CN210036016U - Storage device - Google Patents

Storage device Download PDFInfo

- Publication number

- CN210036016U CN210036016U CN201920249255.XU CN201920249255U CN210036016U CN 210036016 U CN210036016 U CN 210036016U CN 201920249255 U CN201920249255 U CN 201920249255U CN 210036016 U CN210036016 U CN 210036016U

- Authority

- CN

- China

- Prior art keywords

- positioning

- pivoting

- storage device

- piece

- side plates

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Warehouses Or Storage Devices (AREA)

Abstract

The utility model discloses a storing device includes the box that has storage space to injecing in it, and the rack on the pivot spare of upset subassembly is fixed in to one or more upset subassemblies, and wherein the upset subassembly includes the setting element and is fixed in on the box and along the mounting of the direction of height extension of box. The utility model discloses a storage device simple structure can be according to user's demand upset rack, when the user need deposit high higher article, then overturn the rack to parallel with the mounting, when the user need not deposit high higher article, then overturn the rack to perpendicular with the mounting to make storage device can deposit more article, the utility model discloses a storage device's rack can overturn, and the operation of being convenient for, and the rack upset down when the setting element can avoid rack and mounting to be perpendicular has improved the stability of rack.

Description

Technical Field

The utility model relates to an article storage technical field especially relates to a storing device.

Background

At present, most of racks of the storage device appearing in the market are fixed, the arrangement of the racks can enable the storage device to store more articles, but cannot meet the requirement of a user on storing articles with higher height, and when the user needs to store the articles with higher height, the racks can limit the articles, so that the space utilization rate is reduced, and the user experience is influenced.

Although there are racks that can be turned over in the prior art, the racks can be turned over to be parallel to the side walls of the storage device, so that the storage device can store articles with a high height. However, such a storage device is complicated in structure and poor in stability.

SUMMERY OF THE UTILITY MODEL

In view of the above, the present invention has been made in order to provide a storage device that solves the above problems, or at least partially solves the above problems.

An object of the utility model is to provide a storing device that rack can overturn.

It is a further object of the present invention to improve the stability of such a storage device with reversible racks.

The utility model provides a storage device, include: a box body, wherein a storage space is limited in the box body; one or more flip assemblies; a rack.

Optionally, each flipping assembly comprises: the fixing piece is fixed on the box body and extends along the height direction of the box body; the first end of the pivoting piece is pivotally arranged on the fixed piece, and a sliding groove arranged along the extending direction of the pivoting piece is formed in the pivoting piece; the first end of the supporting piece is pivotally arranged on the fixed piece, and the second end of the supporting piece can move along the sliding groove; the positioning piece is rotatably arranged on the pivoting piece and is configured to have a first state of limiting the position of the second end of the supporting piece relative to the sliding groove when the pivoting piece rotates to be vertical to the fixing piece and a second state of releasing the second end of the supporting piece and enabling the second end to move along the sliding groove.

Optionally, the sliding groove is configured such that when the positioning member is in the first state, an end thereof adjacent to the first end of the pivoting member is spaced apart from the second end of the supporting member.

Optionally, the pivot member comprises: the connecting plate is connected with the rack; two pivoting side plates extending from the side edges along the length direction of the connecting plate to the direction opposite to the rack; and sliding grooves are arranged on the two pivoting side plates.

Optionally, the positioning member is disposed between the two pivoting side plates, and the positioning member includes: the two positioning side plates are respectively in pivot connection with the two pivoting side plates; the positioning plate is connected with the two positioning side plates.

Optionally, the width of the two positioning side plates is set to be equal to the distance from the groove edge of the sliding groove far away from the connecting plate to the side of the pivoting side plate far away from the connecting plate.

Optionally, the positioning member is configured such that when in the first state, the two positioning side plates and the end of the positioning plate opposite to the connecting plate are both parallel to and in contact with the connecting plate.

Optionally, the fixture comprises: the fixing plate is fixed on the box body; the two fixed side plates extend from the side edges along the length direction of the fixed plates to the direction opposite to the box body; and the two fixed side plates are respectively in pivot connection with the corresponding pivoting side plates.

