CN218093079U - Pushing system for tunneling construction of T-shaped contact channel of tunnel group - Google Patents

Pushing system for tunneling construction of T-shaped contact channel of tunnel group Download PDFInfo

- Publication number

- CN218093079U CN218093079U CN202221605897.7U CN202221605897U CN218093079U CN 218093079 U CN218093079 U CN 218093079U CN 202221605897 U CN202221605897 U CN 202221605897U CN 218093079 U CN218093079 U CN 218093079U

- Authority

- CN

- China

- Prior art keywords

- pull rod

- reaction frame

- jacking system

- force

- construction

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000010276 construction Methods 0.000 title claims abstract description 59

- 230000005641 tunneling Effects 0.000 title description 37

- 238000006243 chemical reaction Methods 0.000 claims abstract description 66

- 238000004891 communication Methods 0.000 claims abstract description 54

- 230000005540 biological transmission Effects 0.000 claims description 55

- 239000000463 material Substances 0.000 claims description 9

- 230000008878 coupling Effects 0.000 claims description 7

- 238000010168 coupling process Methods 0.000 claims description 7

- 238000005859 coupling reaction Methods 0.000 claims description 7

- 239000007858 starting material Substances 0.000 claims description 6

- 230000002441 reversible effect Effects 0.000 claims description 4

- 230000000149 penetrating effect Effects 0.000 claims description 3

- 238000012546 transfer Methods 0.000 abstract description 17

- 230000001360 synchronised effect Effects 0.000 abstract description 5

- 238000000034 method Methods 0.000 description 29

- 230000008569 process Effects 0.000 description 10

- 229910000831 Steel Inorganic materials 0.000 description 8

- 239000010959 steel Substances 0.000 description 8

- 238000010297 mechanical methods and process Methods 0.000 description 7

- 230000000694 effects Effects 0.000 description 5

- 238000006073 displacement reaction Methods 0.000 description 4

- 230000008014 freezing Effects 0.000 description 4

- 238000007710 freezing Methods 0.000 description 4

- 230000000977 initiatory effect Effects 0.000 description 4

- 238000004458 analytical method Methods 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 3

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 2

- 230000009471 action Effects 0.000 description 2

- 238000009412 basement excavation Methods 0.000 description 2

- 238000013461 design Methods 0.000 description 2

- 230000002452 interceptive effect Effects 0.000 description 2

- 230000007246 mechanism Effects 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 2

- 230000002411 adverse Effects 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 230000001427 coherent effect Effects 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 239000003673 groundwater Substances 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- 230000000670 limiting effect Effects 0.000 description 1

- 238000005065 mining Methods 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 230000003014 reinforcing effect Effects 0.000 description 1

- 230000000717 retained effect Effects 0.000 description 1

- 239000004576 sand Substances 0.000 description 1

Images

Landscapes

- Excavating Of Shafts Or Tunnels (AREA)

Abstract

The utility model provides a top pushes away system for tunnel crowd T type contact channel tunnelling construction, including reaction frame and a plurality of biography power pull rod, but every one end pivot ground of biography power pull rod is connected to on the reaction frame to but/or but other end pivot ground is connected to the main tunnel section of jurisdiction around the initial end of contact channel, but the reaction frame provides the support for the tunnelling equipment in the direction of tunnelling, and the holding power transmits to the main tunnel section of jurisdiction around the initial end of contact channel via passing the power pull rod, and a plurality of biography power pull rods are arranged along contact channel circumference. According to the utility model discloses, the top pushing system has cancelled the support of leaning on back, has not only simplified the structure, makes entire system intensification, with the space release of leaning on of reaction frame moreover, provides the space facility for many contact channel synchronous construction, contact channel and main tunnel construction are in step. And allows the operator to conveniently adjust the angle of the reaction frame and the heading equipment with respect to the central axis of the communication channel to be excavated via the force transfer tie rods.

Description

Technical Field

The utility model relates to an underground works technical field particularly, relates to a top pushing system that is used for tunnel crowd T type contact channel to tunnel construction.

Background

According to the provisions of subway design specifications: and when the coherent length of the tunnel is more than 600m, a communication channel is required to be arranged between the two single-line interval tunnels. The connection channel of the subway tunnel and the municipal highway tunnel is mostly made by a mining method. For example, in an area with abundant groundwater, the area is usually reinforced by adopting a freezing method, and then the connection channel excavation construction is carried out by adopting a mine method. However, the freezing method construction easily causes adverse effects such as frost heaving and thaw collapse, and usually causes a certain ground settlement, and even causes a collapse risk when the ground settlement is large, which is particularly difficult to adapt to urban core areas with complex geological conditions and high environmental protection requirements. The construction method has long construction period, generally needs over 100 days of freezing, and then can start excavation, so that the construction period is often as long as 4-6 months. In addition, for the stratum with a sand layer and confined water, the freezing method has poor effect, is easy to cause accidents, and has large influence on the environment and high risk.

