EP0963008B1 - A connector and a cap therefor - Google Patents

A connector and a cap therefor Download PDFInfo

- Publication number

- EP0963008B1 EP0963008B1 EP99109391A EP99109391A EP0963008B1 EP 0963008 B1 EP0963008 B1 EP 0963008B1 EP 99109391 A EP99109391 A EP 99109391A EP 99109391 A EP99109391 A EP 99109391A EP 0963008 B1 EP0963008 B1 EP 0963008B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- connector

- cap

- housing

- retainer

- connector housing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/46—Bases; Cases

- H01R13/516—Means for holding or embracing insulating body, e.g. casing, hoods

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/44—Means for preventing access to live contacts

- H01R13/447—Shutter or cover plate

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/40—Securing contact members in or to a base or case; Insulating of contact members

- H01R13/42—Securing in a demountable manner

- H01R13/436—Securing a plurality of contact members by one locking piece or operation

- H01R13/4361—Insertion of locking piece perpendicular to direction of contact insertion

Definitions

- the present invention relates to a connector and to a use of a cap for protecting of fitting projecting portions provided at the leading end of terminal fittings of a connector.

- FIGS. 16 and 17 show a connector 100 disclosed in Japanese Unexamined Utility Model Publication No. 7-32868 .

- This connector 100 is a male connector for accommodating male terminal fittings (not shown) therein and is provided at its front part with a hood 101 for surrounding tabs of the male terminal fittings.

- a dust preventing cap 102 is provided at a front opening of the hood 101.

- the prior art male connector 100 is normally provided with the hood 101, which makes the male connector 100 larger in vertical and transverse directions. Depending upon a place where the male connector 100 is used, the male connector 100 may be forced to be smaller by omitting the hood 101. In the case of a module connector to be accommodated in a block connector, it needs not have a hood after being accommodated in a main housing if a main connector is provided with a hood.

- US-A-5 556 288 discloses a protective cover mounted on a connector.

- US-A-5 145 385 discloses an electrical connector device providing interconnection between a male connector piece and a female connector plug.

- US-A-5 730 627 discloses a terminal retaining structure for a connector to securely hold a terminal fitting within a connector housing.

- US-A-3 990 759 discloses a connector housing to accommodate a terminal fitting.

- the connector is provided with a plurality of connector housings inserted in a main housing.

- the main housing comprises engaging portions to be engaged with respective engaging portions of the connector housings to hold the connector housings so as not to come out of the main housing.

- the terminal fitting is a male terminal fitting and the fitting projecting portions are tabs.

- a cap male connector cap for a male connector (hoodless or receptacleless male connector) comprising a connector housing and male terminal fittings which are inserted into cavities formed in the connector housing such that tabs provided at the leading ends thereof project from the front end surface of the connector housing without being surrounded, comprising:

- the tabs projecting from the front end surface of the connector housing without being surrounded are protected by the cap. Accordingly, the deformation and breakage of the tabs can be prevented even if the male connector is left unconnected with its mating connector. Further, since the detection opening is formed in the front surface of the cap main body, the cap needs not be detached from the connector housing when the detection probe is brought into contact with the male terminal fittings for an electrical connection check.

- the connector comprises at least one retainer which is mounted in a side wall portion of the connector housing such that it can be pushed from a standby position to a locking position, and locks the male terminal fittings when reaching the locking position

- the cap main body comprises a retainer protecting rib which projects in vicinity of the retainer in the standby position to prevent the retainer from (inadvertently) shifting to the locking position.

- the retainer protecting rib projecting in vicinity of the retainer prevents the retainer from inadvertently shifting from the standby position to the locking position.

- the connector comprises at least one retainer which is mounted in a side wall portion of the connector housing such that it can be pushed from a standby position to a locking position, and locks the (male) terminal fittings when reaching the locking position

- the cap main body comprises a retainer protecting portion for substantially covering the retainer in the standby position, thereby preventing the retainer from shifting to the locking position.

- the retainer protecting portion covering the retainer prevents the retainer from inadvertently shifting from the standby position to the locking position.

- the cap comprises connecting portions interconnecting a plurality of caps being integrally or unitarily formed or produced, wherein the connecting portions preferably comprise perforations for separating adjacent caps from each other.

- the detachably assembled cap prevents the deformation and breakage of the tabs if the male connector having no hood is left unconnected with its mating connector. Further, by providing no hood, the male connector can be made smaller by the hood.

- a plurality of male connectors form a main connector by being accommodated in a main housing, and the housing side engaging portion acts also as an engaging portion for engaging the main housing and the male connector with each other.

- the housing side engaging portion provided on the connector housing can be engaged with both the cap and the main housing.

- the male connector needs not have two engaging portions and is, therefore, allowed to have a simpler construction.

- the cap substantially covers the entire connector from its front end to its rear end.

- the connector is a male connector

- the terminal fitting is a male terminal fitting

- the fitting projecting portions are tabs.

- FIG. 1 is a side view of a connector housing 1 of a male connector 17.

- the male connector 17 is a so-called module connector.

- a main housing 20 capable of accommodating a plurality of male connectors 17 is provided, and a main connector 21 is assembled by mounting the male connectors 17 in the main housing 20.

- the male connector 17 is provided with a connector housing 1 and male terminal fittings 2 substantially accommodated or accommodatable in the connector housing 1.

- a tab 5 connectable with a mating female terminal fitting extends at a front part of each male terminal fitting 2 (see particularly FIG. 5 ).

- the connector housing 1 is so made e.g. of a synthetic resin as to have a substantially parallelepipedic shape and is connectable with a mating female connector housing (not shown) while substantially accommodating the male terminal fittings 2 therein.

- cavities 4 for at least partially accommodating the male terminal fittings 2 (see FIG. 2 ).

- the cavities 4 penetrate the connector housing 1 along forward and backward directions; and openings left at the rear side of the connector housing 1 serve as terminal insertion openings 4A through which the male terminal fittings 2 are inserted or insertable. Further, openings left at the front side of the connector housing 1 serve as tab insertion openings 4B through which the tabs 5 of the male terminal fittings 2 are inserted.