Optionally, fixed curb plate hole has been seted up on two fixed curb plates respectively, and support piece includes: the supporting pin penetrates through the fixed side plate holes on the two fixed side plates, and two ends of the supporting pin respectively protrude out of the two fixed side plates; two ends of the positioning pin are respectively arranged in the sliding grooves of the two pivoting side plates, and the two ends of the positioning pin respectively protrude out of the two pivoting side plates; and two support plates, each support plate being used for connecting one end of the support pin and one end of the positioning pin opposite to the support pin.

Optionally, the storage device comprises a plurality of turnover assemblies arranged at the same height on the same side wall of the box body, and the turnover assemblies are arranged in parallel at intervals and used for supporting a rack.

Optionally, the storage device further comprises: the synchronous rod is connected with the positioning pieces of the plurality of overturning components; and the plurality of synchronous holes are arranged on the pivoting piece of each overturning assembly and are configured to be used for fixing the synchronous rods when the positioning piece is in the second state.

The utility model discloses a storing device includes the box that has storage space to injecing in it, and the rack on the pivot spare of upset subassembly is fixed in to one or more upset subassemblies, and wherein the upset subassembly includes the setting element and is fixed in on the box and along the mounting of the direction of height extension of box. The utility model discloses a storage device simple structure can be according to user's demand upset rack, when the user need deposit high higher article, then overturn the rack to parallel with the mounting, when the user need not deposit high higher article, then overturn the rack to perpendicular with the mounting to make storage device can deposit more article, the utility model discloses a storage device's rack can overturn, and the operation of being convenient for, and the rack upset down when the setting element can avoid rack and mounting to be perpendicular has improved the stability of rack.

Further, the utility model discloses a turnover component still includes pivot spare and support piece, and wherein pivot spare's first end pivot ground sets up on the mounting, sets up the pivot spare of the sliding tray of arranging along its extending direction on it, and support piece's first end pivot ground sets up on the mounting, and the second end can be followed the sliding tray and removed. And, the sliding tray is constructed as when the setting element limits the second end of support piece to the sliding tray position, its one end that is close to the first end of pivot piece and the second end interval setting of support piece, and the setting of this kind of upset subassembly makes when setting element release support piece's second end and make it move along the sliding tray, only needs upwards rotate the rack, makes support piece's second end move to the first end of pivot piece in the sliding tray, rotates the setting element again, the utility model discloses a process operation of storage device upset rack is simple, need not be with the help of helping hand instrument, easily realizes, the user operation of being convenient for, and can bear the weight of big article.

The above and other objects, advantages and features of the present invention will become more apparent to those skilled in the art from the following detailed description of specific embodiments thereof, taken in conjunction with the accompanying drawings.

Drawings

Some specific embodiments of the present invention will be described in detail hereinafter, by way of illustration and not by way of limitation, with reference to the accompanying drawings. The same reference numbers in the drawings identify the same or similar elements or components. Those skilled in the art will appreciate that the drawings are not necessarily drawn to scale. In the drawings:

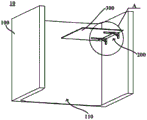

fig. 1 is a schematic structural view of a storage device according to an embodiment of the present invention;

FIG. 2 is a schematic partial enlarged view of region A in FIG. 1;

fig. 3 is a schematic structural view of a fixing member of a storage device according to an embodiment of the present invention;

fig. 4 is a schematic structural view of a pivot member of the storage device according to an embodiment of the present invention;

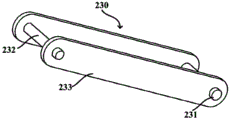

fig. 5 is a schematic structural view of a support member of the storage device according to an embodiment of the present invention;

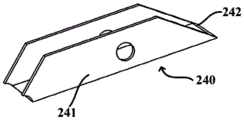

fig. 6 is a schematic structural view of a spacer of a storage device according to an embodiment of the present invention;