In recent years, a method for connecting channel construction by adopting an assembled connecting channel structure and a mechanical method is proposed. In the starting process, the pre-supporting trolley needs to be opened and supported on the main tunnel segment in the upper, lower, left and right directions to form a full-ring integral pre-supporting structure, and the reaction frame is supported on the main tunnel segment on the opposite side of the starting direction to serve as a backrest of the pushing device to bear the pushing force. In the case of subway tunnel construction, the inner diameter of the tunnel is usually 5.5m to 6m, and in some projects it can even be enlarged to 8.1m or more. For the tunnel construction operation of other projects, the inner diameter of the tunnel may be large or small. While current pre-support structures can accommodate the need for tunnel inside diameters varying between 5.5m and 7.1 m. When the tunnel diameter is larger than 7.1m, for example, it is increased to 8.1m, the same supporting method will result in a very bulky system of the pre-supporting structure. And as the diameter of the tunnel is increased, the adaptability and stability of the main tunnel segment structure and the supporting structure, the stress change, the structural strength and the like in the construction process need to be researched again. The current construction method cannot provide any reference.

In addition, a full-ring integral pre-supporting structure is adopted, the space of the whole main tunnel is occupied by the pre-supporting structure, vehicles cannot pass through, and two sides of a construction position cannot be communicated. This just leads to just can carry out the construction of other contact passageways or other constructions of main tunnel after one contact passageway construction finishes, and a plurality of construction processes can't go on in step, leads to the construction progress extension.

On the other hand, in the main components in the prior art, the back rest and the pushing system are supported on the main tunnel segment in all directions. The angle adjustment of the backrest and the pushing system can be carried out only by depending on manual field according to the planned pushing line, the operation mode is complex and time-consuming, and the adjustment effect is poor.

Therefore, there is a need to provide a jacking system for use in connection tunnel, especially tunnel group T-type connection tunnel, tunneling construction to at least partially address the above problems while controlling equipment manufacturing and construction costs.

SUMMERY OF THE UTILITY MODEL

An object of the utility model is to provide a top pushes away system for tunnel crowd T type contact channel tunnelling construction to realize the synchronous construction of multiple process, improve the efficiency of construction, reduction of erection time, and reduce equipment manufacturing cost and construction cost, and the top pushes away the angle that the system can also adjust reaction frame and heading equipment through biography power pull rod with convenient mode.

According to the utility model discloses an aspect, the top pushes away the system and includes reaction frame and a plurality of biography power pull rod, every but the one end pivot ground of biography power pull rod is connected to on the reaction frame to but/or other end pivot ground is connected to around the main tunnel section of jurisdiction of the origin of contact passageway, the reaction frame is used for providing the support for heading equipment in the tunnelling direction, and the holding power via pass the power pull rod transmission extremely around the main tunnel section of jurisdiction of the origin of contact passageway, wherein a plurality of biography power pull rods are followed contact passageway circumference is arranged.

In some embodiments, the force transmission pull rod is detachably arranged by a coupling device.

In some embodiments, the coupling device comprises a pin and a fixedly arranged mounting seat, and the mounting seat and the end of the force transmission pull rod are respectively provided with a mounting hole for the pin to pass through.

In some embodiments, the mount includes two opposing spaced apart side walls, and the end of the force transfer rod is disposed between the two side walls.

In some embodiments, the mount is fixedly disposed on the reaction frame.

In some embodiments, the end of the force transfer pull rod is provided with a fine adjustment structure through which the mounting hole passes and which has a drum-shaped outer convex circumference surrounding the mounting hole.

In some embodiments, the mounting seat is fixed to the primary tunnel segment, or the jacking system comprises a starting sleeve fixedly connected to the primary tunnel segment, and the mounting seat is fixed to the starting sleeve.

In some embodiments, the pivot axis of the force transmission pull rod is perpendicular to the axial direction of the communication channel.

In some embodiments, the force transmission tension rod is configured as an unpowered tension rod.

In some embodiments, a pushing driving unit is disposed on a side of the reaction frame facing the communication channel.

In some embodiments, the jacking drive unit comprises a plurality of hydraulic cylinders arranged in quadrant symmetry around the central axis of the communication channel.

In some embodiments, the force transmission pull rod is configured as a power pull rod capable of providing a driving force.

In some embodiments, the power draw bar is a reverse draw oil jack draw bar.

In some embodiments, each of the power links has an independent control unit.

In some embodiments, an angle adjusting unit is arranged on one side of the reaction frame facing the communication channel, and the angle adjusting unit is configured to be capable of adjusting the angle of the tunneling direction of the tunneling device relative to the central axis of the communication channel.

In some embodiments, the angle adjustment unit comprises a plurality of hydraulic cylinders arranged evenly in quadrant symmetry around the central axis of the communication channel.

