Conductor rail systems or strip lights are used in a variety of forms, as they offer a high degree of flexibility in the individual planning of lighting structures for specific requirements compared to fixed or built-in luminaires. Thus, the busbar systems consist of several individual elements, which are assembled according to the modular principle, so that the entire arrangement can be adapted to the premises to be illuminated. There are known light band systems with which not only two-dimensional, but also three-dimensional structures can be formed.

Das Grundgerüst eines Stromschienensystems wird durch Tragschienen gebildet, die zu der gewünschten Struktur zusammengesetzt werden und der Halterung der Stromversorgungs- und Steuerleitungen sowie der einzelnen Leuchten dienen. Die Tragschienen müssen daher eine hohe Stabilität besitzen und bestehen üblicherweise aus Metall. Sie können unterschiedliche Formen aufweisen, beispielsweise sind Tragschienen mit einem Y-Profil oder einem A-Profil bekannt. Am weitesten verbreitet sind allerdings U-förmige Tragschienen, welche mit ihrem Mittelschenkel an einem Träger, z.B. einer Raumdecke oder Raumwand befestigt werden. An den Tragschienen werden die einzelnen Leuchten-Module befestigt, wobei üblicherweise die Länge einer einzelnen Tragschiene ein Vielfaches der Länge der Leuchten-Module beträgt. Beispielsweise werden Tragschienen mit einer Länge von 3 m oder 4,50 m angeboten, wenn die Leuchten-Module eine Länge von 1,50 aufweisen. Derartige ganzzahlige Längenverhältnisse werden gewählt, um die Planung bei der Gestaltung eines Lichtbandsystems zu vereinfachen.The basic structure of a busbar system is formed by mounting rails, which are assembled to the desired structure and serve to hold the power supply and control lines and the individual lights. The mounting rails must therefore have a high stability and are usually made of metal. They may have different shapes, for example, DIN rails with a Y-profile or an A-profile are known. However, the most widespread are U-shaped mounting rails, which with their middle leg on a support, e.g. a room ceiling or room wall are attached. On the mounting rails, the individual lighting modules are attached, usually the length of a single mounting rail is a multiple of the length of the lighting modules. For example, mounting rails with a length of 3 m or 4.50 m are offered if the luminaire modules have a length of 1.50. Such integer aspect ratios are chosen to simplify planning in designing a lighting system.

Um die Stromversorgung für die Leuchten sicher zu stellen, verlaufen an oder innerhalb der Tragschienen entsprechende Leitungen. Zusätzlich können neben den Leitungen zur Stromversorgung auch weitere Leitungen für die Übertragung von Steuersignalen vorgesehen sein, wodurch sich die Möglichkeit eröffnet, bei Verwendung eines geeigneten Steuersystems die einzelnen Leuchten individuell anzusteuern und zu dimmen.In order to ensure the power supply for the luminaires, corresponding lines run on or within the mounting rails. In addition, other lines for the transmission of control signals can be provided in addition to the lines for power supply, which opens up the possibility of individually controlling and dimming the individual lights when using a suitable control system.

Bei einem bekannten Lichtbandsystem, das von der Anmelderin unter der Bezeichnung "Lichtbandsystem ZX" vertrieben wird, verlaufen die Leitungen in Form einer Durchgangsverdrahtung innerhalb der U-förmigen Tragschienen, wobei in regelmäßigen Abständen, die der Länge der Leuchten-Module entsprechen, Abgriffbuchsen angeordnet sind. Die Abgriffbuchsen werden in die Tragschienen eingeklemmt, wobei Hinterschneidungen entsprechende nach innen gerichtete Vorsprünge der Tragschienen hintergreifen. An den durch die Abgriffbuchsen vorgegebenen Stellen können die Leuchten-Module montiert werden, indem sie auf die nach unten offenen Tragschienen aufgesetzt und befestigt werden. Die Kontaktierung der Leitungen erfolgt über ein an den Leuchten-Modulen befindliches Kontaktierungselement, welches Anschlußkontakte aufweist, die beim Aufsetzen des Leuchten-Moduls auf die Tragschiene in Öffnungen der Abgriffbuchse eingreifen und dabei mit den entsprechenden Drähten in Kontakt treten. Ferner weisen die Leuchten-Module Drehknebel auf, welche nach dem Aufsetzen verdreht werden und dabei für eine mechanische Befestigung an den Tragschienen sorgen.In a known light strip system, which is distributed by the applicant under the name "continuous line system ZX", the lines run in the form of a through-wiring within the U-shaped mounting rails, wherein in regular Distances that correspond to the length of the luminaire modules, Abgriffbuchsen are arranged. The Abgriffbuchsen be clamped in the mounting rails, with undercuts engage behind corresponding projections of the mounting rails. The luminaire modules can be mounted at the points specified by the tapping bushes by placing and fastening them on the support rails that are open at the bottom. The contacting of the lines via a located on the lamp modules contacting element, which has terminal contacts which engage when placing the lamp module on the mounting rail in openings of the pick-up bushing while contact with the corresponding wires in contact. Furthermore, the lighting modules on rotary knobs, which are rotated after placement, thereby ensuring a mechanical attachment to the mounting rails.

Bei dem eben beschriebenen Stromschienensystem können die Leuchten-Module jeweils nur an den Stellen angeordnet werden, die durch die Abgriffbuchsen vorgegeben sind, da andernfalls keine elektrische Kontaktierung möglich ist. Um solche Einschränkungen zu vermeiden und damit eine größere Flexibilität für der Anordnung der einzelnen Leuchten zu erhalten, wurden Stromschienensysteme entwickelt, welche ein von den Tragschienen gehaltenes Stromleitprofil aufweisen. Dieses Stromleitprofil besteht aus länglichen Körpern aus nicht-leitendem Material - üblicherweise Kunststoff - mit in Längsrichtung der Tragschienen verlaufenden und von einer Kontaktierungsseite her zugänglichen Nuten zur Aufnahme von Drähten für die Stromversorgung und/oder Übertragung von Steuersignalen. Da in diesem Fall die nicht-isolierten Drähte zumindest über die Länge eines einzelnen Stromleitprofil-Körpers zu der Kontaktierungsseite hin offen liegen, kann innerhalb dieses Bereichs eine Leuchte an beliebiger Stelle angeordnet werden, so daß eine größere Freiheit bei der Planung und Realisierung des Lichtbandsystems besteht.In the busbar system just described, the luminaire modules can each be arranged only at the locations that are predetermined by the Abgriffbuchsen, otherwise no electrical contact is possible. In order to avoid such restrictions and thus to obtain greater flexibility for the arrangement of the individual luminaires, busbar systems were developed which have a Stromleitprofil held by the support rails. This Stromleitprofil consists of elongated bodies of non-conductive material - usually plastic - extending in the longitudinal direction of the support rails and accessible from a contacting side grooves for receiving wires for the power supply and / or transmission of control signals. In this case, since the non-insulated wires are exposed to the contacting side at least over the length of a single current-conducting profile body, a luminaire can be disposed at any position within that range, so that there is greater freedom in planning and realization of the lighting system ,

Die Länge eines einzelnen Stromleitprofil-Körpers ist auf die Länge der Tragschiene abgestimmt. Da Tragschienen in verschiedenen Längen angeboten werden, ist es somit erforderlich, auch Stromleitprofil-Körper in den entsprechenden Größen anzubieten, wodurch die Gesamtkosten für das Stromschienensystem erhöht werden, da eine Vielzahl von Teilen zur Verfügung gestellt werden muß. Darüber hinaus ist es erforderlich beim Zusammensetzen zweier Tragschienen die beiden Stromleitprofile ebenfalls miteinander zu verbinden. Diese Verbindung ist insofern problematisch, als auch in diesem Bereich gewährleistet sein muß, daß keine unbeabsichtigte Berührung eines Drahtes möglich ist. Eine entsprechende Norm hierzu fordert, daß ein 1mm-dicker Prüfdraht in Geradeaus-Dehnung nicht auf einen der Drähte treffen kann. Die Verbindung erfolgt daher mit Hilfe eines sog. Reihenverbinders, der selbst allerdings keine Kontaktierungsmöglichkeit bietet, was zur Folge hat, daß innerhalb des Verbindungsbereichs zwischen zwei Tragschienen nach wie vor keine Kontaktierungsmöglichkeit besteht.The length of a single Stromleitprofil body is tuned to the length of the mounting rail. Since support rails are offered in different lengths, it is thus necessary to offer Stromleitprofil body in the appropriate sizes, whereby the total cost of the busbar system can be increased, since a large number of parts must be provided. In addition, it is necessary when assembling two mounting rails to connect the two Stromleitprofile also together. This compound is problematic in that it must be ensured in this area that no accidental contact of a wire is possible. A corresponding standard requires that a 1mm-thick test wire in straight-line stretch can not hit one of the wires. The connection therefore takes place with the help of a so-called row connector, which, however, itself offers no possibility of contacting, which has the consequence that within the connection area between two support rails still no contacting possible.

Die das Stromleitprofil bildenden Kunststoffkörper werden durch Extrusion hergestellt. Dieses Verfahren ist insofern von Nachteil, als damit Kunststoffteile lediglich mit einer begrenzten Präzision hergestellt werden können, da sich der Kunststoff nach dem Verlassen der Extrusionsdüse sehr schnell abkühlt und seine Form verändert. Dies hat zur Folge, daß einstückige Stromleitprofil-Körper nur bis zu einer gewissen Komplexität hergestellt werden können.The Stromleitprofil forming plastic body are produced by extrusion. This method is disadvantageous in that it allows plastic parts to be manufactured only with limited precision, since the plastic cools very quickly after leaving the extrusion die and changes its shape. This has the consequence that one-piece Stromleitprofil body can be made only to a certain complexity.

Es ist daher Aufgabe der vorliegenden Erfindung, eine Technik bereitzustellen, die ein Stromschienensystem für Leuchten mit einem in seiner Länge einfach an die Länge einer Tragschiene anzupassenden und kostengünstig herzustellenden Stromleitprofil ermöglicht.It is therefore an object of the present invention to provide a technique which allows a bus bar system for luminaires with a length to be easily adapted to the length of a mounting rail and inexpensively manufactured Stromleitprofil.

Die Aufgabe wird durch ein Stromschienensystem, welches die Merkmale des Anspruches 1 aufweist, bzw. durch ein Drahthalterungselement gemäß Anspruch 14 gelöst. Das Stromschienensystem zeichnet sich dadurch aus, daß das von einer einzelnen Tragschiene gehaltene Stromleitprofil aus mindestens zwei aneinandergefügten Drahthalterungselementen aus nicht-leitendem Material besteht, welche die Nuten zur Aufnahme der Drähte aufweisen. Die Drahthalterungselemente sind dabei in ihren Endbereichen derart ausgebildet, daß sie beim Aneinanderfügen mit an ihren Enden befindlichen Vorsprüngen derart überlappend ineinandergreifen, daß sie in dem Verbindungsbereich zwischen zwei Drahthalterungselementen den Nuten entsprechende und zu der Kontaktierungsseite hin offene Kanäle bilden. Diese Kanäle sind lediglich von der Kontaktierungsseite her zugänglich, ansonsten jedoch wie auch die Nuten der Drahthalterungselemente umschlossen, so daß die zuvor erwähnte Sicherheitsnorm auch in diesen Bereichen erfüllt ist. Somit wird über die gesamte Länge einer Tragschiene hinweg eine durchgängige aber sichere Kontaktierungsmöglichkeit geschaffen.The object is achieved by a busbar system, which has the features of claim 1, or by a wire-holding element according to

Durch das modulare Zusammenfügen des Stromleitprofils aus mehreren einzelnen Drahthalterungselementen besteht die Möglichkeit, Tragschienen unterschiedlichster Längen anzubieten, zu deren Bestückung mit einem Stromleitprofil allerdings lediglich Drahthalterungselemente einer einzigen Länge zu verwenden, da das Stromleitprofil lediglich durch eine Veränderung der Anzahl der Drahthalterungselemente an die Länge der Tragschiene angepaßt werden kann. Dies hat einen deutlich niedrigeren Produktionsaufwand zur Folge. Ferner müssen keine langgezogenen und teuer herzustellenden einstückigen Kunststoffteile erstellt werden. Die Drahthalterungselemente können beispielsweise mittels dem wesentlich leichter zu beherrschenden und kostengünstigeren Spritzgußverfahren erzeugt werden.Due to the modular joining of the Stromleitprofils of several individual wire holder elements, it is possible to offer mounting rails of different lengths, to use them with a Stromleitprofil only wire holder elements of a single length, since the Stromleitprofil only by changing the number of wire holder elements to the length of the mounting rail can be adapted. This results in a significantly lower production cost. Furthermore, no elongated and expensive be created to be produced one-piece plastic parts. The wire-holding elements can be produced, for example, by means of the much easier-to-control and less expensive injection molding process.

Weiterbildungen der Erfindung sind Gegenstand der Unteransprüche.Further developments of the invention are the subject of the dependent claims.

Bei aus Kunststoffteilen bestehenden Stromleitprofilen ist insbesondere zu beachten, daß diese einer nicht zu- vernachlässigenden Wärmestrahlung ausgesetzt sein können, insbesondere in der Nähe von an oder besonders in den Tragschienen angeordneten Vorschaltgeräten für die Leuchten. Dies hat zur Folge, daß sich die Kunststoffteile ausdehnen bzw. bei Nichtbestrahlung zusammenziehen können. Dabei ist besonders problematisch, daß der Ausdehnungskoeffizient von Kunststoff ca. 10x größer ist als der von Metall, so daß sich die einzelnen Drahthalterungselemente in ihrer Länge deutlich verändern können, während hingegen die von dem Stromleitprofil gehaltenen Drähte nahezu gleichlang bleiben. Mit einer vorteilhaften Weiterbildung der Erfindung wird daher erreicht, daß die auf eine größere Länge hintereinander angeordneten Drahthalterungselemente ein Ausdehnungsspiel haben, wobei nach wie vor gewährleistet bleibt, daß über den Verbindungsbereich hinweg eine Kontaktierungsmöglichkeit besteht und dennoch ein Berührungsschutz gegeben ist. Hierzu weisen die Drahthalterungselemente an ihren Enden Verriegelungselemente auf, welche beim Zusammensetzen zweier Drahthalterungselemente ineinandergreifen und eine gegenseitige Verschiebung oder Entfernung in Längsrichtung auf ein vorbestimmtes Bewegungsspiel begrenzen. Kühlen die Drahthalterungselemente ab und ziehen sich zusammen, so entfernen sie sich bis zu einer vorgegebenen Maximalentfernung, bei der immer noch der Berührungsschutz gegeben ist; werden sie erhitzt, nähern sie sich aneinander an. Auf diese Weise wird temperaturunabhängig ein durchgängiges Stromleitprofil gebildet. Vorzugsweise haben die Drahthalterungselemente eine Länge von ca. 500 mm, wobei das erlaubte Spiel, mit dem sich zwei aneinander grenzende Drahthalterungselemente gegeneinander verschieben können, ca. 8 mm beträgt, was für die in dem Stromschienensystem üblicherweise auftretenden Temperaturunterschiede ausreichend ist.In the case of current-conducting profiles consisting of plastic parts, it should be noted in particular that they can be exposed to a non-negligible thermal radiation, in particular in the vicinity of ballasts for the luminaires arranged on or especially in the mounting rails. This has the consequence that the plastic parts can expand or contract when not irradiated. It is particularly problematic that the coefficient of expansion of plastic is about 10 times greater than that of metal, so that the individual wire support elements can change significantly in length, while the wires held by the Stromleitprofil remain virtually the same length. With an advantageous development of the invention it is therefore achieved that the wire holder elements arranged one behind the other at a greater length have an expansion clearance, whereby it is still ensured that there is a possibility of contacting over the connection region and nevertheless contact protection is provided. For this purpose, the wire support elements have at their ends locking elements which engage in the assembly of two wire-holding elements and limit a mutual displacement or distance in the longitudinal direction to a predetermined movement play. When the wire-retaining elements cool and contract, they move away to a predetermined maximum distance, which still provides protection against contact; when heated, they approach each other. In this way, a continuous Stromleitprofil is formed independently of temperature. Preferably, the wire support members have a length of about 500 mm, wherein the allowed game, with which two adjacent wire support members can move against each other, about 8 mm, which is sufficient for the temperature differences usually occurring in the busbar system.

Die Verriegelungselemente haben ferner den Vorteil, daß die Drahthalterungselemente zu einer Schiene zusammengehängt werden können, die als Gesamtheit in die Tragschiene eingeführt werden kann, wodurch die Montage erleichtert wird. Vorzugsweise weisen die Drahthalterungselemente Führungsarme auf, welche in entsprechende Führungsnuten, die an oder in der Tragschiene vorgesehen sind, eingreifen, so daß die Drahthalterungselemente sicher gelagert werden. Dabei können die Tragschienen beispielsweise ein A-Profil, ein Y-Profil oder ein U-Profil aufweisen, wobei die Drahthalterungselemente entsprechend dem Profil an der Außenseite der Tragschiene oder innerhalb davon angeordnet sind.The locking elements also have the advantage that the wire support members can be hung together to form a rail, which can be inserted as a whole in the mounting rail, whereby the assembly is facilitated. Preferably, the wire support members on guide arms which engage in corresponding guide grooves which are provided on or in the support rail, so that the wire support members are securely stored. The mounting rails may have, for example, an A-profile, a Y-profile or a U-profile, wherein the wire support members are arranged according to the profile on the outside of the support rail or within thereof.

Handelt es sich um eine U-förmige Tragschiene, so können an beiden Seitenwänden innerhalb der Tragschiene Drähte verlaufen, wobei es denkbar wäre, jeweils getrennt Stromleitprofile einzusetzen. Vorzugsweise bestehen allerdings die Drahthalterungselemente aus zwei Seitenflügeln, welche die Nuten zur Aufnahme der Drähte aufweisen und an den Seitenwänden anzuordnen sind, wobei diese Seitenflügel in regelmäßigen Abständen über Verbindungsstege miteinander verbunden sind. Diese Verbindungsstege sind an dem Mittelschenkel der Drahtschiene angeordnet. Ferner kann einer der beiden Seitenflügel einen parallel zu dem Mittelschenkel der Tragschiene angeordneten Horizontalschenkel aufweisen, der gemeinsam mit von den Verbindungsstegen hervorstehenden Halteschenkeln über die Länge der Tragschiene hinweg einen zusätzlichen Hohl- oder Aufnahmeraum bildet, der für die Aufnahme von zusätzlichen Kabeln oder Leitungen verwendet werden kann.If it is a U-shaped mounting rail, so can run on both side walls within the support rail wires, it would be possible to use each separately Stromleitprofile. Preferably, however, the wire support members consist of two side wings, which have the grooves for receiving the wires and are to be arranged on the side walls, these side wings are connected to each other at regular intervals via connecting webs. These connecting webs are arranged on the middle leg of the wire rail. Furthermore, one of the two side wings may have a parallel to the center leg of the support rail arranged horizontal leg, which forms together with protruding from the connecting webs retaining legs over the length of the support rail away an additional hollow or receiving space, which are used for receiving additional cables or lines can.

Das erfindungsgemäße Konzept eines modular gebildeten Stromleitprofils aus einer Vielzahl von aneinandergereihten Drahthalterungselementen bietet die Möglichkeit, über eine beliebige Länge hinweg eine durchgängige Kontaktierungsmöglichkeit zu realisieren, indem das Stromleitprofil nach dem Zusammenschluß der Tragschienen in diese eingesetzt wird. Aus Gründen einer einfachen Montage werden allerdings die Tragschienen üblicherweise bereits fertig bestückt, d.h. mit einem bereits eingesetzten Stromleitprofil mit den darin angeordneten Drähten verkauft. Dies aus dem Grund, da es beim Erstellen eines Lichtbandsystems einfacher ist, die bereits fertig bestückten Tragschienen zusammenzusetzen, als zunächst leere Tragschienen aneinanderzufügen und anschließend die Stromleitprofile einzusetzen. Somit ergibt sich wiederum das Problem, daß zwischen zwei Tragschienen eine Schnittstelle auftritt, an der die Drähte zweier Stromleitprofile miteinander verbunden werden müssen.The inventive concept of a modular Stromleitprofils of a plurality of juxtaposed wire support elements provides the ability to realize over an arbitrary length across a continuous contacting possibility by the Stromleitprofil is used after the merger of the support rails in this. For ease of assembly, however, the DIN rails are usually already assembled ready, i. sold with an already inserted Stromleitprofil with the wires arranged therein. This is because it is easier when creating a trunking system to assemble the already assembled mounting rails, as first add together empty mounting rails and then use the Stromleitprofile. Thus, in turn, there is the problem that between two mounting rails an interface occurs at which the wires of two Stromleitprofile must be connected to each other.

Eine Weiterbildung der Erfindung betrifft daher ein Verbindungselement, welches auch an diesen Schnittstellen eine Kontaktierungsmöglichkeit bildet. Im Gegensatz zu dem bekannten Reihenverbinder weist das Verbindungselement von der Kontaktierungsseite und den beiden Stirnseiten her zugängliche rillenförmige Ausnehmungen auf, welche den Nuten der Stromleitprofile entsprechen, wobei in die Ausnehmungen jeweils ein Metallverbinder eingesetzt ist, an den die miteinander zu verbindenden Drähte von beiden Seiten her anschließbar sind. Dieses ebenfalls aus einem nicht-leitenden Material bestehende Verbindungselement schließt die Lücke zwischen den Stromleitprofilen zweier Tragschienen und stellt sicher, daß über die gesamte Länge des Stromschienensystems hinweg ein Leuchten-Modul befestigt und an die Leitungen des Stromschienensystems angeschlossen werden kann, da die Metallverbinder in dem Übergangsbereich die Kontaktierungsflächen für die Anschlußkontakte des Leuchten-Moduls bilden. Vorzugsweise weisen die Metallverbinder eine längliche Kontaktierungsplatte sowie an beiden Enden davon angeordnete U-förmige Federelemente auf, durch welche die Drähte beim Einführen verklemmt und gegen die Kontaktierungsplatte gedrückt werden. Gleichzeitig wird durch die Federelemente gewährleistet, daß sich die Drähte bei einer Wärmeausdehnung der Drahthalterungselemente nicht pumpenartig verschieben und möglicherweise sogar auswandern können. Bei U-förmigen Tragschienen, bei denen an beiden Seitenwänden Stromleitprofile angeordnet sind, erfolgt eine mechanische Verbindung zweier benachbarter Tragschienen vorzugsweise mit Hilfe einer kurzen U-förmigen Verbindungsschiene, welche jeweils zur Hälfte in beide Tragschienen eingreift und an deren Seitenschenkel die Verbindungselemente angeordnet sind.A further development of the invention therefore relates to a connecting element which also forms a contacting possibility at these interfaces. In contrast to the known row connector, the connecting element of the contacting side and the two end faces accessible groove-shaped recesses corresponding to the grooves of the Stromleitprofile, wherein in the recesses in each case a metal connector is used, to which the wires to be joined together from both sides can be connected. This also consists of a non-conductive material connecting element closes the gap between the Stromleitprofilen two mounting rails and ensures that over the entire length of the busbar system away a luminaire module attached and to the lines of the Busbar system can be connected, since the metal connectors in the transition region form the contact surfaces for the terminal contacts of the lamp module. The metal connectors preferably have an elongated contacting plate and U-shaped spring elements arranged at both ends thereof, by means of which the wires are clamped during insertion and pressed against the contacting plate. At the same time, it is ensured by the spring elements that the wires can not move in a pump-like manner during thermal expansion of the wire-holding elements and possibly even emigrate. In U-shaped mounting rails in which Stromleitprofile are arranged on both side walls, a mechanical connection of two adjacent mounting rails preferably by means of a short U-shaped connecting rail, which engages half in both mounting rails and at the side legs, the connecting elements are arranged.

Eine andere Weiterbildung befaßt sich mit einer möglichst einfach durchzuführenden Kontaktierung der Drähte innerhalb einer U-förmigen Tragschiene durch ein Leuchten-Modul. Hierfür weist das Leuchten-Modul ein Kontaktierungselement mit mehreren Anschlußkontakten auf, wobei das Kontaktierungselement von der offenen Seite her in die Tragschiene einzuführen und anschließend teilweise - vorzugsweise um 45° - zu verdrehen ist. Durch das Verdrehen werden die Anschlußkontakte in die Nuten des Stromleitprofils eingeführt und mit den Drähten in Kontakt gebracht. Dabei kann das Kontaktierungselement vorzugsweise derart ausgestaltet sein, daß zumindest einer der Anschlußkontakte in seiner Höhe verstellbar ist. Da die in unterschiedlicher Höhe angeordneten Drähte des Stromleitprofils verschiedene Funktionen haben, kann durch Verschieben der Anschlußkontakte eine wahlweise Kontaktierung erreicht werden. Dies bietet die Möglichkeit, den an das Stromschienensystem angeschlossenen Leuchten unterschiedliche Funktionen zuzuweisen, beispielsweise einige der Leuchten lediglich als Notstromleuchten zu verwenden. Ferner können an dem Kontaktierungselement Verriegelungselemente vorgesehen sein, welche bei dem Verdrehen und. Kontaktieren der Drähte zusätzlich hervorstehende Teile der Tragschiene hintergreifen, wodurch gleichzeitig eine mechanische Befestigung an der Tragschiene ermöglicht wird. Auf diese Weise kann mit Hilfe eines einfachen Handgriffs sowohl eine elektrische Kontaktierung als auch eine mechanische Befestigung des Leuchten-Moduls durchgeführt werden.Another development is concerned with a possible easy to carry out contacting the wires within a U-shaped mounting rail by a luminaire module. For this purpose, the luminaire module has a contacting element with a plurality of terminal contacts, wherein the contacting element from the open side to introduce into the mounting rail and then partially - preferably by 45 ° - to twist. By turning the terminal contacts are inserted into the grooves of the Stromleitprofils and brought into contact with the wires. In this case, the contacting element may preferably be designed such that at least one of the terminal contacts is adjustable in height. Since the arranged at different heights wires of the Stromleitprofils have different functions, an optional contact can be achieved by moving the terminal contacts. This offers the possibility to assign different functions to the lights connected to the busbar system, for example, to use some of the lights only as emergency lights. Further, locking elements may be provided on the contacting element, which in the twisting and. Contacting the wires additionally engage behind protruding parts of the mounting rail, which at the same time a mechanical attachment to the mounting rail is made possible. In this way, both an electrical contact and a mechanical attachment of the luminaire module can be performed by means of a simple handle.

Im folgenden soll die vorliegende Erfindung anhand der beiliegenden Zeichnung näher erläutert werden. Es zeigen:

- Fig. 1 die Tragschiene eines erfindungsgemäßen Stromschienensystems mit einem eingesetzten Kontaktierungselement im Schnitt;

- Fig. 2 die in Fig. 1 dargestellte Tragschiene ohne das Kontaktierungselement im Schnitt;

- Fig. 3 ein Drahthalterungselement in perspektivischer Darstellung;

- Fig. 4 das in Fig. 3 dargestellte Drahthalterungselement im Schnitt;

- Fig. 5 den Übergangsbereich zwischen zwei zusammengesetzten Drahthalterungselementen von der Kontaktierungsseite her;

- Fig. 6 den Übergangsbereich zwischen zwei Drahthalterungselementen von der Rückseite her;

- Fig. 7 die Anordnung eines Verbindungselements und einer Verbindungsschiene zum Verbinden zweier Tragschienen;

- Fig. 8 den Aufbau des Verbindungselements;

- Fig. 9a einen in dem Verbindungselement verwendeten Metallverbinder;

- Fig. 9b ein Federelement des in Fig. 9a dargestellten Metallverbinders; und

- Fig. 10 das in Fig. 1 dargestellte Kontaktierungselement in perspektivischer Darstellung.

- Figure 1 shows the support rail of a bus bar system according to the invention with an inserted contacting element in section.

- FIG. 2 shows the support rail shown in FIG. 1 without the contacting element in section; FIG.

- 3 shows a wire-holding element in perspective view;

- FIG. 4 shows the wire-holding element illustrated in FIG. 3 in section; FIG.

- 5 shows the transition region between two composite wire-holding elements from the contacting side;

- 6 shows the transition region between two wire-holding elements from the rear side;

- 7 shows the arrangement of a connecting element and a connecting rail for connecting two mounting rails.

- 8 shows the construction of the connecting element;

- FIG. 9a shows a metal connector used in the connecting element; FIG.

- FIG. 9b shows a spring element of the metal connector shown in FIG. 9a; FIG. and

- Fig. 10, the contacting element shown in Fig. 1 in a perspective view.

Basiselement des in Fig. 1 dargestellten Stromschienensystems ist eine aus Metall bzw. Blech bestehende U-förmige Tragschiene 1, welche mit ihrem Mittelschenkel 2 durch nicht dargestellte Befestigungsmittel an einem Träger, z.B. einer Raumdecke oder einer Raumwand befestigbar ist. Die Abdeckung der offenen unteren Seite der Tragschiene 1 erfolgt durch eine Abdeckschiene 5. Im dargestellten Fall ist diese Abdeckschiene 5 Bestandteil eines an der Tragschiene 1 befestigten Leuchten-Moduls, wobei in Fig. 1 lediglich das Kontaktierungselement des Leuchten-Moduls in Form eines Drehabgriffs 50 dargestellt ist, nicht allerdings dessen weiteren Bestandteile, beispielsweise die Lampe oder das dazugehörige Steuer- bzw. Betriebsgerät, bei dem es sich um ein elektronisches Vorschaltgerät (EVG) handeln kann. Der Innenraum der Tragschiene 1 dient in diesem Fall dann auch als Aufnahmeraum für die Betriebsgeräte der Lampen.Base element of the busbar system shown in Fig. 1 is a metal or sheet metal existing U-shaped mounting rail 1, which is fastened with its

Diejenigen Bereiche der Tragschiene 1, an denen keine Leuchten-Module angeordnet sind, können aus optischen und Sicherheitsgründen ebenfalls mit einer Abdeckschiene 5 verschlossen werden, wobei das Befestigen der Abdeckschiene 5 mittels Verklemmen oder Verrasten erfolgt.Those areas of the mounting rail 1, on which no luminaire modules are arranged, can also be closed with a

Im vorliegenden Beispiel sind an den Innenseiten der beiden Seitenwände 3a und 3b der Tragschiene 1 Stromleitprofile angeordnet, welche erfindungsgemäß durch mehrere aus Kunststoff bestehende und zusammengesetzte Drahthalterungselemente 10 gebildet werden, die jeweils zwei Seitenflügel 10a und 10b mit mehreren Nuten 11 zur Aufnahme der Drähte 6 enthalten. Dabei sind in dem rechten Seitenflügel 10a fünf Drähte 6 angeordnet, während auf der linken Seite sechs Drähte 6 verlaufen.In the present example, 1 Stromleitprofile are arranged on the inner sides of the two

Die in dem rechten Seitenflügel 10a angeordneten Drähte 6 können in der Reihenfolge von oben nach unten beispielsweise folgende Funktion haben.

- Notstrom 1

- Notstrom 2

- Neutralleiter vom Standardnetz

- D1 = Steuerleitung für Lichtsteuerung

- D2 = Steuerleitung für Lichtsteuerung.

- Emergency power 1

-

Emergency power 2 - Neutral from the standard network

- D1 = control cable for lighting control

- D2 = control cable for lighting control.

Die Funktionen der in dem linken Seitenflügel 10b angeordneten Drähte 6 sind beispielsweise:

- Phase von Notstrom 1

Phase von Notstrom 2- Standardphase 3

Standardphase 2- Standardphase 1

- Erde.

- Phase of emergency power 1

- Phase of

emergency power 2 - Standard phase 3

-

Standard phase 2 - Standard phase 1

- Earth.

Sowohl die Anzahl der verwendeten Drähte sowie deren Anordnung und Funktion ist lediglich beispielhaft dargestellt und kann den individuellen Bedürfnissen angepaßt werden.Both the number of wires used and their arrangement and function is shown only by way of example and can be adapted to individual needs.

Durch eine Kontaktierung der entsprechenden Drähte 6 kann der angeschlossenen Leuchte eine gewünschte Funktion zugewiesen werden, beispielsweise kann die Leuchte als Notlichtleuchte verwendet werden. Durch das Verwenden der beiden Steuerleitungen für die Lichtsteuerung besteht die Möglichkeit, mit diesen beiden Leitungen ein Bussystem zu bilden, über das eine Vielzahl von Leuchten mit Hilfe von digitalen Steuerbefehlen angesteuert werden kann, wie dies von komplexeren Beleuchtungssystemen her bekannt ist.By contacting the corresponding

Die Kontaktierung der Drähte 6 erfolgt über mehrere an dem Drehabgriff 50 angeordnete Anschlußkontakte 53 und 54, welche in die entsprechenden Nuten 11 eingreifen und gegen die Drähte 6 zur Anlage kommen. Um eine variable und einfache Kontaktierung zu ermöglichen, ist beispielsweise der Anschlußkontakt 53 mittels einem Trägerelement 55 höhenverstellbar an dem Drehabgriff 50 angeordnet. Durch einfaches Verschieben des Trägerelementes 55 kann somit der an das Stromschienensystem angeschlossene Leuchte die gewünschte Funktion zugewiesen werden. Für die Erdung ist ferner ein in einem Schlitz 63 des Drehabgriffs 50 geführtes Drahtelement 62 vorgesehen, dessen Ende 62b den zur Erdung vorgesehenen linken unteren Draht 6 kontaktiert. Der genauere Aufbau und die Funktionsweise des Kontaktierungselements 50 werden zu einem späteren Zeitpunkt noch ausführlicher erläutert. Die Netzeinspeisung für das Stromschienensystem kann zum Beispiel durch einen entsprechend adaptierten Drehabgriff erfolgen, der in Längsrichtung an beliebiger Stelle positioniert wird.The contacting of the

Eine sichere Halterung der beiden Seitenflügel 10a, 10b des Drahthalterungselements 10 erfolgt durch mehrere Führungsarme 121 - 124, welche in entsprechende Führungsnuten 41 - 44 der U-förmigen Tragschiene 1 eingreifen. Die zu einem Stromleitprofil aneinandergereihten mehreren Drahthalterungselemente 10 werden bei der Montage in Längsrichtung in die Tragschiene 2 eingeschoben. An der Rückseite der Seitenflügel 10a und 10b, d.h. an der der Kontaktierungsseite gegenüberliegenden Seite der Nuten 11 befinden sich mehrere Stützstreben 16, welche für eine stabile Lagerung der Nuten 11 innerhalb der Tragschiene 2 sorgen, so daß diese beim Kontaktieren nicht zurückgedrängt werden. Auf diese Weise wird eine zuverlässige Kontaktierung der Drähte 6 unterstützt.A secure mounting of the two

Die Verbindung der beiden Seitenflügel 10a und 10b erfolgt in regelmäßigen Abständen über Verbindungsstege 13, welche an dem Mittelschenkel 2 der Tragschiene 1 angeordnet sind. Die Verbindungsstege 13 weisen ferner nach unten abstehende Halteschenkel 15 auf, die gemeinsam mit einem von dem rechten Seitenflügel 10a horizontal abstehenden Horizontalschenkel 14 einen zusätzlichen Hohlraum 8 bilden. Dieser Hohlraum kann für die Lagerung zusätzlicher Kabel oder Leitungen verwendet werden. Darüber hinaus hat der Horizontalschenkel 14 noch die Aufgabe, zu verhindern, daß das Kontaktierungselement 50 seitenverkehrt in die Tragschiene 1 eingeführt wird, wie ebenfalls später noch erläutert wird.The connection of the two

Die Form der Nuten 11 der Drahthalterungselemente 10 ist derart gewählt, daß ein Berührungsschutz gewährleistet ist, wie im folgenden anhand von Fig. 2 erläutert werden soll. Hier ist wiederum die Tragschiene 1 mit einem darin angeordneten Stromleitprofil dargestellt, allerdings nunmehr ohne den Drehabgriff 50. Die eingangs erwähnte Sicherheitsnorm sieht vor, daß die in dem Stromleitprofil angeordneten Drähte 6 nicht derart frei liegen dürfen, daß ein 1mm-dicker Prüfdraht 7 in Geradeaus-Dehnung auf einen stromführenden Draht 6 treffen kann. In der Darstellung ist dabei für den links unten angeordneten Draht 6 der Eintrittswinkel für den Prüfdraht 7 am günstigsten. Wie Fig. 2 zu entnehmen ist, sind die Breiten, Tiefen und Öffnungsformen der Nuten 11 derart bemessen, daß selbst bei dem kleinsten Eintrittswinkel der Prüfdraht 7 keinen der Drähte 6 kontaktieren kann. Auf diese Weise wird ein unbeabsichtigtes Berühren der Drähte 6 vermieden und die entsprechende Sicherheitsnorm erfüllt.The shape of the

Anhand der Fig. 3 bis 6 soll nunmehr die konkrete Ausgestaltung der erfindungsgemäßen Drahthalterungselemente 10 erläutert werden, wobei Fig. 3 ein Drahthalterungselement 10 in perspektivischer Darstellung zeigt. Wesentliche Elemente des Drahthalterungselements 10 sind dabei die beiden Seitenflügel 10a und 10b, welche die Nuten 11 zur Lagerung der Drähte aufweisen. Sie sind über zwei Verbindungsstege 13 miteinander verbunden. Auf diese Weise kann zusätzlich mit Hilfe des Horizontalschenkels 14 und den von den Verbindungsstegen 13 abstehenden Halteschenkeln 15 der zuvor erwähnte Hohlraum 8 gebildet werden, der zur Lagerung weiterer für das Beleuchtungssystem nützlicher Leitungen oder Kabel benutzt werden kann. An den beiden Seitenflügeln 10a, 10b befinden sich ferner auch die Führungsarme 121 bis 124, welche in die Ausnehmungen 41 bis 44 der Tragschiene 1 beim Einsetzen eingreifen. Die Darstellungen in Fig. 3 und Fig. 4 zeigen dabei das Drahthalterungselement 10 unmittelbar nach der Herstellung. Um das Drahthalterungselement 10 in die Tragschiene 1 einzuführen, werden die Seitenflügel 10a und 10b um die beiden Faltstellen A und B um 90° nach unten geklappt (siehe Fig. 4) und anschließend in die Tragschiene 1 eingeschoben, wodurch sich die in den Fig. 1 und 2 dargestellte Anordnung ergibt.The specific embodiment of the

An ihren Enden weisen die beiden Seitenflügel 10a und 10b Vorsprünge 17 bzw. 22 auf, mit deren Hilfe zwei zusammengefügte Drahthalterungselemente 10 überlappend ineinandergreifen. An einem der beiden Enden sind ferner Verriegelungsköpfe 18 vorgesehen, welche ein Entfernen zweier zusammengefügter Drahthalterungselemente 10 in Längsrichtung nur bis zu einer gewissen Maximalentfernung zulassen, so daß ein aus mehreren Drahthalterungselementen 10 zusammengesetztes Stromleitprofil in seiner Länge flexibel ist und damit Längenveränderungen der einzelnen aus Kunststoff bestehenden Drahthalterungselemente 10 aufgrund von Temperatunterschieden kompensiert werden können.At their ends, the two

Dies soll anhand der Fig. 5 und 6 verdeutlicht werden, welche zwei zusammengesetzte Drahthalterungselemente in vergrößerter Darstellung zeigen, zum einen von der Kontaktierungsseite her (Fig. 5) und zum anderen von der gegenüberliegenden Rückseite (Fig. 6) her. Die zu dem ersten Drahthalterungselement 101 gehörenden Teile sind dabei mit dem Index 1 versehen, während die zu dem zweiten Drahthalterungselement 102 gehörenden Elemente den Index 2 aufweisen. Nach dem Zusammenfügen der beiden Drahthalterungselemente 101 und 102 greifen diese beiden derart überlappend ineinander, daß jeweils durch einen Vorsprung 17, des ersten Drahthalterungselements 101 sowie durch einen Vorsprung 222 des zweiten Drahthalterungselements 102 ein Kanal 23 gebildet wird, der die Nuten 11 der beiden Drahthalterungselemente 101 und 102 miteinander verbindet. Wie auch die Nuten 11 sind sämtliche auf diese Weise gebildeten Kanäle 23 in dem Verbindungsbereich lediglich von der Kontaktierungsseite, also von oben her zugänglich, nicht allerdings von der Seite. Dadurch wird auch in dem Bereich der Kanäle 23 der geforderte Berührungsschutz gewährleistet.This will be clarified with reference to FIGS. 5 and 6, which show two composite wire support elements in an enlarged view, on the one hand from the contacting side (FIG. 5) and on the other from the opposite rear side (FIG. 6). The parts belonging to the first wire-holding

Der Darstellung in Fig. 6 ist zu entnehmen, daß die beiden Verriegelungsköpfe 182 ein Entfernen der beiden Drahthalterungselemente 101 und 102 nur bis zu einer Maximalentfernung zulassen, die dadurch vorgegeben ist, daß die an den Enden der Verriegelungsköpfe 18 seitlich vorstehenden Verriegelungsvorsprünge 192 gegen Stoppwände 201 zur Anlage kommen. Dabei ist diese vorgegebene maximale Entfernung sowie die Länge der ineinandergreifenden Vorsprünge 17 und 22 derart bemessen, daß selbst bei der Maximalentfernung der beiden Drahthalterungselemente 101 und 102 voneinander noch die zuvor erläuterten Kanäle 23 gebildet werden und der Berührungsschutz gewährleistet ist. Auf der anderen Seite können sich die Enden der beiden Drahthalterungselemente 101, 102 soweit aneinander annähern, bis ihre beiden Stirnseiten 211 und 212 gegeneinander in Anlage kommen. Dies bedeutet, daß beide Drahthalterungselemente 101, 102 mit einem gewissen Spiel gegeneinander verschiebbar sind, wobei jedoch zu jedem Zeitpunkt der Berührungsschutz erzielt wird. Auf diese Weise können Veränderungen der Länge eines einzelnen Drahthalterungselements 10, welches sich beispielsweise aufgrund von erhöhter Temperatur ausdehnt oder bei niedrigeren Temperaturen zusammenzieht, kompensiert werden. Dies ist insbesondere deswegen wichtig, da im Gegensatz zu den aus Kunststoff bestehenden Drahthalterungselementen 10 die darin gelagerten Drähte 6 selbst keine derartig großen Längenveränderungen vollführen können, da der Temperaturkoeffizient von Metall nur 1/10 des Ausdehnungskoeffizients von Kunststoff beträgt. Bei einer Länge von ca. 500mm für ein einzelnes Drahthalterungselement 10 kann somit ein zulässige Spiel, mit dem sich die aneinandergrenzenden Drahthalterungselemente 10 gegeneinander verschieben können, ca. 8mm betragen.The illustration in Fig. 6 it can be seen that the two locking heads 18 2 allow removal of the two

Die dargestellten Drahthalterungselemente 10 können aus Kunststoff in einfacher Weise im Spritzgußverfahren erzeugt werden, wodurch sie sehr kostengünstig herzustellen sind. Ferner ist es ausreichend, Drahthalterungselemente 10 in lediglich einer einzigen Länge herzustellen, da zur Anpassung des gebildeten Stromleitprofils an die unterschiedlichen Längen der Drahtschienen lediglich die Anzahl der verwendeten Drahthalterungselemente 10 angepaßt werden muß, was wiederum den Herstellungsaufwand des gesamten Systems deutlich reduziert. Die ineinandergreifenden Vorsprünge sowie die Verriegelungselemente können dabei auch anders ausgestaltet sein.The