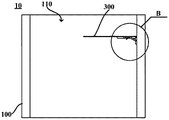

fig. 7 is a schematic structural view of a positioning member of a storage device according to an embodiment of the present invention in a first state;

FIG. 8 is a schematic partial enlarged view of region B in FIG. 7;

FIG. 9 is a mating view of the positioning member and the pivot member with the positioning member of FIG. 7 in a first state;

fig. 10 is a schematic structural view of a first process in which a positioning member of a storage device according to an embodiment of the present invention is in a second state;

FIG. 11 is a schematic partial enlarged view of region C in FIG. 10;

fig. 12 is an assembly view of a positioning member and a synchronizing bar of the storage device according to an embodiment of the present invention;

fig. 13 is a schematic structural view of a second process in which a positioning member of a storage device according to an embodiment of the present invention is in a second state;

FIG. 14 is a schematic, fragmentary, enlarged view of region D of FIG. 13;

fig. 15 is a schematic structural view of a third process in which a positioning member of a storage device according to an embodiment of the present invention is in a second state;

FIG. 16 is a schematic partial enlarged view of region E in FIG. 15;

figure 17 is a fitting view of the positioning member and the pivoting member of the third process with the positioning member shown in figure 15 in the second state.

Detailed Description

Fig. 1 is a schematic structural view of a storage device 10 according to an embodiment of the present invention, and fig. 2 is a schematic partial enlarged view of a region a in fig. 1. In other embodiments of the present invention, the storage device 10 may further include a door disposed at the front of the box 100 for opening and closing the storage space 110, wherein the box 100 defines the storage space 110 therein, and the schematic diagram shown in the present embodiment does not show the top plate, the bottom plate, and other components of the box 100.

The storage device 10 of the present embodiment may further include two turning assemblies 200, wherein the two turning assemblies 200 are disposed at the same height on the same sidewall of the box 100, and the two turning assemblies 200 are disposed in parallel and spaced apart for supporting one rack 300. Each of the flipping units 200 includes a fixing member 210 fixed to the box 100 and extending along the height direction of the box 100, a pivoting member 220 having a first end pivotally disposed on the fixing member 210 and a sliding slot 221 disposed along the extending direction thereof, a supporting member 230 having a first end pivotally disposed on the fixing member 210 and a second end movable along the sliding slot 221, and a positioning member 240 rotatably disposed on the pivoting member 220.

Fig. 3 is a schematic structural diagram of the fixing member 210 of the storage device 10 according to an embodiment of the present invention, each fixing member 210 includes a fixing plate 211 and two fixing side plates 212, wherein the fixing plate 211 is fixed on the box body 100, the two fixing side plates 212 extend from the side along the length direction of the fixing plate 211 to the direction opposite to the box body 100, and fixing side plate holes 213 are further respectively opened on each fixing side plate 212.

Fig. 4 is a schematic structural diagram of a pivoting member 220 of a storage device 10 according to an embodiment of the present invention, the pivoting member 220 includes a connecting plate 222 and two pivoting side plates 223, wherein the connecting plate 222 is fixedly connected to a rack 300 of the storage device 10, the two pivoting side plates 223 extend from sides along a length direction of the connecting plate 222 to a direction opposite to the rack 300, sliding grooves 221 are disposed on the two pivoting side plates 223, and the two pivoting side plates 223 are respectively pivotally connected to corresponding fixed side plates 212.

The turnover assembly 200 is disposed such that when the pivoting member 220 rotates relative to the fixed member 210, the pivoting member 220 rotates the rack 300.

Fig. 5 is a schematic structure diagram of a support member 230 of the storage device 10 according to an embodiment of the present invention, the support member 230 includes a support pin 231, a positioning pin 232, two support plates 233, wherein the support pin 231 penetrates through fixed side plate holes 213 of the two fixed side plates 212, and both ends of the support pin protrude out of the two fixed side plates 212, both ends of the positioning pin 232 are disposed in sliding grooves 221 of the two pivoting side plates 223, both ends of the positioning pin 232 protrude out of the two pivoting side plates 223, and each support plate 233 is used for connecting one end of the support pin 231 and one end of the positioning pin 232 opposite thereto.