In some embodiments, one end of the plurality of hydraulic cylinders is connected to the reaction frame and the other end is connected to an annular abutment member for abutment with the tunnelling apparatus or a segment of the communication duct.

In some embodiments, the jacking system further comprises a slide rail extending along a central axis of the communication channel, the reaction frame being movable along the slide rail.

In some embodiments, the reaction frame is provided with a material transportation hole penetrating through the reaction frame at a position corresponding to the communication channel.

According to the utility model discloses a top pushes away the system and has following profitable technological effect:

the pushing system cancels the back support, not only simplifies the structure, intensifies the whole pushing system, but also releases the back space of the reaction frame, and provides space convenience for synchronous construction of a plurality of contact channels, synchronous construction of the mechanical contact channels and synchronous construction of the main tunnel. In addition, because the end part of the force transmission pull rod is arranged to be in pivotal connection, an operator can conveniently adjust the angles of the reaction frame and the tunneling equipment relative to the central axis of the communication channel to be excavated through the force transmission pull rod.

The utility model provides a top pushes away system is low in manufacturing cost not only, moreover because its convenient operation practices thrift the construction space, can make multichannel construction process go on in step to make construction cost obviously reduce.

Drawings

For a better understanding of the above and other objects, features, advantages and functions of the present invention, reference should be made to the preferred embodiments illustrated in the accompanying drawings. Like reference numerals in the drawings refer to like parts. It will be appreciated by persons skilled in the art that the drawings are intended to illustrate preferred embodiments of the invention without any limiting effect on the scope of the invention, and that the various components in the drawings are not to scale. Wherein,

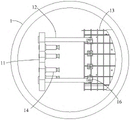

FIG. 1 is a perspective view of a preferred embodiment jacking system according to the present invention;

FIG. 2 is a side view of the jacking system shown in FIG. 1;

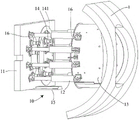

FIG. 3 is a perspective view of a jacking system in accordance with another preferred embodiment of the present invention;

FIG. 4 is a perspective view of the reaction frame of the pusher system shown in FIG. 3;

fig. 5 is a schematic diagram of the state of readiness of the jacking system according to the present invention prior to initiating a drive;

fig. 6 to 9 are schematic views of different states of the jacking system according to the present invention during the tunneling process;

FIG. 10 is a model of stress analysis of a main tunnel segment and a communication channel portal ring;

fig. 11 and 12 are the stress analysis results of the main tunnel segment and the communication channel entrance ring under different pushing pressures, respectively;

FIG. 13 is a schematic view of a main tunnel section during mechanical contact tunnel construction using a pusher system according to the present invention; and

fig. 14 shows the fine adjustment of the force transmission pull rod.

Detailed Description

Referring now to the drawings, specific embodiments of the present invention will be described in detail. What has been described is merely a preferred embodiment according to the present invention, on the basis of which other ways of implementing the invention can be conceived by a person skilled in the art, which other ways likewise fall within the scope of the invention.

In order to realize the intercommunication of underground space networks, a large number of T-shaped connecting tunnels need to be built. Such as: subway, highway section contact passageway, subway access & exit and air shaft, municipal administration piping lane access shaft, long tunnel middle air shaft, water utilities tunnel connecting wire etc.. The utility model provides a top pushes away system suitable for mechanical method carries out tunnel crowd T type contact passageway construction. Wherein, the connection channel can be an assembled connection channel formed by assembling units such as pipe pieces or pipe joints. The communication channel can be used for communicating two subway main tunnels.

Referring to fig. 1 and 2, a jacking system 10 according to a preferred embodiment comprises a reaction frame 11 and a plurality of force transfer levers 12. When the mechanical method communication channel construction is carried out, the pushing system 10 is fixed at the position, corresponding to the communication channel to be tunneled, in the main tunnel 1. A plurality of force transfer tension rods 12 are arranged at intervals along the circumference of the communication channel for connecting the reaction frame 11 with the corresponding segments of the primary tunnel 1 (which may be referred to as primary tunnel segments) around the initiation end of the communication channel. The reaction frame 11 is used to provide support for the tunnelling apparatus. Wherein the supporting forces are finally transferred to the primary tunnel segments around the initiating end of the communication channel via the force transfer tie 12. The force supporting the heading equipment to advance is thus provided by the primary tunnel segments on the same side.