- a front end surface 18 of the connector housing 1 is substantially in alignment with the positions of the tab insertion openings 4B.

- the tabs 5 are exposed from the front end surface 18 of the connector housing 1 substantially without being surrounded.

- a pair of housing side engaging portions 10 project preferably backward (as seen in a mating direction MD ( FIG. 7 ) of the male connector 17 with the cap 3).

- the housing side engaging portions 10 are elastically deformable inward and are engageable with cap side engaging portions 11 provided in the cap 3 to be described later.

- retainer mounting openings 7 which communicate with the cavities 4.

- a retainer 8 is mounted in each retainer mounting opening 7.

- the retainers 8 are integrally or unitarily formed with the connector housing 1 via hinges 9, and are rotatable or pivotable about the hinges 9. Further, a terminal engaging portion 8A projects from a surface of each retainer 8, which surface faces inward of the connector housing 1.

- the retainer 8 has two insertion positions where its depth of insertion into the retainer mount openings 7 differs. One insertion position where the retainer 8 is lightly inserted is a standby position where the insertion of the male terminal fittings 2 into the cavities 4 is permitted.

- Another insertion position where the retainer 8 is pushed deeper than in the standby position is a locking position.

- the outer surfaces of the retainers 8 are substantially in flush with the outer wall surfaces of the connector housing 1 when the retainers 8 reach their locking positions, whereas they project from the outer wall surfaces of the connector housing 1 when the retainers 8 are in the standby positions.

- FIG. 3 shows the cap 3.

- This cap 3 is integrally or unitarily made e.g. of a synthetic resin and is provided with a hollow cap main body 12 from its front part to its middle part and the cap side engaging portion 11 which is provided behind the cap main body 12 to engage the cap 3 with the connector housing 1.

- the cap main body 12 has substantially the same outer dimensions as the connector housing 1 and is longer than the length of the tabs projecting from the front end surface 18 of the connector housing 1.

- the cap main body 12 substantially surrounds a projection space where the tabs 5 project.

- a detection opening 13 is open in the front end surface of the cap main body 12. With the cap 3 and the connector housing 1 assembled with each other, the detection opening 13 permits the insertion of a detection probe 14 for an electrical conduction check when the male terminal fittings 2 are mounted in the cavities 4.

- a pair of grips 15 project from the left and right side wall surfaces of the cap main body 12. The cap 3 and the connector housing 1 can be smoothly assembled and detached by manoeuvring the grips 15.

- the cap side engaging portion 11 is formed at a rear end of the cap main body 12 and is comprised of a substantially tubular portion 11 A for substantially covering a front end portion of the connector housing 1 and elastic pieces 11 B extending backward from the left and right side walls of the tubular portion 11A.

- the tubular portion 11A is formed slightly larger than the cap main body 12, and the connector housing 1 is insertable thereinto.

- the elastic pieces 11B are elastically deformable sideways. At the leading end of each elastic piece 11B, a claw 11C projects inward.

- the connector housing 1 and the cap 3 are substantially engaged by the engagement of the claws 11C and the housing side engaging portions 10 of the connector housing 1.

- Retainer protecting ribs 16 project at rear end portions of the tubular portion A covering the upper and lower parts of the connector housing 1.

- the vertical projecting length of the retainer protecting ribs 16 is so set as to be equal to or slightly longer than the projecting length of the retainers 8 in the standby position from the connector housing 1 when the cap 3 is mounted on the connector 1 (see FIG. 5 ).

- the retainers 8 of the connector housing 1 are rotated or pivoted about the hinges 9 to the respective standby positions in the retainer mounting openings 7.

- the cap 3 is mounted on the front portion of the connector housing 1.

- the elastic pieces 11 B are slightly elastically deformed outward and the claws 11C are engaged with the housing side engaging portions 10 after moving over them (It should be noted that the engagement of the claws 11C and the housing side engaging portions 10 is shown in FIG. 7 ).

- the cap side engaging portion 11 and the housing side engaging portions 10 are engaged to hold the connector housing 1 and the cap 3 locked.

- the retainer protecting ribs 16 of the cap 3 project in vicinity of or adjacent to the retainers 8. This prevents the retainers 8 from inadvertently shifting from the standby positions to the locking positions.

- the male terminal fittings 2 are inserted into the cavities 4 of the connector housing 1.

- the locking portions 6 engage the male terminal fittings 2, thereby partly locking the male terminal fittings 2 in the cavities 4 (see FIG. 5 ).

- the tabs 5 projecting from the front end surface 18 of the connector housing 1 without being surrounded are substantially protected by the cap 3. Accordingly, the deformation and breakage of the tabs 5 can be prevented even when the male connector 17 is left unconnected with a mating connector.

- the detection probe 14 can be substantially inserted through the detection opening 13 formed in the front surface of the cap main body 12 when an electrical conduction check for the male terminal fittings 2 is performed.

- the electrical conduction check can be efficiently performed without making it necessary to detach the cap 3 from the male connector 17.

- the male connector 17 having no hood or receptacle (hood-less or receptacle-less connector) is left unconnected with its mating connector, the deformation and breakage of the tabs 5 are prevented by the cap 3 detachably assembled. Further, by omitting the hood, the male connector 17 can be made smaller by the hood.

- the male connector 17 can be assembled into the main housing 20 after the cap 3 is detached therefrom (see FIG. 9 ).

- the main housing 20 is integrally made e.g. of a synthetic resin and can accommodate a plurality of male connectors 17 therein. As shown in FIGS. 10-12 , a plurality of connector accommodating chambers 22 in which the male connectors 17 are mountable are provided in the main housing 20.

- the connector accommodating chambers 22 penetrate the main housing 20 along forward and backward directions (a connecting direction of the main connector 21 with an unillustrated mating connector is assumed to be a forward direction).

- a hood or receptacle 23 capable of at least partially accommodating the mating connector is formed at a front part of the main housing 20. When the male connectors 17 are mounted in the main housing 20, the hood 23 substantially surrounds the tabs 5.

- each connector accommodating chamber 22 On one of the inner wall surfaces defining each connector accommodating chamber 22 which faces the housing side engaging portions 10 of the male connector 17 are provided connector engaging portions 24. These connector engaging portions 24 are engageable with the housing side engaging portions 10 and hold the male connector 17 so as not to come out of the main housing 20.

- Each male connector 17 is mounted in the main housing 21 as follows. First, the male connector 17 is inserted into the corresponding connector accommodating chamber 22 from front. When the engaging portions 10, 24 are brought into contact with each other, the housing side engaging portions 10 are elastically deformed inward. When the male connector 17 is further pushed into the connector accommodating chamber 22, the housing side engaging portions 10 restore their original shapes after moving over the connector engaging portions 24, with the result that the engaging portions 10, 24 are substantially engaged with each other (see FIGS. 11 and 12 ). In this way, the assembling of the main connector 21 is completed.

- the housing side engaging portions 10 provided on the male connector housing 17 are engageable with the engaging portions 11, 24 of the cap 3 and the main housing 20.

- the male connector 17 needs not have two kinds of engaging portions and, therefore, is allowed to have a simpler construction.

- the second embodiment differs from the first embodiment only in the shape of a cap 30. Accordingly, no description is given on the same or similar construction as the first embodiment by identifying it by the same or similar reference numerals.

- FIG. 13 shows a plurality of caps 30 which are formed while being interconnected with each other. Such an assembly of the caps 30 is formed by, e.g. vacuum forming. Perforations 31 are formed in connecting portions of the respective caps 30. Depending on a necessary number of the caps 30, the caps 30 can be cut off along the perforations 31.

- Each cap 30 is comprised of a cap main body 32 for substantially surrounding a projection space of the tabs 5 at a front side of the male connector 17 and a retainer protecting portion 33 provided at a rear part of the cap main body 32.

- the inner configuration of the cap main body 32 is slightly larger than the outer configuration of the outer diameter of the connector housing 1, so that the cap 30 can be so assembled as to cover the outer wall surfaces of the connector housing 1, Further, contact portions 34 project from inner wall surfaces of the cap main body 32.

- the front end of the connector housing 1 is positioned in the cap 30 by the front end surface 18 of the connector housing 1 coming into contact with the contact portions 34 (see FIG. 15 ).

- a length between the contact portions 34 and the front end of the cap main body 32 is substantially longer than a projecting length of the tabs 5 from the front end surface 18 of the connector housing 1. Further, the front end surface of the cap main body 32 is formed with a detection opening 35 for permitting the insertion of the detection probe 14.

- the retainer protecting portion 33 has upper, lower, left and right walls and substantially covers the retainers 8 in the assembled state of the cap 30.

- the position of the retainer protecting portion 33 is before the retainers 8 in their standby positions when the cap 30 is assembled with the male connector 17.

- the left and right side wall surfaces of the retainer protecting portion 33 extend along the left and right surfaces of the cap main body 32, whereas the upper and lower wall surfaces thereof are located above and below the cap main body 32.

- a distance between the upper and lower inner wall surfaces of the retainer protecting portion 33 and the upper and lower outer wall surfaces of the cap main body 32 is slightly longer than a projecting distance of the retainers 8 in their standby positions.

- the rear end of the retainer protecting portion 33 is located slightly behind the rear end position of the male connector 17 when the cap 30 is assembled with the male connector 17 (see FIG. 15 ).

- claws or connector engaging portions project on the inner wall surfaces of the retainer protecting portion 33 in positions corresponding to the housing side engaging portions 10 of the connector housing 1, and are adapted to engage the connector housing 1 and the cap 30 with each other.

- the retainers 8 in the standby positions are prevented from shifting to the locking positions by being covered by the retainer protecting portions 33 when the cap 30 is assembled with the connector housing 1.

- the retainer shift preventing function is further improved.

- the cap 30 substantially covers the entire male connector 17 from its front end to its rear end, it has a function of protecting the entire male connector 17.

- a plurality of caps 30 are integrally formed and interconnected via the perforations 31.

- a necessary number of caps 30 can be cut off to be used.

- a production cost is lower as compared to a case where the caps 30 are individually formed.

Landscapes

- Connector Housings Or Holding Contact Members (AREA)

Description

- The present invention relates to a connector and to a use of a cap for protecting of fitting projecting portions provided at the leading end of terminal fittings of a connector.

-

FIGS. 16 and17 show aconnector 100 disclosed inJapanese Unexamined Utility Model Publication No. 7-32868 connector 100 is a male connector for accommodating male terminal fittings (not shown) therein and is provided at its front part with ahood 101 for surrounding tabs of the male terminal fittings. Adust preventing cap 102 is provided at a front opening of thehood 101. - As described above, the prior

art male connector 100 is normally provided with thehood 101, which makes themale connector 100 larger in vertical and transverse directions. Depending upon a place where themale connector 100 is used, themale connector 100 may be forced to be smaller by omitting thehood 101. In the case of a module connector to be accommodated in a block connector, it needs not have a hood after being accommodated in a main housing if a main connector is provided with a hood. - However, in the male connector having the

hood 101 omitted in order to solve the above problem, tabs of male terminal fittings are exposed from the front surface of the connector without being surrounded. Thus, the tabs may be deformed or broken if the male connector is left unconnected with a mating female connector. -

US-A-5 556 288 discloses a protective cover mounted on a connector. -

US-A-5 145 385 discloses an electrical connector device providing interconnection between a male connector piece and a female connector plug. -

US-A-5 730 627 discloses a terminal retaining structure for a connector to securely hold a terminal fitting within a connector housing. -

US-A-3 990 759 discloses a connector housing to accommodate a terminal fitting. -

DE 43 05 844 A discloses a connector according to the preamble ofclaim 1. The connector is provided with a plurality of connector housings inserted in a main housing. The main housing comprises engaging portions to be engaged with respective engaging portions of the connector housings to hold the connector housings so as not to come out of the main housing. - It is the object of the invention to allow a connector to have a simple construction and which comprises fitting projecting portions which are prevented from being deformed and/or broken.

- This object is fulfilled by a connector having the features disclosed in

claim 1 and a cap having the features disclosed inclaim 4. Preferred embodiments are defined in the dependent subclaims. - According to a preferred embodiment of the invention, the terminal fitting is a male terminal fitting and the fitting projecting portions are tabs. According to a preferred embodiment, there is provided a cap (male connector cap) for a male connector (hoodless or receptacleless male connector) comprising a connector housing and male terminal fittings which are inserted into cavities formed in the connector housing such that tabs provided at the leading ends thereof project from the front end surface of the connector housing without being surrounded, comprising:

- a cap main body for surrounding a projection space of the tabs,

- a cap engaging portion provided on the cap main body so as to be engageable with the connector housing, and

- a detection opening formed in the front surface of the cap main body so as to permit the insertion of a detection probe.

- Accordingly, the tabs projecting from the front end surface of the connector housing without being surrounded are protected by the cap. Accordingly, the deformation and breakage of the tabs can be prevented even if the male connector is left unconnected with its mating connector. Further, since the detection opening is formed in the front surface of the cap main body, the cap needs not be detached from the connector housing when the detection probe is brought into contact with the male terminal fittings for an electrical connection check.

- Further preferably, the connector comprises at least one retainer which is mounted in a side wall portion of the connector housing such that it can be pushed from a standby position to a locking position, and locks the male terminal fittings when reaching the locking position, and the cap main body comprises a retainer protecting rib which projects in vicinity of the retainer in the standby position to prevent the retainer from (inadvertently) shifting to the locking position.

- Accordingly, the retainer protecting rib projecting in vicinity of the retainer prevents the retainer from inadvertently shifting from the standby position to the locking position.

- Further preferably, the connector comprises at least one retainer which is mounted in a side wall portion of the connector housing such that it can be pushed from a standby position to a locking position, and locks the (male) terminal fittings when reaching the locking position, and the cap main body comprises a retainer protecting portion for substantially covering the retainer in the standby position, thereby preventing the retainer from shifting to the locking position.

- Accordingly, the retainer protecting portion covering the retainer prevents the retainer from inadvertently shifting from the standby position to the locking position.

- Most preferably, the cap comprises connecting portions interconnecting a plurality of caps being integrally or unitarily formed or produced, wherein the connecting portions preferably comprise perforations for separating adjacent caps from each other.

- Accordingly, the detachably assembled cap prevents the deformation and breakage of the tabs if the male connector having no hood is left unconnected with its mating connector. Further, by providing no hood, the male connector can be made smaller by the hood.

- A plurality of male connectors form a main connector by being accommodated in a main housing, and the housing side engaging portion acts also as an engaging portion for engaging the main housing and the male connector with each other.

- Accordingly, the housing side engaging portion provided on the connector housing can be engaged with both the cap and the main housing. Thus, the male connector needs not have two engaging portions and is, therefore, allowed to have a simpler construction.

- Further preferably, the cap substantially covers the entire connector from its front end to its rear end.

- Most preferably, the connector is a male connector, the terminal fitting is a male terminal fitting and the fitting projecting portions are tabs.

- These and other objects, features and advantages of the present invention will become more apparent upon a reading of the following detailed description and accompanying drawings in which:

-

FIG. 1 is a side view of a connector housing according to a first embodiment, -

FIG. 2 is a side view in section of the connector housing, -

FIG. 3 is a perspective view of a cap, -

FIG. 4 is a side view of the connector housing assembled with the cap when retainers are in their standby positions, -

FIG. 5 is a side view in section of the connector housing assembled with the cap and having male terminal fittings mounted therein when the retainers in their standby positions, -

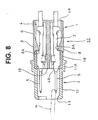

FIG. 6 is a front view of the connector housing assembled with the cap and having the male terminal fittings mounted therein, -

FIG. 7 is a plan view of the connector housing assembled with the cap and having the male terminal fittings mounted therein, -

FIG. 8 is a side view in section of the male connector when the retainers are pushed to their locking positions, -

FIG. 9 is a side view in section of the male connector when the cap is detached therefrom, -

FIG. 10 is a side view in section of a main housing, -

FIG. 11 is a side view in section of a main connector when the male connector is accommodated in the main housing, -

FIG. 12 is a plan view of the main connector, -

FIG. 13 is a perspective view of an assembly of caps according to a second embodiment, -

FIG. 14 is a perspective view of the male connector before the cap is assembled with the connector housing with the retainers in their standby positions, -

FIG. 15 is a side view in section of the connector housing assembled with the cap and having the male terminal fittings mounted therein, -

FIG. 16 is a perspective view of a prior art connector, and -

FIG. 17 is a perspective view of the prior art connector when a dust preventing cap is assembled. - Next, a first embodiment of the invention is described in detail with reference to

FIGS. 1 to 12 . -

FIG. 1 is a side view of aconnector housing 1 of amale connector 17. Themale connector 17 is a so-called module connector. As described later, amain housing 20 capable of accommodating a plurality ofmale connectors 17 is provided, and amain connector 21 is assembled by mounting themale connectors 17 in themain housing 20. - The

male connector 17 is provided with aconnector housing 1 andmale terminal fittings 2 substantially accommodated or accommodatable in theconnector housing 1. Atab 5 connectable with a mating female terminal fitting (not shown) extends at a front part of each male terminal fitting 2 (see particularlyFIG. 5 ). - The

connector housing 1 is so made e.g. of a synthetic resin as to have a substantially parallelepipedic shape and is connectable with a mating female connector housing (not shown) while substantially accommodating themale terminal fittings 2 therein. In theconnector housing 1 are providedcavities 4 for at least partially accommodating the male terminal fittings 2 (seeFIG. 2 ). Thecavities 4 penetrate theconnector housing 1 along forward and backward directions; and openings left at the rear side of theconnector housing 1 serve asterminal insertion openings 4A through which the maleterminal fittings 2 are inserted or insertable. Further, openings left at the front side of theconnector housing 1 serve astab insertion openings 4B through which thetabs 5 of the maleterminal fittings 2 are inserted. Afront end surface 18 of theconnector housing 1 is substantially in alignment with the positions of thetab insertion openings 4B. Thus, when the maleterminal fittings 2 are mounted in theconnector housing 1, thetabs 5 are exposed from thefront end surface 18 of theconnector housing 1 substantially without being surrounded. Further, a lockingportion 6, which is elastically deformable in a lateral direction, e.g. upward and downward, projects from a part of a wall surface defining eachcavity 4 so as to be engageable with the maleterminal fitting 2. - At the lateral or left and right side walls of the

connector housing 1, a pair of housingside engaging portions 10 project preferably backward (as seen in a mating direction MD (FIG. 7 ) of themale connector 17 with the cap 3). The housingside engaging portions 10 are elastically deformable inward and are engageable with capside engaging portions 11 provided in thecap 3 to be described later. - In the middle of upper and

lower walls 19 of theconnector housing 1 are formedretainer mounting openings 7 which communicate with thecavities 4. Aretainer 8 is mounted in eachretainer mounting opening 7. Theretainers 8 are integrally or unitarily formed with theconnector housing 1 viahinges 9, and are rotatable or pivotable about thehinges 9. Further, aterminal engaging portion 8A projects from a surface of eachretainer 8, which surface faces inward of theconnector housing 1. Theretainer 8 has two insertion positions where its depth of insertion into theretainer mount openings 7 differs. One insertion position where theretainer 8 is lightly inserted is a standby position where the insertion of the maleterminal fittings 2 into thecavities 4 is permitted. Another insertion position where theretainer 8 is pushed deeper than in the standby position is a locking position. The outer surfaces of theretainers 8 are substantially in flush with the outer wall surfaces of theconnector housing 1 when theretainers 8 reach their locking positions, whereas they project from the outer wall surfaces of theconnector housing 1 when theretainers 8 are in the standby positions. -

FIG. 3 shows thecap 3. Thiscap 3 is integrally or unitarily made e.g. of a synthetic resin and is provided with a hollow capmain body 12 from its front part to its middle part and the capside engaging portion 11 which is provided behind the capmain body 12 to engage thecap 3 with theconnector housing 1. - The cap

main body 12 has substantially the same outer dimensions as theconnector housing 1 and is longer than the length of the tabs projecting from thefront end surface 18 of theconnector housing 1. When thecap 3 is mounted on theconnector housing 1, the capmain body 12 substantially surrounds a projection space where thetabs 5 project. Further, adetection opening 13 is open in the front end surface of the capmain body 12. With thecap 3 and theconnector housing 1 assembled with each other, thedetection opening 13 permits the insertion of adetection probe 14 for an electrical conduction check when the maleterminal fittings 2 are mounted in thecavities 4. A pair ofgrips 15 project from the left and right side wall surfaces of the capmain body 12. Thecap 3 and theconnector housing 1 can be smoothly assembled and detached by manoeuvring thegrips 15. - The cap

side engaging portion 11 is formed at a rear end of the capmain body 12 and is comprised of a substantiallytubular portion 11 A for substantially covering a front end portion of theconnector housing 1 andelastic pieces 11 B extending backward from the left and right side walls of thetubular portion 11A. Thetubular portion 11A is formed slightly larger than the capmain body 12, and theconnector housing 1 is insertable thereinto. Theelastic pieces 11B are elastically deformable sideways. At the leading end of eachelastic piece 11B, aclaw 11C projects inward. Theconnector housing 1 and thecap 3 are substantially engaged by the engagement of theclaws 11C and the housingside engaging portions 10 of theconnector housing 1. -

Retainer protecting ribs 16 project at rear end portions of the tubular portion A covering the upper and lower parts of theconnector housing 1. The vertical projecting length of theretainer protecting ribs 16 is so set as to be equal to or slightly longer than the projecting length of theretainers 8 in the standby position from theconnector housing 1 when thecap 3 is mounted on the connector 1 (seeFIG. 5 ). - Next, how the thus constructed

male connector 17 andcap 3 are assembled and detached is described. - The

retainers 8 of theconnector housing 1 are rotated or pivoted about thehinges 9 to the respective standby positions in theretainer mounting openings 7. - Next, the

cap 3 is mounted on the front portion of theconnector housing 1. When the front portion of theconnector housing 1 is fitted into thetubular portion 11 A of thecap 3, theelastic pieces 11 B are slightly elastically deformed outward and theclaws 11C are engaged with the housingside engaging portions 10 after moving over them (It should be noted that the engagement of theclaws 11C and the housingside engaging portions 10 is shown inFIG. 7 ). In this state, the capside engaging portion 11 and the housingside engaging portions 10 are engaged to hold theconnector housing 1 and thecap 3 locked. Further, at this time, theretainer protecting ribs 16 of thecap 3 project in vicinity of or adjacent to theretainers 8. This prevents theretainers 8 from inadvertently shifting from the standby positions to the locking positions. - Subsequently, the male

terminal fittings 2 are inserted into thecavities 4 of theconnector housing 1. When the maleterminal fittings 2 are pushed to their proper insertion positions, the lockingportions 6 engage the maleterminal fittings 2, thereby partly locking the maleterminal fittings 2 in the cavities 4 (seeFIG. 5 ). At this time, thetabs 5 projecting from thefront end surface 18 of theconnector housing 1 without being surrounded are substantially protected by thecap 3. Accordingly, the deformation and breakage of thetabs 5 can be prevented even when themale connector 17 is left unconnected with a mating connector. - Subsequently, when the

retainers 8 are pushed from the standby positions to the locking positions, theterminal engaging portions 8A of theretainers 8 engage the maleterminal fittings 2, thereby fully locking the maleterminal fittings 2 in the cavities 4 (seeFIG. 8 ). In this state, thedetection probe 14 can be substantially inserted through thedetection opening 13 formed in the front surface of the capmain body 12 when an electrical conduction check for the maleterminal fittings 2 is performed. Thus, the electrical conduction check can be efficiently performed without making it necessary to detach thecap 3 from themale connector 17. - If the

male connector 17 having no hood or receptacle (hood-less or receptacle-less connector) is left unconnected with its mating connector, the deformation and breakage of thetabs 5 are prevented by thecap 3 detachably assembled. Further, by omitting the hood, themale connector 17 can be made smaller by the hood. - If necessary, the

male connector 17 can be assembled into themain housing 20 after thecap 3 is detached therefrom (seeFIG. 9 ). - Next, the assembling of the

male connectors 17 into themain housing 20 is described with reference toFIGS. 10 to 12 . - The

main housing 20 is integrally made e.g. of a synthetic resin and can accommodate a plurality ofmale connectors 17 therein. As shown inFIGS. 10-12 , a plurality ofconnector accommodating chambers 22 in which themale connectors 17 are mountable are provided in themain housing 20. The connectoraccommodating chambers 22 penetrate themain housing 20 along forward and backward directions (a connecting direction of themain connector 21 with an unillustrated mating connector is assumed to be a forward direction). A hood orreceptacle 23 capable of at least partially accommodating the mating connector is formed at a front part of themain housing 20. When themale connectors 17 are mounted in themain housing 20, thehood 23 substantially surrounds thetabs 5. - On one of the inner wall surfaces defining each

connector accommodating chamber 22 which faces the housingside engaging portions 10 of themale connector 17 are providedconnector engaging portions 24. Theseconnector engaging portions 24 are engageable with the housingside engaging portions 10 and hold themale connector 17 so as not to come out of themain housing 20. - Each

male connector 17 is mounted in themain housing 21 as follows. First, themale connector 17 is inserted into the correspondingconnector accommodating chamber 22 from front. When the engagingportions side engaging portions 10 are elastically deformed inward. When themale connector 17 is further pushed into theconnector accommodating chamber 22, the housingside engaging portions 10 restore their original shapes after moving over theconnector engaging portions 24, with the result that the engagingportions FIGS. 11 and12 ). In this way, the assembling of themain connector 21 is completed. - As described above, in this embodiment, the housing

side engaging portions 10 provided on themale connector housing 17 are engageable with the engagingportions cap 3 and themain housing 20. Thus, themale connector 17 needs not have two kinds of engaging portions and, therefore, is allowed to have a simpler construction. - Next, a second embodiment of the invention is described with reference to

FIGS. 13 to 15 . The second embodiment differs from the first embodiment only in the shape of acap 30. Accordingly, no description is given on the same or similar construction as the first embodiment by identifying it by the same or similar reference numerals. -

FIG. 13 shows a plurality ofcaps 30 which are formed while being interconnected with each other. Such an assembly of thecaps 30 is formed by, e.g. vacuum forming.Perforations 31 are formed in connecting portions of therespective caps 30. Depending on a necessary number of thecaps 30, thecaps 30 can be cut off along theperforations 31. - Each

cap 30 is comprised of a capmain body 32 for substantially surrounding a projection space of thetabs 5 at a front side of themale connector 17 and aretainer protecting portion 33 provided at a rear part of the capmain body 32. - The inner configuration of the cap

main body 32 is slightly larger than the outer configuration of the outer diameter of theconnector housing 1, so that thecap 30 can be so assembled as to cover the outer wall surfaces of theconnector housing 1, Further,contact portions 34 project from inner wall surfaces of the capmain body 32. The front end of theconnector housing 1 is positioned in thecap 30 by thefront end surface 18 of theconnector housing 1 coming into contact with the contact portions 34 (seeFIG. 15 ). A length between thecontact portions 34 and the front end of the capmain body 32 is substantially longer than a projecting length of thetabs 5 from thefront end surface 18 of theconnector housing 1. Further, the front end surface of the capmain body 32 is formed with adetection opening 35 for permitting the insertion of thedetection probe 14. - The

retainer protecting portion 33 has upper, lower, left and right walls and substantially covers theretainers 8 in the assembled state of thecap 30. The position of theretainer protecting portion 33 is before theretainers 8 in their standby positions when thecap 30 is assembled with themale connector 17. The left and right side wall surfaces of theretainer protecting portion 33 extend along the left and right surfaces of the capmain body 32, whereas the upper and lower wall surfaces thereof are located above and below the capmain body 32. A distance between the upper and lower inner wall surfaces of theretainer protecting portion 33 and the upper and lower outer wall surfaces of the capmain body 32 is slightly longer than a projecting distance of theretainers 8 in their standby positions. Further, the rear end of theretainer protecting portion 33 is located slightly behind the rear end position of themale connector 17 when thecap 30 is assembled with the male connector 17 (seeFIG. 15 ). - Though unillustrated, claws or connector engaging portions project on the inner wall surfaces of the

retainer protecting portion 33 in positions corresponding to the housingside engaging portions 10 of theconnector housing 1, and are adapted to engage theconnector housing 1 and thecap 30 with each other. - The same action and effects as the first embodiment can be obtained by the second embodiment constructed as above.

- Further, in this embodiment, the

retainers 8 in the standby positions are prevented from shifting to the locking positions by being covered by theretainer protecting portions 33 when thecap 30 is assembled with theconnector housing 1. Thus, as compared with theretainer protecting ribs 16 of the first embodiment, the retainer shift preventing function is further improved. - In addition, since the

cap 30 substantially covers the entiremale connector 17 from its front end to its rear end, it has a function of protecting the entiremale connector 17. - Further, a plurality of

caps 30 are integrally formed and interconnected via theperforations 31. Thus, a necessary number ofcaps 30 can be cut off to be used. Furthermore, since a batch ofcaps 30 are integrally formed, a production cost is lower as compared to a case where thecaps 30 are individually formed. - The present invention is not limited to the foregoing embodiments. For example, the following embodiments are also embraced by the scope of the present invention as defined in the claims.

- (1) Although the male connectors of the foregoing embodiments are module connectors, the present invention is also applicable to usual male connectors.

- (2) According to the invention, the retainer protecting rib or the retainer protecting portion may not be provided on the cap.

-

- 1 ...

- Connector Housing

- 2 ...

- (Male) Terminal Fitting

- 3, 30 ...

- Cap (Cap for Male Connector)

- 4 ...

- Cavity

- 5 ...

- Tab (Fitting Projecting Portions)

- 8 ...

- Retainer

- 10 ...

- Housing Side Engaging Portion

- 11 ...

- Cap Side Engaging Portion

- 12, 32 ...

- Cap Main Body

- 13, 35 ...

- Detection Opening

- 14 ...

- Detection Probe

- 16 ....

- Retainer Protecting Rib

- 17 ...

- (Male) Connector

- 20 ...

- Main Housing

- 21 ...

- Main Connector

- 33 ...

- Retainer Protecting Portion

Claims (8)

- A connector, comprising:a plurality of connector housings (1),terminal fittings (2) which are at least partially inserted or insertable into cavities (4) formed in the connector housing (1) so that fitting projecting portions (5) provided at the leading ends of said terminal fittings (2) project from a front end surface (18) of the connector housing (1) without being surrounded, anda main housing (20) having accommodating chambers (22) provided therein to accommodate said plurality of connector housings (1), wherein a hood (23) of said main housing (20) substantially surrounds said fitting projecting portions (5) when said connector housing (1) having inserted therein said terminal fittings (2) is mounted in said main housing (20), whereinsaid main housing (20) comprises at least one connector engaging portion (24) provided on an inner wall surface defining an accommodating chamber (22) and projecting into the accommodating chamber (22), said engaging portion (24) to be engaged with an elastically deformable housing side engaging portion (10) of said connector housing (1) to hold the connector housing (1) so as not to come out of the main housing (20).

- A connector according to claim 1, wherein the terminal fitting (2) is a male terminal fitting (2) and the fitting projecting portions (5) are tabs (5).

- A connector according to claim 1 or 2, wherein the connector housing (1) comprises at least one retainer (8) which is mounted in a side wall portion of the connector housing (1) such that it can be pushed from a standby position (FIG. 2; 5) to a locking position (FIG. 8), and locks the terminal fittings (2) when reaching the locking position (FIG. 8).

- Use of a cap (3; 30) for protecting of an fitting projecting portions provided at the leading end of terminal fittings of a connector according to one of claims 1 to 3, comprising:a cap main body (12; 32) for substantially surrounding a projection space of the fitting projecting portions (5) of said terminal fittings (2) when said connector housing (1) is disconnected from said main housing (20),a cap engaging portion (11) provided on the cap main body (12; 32) so as to be engageable with engaging portions (10) provided on the connector housing (1), anda detection opening (13; 35) formed in the front surface of the cap main body (12; 32) so as to permit the insertion of a detection probe (14).

- Use of a cap according to claim 4, wherein the cap main body (12) comprises a retainer protecting rib (16) which projects in vicinity of the retainer (8) in the standby position (FIG. 5) to prevent the retainer (8) from shifting to the locking position (FIG. 8).

- Use of a cap according to claim 4 or 5 , wherein the cap main body (32) comprises a retainer protecting portion (33) for substantially covering the retainer (8) in the standby position (FIG. 15), thereby preventing the retainer (8) from shifting to the locking position.

- Use of a cap according to one or more of the preceding claims, comprising connecting portions interconnecting a plurality of caps (30) being integrally or unitarily formed, wherein the connecting portions preferably comprise perforations (31) for separating adjacent caps (30) from each other.

- Use of a cap according to one of claims 4 to 7, wherein the cap (30) substantially covers the entire connector housing (1) from its front end to its rear end.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP01101193A EP1100156B1 (en) | 1998-06-04 | 1999-06-02 | A connector and a connector assembly |

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP15607598 | 1998-06-04 | ||

| JP15607598 | 1998-06-04 | ||

| JP6196999 | 1999-03-09 | ||

| JP06196999A JP3387438B2 (en) | 1998-06-04 | 1999-03-09 | Male connector and male connector cap |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP01101193A Division EP1100156B1 (en) | 1998-06-04 | 1999-06-02 | A connector and a connector assembly |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0963008A2 EP0963008A2 (en) | 1999-12-08 |

| EP0963008A3 EP0963008A3 (en) | 2001-04-18 |

| EP0963008B1 true EP0963008B1 (en) | 2008-03-19 |

Family

ID=26403047

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP99109391A Expired - Lifetime EP0963008B1 (en) | 1998-06-04 | 1999-06-02 | A connector and a cap therefor |

| EP01101193A Expired - Lifetime EP1100156B1 (en) | 1998-06-04 | 1999-06-02 | A connector and a connector assembly |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP01101193A Expired - Lifetime EP1100156B1 (en) | 1998-06-04 | 1999-06-02 | A connector and a connector assembly |

Country Status (4)

| Country | Link |

|---|---|

| EP (2) | EP0963008B1 (en) |

| JP (1) | JP3387438B2 (en) |

| CN (1) | CN1171358C (en) |

| DE (2) | DE69935145T2 (en) |

Families Citing this family (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20020076990A1 (en) * | 2000-12-15 | 2002-06-20 | Sumitomo Wiring Systems Ltd. | Apparatus for processing a stacked-type connector of a wire harness, a housing holder, apparatus and method and for stacking housings of a stacked-type connectors, and apparatus for pressing a joint portion of stacked-type connector |

| JP3846624B2 (en) * | 2001-10-16 | 2006-11-15 | 住友電装株式会社 | Joint connector |

| DE102005012441B4 (en) * | 2005-03-17 | 2006-11-02 | Tyco Electronics Amp Gmbh | Electrical connector and method of making an electrical connector |

| JP4654094B2 (en) | 2005-08-31 | 2011-03-16 | 矢崎総業株式会社 | connector |

| JP4541286B2 (en) * | 2005-11-30 | 2010-09-08 | 矢崎総業株式会社 | Connector locking mechanism and connector provided with the locking mechanism |

| DE602006004152D1 (en) * | 2005-12-20 | 2009-01-22 | Sumitomo Wiring Systems | Connector and connector assembly |

| US8951066B2 (en) | 2011-07-22 | 2015-02-10 | Lear Corporation | Electrical connector |

| US8721374B2 (en) * | 2011-07-22 | 2014-05-13 | Lear Corporation | Electrical connector |

| DE102011057192A1 (en) * | 2011-12-30 | 2013-07-04 | Huf Hülsbeck & Fürst Gmbh & Co. Kg | Housing for receiving an electronics unit |

| DE102013109640B4 (en) | 2013-09-04 | 2018-05-24 | Wago Verwaltungsgesellschaft Mbh | Spring-cage terminal and terminal component |

| CN104362460B (en) * | 2014-11-24 | 2016-06-29 | 南京康尼科技实业有限公司 | A kind of locating detent for track traffic adapter |

| JP2017157501A (en) * | 2016-03-04 | 2017-09-07 | 住友電装株式会社 | connector |

| US9780477B1 (en) * | 2016-06-01 | 2017-10-03 | Lear Corporation | Box terminal with insertion limiter |

| JP6473728B2 (en) | 2016-10-06 | 2019-02-20 | 矢崎総業株式会社 | Protective cap |

| JP6539634B2 (en) | 2016-10-17 | 2019-07-03 | 矢崎総業株式会社 | connector |

| JP6840517B2 (en) * | 2016-11-18 | 2021-03-10 | 日本航空電子工業株式会社 | Connector and composite connector |

| CN108539453B (en) * | 2018-03-23 | 2020-06-16 | 烽火通信科技股份有限公司 | Protective cover, back plate assembly, dismounting tool and method for dismounting protective cover |

| JP7202531B2 (en) * | 2019-10-25 | 2023-01-12 | 株式会社オートネットワーク技術研究所 | connector |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4305844A1 (en) * | 1993-02-25 | 1994-09-01 | Contact Gmbh | Plug connector |

| US5951326A (en) * | 1997-03-06 | 1999-09-14 | Yazaki Corporation | Connector and connector assembling method |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ZA743170B (en) * | 1974-05-17 | 1975-08-27 | J G Spargo | Insulators |

| GB8409455D0 (en) * | 1984-04-12 | 1984-05-23 | Lucas Ind Plc | Electrical connector |

| US4734054A (en) * | 1985-07-08 | 1988-03-29 | Siemens Aktiengesellschaft | Plug connector |

| US5145385A (en) * | 1990-06-14 | 1992-09-08 | Kabushiki Kaisha T An T | Electrical connector device |

| US5556288A (en) * | 1991-11-29 | 1996-09-17 | Yazaki Corporation | Protective cover for connector |

| EP0670500B1 (en) * | 1994-03-03 | 2000-05-31 | Sumitomo Wiring Systems, Ltd. | Connector and connector testing apparatus |

| JP2852497B2 (en) * | 1995-03-16 | 1999-02-03 | モレックス インコーポレーテッド | Electrical connector |

| JPH097676A (en) * | 1995-06-23 | 1997-01-10 | Yazaki Corp | Terminal locking structure of connector |

-

1999

- 1999-03-09 JP JP06196999A patent/JP3387438B2/en not_active Expired - Lifetime

- 1999-05-31 CN CNB991078853A patent/CN1171358C/en not_active Expired - Lifetime

- 1999-06-02 DE DE69935145T patent/DE69935145T2/en not_active Expired - Lifetime

- 1999-06-02 EP EP99109391A patent/EP0963008B1/en not_active Expired - Lifetime

- 1999-06-02 EP EP01101193A patent/EP1100156B1/en not_active Expired - Lifetime

- 1999-06-02 DE DE1999638376 patent/DE69938376T2/en not_active Expired - Lifetime

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4305844A1 (en) * | 1993-02-25 | 1994-09-01 | Contact Gmbh | Plug connector |

| US5951326A (en) * | 1997-03-06 | 1999-09-14 | Yazaki Corporation | Connector and connector assembling method |

Also Published As

| Publication number | Publication date |

|---|---|

| CN1171358C (en) | 2004-10-13 |

| DE69938376T2 (en) | 2009-04-02 |

| JP2000058190A (en) | 2000-02-25 |

| DE69938376D1 (en) | 2008-04-30 |

| JP3387438B2 (en) | 2003-03-17 |

| EP0963008A3 (en) | 2001-04-18 |

| EP1100156B1 (en) | 2007-02-14 |

| DE69935145D1 (en) | 2007-03-29 |

| CN1238580A (en) | 1999-12-15 |

| EP1100156A1 (en) | 2001-05-16 |

| EP0963008A2 (en) | 1999-12-08 |

| DE69935145T2 (en) | 2007-11-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US6146200A (en) | Connector and a cap therefor | |

| EP0963008B1 (en) | A connector and a cap therefor | |

| US6638108B2 (en) | Connector with plural housings accommodated in a casing | |

| EP0971442B1 (en) | An electrical connector with a side type retainer | |

| EP1923962B1 (en) | A connector and method of preassembling it | |

| US6159047A (en) | Electrical connector | |

| EP1158621B1 (en) | A connector housing | |

| EP0959532B1 (en) | A lever type connector | |

| US7114997B2 (en) | Electrical connector | |

| JPH06236784A (en) | Electric connector with terminal position guaranteed member | |

| US6568948B2 (en) | Connector | |

| US6129574A (en) | Connector having a construction for preventing an erroneous assembling of a connector housing and a cover | |

| JP2002305052A (en) | Connector | |

| US5755600A (en) | Connector with terminal locking member | |

| KR20040019874A (en) | Connector assembly and connector therefor | |

| EP1094559B1 (en) | Electrical connector having a terminal retainer | |

| JPH09245869A (en) | Connector with terminal locking fixture | |

| JP3646836B2 (en) | connector | |

| EP1801926B1 (en) | A connetor and connector assembly | |

| EP1528635B1 (en) | A divided connector, a method of assembling it and a method of connecting it with a mating connector | |

| US7063577B2 (en) | Split-type connector assembly and method of assembling it | |

| US6152783A (en) | Double locking member for a connector | |

| JP3634111B2 (en) | Female connector | |

| EP0997986B1 (en) | Electrical connector | |

| JPH1050382A (en) | Connector |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19990624 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): DE FR GB IT |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| AKX | Designation fees paid |

Free format text: DE FR GB IT |

|

| 17Q | First examination report despatched |

Effective date: 20040513 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE FR GB IT |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REF | Corresponds to: |

Ref document number: 69938376 Country of ref document: DE Date of ref document: 20080430 Kind code of ref document: P |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20081222 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20080619 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080619 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080319 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 18 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 19 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R084 Ref document number: 69938376 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20180522 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20180511 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 69938376 Country of ref document: DE |