Fig. 6 is a schematic structural diagram of a positioning member 240 of the storage device 10 according to an embodiment of the present invention, the positioning member 240 is disposed between two pivoting side plates 223, and the positioning member 240 includes two positioning side plates 241 and a positioning plate 242, wherein the two positioning side plates 241 are respectively pivotally connected to the two pivoting side plates 223, and the positioning plate 242 connects the two positioning side plates 241.

The positioning member 240 of the turnover assembly 200 of the storage device 10 of the present embodiment is configured to have a first state defining the position of the second end of the supporting member 230 relative to the sliding groove 221 when the pivoting member 220 is rotated to be perpendicular to the fixing member 210, and a second state releasing the second end of the supporting member 230 and moving it along the sliding groove 221.

Fig. 7 is a schematic structural view of a positioning member 240 of the storage device 10 in a first state according to an embodiment of the present invention, fig. 8 is a schematic enlarged partial view of a region B in fig. 7, and fig. 9 is a matching view of the positioning member 240 and the pivoting member 220 in the first state of the positioning member 240 shown in fig. 7. With the pivoting side plate 223 of the pivoting member 220 located forward omitted in fig. 9.

When the positioning member 240 is in the first state, the positioning member 240 may block the positioning pin 232 of the supporting member 230 from moving to one side of the middle of the storage space 110. At this time, the two positioning side plates 241 and the opposite ends of the positioning plate 242 and the connecting plate 222 are parallel to and contact with the connecting plate 222. Due to the structure of the positioning member 240 and the cooperation of the positioning pin 232, the positioning member 240 is not rotated by the gravity of the rack 300 and the articles thereon, so that the movement of the positioning pin 232 is stably limited, and the stability of the storage device 10 is improved.

When a user does not need to store articles with a high height, the storage device 10 can be stably perpendicular to the fixing member 210 by only turning the rack 300 to be perpendicular to the fixing member 210 and rotating the positioning member 240 to the position shown in fig. 8, so that more articles can be stored, and the space utilization rate is improved.

Fig. 10 is a schematic structural view of a first process in which a positioning member 240 of the storage device 10 is in a second state according to an embodiment of the present invention, and fig. 11 is a schematic partial enlarged view of a region C in fig. 10.

The sliding slot 221 of the present embodiment is configured such that when the positioning member 240 is in the first state, one end of the positioning member 240 close to the first end of the pivoting member 220 is spaced apart from the second end of the supporting member 230, and the sliding slot 221 is configured such that when the positioning member 240 is in the first state, the positioning member 240 can rotate by rotating the rack 300 upward to move the positioning pin 232 along the sliding slot 221 to the end close to the first end of the pivoting member 220, and by rotating the positioning member 240, the positioning member 240 can not block the positioning pin 232 from moving along the sliding slot 221, and at this time, the positioning member 240 is in the second state of releasing the second end of the supporting member 230 and moving along the sliding slot 221.

The storage device 10 may further include a synchronization rod 400, the synchronization rod 400 connects the same portions of the positioning members 240 of the two turnover assemblies 200, and fig. 12 is an assembly view of the positioning members 240 and the synchronization rod 400 of the storage device 10 according to an embodiment of the present invention. In some embodiments of the present invention, the positioning element 240 and the synchronization rod 400 may be fixed by welding or by other methods such as integral molding.

In some embodiments of the present invention, the storage device 10 has only one turning assembly 200, and the synchronization rod 400 is not required to be disposed, and in other embodiments of the present embodiment, the storage device 10 may have two or more turning assemblies 200 disposed on the same sidewall of the box 100, and the synchronization rod 400 is connected to the same portion of the positioning member 240 of the two or more turning assemblies 200. The synchronization rod 400 can ensure that the rotation angles of the plurality of positioning members 240 are the same, and a user does not need to adjust the angle of each positioning member 240 individually, thereby improving user experience, and preventing the rotation angles of the plurality of positioning members 240 from being different, thereby ensuring stability of the rack 300 of the storage device 10.