As shown in fig. 10, the diameter of the main tunnel segment is R1, and the communication channel with the diameter of R2 is excavated on the main tunnel segment, so as to analyze the stress of the main tunnel segment and the portal ring forming the communication channel. The result shows that by adopting the pushing system 10, the local concentrated stress of the main tunnel segment can reach as high as 10-20 MPa, and is mainly concentrated on the periphery of the force transmission pull rod, and the local concentrated stress can be responded by locally reinforcing the periphery of the force transmission pull rod. Under the action of 250-450 kPa pushing distribution force, the horizontal lateral displacement of the opening position of the connecting channel is maximally between-1.0 and-1.5 mm, and the horizontal lateral displacement is in a transverse inward convergence trend, so that the influence on an uncut whole ring adjacent to the main tunnel segment is small. Specifically, taking R1 as 8.1m and R2 as 3.65m as an example, the stress analysis results of the main tunnel segment and the portal ring forming the communication channel are shown in fig. 11 and 12, respectively. It can be seen that when the main tunnel segment is subjected to a maximum jacking force of 450kPa, the maximum displacement deformation of the main tunnel segment is-1.2 mm, and the maximum displacement deformation of the portal ring forming the communication passage is-1.2 mm. Therefore, utilize and be according to the utility model discloses a top pushes away system 10 and carries out the construction of mechanical method contact passageway and can satisfy the main tunnel section of jurisdiction stress redistribution of contact passageway broken hole in-process, can guarantee the safety and stability of structure atress, consequently is feasible. The same applies even for large diameter tunnels, e.g. 8.0m and above.

Utilize according to the utility model discloses a top pushes away system 10 and carries out mechanical method contact passageway construction, can omit the bearing structure who sets up between the originated end one side that deviates from the contact passageway of main tunnel 1 and reaction frame 11 (also, reaction frame 11 is the reaction frame that does not have to lean against) to make main tunnel 1 still can remain sufficient current space when carrying out mechanical method contact passageway construction (see fig. 13). Vehicle, personnel, material etc. can utilize the current space that deviates from contact passageway one side that is located reaction frame 11 to shift between the different positions in main tunnel 1 for multiple construction processes can go on in step, especially can carry out many contact passageway constructions simultaneously in the different positions in the main tunnel that has accomplished, can shorten construction cycle greatly. Preferably, the maximum distance between the side of the reaction frame facing away from the contact tunnel and the tube sheet wall of the main tunnel can be set to be not less than one third of the radial dimension of the main tunnel in order to ensure that the passage space has sufficient dimensions for passage. The maximum distance of the passage space may even be set to be not less than half the radial dimension of the main tunnel when the diameter of the main tunnel is large.

The following describes the jacking system and the construction method using the jacking system in detail with reference to the accompanying drawings.

According to the utility model discloses a top pushes away the system and can be applicable to two kinds of construction methods of shield method and push pipe method. Correspondingly, the tunneling equipment is a shield tunneling machine (namely a shield tunneling machine) and a pipe jacking tunneling machine respectively. Corresponding to the shield method, the splicing units are segments. Corresponding to the pipe jacking method, the assembly units are pipe joints. In order to support the heading equipment, the reaction frame 11 is made of a rigid material, such as steel or a composite material. The size of the reaction frame 11 is adapted to the size of the tunneling equipment for excavating the communication channel, and the rigidity is set to meet the requirement of deformation resistance during incremental launching tunneling construction. In the drawings, the reaction frame 11 is shown as being substantially rectangular in shape. However, it will be appreciated that the reaction frame 11 may alternatively be configured as a circle, torus, or any other shape that meets the requirements of the construction.

From the foregoing, the force transfer tie rods 12, which serve as a mechanism for transferring force between the reaction frame 11 and the main tunnel segment, are provided in plurality at intervals along the circumferential direction of the communication passage to provide a uniform force transfer effect. In the embodiment shown in fig. 1 and 2, the force transmission pull rod 12 is an unpowered pull rod, which only functions as a connection and a transmission force, but does not provide any driving action. Preferably, the unpowered pull rod can be a steel structure pull rod, and can be round steel, square steel, steel pipe or section steel and the like.

When the tunneling equipment is a pipe jacking method tunneling machine, the tunneling equipment needs to be driven by a pushing system. Therefore, the reaction frame 11 is provided with a pushing drive unit 14 on a side thereof facing the communication passage. In some embodiments, the ejection drive unit 14 may be a hydraulic cylinder. Preferably, the jacking drive unit 14 comprises a plurality of hydraulic cylinders arranged in a quadrant-symmetrical manner around the central axis of the communication channel in order to provide a uniform driving force to the tunnelling apparatus in the circumferential direction. By controlling the strokes of the hydraulic cylinders at different positions, the pushing driving unit 14 can also adjust the angle of the tunneling direction of the tunneling device relative to the central axis of the communication channel, so that the tunneling direction is consistent with the central axis, or other angle adjustment requirements are met. In addition, when the tunneling equipment is a shield tunneling machine, the tunneling equipment does not need to be provided with driving force by a pushing system. At this time, the jack drive unit 14 serves only as an angle adjustment unit, and since it is not necessary to provide a very large driving force, a hydraulic cylinder of a smaller size and specification can be selected accordingly. Further, abutment members 141 may be provided, each of which is connected to an end of the hydraulic cylinder facing away from the reaction frame 11. The angle adjusting unit is abutted with the segment of the heading equipment or the communication passage through an abutting piece 141. In some embodiments, the abutment 141 may be a ring-shaped top iron.

Fig. 3 shows an embodiment where the force transmission pull rod 12 is a power pull rod capable of providing a driving force. The force transmission pull rod 12 can be a reverse-pull oil jacking pull rod, in particular to a hydraulic jack system taking a reverse pull force as a main force, and the length of a central rod and the reverse pull force can meet the requirement of pushing a pipe jacking method tunneling machine to tunnel. That is, the force transmission pull rod 12 is configured to provide a driving force for pushing the heading device in a manner of pulling the reaction frame 11 to move. This eliminates the need for a power means on the back side of the reaction frame 11 to move it forward. Preferably, each force transmission pull rod 12 has an independent control unit, which can be extended or retracted independently. The fine adjustment of the angular relationship between the heading direction of the heading device and the central axis of the communication channel can be realized by adjusting the stroke of the different force transmission pull rods 12, so that an angle adjusting unit can be omitted. However, it is understood that the angle adjusting unit may be retained to provide an auxiliary angle adjusting function or an auxiliary driving function. Preferably, the force transmission pull rod 12 may be provided as an expandable and telescopic multi-section structure. The adjustment of the driving force can also be achieved by adjusting the number of force transmission rods 12.

It will be appreciated that in embodiments where the force transmission tension rod 12 is configured as an unpowered tension rod, the reaction frame 11 is always kept in a fixed position. Whereas in the embodiment where the force transmission pull rod 12 is configured as a power pull rod the reaction frame 11 is moved back and forth along the centre axis of the communication channel as the force transmission pull rod 12 provides the driving force. Preferably, as shown in fig. 4, the jacking system 10 is provided with a slide rail 15, which may be made of rigid material such as steel, fixedly arranged and extending along the central axis of the communication channel. The reaction frame 11 is movable along the slide rails 15, lateral limitation and longitudinal guidance being provided by the slide rails 15. The reaction frame 11 and the slide rail 15 can be guided and limited by the structure of the protrusion and the slide groove. For example, the bottom of the reaction frame 11 is provided with a recess as a slide groove, and the slide rail 15 is accommodated as a projection in the recess. Alternatively, the slide rail 11 may be provided with a slide groove extending along the central axis of the communication channel, and the reaction frame 11 may be provided with a corresponding projection. The section of the matching of the sliding groove and the protruding part can be a circular ring type, a circle, a rectangle and the like.

With continued reference to fig. 1-3, the originating end of the communication channel is preferably provided with an originating sleeve 13 fixedly connected to the primary tunnel segment. The fixed connection mode can be pre-buried, welded, bolted, sleeve connection and the like. Further, the end of the force transmission rod 12 facing the communication channel can be connected to the starting sleeve 13. In other words, the force transmission tie 12 indirectly connects the reaction frame 11 to the primary tunnel segment via the starter sleeve 13. Of course, in other embodiments, the force transfer tie 12 may also be connected directly to the primary tunnel segment. Alternatively, it is also possible that part of the force transfer tie 12 is connected to the main tunnel segment and part of the force transfer tie 12 is connected to the originating sleeve 13.

Preferably, the force transmission rod 12 and the originating sleeve 13 or the main tunnel segment may be pivotably connected by a coupling means, wherein the pivot axis is perpendicular to the length direction of the force transmission rod 12. And/or the force transmission tension rod 12 and the reaction frame 11 can be connected in the same way by a coupling device. The coupling means may in particular be a pin and a structure cooperating with the pin. In addition, the pins may be arranged in a detachable manner, so that the force transmission tension rod 12 is detachable from the starter sleeve 13 or the primary tunnel segment and/or from the reaction frame 11. The connection mode can be used for adjusting the relative position relation between the pushing system and the main tunnel, fitting the design angle and facilitating the normal work of the tunneling equipment and the pushing system.

Specifically, as shown in fig. 1-3, the structure that mates with the pin may be a fixedly disposed mount 16. The mounting 16 and the end of the force transmission rod 12 have mounting holes for the pins to pass through. Preferably, the mounting block 16 includes two spaced apart side walls with mounting holes in the two side walls aligned with one another. The ends of the force transmission rods 12 are received in the space between the two side walls and then the pins are passed through the respective mounting holes to complete the pivotable connection of the force transmission rods 12. It will be appreciated that the force transfer pull rod 12 can be removed by removing the pin from the mounting hole. The mounting 16 may be arranged in different positions depending on the position of the connection of the force transmission rod 12. For example, in the embodiment in which the force transmission rod 12 is connected to the starting sleeve 13, the mounting socket 16 is fixed on the outside of the starting sleeve 13; in the embodiment where the force transfer tie 12 is attached to the primary tunnel segment, the mounting 16 is fixed to the primary tunnel segment. The mounting 16 can also be fixed to the reaction frame 11 when the force-transmitting rod 12 is pivotally connected to the reaction frame 11.

Further, the end of the force transmission lever 12 intended for pivotal connection is preferably provided with a fine adjustment structure 121, as shown in fig. 14. The fine adjustment structure 121 is movably arranged so that the force transmission pull rod 12 can be finely adjusted with respect to its position in a manner deflected with respect to the pivot axis. Specifically, the fine adjustment structure 121 may have an oblate shape, and the mounting hole 122 penetrates the fine adjustment structure 121 in the axial direction of the oblate shape, and is formed as a convex drum-shaped surface around the outer circumferential surface of the mounting hole 122 in the axial direction. That is, the radial dimension of the central portion of the oblate shape is larger than the radial dimensions of the both ends in the axial direction. Such a configuration allows the force transmission stay 12 to pivot about the pivot axis while also allowing a slight deflection thereof relative to the pivot axis within a certain range, thereby allowing fine adjustment of the force transmission stay 12.

The method of using the incremental launching system according to the present invention for the tunneling construction of the communication tunnel, particularly the process before the initiation of the tunneling, will be described with reference to fig. 5 to 9.

In addition to the pushing system 10 and the heading device 3, the mechanical method communication channel construction also requires supporting equipment, such as the transport system 2 for transporting materials shown in fig. 5. Prior to tunnelling, the jacking system 10, tunnelling apparatus 3, starting sleeve 13 and transport system 2 etc. may be combined into an integral structure. The complete integrated structure can then be transported to the location in the main tunnel where the communication channel is to be excavated. The whole set of integrated structure is fixed at the position by using the fixed supporting legs and other auxiliary structures.

Further, the overall positional relationship of the starting sleeve 13, the heading device 3 and the jacking system 10 is adjusted to the direction of heading by the starting adjustment platform. The starting sleeve 13 and the end of the force transmission rod 12 facing the communication channel to be excavated are then connected to the main tunnel segment. Wherein the force transfer tie 12 may be connected in its entirety to the starter sleeve 13, or the force transfer tie 12 may be connected in its entirety directly to the primary tunnel segment. Alternatively, it is also possible to connect part of the force transfer tie 12 to the starter sleeve 13 and part of the force transfer tie 12 directly to the main tunnel segment. Additionally, it will be appreciated that in some embodiments, the originating sleeve 13 may also be omitted.

Further, the starting direction of the heading device 3 is adjusted by adjusting the relative positional relationship between the heading device 3 and the reaction frame 11. One end of the force transmission pull rod 12 facing the reaction frame 11 is connected with the reaction frame 11, and the front end and the rear end of the force transmission pull rod 12 are locked by a fixing mechanism. The entire integrated structure is thus connected to the main tunnel 1 as a fixed whole. The ripping apparatus 3 may then be translated to the planned starting location by the auxiliary device.

The preparation procedure described above is applicable to both the pusher system of the embodiment in which the force transmission pull rod 12 is a power pull rod or an unpowered pull rod, and to the construction by the shield method and the pipe-jacking method.

For the shield construction, the subsequent steps are the same regardless of whether the force transmission pull rod 12 is an unpowered pull rod or a powered pull rod. After the pushing system 10 is adjusted to a precise position according to the planned route of the communication channel to be tunneled, auxiliary duct pieces and steel structures before starting need to be installed. Then starting tunneling is carried out, tunneling is carried out in sequence, and the connection channel assembling units 31 (namely pipe pieces) are assembled, and the process is repeated circularly until the connection channel construction is completed. Preferably, as shown in fig. 4, the reaction frame 11 is provided with a material conveying hole 111 penetrating therethrough. Materials such as connecting channel segments and the like for assembly required in the tunneling process of shield construction can be conveyed to the tunneling equipment 3 through the material conveying holes 111.

For the pipe-jacking construction, when the force-transmitting pull rod 12 is an unpowered pull rod, the pushing system 10 needs to be installed after being adjusted to a precise position according to a planned route of a communication channel to be tunneled, and the pushing drive unit 14 directly acts on the reaction frame 11. And then starting tunneling, abutting the pushing driving unit 14 on the tunneling equipment 3, and driving the pushing driving unit to advance forward by the distance of one pipe joint (namely the splicing unit 31) along the direction to be tunneled. Compared with the shield construction method, the pipe jacking method needs to be assembled at the position of the pushing system 10, and the pipe joints of the communication channel need to be transported in place from the side part of the pushing system 10. At this point, at least one of the two ends of the force transmission pull rod 12 interfering with the pipe section transport channel is first disconnected and removed. And simultaneously retracting the pushing driving unit 14, and then transporting the pipe sections to be assembled in place through the transportation system 2 to complete the assembly. Then the pushing drive unit 14 is extended out to closely contact and abut with the assembled communication channel pipe joint. Restoring the force-transmitting rod 12 to the connected state. And driving the tunneling equipment 3 to advance forward by the distance of one pipe joint along the heading direction by using the pushing driving unit 14 again, and repeating the steps to finish the tunneling and the assembly of each connecting channel pipe joint until the connecting channel construction is finished.

For the pipe-jacking construction mode, when the force transmission pull rod 12 is a power pull rod, after the pushing system 10 is adjusted to the accurate position according to the planned line of the communication channel to be tunneled, at least one of the two ends of the force transmission pull rod 12 interfering with the pipe joint transportation channel is disconnected and removed. Wherein the removal may be by retracting the counter-pull jack rod or pivoting about the end that remains attached to a position that does not interfere with the pipe joint transport passageway. And then the pipe joints to be assembled are transported in place through the transportation system 2, and the assembly is completed. Before the beginning of tunneling, the force transmission pull rod 12 which is disconnected is restored to the connection state, then the force transmission pull rod 12 is driven to drive the reaction frame 11, and the assembled connection channel pipe joint and the tunneling equipment 3 are pushed forward by the distance of one pipe joint along the direction to be tunneled. Then the force transmission pull rod 12 is driven reversely to drive the reaction frame 11 to retract. And repeating the steps to complete the tunneling and the assembly of each connecting channel pipe joint until the construction of the connecting channel is completed.

Preferably, the starting sleeve 13 is provided with a backstop device. After the pipe joint is tunneled, the pipe joint can be fixed by using a retaining device, and then the force transmission pull rod 12 is driven reversely to drive the reaction frame 11 to return, so that the pipe joint is prevented from returning under pressure.

The foregoing description of various embodiments of the invention is provided to one of ordinary skill in the relevant art for the purpose of illustration. It is not intended to be exhaustive or to limit the invention to the precise form disclosed. As above, various alternatives and modifications of the present invention will be apparent to those of ordinary skill in the art. Thus, while some alternative embodiments are specifically described, other embodiments will be apparent to, or relatively easily developed by, those of ordinary skill in the art. The present invention is intended to embrace all such alternatives, modifications and variances of the present invention described herein, as well as other embodiments that fall within the spirit and scope of the present invention as described above.

Claims (19)

1. The utility model provides a thrusting system for tunnel crowd T type contact passage tunnelling construction, the contact passage is used for liaison at least one main tunnel, its characterized in that, the thrusting system includes reaction frame (11) and a plurality of power transmission pull rod (12), every but the one end pivot ground of power transmission pull rod (12) is connected to on the reaction frame (11) to and/or other end pivot ground is connected to around the main tunnel section of jurisdiction of the originated end of contact passage, reaction frame (11) are used for providing the support for the tunnelling equipment in the direction of tunnelling, and the holding power via power transmission pull rod (12) transmit to around the main tunnel section of jurisdiction of the originated end of contact passage, wherein a plurality of power transmission pull rod (12) are followed contact passage circumference is arranged.

2. The jacking system of claim 1, wherein said force-transmitting pull rod (12) is detachably arranged by means of a coupling device.

3. The jacking system of claim 2, wherein said coupling means comprises a pin and a fixedly arranged mounting seat, said mounting seat and the end of said force-transmitting pull rod (12) being provided with a mounting hole for said pin to pass through, respectively.

4. The jacking system of claim 3, wherein said mounting seat includes two opposed spaced apart side walls, said force-transmitting rod (12) having an end portion disposed between said two side walls.

5. The jacking system according to claim 3, wherein said mounting seat is fixedly arranged on said reaction frame (11).

6. The jacking system of claim 3, wherein said mounting seat is fixed to said primary tunnel segment, or said jacking system comprises a starter sleeve fixedly attached to said primary tunnel segment, said mounting seat being fixed to said starter sleeve.

7. The jacking system of claim 3, wherein an end portion of said force-transmitting pull rod (12) is provided with a fine-tuning structure, said mounting hole passing through said fine-tuning structure, and said fine-tuning structure having a drum-shaped outer convex circumferential surface surrounding said mounting hole.

8. The jacking system of claim 1, wherein said force-transmitting pull rod (12) has a pivot axis perpendicular to the axial direction of said communication channel.

9. Jacking system according to claim 1, wherein said force transmission pull rod (12) is configured as an unpowered pull rod.

10. The jacking system according to claim 9, wherein a side of said reaction frame (11) facing said communication passage is provided with a jacking drive unit (14).

11. Jacking system according to claim 10, wherein said jacking drive unit (14) comprises a plurality of hydraulic cylinders arranged in a quadrant-symmetric manner around the central axis of said communication channel.

12. The jacking system of claim 1, wherein said force-transmitting pull rod (12) is configured as a power pull rod capable of providing a driving force.

13. The jacking system of claim 12, wherein said power draw bar is a reverse draw jack draw bar.

14. The jacking system of claim 12, wherein each of said power links has an independent control unit.

15. The jacking system as claimed in any one of claims 9 to 10 and 12 to 14, wherein a side of said reaction frame (11) facing said communication passage is provided with an angle adjustment unit configured to be able to adjust an angle of a heading direction of a heading device with respect to a central axis of said communication passage.

16. The jacking system of claim 15, wherein the angle adjustment unit comprises a plurality of hydraulic cylinders uniformly arranged in quadrant symmetry about the central axis of said communication channel.

17. The jacking system as claimed in claim 16, wherein one end of said plurality of hydraulic cylinders is connected to said reaction frame (11) and the other end is connected to an annular abutment member (141), said abutment member (141) being adapted to abut against a segment of said tunnelling apparatus or said communication channel.

18. The jacking system according to any one of claims 12 to 14, further comprising a sliding rail (15) extending along a central axis of said communication channel, said reaction frame (11) being movable along said sliding rail (15).

19. The jacking system according to claim 1, wherein said reaction frame (11) is provided with a material conveying hole penetrating said reaction frame (11) at a position corresponding to said communication passage.

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202221605897.7U CN218093079U (en) | 2022-06-24 | 2022-06-24 | Pushing system for tunneling construction of T-shaped contact channel of tunnel group |

| PCT/CN2023/093092 WO2023246349A1 (en) | 2022-06-24 | 2023-05-09 | Jacking system for contact channel tunneling construction and construction method using same |

| AU2023285921A AU2023285921A1 (en) | 2022-06-24 | 2023-05-09 | Jacking system for contact channel tunneling construction and construction method using same |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202221605897.7U CN218093079U (en) | 2022-06-24 | 2022-06-24 | Pushing system for tunneling construction of T-shaped contact channel of tunnel group |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN218093079U true CN218093079U (en) | 2022-12-20 |

Family

ID=84476789

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202221605897.7U Active CN218093079U (en) | 2022-06-24 | 2022-06-24 | Pushing system for tunneling construction of T-shaped contact channel of tunnel group |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN218093079U (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2023246349A1 (en) * | 2022-06-24 | 2023-12-28 | 宁波用躬科技有限公司 | Jacking system for contact channel tunneling construction and construction method using same |

-

2022

- 2022-06-24 CN CN202221605897.7U patent/CN218093079U/en active Active

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2023246349A1 (en) * | 2022-06-24 | 2023-12-28 | 宁波用躬科技有限公司 | Jacking system for contact channel tunneling construction and construction method using same |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN109899074B (en) | Integral station-crossing secondary starting construction method for sliding steel sleeve shield tunneling machine | |

| CN115059487B (en) | Pushing system for tunneling construction of communication channel and construction method using pushing system | |

| WO2023246349A1 (en) | Jacking system for contact channel tunneling construction and construction method using same | |

| CN218093079U (en) | Pushing system for tunneling construction of T-shaped contact channel of tunnel group | |

| CN111188641A (en) | Shield tunnel steel pipe sheet lining reinforcing mechanical arm | |

| CN218093039U (en) | Pushing system for tunneling construction of T-shaped contact channel of tunnel group | |

| RU2719885C1 (en) | Tubular drill rod, as well as system and method of pipeline laying | |

| CN105889625A (en) | Combined type steel tube intermediate jacking station equipment for jacking pipe construction and construction method | |

| CN218953333U (en) | Force transmission mechanism of pushing system for tunneling construction of T-shaped connecting channel of tunnel group | |

| CN111622764B (en) | Shield tunneling machine and station passing method thereof | |

| US3645105A (en) | Internal tensioning system for laying pipeline | |

| JP2008088705A (en) | Shield method and shield machine | |

| EP3626931B1 (en) | Movable shove frame structure, device for starting tunnels and method for starting the construction of tunnels | |

| CN219197335U (en) | Pushing system for tunneling construction of T-shaped connecting channels of tunnel group | |

| CN217055188U (en) | Starting receiving device for shield construction | |

| CN210829276U (en) | Shield does not have burden ring and begins structure | |

| CN219910759U (en) | Pushing system for tunneling construction of T-shaped connecting channels of tunnel group | |

| CN110513118B (en) | Shield non-negative ring originating structure and originating process | |

| CN115822634B (en) | Tunneling construction system and method for communication part of main tunnel and branch tunnel | |

| EP1028226A2 (en) | Method and device for constructing an underground tunnel | |

| JP4926007B2 (en) | Excavation equipment for tunnel expansion | |

| CN115163102A (en) | Connection channel tunneling equipment and construction method thereof | |

| JP7398330B2 (en) | Starting equipment for propulsion devices for constructing curved tunnels, underground beams, or advance support | |

| CN116906081A (en) | Grouting device between jacking pipe relays and jacking pipe closed construction method | |

| JP2002188756A (en) | Pipe laying method in tunnel and apparatus therefor |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |