EP0752033B1 - Structure consisting of prefabricated components - Google Patents

Structure consisting of prefabricated components Download PDFInfo

- Publication number

- EP0752033B1 EP0752033B1 EP95913027A EP95913027A EP0752033B1 EP 0752033 B1 EP0752033 B1 EP 0752033B1 EP 95913027 A EP95913027 A EP 95913027A EP 95913027 A EP95913027 A EP 95913027A EP 0752033 B1 EP0752033 B1 EP 0752033B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- semi

- structure according

- finished parts

- formwork

- beams

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000004570 mortar (masonry) Substances 0.000 claims abstract description 15

- 239000004567 concrete Substances 0.000 claims abstract description 13

- 229910000831 Steel Inorganic materials 0.000 claims description 17

- 239000010959 steel Substances 0.000 claims description 17

- 229910000746 Structural steel Inorganic materials 0.000 claims description 9

- 230000009977 dual effect Effects 0.000 claims 1

- 239000000945 filler Substances 0.000 claims 1

- 239000004566 building material Substances 0.000 abstract description 3

- 238000009415 formwork Methods 0.000 description 51

- 238000007373 indentation Methods 0.000 description 17

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 12

- 239000000463 material Substances 0.000 description 8

- 238000006073 displacement reaction Methods 0.000 description 7

- SZUVGFMDDVSKSI-WIFOCOSTSA-N (1s,2s,3s,5r)-1-(carboxymethyl)-3,5-bis[(4-phenoxyphenyl)methyl-propylcarbamoyl]cyclopentane-1,2-dicarboxylic acid Chemical compound O=C([C@@H]1[C@@H]([C@](CC(O)=O)([C@H](C(=O)N(CCC)CC=2C=CC(OC=3C=CC=CC=3)=CC=2)C1)C(O)=O)C(O)=O)N(CCC)CC(C=C1)=CC=C1OC1=CC=CC=C1 SZUVGFMDDVSKSI-WIFOCOSTSA-N 0.000 description 6

- 229940126543 compound 14 Drugs 0.000 description 6

- 229910052742 iron Inorganic materials 0.000 description 6

- 238000004382 potting Methods 0.000 description 6

- 230000002787 reinforcement Effects 0.000 description 6

- 238000004519 manufacturing process Methods 0.000 description 4

- 239000011449 brick Substances 0.000 description 3

- 238000010276 construction Methods 0.000 description 3

- 230000000694 effects Effects 0.000 description 3

- 238000000465 moulding Methods 0.000 description 3

- 230000003014 reinforcing effect Effects 0.000 description 3

- 238000012423 maintenance Methods 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- 229910052751 metal Inorganic materials 0.000 description 2

- 238000000034 method Methods 0.000 description 2

- 238000005266 casting Methods 0.000 description 1

- 150000001875 compounds Chemical class 0.000 description 1

- 238000009413 insulation Methods 0.000 description 1

- 238000005304 joining Methods 0.000 description 1

- 239000000047 product Substances 0.000 description 1

- 230000001681 protective effect Effects 0.000 description 1

- 238000009416 shuttering Methods 0.000 description 1

- 239000003351 stiffener Substances 0.000 description 1

- 239000013589 supplement Substances 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B1/00—Constructions in general; Structures which are not restricted either to walls, e.g. partitions, or floors or ceilings or roofs

- E04B1/02—Structures consisting primarily of load-supporting, block-shaped, or slab-shaped elements

- E04B1/04—Structures consisting primarily of load-supporting, block-shaped, or slab-shaped elements the elements consisting of concrete, e.g. reinforced concrete, or other stone-like material

Definitions

- the invention relates to a building consisting of prefabricated components, these components, in particular wall and ceiling panels, being manufactured with the aid of a lost formwork, and this lost formwork being produced from semi-finished parts.

- the present invention has for its object to provide a structure of the type mentioned, which can be constructed quickly and inexpensively from an economic point of view and still has a long service life.

- the semi-finished parts are advantageously made lying on formwork, if possible in the area of the construction site, in handy formats. These semi-finished parts can be of different dimensions, which are so light that they can be transported by hand. Then, when the mortar or Torkret concrete has set, the semi-finished parts are put together to form a lost formwork.

- these semi-finished parts are sufficiently rigid, they are advantageously reinforced with reinforcement made of structural steel.

- they are preferably provided with adjustments, for example in the form of sleeves and spikes, tongue and groove.

- Corresponding semi-finished parts are also inserted into the lost formwork for openings for doors, windows, recesses etc.

- the erected and aligned semi-finished parts are connected with wire or connecting reinforcement and then gate-locked at the connection points or fixed with mortar.

- the Torkret material or mortar has set, the lost formwork can be filled with filling material such as concrete, lightweight concrete or other building materials.

- the lost formwork is used as a molding box for brick assembly blocks or for other blocks or various types of filling material.

- the part created in this way is a prefabricated component, in particular wall, ceiling or roof panels for buildings of all kinds.

- the semi-finished parts for the production of the lost formwork have profiles, preferably conical indentations, which offer space for structural reinforcement and potting compound as well as for displacement aids.

- These displacement aids can be continuous, horizontal metal profiles with height-adjustable elements, for example screws, reinforcing bars or profiled steel for the vertical one Aligning the prefabricated components and to prevent them from tipping over, such as complete offset gauges for completely aligning the prefabricated components in any desired position, for example in an inclined position.

- a faster workflow can alternatively be achieved by placing a band iron around the entire formwork in the outer area, which is preferably located in the conical groove of the semi-finished parts. If the band iron is sufficiently dimensioned, the formwork element can be filled up immediately. This saves the setting time of locking the connection points.

- tie rod is attached at certain intervals, so that the side walls are prevented from kinking.

- This tie rod can, for example, be made of structural steel (round steel), which is secured on both sides with a formwork turnbuckle.

- the semi-finished parts can be mitered at the corners, so that they can also be mitred. This allows the part to be advantageously manufactured without corner pieces. This The advantage of this procedure is that users can simply put the individual parts together.

- light concrete can alternatively be provided for the production of the semi-finished parts for filling concrete or mortar, which has the advantage that the outer walls have no cold bridges, i. H. the individual parts have a heat-insulating effect.

- indentations or recesses can be provided at the ends in a further embodiment of the invention, into which flat iron or round steel are inserted with a precise fit when the parts are assembled.

- a building 20 is shown schematically, which consists of prefabricated with the help of a lost formwork 2 components 1 and 1 '.

- This lost formwork 2 is made from semi-finished parts 3 or 3 'or 3 ", whereby these semi-finished parts, which are shown in more detail in the following figures, only form the end faces or narrow sides of the prefabricated components 1 and 1'.

- These components 1 can be provided with cutouts 18 for windows or 18 'for doors.

- Each of these components 1 has a conical indentation 6, which will be described later and which can be filled with casting compound 14.

- auxiliary displacement devices 15 can be arranged which, for example, protrude over the respective components 1 as cones made of structural steel and serve as reinforcing bars.

- the ceiling structure of the structure 20 can also consist of prefabricated components 1 'according to the invention, which in turn is designed so that the lost formwork is made from semi-finished parts, these semi-finished parts in turn only being used on the front or narrow sides of the prefabricated components 1'.

- Each of these components 1 ' has an indentation 6' described in more detail later. Two adjacent recesses 6 'of adjacent components 1' thus form a space which can be filled with potting compound 14.

- a formwork 10 which has two flat surfaces 25 and 26 in cross section. On the inside, these two surfaces between 25 and 26 merge into two inclined surfaces 27 and 28, which are delimited in the upper area by a further flat surface 29.

- the surfaces 27, 28 and 29 serve to create a profile in the form of a conical indentation 6 for the semi-finished part 3. This conical indentation is used to hold potting compound 14 or displacement aids 15 shown in FIG. 1.

- the formwork 10 is delimited at its end regions by boundary walls 30. Mortar 4 or Torkret concrete is introduced into this formwork 10, reinforcements 5 made of structural steel and adjusting elements 17 also being embedded in this material. Furthermore, according to FIGS. 2a and 2b, connecting or transport loops 9 can be embedded in the material 4 at the ends.

- the formwork 10 can be designed so that it is essentially two at right angles faces 31 and 32 which are in relation to one another and are delimited by side walls 30.

- mortar or gate chalk is poured into this formwork 10, reinforcements 5 made of structural steel, connecting or transport loops 9 and adjusting elements in the form of sleeves 17 are embedded in the material.

- the semi-finished parts 3 can be removed from the respective formwork 10 or 10 '.

- FIG. 4 there is, for example, a bar as a semi-finished part 3, which in the end regions has the connecting or. Has transport loops 9 and is provided on the outside with the conical indentations 6.

- FIGS. 3 and 5 there is also the possibility of designing the semi-finished parts 3 "as angle pieces 8, again with the corresponding conical indentations 6, with loops 9 and with adjustments 17.

- FIGS. 3a and 4a show recesses 17 ', each of which in the end areas of the semi-finished parts 3 or 3 ".

- Profile elements 17 for example made of flat iron or round steel, can be inserted with a precise fit when assembling the parts; they replace or supplement the adjustments 17.

- the angle pieces 8, which consist of the semi-finished parts 3 "and the beams, which are formed from the semi-finished parts 3, can be assembled according to FIG. 5 into a frame 40 (lost formwork 2).

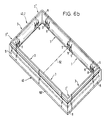

- This frame 40 is shown in more detail in FIG. 6:

- the loops 9 can be connected to one another at the ends of the angle pieces 8 or the beams via connections 11 in the form of structural steel or wire, so that overall a provisionally created frame 40 results, which on the outside, for example, all around with the conical indentation 6 is provided and represents the lost formwork 2.

- the frame (lost formwork 2) can also be designed so that only semi-finished parts 3 are used, which are each mitered at the corners, so that they are also mitred.

- the frame 40 can thus advantageously be manufactured without the corner pieces. This procedure has the advantage that users have the semi-finished parts 3 assembled into the frame 40 in a simplified manner.

- FIG. 6a This figure shows a lost formwork, which is composed of the semi-finished parts 3 or 3 "and connected to one another with connections 11 via the loop 9. If a faster workflow is desired, then alternatively 6, a band iron 50, which holds the semi-finished parts together like a ring, is placed around the entire formwork in the outer area. This ring preferably lies in a groove 51, ie the conical indentation 6 of the semi-finished parts 3 or 3 ′′.

- the formwork element can then be filled up immediately. This saves the setting time of locking the connection points in the area of elements 9 and 11.

- FIG. 6b there is alternatively also the possibility of joining or holding together the semi-finished parts 3 and 3 ′′ in the form of squared timbers 50 ′ or steel beams, which have the same effect as the ring 50 according to FIG. 6a.

- Another advantage is that the lost formwork has more weight; this means that when filling in the lost formwork, floating when concreting or shaking is less likely to occur, since the additional weight of the steel girders or wooden bars 50 'increases the dead weight.

- tie rod 52 can be a structural steel (round steel), which is secured on both sides with a formwork turnbuckle, not shown.

- FIG. 6c a double-row arrangement of the perforations 19 is also shown in the lower right area, which are preferably always in the area of the conical indentations 6. This results in an improved adjustment and an additional hold.

- this frame 40 is fixed on the inside at least in the areas of the adjoining ends of the beams 3 and the angle pieces 3 ′′ with Torkret 7 or 7 ′ or with mortar. This advantageously ensures that the lost formwork 2 is rigid and is dimensionally stable and does not float when filled with product.

- the lost formwork 2 can be filled with filling material 12, for example in the form of concrete, lightweight concrete or other building materials, according to FIG. 8.

- these frames can be filled as a molding box for brick assembly blocks. Furthermore, this frame can be used as a molding box for brick assembly modules, or other modules or for all kinds of contents.

- the part now set according to FIG. 8 is a prefabricated component 1 which can be used for buildings 20 of any kind.

- FIG. 9 shows a section along the line IX-IX in FIG. 1.

- the conical indentations 6 of the semi-finished parts 3 lying opposite one another create a space which can be fitted with displacement aids, for example in the form of reinforcing bars 15.

- potting compound 14 is introduced into this intermediate space, which connects the two adjacent semi-finished parts 3 and thus the components 1 to one another.

- FIG. 10 there is also the possibility of providing a part as molded formwork 10 "which has two level surfaces 33 and 34 which are offset in height and which are connected to one another by an inclined surface 35. Furthermore, analogous to the embodiment according to FIG. 2a, one is in the end region Boundary wall 30 is provided.

- this semi-finished part 3 ' can be created, which serves as part of the lost formwork 2 for the manufacture of a ceiling slab 1' according to Fig. 1.

- this semi-finished part 3 ' with stiffeners 5, loops 9, for Transport and for connection as well as provided with adjustments 17.

- Fig. 11 shows a semi-finished part 3 in the foot area.

- a, for example continuous, horizontal metal profile 13 is arranged in the conical indentation 6, which has a height-adjustable element, for example in the form of a screw, in the lower region. This makes it possible to adjust the component 1 in a functionally correct manner with respect to the floor.

- Fig. 12 shows two abutting ends of semi-finished parts 3 ', as they were created by the formwork according to Fig. 2c. As can be seen, there is a large space which is filled with potting compound 14 and with auxiliary displacement devices 15 and reinforcements 5.

- the potting compound 14 can serve as a load-bearing support.

- auxiliary displacement devices 13 and 15 serve as a substructure or as fastening devices for protective and working scaffolds or as fastening devices for hoists of all types in order to be able to move the components 1 and 1 'accordingly.

- light concrete for example, can alternatively be provided for filling concrete or mortar, which has the advantage that the outer walls have no cold bridges, i. H. the parts have an insulating effect, in particular heat insulation.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Electromagnetism (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Physics & Mathematics (AREA)

- Rod-Shaped Construction Members (AREA)

- Forms Removed On Construction Sites Or Auxiliary Members Thereof (AREA)

- Residential Or Office Buildings (AREA)

- Panels For Use In Building Construction (AREA)

- Conveying And Assembling Of Building Elements In Situ (AREA)

- Road Signs Or Road Markings (AREA)

- Drying Of Solid Materials (AREA)

- Moulds, Cores, Or Mandrels (AREA)

- Building Environments (AREA)

- Buildings Adapted To Withstand Abnormal External Influences (AREA)

- On-Site Construction Work That Accompanies The Preparation And Application Of Concrete (AREA)

Abstract

Description

Die Erfindung bezieht sich auf ein Bauwerk, bestehend aus vorgefertigten Bauteilen, wobei diese Bauteile, insbesondere Wand- und Deckenplatten, mit Hilfe einer verlorenen Schalung gefertigt sind, und diese verlorene Schalung aus Halbfertigteilen hergestellt ist.The invention relates to a building consisting of prefabricated components, these components, in particular wall and ceiling panels, being manufactured with the aid of a lost formwork, and this lost formwork being produced from semi-finished parts.

Als Stand der Technik ist es bereits bekannt (GB-A-683767; FR-A-2206420), Bauwerke aus vorgefertigten Teilen zu erstellen. Der Aufbau derartiger Bauwerke erfolgt schnell, ist jedoch zumeist kostenaufwendig. Diese Kosten setzen sich aus hohen Lohnkosten, Vorhaltungskosten für Schalung, Hebezeug, Transportkosten und sonstigen Nebenkosten zusammen.It is already known as prior art (GB-A-683767; FR-A-2206420) to build structures from prefabricated parts. The construction of such structures is quick, but is usually expensive. These costs consist of high labor costs, maintenance costs for formwork, hoists, transport costs and other ancillary costs.

Demgegenüber liegt der vorliegenden Erfindung die Aufgabe zugrunde, ein Bauwerk der eingangs genannten Art zu schaffen, welches unter wirtschaftlichen Gesichtspunkten schnell und preisgünstig aufzubauen ist und trotzdem eine hohe Lebensdauer besitzt.In contrast, the present invention has for its object to provide a structure of the type mentioned, which can be constructed quickly and inexpensively from an economic point of view and still has a long service life.

Diese Aufgabe wird mit den Merkmalen des Anspruchs 1 gelöst. Hierdurch ergibt sich der Vorteil, daß das aus vorgefertigten Bauteilen bestehende Bauwerk schnell und preisgünstig zu erstellen ist, da die vorgenannten Kosten erheblich reduziert werden. Je weniger Schalung z.B. erforderlich ist, desto weniger Vorhaltekosten fallen für diese Schalungen an. Weiterhin liegen gegenüber dem bekannten Stand der Technik weniger Ein- und Ausschalungsflächen vor, woraus eine Reduzierung der Lohnkosten resultiert.This object is achieved with the features of

Die Halbfertigteile werden vorteilhafterweise liegend auf Schalung, möglichst im Bereich der Baustelle, in handlichen Formaten erstellt. Diese Halbfertigteile können in unterschiedlichen Abmessungen vorliegen, welche so leicht sind, daß sie von Hand zu transportieren sind. Anschließend, wenn der Mörtel bzw. Torkret-Beton abgebunden sind, werden die Halbfertigteile zu einer verlorenen Schalung zusammengesetzt.The semi-finished parts are advantageously made lying on formwork, if possible in the area of the construction site, in handy formats. These semi-finished parts can be of different dimensions, which are so light that they can be transported by hand. Then, when the mortar or Torkret concrete has set, the semi-finished parts are put together to form a lost formwork.

Damit diese Halbfertigteile genügend biegesteif sind, erhalten sie vorteilhafterweise eine Bewehrung aus Baustahl. Um weiterhin die einzelnen Halbfertigteile leichter und genauer ausrichten zu können, sind sie vorzugsweise mit Justierungen versehen, beispielsweise in Form von Hülsen und Dornen, Nut und Feder. Für Öffnungen für Türen, Fenster, Aussparungen usw. werden ebenfalls entsprechende Halbfertigteile in die verlorene Schalung eingesetzt.So that these semi-finished parts are sufficiently rigid, they are advantageously reinforced with reinforcement made of structural steel. In order to be able to align the individual semi-finished parts more easily and precisely, they are preferably provided with adjustments, for example in the form of sleeves and spikes, tongue and groove. Corresponding semi-finished parts are also inserted into the lost formwork for openings for doors, windows, recesses etc.

Die aufgestellten und ausgerichteten Halbfertigteile werden mit Draht oder Anschlußbewehrung verbunden und dann an den Verbindungsstellen torkretiert bzw. mit Mörtel fixiert. Hat das Torkret-Material bzw. der Mörtel abgebunden, so kann die verlorene Schalung mit Füllgut, wie Beton, Leichtbeton oder sonstigen Baustoffen aufgefüllt werden. Es besteht auch die Möglichkeit, daß die verlorene Schalung als Formkasten für Ziegelmontage-Bausteine bzw. für sonstige Bausteine oder verschiedenartiges Füllgut dient. Das so erstellte Teil ist ein vorgefertigtes Bauteil, insbesondere Wand-, Decken- oder Dachplatte für Bauwerke aller Art.The erected and aligned semi-finished parts are connected with wire or connecting reinforcement and then gate-locked at the connection points or fixed with mortar. If the Torkret material or mortar has set, the lost formwork can be filled with filling material such as concrete, lightweight concrete or other building materials. There is also the possibility that the lost formwork is used as a molding box for brick assembly blocks or for other blocks or various types of filling material. The part created in this way is a prefabricated component, in particular wall, ceiling or roof panels for buildings of all kinds.

Die Halbfertigteile zur Herstellung der verlorenen Schalung weisen Profilierungen, vorzugsweise konische Einbuchtungen auf, welche Platz für konstruktive Bewehrung und Vergußmasse sowie für Versetzhilfsvorrichtungen bieten. Diese Versetzhilfsvorrichtungen können durchlaufende, waagerechte Metallprofile mit höhenverstellbaren Elementen, beispielsweise Schrauben sein, Armierungseisen oder auch Profilstahl zum senkrecht verlaufenden Ausrichten der vorgefertigten Bauteile und zur Kippsicherung wie komplette Versetzlehren zum kompletten Ausrichten der vorgefertigten Bauteile in jeder gewünschten Lage, beispielsweise auch in Schräglage.The semi-finished parts for the production of the lost formwork have profiles, preferably conical indentations, which offer space for structural reinforcement and potting compound as well as for displacement aids. These displacement aids can be continuous, horizontal metal profiles with height-adjustable elements, for example screws, reinforcing bars or profiled steel for the vertical one Aligning the prefabricated components and to prevent them from tipping over, such as complete offset gauges for completely aligning the prefabricated components in any desired position, for example in an inclined position.

Ein rascherer Arbeitsablauf kann alternativ dadurch erzielt werden, daß um die gesamte Schalung im Außenbereich ein Bandeisen angelegt wird, welches vorzugsweise in der konischen Nut der Halbfertigteile liegt. Bei ausreichender Dimensionierung des Bandeisens kann dann sofort mit dem Auffüllen des Schalungselements begonnen werden. Damit spart man die Abbindezeit des Torkretierens der Verbindungspunkte.A faster workflow can alternatively be achieved by placing a band iron around the entire formwork in the outer area, which is preferably located in the conical groove of the semi-finished parts. If the band iron is sufficiently dimensioned, the formwork element can be filled up immediately. This saves the setting time of locking the connection points.

Statt des Bandeisens besteht alternativ darüberhinaus die Möglichkeit, die Halbfertigteile mit Hilfe von Kanthölzern oder Stahlträgern zusammenzuhalten. Dadurch kann am gleichen Tage bzw. unmittelbar danach das betreffende Teil aufgefüllt werden. Ein weiteres Merkmal gibt sich daraus, daß das Halbfertigteil bzw. die verlorene Schalung mehr Eigengewicht aufweist als bei bisher bekannten Konstruktionen. Das bedeutet, daß beim Ausfüllen der verlorenen Schalung ein Aufschwimmen beim Betonieren bzw. Rütteln weniger leicht entsteht, da durch das zusätzliche Gewicht der Stahlträger oder Holzriegel das Eigengewicht erhöht wird.Instead of strip iron, there is also the alternative of holding the semi-finished parts together with the help of squared timber or steel girders. This allows the part in question to be refilled on the same day or immediately thereafter. Another feature is that the semi-finished part or the lost formwork has more weight than in previously known constructions. This means that when filling in the lost formwork, floating when concreting or shaking is less likely to occur, since the additional weight of the steel girders or wooden bars increases their own weight.

Bei sehr langen verlorenen Schalungen besteht alternativ im Rahmen der Erfindung die Möglichkeit, daß man in gewissen Abständen einen Zuganker anbringt, damit ein Abknicken der Seitenwände verhindert wird. Dieser Zuganker kann beispielsweise aus Baustahl gefertigt sein (Rundstahl), der beidseitig mit einem Schalungsspannschloß gesichert wird.In the case of very long, lost formwork, there is an alternative within the scope of the invention that a tie rod is attached at certain intervals, so that the side walls are prevented from kinking. This tie rod can, for example, be made of structural steel (round steel), which is secured on both sides with a formwork turnbuckle.

In weiterer Ausgestaltung der Erfindung können die Halbfertigteile jeweils an den Ecken auf Gehrung eingeschalt werden, so daß sie auch auf Gehrung zusammengesetzt werden. Damit läßt sich vorteilhafterweise das Teil ohne Eckstücke fertigen. Dieses Vorgehen hat den Vorteil, daß Anwender die einzelnen Teile vereinfacht aneinander fügen können.In a further embodiment of the invention, the semi-finished parts can be mitered at the corners, so that they can also be mitred. This allows the part to be advantageously manufactured without corner pieces. This The advantage of this procedure is that users can simply put the individual parts together.

Nach einem weiteren Merkmal der Erfindung kann zur Herstellung der Halbfertigteile alternativ für Füllbeton oder Mörtel Leichtbeton vorgesehen werden, was den Vorteil hat, daß die Außenwände keine Kältebrücken haben, d. h. die einzelnen Teile wirken wärmeisolierend.According to a further feature of the invention, light concrete can alternatively be provided for the production of the semi-finished parts for filling concrete or mortar, which has the advantage that the outer walls have no cold bridges, i. H. the individual parts have a heat-insulating effect.

Zur Verbindung der einzelnen Halbfertigteile bzw. zur paßgenauen Justierung können an den Enden in weiterer Ausgestaltung der Erfindung Einbuchtungen bzw. Ausnehmungen vorgesehen sein, in welche paßgenau Flacheisen oder Rundstahl beim Zusammenbau der Teile eingelegt werden.To connect the individual semi-finished parts or for precise adjustment, indentations or recesses can be provided at the ends in a further embodiment of the invention, into which flat iron or round steel are inserted with a precise fit when the parts are assembled.

Weiterhin besteht die Möglichkeit, an den Enden der Halbfertigteile Lochungen vorzusehen, welche durch die ganze Wandstärke der Teile durchgehen und vorzugsweise im Bereich der konischen Einbuchtungen liegen. Beim Zusammenbau der Halbfertigteile wird dann durch die Lochungen ein Stahlbügel aus Rundstahl (U-förmig) gebogen; auf der Innenseite der Schalung werden die Enden der Bügel dann umgebogen und halten so die Teile zusammen.There is also the possibility of providing perforations at the ends of the semi-finished parts, which pass through the entire wall thickness of the parts and are preferably in the region of the conical indentations. When assembling the semi-finished parts, a steel bracket made of round steel (U-shaped) is then bent through the perforations; the ends of the brackets are then bent over on the inside of the formwork and thus hold the parts together.

Es besteht hierbei die Möglichkeit einer doppelreihigen Anordnung der Lochungen, und zwar vorzugsweise im Bereich der konischen Einbuchtungen, woraus eine verbesserte Justierung und ein besserer Halt resultiert.There is the possibility of a double-row arrangement of the perforations, preferably in the area of the conical indentations, which results in an improved adjustment and a better hold.

Die Erfindung wird nachfolgend anhand von in der Zeichnung dargestellten Ausführungsbeispielen näher beschrieben. In der Zeichnung zeigen:

- Fig. 1

- eine perspektivische Ansicht eines schematisch dargestellten Bauwerkes

- Fig. 2a

- eine Seitenansicht eines in einer Formschalung angeordneten Halbfertigteils im senkrechten Mittelschnitt

- Fig. 2b

- eine Draufsicht auf das Halbfertigteil nach Fig. 2a, teils gebrochen

- Fig. 2c

- ein in einer Formschalung angeordnetes Halbfertigteil im senkrechten Mittelschnitt in anderer Ausführungsform

- Fig. 3

- ein als Winkelstück ausgebildetes Halbfertigteil in perspektivischer Ansicht

- Fig. 3a

- eine andere Ausführungsmöglichkeit der Gestaltung des Winkelstückes in perspektivischer Ansicht

- Fig. 4

- ein als Balken ausgebildetes Halbfertigteil in perspektivischer Ansicht

- Fig. 4a

- eine weitere Ausführungsmöglichkeit des als Balken ausgebildeten Halbfertigteils in perspektivischer Ansicht

- Fig. 5

- ein aus Halbfertigteilen hergestellter Rahmen in perspektivischer Ansicht

- Fig. 5a

- ein aus Halbfertigteilen hergestellter Rahmen in perspektivischer Ansicht in weiterer Ausführungsmöglichkeit

- Fig. 6

- eine nähere Darstellung des Rahmens nach Fig. 5 in perspektivischer Ansicht

- Fig. 6a,b,c

- verschiedene Ausführungsmöglichkeiten des Rahmens in perspektivischer Darstellung

- Fig. 7

- ein nach Fig. 5 und 6 erstellter Rahmen, bestehend aus Halbfertigteilen mit an den Verbindungsstellen mit Torkret-Beton bzw. Mörtel versehene Fixierung, in perspektivischer Ansicht

- Fig. 8

- ein aus Halbfertigteilen bestehendes Bauteil gemäß der vorliegenden Erfindung in perspektivischer Ansicht, teils gebrochen

- Fig. 9

- einen Schnitt gemäß der Linie IX - IX in Fig. 1

- Fig. 10

- ein in einer Formschalung angeordnetes Halbfertigteil, welches als Deckenplatte einsetzbar ist, senkrecht geschnitten

- Fig. 11

- einen Schnitt durch ein Halbfertigteil und eine Wandplatte, im Bodenbereich, mit Justierelementen, senkrecht geschnitten

- Fig. 12

- ein waagrechter Schnitt durch zwei aneinander grenzende Enden von Halbfertigteilen und Wandplatten gemäß Fig. 2c

- Fig. 1

- a perspective view of a schematically illustrated building

- Fig. 2a

- a side view of a semi-finished part arranged in a formwork in the vertical central section

- Fig. 2b

- a plan view of the semi-finished part of FIG. 2a, partly broken

- Fig. 2c

- a semi-finished part arranged in a formwork in the vertical center section in another embodiment

- Fig. 3

- a semi-finished part designed as an elbow in perspective view

- Fig. 3a

- another embodiment of the design of the elbow in a perspective view

- Fig. 4

- a semi-finished part designed as a bar in a perspective view

- Fig. 4a

- a further embodiment of the semi-finished part designed as a bar in a perspective view

- Fig. 5

- a perspective view of a frame made from semi-finished parts

- Fig. 5a

- a frame made of semi-finished parts in a perspective view in another embodiment

- Fig. 6

- a closer view of the frame of FIG. 5 in a perspective view

- 6a, b, c

- different execution options of the frame in perspective

- Fig. 7

- 5 and 6 created frame, consisting of semi-finished parts with fixation provided at the joints with Torkret concrete or mortar, in a perspective view

- Fig. 8

- a component consisting of semi-finished parts according to the present invention in perspective view, partly broken

- Fig. 9

- a section along the line IX - IX in Fig. 1st

- Fig. 10

- a semi-finished part arranged in a formwork, which can be used as a ceiling slab, cut vertically

- Fig. 11

- a section through a semi-finished part and a wall plate, in the floor area, with adjustment elements, cut vertically

- Fig. 12

- a horizontal section through two adjacent ends of semi-finished parts and wall panels according to FIG. 2c

In Fig. 1 ist schematisch ein Bauwerk 20 dargestellt, welches aus mit Hilfe einer verlorenen Schalung 2 vorgefertigten Bauteilen 1 bzw. 1' besteht. Diese verlorene Schalung 2 ist aus Halbfertigteilen 3 bzw. 3' bzw. 3" hergestellt, wobei diese in den nachfolgenden Figuren noch näher dargestellten Halbfertigteile nur die Stirnseiten bzw. Schmalseiten der vorgefertigten Bauteile 1 bzw. 1' bilden.In Fig. 1, a

Diese Bauteile 1 können mit Ausschnitten 18 für Fenster bzw. 18' für Türen versehen sein. Jeder dieser Bauteile 1 weist eine später noch näher beschriebene konische Einbuchtung 6 auf, welche mit Vergußmasse 14 verfüllbar ist.These

Weiterhin können im Bereich der verlorenen Schalung 2 Versetzhilfsvorrichtungen 15 angeordnet sein, welche beispielsweise als aus Baustahl bestehende Zapfen über die jeweiligen Bauteile 1 hinausragen und als Armierungseisen dienen. Die Deckenkonstruktion des Bauwerks 20 kann ebenfalls erfindungsgemäß aus vorgefertigten Bauteilen 1' bestehen, welche wiederum so gestaltet ist, daß die verlorene Schalung aus Halbfertigteilen hergestellt ist, wobei diese Halbfertigteile wiederum nur an den Stirn- bzw. Schmalseiten der vorgefertigten Bauteile 1' Anwendung finden. Jedes dieser Bauteile 1' weist hierbei eine noch später näher beschriebene Einbuchtung 6' auf. Zwei aneinander grenzende Einbuchtungen 6' benachbarter Bauteile 1' bilden damit einen Raum, welcher mit Vergußmasse 14 verfüllbar ist.Furthermore, in the area of the lost

In Fig. 2a ist im senkrechten Schnitt die Erstellung eines Halbfertigteils 3 dargestellt: Wie erkennbar, findet eine Formschalung 10 Anwendung, welche im Querschnitt zwei ebene Flächen 25 und 26 aufweist. Innenseitig gehen diese zwei Flächen zwischen 25 und 26 in zwei zueinander geneigte Flächen 27 und 28 über, welche im oberen Bereich durch eine weitere ebene Fläche 29 begrenzt sind. Die Flächen 27, 28 und 29 dienen dazu, für das Halbfertigteil 3 eine Profilierung in Form einer konischen Einbuchtung 6 zu schaffen. Diese konische Einbuchtung dient zur Aufnahme von Vergußmasse 14 bzw. von in Fig. 1 dargestellten Versetzhilfsvorrichtungen 15.In Fig. 2a, the creation of a

Die Formschalung 10 ist an ihren Endbereichen durch Begrenzungswände 30 begrenzt. In diese Formschalung 10 wird Mörtel 4 bzw. Torkret-Beton eingebracht, wobei außerdem Bewehrungen 5 aus Baustahl sowie Justierelemente 17 in dieses Material eingebettet sind. Weiterhin können gemäß Fig. 2a bzw. 2b an den Enden Verbindungs- bzw. Transportschlaufen 9 in das Material 4 eingebettet sein.The

Bei der Ausführungsform nach Fig. 2c kann die Formschalung 10' so gestaltet sein, daß sie im wesentlichen zwei rechtwinklig zueinander stehende Flächen 31 und 32 aufweist, welche von Seitenwänden 30 begrenzt sind. Wiederum wird in diese Formschalung 10' Mörtel bzw. Torkret eingegossen, wobei Bewehrungen 5 aus Baustahl, Verbindungs- bzw. Transportschlaufen 9 und Justierelemente in Form von Hülsen 17 in das Material eingebettet sind.In the embodiment of Fig. 2c, the formwork 10 'can be designed so that it is essentially two at right angles faces 31 and 32 which are in relation to one another and are delimited by

Nachdem der Mörtel 4 bzw. der Torkret abgebunden hat, lassen sich die Halbfertigteile 3 aus der jeweiligen Formschalung 10 bzw. 10' entnehmen.After the mortar 4 or the door scrub has set, the

Nach Fig. 4 liegt hierbei beispielsweise als Halbfertigteil 3 ein Balken vor, welcher in den Endbereichen die Verbindungs-bzw. Transportschlaufen 9 aufweist und außenseitig mit den konischen Einbuchtungen 6 versehen ist.According to FIG. 4, there is, for example, a bar as a

Nach Fig. 3 und 5 besteht auch die Möglichkeit, die Halbfertigteile 3" als Winkelstücke 8 auszubilden, wiederum mit den entsprechenden konischen Einbuchtungen 6, mit Schlaufen 9 sowie mit Justierungen 17. Fig. 3a und Fig. 4a zeigen Aussparungen 17', welche jeweils in den Endbereichen der Halbfertigteile 3 bzw. 3'' eingearbeitet sind. Paßgenau können Profilelemente 17'', beispielsweise aus Flacheisen oder Rundstahl beim Zusammenbau der Teile eingelegt werden; sie ersetzen oder ergänzen die Justierungen 17.According to FIGS. 3 and 5, there is also the possibility of designing the

Die Winkelstücke 8, welche aus den Halbfertigteilen 3" sowie die Balken, welche aus den Halbfertigteilen 3 gebildet sind, lassen sich nach Fig. 5 zu einem Rahmen 40 (verlorene Schalung 2) zusammensetzen. Dieser Rahmen 40 ist in Fig. 6 näher dargestellt: wie ersichtlich, können an den Enden der Winkelstücke 8 bzw. der Balken die Schlaufen 9 über Verbindungen 11 in Form von Baustahl oder von Draht miteinander verbunden werden, so daß sich insgesamt ein vorläufig erstellter Rahmen 40 ergibt, welcher außenseitig z.B. rundherum mit der konischen Einbuchtung 6 versehen ist und die verlorene Schalung 2 darstellt.The

Nach Fig. 5a läßt sich der Rahmen (verlorene Schalung 2) auch so gestalten, daß nur noch Halbfertigteile 3 Anwendung finden, welche jeweils an den Ecken auf Gehrung eingeschalt werden, so daß sie auch auf Gehrung zusammengesetzt sind. Damit läßt sich der Rahmen 40 vorteilhafterweise ohne die Eckstücke fertigen. Dieses Vorgehen hat den Vorteil, daß Anwender auf vereinfachte Weise die Halbfertigteile 3 zu dem Rahmen 40 zusammenfügen lassen.According to Fig. 5a, the frame (lost formwork 2) can also be designed so that only

Dieser Rahmen ist alternativ in Fig. 6a im einzelnen dargestellt: Diese Figur zeigt eine verlorene Schalung, welche aus den Halbfertigteilen 3 bzw. 3" zusammengesetzt und mit Verbindungen 11 über die Schlaufe 9 miteinander verbunden ist. Ist ein rascherer Arbeitsablauf erwünscht, so kann alternativ zu Fig. 6 um die gesamte Schalung im Außenbereich ein Bandeisen 50 angelegt werden, welches die Halbfertigteile wie ein Ring zusammenhält. Dieser Ring liegt vorzugsweise in einer Nut 51, d. h. der konischen Einbuchtung 6 der Halbfertigteile 3 bzw. 3''.This frame is alternatively shown in detail in Fig. 6a: This figure shows a lost formwork, which is composed of the

Bei ausreichender Dimensionierung des Rings 50 kann dann sofort mit dem Auffüllen des Schalungselements begonnen werden. Damit spart man die Abbindezeit des Torkretierens der Verbindungspunkte im Bereich der Elemente 9 und 11.If the

Nach Fig. 6b besteht alternativ auch die Möglichkeit des Zusammenfügens bzw. ringartigen Zusammenhaltens der Halbfertigteile 3 und 3'' in Form von Kanthölzern 50' oder Stahlträgern, welche den gleichen Effekt haben wie der Ring 50 nach Fig. 6a. Damit ergibt sich vorteilhafterweise ein Zusammenhalten der Halbfertigteile, so daß am gleichen Tag bzw. unmittelbar danach das Teil aufgefüllt bzw. betoniert werden kann. Ein weiterer Vorteil besteht hierbei darin, daß die verlorene Schalung mehr Eigengewicht aufweist; das bedeuted, daß beim Ausfüllen der verlorenen Schalung ein Aufschwimmen beim Betonieren bzw. Rütteln weniger leicht ent-steht, da durch die zusätzlichen Gewichte der Stahlträger oder Holzriegel 50' das Eigengewicht erhöht wird.According to FIG. 6b there is alternatively also the possibility of joining or holding together the

Bei sehr langen verlorenen Schalungen ist es sinnvoll, nach Fig. 6b in gewissen Abständen einen Zuganker 52 anzubringen, damit ein Ausknicken der Seitenwände der Halbfertigteile 3 bzw. 3' verhindert wird. Dieser Zuganker 52 kann ein Baustahl (Rundstahl) sein, welcher beidseitig mit einem nicht näher dargestellten Schalungsspannschloß gesichert wird.In the case of very long lost formwork, it makes sense to attach a

Nach Fig. 6c besteht die Möglichkeit, an den Enden der Halbfertigteile Lochungen 19 anzubringen, welche durch die ganze Wandstärke der Halbfertigteile hindurchgehen und vorzugsweise jeweils im Bereich der konischen Einbuchtungen 6 liegen.According to FIG. 6 c, there is the possibility of making

Beim Zusammenbau der Halbfertigteile 3 udn 3" wird dann durch die Lochungen ein Stahlbügel 11' aus Rundstahl (U-förmig gebogen) geschoben; auf der Innenseite der Schalung 40 werden die Enden der Stahlbügel 11' umgebogen und halten so die Halbfertigteile zusammen. Damit können die in Fig. 6 dargestellten Schlaufen 9 und Verbindungen 11 entfallen.When assembling the

In Fig. 6c ist im rechten unteren Bereich auch eine doppelreihige Anordnung der Lochungen 19 dargestellt, welche vorzugsweise stets im Bereich der konischen Einbuchtungen 6 liegen. Es ergibt sich hier eine verbesserte Justierung und ein zusätzlicher Halt.In FIG. 6c, a double-row arrangement of the

Nach Fig. 7 wird dieser Rahmen 40 innenseitig mindestens in den Bereichen der aneinander grenzenden Enden der Balken 3 und der Winkelstücke 3" mit Torkret 7 bzw. 7' bzw. mit Mörtel fixiert. Hierdurch wird vorteilhafterweise erreicht, daß die verlorene Schalung 2 biegesteif und formbeständig wird und beim Auffüllen mit Füllgut nicht aufschwimmt.7, this

Hat nun das Torkret-Material 7 bzw. 7' bzw. der Mörtel abgebunden, kann nach Fig. 8 die verlorene Schalung 2 mit Füllgut 12, beispielsweise in Form von Beton, Leichtbeton oder sonstigen Baustoffen, aufgefüllt werden.If the Torkret material 7 or 7 'or the mortar has set, the lost

Es besteht auch die Möglichkeit, daß diese Rahmen als Formkasten für Ziegelmontage-Bausteine aufgefüllt werden. Weiterhin kann dieser Rahmen als Formkasten für Ziegelmontage-Bausteine, oder sonstige Bausteine bzw. für Füllgut aller Art dienen.There is also the possibility that these frames can be filled as a molding box for brick assembly blocks. Furthermore, this frame can be used as a molding box for brick assembly modules, or other modules or for all kinds of contents.

Das nach Fig. 8 nun abgebundene Teil ist ein vorgefertigtes Bauteil 1, welches für Bauwerke 20 jeglicher Art verwendbar ist.The part now set according to FIG. 8 is a

Fig. 9 zeigt einen Schnitt gemäß der Linie IX - IX in Fig. 1. Wie ersichtlich, wird durch die einander gegenüber liegenden konischen Einbuchtungen 6 der Halbfertigteile 3 ein Raum geschaffen, welcher mit Versetzhilfsvorrichtungen, beispielsweise in Form von Armierungseisen 15 bestückt werden kann. Weiterhin wird in diesen Zwischenraum Vergußmasse 14 eingebracht, welche die beiden aneinander grenzenden Halbfertigteile 3 und damit die Bauteile 1 miteinander verbindet.FIG. 9 shows a section along the line IX-IX in FIG. 1. As can be seen, the

Nach Fig. 10 besteht auch die Möglichkeit, als Formschalung 10" ein Teil vorzusehen, welches zwei höhenmäßig versetzte ebene Flächen 33 und 34 aufweist, die durch eine Schrägfläche 35 miteinander verbunden sind. Weiterhin ist analog der Ausführungsform gemäß Fig. 2a jeweils im Endbereich eine Begrenzungswand 30 vorgesehen.According to FIG. 10, there is also the possibility of providing a part as molded

Mit Hilfe dieser Formschalung 10" läßt sich ein Halbfertigteil 3' erstellen, welches als Teil der verlorenen Schalung 2 zur Herstellung einer Deckenplatte 1' gemäß Fig. 1 dient. Analog den vorgenannten Ausführungen ist dieses Halbfertigteil 3' mit Versteifungen 5, Schlaufen 9, zum Transport und zur Verbindung sowie mit Justierungen 17 versehen. Nachdem der Mörtel 4 in der Formschalung 10" abgebunden hat, läßt sich dieses Halbfertigteil 3' aus der Formschalung 10" herausheben und kann, da mit der Einbuchtung 6' und den anderen Elementen versehen, die Basis zur Erstellung eines Bauteils 1' bilden, und zwar analog den Ausführungen zu Fig. 3 - Fig. 8 .With the help of this

Fig. 11 zeigt ein Halbfertigteil 3 im Fußbereich. Wie ersichtlich, ist in der konischen Einbuchtung 6 ein beispielsweise durchlaufendes, waagrechtes Metallprofil 13 angeordnet, welches im unteren Bereich ein höhenverstellbares Element, beispielsweise in Form einer Schraube, besitzt. Hierdurch ist es möglich, das Bauteil 1 gegenüber dem Boden funktionsrichtig zu justieren.Fig. 11 shows a

Fig. 12 zeigt zwei aneinanderstoßende Enden von Halbfertigteilen 3', wie sie durch die Formschalung nach Fig. 2c erstellt wurden. Wie ersichtlich, liegt ein großer Zwischenraum vor, welcher mit Vergußmasse 14 sowie mit Versetzhilfsvorrichtungen 15 und Bewehrungen 5 aufgefüllt wird. Hierbei kann die Vergußmasse 14 als tragende Stütze dienen.Fig. 12 shows two abutting ends of semi-finished parts 3 ', as they were created by the formwork according to Fig. 2c. As can be seen, there is a large space which is filled with potting

Weiterhin besteht bei allen Bauformen die Möglichkeit, daß die Versetzhilfsvorrichtungen 13 bzw. 15 als Unterkonstruktion bzw. als Befestigungsvorrichtungen für Schutz- und Arbeitsgerüste bzw. als Befestigungsvorrichtungen für Hebezeuge aller Art dienen, um die Bauteile 1 bzw. 1' entsprechend versetzen zu können.Furthermore, there is the possibility in all designs that the

Zur Herstellung der Halbfertigteile, wie sie in den Fig. 2a, 2b und 2c dargestellt sind, kann alternativ für Füllbeton oder Mörtel beispielsweise Leichtbeton vorgesehen werden, was den Vorteil hat, daß die Außenwände keine Kältebrücken besitzen, d. h. die Teile wirken isolierend, insbesondere wärmeisolierend.For the production of the semi-finished parts, as shown in FIGS. 2a, 2b and 2c, light concrete, for example, can alternatively be provided for filling concrete or mortar, which has the advantage that the outer walls have no cold bridges, i. H. the parts have an insulating effect, in particular heat insulation.

Insgesamt ergibt sich damit mit Hilfe der in Formschalungen 10 bzw. 10' bzw. 10" hergestellten Halbfertigteile 3 bzw. 3' bzw. 3" die Möglichkeit der Erstellung von Bauteilen 1 bzw. 1', welche mit geringen Kosten zu produzieren sind und damit insgesamt zur Reduzierung der Kosten eines Bauwerkes 20 beitragen.All in all, with the help of the

Claims (14)

- A structure (20), consisting of prefabricated components (1, 1'), these components, in particular wall and ceiling slabs, having been produced with the aid of a lost mould (2) and this lost mould (2) being produced from semi-finished parts (3, 3', 3''),

characterised in thatthe semi-finished parts are in the form of beams (3, 3') and angle pieces (3''),that the beams (3, 3') and the angle pieces (3'') are initially assembled by means of in each case at least one wire or structural steel connection (11) in the region of connecting loops (9) to form a frame (40) andthat the frame (40) is fixed on the inside at least in the region of the adjoining ends of the beams (3, 3') and of the angle pieces (3'') with Torcrete (7, 7') or with mortar (4). - A structure according to Claim 1, characterised in that the lost mould (2) can be filled with filler (12) once the Torcrete (7, 7') or the mortar (4) has set.

- A structure according to Claim 1, characterised in that the beams (3, 3') and the angle pieces (3'') are enclosed by a ring (50; 50') running around the external periphery.

- A structure according to Claim 1, characterised in that the ring (50) is made of steel strip.

- A structure according to Claims 3 and 4, wherein the beam and angle pieces each have a groove as a conical recess, characterised in that the ring (50) made from steel strip is arranged in the groove.

- A structure according to Claim 3, characterised in that the ring (50') is designed as a square timber or as a steel girder.

- A structure according to one or more of the preceding claims, characterised in that at least one tie rod (52) is arranged at least between the beams (3, 3') of the semi-finished parts.

- A structure according to Claim 7, characterised in that the tie rod (52) made of structural steel is fastened at at least one end to the adjoining beam by means of a mould turnbuckle.

- A structure according to Claim 1, characterised by perforations (19) made in the semi-finished parts (3, 3', 3'') at their adjoining ends for connecting loops (11') to pass through.

- A structure according to Claim 9, characterised in that the perforations (19) are arranged in the region of a circumambient groove (51) designed as a conical recess (6).

- A structure according to Claims 9 and 10, characterised by dual rows of perforations (19) at least in one region of the semi-finished parts (3, 3', 3'').

- A structure according to Claim 1, characterised in that the end regions of the semi-finished parts (3, 3', 3'') have recesses (17') into which profiled elements (17'') can be inserted when the semi-finished parts are assembled.

- A structure according to one or more of the preceding claims, characterised in that the semi-finished parts (3) are each mitred and assembled at the end regions.

- A structure according to one or more of Claims 1 to 13, characterised in that the semi-finished parts (3) are made from lightweight concrete.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE4411122 | 1994-03-30 | ||

| DE4411122A DE4411122A1 (en) | 1994-03-30 | 1994-03-30 | Building consisting of prefabricated components |

| PCT/DE1995/000355 WO1995027106A1 (en) | 1994-03-30 | 1995-03-15 | Structure consisting of prefabricated components |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0752033A1 EP0752033A1 (en) | 1997-01-08 |

| EP0752033B1 true EP0752033B1 (en) | 1997-12-03 |

Family

ID=6514286

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP95913027A Expired - Lifetime EP0752033B1 (en) | 1994-03-30 | 1995-03-15 | Structure consisting of prefabricated components |

Country Status (12)

| Country | Link |

|---|---|

| US (1) | US6105326A (en) |

| EP (1) | EP0752033B1 (en) |

| JP (1) | JPH09511297A (en) |

| KR (1) | KR100385012B1 (en) |

| CN (1) | CN1076776C (en) |

| AT (1) | ATE160836T1 (en) |

| AU (1) | AU2066695A (en) |

| CA (1) | CA2186729A1 (en) |

| DE (2) | DE4411122A1 (en) |

| DK (1) | DK0752033T3 (en) |

| ES (1) | ES2113193T3 (en) |

| WO (1) | WO1995027106A1 (en) |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AUPN715995A0 (en) * | 1995-12-14 | 1996-01-18 | Velstron Pty Ltd | A building system |

| US20030009963A1 (en) * | 2001-03-11 | 2003-01-16 | Crowell James H. | Building system, structure and method |

| AU2003248193B2 (en) * | 2003-09-22 | 2010-06-03 | Brent William Gray | Concrete wall assemblies |

| US7395999B2 (en) * | 2004-05-04 | 2008-07-08 | Polycrete Systems, Ltd | Reinforced polymer panel and method for building construction |

| DE102004060090B4 (en) * | 2004-12-13 | 2009-02-26 | Rolf Schmidt-Lutz | Component and method for its production |

| US20100090465A1 (en) * | 2008-10-15 | 2010-04-15 | Robert Eric Heidel | Process of installing prefabricated sections of pressurized and/or non-pressurized fluid-, utility-, and/or matter-carrying and encapsulated mediums with turbine systems attached into medium systems |

| CN101851979B (en) * | 2010-04-02 | 2012-11-14 | 清远市建巢工业设计有限公司 | Prefabricated reinforced concrete unit body for construction and method for building construction |

| US9428901B2 (en) * | 2012-05-14 | 2016-08-30 | Nev-X Systems Limited | Modular building system |

| JP6925634B2 (en) * | 2018-10-25 | 2021-08-25 | 国立大学法人 東京大学 | Building structures, structure construction systems, and construction methods for building structures |

| CN112962785A (en) * | 2021-02-03 | 2021-06-15 | 胡鹏 | Precast concrete hollow slab combined building and construction method thereof |

Family Cites Families (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2206350A (en) * | 1938-09-22 | 1940-07-02 | Clair S Gerlach | Building block |

| US2411011A (en) * | 1942-01-26 | 1946-11-12 | Arthur E Troiel | Means and method of grouting |

| BE489639A (en) * | 1948-06-16 | |||

| US2644997A (en) * | 1952-04-16 | 1953-07-14 | Billings Frank | Wall form |

| US3434263A (en) * | 1965-07-19 | 1969-03-25 | Keystone Consolidated Ind Inc | Shear link and method of using same |

| US3436886A (en) * | 1967-01-23 | 1969-04-08 | Commercial Builders Corp | Frame mounting in wall panel system |

| DE2209614A1 (en) * | 1972-02-29 | 1973-09-06 | Friedrich Dipl Ing Differenz | COMPOSITE COMPONENT OR - COMPONENT AND METHOD OF MANUFACTURING IT |

| US3828502A (en) * | 1972-09-08 | 1974-08-13 | Phelps Dodge Ind Inc | Modular wall section for buildings |

| FR2206420B1 (en) * | 1973-03-21 | 1976-05-07 | Segeba | |

| DE2407727A1 (en) * | 1974-02-18 | 1975-09-04 | Wilhelm Dankelmeier | Lightweight prefabricated-component building frame structure - comprising flat shaped-sections with central lengthways crease |

| US3996714A (en) * | 1975-08-11 | 1976-12-14 | Hazelett Jr Earl T | Panel wall structure |

| US4249354A (en) * | 1979-03-05 | 1981-02-10 | Wynn Gayle B | Reinforced insulated wall construction |

| FR2464340A1 (en) * | 1979-08-31 | 1981-03-06 | Entreprises Soc Gle | Wall slab to floor beam joint for precast concrete frame - has horizontal slab base with corner angle irons welded to bearing plates set in beam ends |

| CA1174824A (en) * | 1980-10-23 | 1984-09-25 | Sergio Iorio Peretto | Process for manufacturing a frame suitable for encasing a portion of an external wall and frames obtained thereby |

| US4532745A (en) * | 1981-12-14 | 1985-08-06 | Core-Form | Channel and foam block wall construction |

| DE8914861U1 (en) * | 1989-11-27 | 1990-07-26 | Stellamanns, Stefan, 3138 Dannenberg | Prefabricated element for building construction |

| US4970838A (en) * | 1990-01-05 | 1990-11-20 | Phillips Charles N | Reinforced concrete building and method of construction |

| DE9203276U1 (en) * | 1992-03-11 | 1993-07-15 | Peca-Verbundtechnik GmbH, 8312 Dingolfing | formwork |

| DE4229985A1 (en) * | 1992-09-08 | 1994-03-10 | Andreas Braun | Seal for abutting ends of prefab. wall elements in building - incorporates sealing members held in large rectangular section grooves in abutting wall ends |

| US5619823A (en) * | 1995-07-11 | 1997-04-15 | Ingersoll-Rand Co. | Pre-finished metal door frame |

-

1994

- 1994-03-30 DE DE4411122A patent/DE4411122A1/en not_active Withdrawn

-

1995

- 1995-03-15 KR KR1019960705538A patent/KR100385012B1/en not_active IP Right Cessation

- 1995-03-15 DK DK95913027T patent/DK0752033T3/en active

- 1995-03-15 WO PCT/DE1995/000355 patent/WO1995027106A1/en active IP Right Grant

- 1995-03-15 ES ES95913027T patent/ES2113193T3/en not_active Expired - Lifetime

- 1995-03-15 AU AU20666/95A patent/AU2066695A/en not_active Abandoned

- 1995-03-15 EP EP95913027A patent/EP0752033B1/en not_active Expired - Lifetime

- 1995-03-15 US US08/716,276 patent/US6105326A/en not_active Expired - Fee Related

- 1995-03-15 CN CN95192401A patent/CN1076776C/en not_active Expired - Fee Related

- 1995-03-15 CA CA002186729A patent/CA2186729A1/en not_active Abandoned

- 1995-03-15 DE DE59501079T patent/DE59501079D1/en not_active Expired - Fee Related

- 1995-03-15 AT AT95913027T patent/ATE160836T1/en not_active IP Right Cessation

- 1995-03-15 JP JP7525336A patent/JPH09511297A/en not_active Ceased

Also Published As

| Publication number | Publication date |

|---|---|

| CA2186729A1 (en) | 1995-10-12 |

| CN1076776C (en) | 2001-12-26 |

| DK0752033T3 (en) | 1998-08-10 |

| ES2113193T3 (en) | 1998-04-16 |

| ATE160836T1 (en) | 1997-12-15 |

| JPH09511297A (en) | 1997-11-11 |

| CN1145102A (en) | 1997-03-12 |

| WO1995027106A1 (en) | 1995-10-12 |

| US6105326A (en) | 2000-08-22 |

| DE4411122A1 (en) | 1995-10-05 |

| EP0752033A1 (en) | 1997-01-08 |

| KR970702407A (en) | 1997-05-13 |

| KR100385012B1 (en) | 2003-08-21 |

| AU2066695A (en) | 1995-10-23 |

| DE59501079D1 (en) | 1998-01-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2088244B1 (en) | Reinforced concrete or composite bridge and method for their production | |

| DE69913977T2 (en) | METHOD FOR PRODUCING A PANEL BOTTOM AND A PANEL BOTTOM | |

| EP0385923B1 (en) | Structural member for the construction of buildings, parts of buildings or the like | |

| EP0752033B1 (en) | Structure consisting of prefabricated components | |

| DE3403537A1 (en) | Prefabricated balcony-construction element for buildings | |

| DE68917560T2 (en) | Method for connecting a matrix material to a functional carrier and devices produced using this method. | |

| DE3432940A1 (en) | Prefabricated masonry structure | |

| DE2700022A1 (en) | Large prefabricated wall element - has vertical concrete pillars extending through holes to link top and bottom concreted chords | |

| DE4323011A1 (en) | Precast reinforced concrete component and building erected with it | |

| DE10321947B4 (en) | Method for erecting a wooden house or the like. Bauwerkes | |

| DE1299838B (en) | Prefabricated assembly skeleton construction made of prestressed concrete | |

| DE19941603C2 (en) | Reinforced concrete part for the production of foundations for buildings | |

| AT404950B (en) | PRECAST ELEMENTS FOR THE BUILDING OF BUILDINGS | |

| DE2636168C2 (en) | Buildings made from load-bearing prefabricated components | |

| DE60304547T2 (en) | Prefabricated reinforced concrete column and reinforced concrete beams | |

| DE69116333T2 (en) | MULTI-STOREY CAR PARK WITH FLOORS FROM PRE-FABRIC PANELS | |

| DE3873096T2 (en) | LOAD-BEARING HORIZONTAL STRUCTURE SYSTEM FOR A BUILDING. | |

| DE878702C (en) | Pre-fabricated reinforced concrete component in the form of a board or plank | |

| DE102021133372B3 (en) | construction system | |

| DE20215502U1 (en) | Steel composite construction for storey floors has steel box girder with upper flange and sides having openings for inserting of reinforcing elements and/or for introducing and compacting of concrete | |

| AT372734B (en) | CONSTRUCTION | |

| EP0698700B1 (en) | Floor construction and method for manufacturing the same | |

| DE3418313A1 (en) | Prefabricated element for a wall | |

| EP0104262A1 (en) | Composite self-supporting slab - product - method - device - application | |

| DE905883C (en) | Process for the production, in particular, of exterior and intermediate walls of buildings |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19961010 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE DK ES FR GB IT LI NL PT SE |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| 17Q | First examination report despatched |

Effective date: 19970303 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK ES FR GB IT LI NL PT SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 19971203 |

|

| REF | Corresponds to: |

Ref document number: 160836 Country of ref document: AT Date of ref document: 19971215 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 59501079 Country of ref document: DE Date of ref document: 19980115 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19980303 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19980303 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19980304 |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: KEMENY AG PATENTANWALTBUERO |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2113193 Country of ref document: ES Kind code of ref document: T3 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20030224 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20030317 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20030318 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20030321 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DK Payment date: 20030324 Year of fee payment: 9 Ref country code: CH Payment date: 20030324 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20030325 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20030326 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040315 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040315 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040316 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040331 Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040331 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040331 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040331 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20040525 Year of fee payment: 10 |

|

| BERE | Be: lapsed |

Owner name: *SCHMIDT-LUTZ ROLF Effective date: 20040331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20041001 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20040315 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20041130 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20041001 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20040316 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20051001 |