Fig. 13 is a schematic structural view of a second process in which the positioning member 240 of the storage device 10 according to an embodiment of the present invention is in the second state, and fig. 14 is a schematic partial enlarged view of a region D in fig. 13. At this time, the positioning member 240 releases the positioning pin 232 of the supporting member 230 and moves along the sliding slot 221, the positioning member 240 does not block the positioning pin 232 from moving along the sliding slot 221, and the positioning pin 232 can move along the sliding slot 221 with the operation of the user, so that the pivoting member 220 rotates the rack 300.

Fig. 15 is a schematic structural view of a third process in which the positioning member 240 of the storage device 10 according to an embodiment of the present invention is in the second state, and fig. 16 is a schematic partial enlarged view of a region E in fig. 15. At this time, the rack 300 is parallel to the fixing member 210 and is attached to the sidewall of the box 100, so that the user can store articles with a relatively high height in the storage space 110, thereby improving the space utilization rate and improving the user experience.

Fig. 17 is a fitting view of the positioning member 240 and the pivoting member 220 in the third process of the positioning member 240 shown in fig. 15 in the second state, in which the pivoting side plate 223 located at the front is omitted. Referring to fig. 17, the widths of the two positioning side plates 241 are respectively set to be equal to the distance from the groove edge of the slide groove 221 away from the link plate 222 to the side of the pivoting side plate 223 away from the link plate 222.

Moreover, the storage device 10 of the present embodiment may further include a plurality of synchronization holes 500, each of the pivoting side plates 223 is provided with a synchronization hole 500, and when the positioning member 240 is in the second state, the synchronization rod 400 is fixed.

The arrangement of the synchronization hole 500 and the width of the positioning side plate 241 can ensure that the pivoting member 220 has a state of being parallel to the fixed member 210, and the positioning member 240 or the synchronization rod 400 does not block the pivoting member 220 from being parallel to the fixed member 210 during the rotation of the pivoting member 220, thereby ensuring that the rack 300 can achieve a state of being parallel to the fixed member 210 and improving space utilization.

In some embodiments of the present invention, the storage device 10 may have a rack 300, the rack 300 is connected to the turnover assembly 200 on a side wall or a rear wall of the storage device 10, and the rack 300 may partially cover the horizontal section of the storage space 110 or completely cover the horizontal section of the storage space 110. When the rack 300 is connected to the box 100 through one of the turnover assemblies 200, the pivot 220 of the turnover assembly 200 may be disposed at the middle of one end of the rack 300 connected to the box 100 to improve stability of the rack for storing articles.

In some embodiments of the present invention, the storage device 10 may have a plurality of racks 300, each rack 300 is connected to the turnover assembly 200 on one side wall or the rear wall of the storage device 10, and the plurality of racks 300 may be disposed at the same height of the box 100 or at different heights of the box 100.

In some embodiments, the storage device 10 may further include a refrigeration system (not shown). A refrigeration system may be disposed within the cabinet 100 and configured to provide cooling to the storage space 110. Such a storage device 10 with a refrigeration system may also be generally referred to as a refrigerating and freezing device, and may be, for example, a refrigerator having at least a refrigerating compartment and a freezing compartment, wherein the rack 300 and the turnover assembly 200 may be disposed in the refrigerating compartment. The refrigeration system may be a conventional compression refrigeration system or a semiconductor refrigeration system, etc., which provides refrigeration to the storage space 110, for example, by direct and/or air cooling, to provide the storage space 110 with a desired storage temperature. Since such refrigeration systems per se are well known and readily implemented by those skilled in the art, further description of the refrigeration system per se is not provided herein.

The utility model discloses a storing device 10 includes box 100 that has the storing space 110 defined therein, one or more upset subassemblies 200, is fixed in the rack 300 on the pivot member 220 of upset subassembly 200, and wherein upset subassembly 200 includes setting element 240 and is fixed in on the box 100 and along the mounting 210 of the direction of height extension of box 100. The utility model discloses a storage device 10 simple structure can overturn rack 300 according to user's demand, when the user need not deposit high higher article, then overturn rack 300 to perpendicular with mounting 210 to rotatory setting element 240 avoids support piece 230's locating pin 232 to one side at storage space 110 middle part to remove through setting element 240, guarantees the stationarity that rack 300 placed, so that storage device 10 can deposit more article.

When a user needs to store an article with a higher height, the rack 300 is firstly turned upwards, so that the positioning pin 232 moves towards one end close to the first end of the pivoting member 220 along the sliding slot 221, and the positioning member 240 can rotate, and by rotating the positioning member 240, the positioning member 240 is in a second state of releasing the second end of the supporting member 230 and moving along the sliding slot 221, at this time, the positioning pin 232 can move to any position of the sliding slot 221, and the user can turn the rack 300 to be parallel to the fixing member 210, so that the storage device 10 can store the article with the higher height.

The rack 300 of the storage device 10 of the present invention can be turned over and operated conveniently, and can bear heavy articles, and the positioning member 240 can prevent the rack 300 from turning over downward when the rack 300 is perpendicular to the fixing member 210, so as to improve the stability of the rack 300.

Thus, it should be appreciated by those skilled in the art that while a number of exemplary embodiments of the invention have been shown and described in detail herein, many other variations and modifications can be made, consistent with the principles of the invention, which are directly determined or derived from the disclosure herein, without departing from the spirit and scope of the invention. Accordingly, the scope of the present invention should be understood and interpreted to cover all such other variations or modifications.

Claims (10)

1. A storage device, characterized by comprising:

a box body, wherein a storage space is limited in the box body;

one or more flip assemblies, each flip assembly comprising:

the fixing piece is fixed on the box body and extends along the height direction of the box body;

the first end of the pivoting piece is pivotally arranged on the fixed piece, and a sliding groove arranged along the extending direction of the pivoting piece is formed in the pivoting piece;

the first end of the supporting piece is pivotally arranged on the fixed piece, and the second end of the supporting piece can move along the sliding groove;

the positioning piece is rotatably arranged on the pivoting piece and is configured to have a first state of limiting the position of the second end of the supporting piece relative to the sliding groove when the pivoting piece rotates to be vertical to the fixing piece and a second state of releasing the second end of the supporting piece and enabling the second end of the supporting piece to move along the sliding groove; and the rack is fixedly connected with the pivoting piece.

2. Storage device according to claim 1, characterized in that

The sliding groove is configured such that when the positioning member is in the first state, an end thereof adjacent to the first end of the pivoting member is spaced apart from the second end of the supporting member.

3. Storage device according to claim 1, characterized in that said pivoting member comprises:

a connecting plate connected with the rack;

two pivoting side plates extending from the sides along the length of the connecting plate in a direction opposite to the rack; and is

The two pivoting side plates are provided with the sliding grooves.

4. A storage device as defined in claim 3, wherein said positioning member is disposed between said two pivoting side panels, and said positioning member comprises:

the two positioning side plates are respectively in pivot connection with the two pivoting side plates;

and the positioning plate is connected with the two positioning side plates.

5. Storage device according to claim 4, characterized in that

The width of the two positioning side plates is respectively set to be equal to the distance from the edge of the sliding groove far away from the connecting plate to one side of the pivoting side plate far away from the connecting plate.

6. Storage device according to claim 5, characterized in that

The positioning piece is configured in the first state, and the two positioning side plates and one end, opposite to the connecting plate, of the positioning plate are parallel to and in contact with the connecting plate.

7. A storage device as defined in claim 3, wherein said securing member comprises:

the fixing plate is fixed on the box body;

the two fixed side plates extend from the side edges along the length direction of the fixed plates to the direction opposite to the box body; and is

The two fixed side plates are respectively in pivot connection with the corresponding pivoting side plates.

8. The storage device of claim 7, wherein two of the fixed side plates are respectively provided with a fixed side plate hole, and the support member comprises:

the supporting pin penetrates through fixed side plate holes in the two fixed side plates, and two ends of the supporting pin respectively protrude out of the two fixed side plates;

two ends of the positioning pin are respectively arranged in the sliding grooves of the two pivoting side plates, and the two ends of the positioning pin respectively protrude out of the two pivoting side plates;

and each support plate is used for connecting one end of the support pin and one end of the positioning pin opposite to the support pin.

9. The storage device according to claim 1, characterized in that it comprises a plurality of said turnover assemblies arranged at the same height of the same side wall of said box, and

the plurality of turnover assemblies are arranged in parallel at intervals and used for supporting a rack.

10. The storage device of claim 9, further comprising:

the synchronous rod is connected with the positioning pieces of the plurality of overturning components;

and the plurality of synchronous holes are arranged on the pivoting piece of each overturning assembly and are configured to be used for fixing the synchronous rod when the positioning piece is in the second state.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201920249255.XU CN210036016U (en) | 2019-02-27 | 2019-02-27 | Storage device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201920249255.XU CN210036016U (en) | 2019-02-27 | 2019-02-27 | Storage device |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN210036016U true CN210036016U (en) | 2020-02-07 |

Family

ID=69353704

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201920249255.XU Active CN210036016U (en) | 2019-02-27 | 2019-02-27 | Storage device |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN210036016U (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115325763A (en) * | 2021-05-10 | 2022-11-11 | 青岛海尔电冰箱有限公司 | Storage device for refrigerator and refrigerator |

| WO2023185281A1 (en) * | 2022-03-31 | 2023-10-05 | 青岛海尔电冰箱有限公司 | Refrigerator |

-

2019

- 2019-02-27 CN CN201920249255.XU patent/CN210036016U/en active Active

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115325763A (en) * | 2021-05-10 | 2022-11-11 | 青岛海尔电冰箱有限公司 | Storage device for refrigerator and refrigerator |

| CN115325763B (en) * | 2021-05-10 | 2024-01-05 | 青岛海尔电冰箱有限公司 | Storage device for refrigerator and refrigerator |

| WO2023185281A1 (en) * | 2022-03-31 | 2023-10-05 | 青岛海尔电冰箱有限公司 | Refrigerator |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN105247307A (en) | Shelf assembly for refrigerator | |

| CN102395849B (en) | Sliding shelves for refrigerators and freezers | |

| US9322592B2 (en) | Refrigerator | |

| EP2549212A2 (en) | Refrigerator | |

| CN210036016U (en) | Storage device | |

| US20100109496A1 (en) | Butter compartment for a refrigerator | |

| US7316326B2 (en) | Tray apparatus for refrigerator | |

| US10827834B2 (en) | Bottle support assembly for a refrigerator appliance | |

| EP2749828B1 (en) | Shelf assembly for refrigerator and refrigerator | |

| US11892231B2 (en) | Refrigerator dead space storage systems | |

| CN203364544U (en) | Egg holder assembly and refrigerator | |

| EP3279594A1 (en) | Refrigerator | |

| CN102538371A (en) | Storage rack assembly and refrigerator provided with same | |

| WO2014207862A1 (en) | Refrigerator | |

| US20140184036A1 (en) | Goods storage apparatus for a vending machine | |

| CN103322762A (en) | Shelf component for refrigerator and refrigerator | |

| WO2015104000A1 (en) | Pull-out shelving assembly and refrigerator having said assembly | |

| CN107477964B (en) | Refrigerator with folding bottle seat | |

| CN109780808B (en) | Storage device and refrigerator with same | |

| JP2002005567A (en) | Refrigerator cabinet having shelf | |

| CN106969587A (en) | Thing component is put for refrigerator | |

| CN215324854U (en) | Storage goods shelf device for logistics storage | |

| CN217013238U (en) | Article placing shelf | |

| CN217610042U (en) | Storage device | |

| EP3916329B1 (en) | Appliance with a shelf assembly |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant |